An iron supplement for complex iron desulfurization solution and preparation method thereof

A desulfurization solution, iron supplement technology, applied in separation methods, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., to achieve the effects of avoiding corrosion, low price, and wide selection of equipment materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

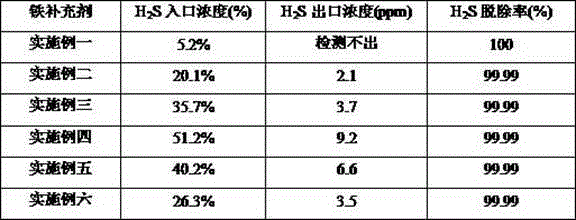

Embodiment 1

[0024] Add 550Kg deionized water, 790KgEDTA, 100KgFe to the stirred tank in turn 2 o 3 ·H 2 O, then add NaOH to the reaction kettle to adjust the pH value between 7 and 9, raise the temperature to 50°C, stir and react for 3 hours to obtain the iron supplement, and the total iron content in it is 58g / L by analysis. The desulfurization performance of the iron supplement is shown in Table 1.

Embodiment 2

[0026] Add 950Kg deionized water, 400KgEDTA, 100KgFe to the stirred tank in turn 2 o 3 ·H 2 O, then add NaOH to the reactor to adjust the pH value between 7 and 9, raise the temperature to 80°C, stir and react for 4 hours to obtain the iron supplement, and the total iron content in it is 57g / L by analysis. The desulfurization performance of the iron supplement is shown in Table 1.

Embodiment 3

[0028] Add 980Kg deionized water, 665KgHEDTA, 100KgFe 2 o 3 ·FeO·H 2 O, then add KOH to the reaction kettle to adjust the pH value between 7 and 9, raise the temperature to 60°C, stir and react for 5 hours to obtain the iron supplement, and the total iron content in it is analyzed to be 50g / L. The desulfurization performance of the iron supplement is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com