Automobile composite board spring

A technology of composite plate and leaf spring, applied in the direction of high internal friction spring, elastic suspension, vehicle parts, etc., can solve the problems of poor strength such as torsion, shearing, wear, increased fuel consumption, hidden dangers, etc., to ensure strength and fatigue Longevity, guaranteed overall strength, and the effect of preventing overall damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

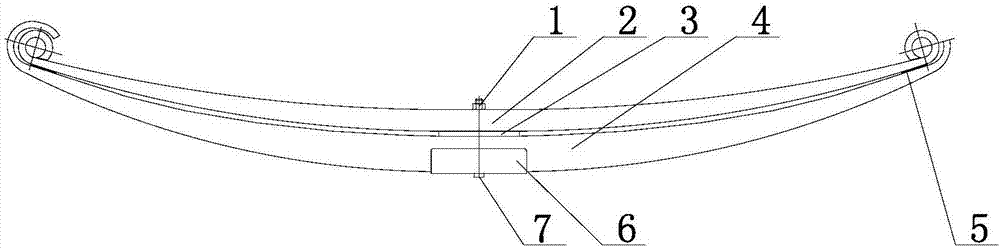

[0023] Such as figure 1 As shown, the automobile composite leaf spring includes a leaf spring 2 at the top and a composite spring 4 at the bottom. The leaf spring 2 and the composite spring 4 are stacked up and down and connected as a whole by fasteners. The leaf spring sheet 2 in the present embodiment is a variable cross-section, and its thickness is 8-18mm (thickness gradually decreases from the center to both ends); the composite material spring sheet 4 adopts glass fiber reinforced composite material, and its thickness is 20-65mm.

[0024] A central gasket 3 and two end wear-reducing blocks 5 are arranged between the leaf spring sheet 2 and the composite material spring sheet 4, wherein the central gasket 3 (made of steel material, such as low alloy steel, etc.) is located in the middle , both ends of wear-reducing blocks 5 (made of steel materials, such as low-alloy steel, etc.) are symmetrically arranged on the left and right; The spring sheet installation pad 6 adopts...

Embodiment 2

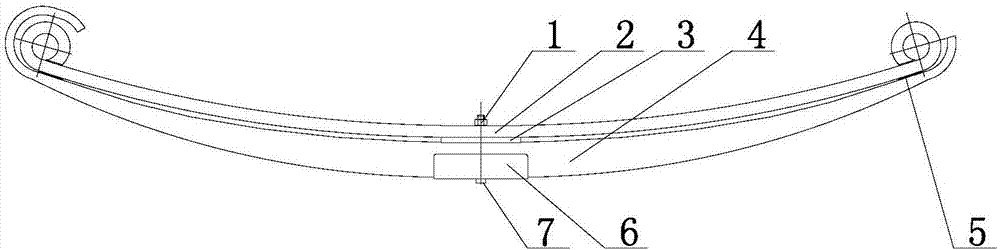

[0029] Such as figure 2 As shown, the leaf spring sheet 2 of the automobile composite leaf spring is an equal section, and its thickness is 12mm; the composite material spring sheet 4 adopts carbon fiber reinforced composite material, and its thickness is 20-65mm, and other structures are the same as in Embodiment 1.

[0030] Since the weight of carbon fiber composite material is 22% of that of steel, the weight of the whole set of automobile leaf springs can be further reduced by 50%-320%. It has been reduced from 29.6kg to the current 10.3kg; the fatigue strength has been increased from no more than 650MPa to more than 1000MPa; the fatigue life has been increased from 80,000 times to 200,000 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com