High-strength high-heat-conductivity copper-molybdenum alloy wire material and preparation method thereof

A copper-molybdenum alloy, high-strength technology, applied in the field of copper-molybdenum alloy, can solve the problem of copper-molybdenum alloy interface problem that the strength of copper-molybdenum alloy cannot meet the application requirements, and achieve the effects of less inclusions, excellent product performance and low gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

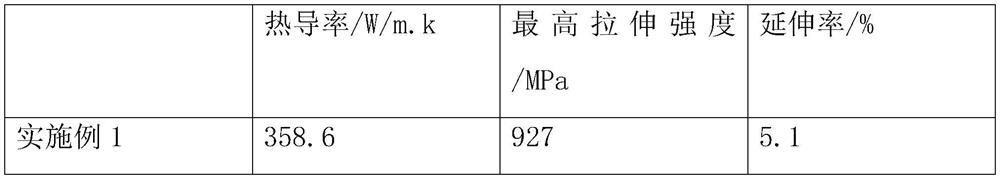

Embodiment 1

[0026] This embodiment provides a high-strength and high-thermal-conductivity copper-molybdenum alloy wire material, which is composed of the following raw material components in weight percentage: molybdenum 4wt%, 0.03wt% rare earth elements, and the rest is copper.

[0027] The rare earth elements are La and Y, and the weight ratio of La and Y is 1:1.

[0028] Molybdenum is electrolytic molybdenum with a purity ≥ 99.9990%.

[0029] Copper is electrolytic copper with purity ≥99.9990%.

[0030] The preparation method of the above-mentioned high-strength and high-thermal-conductivity copper-molybdenum alloy wire material has the following steps:

[0031] S1. Weigh raw materials: weigh molybdenum, rare earth elements, copper, and set aside;

[0032] S2. Arc smelting: put the weighed molybdenum, rare earth elements, and copper into an arc smelting furnace, use an arc gun to melt, stir evenly, and water-cool to obtain a copper-molybdenum intermediate alloy ingot;

[0033] S3. H...

Embodiment 2

[0041] This embodiment provides a high-strength and high-thermal-conductivity copper-molybdenum alloy wire material, which is composed of the following raw material components in weight percentage: molybdenum 3wt%, 0.02wt% rare earth elements, and the rest is copper.

[0042] The rare earth elements are La and Y, and the weight ratio of La and Y is 1:1.

[0043] Molybdenum is electrolytic molybdenum with a purity ≥ 99.9990%.

[0044] Copper is electrolytic copper with purity ≥99.9990%.

[0045] The preparation method of the above-mentioned high-strength and high-thermal-conductivity copper-molybdenum alloy wire material has the following steps:

[0046] S1. Weigh raw materials: weigh molybdenum, rare earth elements, copper, and set aside;

[0047] S2. Arc smelting: put the weighed molybdenum, rare earth elements, and copper into an arc smelting furnace, use an arc gun to melt, stir evenly, and water-cool to obtain a copper-molybdenum intermediate alloy ingot;

[0048] S3. H...

Embodiment 3

[0056] This embodiment provides a high-strength and high-thermal-conductivity copper-molybdenum alloy wire material, which is composed of the following raw material components in weight percentage: molybdenum 5wt%, 0.04wt% rare earth elements, and the rest is copper.

[0057] The rare earth elements are La and Y, and the weight ratio of La and Y is 1:1.

[0058] Molybdenum is electrolytic molybdenum with a purity ≥ 99.9990%.

[0059] Copper is electrolytic copper with purity ≥99.9990%.

[0060] The preparation method of the above-mentioned high-strength and high-thermal-conductivity copper-molybdenum alloy wire material has the following steps:

[0061] S1. Weigh raw materials: weigh molybdenum, rare earth elements, copper, and set aside;

[0062] S2. Arc smelting: put the weighed molybdenum, rare earth elements, and copper into an arc smelting furnace, use an arc gun to melt, stir evenly, and water-cool to obtain a copper-molybdenum intermediate alloy ingot;

[0063] S3. H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com