Patents

Literature

49results about How to "No enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

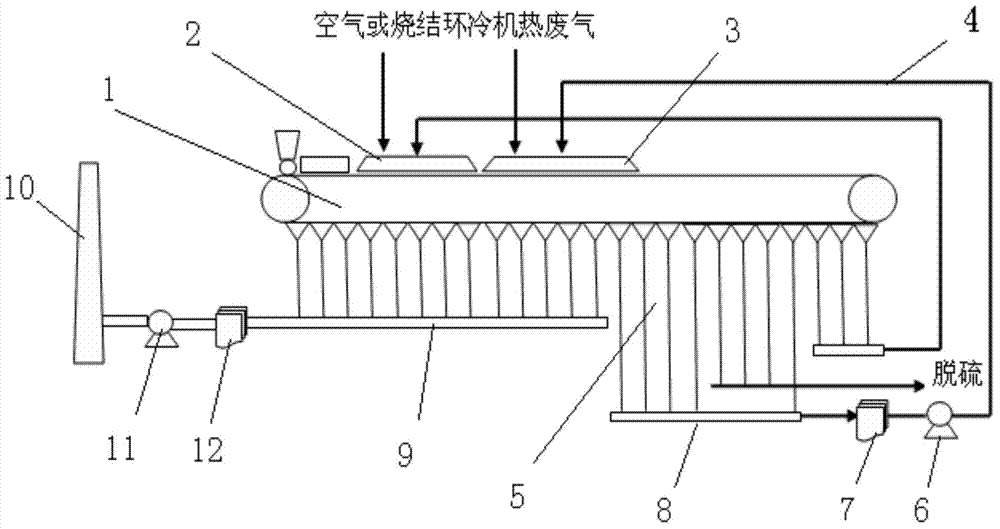

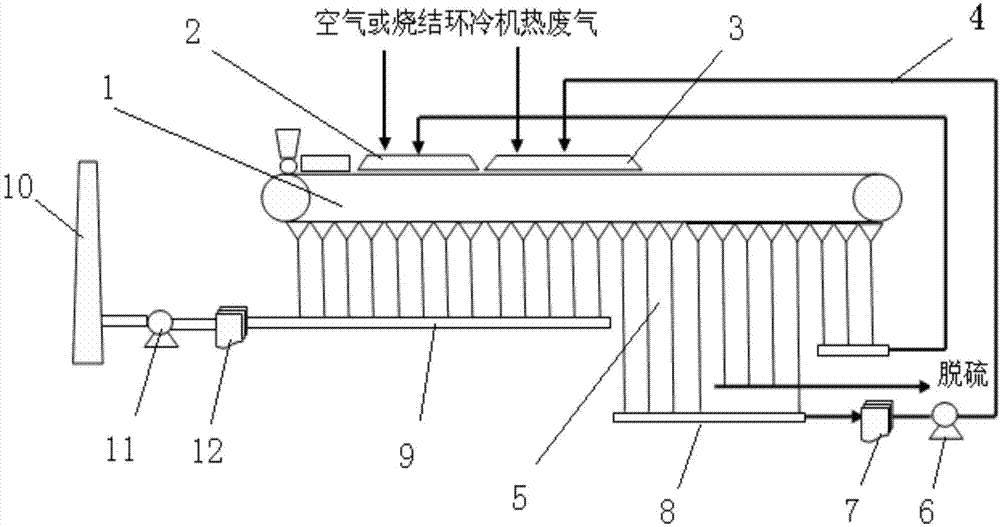

Iron mine sintering flue gas segmented circulation method

ActiveCN103499216AGuaranteed emission reductionAvoid enrichmentIncreasing energy efficiencyWaste heat treatmentFlue gasDust emission

The invention discloses an iron mine sintering flue gas segmented circulation method. Sintering flue gas high in O2 content on the tail portion of a sintering machine is circulated to the interior of a head flue cover of a sintering feed surface of the head portion of the sintering machine, flue gas of two to three bellows highest in SO2 content in a bellow on the tail portion of the sintering machine is conveyed to a desulfurization system to be desulfurized, and flue gas in other bellows is circulated to a middle flue cover of a sintering feed surface of the middle portion of the sintering machine. After segmented flue gas circulation is adopted, SO2 will not be accumulated in sintering ore, dust emission is reduced by 20-40%, NOx emission is reduced by 20-40%, dioxin emission is reduced by 50-80%, and CO2 emission is reduced by 20-45%.

Owner:CENT SOUTH UNIV

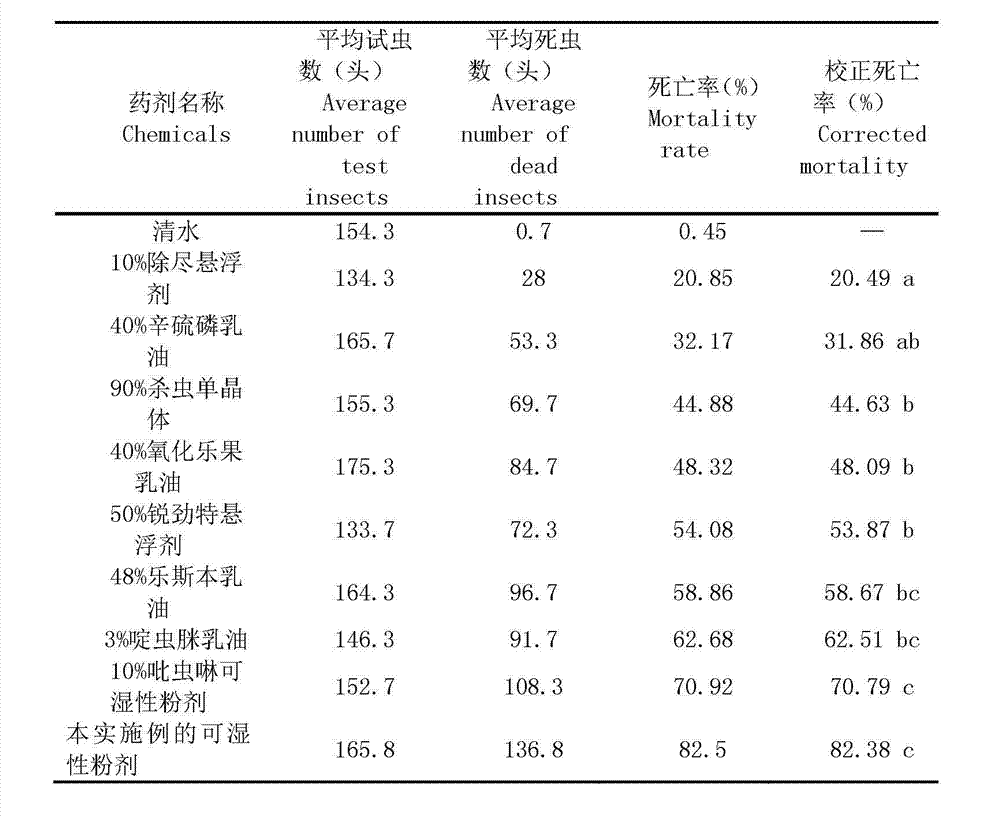

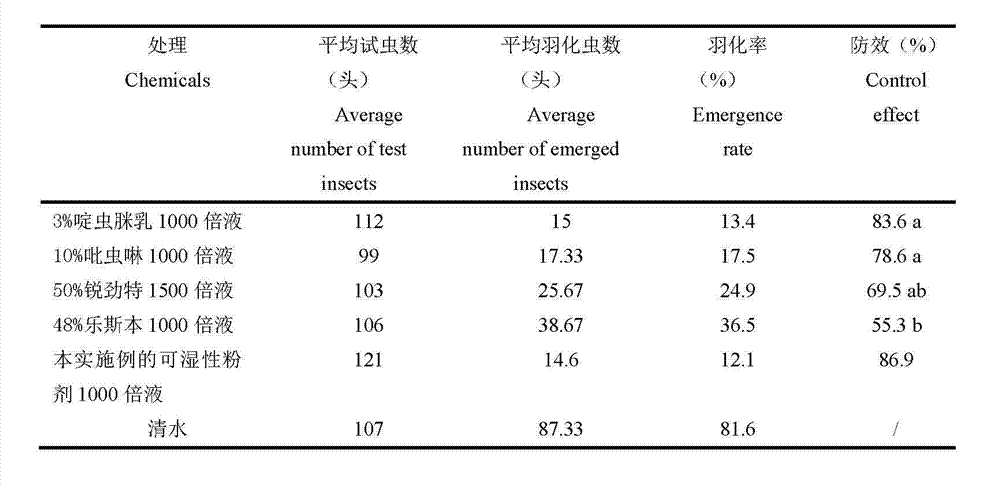

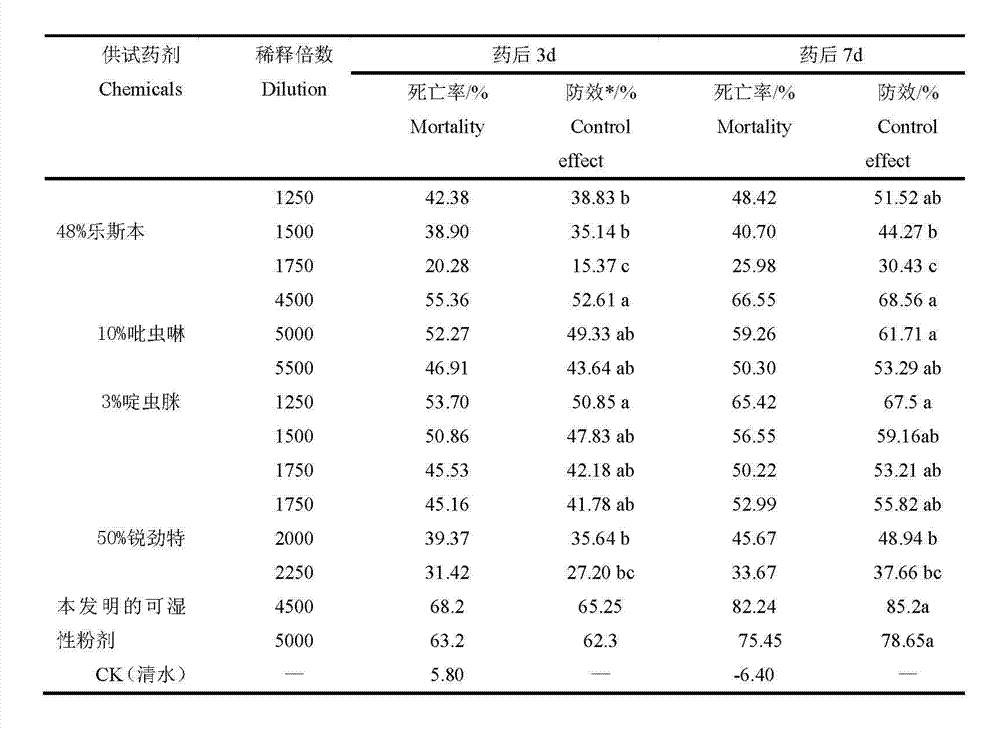

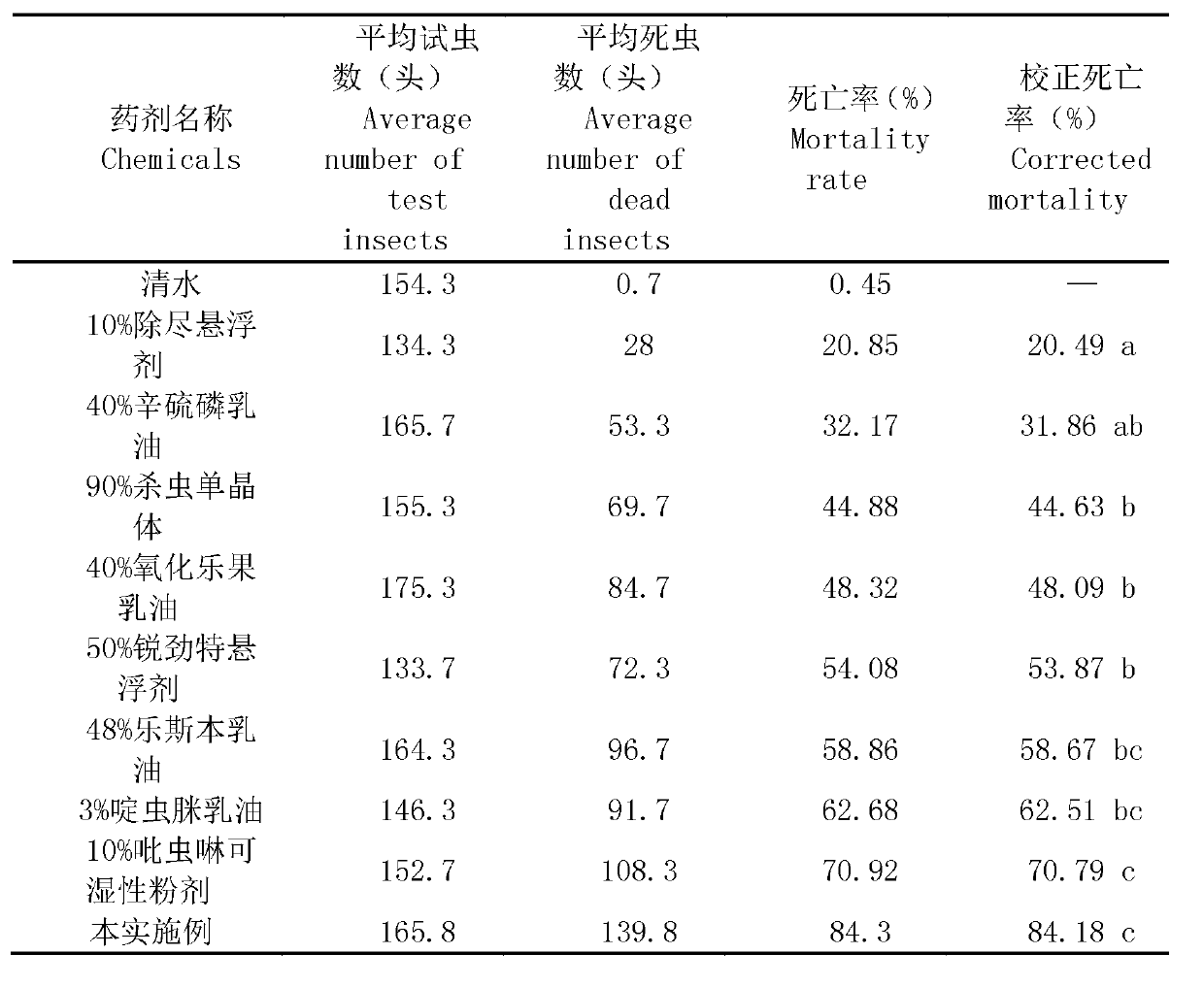

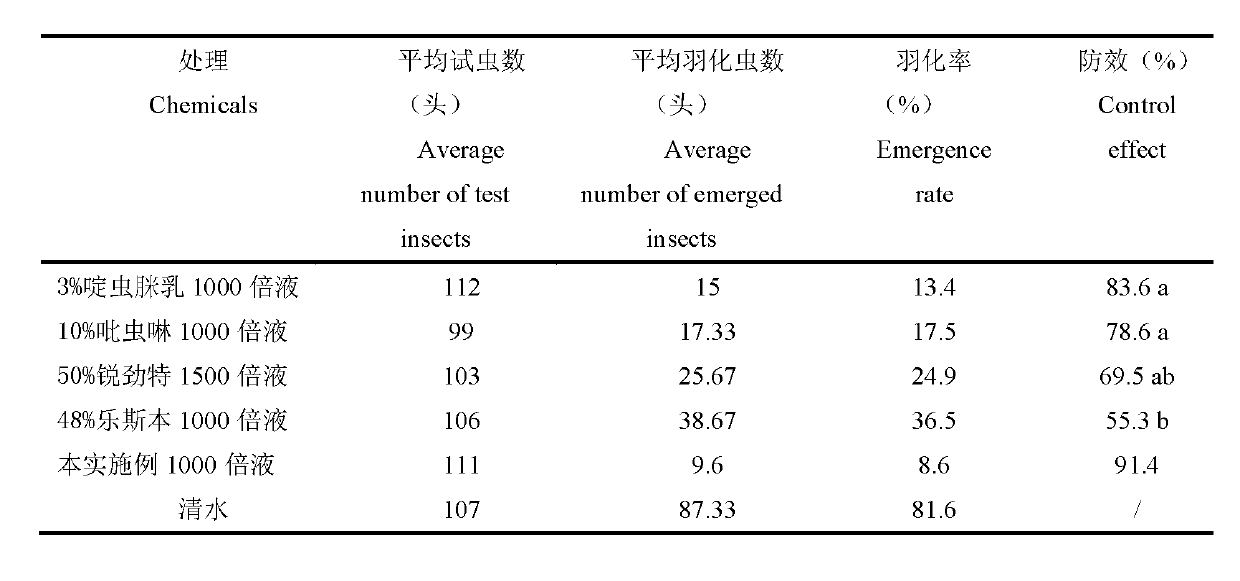

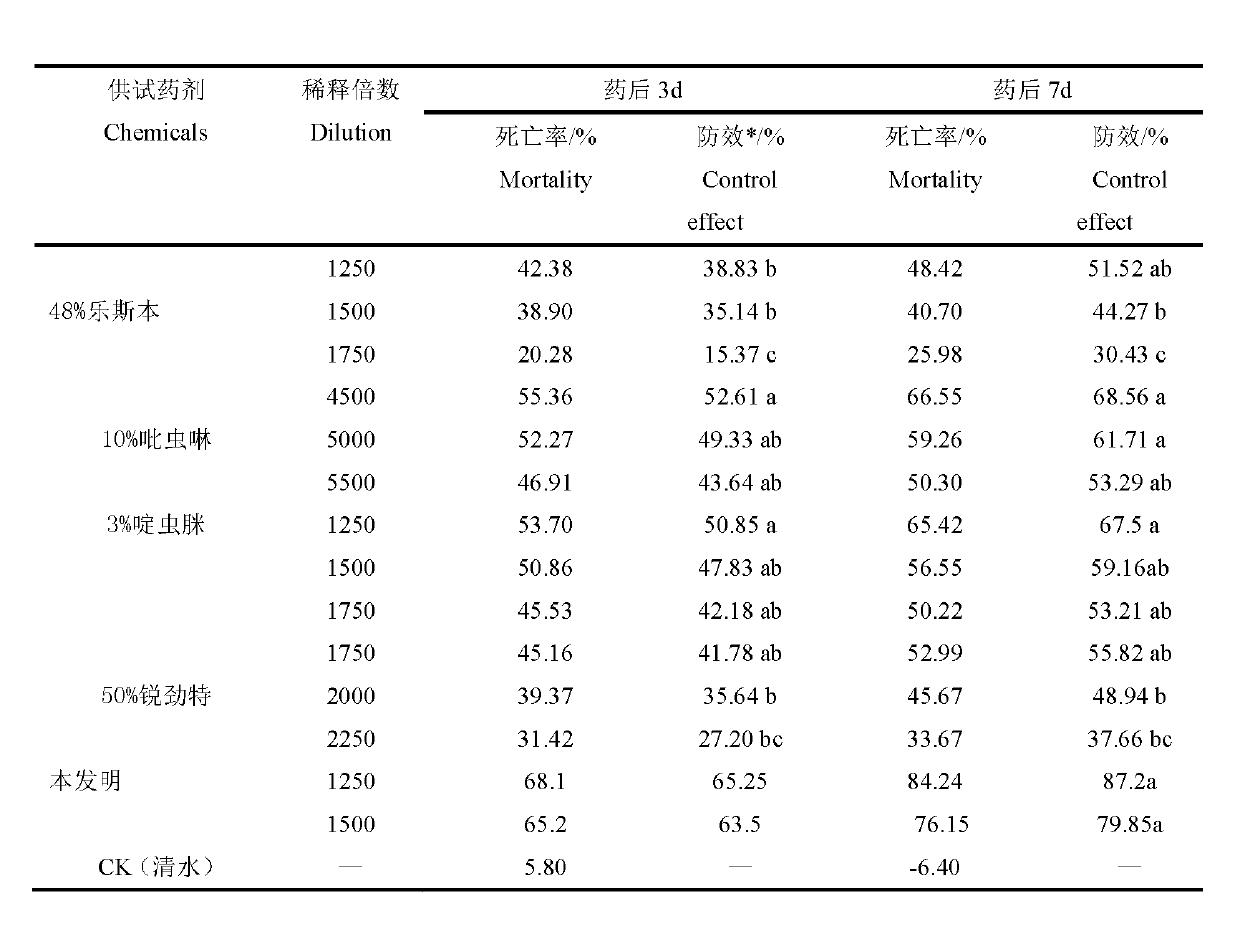

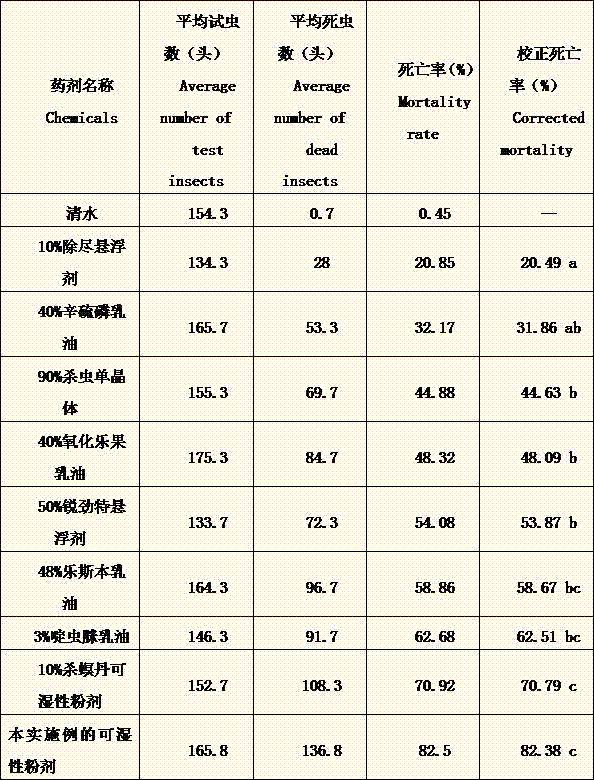

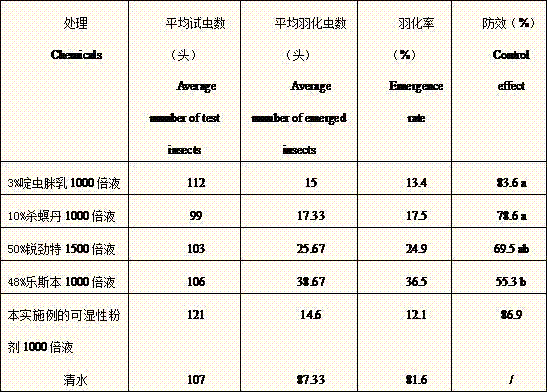

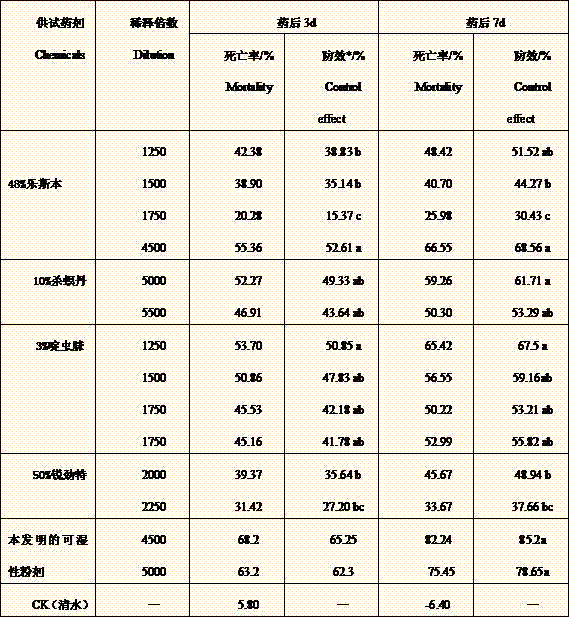

Imidacloprid complex pesticide for controlling pest of willow twig gall midge

InactiveCN102726465AProtect the environmentGood control effectBiocideAnimal repellantsCypressOrganic solvent

The invention relates to an imidacloprid complex pesticide for controlling the pest of willow twig gall midge. Active components in each 100 parts of the imidacloprid complex pesticide comprise, by weight, 9 to 11 of imidacloprid, 7 to 9 of angled bittersweet, 4 to 6 of lilac daphne flower bud, 4 to 6 of cyrtomium rhizome, 4 to 6 of neem fruit, 4 to 6 of euphorbia root, 4 to 6 of lightyellow sophora root, 4 to 6 of garlic, 4 to 6 of coptis, 4 to 6 of daturae flower, 2 to 3 of betel nut, 2 to 3 of common cnidium fruit, 2 to 3 of broom cypress fruit, 2 to 3 of Chinese honey locust leaves, 2 to 3 of ailanthus leaves, 2 to 3 of pine needle, 2 to 3 of stemona root and 2 to 3 of common threewingnut root. Each of the above-mentioned Chinese herbal medicines is extracted by using water or an organic solvent, and all the obtained extract products are used as raw materials for the pesticide. Production cost for the imidacloprid complex pesticide provided in the invention is low, and the raw materials are widely available; the pesticide has the characteristics of high efficiency, low toxicity, high security and environmental protection, enables resistance not to be generated and has special efficacy on controlling the pest of willow twig gall midge.

Owner:安徽华安达集团工艺品有限公司

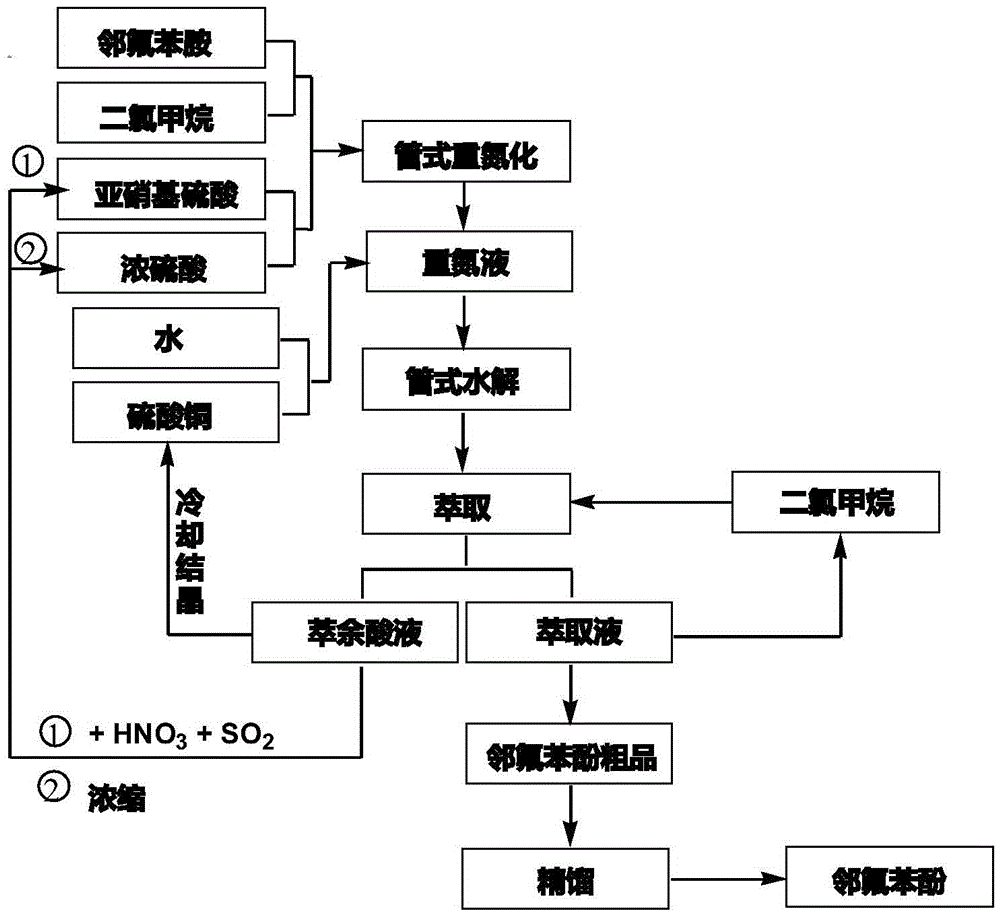

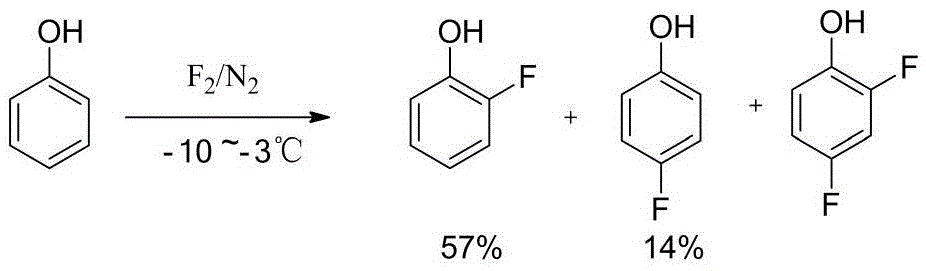

Tubular continuous o-fluorophenol production method

InactiveCN105481654ASolve the phenomenon of uneven temperature distributionAchieve recyclingOrganic chemistryOrganic compound preparationNitrosylsulfuric acidAfter treatment

The present invention discloses a tubular continuous o-fluorophenol production method comprising tubular diazo reaction of a nitrosyl sulfuric acid solution and an o-fluoroaniline solution in a tubular reactor to obtain a diazo solution; tubular hydrolysis reaction of the diazo solution and a copper sulphate water solution in the tubular reactor to obtain a hydrolysis solution; and after-treatment of the hydrolysis solution to obtain o-fluorophenol. The method uses the tubular reactor for the tubular diazo reaction and the tubular hydrolysis reaction to solve the phenomenon of material backmixing and uneven temperature distribution of kettle-type reaction, reduces the incidence of side effects, and improves the yield of the product.

Owner:ZHEJIANG LINJIANG CHEM

Pd/Al2O3 catalyst prepared by adopting spraying method and application of Pd/Al2O3 catalyst in catalytically reducing bromate in water

InactiveCN104437476AReduce wasteEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by reductionHydrogenBromate

The invention belongs to the technical field of ecomaterials, and particularly relates to a Pd / Al2O3 catalyst prepared b adopting a spraying method and application of the Pd / Al2O3 catalyst in catalytically reducing bromate in water. The Pd / Al2O3 catalyst is prepared by adopting the following steps: preparing a hydrochloric acid solution of palladium chloride, wherein the concentration of the hydrochloric acid solution is 1g / L to 100g / L, and the concentration of hydrochloric acid is 40ml / L to 80ml / L; carrying out the primary spraying after the palladium chloride is completely dissolved, uniformly spraying the palladium chloride solution onto the surface of aluminum oxide by utilizing a spraying device under the stirring condition to obtain a catalyst, drying the catalyst for 20 to 40 minutes at the temperature of 100 to 150 DEG C after the palladium chloride solution is uniformly sprayed, and carrying out the secondary spraying; drying the catalyst for 10 to 15 hours at the temperature of 100 to 150 DEG C after the secondary spraying; and calcining a precursor of the catalyst for 1 to 3 hours after twice spraying at the temperature of 400 to 500 DEG C, and then reducing the precursor of the catalyst by utilizing hydrogen at the temperature of 200 to 400 DEG C to obtain the Pd / Al2O3 catalyst. The catalyst prepared by adopting the spraying method has advantages that active ingredient palladium of the catalyst is concentrated on the surface of aluminum oxide particles, and the performance of the catalyst can be relatively efficiently played.

Owner:ZHANGJIAGANG GREEN TECH ENVIRONMENTAL PROTECTION EQUIP +1

Environment-friendly compound feeds capable of improving fertility of sciaenops ocellatus parent fish

InactiveCN103518948AShorten the time to sexual maturityReasonable collocationAnimal feeding stuffBiotechnologyAnimal science

The invention relates to environment-friendly compound feeds capable of improving the fertility of sciaenops ocellatus parent fish. The compound feeds are characterized in that the compound feeds consist of a basic feed component and a Chinese herbal medicinal additive, wherein the weight part ratio of the basic feed component to the Chinese herbal medicinal additive is (99.5-99.9):(0.1-0.5); the basic feed component consists of the following raw materials in parts by weight: 20 to 40 parts of fish meal, 10 to 30 parts of soybean meal, 5 to 15 parts of peanut meal, 4 to 10 parts of chicken meal, 10 to 30 parts of strong flour, 5 to 15 parts of beer yeast, 3 to 10 parts of squid paste, 1 to 5 parts of phospholipid oil, 1 to 5 parts of fish oil, 0.2 to 0.5 part of decavitamin, 0.5 to 1.5 parts of complex mineral, 0.3 to 1.0 part of a feed attractant, 0.1 to 0.3 part of L-ascorbate-2-phosphate, 1 to 3 parts of calcium dihydrogenphosphate, 0.01 to 0.05 part of a mildew-proof agent, 0.2 to 0.8 part of Te Mianwang, 0.1 to 0.3 part of salt, 0.05 to 0.15 part of choline chloride and 0.01 to 0.03 part of vitamin E. The feeds are nutritional and environment-friendly, the sexual maturity time of the sciaenops ocellatus parent fish can be shortened, the gonad development of the sciaenops ocellatus parent fish can be promoted, and the fertility of the sciaenops ocellatus parent fish can be improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Novel process for preparing vanadic anhydride from firing residue of vanadium-containing stone coal

InactiveCN101289225ALess investmentAvoid pollutionEnergy inputVanadium oxidesWater useAmmonium metavanadate

The invention relates to a novel technology for preparing vanadium pentoxide by using stone coal ignited residue containing scherbinaite, which comprises the following steps: the stone coal ignited residue containing scherbinaite is directly filled in a cement leaching tank without being smashed or ball-milled, and then leached by a dilute sodium carbonate solution at normal temperature or by heating at the temperature of 60 DEG C to 100 DEG C; the obtained leach solution is adsorbed by resin and desorbed by saturated sodium chloride; the desorbed solution is dephosphorized and then added with ammonium chloride to precipitate vanadium, so as to obtain ammonium metavanadate, and the ammonium metavanadate is pyrolyzed to obtain the vanadium pentoxide. The invention has the advantages that (1) the nubbly stone coal ignited residue containing the scherbinaite is directly filled in the cement leaching tank for leaching so that the investment of fixed assets is saved and the problem of dust pollution in workshop is solved; (2) energy is saved by utilizing the waste heat of a roasting furnace for heating the leach solution, the leaching speed is quickened, the recovery rate is improved and the grade of vanadium contained in the leach solution is enriched; (3) by adopting the dilute sodium carbonate solution to substitute sulphuric acid for warming leaching, per ton of fine vanadium consumes approximately 2 tons of sodium carbonate only, therefore, production cost is saved compared with leaching per ton by sulphuric acid; (4) the water used for working can be recycled, thus realizing zero release; the leach residue is slightly alkaline and meets the national placement standards of general wastes.

Owner:杨秋良

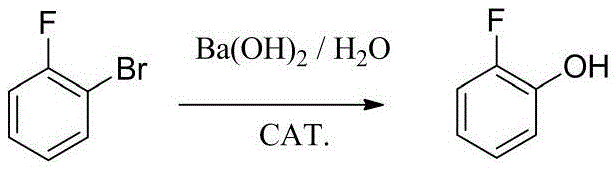

Forming technology of diamond bead cold pressed blank

ActiveCN103263875ANo enrichmentMeet preparation requirementsGranulation by material expressionDisadvantageA diamond

The invention discloses a forming technology of a diamond bead cold pressed blank, comprising the following steps of: (1) pelletizing powder material to be compressed, to obtained pelletized powder; (2) simultaneously and bilaterally compressing the pelletized powder; (3) when compressed, automatically sinking a lower pressure head, to change a final forming position; (4) and sintering after completing compression, and then completing preparation of the diamond beads after stirring. The technology not only can solve disadvantages of traditional manual cold press, simultaneously, but also can provide a diamond bead cold press forming technology with wider adaptability and more stable performances, and further promotes development of a diamond rope saw.

Owner:长沙百通新材料科技有限公司

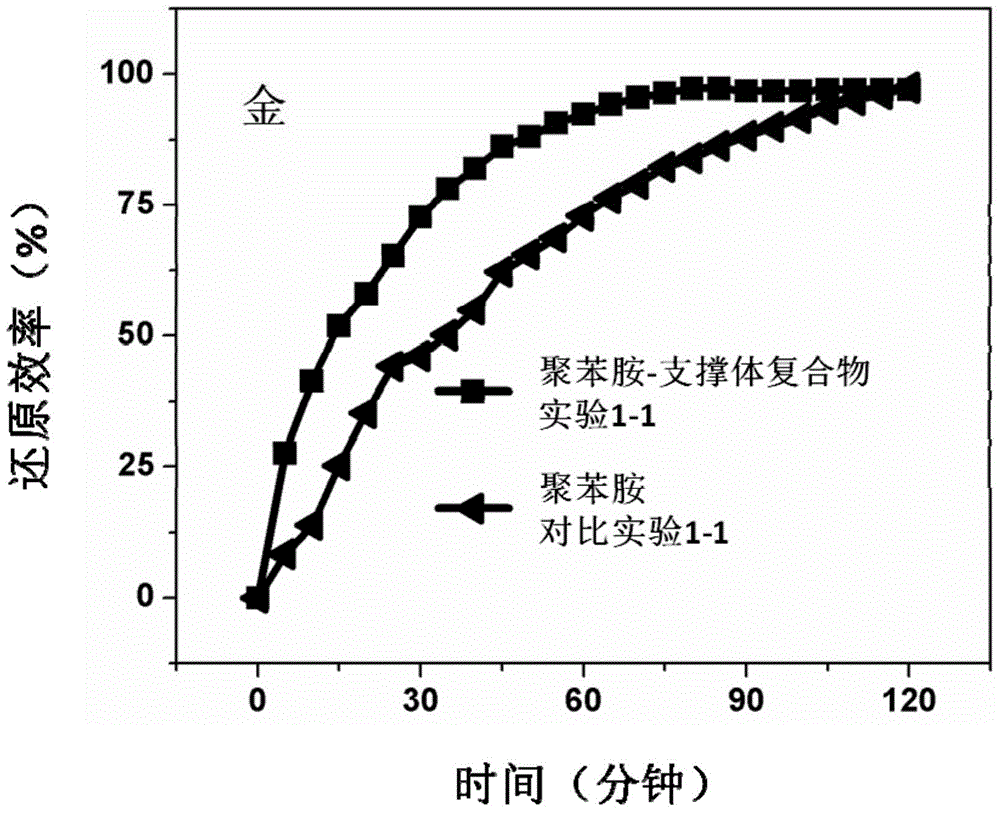

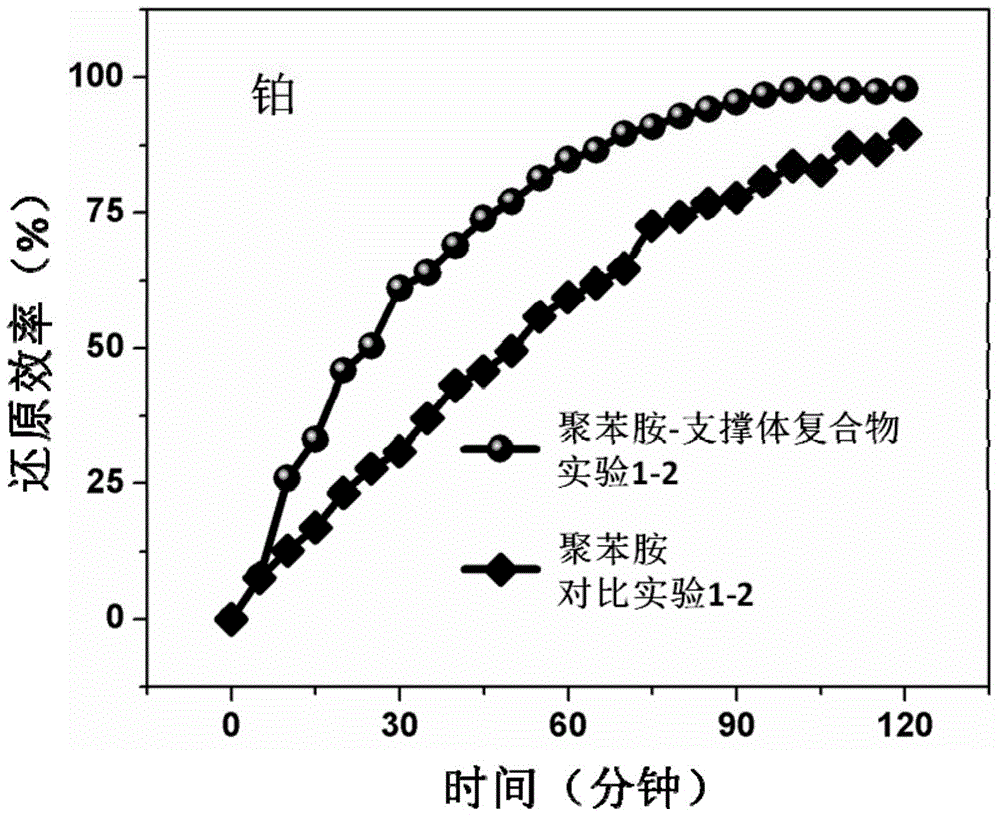

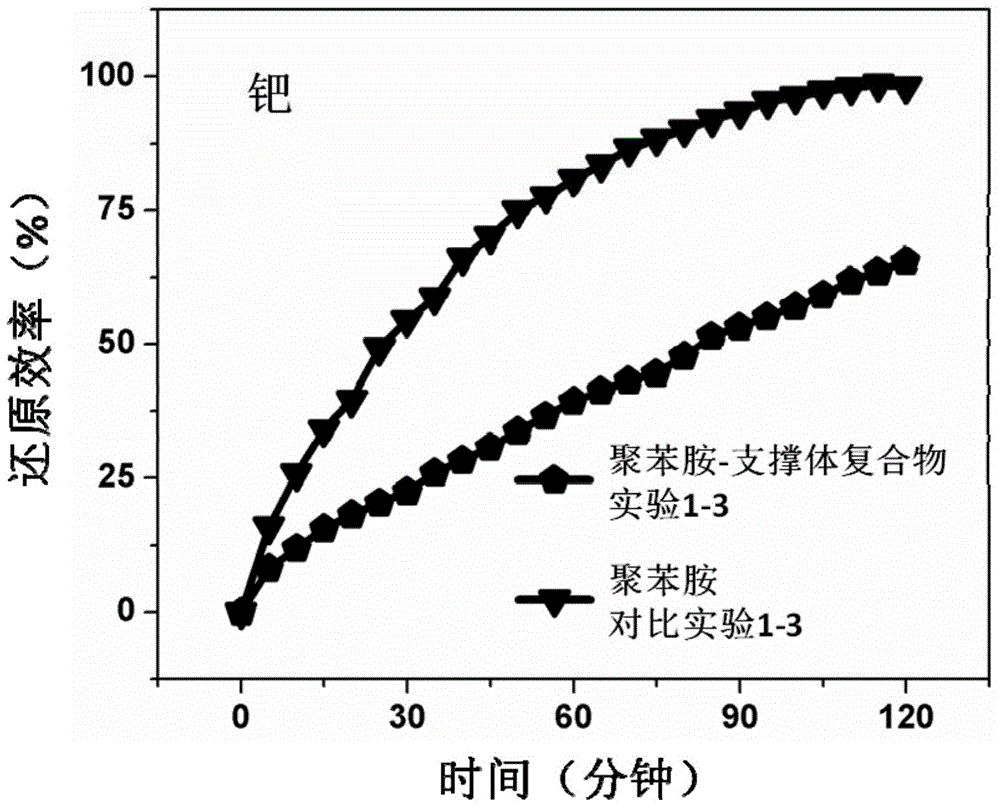

Conductive polymer-supporter composite material, preparation method and applications

InactiveCN104629047AAvoid reunionAvoid sticking and other problemsProcess efficiency improvementPolypyrroleHeteroatom

The invention provides a conductive polymer-supporter composite material, which is composed of a conductive polymer material and a supporter material, wherein the supporter material is taken as the carrier, and the conductive polymer material is dispersed on the surface of the supporter material. The conductive polymer material can be one of polyaniline, polypyrrole, polythiophene, and ring / heteroatom substituted derivatives thereof. The composite material has a high specific surface area, can effectively avoid the agglomeration and adhesion among conductive polymer materials (polyaniline, polypyrrole, polythiophene, and the like), and has a high adsorption and reduction performance on recycling metal elements in wastes, and the metal recovery efficiency is effectively increased.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Acetamiprid complex pesticide for controlling pest of willow twig gall midge

The invention relates to an acetamiprid complex pesticide for controlling the pest of willow twig gall midge. Active components in each 100 parts of the acetamiprid complex pesticide comprise, by weight, 4 to 6 of imidacloprid, 9 to 11 of angled bittersweet, 9 to 11 of euphorbia root, 9 to 11 lightyellow sophora root, 4 to 6 of lilac daphne flower bud, 4 to 6 of cyrtomium rhizome, 4 to 6 of neem fruit, 4 to 6 of prickly ash peel, 4 to 6 of coptis, 4 to 6 of monkshood, 2 to 3 of betel nut, 2 to 3 of common cnidium fruit, 2 to 3 of aloe, 2 to 3 of morning glory seeds, 2 to 3 of honeycomb, 2 to 3 of pine needle, 2 to 3 of stemona root and 2 to 3 of common threewingnut root. Each of the above-mentioned Chinese herbal medicines is extracted by using water or an organic solvent, and all the obtained extract products are used as raw materials for the pesticide. Production cost for the imidacloprid complex pesticide provided in the invention is low, and the raw materials are widely available;the pesticide has the characteristics of high efficiency, low toxicity, high security and environmental protection, enables resistance not to be generated and has special efficacy on controlling the pest of willow twig gall midge.

Owner:安徽华安达集团工艺品有限公司

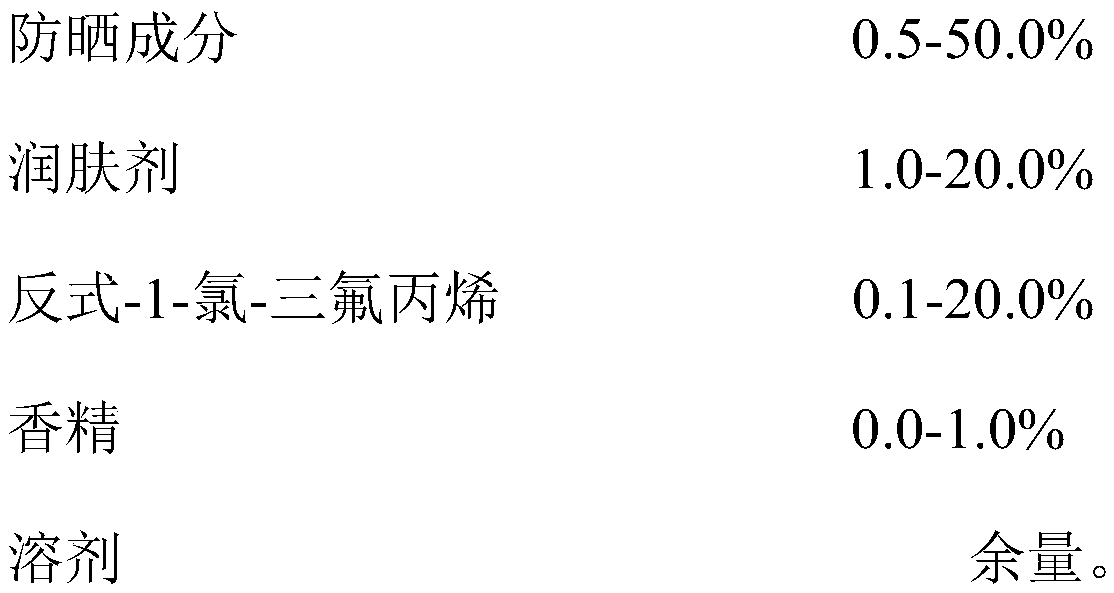

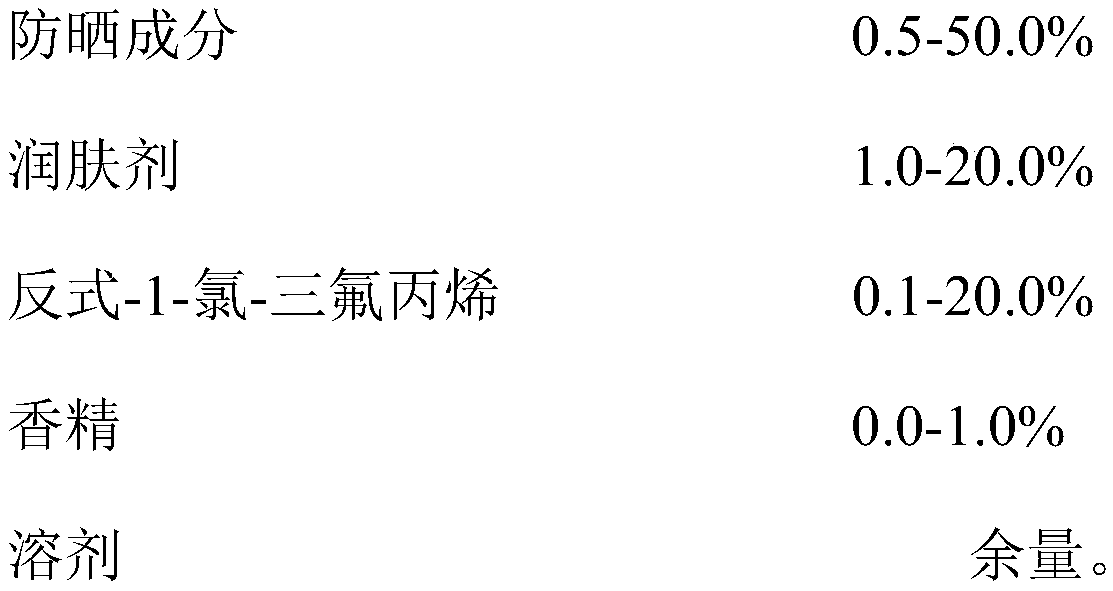

Sun-screening agent spray

InactiveCN109431826AEconomic savingsPrevent intrusionCosmetic preparationsToilet preparationsCooling effectAgricultural engineering

The invention discloses sun-screening agent spray. Sun-screening components with strong light sensitivity, an emollient, a solvent, a cooling agent, and the like are stored into an aerosol tank in anisolating mode through a bag, and a propellant is charged between the aerosol tank and the bag, wherein the cooling agent is preferably trans-1-chloro-trifluoropropene. The spray disclosed by the invention is cool, quick-drying and free of unpleasant smell. According to the invention, in use of a spray tank, a spray valve which can be rotated by 360 degrees is adopted to the operation and use of the sun-screening agent spray, and the sun-screening agent spray is safe (non-combustible), environmentally friendly (low-GWP and low-VOC), efficient and convenient, can effectively protect the effectiveness of a sun-screening agent within a quality guarantee period, and has cooling effect. The sun-screening agent spray disclosed by the invention is easy to carry, easy to use, easy to store, and safe and reliable, and has very excellent application performance.

Owner:ZHONGSHAN TIANTU FINE CHEM CO LTD

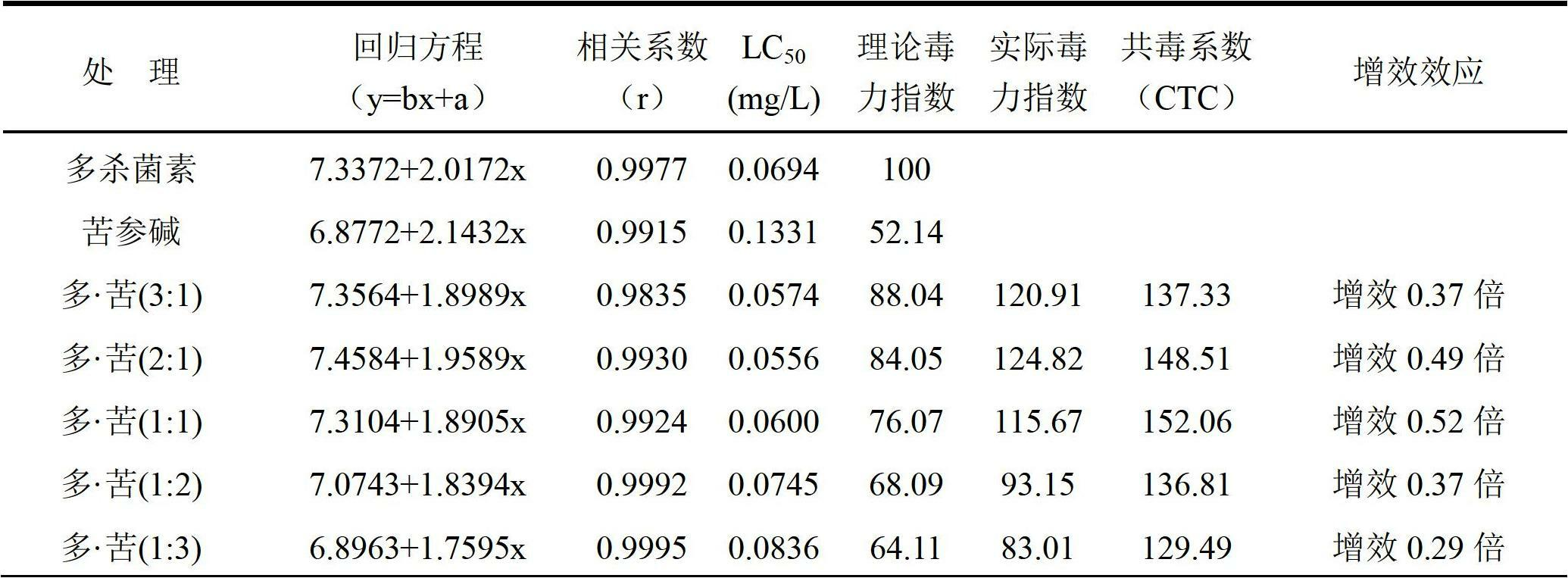

Biological source compound insecticide and application thereof

InactiveCN102669124AEfficient combinationGood poison effectBiocideAnimal repellantsSpinosadSophocarpidine

The invention discloses a biological source compound insecticide and application thereof, belonging to the field of compound insecticides. The major active ingredients of the compound insecticide include spinosyns and sophocarpidine; and each liter of insecticide diluted in filed contains 5-20mg of the mixture of the compounded active ingredients of spinosyns and sophocarpidine. The invention also discloses application of the compound insecticide in preventing and controlling plutella xylostella and thrips. In the invention, by compounding two known pesticides in a certain manner, a synergistic efficient insecticide is obtained, and an obvious synergistic effect is shown in the simulation test and field test; and in the invention, the spinosyns and sophocarpidine are biological source preparations which bring little pollution to the environment and products and can be automatically degraded so as to avoid the enrichment.

Owner:JIANGSU LVDUN PLANT PROTECTION AGROCHEM EXPERIMENTAL +1

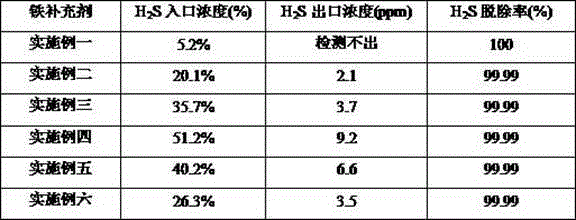

Iron supplement for chelating iron desulfurization solution as well as preparation method thereof

ActiveCN103878029ANo enrichmentPrevent crystallizationOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationIron supplementImpurity

The invention relates to an iron supplement for a chelating iron desulfurization solution as well as a preparation method thereof. The iron supplement is prepared from hydrous oxide of iron (FexOy.H2O) as well as a metal chelating agent and alkaline by reaction at certain temperature. Compared with the conventional iron supplements, because the iron supplement does not contain impurity anions, such as Cl<1->, NO3<1-> and SO4<-2>, the problem of equipment corrosion caused by Cl<1-> is eliminated effectively; the problem of subsequent wastewater treatment caused by NO3<1-> is also eliminated; most importantly, the separation by crystallization of salt caused by enrichment of SO4<-2> is prevented; the loss of the desulfurization solution can be reduced obviously; the running safety of equipment can be ensured.

Owner:宁夏胜蓝化工环保科技有限公司

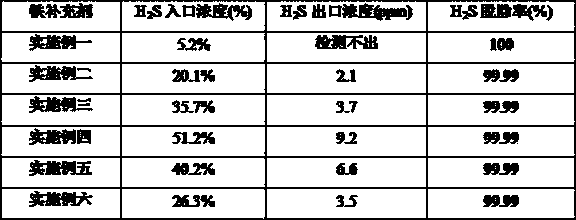

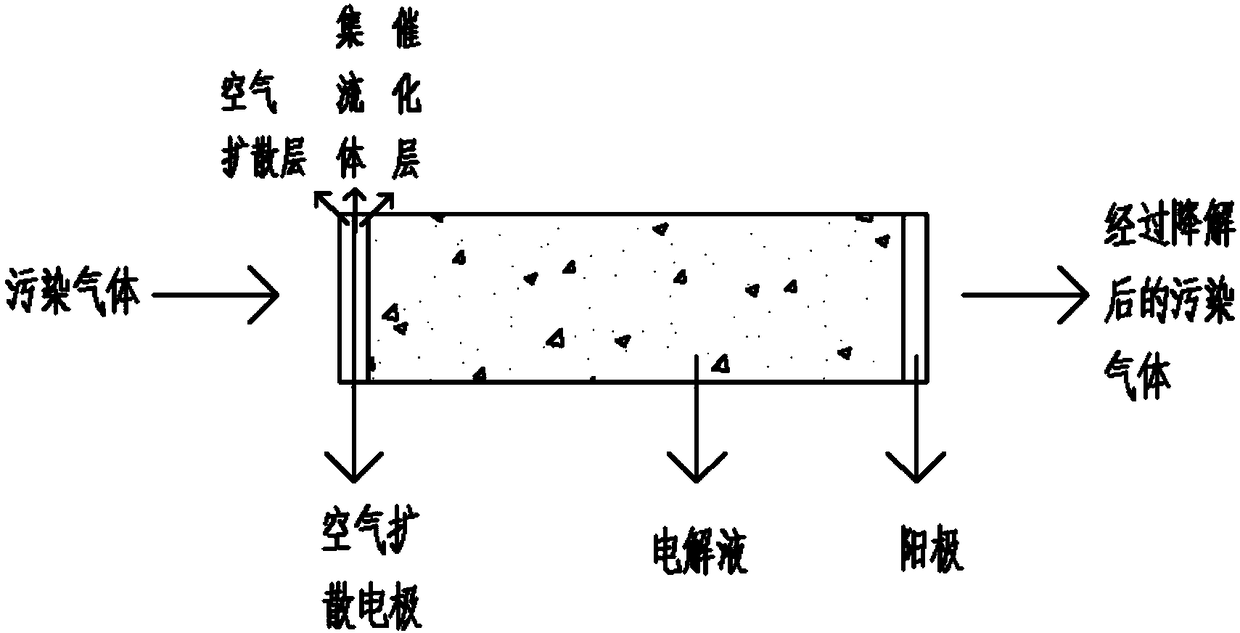

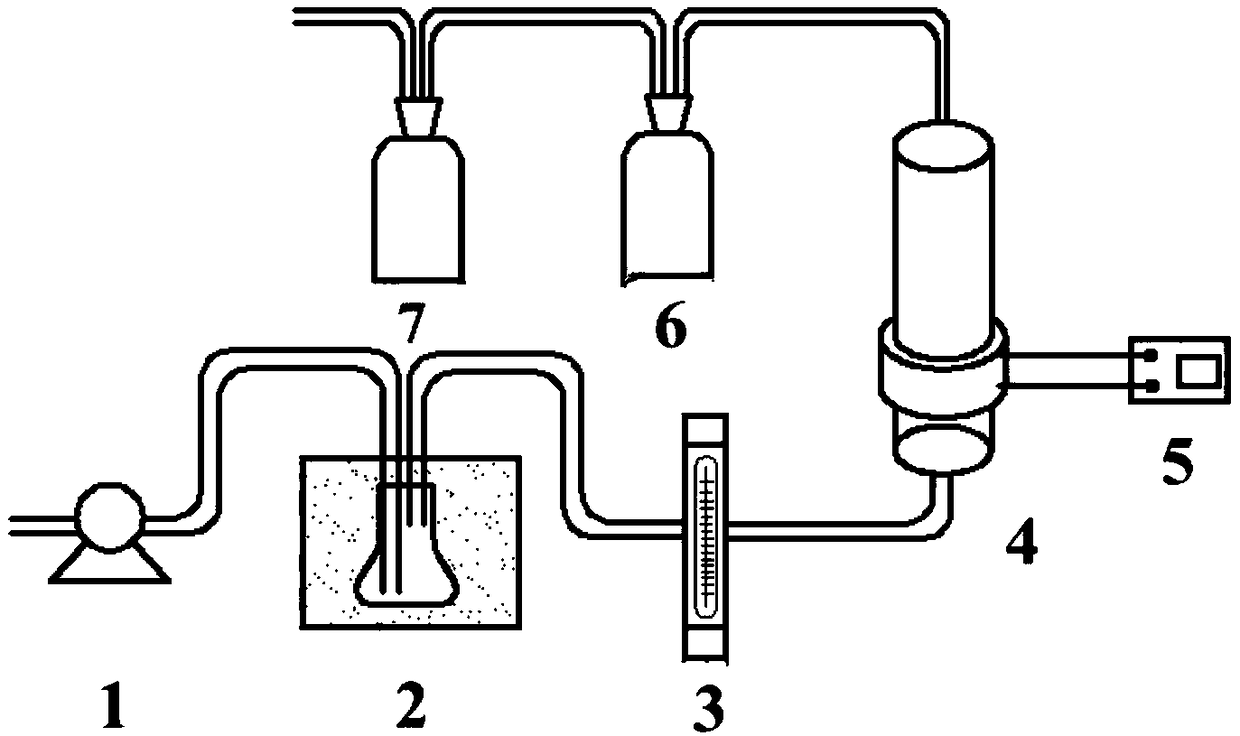

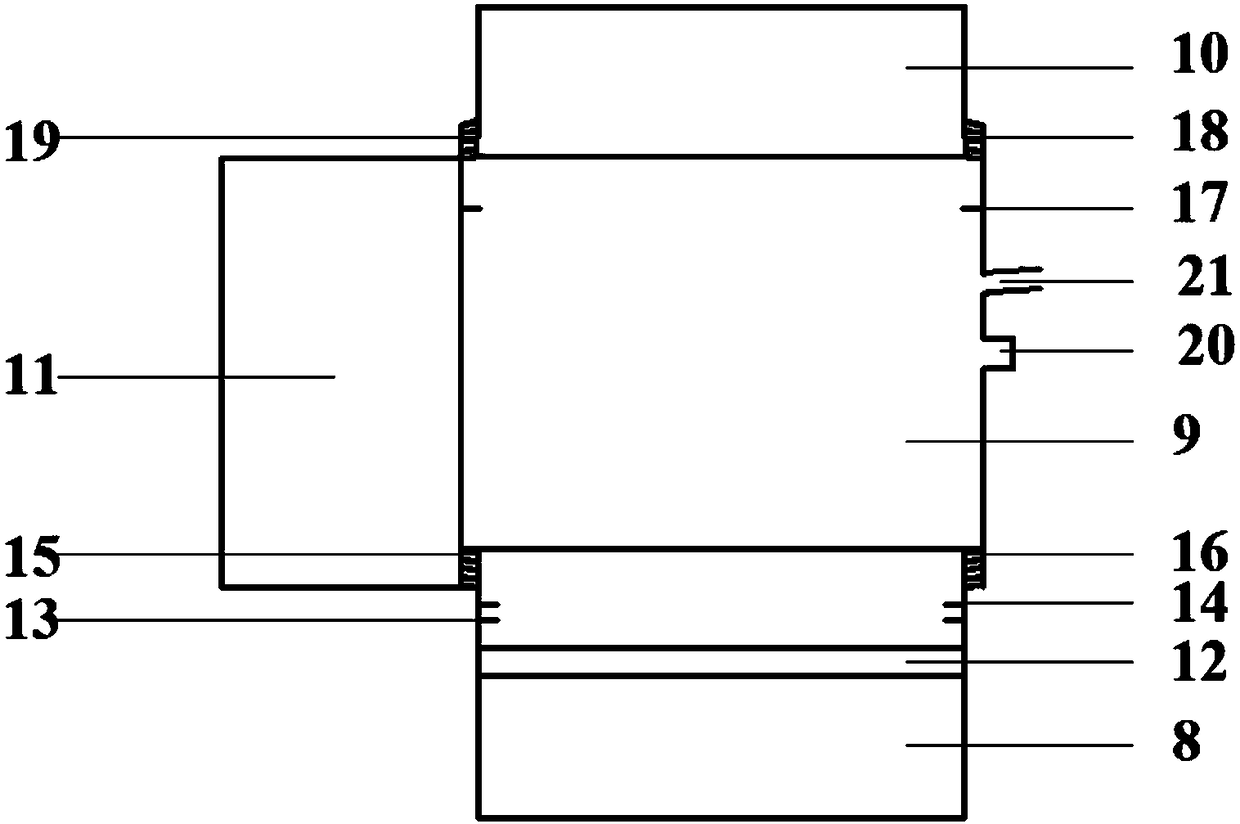

Flow reactor, device and method for electrochemically degrading volatile organic pollutants

PendingCN108325350AEfficient degradationMeet the process requirementsGas treatmentDispersed particle separationElectrochemical degradationEnvironmental engineering

The invention discloses a flow reactor, a device and a method for electrochemically degrading volatile organic pollutants. The flow reactor is a hollow cylinder and comprises a gas inlet tank, a casing and a gas outlet tank sequentially from bottom to top; the gas inlet tank has a bottom surface and no cover, small holes for accommodating a gas inlet pipe are formed in the side wall, and a diaphragm type microporous air diffuser and a cathode air diffusion electrode are sequentially arranged above the small holes and in the gas inlet tank; the casing has no bottom or cover, and an anode platinum sheet with small holes is arranged at the top; the gas outlet tank has a cover and has no bottom, and a lead-out pipe is arranged at the top. The invention also discloses a device comprising the flow reactor and used for electrochemically degrading volatile organic pollutants and a method for electrochemically degrading volatile organic pollutants with the device. The device is simple and convenient to operate, cannot cause secondary pollution and can effectively degrade organic matter and the like.

Owner:HOHAI UNIV

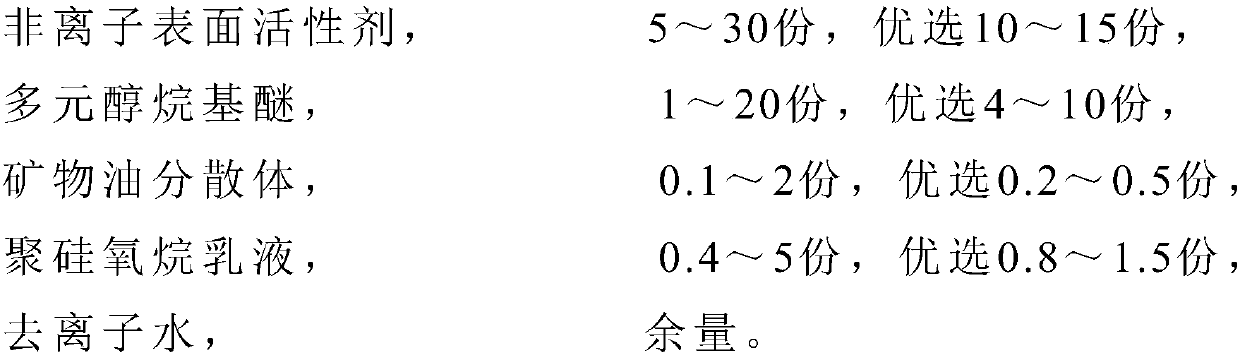

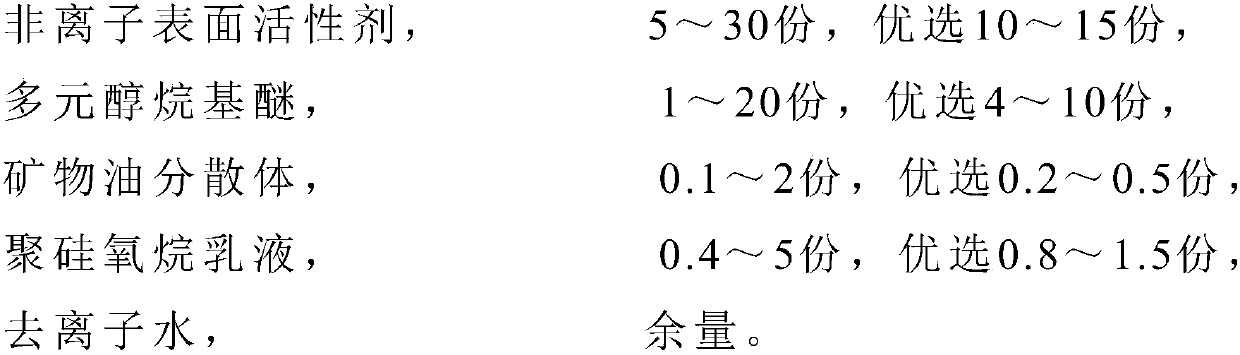

Special biodegradable cleaning agent for building roof and preparation method thereof

ActiveCN108048234AAvoid pollutionEasily biodegradableOrganic detergent compounding agentsPolymeric surface-active compoundsEmulsionCleansing Agents

The invention provides a special biodegradable cleaning agent for a building roof and a preparation method thereof. The cleaning agent is prepared from a nonionic surfactant, polyol alkyl ether, mineral oil dispersoid, a polysiloxane emulsion, an anionic surfactant, components of hydramine compounds, and deionized water. The special biodegradable cleaning agent can rapidly and effectively remove oily dirt required to be washed in a targeted manner, can be rapidly emulsified, dispersed and dissolved in water, is nontoxic or low-toxic, does not have pungent smell, is green and environmentally friendly, has biodegradability, and is convenient to operate.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

Mosquito disease and pest preventing cartap compound insecticide

InactiveCN107258835ANo pollutionNo drug resistanceBiocideDead animal preservationBetel nutsBacillus thuringiensis

The invention discloses a mosquito disease and pest preventing cartap compound insecticide. The cartap compound insecticide is characterized by being prepared from, by weight, 9-11 parts of cartap, 7-9 parts of bamboo charcoal fiber, 4-6 parts of bacillus thuringiensis, 4-6 parts of cyrtomium rhizome, 4-6 parts of neem nuts, 4-6 parts of roots of stellera chamaejasme, 4-6 parts of coptis chinensis, 4-6 parts of flos daturae, 2-3 parts of betel nuts, 2-3 parts of fructus cnidii, 2-3 parts of fructus kochiae, 2-3 parts of honeylocust tree leaves, 2-3 parts of ailanthus leaves, 2-3 parts of a binder dose, 2-3 parts of a wetting and dispersing agent, 2-3 parts of warning color, 4-6 parts of radix sophorae flavescentis and 4-6 parts of garlic. The traditional Chinese herbal medicine is dispensed to the insecticide in the form of a water extract or an organic solvent after being subjected to water extraction or organic solvent extraction.

Owner:合肥裕亿农业技术开发有限公司

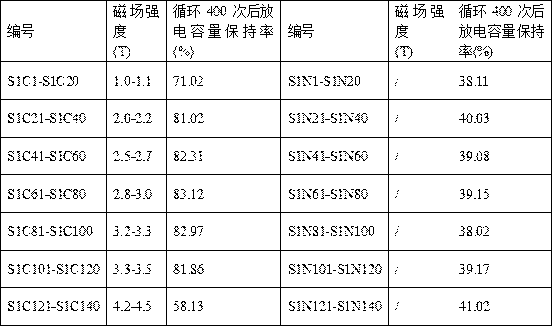

Method for improving charging efficiency of secondary battery

ActiveCN110783645AExtended service lifeFacilitate the reduction reactionSecondary cells charging/dischargingActive componentParticle physics

The invention relates to the field of secondary batteries, and in particular relates to a method for improving the charging efficiency of a secondary battery. According to the method, a source magnetic field is applied to the secondary battery; the source magnetic field acts between the positive electrode and the negative electrode of the secondary battery to form a promoting magnetic field; and under the action of the promoting magnetic field, the movement of some charged particles is accelerated to cause the charged particles to form the state of curvilinear motion. According to the invention, the formed promoting magnetic field is applied to effectively regulate and control the charging process of the secondary battery and improve the charging efficiency; concentration and particle enrichment in the battery are prevented under the effect of the promoting magnetic field, thereby improving the uniformity of the movement of the charged particles; the reaction area of the negative electrode is increased; the reduction reaction of the negative electrode during charging is improved, and the charging efficiency is improved; active components of the negative electrode can be effectivelyprotected, and loss and shedding thereof are reduced; and the service life of the battery is prolonged.

Owner:ZHEJIANG UNIV OF TECH

An iron supplement for complex iron desulfurization solution and preparation method thereof

ActiveCN103878029BNo enrichmentPrevent crystallizationOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationWastewaterIron supplement

The invention relates to an iron supplement for a chelating iron desulfurization solution as well as a preparation method thereof. The iron supplement is prepared from hydrous oxide of iron (FexOy.H2O) as well as a metal chelating agent and alkaline by reaction at certain temperature. Compared with the conventional iron supplements, because the iron supplement does not contain impurity anions, such as Cl<1->, NO3<1-> and SO4<-2>, the problem of equipment corrosion caused by Cl<1-> is eliminated effectively; the problem of subsequent wastewater treatment caused by NO3<1-> is also eliminated; most importantly, the separation by crystallization of salt caused by enrichment of SO4<-2> is prevented; the loss of the desulfurization solution can be reduced obviously; the running safety of equipment can be ensured.

Owner:宁夏胜蓝化工环保科技有限公司

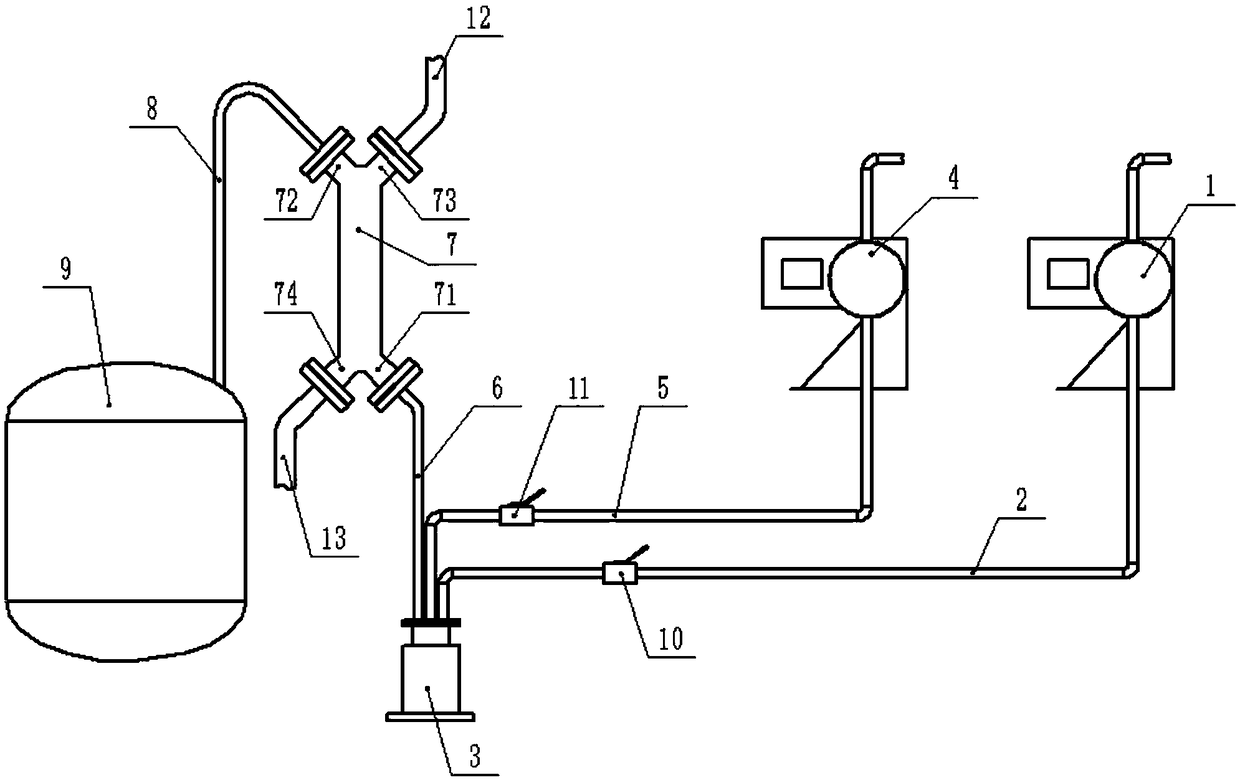

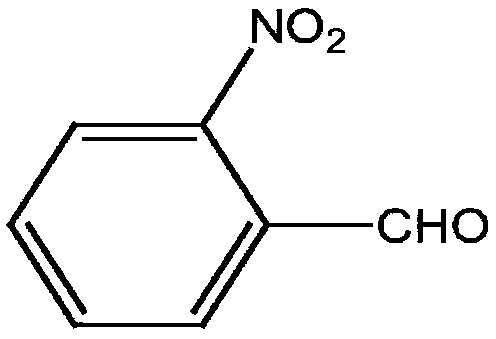

Nitrating device and nitrating process and method for preparing o-nitrobenzaldehyde

InactiveCN108947848AIncrease initial reaction speedSmooth feedingNitro compound preparationProduction lineLiquid storage tank

The invention discloses a nitrating device for preparing o-nitrobenzaldehyde. The nitrating device comprises a first flow pump, a pipeline I, a magnetic stirrer, a second flow pump, a pipeline II, a pipeline III, a spiral-pipe heat exchanger, a pipeline IV and a liquid storage tank, wherein the first flow pump is connected to the magnetic stirrer by the pipeline I; the second flow pump is connected to the magnetic stirrer by the pipeline II; the magnetic stirrer is connected to the spiral-pipe heat exchanger by the pipeline III; the spiral-pipe heat exchanger is connected to the liquid storagetank by the pipeline IV. The invention also discloses a nitrating process and method for preparing the o-nitrobenzaldehyde. The nitrating device and the nitrating process and method disclosed by theinvention has the advantages that the initial reaction speed is increased; continuous feeding is achieved; the reaction time is short, and the total amount of participated reaction materials is less;when the factors such as power failure, water supply shutdown and stirring stoppage and the like occur, since the total amount of reaction materials in a reaction device is less, no explosion risk iscaused; a pipeline reactor adopts a production-line process, and is small in device and large in yield.

Owner:安庆长宏科技股份有限公司

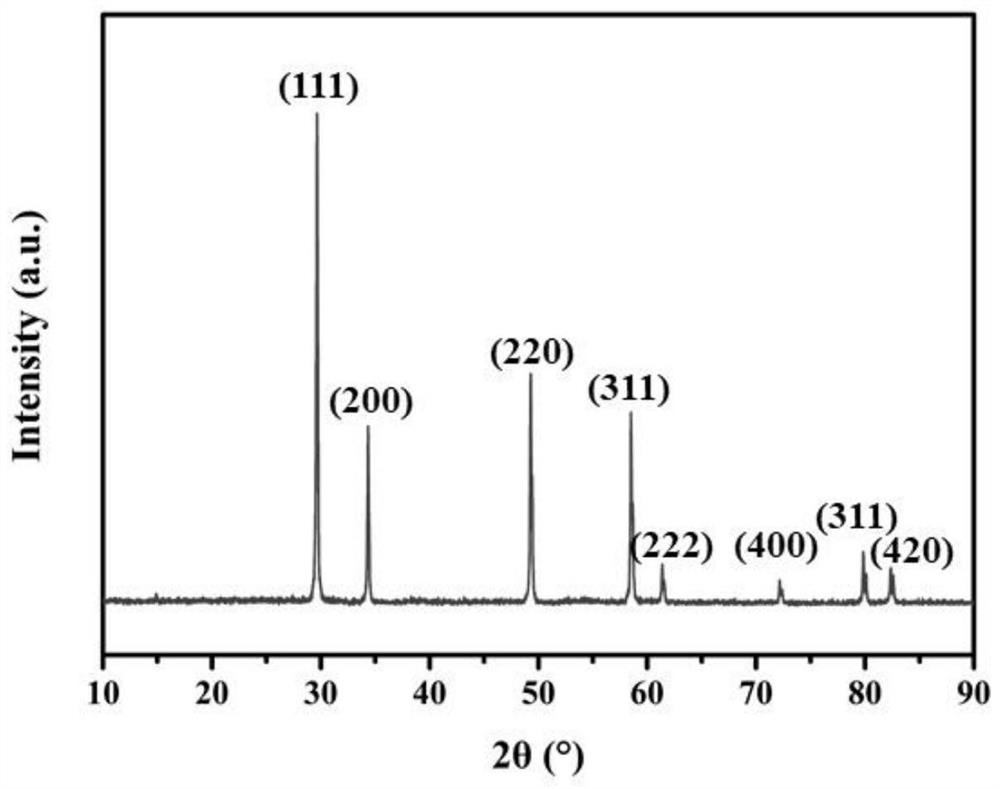

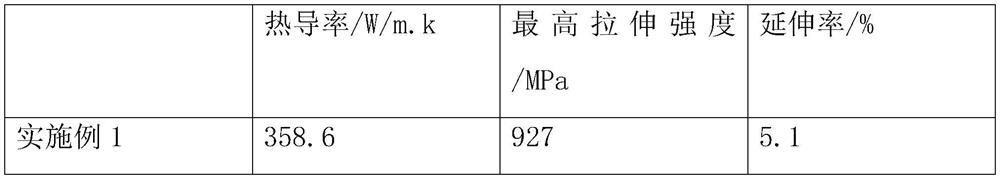

High-thermal-conductivity brazing filler metal suitable for packaging power semiconductor device

InactiveCN109759740AExcellent nano characteristicsNo enrichmentWelding/cutting media/materialsSoldering mediaHeat conductingFiller metal

The invention discloses a high-thermal-conductivity brazing filler metal suitable for packaging a power semiconductor device. The high-thermal-conductivity brazing filler metal is composed of the following components of, in percentage by weight, 0.01-0.5% of nano heat-conducting material and the balance Sn, wherein the nano heat-conducting material is MgO and / or ZnO and NiO. The brazing filler metal is made of the nano heat-conducting material, the heat conduction performance of the brazing filler metal is good, welding temperature is low in the using process, energy consumption is low, the welding process is excellent in operation, residual corrosion after welding is small, so that the brazing filter material is suitable for packaging the power semiconductor device, and can replace an existing aluminum soft soldering flux. The invention further discloses a preparation method of the high-thermal-conductivity brazing filler metal suitable for packaging the power semiconductor device. The preparation method disclosed by the invention has the advantages that steps are few, specific equipment is not required to be customized, the production is simple and convenient, and the productioncost is low.

Owner:广东中实金属有限公司

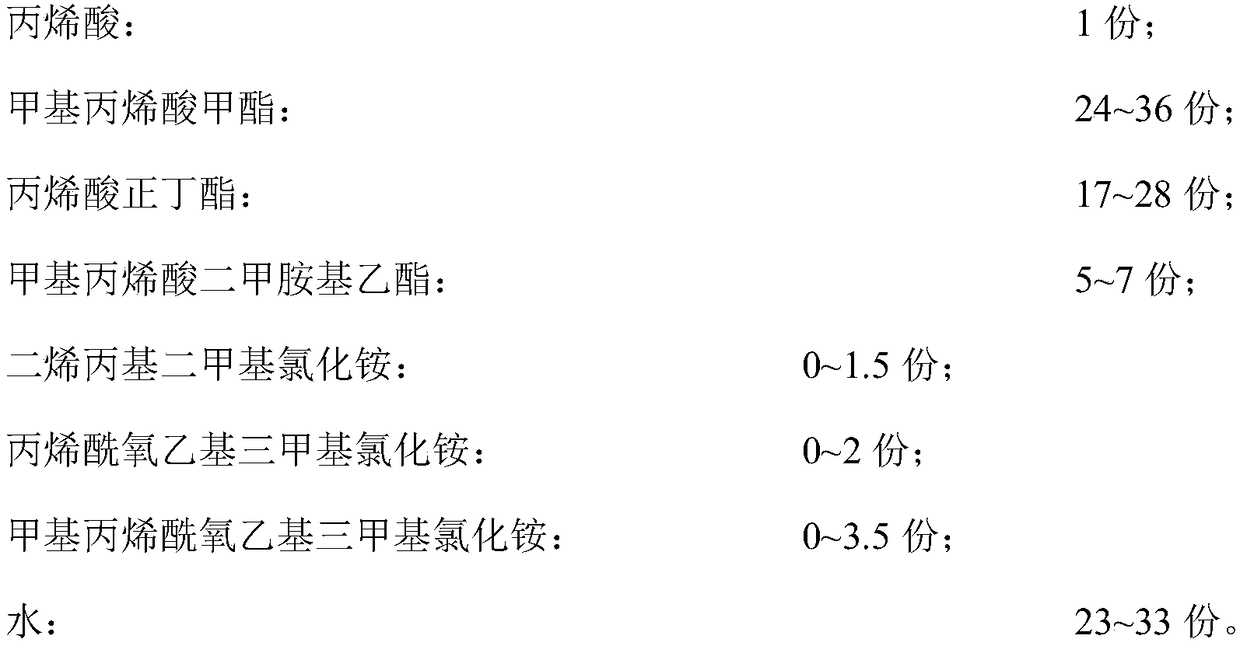

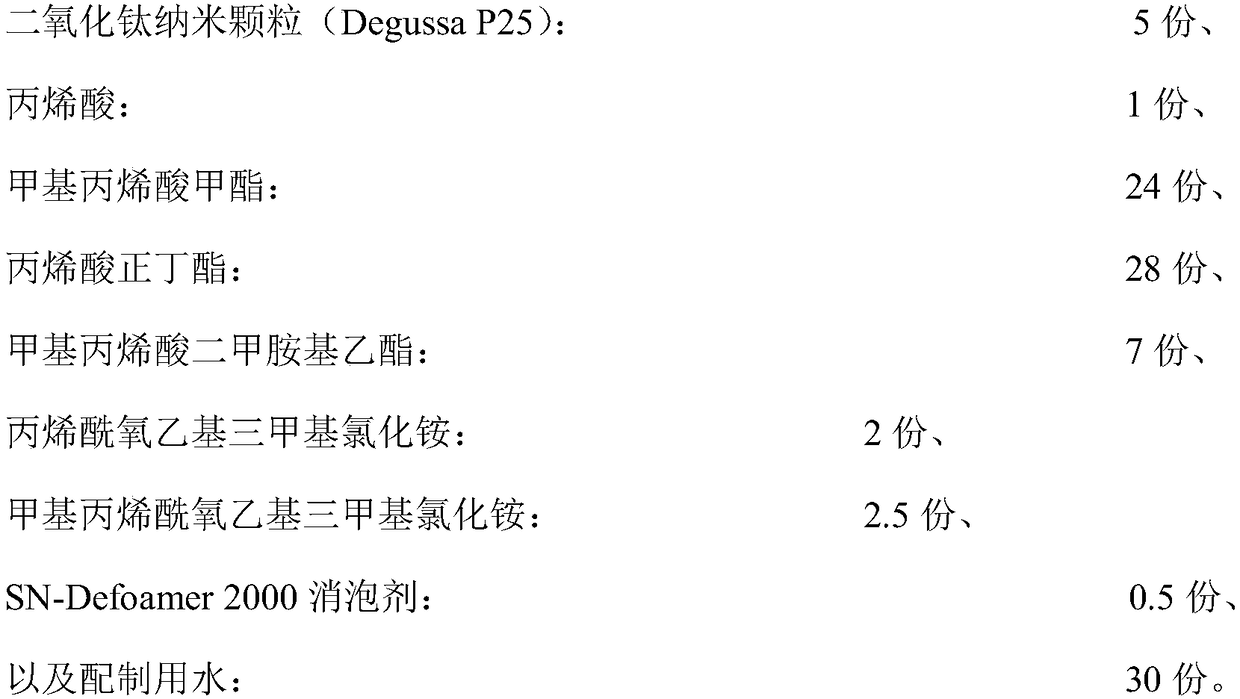

Organic-inorganic composite emulsion for metal surface treatment

InactiveCN108822249APlay a role in modifyingAchieve compositeCoatingsPolymeric surfaceMaterials science

The invention belongs to the technical field of metal surface treatment, and provides an organic-inorganic composite emulsion for use in the field of metal surface treatment and a preparation method thereof. The organic-inorganic composite emulsion is composed of the following raw materials in parts by weight: 5-15 parts of titanium dioxide nanoparticles; 1 part of acrylic acid; 24-36 parts of methyl methacrylate; 17-28 parts of n-butyl acrylate; 5 to 7 parts of methacrylic acid-dimethylaminoethyl ester; 0 to 1.5 parts of 65 wt% diallyldimethylammonium chloride; 0 to 2 parts of 78 wt% acryloyloxyethyltrimethylammonium chloride; 0 to 3.5 parts of 80wt% methacryloyloxyethyltrimethylammonium chloride; and 23 to 33 parts of water. The titanium dioxide nanoparticles act as a modifier for the emulsion and are used as a photoinitiator. Finally, the titanium dioxide nanoparticles are attached to one end of a polymer chain. Organic and inorganic phases are connected by chemical bonds, and separation and enrichment of the organic and inorganic phases does not occur in various environments. The surface of the polymer in the emulsion is positively charged and has good adhesion to a metal.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

A method for directly separating rare earth elements in uranium dioxide or spent fuel

ActiveCN108538417BThe synthesis steps are simpleEase of industrial productionShaking/oscillating/vibrating mixersNuclear energy generationFuel reprocessingRare-earth element

The invention relates to a method for directly separating rare earth elements in uranium dioxide or spent fuel, the method comprising the following steps: (1) placing simulated spent fuel in a functionalized ionic liquid, and mixing it uniformly to obtain a solid mixed liquid; (2) placing The solid mixture is stirred and dissolved, and centrifuged to obtain the supernatant and the undissolved uranium dioxide solid or undissolved spent fuel in the lower layer; (3) the metal ion content in the supernatant is measured by ICP-OES, Then calculate the content of the rare earth compound or other fission products dissolved in the ionic liquid; (4) directly perform reprocessing of spent fuel elements on the lower uranium dioxide solid or undissolved spent fuel. The invention has the characteristics of simple process, easy operation, good economy, and environmental protection, and can be used for the removal of rare earth compounds (neutron poisons) in spent fuel reprocessing, including some fission products with large fission yield, and is suitable for industrial applications .

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI +1

Catalyst and application thereof in preparation of heptafluoropropane

InactiveCN110841667AExtended service lifeRaw materials are cheap and easy to getPhysical/chemical process catalystsHalogenated hydrocarbon preparationPtru catalystEngineering

The invention discloses a catalyst. The catalyst is prepared from a mixture of at least three selected from the group consisting of metal fluorides and metal oxides, clay which is fully soaked in hydrofluoric acid, dried and crushed, and rice husk carbon which is fully soaked in hydrofluoric acid and dried according to a mass ratio of 1: (1-3): (1-3). The invention also discloses application of the catalyst in preparation of heptafluoropropane. The raw materials used by a fluorination catalytic system in the invention are cheap and easily available; cost is low; no polymer is enriched in the reaction process; the service life of the catalyst is greatly prolonged; a preparation method for the catalyst is simple in process, low in equipment requirement and mild in reaction conditions, and the conversion rate of the raw materials reaches 95% or above; and the fluorination catalytic system is non-decomposable and non-flammable in a dry environment, and can be continuously used.

Owner:浙江利化新材料科技有限公司

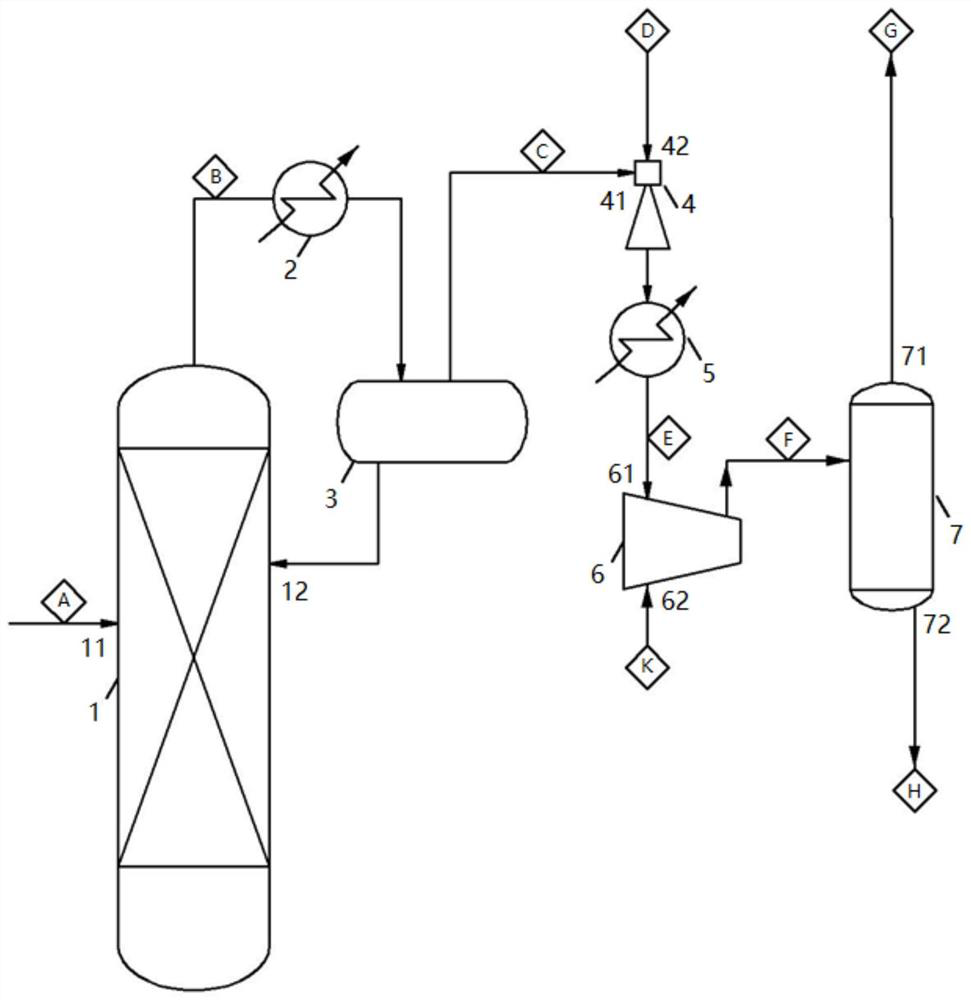

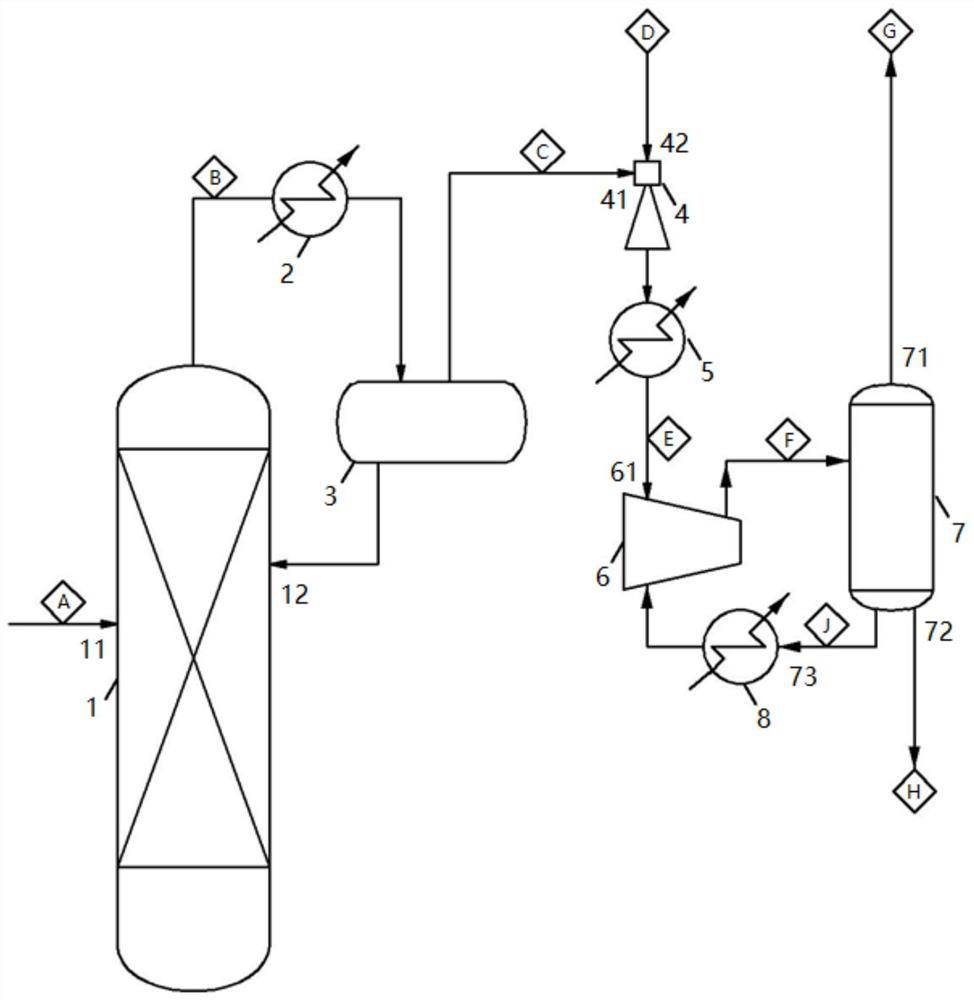

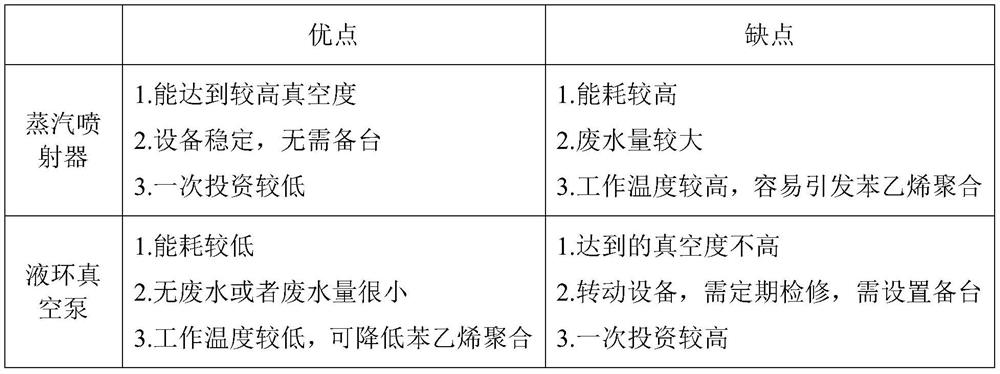

Device and method for removing light components in styrene monomer

PendingCN114573414ASufficient vacuumWill not cause accumulationChemical industryDistillation purification/separationThermodynamicsIntermediate heat exchanger

The invention belongs to the field of styrene refining, and relates to a device and a method for removing light components in a styrene monomer. The device comprises a styrene light component removal rectifying tower, a tower top condenser, a tower top reflux tank, an ejector, an intermediate heat exchanger, a liquid ring vacuum pump and a gas-liquid separation tank. According to the device and the method for removing the light components in the styrene monomer, the problems of removal and discharge of the light components can be effectively solved, and polymerization of styrene can be reduced. Compared with a single liquid ring vacuum pump system, the system has the advantages of high vacuum degree, low equipment investment, no light component enrichment and the like; compared with a multi-stage ejector system, the multi-stage ejector system has the advantages of low operation cost, low energy consumption, low wastewater amount, low working temperature and the like.

Owner:SINOPEC ENG +1

A kind of rare earth niobate high-entropy powder, porous high-entropy ceramic and preparation method and application

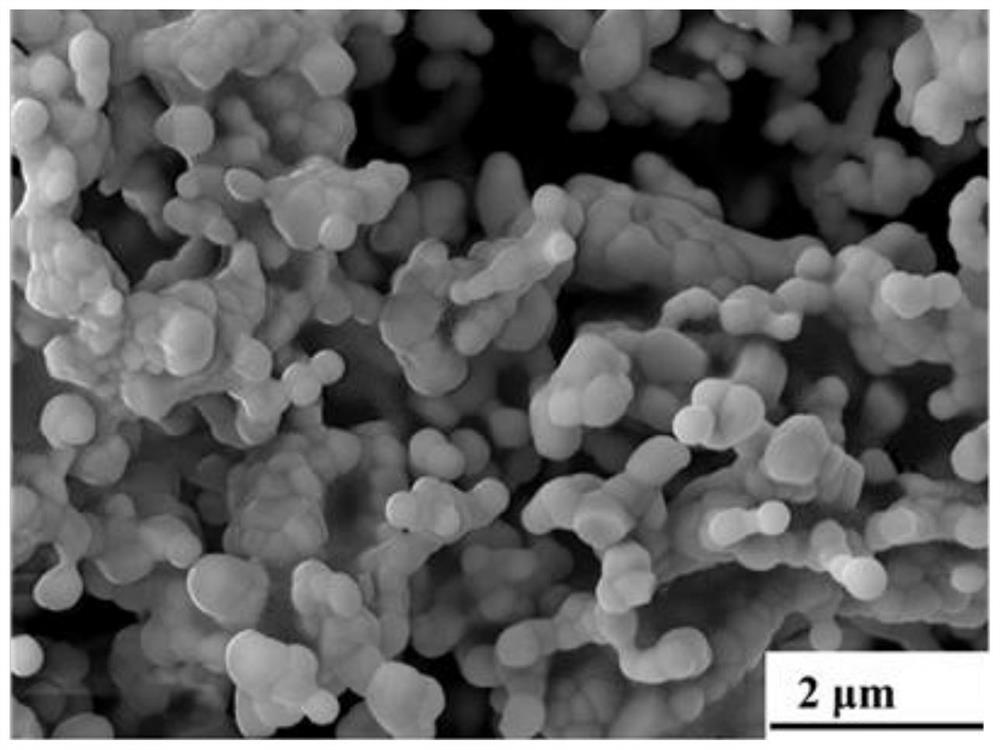

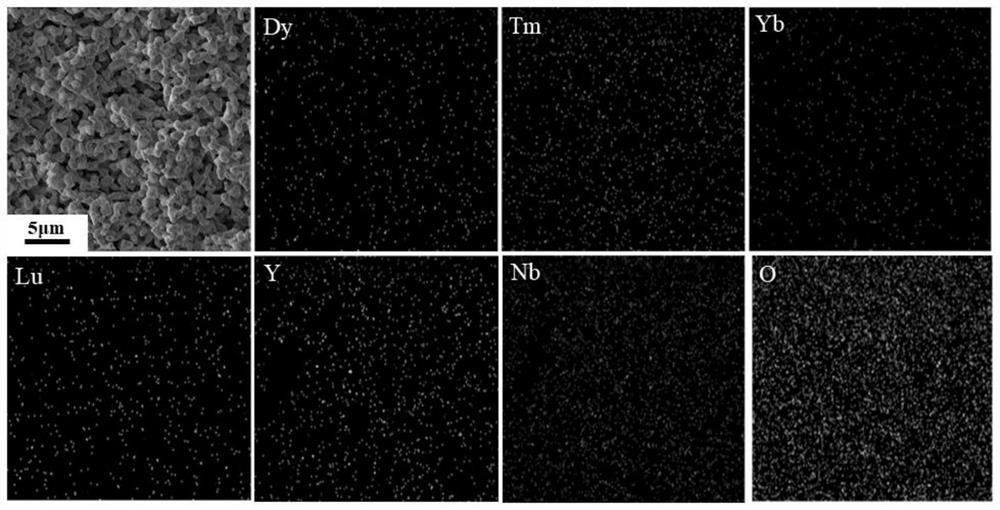

ActiveCN113620722BIncrease scatteringLower lattice thermal conductivityCeramicwareYTTERBIUM OXIDELutetium

The invention discloses a rare earth niobate high-entropy powder, a porous high-entropy ceramic, a preparation method and an application, and belongs to the technical field of high-entropy materials. The raw materials of the rare earth niobate high-entropy powder include rare earth trioxide and niobium pentoxide; the rare earth trioxide is dysprosium oxide, holmium oxide, erbium oxide, thulium oxide, ytterbium oxide, lutetium oxide, and yttrium oxide. In the mixture of 5-7 different trioxides, in any two trioxides, the molar ratio of the trioxide with a large amount to the trioxide with a small amount is 1-3. The present invention introduces different rare earth metal cations through the high entropy of niobate ceramic components. Due to the difference in atomic size in the high entropy phase, its atomic occupancy is shifted, which further leads to lattice distortion and increases the Phonon scattering; Rare earth niobate porous high-entropy ceramics have excellent thermal insulation properties due to the introduction of pore structure that reduces the solid-phase thermal conductivity of the material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

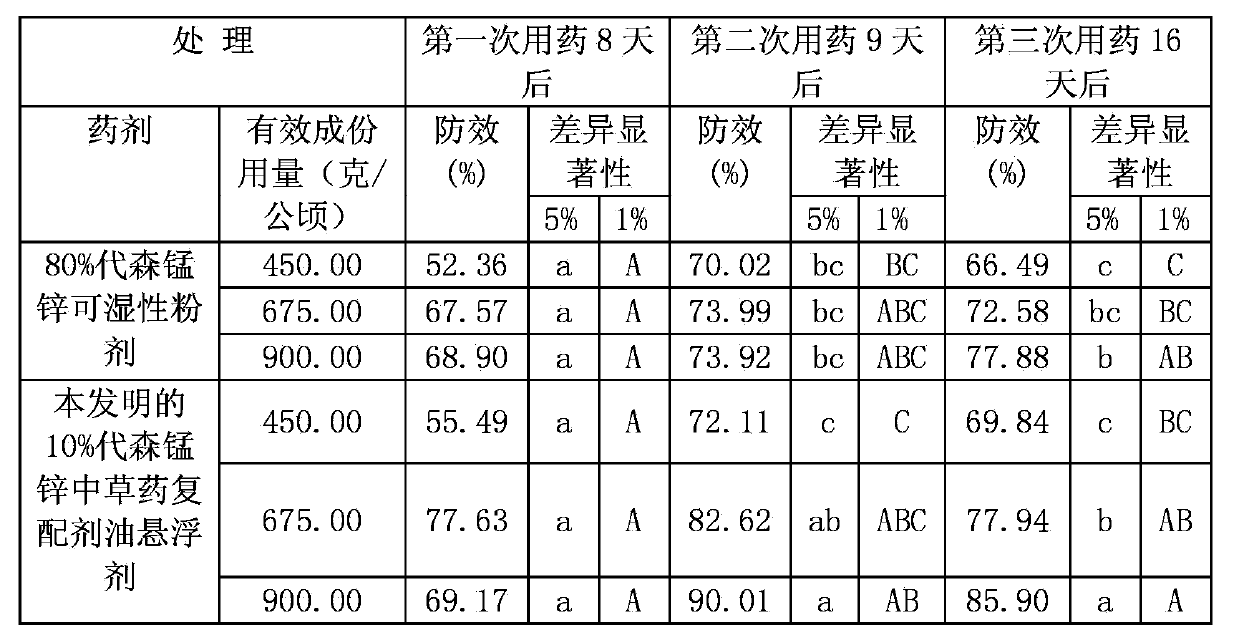

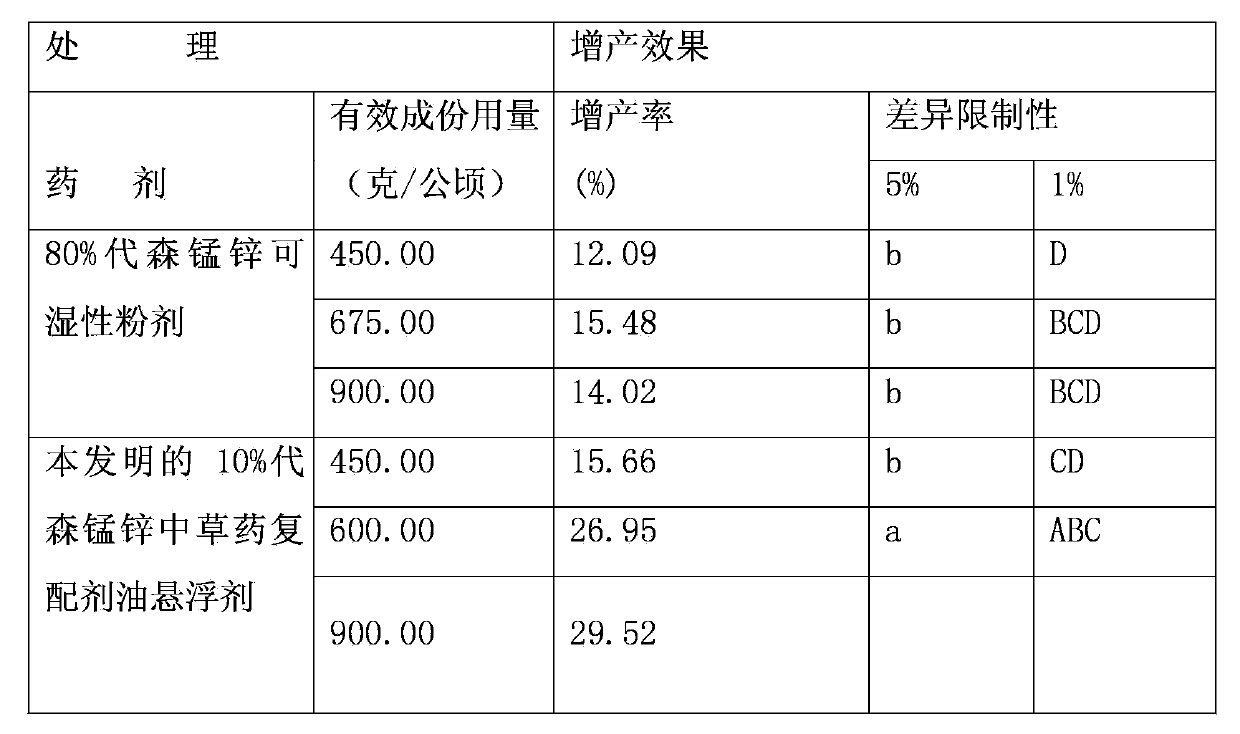

Mancozeb Chinese herbal medicine complex bactericide used for controlling paddy rice sheath blight

The invention relates to a mancozeb Chinese herbal medicine complex bactericide used for controlling paddy rice sheath blight. Every 100 parts of the complex bactericide is prepared from the raw materials of, by weight: 8-12 parts of mancozeb, 9-11 parts of celastrus angulatus, 9-11 parts of fischer euphorbia root, 9-11 parts of lightyellow sophora root, 4-6 parts of amur corktree bark, 4-6 parts of male fern rhizome, 4-6 parts of Hindu datura flower, 4-6 parts of Chinese pulsatilla, 4-6 parts of Baikal skullcap root, 4-6 parts of common monkshood mother-root, 2-3 parts of betel nut, 2-3 parts of common cnidium fruit, 2-3 parts of dayflower, 2-3 parts of lobedleaf pharbitis seed, 2-3 parts of honeycomb, 2-3 parts of pine needles, 2-3 parts of sessile stemona root tuber, 2-3 parts of common threewingnut root, 4-6 parts of black falsehellebore root, and balance of auxiliary materials. Water extraction products or organic solvent extraction products of the Chinese herbal medicines are adopted as the raw materials. The production cost of the complex preparation provided by the invention is low, and the raw material source is wide. The bactericide provided by the invention has the characteristics of high efficiency, low toxicity, high safety, environment friendliness, and no drug resistance. The bactericide has a special effect in controlling paddy rice sheath blight diseases.

Owner:QINGDAO AGRI UNIV

An artificial breeding pond for reducing the occurrence of digestive tract diseases in loach

Owner:郎溪县兴贵水产品养殖家庭农场

Method for generating polyvalent alcohol and formiate by extractive crystallization separating cannizzaro process

InactiveCN101139248BNo pyrolysis phenomenonReduce the pollution of three wastesOrganic compound preparationHydroxy compound preparationPolyolAlcohol

The present invention relates to an extracted, crystalloid and separated Cannizzaros reaction to prepare polyatomic alcohol and formate. The steps are as follows: (1) Solution agent A is added into the mixture liquid between polyatomic alcohol and formate to form an oil phase of the extracting liquid; the formate together with the residual liquid is to form a water-phase of the extracted liquid; (2) the oil phase and the water phase of the extracted liquid are separated; (3) the water phase of the extracted liquid is crystallized and vaporized to obtain formate crystal; (4) the second solution agent B is added into the oil phase of the extracted liquid in step 2 so as to the polyatomic alcohol is separated out with a crystal mode in the mixture agent between A and B; (5) the solid phase of the polyatomic alcohol is separated from the mixture agent between A and B; (6) The mixing agent of A and B is distilled to separate out the solution agent A and the solution agent B; (7) the solid phase of the polyatomic alcohol is dried to recycle the mixing solution agent A and B left in the solid phase of polyatomic alcohol. The present invention is with much lower investment, shorter producing period, simpler operation, much better product quality and higher benefit.

Owner:刘荣

Iron mine sintering flue gas segmented circulation method

ActiveCN103499216BNo enrichmentRaise the sintering temperatureIncreasing energy efficiencyWaste heat treatmentFlue gasDust emission

Owner:CENT SOUTH UNIV

High-strength high-heat-conductivity copper-molybdenum alloy wire material and preparation method thereof

InactiveCN114250382ANo enrichmentReasonable ratioFurnace typesHeat treatment furnacesRare-earth elementAlloy

The invention discloses a high-strength and high-thermal-conductivity copper-molybdenum alloy wire material and a preparation method thereof, and relates to the technical field of copper-molybdenum alloys, and the high-strength and high-thermal-conductivity copper-molybdenum alloy wire material is composed of the following raw material components in percentage by weight: 3wt%-5wt% of molybdenum, 0.02 wt%-0.04 wt% of rare earth elements and the balance of copper. The high-strength and high-thermal-conductivity copper-molybdenum alloy wire material is reasonable in proportion of copper, molybdenum and rare earth elements in the raw material components, low in gas content, few in inclusions, uniform in structure component, free of macroscopic and microcosmic defects such as copper and molybdenum enrichment and the like, high in conductivity and thermal conductivity, high in strength and high in toughness.

Owner:无锡市蓝格林金属材料科技有限公司

High-strength and high-toughness copper-zinc alloy wire material and preparation method thereof

The invention discloses a high-strength and high-toughness copper-zinc alloy wire material and a preparation method thereof, and relates to the technical field of copper-zinc alloys, and the high-strength and high-toughness copper-zinc alloy wire material comprises the following raw material components in percentage by weight: 2wt%-4wt% of zinc, 0.01 wt%-0.03 wt% of rare earth elements and the balance of copper. The high-strength and high-toughness copper-zinc alloy wire material is reasonable in proportion of copper, zinc and rare earth elements in the raw material components, low in gas content, few in inclusions, uniform in structure component, free of macroscopic and microcosmic defects such as copper and zinc enrichment and the like, high in corrosion resistance, high in strength and high in toughness.

Owner:无锡市蓝格林金属材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com