Iron mine sintering flue gas segmented circulation method

A technology for sintering flue gas and flue gas components, applied in the field of iron ore sintering, can solve problems such as sulfur enrichment and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

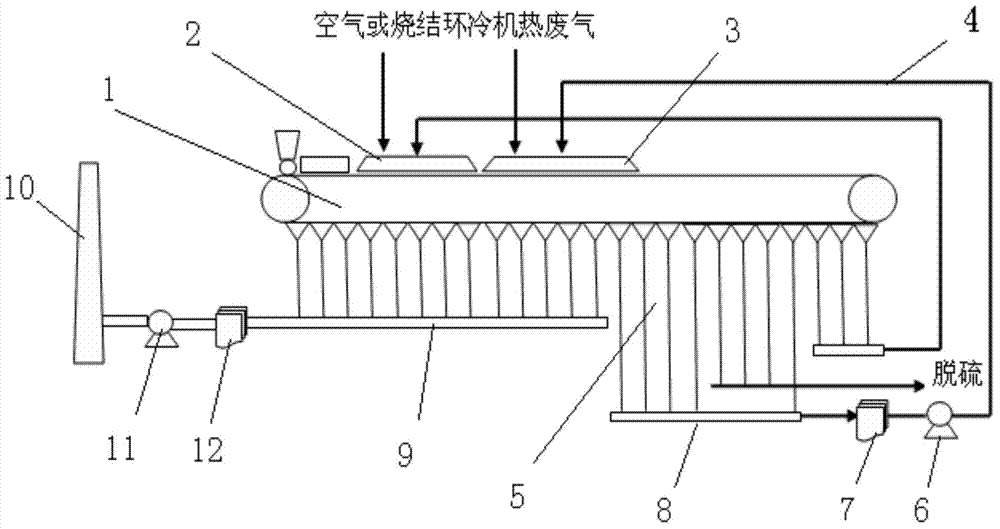

Embodiment 1

[0022] According to the mass ratio of 60.73% mixed iron ore, 5.58% dolomite, 2.16% limestone, 4.62% quicklime, 23.08% sintered ore return, and 3.85% coke powder (the chemical composition of the obtained sintered ore is: TFe57.5%, SiO 2 4.82%, R2.0, MgO2.0%). The area of sintering machine 1 is 450m 2 , a total of 24 bellows 5. The flue gas drawn from the wind boxes 5 (accounting for 1 / 6 of the length of the sintering machine) from the tail 21 to 24 of the sintering machine 1 is circulated to the head hood 2 of the sintering material layer at the head, and the temperature of the gas entering the material surface is 200°C, o 2 The content is 18%, and the head fume cover 2 accounts for 25% of the area of the sintering machine 1. SO 2 The flue gas from No. 17-19 bellows 5 with the highest concentration is sent to the desulfurization system for desulfurization, and the flue gas from the remaining bellows 5 in the middle tail is circulated to the middle smoke hood 3 on the mi...

Embodiment 2

[0024] According to the mass ratio of mixed iron ore 61.03%, dolomite 6.12%, limestone 2.27%, quicklime 3.50%, sintered return ore 23.08%, anthracite 4.00% (the chemical composition of the obtained sintered ore is: TFe58.02%, SiO 2 5.05%, R1.90, MgO2.20%). The area of sintering machine 1 is 360m 2 , a total of 20 bellows. The flue gas drawn from the No. 19-20 bellows 5 at the end of the sintering machine 1 (accounting for 1 / 10 of the length of the sintering machine) is circulated to the head hood 2 of the sintering material layer at the head, and the temperature of the gas entering the material surface is 300°C, O 2 The content is 19%, and the head hood 2 accounts for 15% of the area of the sintering machine. SO 2 The flue gas from No. 16 to No. 17 wind boxes 5 with the highest concentration is sent to the desulfurization system for desulfurization, and the flue gas from the remaining wind boxes 5 in the middle and tail is circulated to the middle fume hood 3 on the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com