Patents

Literature

96results about How to "Homogeneous tissue composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

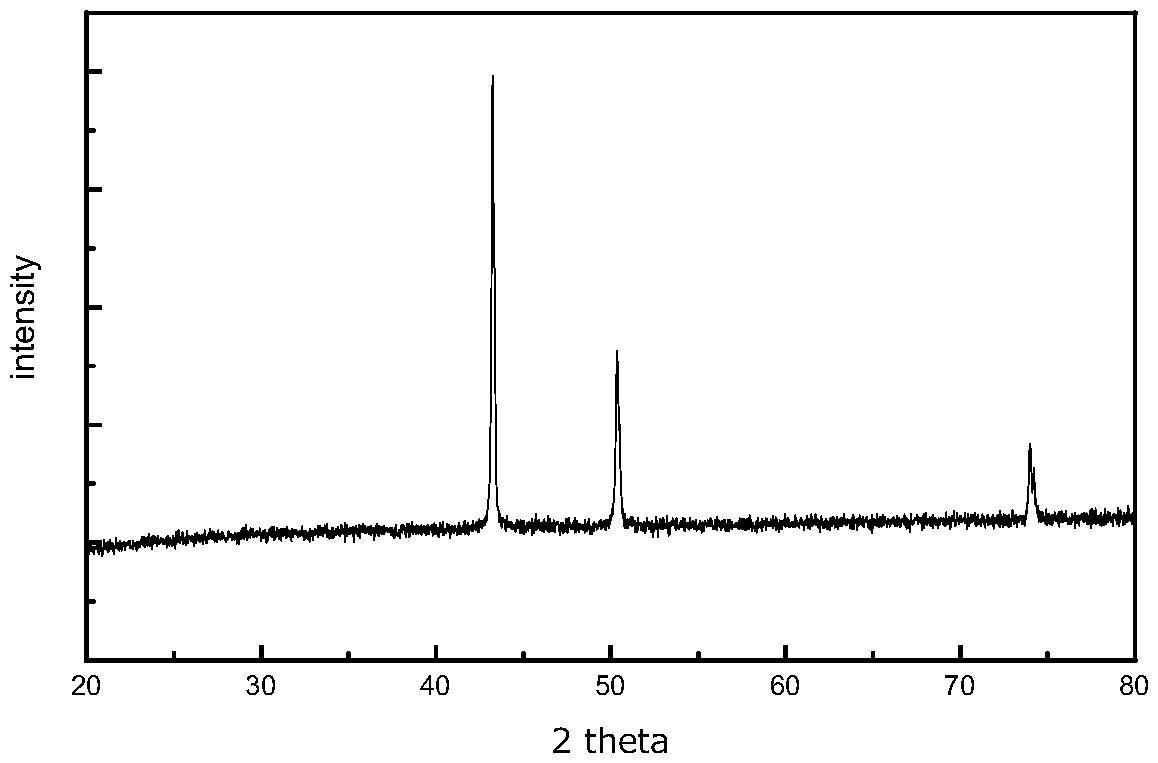

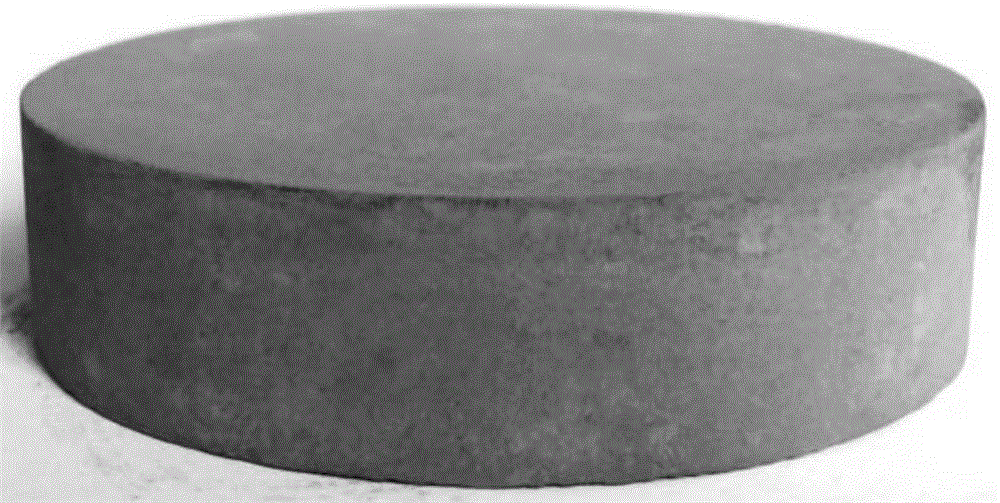

Manufacturing method for large-size high-density high-uniformity CuCr alloy

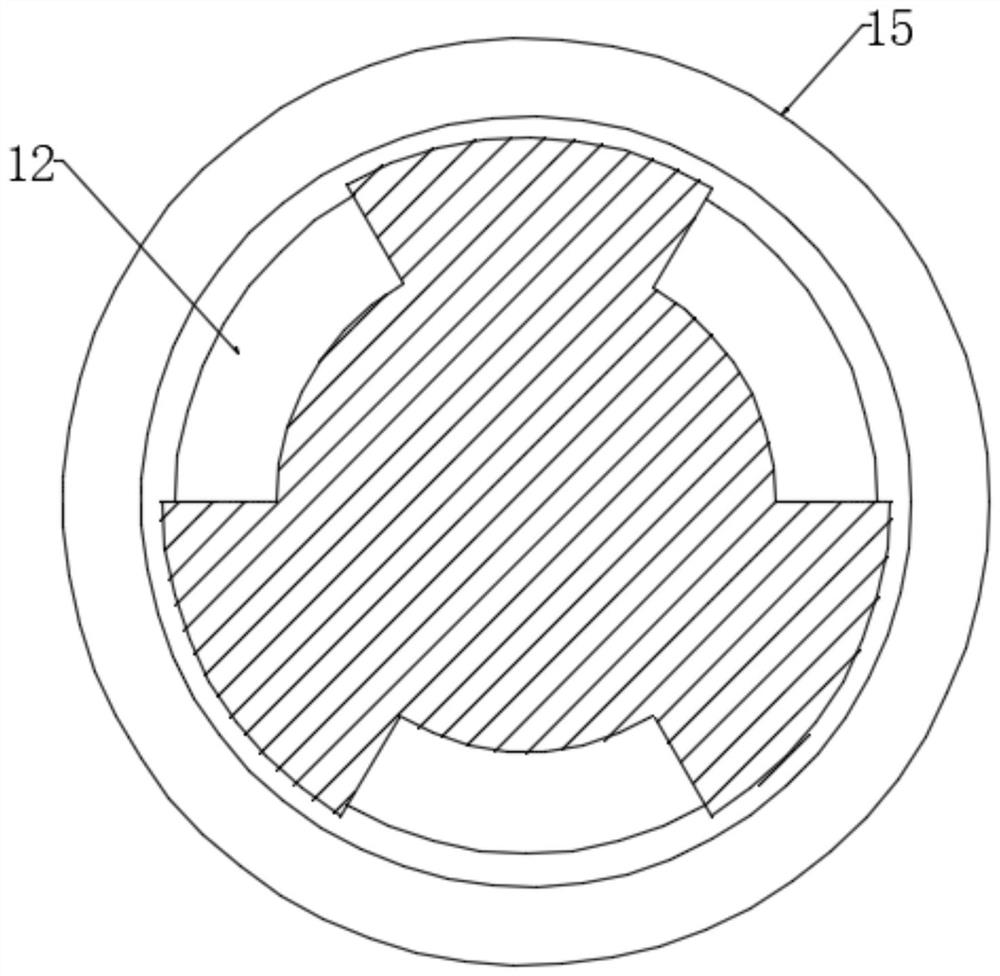

The invention discloses a manufacturing method for a large-size high-density high-uniformity CuCr alloy. The manufacturing method is characterized in that CuCr mixed powder is solidified and formed through discharge plasma sintering, by optimizing a sintering die structure, the temperature is increased to 800 DEG C to 880 DEG C through a step heating manner at 10 DEG C / min to 50 DEG C / min and then kept for 2 minutes to 8 minutes while axial mechanical pressure is applied, and a sintered cylinder ingot with the diameter not smaller than 50 mm, the long diameter ratio of 0.04-1.0, the density larger than 99.0%, axial and radial fluctuation less than 1% and an uniform component structure can be obtained. According to the manufacturing method, different sintering conditions can be selected according to the size demand of the CuCr alloy, the process is simple, the period is short, the production efficiency is high, and the obtained CuCr alloy can be made into a finished product through a small amount of subsequent machining and then used as a part of a vacuum circuit breaker in large-power transmission and transformation equipment.

Owner:HEFEI UNIV OF TECH +1

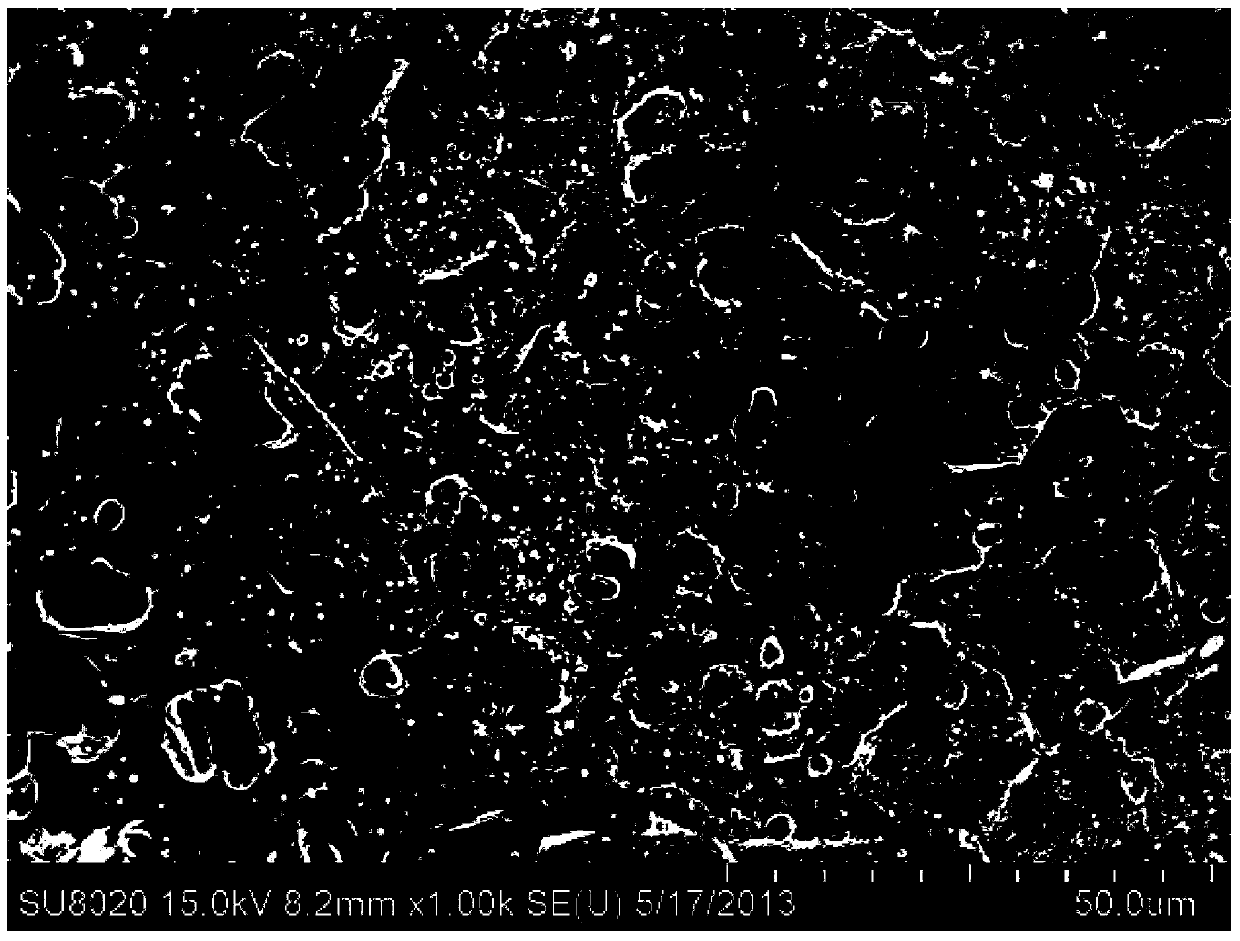

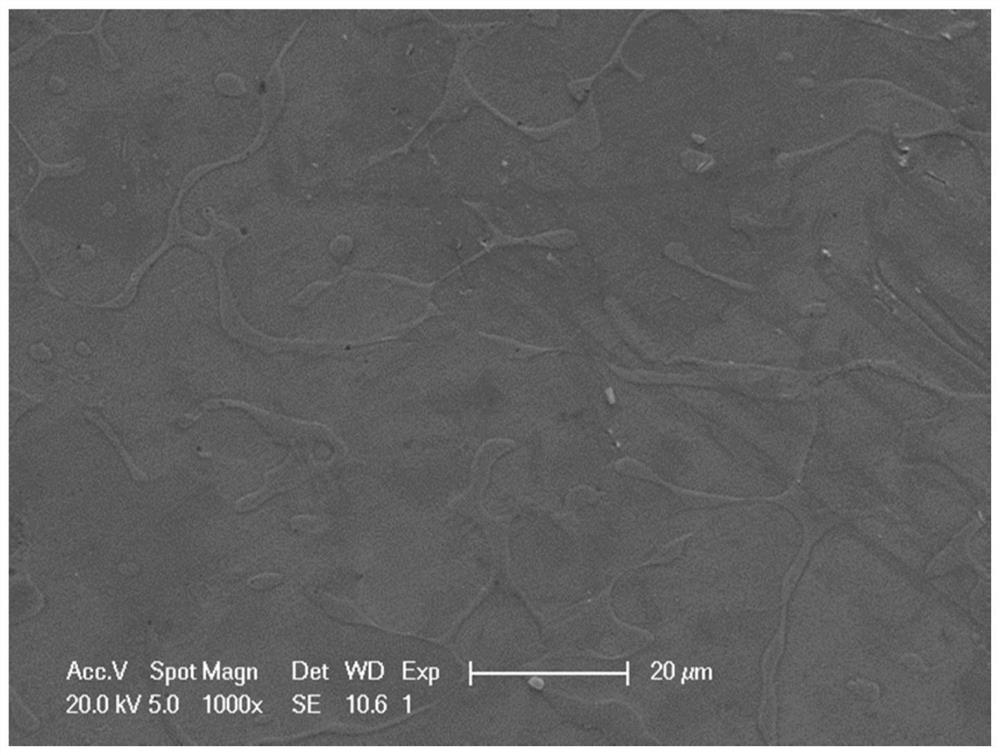

Method for metallizing surface of alumina ceramic substrate

ActiveCN103469183AReduced stabilityNo pollutionLiquid/solution decomposition chemical coatingCopper platingRoom temperature

The invention discloses a method for metallizing surface of an alumina ceramic substrate. The method comprises unit processes of coarsening pretreatment, primary nickel plating and secondary copper plating, wherein the coarsening pretreatment comprises: ultrasonically treating the alumina ceramic substrate in coarsening liquid for 20-40 min, and then, washing the alumina ceramic substrate through deionized water to obtain a pre-treated substrate; the primary nickel plating comprises: putting the pre-treated substrate in a plating solution I, ultrasonically depositing for 40-60 min at room temperature, washing the pre-treated substrate through deionized water after taking out the same, and drying the pre-treated substrate to obtain a nickel-plated substrate; the secondary copper plating comprises: putting the nickel-plated substrate in a plating solution II, reacting at 60-80 DEG C for 40-60 min, taking out the nickel-plated substrate after cooling the same, washing the nickel-plated substrate through deionized water, and drying the nickel-plated substrate to obtain a copper-plated substrate. A metal copper layer on the surface of the alumina ceramic substrate prepared by the method disclosed by the invention is good in combination with the substrate, good in coating density and uniform in structure components.

Owner:HEFEI UNIV OF TECH

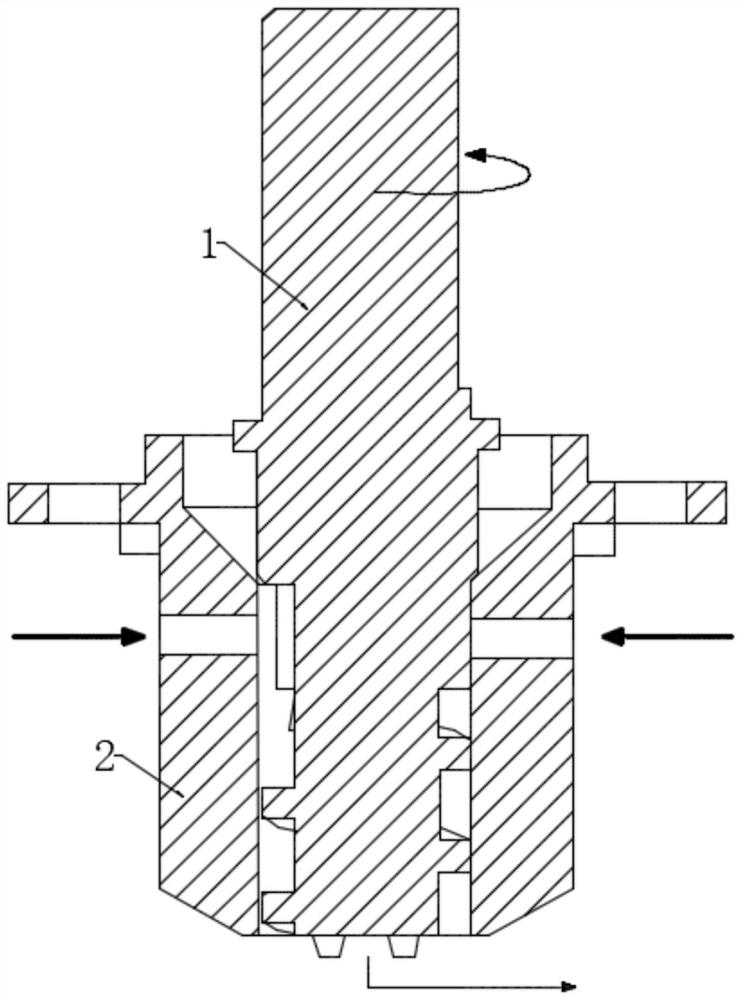

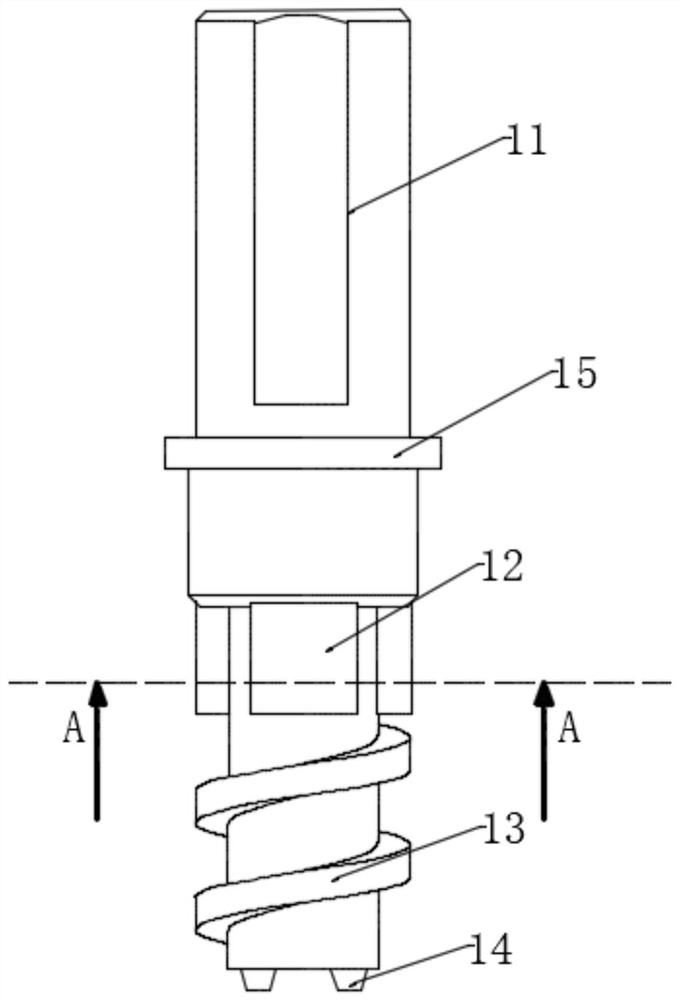

Synchronous uninterrupted wire feeding all-solid-phase friction stir additive manufacturing method and synchronous uninterrupted wire feeding all-solid-phase friction stir additive manufacturing device

PendingCN114799480AImprove production efficiencyAvoid solid-to-liquid-to-solid transitionsAdditive manufacturing apparatusNon-electric welding apparatusPlasticultureUltimate tensile strength

The invention discloses a synchronous uninterrupted wire feeding all-solid-phase friction stir additive manufacturing method and device, and belongs to the field of solid-phase additive manufacturing. According to the scheme, a filamentous additive raw material is synchronously and uninterruptedly fed into a space between a material storage cavity in a wire feeding device and a material crushing blade on a friction stir device through a plurality of wire feeding channels; then the granular additive raw materials crushed by material crushing blades on the stirring friction device move downwards to be accumulated along a screw rod part, the granular additive raw materials are continuously thermally plasticized along with continuous rotation of the stirring friction device, and the additive raw materials in the thermal plasticization state are stirred and mixed through a plurality of boss structures below the stirring friction device; and finally, the additive raw materials with the texture and the uniform state are subjected to additive forming through the gap between the wire feeding device and the base plate, the defect of interlayer interface bonding of all-solid-phase additive manufacturing is greatly overcome, the strength of interlayer bonding force is enhanced, and the solid-phase additive manufacturing efficiency of the large structural part is remarkably improved.

Owner:HARBIN INST OF TECH

Preparation method of TiCu50 master alloy material by vacuum consumable arc melting

The invention discloses a preparation method of a TiCu50 master alloy material by vacuum consumable arc melting, which mainly comprises the following steps: (1) mixing raw materials: according to theweight percentage content, the percentage contents of raw material are: Cu 50%, and TiO 50%, the required raw materials are weighted according to the proportion, and the raw materials are mixed in a mixer; (2) pressing: the mixed powder is loaded into a rubber sleeve and is subjected to mechanical vibration, rolling and reverse material mounding, and then the cold isostatic pressing method is adopted to press the mixed powder, and then the pressure-keeping treatment is carried out; (3) sintering: the pressed consumable electrode is loaded into a vacuum sintering furnace for sintering, and thesintering temperature, the holding time and the vacuum degree are controlled; Step (4) smelting: the sintered consumable electrode is charged into a vacuum consumable arc smelting furnace for smelting. The TiCu50 master alloy material prepared by the invention has low gas content and less impurities, and is uniform in composition, and has no macroscopic and microscopic defects such as enrichment of Cu and Ti.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

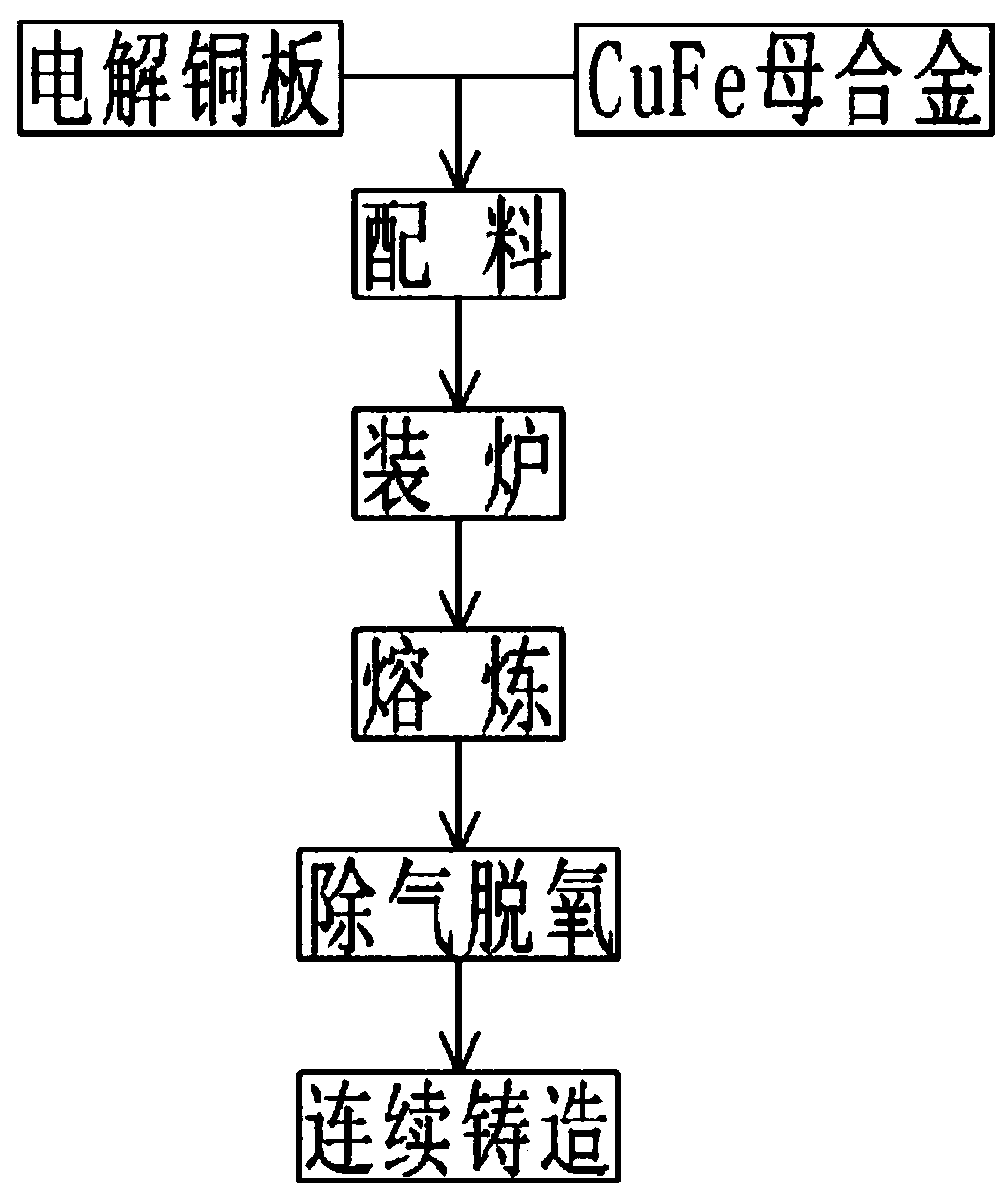

Non-vacuum smelting and continuous casting technology for copper-iron alloy

The invention discloses a technology for smelting and continuous casting of a copper-iron alloy in a non-vacuum manner. The technology comprises the following steps that firstly, burdening is conducted, according to weight percent, the percent content of the Fe element in raw materials is 5%-20%, and the percent content of the Cu element is 80%-95%; secondly, charging is conducted, the mixed raw materials are arranged in a furnace, and a covering agent, a CuFe mother alloy and an electrolytic copper plate are sequentially arranged in the smelting furnace; thirdly, smelting is conducted, temperature rise is conducted for melting, and in the temperature rise melting process, gas protection is conducted in a furnace opening of the smelting furnace; fourthly, gas removal and deoxidation are conducted, argon gas removal, pure titanium deoxidation and CuMg alloy deoxidation are sequentially conducted; and fifthly, continuous casting is conducted, a runner is subjected to gas protection in the pouring process, the casting speed of a casting machine is strictly controlled, and electromagnetic stirring is conducted. The technology is stable, operation is simple and convenient, the fusion casting production cost is low, and the prepared CuFe is free of the obvious segregation phenomenon.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Preparation method for CuFe mother alloy material by adopting vacuum induction melting

The invention discloses a preparation method for a CuFe mother alloy material by adopting vacuum induction melting. The preparation method for the CuFe mother alloy material by adopting vacuum induction melting comprises the steps of (1) weighing Cu and Fe raw materials according to the proportion, loading in a crucible, placing in a vacuum melting furnace, closing a furnace cover and a deflationvalve, and cleaning an observation window; (2) starting a mechanical pump and a low-vacuum baffle valve: when the vacuum pressure P in the vacuum melting furnace is less than or equal to 0.08MPa, starting the roots pump; when vacuumizing until the P is less than or equal to 4Pa, rising the power of the vacuum melting furnace to 25KW, preserving heat for 8min, rising the power of the vacuum meltingfurnace to 45KW, preserving heat for 8min, rising the power of the vacuum melting furnace to 65KW, and reducing the power to 20KW after raw materials in the crucible are uniform; and filling argon into a furnace body, closing an argon filling valve when the pressure in the furnace rises to 0.08Mpa, rising the power to 70KW, and refining for 2min; and (3) reducing the power of the vacuum melting furnace to 40KW, keeping for 0.5min, starting to cast in a casting mould, cooling for 60min after finishing casting, and discharging.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Homogenization heat treatment process of large-size magnesium alloy ingot

The invention relates to a homogenization heat treatment process of a large-size magnesium alloy ingot, belonging to the technical field of magnesium alloy material preparation. The process is characterized by heating a large-size magnesium alloy ingot to 320-350 DEG C at a heating rate of 10-30 DEG C / min and then heating the large-size magnesium alloy ingot to 410-430 DEG C at a heating rate of 12-27 DEG C / h, insulating the large-size magnesium alloy ingot and then cooling the large-size magnesium alloy ingot to the room temperature at a cooling speed of 2-10 DEG C / min, thus obtaining the finished product, wherein the diameter phi of the large-size magnesium alloy ingot is not less than 220mm. The process has the beneficial effects that quick heating is carried out at the early stage of homogenization to release the casting stress to prevent growth of grains in the homogenization process; later, slow heating is carried out till the homogenization temperature to ensure that all the parts are heated uniformly to prevent overburning; then cooling is carried out at a cooling speed of 2-10 DEG C / min till the room temperature is reached, thus preventing cracking due to too quick cooling and also avoiding precipitation strengthening, which is unfavourable for subsequent deformation, due to too slow cooling; dendritic segregation of the large-size magnesium alloy ingot treated by the process is basically eliminated and the components in various parts of the large-size magnesium alloy ingot are uniform; besides, the equipment used in the process is a conventional resistance furnace, is mature in process and is safe and reliable.

Owner:CENT SOUTH UNIV

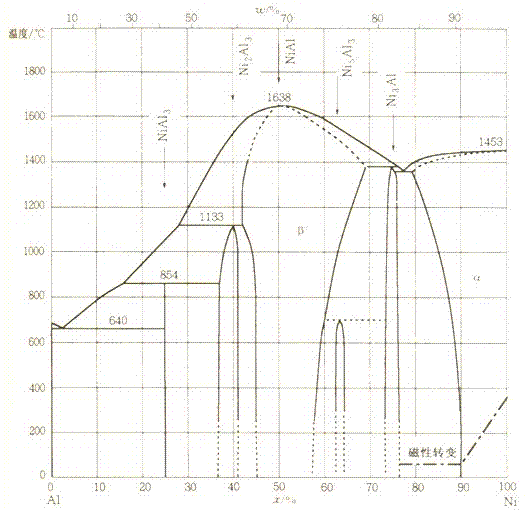

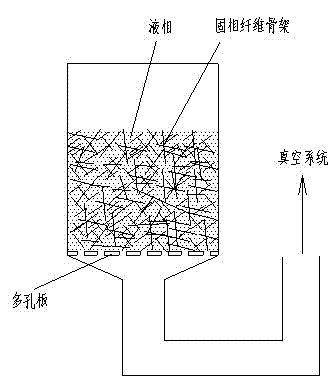

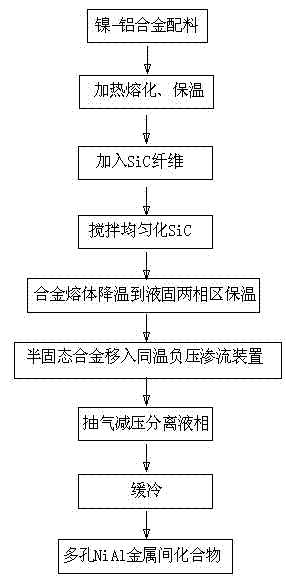

Preparation method for porous NiAl intermetallic compound

The invention discloses a preparation method for a porous NiAl intermetallic compound, and belongs to the field of porous materials. The method comprises the following steps of: dosing nickel-aluminum alloy according to a certain mass percentage; heating until the alloy is molten, preserving heat and then adding SiC fiber; then cooling the alloy melt to a liquid and solid two-phase region for thermal insulation; and finally, separating a liquid phase under reduced pressure from semi-solid alloy obtained by thermal insulation and cooling to obtain the porous NiAl intermetallic compound. A product has an easily controlled shape, a simple and uniform component of organization and a controllable pore structure. The preparation method provided by the invention has the characteristics of high efficiency, low cost and capability of realizing industrial production.

Owner:KUNMING UNIV OF SCI & TECH

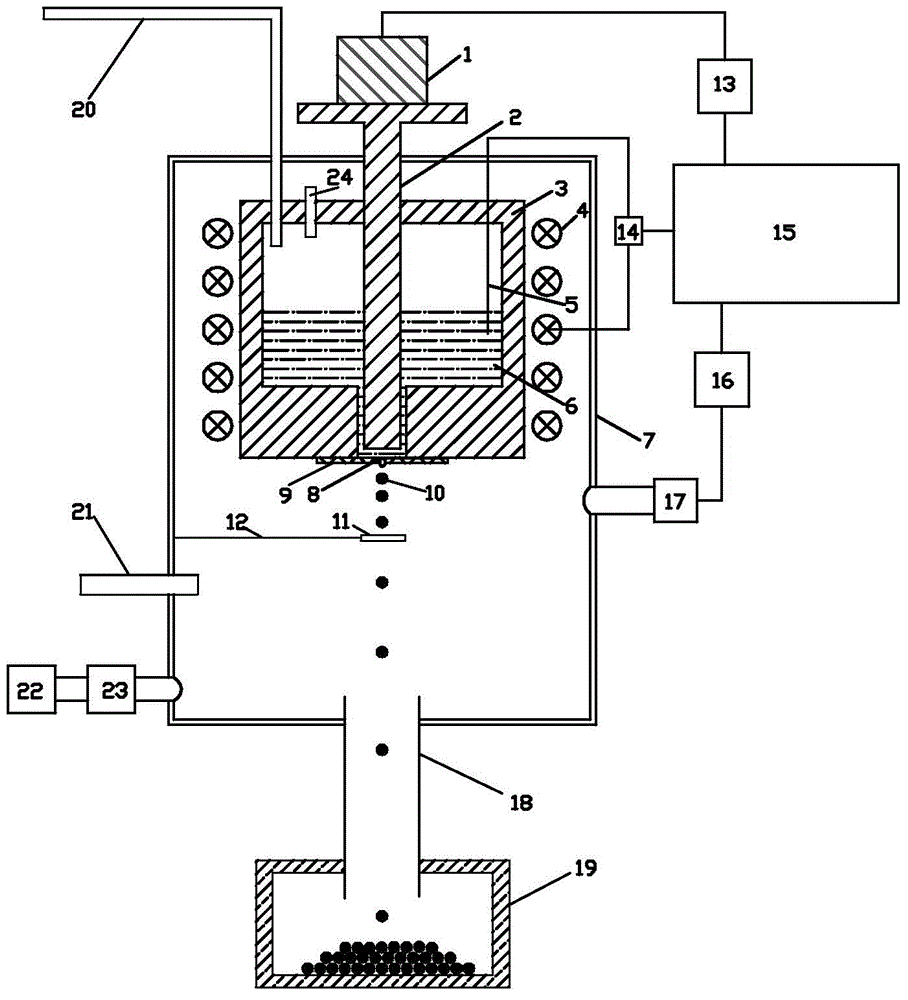

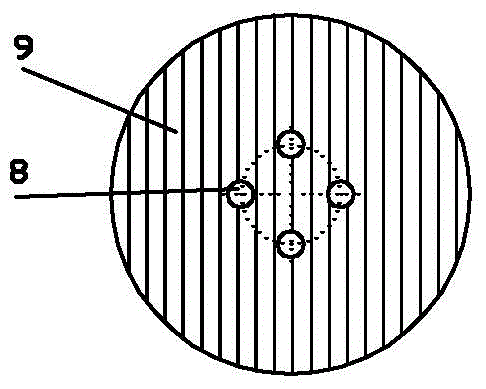

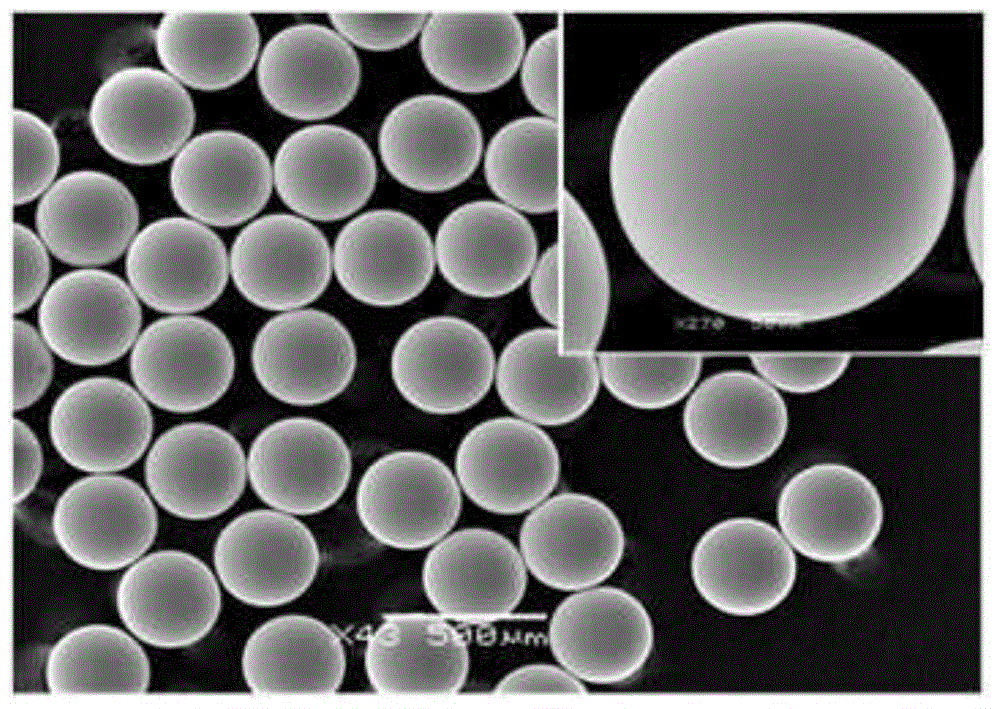

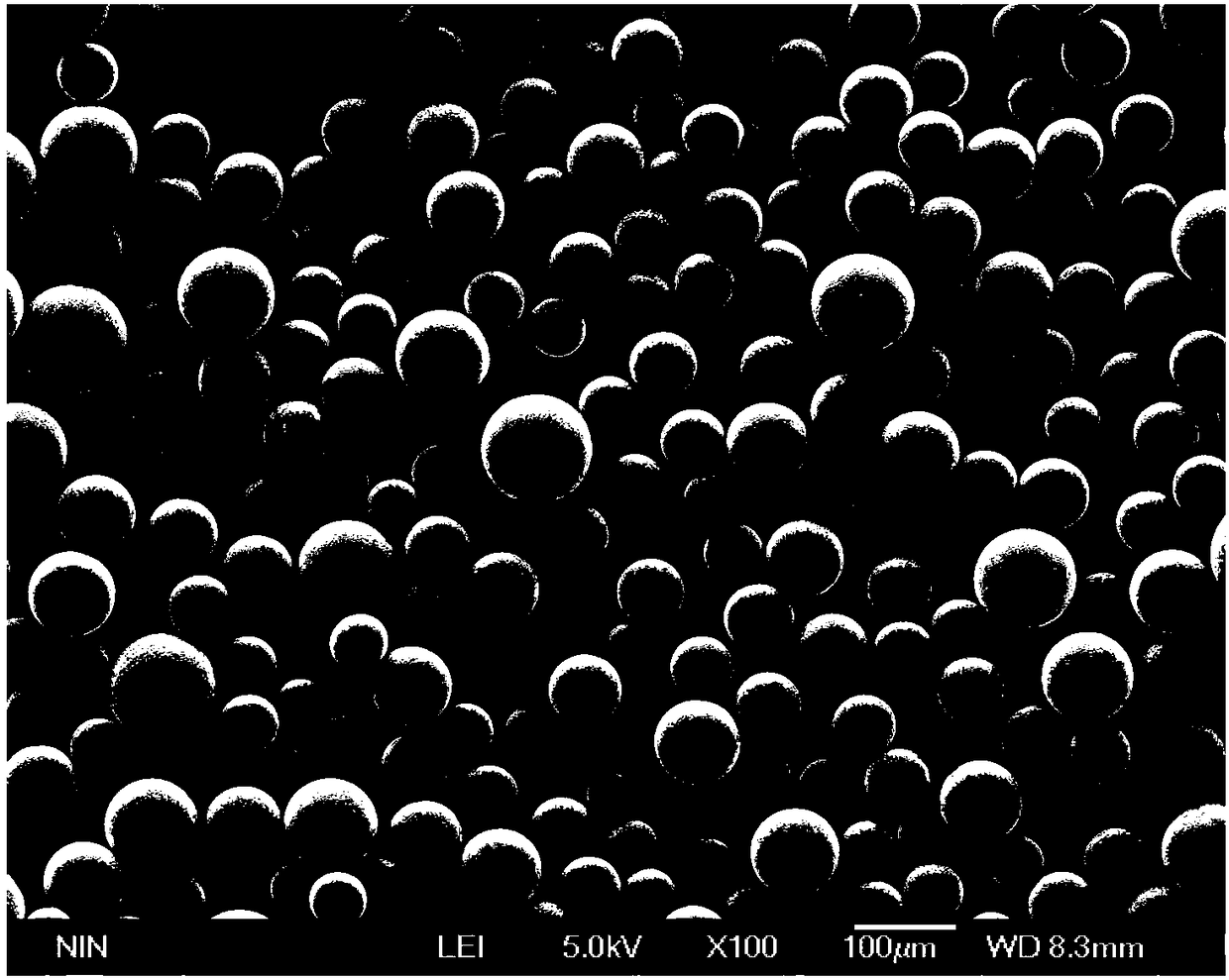

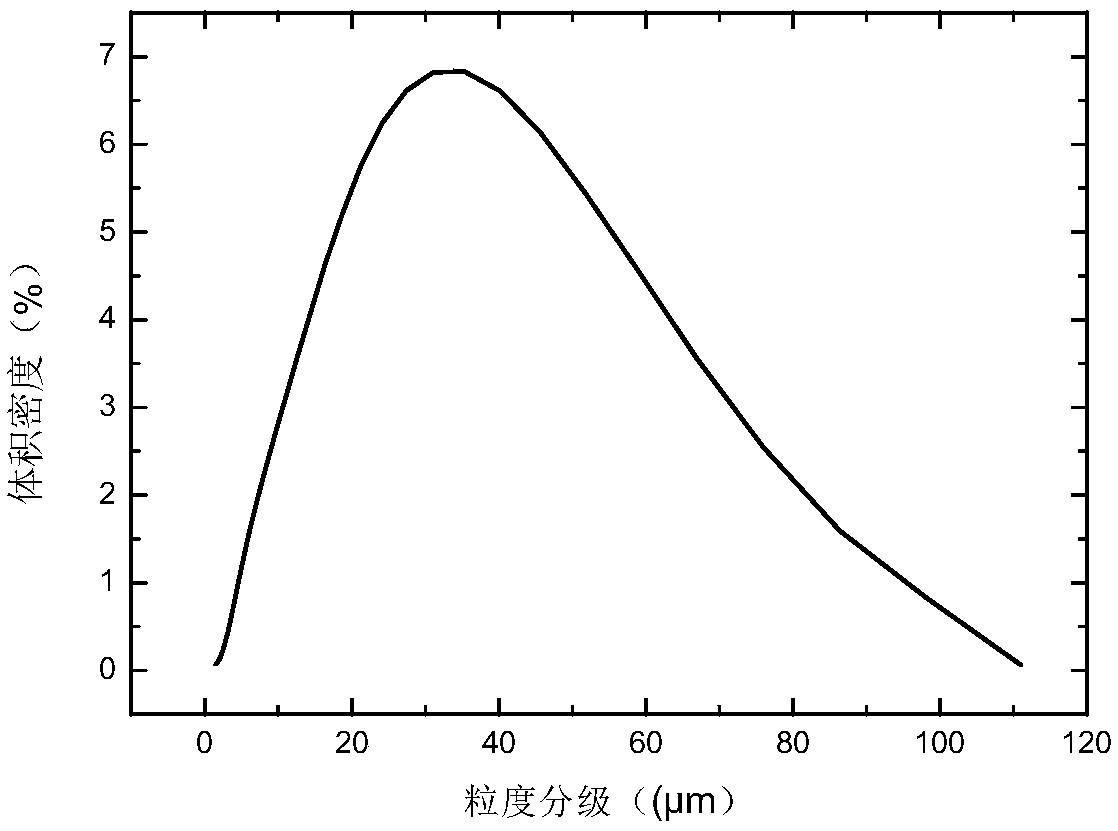

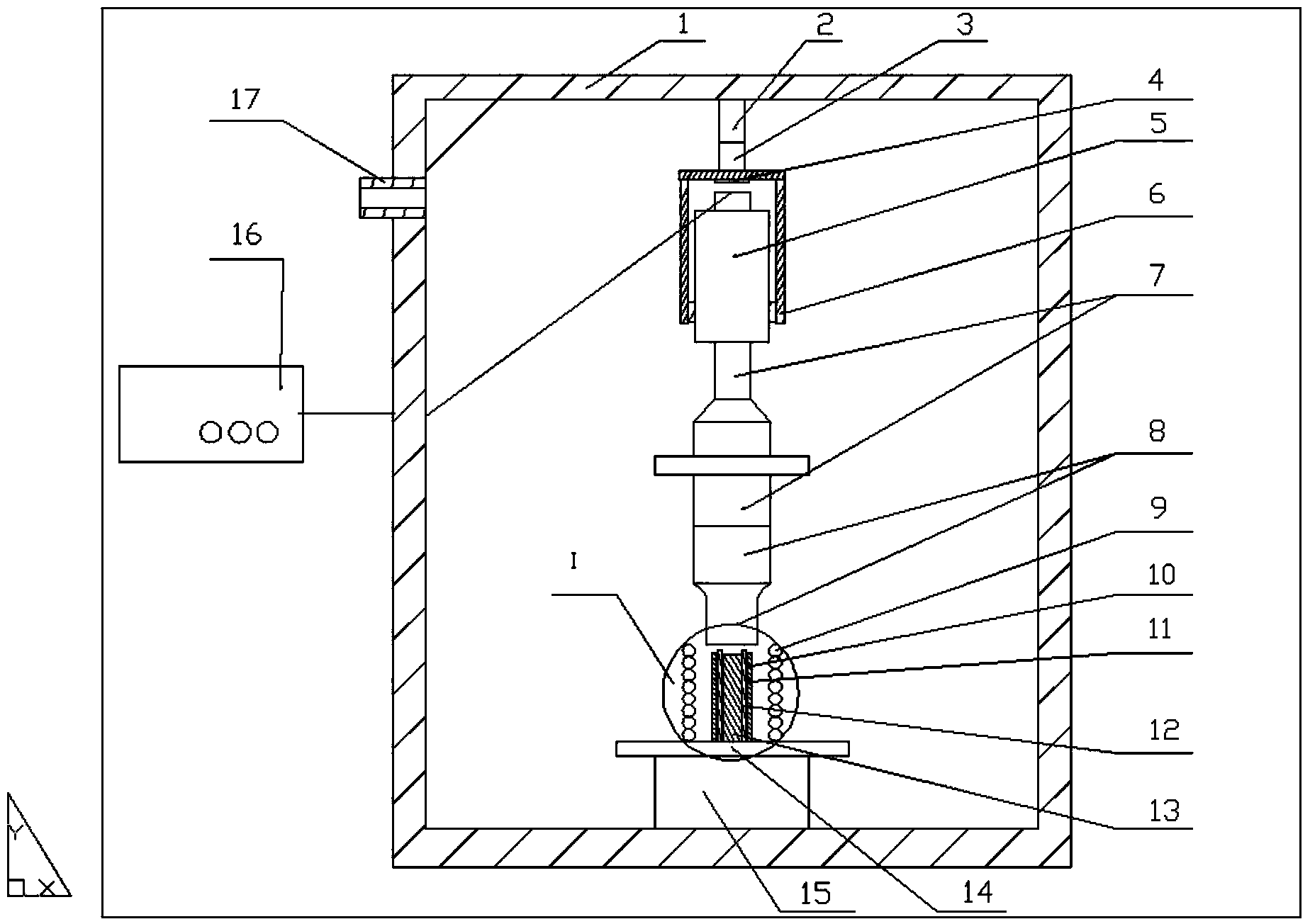

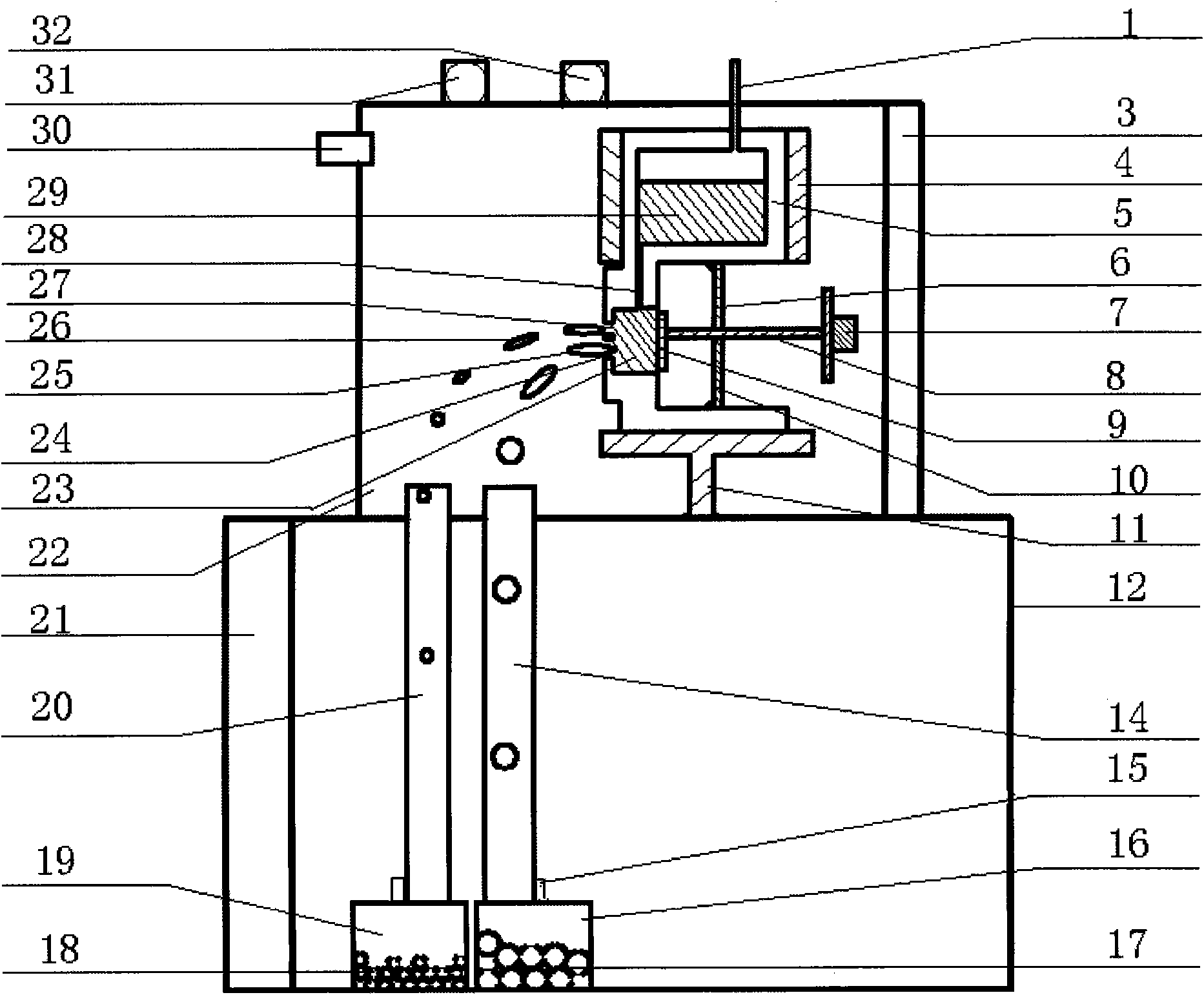

Method and device for manufacturing metallic glass particles

ActiveCN104096845AConsistent thermal stateAvoid uncontrollable factors such as heterogeneous nucleationElectricityDifferential pressure

The invention discloses a method and a device for manufacturing metallic glass particles, and belongs to the field of technologies for manufacturing metallic glass. The method includes generating stable differential pressures of 0-50KPa for metal melts in molten states under a vacuum condition; generating certain pulse signals for a piezoelectric ceramic to act on the metal melts; ejecting tiny liquid droplets from a hole in the bottom of a crucible; quickly cooling and solidifying the tiny liquid droplets without containers to form the spherical metallic glass particles. The device comprises a vacuum chamber. A particle collecting device is mounted at the bottom of the vacuum chamber, a liquid droplet ejecting system is mounted on the top of the vacuum chamber and is positioned right above the particle collecting device, and an image acquiring system is connected onto the vacuum chamber of a vacuum system. The method and the device have the advantages that the metallic glass particles are manufactured by a pulse hole ejecting process, the tiny liquid droplets are quickly solidified without the containers, accordingly, the particles with uniform and consistent particle sizes and high sphericity can be obtained, the particle sizes can be controlled, the manufacturing efficiency is high, and problems of low cooling speed, uneven particle size distribution, inconsistent thermal history and the like of an existing technology for manufacturing metallic glass particles can be solved.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

Copper-iron alloy material and preparation method and application thereof

The invention provides a copper-iron alloy material and a preparation method and application thereof. The copper-iron alloy material comprises, by weight, 5-20wt. % of iron, 0.002-0.05wt.% of RE and the balance copper. The copper-iron alloy material is easy to operate, the smelting temperature is greatly reduced, the smelting temperature in a crucible furnace is 1200-1250 DEG C, and compared withthe temperature of 1600 DEG C or above in a traditional method, energy consumption can be reduced; a vacuum smelting technology is adopted, oxidation in the high-temperature process can be avoided, the high purity of the material is guaranteed, and the oxygen element content can be lower than 150ppm; and the vacuum smelting technology is adopted, subsequent cold drawing deformation is combined, the structure components of a copper-iron alloy wire are uniform, the ductility of the copper-iron alloy wire can reach 24% or above, the wire breaking problem in electromagnetic shielding wire preparation can be reduced, the yield is increased, and the performance requirements for electric conduction and magnetic shielding of the electromagnetic shielding material can be met.

Owner:SOUTHEAST UNIV

Preparation method of super-thick aluminum alloy plate

ActiveCN110952006AHomogeneous tissue compositionImprove corrosion resistanceFurnace typesHeat treatment furnacesRare-earth elementUltrasonic vibration

The invention belongs to the technical field of aluminum alloy machining, and relates to a preparation method of a super-thick aluminum alloy plate. The raw materials comprise 0.15-0.7% of Si, 0.1-0.4% of Cu, 0.7-1.2% of Mg, 0.3-0.65% of Zn, 0.02-0.07% of Zr, 0.07-0.2% of Sc, 0.01-0.03% of La, 0.02-0.06% of Pm, 0.025-0.055% of Eu, 0.003-0.01% of Gd, 0.05% or less of single impurity, 0.15 % or lessof impurities in total, and the balance of Al. Zr, Sc and rare earth elements of La, Pm, Eu and Gd are added to alloy components; and an ultrasonic vibration system is adopted for vibration dispersion in the casting process, so that the grain structure is more uniform, the tensile strength and the yield strength are both improved, and meanwhile, the corrosion resistance is also improved.

Owner:CHINA ZHONGWANG

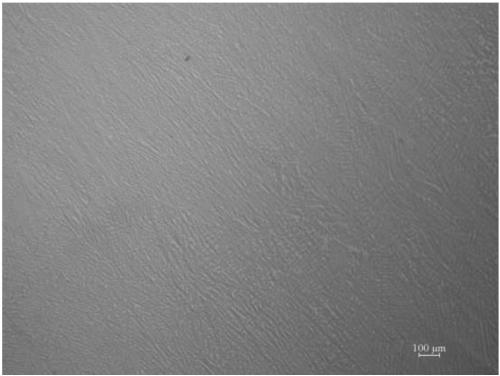

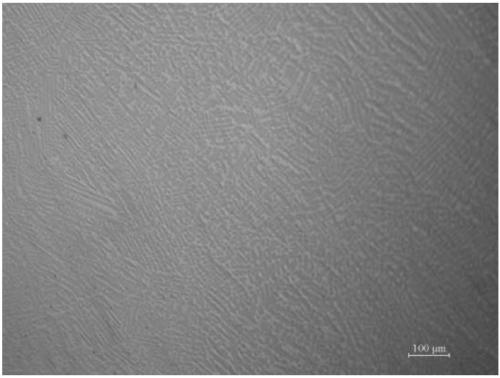

High-thermal-conductivity copper iron alloy material and preparation method and application thereof

The invention provides a high-thermal-conductivity copper iron alloy material and a preparation method and application thereof. The copper and iron alloy material comprises the following chemical components in percentage by weight: 10-30% of Fe, and the balance of Cu. The preparation method comprises the following steps: (1) burdening: corresponding raw materials are weighed in proportion; (2) smelting: the raw materials are loaded in a vacuum medium-frequency induction furnace, and are heated to 1500-1700 DEG C after loading, wherein Fe is fed by adopting a Cu-Fe intermediate alloy mode, andCu adopts an electrolytic copper plate; (3) degassing and casting: the refining, the degassing and the deoxidation are performed after the smelting; and melts are leaded down for continuous casting asingots with different specifications according to demands; and (4) molding: the ingots are prepared as products with different requirements and specifications by several different processes of forging, rolling, extrusion and drawing. The prepared CuFe alloy material is low in gas content, few in inclusion, uniform in structure component and free of macroscopic and microscopic defects as Cu and Feenrichment, and can be used as an excellent heat conducting material applied to multiple fields.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

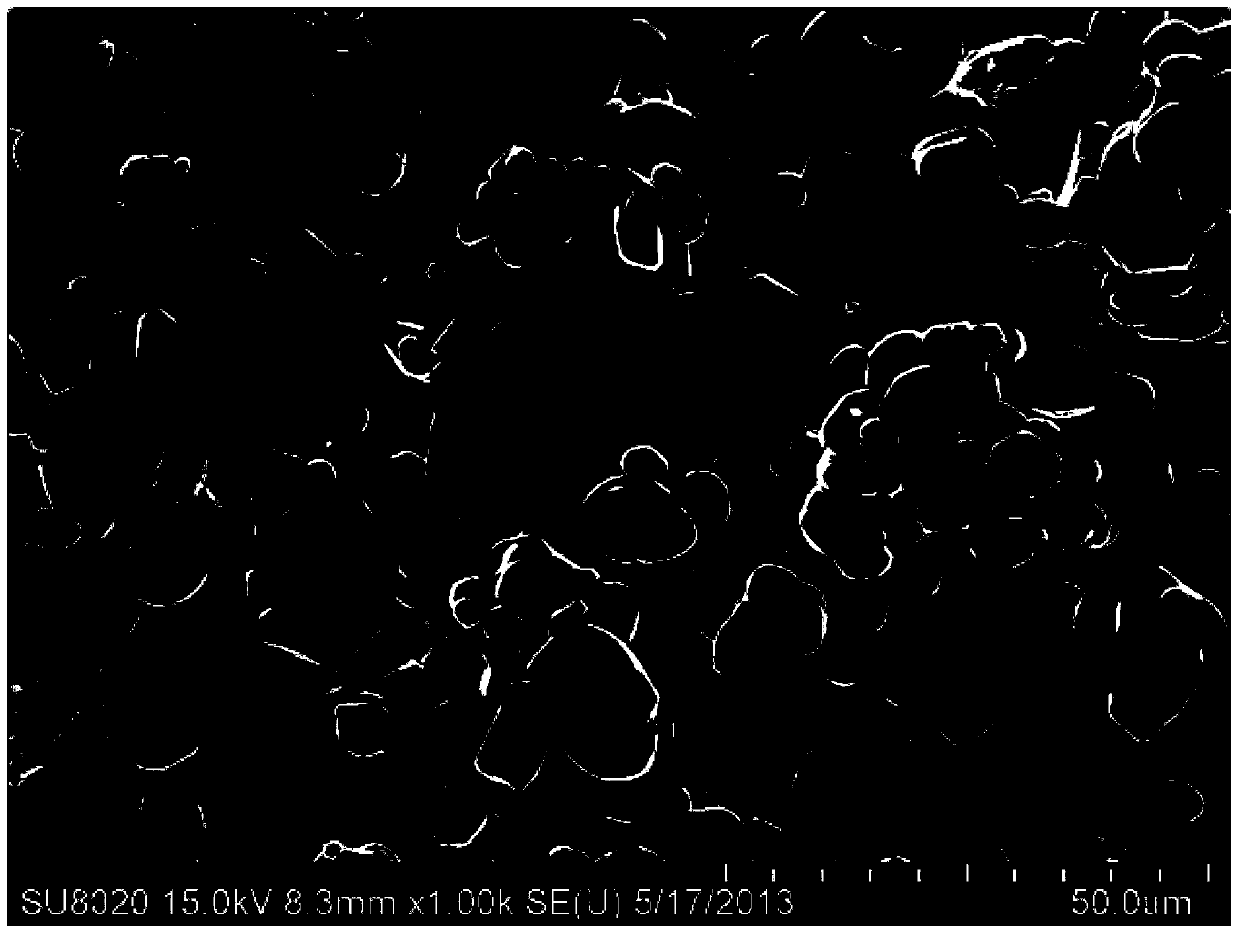

Production process of high-strength 6-series aluminum alloy cast rod

InactiveCN109468475AHomogeneous tissue compositionHigh mechanical strengthCrystalliteAluminium alloy

The invention belongs to the field of preparation of aluminum alloy rods, and relates to a production process of a high-strength 6-series aluminum alloy cast rod. The Al5CuTi2 refining agent preparedby the process disclosed by the invention is used for replacing the existing common Al-Ti-B 3D refining agent. The smelted molten aluminum is subjected smelting and refining to prepare the high-quality aluminum alloy cast ingot, the grain size of the aluminum alloy in the aluminum alloy cast ingot can be greatly reduced, the grain size of the aluminum alloy can be reduced to 20-80 microns, other eutectic crystal grains can be reduced to about 9 microns, the structure components in the aluminum alloy cast ingot are more uniform, the phenomenon of surface cracks of the aluminum ingot is reduced,the mechanical strength and the finished product rate of the aluminum alloy cast ingot are improved, and the rate of finished products can reach 99%.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

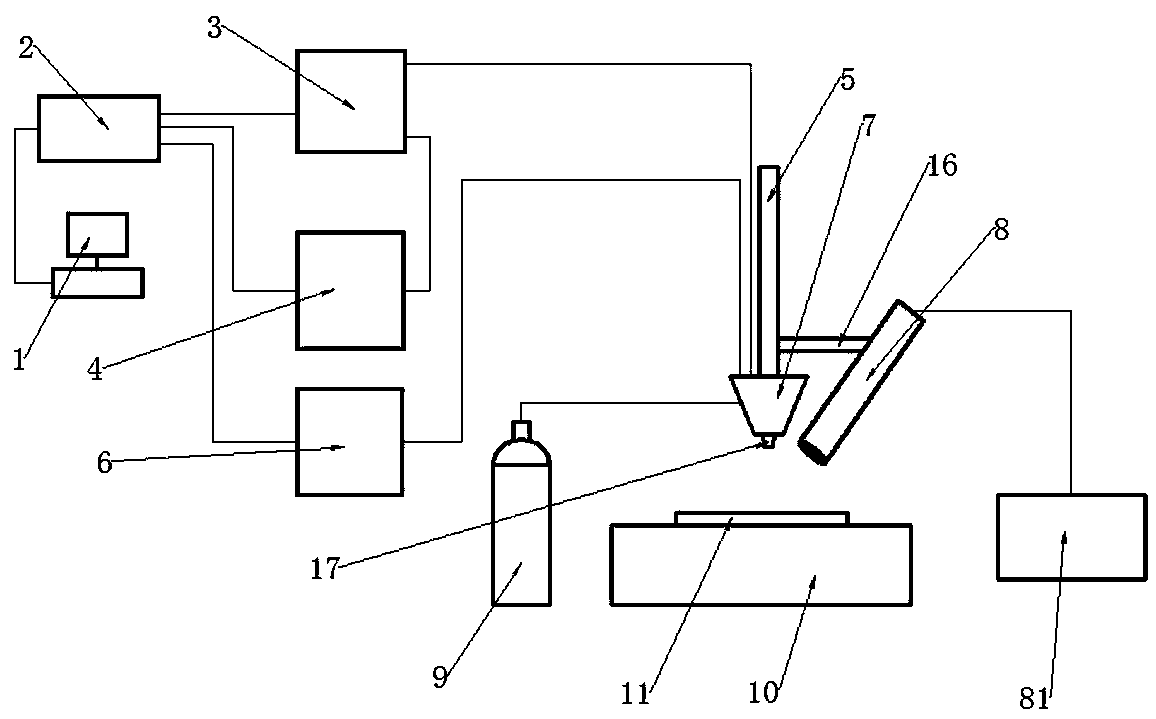

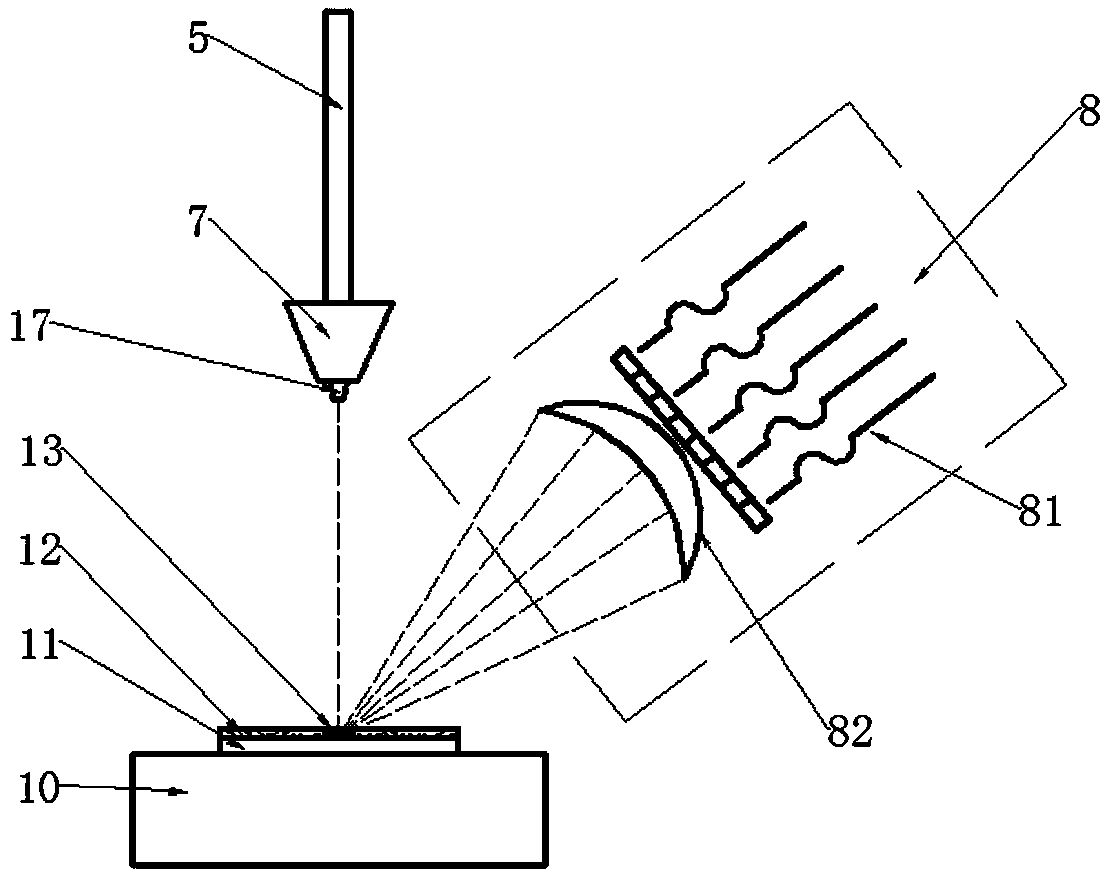

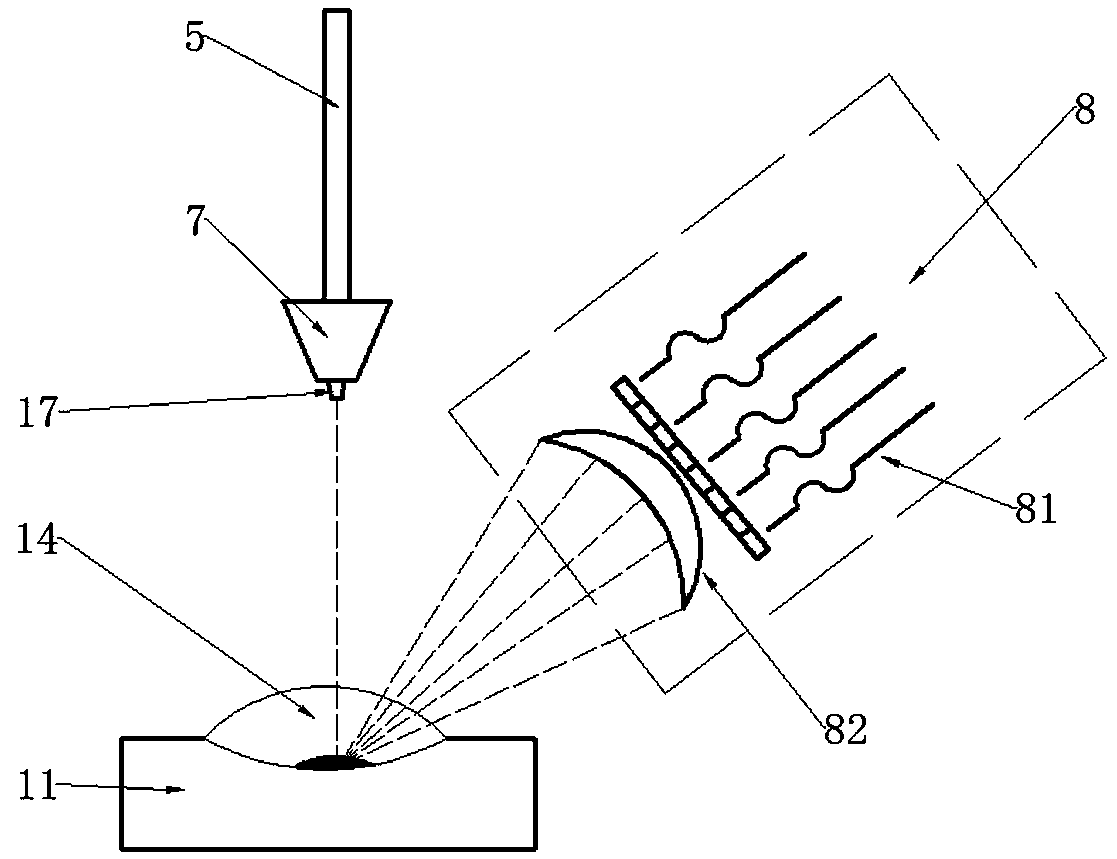

Method for carrying out nano ceramic coating laser cladding on surface of metal under assistance of ultrasonic fixed-point focusing

PendingCN110158082APromote interdiffusionGood metallurgical bondMetallic material coating processesCavitationCeramic coating

The invention relates to a method for carrying out nano ceramic coating laser cladding on the surface of metal under assistance of ultrasonic fixed-point focusing. In a laser cladding process, fixed-point ultrasonic focusing is introduced to act on a bonding surface of a metal matrix and a nano ceramic powder layer, mutual diffusion of elements between the metal matrix and the nano ceramic powderlayer is promoted, so that good metallurgical bonding is formed between the metal matrix and the nano ceramic powder layer; meanwhile, the heat effect, the cavitation effect and the sound flow effectgenerated by ultrasonic focal points can promote formation of crystal nucleus and the fluidity of liquid meta, structure components are more uniform, the structure is more compact, and the strength,the wear resistance and other performances of a cladding layer are improved. The utrasonic fixed-point focusing is adopted, so that the defects that a traditional ultrasonic wave can only act on all molten pools and matrix, so that a cladding layer is thinned and diffuse to the periphery are overcome, the size of the bonding surface of the cladding layer and the matrix as well as the thickness ofthe cladding layer can be accurately controlled, in addition, the flexibility degree is high, and the method is suitable for various complex laser cladding processing environments.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

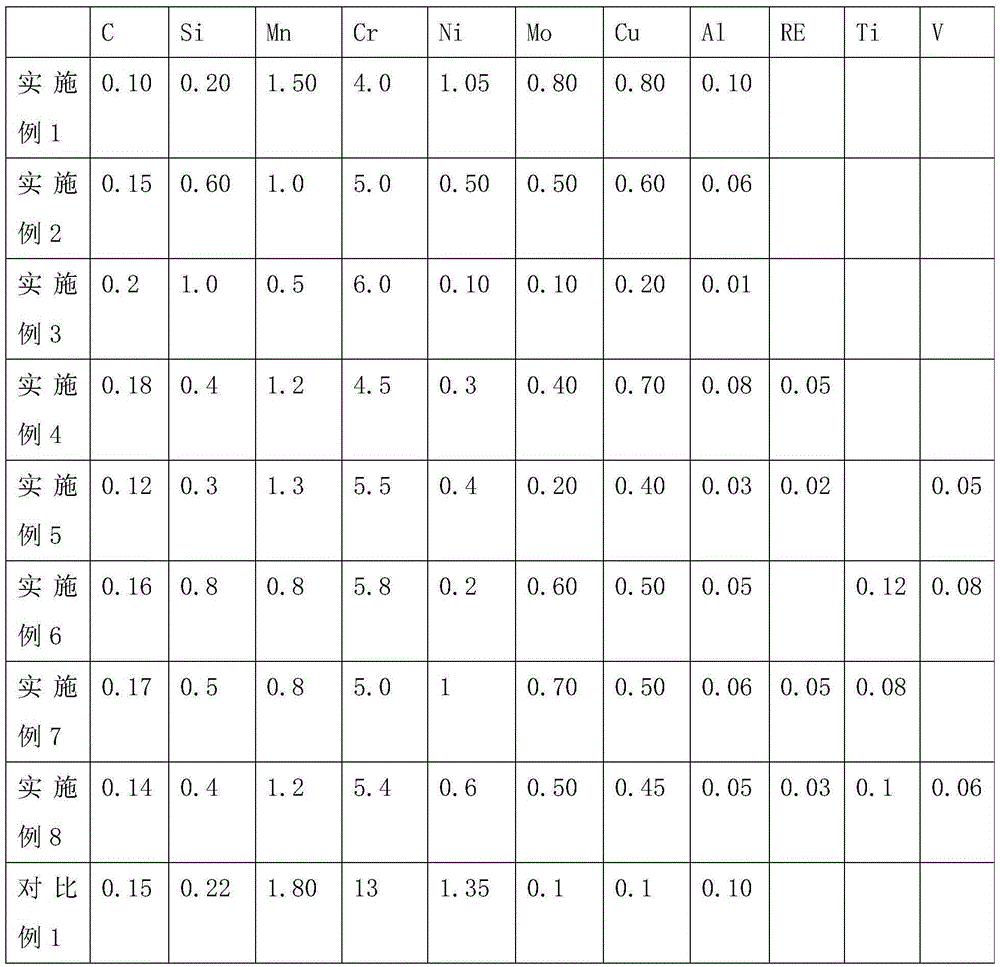

Corrosion-resistant steel for oil well and production method for corrosion-resistant steel

InactiveCN105256243AReduce manufacturing costStrong stress corrosion resistanceChemical compositionMechanical property

The invention provides corrosion-resistant steel for an oil well and relates to the technical field of steel. The corrosion-resistant steel is prepared from, by mass, 0.10%-0.20% of C, 0.20%-1% of Si, 0.05%-1.5% of Mn, 4.0%-6.0% of Cr, 0.10-1.0% of Ni, 0.10%-0.8% of Mo, 0.20%-0.80% of Cu, 0.01%-0.10% of Al and the balance Fe and inevitable impurity elements, wherein the total content of the inevitable impurity elements is not higher than 0.5%. The corrosion-resistant steel for the oil well achieves the mechanical properties that the yield strength ranges from 1,020 MPa to 1,150 MPa, the tensile strength ranges from 1,140 MPa to 1,300 MPa, the elongation is around 20%, and the Kv of a 140 ksi steel grade casting pipe product is around 30 J at 0 DEG C. In addition, the corrosion-resistant steel for the oil well belongs to the category of low-alloy steel, and the content of Cr and Ni is low; and the CO2 corrosion resisting performance and the H2S corrosion resisting performance of the steel are improved through the methods such as simultaneously adding a small quantity of elements retarding the anode process and elements promoting the cathode process and the surface activity. The corrosion-resistant steel for the oil well is low manufacturing cost and high in CO2 corrosion and H2S stress corrosion resistance.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

Preparation method of Ti-25Nb alloy sheet

The invention provides a preparation method of a Ti-25Nb alloy sheet, which comprises the following steps: 1. carrying out vacuum consumable arc-melting on raw materials sponge titanium and Ti-47Nb interalloy to obtain a Ti-25Nb alloy cast ingot; 2. carrying out cogging and forging; 3. forging a sheet blank; 4. carrying out hot rolling; 5. sequentially carrying out quenching, shot blasting and pickling treatment; and 6. carrying out cold rolling to obtain the Ti-25Nb alloy sheet of which the thickness is 0.3-1mm. The Ti-25Nb alloy sheet prepared by the method provided by the invention has the advantages of no inclusion, no composition segregation, more uniform structural composition, high flatness, smooth surface and no defects, such as cracking, peeling, stratifying, folding and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Alloy and manufacturing method thereof

The invention discloses an alloy and a manufacturing method thereof, and relates to the field of powder metallurgy. The method aims solving the problem that The method aims solving the problem that density of high-temperature alloy workpiece and the like caused by closed-hole pores which are easily formed due to the fact that hollow powder is existed in an existing power metallurge high-temperature alloy. The method comprises the following steps of an alloy ingot is smelted in a vacuum induction smelting furnace to form a first bar, wherein the alloy ingot comprises 20-22% of nickel, 15.5-17.5% of iron, 16-18.5% of chromium, 11.5-13% of molybdenum, 5.0-6.5% of niobium, 3.2-4.5% of tungsten, 0.45-0.60% of carbon, and the balance cobalt and impurities; shrinkage holes of the first bar are cut off to form a second bar, and the second bar is formed alloy powder by a plasma rotating electrode atomizing device; and the alloy powder is put into a graphite mould to carry out vacuum hot-pressing sintering to obtain the alloy.

Owner:西安赛隆增材技术股份有限公司

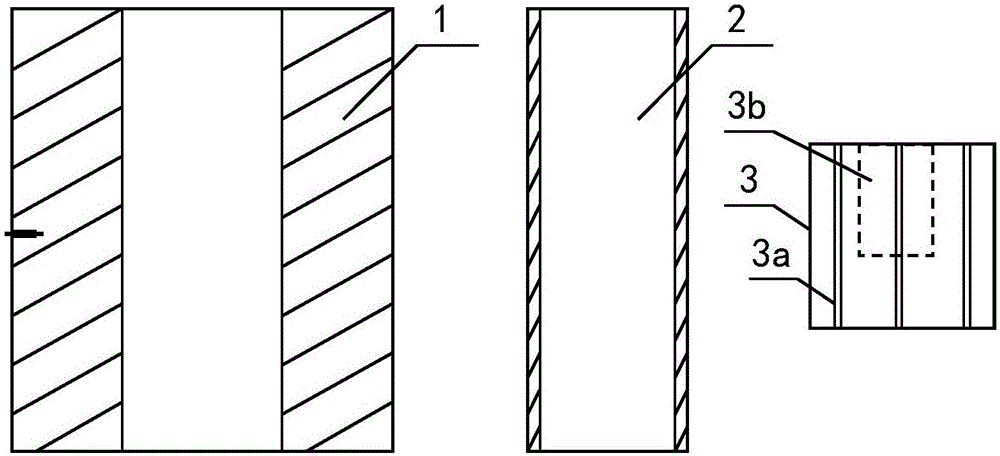

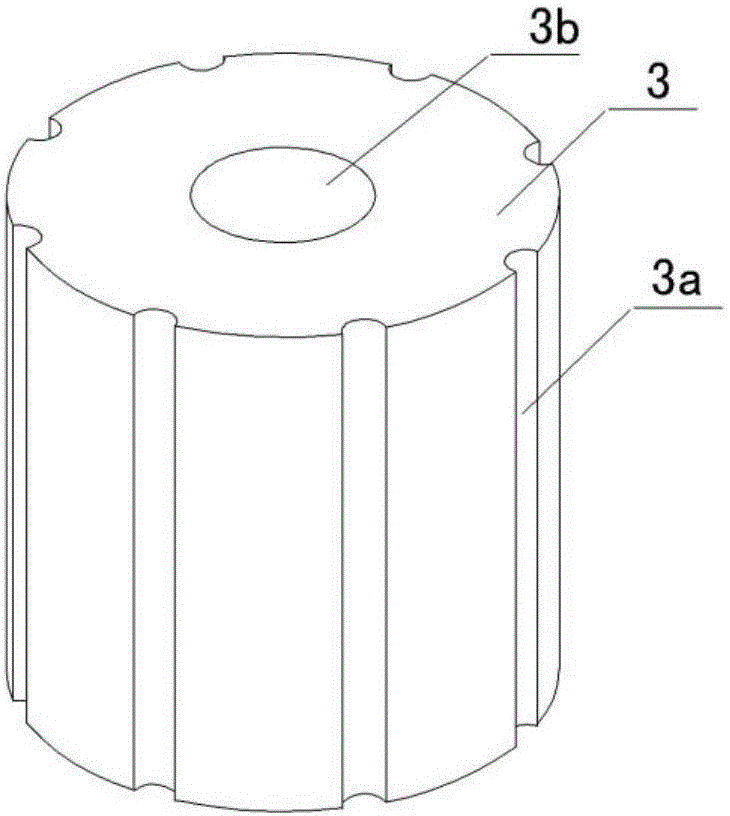

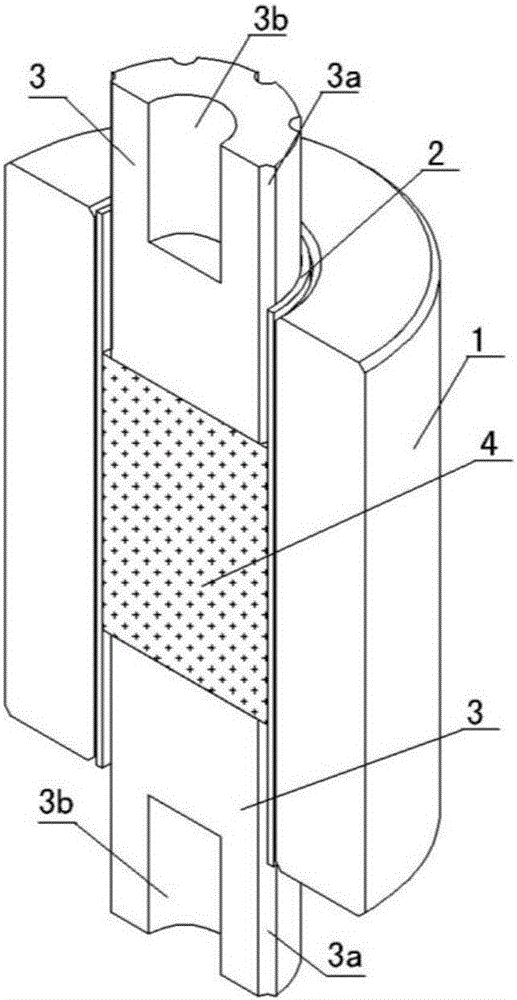

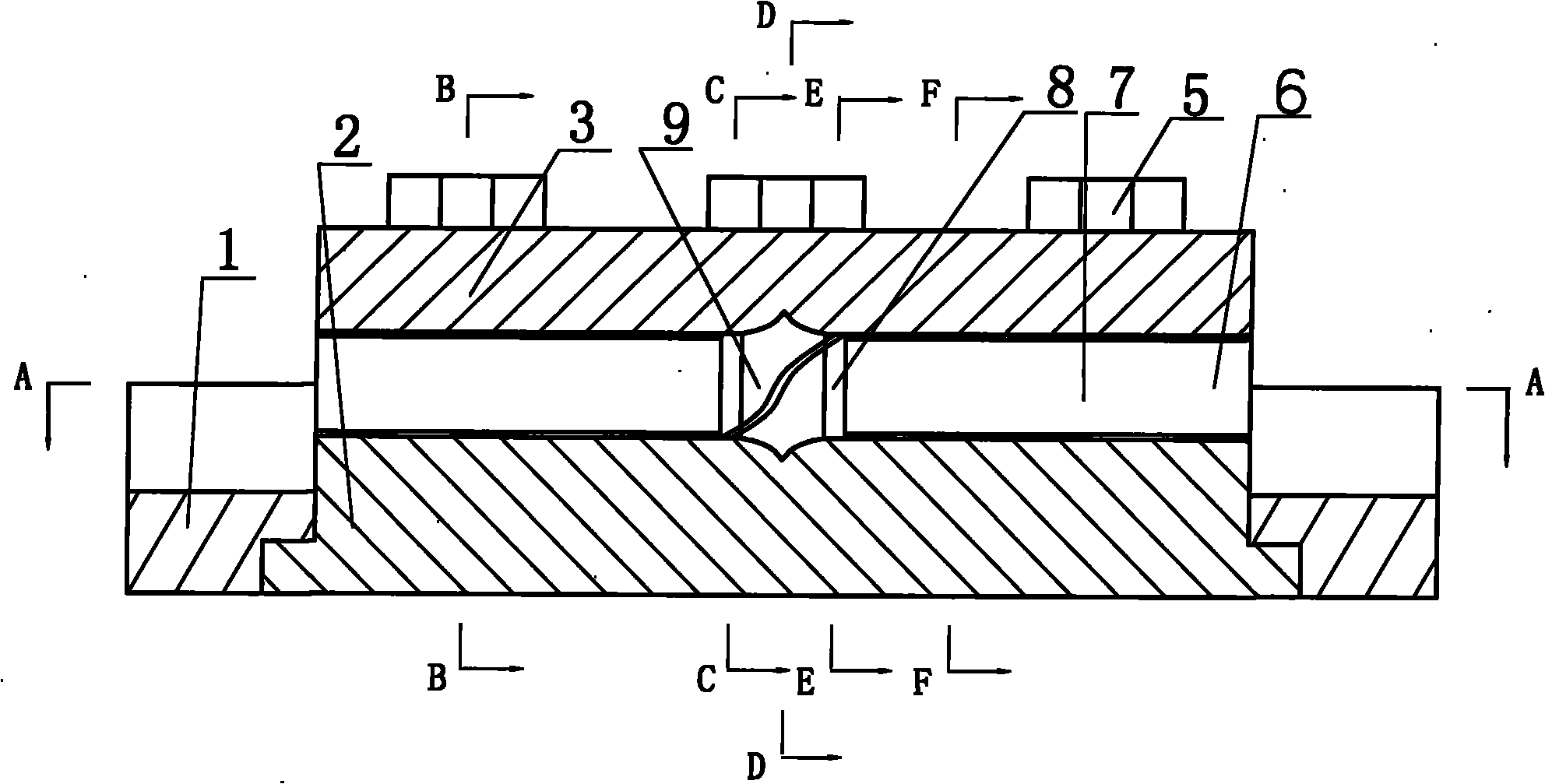

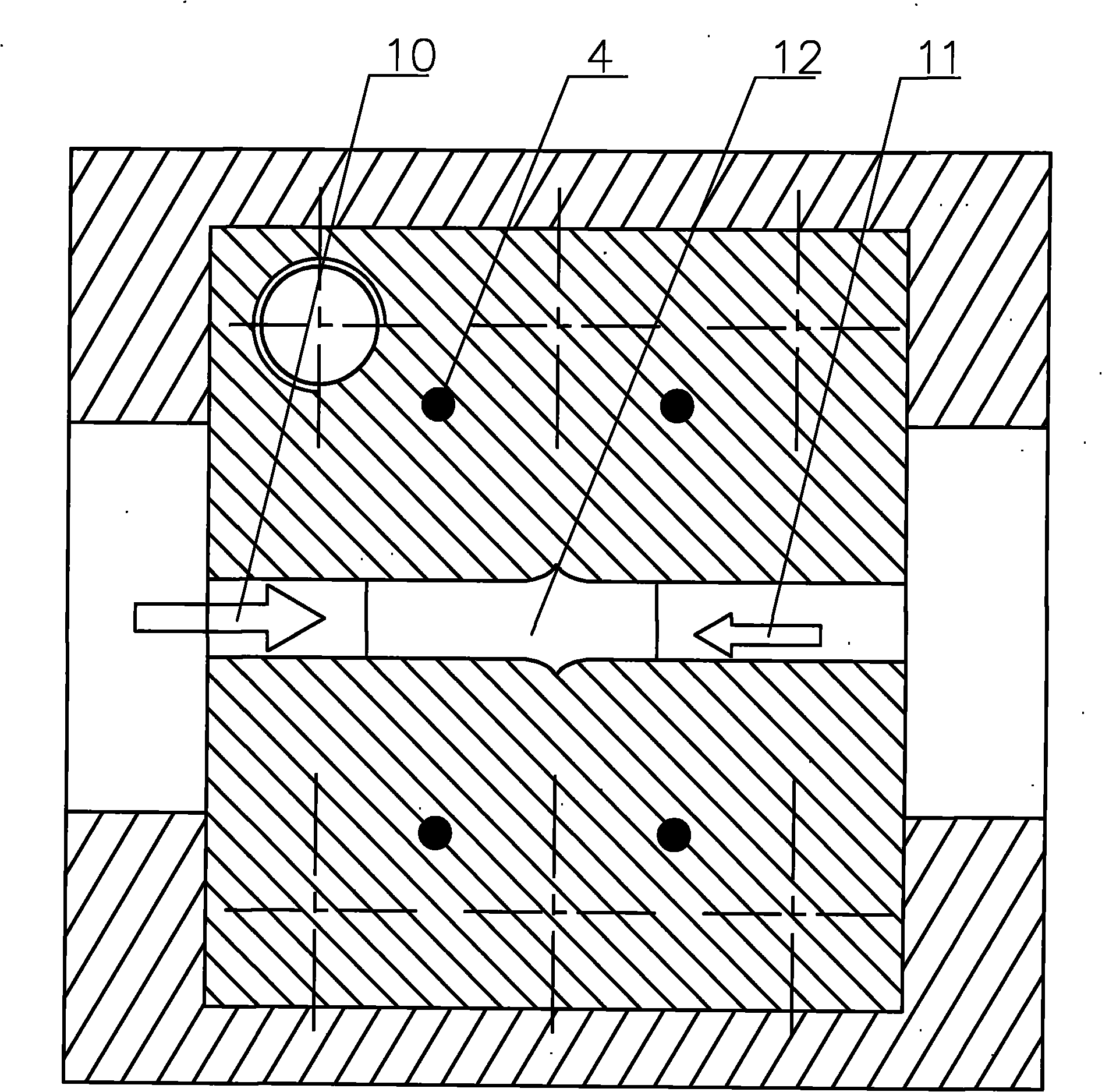

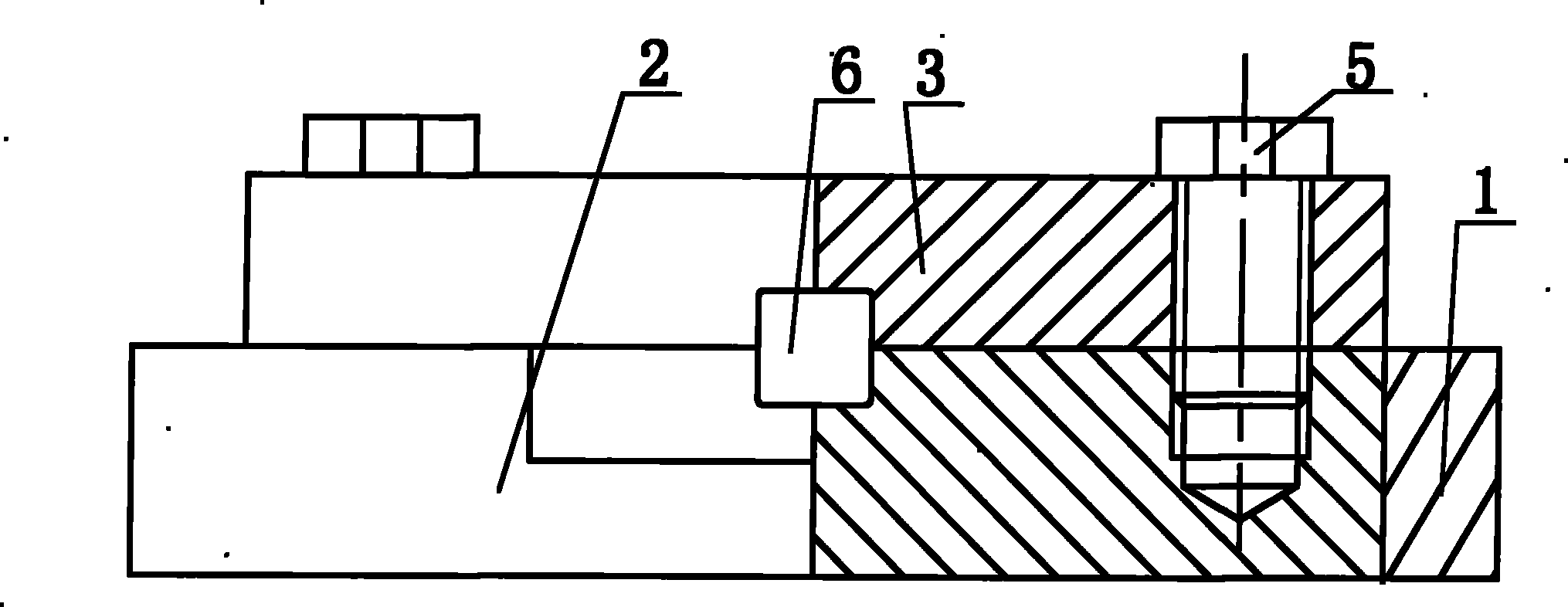

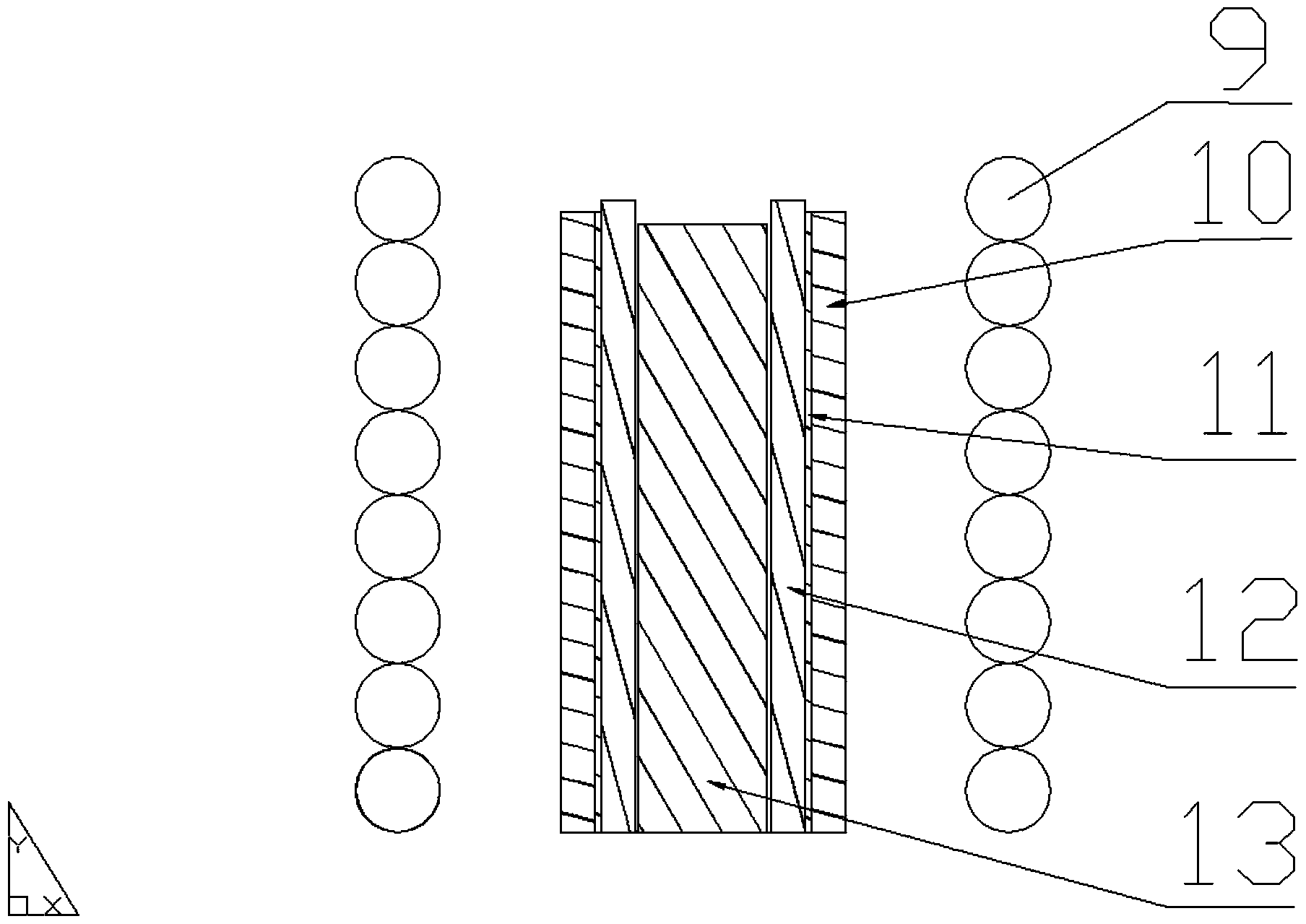

Extrusion die with an equal-passage spiral cavity for molding magnesium alloy square rods and extrusion method

InactiveCN101773946AImprove uniformityFine surface grainsExtrusion diesExtrusion control devicesMaterials scienceMagnesium alloy

The invention relates to an extrusion die with an equal-passage spiral cavity for molding magnesium alloy square rods and an extrusion method. Currently, magnesium alloy rods made through extrusion molding have uneven texture at the positions with equal radius because the bending radii of the blanks are different in the bending process. The extrusion die with the equal-passage spiral cavity for molding the magnesium alloy square rods comprises a fixed plate (1) which is connected and fixed with a lower die (2); the lower die and an upper die (3) are fixed through positioning pins and are connected with each other through bolts (5); the curved surfaces of the opposite end faces of the upper die and the lower die form a passage (6); and a spiral passage(9) is arranged at the middle segment of the passage. The extrusion die is used for producing the magnesium alloy rods through extrusion molding.

Owner:HARBIN UNIV OF SCI & TECH

Preparation and application methods of brazing filler metal used for brazing between high-silicon aluminum alloy and kovar alloy

InactiveCN110280927AUniform thicknessHomogeneous tissue compositionWelding/cutting media/materialsSoldering mediaKovarFiller metal

The invention discloses preparation and application methods of brazing filler metal used for brazing between dissimilar materials, namely a high-silicon aluminum alloy and a kovar alloy. The preparation method comprises the steps that raw materials are weighed according to the fact that the brazing filler metal is composed of, by mass percent, 15%-45% of an Al30Si alloy, 18%-30% of Cu, 0.5%-5% of Ni and the balance Al; the raw materials are ground and cleaned; the raw materials are subjected to high-temperature smelting; quenching is performed for preparing the foil-shaped brazing filler metal; and the like. The application method comprises the processes that to-be-welded surfaces are pretreated; the foil-shaped brazing filler metal is pretreated; and welding is performed. The preparation and application methods provided by the invention aim at solving the problems that the performance difference between the dissimilar materials, namely high-silicon aluminum and the kovar alloy is large, and welding is difficult; and the foil-shaped brazing filler metal prepared through the method is consistent in thickness and uniform in component, the brazing filler metal has metallurgical reaction with elements in high-silicon aluminum alloy and kovar alloy base materials in the high-temperature welding process, new phases are formed, and in addition, formed weld joints are good in continuity, high in compactness, high in connecting strength and can be widely applied to T / R module shell sealing.

Owner:HENAN POLYTECHNIC UNIV +1

High-performance copper alloy

The invention relates to a high-performance copper alloy, and belongs to the field of copper alloy materials and powder metallurgy. The copper alloy comprises Cu, Cr, Zr and M according to the mass percentages of 0.1% to 5.0% of Cr, 0.1% to 5.0% of Zr, and 0.05% to 0.5% of M. M is composed of Re and at least two elements of Mg, Ag, B, Ga, Si, Li, Ti, Fe and Mn. RE is composed of at least three elements of Ce, La, Yb, Pr, Nd and Sm. According to the high-performance copper alloy, the Cu-Cr-Zr-M copper powder is prepared by adopting a gas atomization technology, a supersaturated solid solution with uniform ingredients and fine microstructures is obtained, then the powder is subjected to extrusion molding with a powder sheath and heat treatment, and the Cu-Cr-Zr-M copper powder with excellentperformance is prepared. The high-performance copper alloy is reasonable in component designing, and simple and controllable in preparation technology, a product is good in performance, and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

Pollution-free and efficient method for refining titanium-aluminum alloy

The invention discloses a pollution-free and efficient method for refining titanium-aluminum alloy, which solves the problems that a traditional titanium-aluminum alloy casted is thick in tissue, very bad in room temperature plasticity and large in brittleness, is difficult to form, and has very serious segregation. The pollution-free and efficient method comprises the steps below: firstly, a material is placed in a bar layer of a titanium-aluminum alloy melt melting device in the middlemost of a coiler; secondly, an induction coil is connected with an electrode; thirdly, a loudspeaker is fixed on an upper locating device through a connecting rod; fourthly, a tool head of an ultrasonic machine is in contact with the top of a formwork through the locating device; fifth, a vacuum pump is started; sixth, the induction coil is applied with power; seventh, when the power is unloaded, an ultrasonic generating device is used for adding an ultrasonic wave for the ultrasonic treatment time for 0-90s; and eighth, the formwork is taken out and crushed to obtain a refined titanium-aluminum rod. The pollution-free and efficient method provided by the invention is applied to the field of ultrasonically refining titanium-aluminum alloy.

Owner:HARBIN INST OF TECH

Method and device for ejecting and preparing homogeneous particles by pulsing lateral parts of holes

The invention relates to a method and a device for ejecting and preparing homogeneous particles by pulsing lateral parts of holes. The method comprises the following steps that: under the condition of pressure difference between inert gases inside and outside a melting pool, a raw material is heated to a molten state by a heater; piezoelectric ceramic is stimulated by a pulse driving signal to generate a displacement towards one side of a crucible with the holes; the displacement is transmitted to a molten body by a transmission rod and a pressing plate to ensure that a certain quantity of micro molten bodies are ejected through small holes of different sizes on the lateral part of the crucible and then perform similarly horizontal projectile motion at different initial speeds; and the ejected micro molten bodies generate different horizontal displacements during falling, so that the homogeneous particles of different particle sizes can be obtained hierarchically at the bottom. The particles prepared by the method and the device have a uniform size, homogeneous components, controllable particle sizes and high sphericity; and the method and the device are suitable for various materials with lower melting points, can meet the requirements of continuity and stability in a production process, particularly can fulfill the aim of automatic layering at the bottom, greatly improve the production efficiency, and fully meet the requirements and development of modern microelectronic packaging industries.

Owner:DALIAN LONGTIAN TECH

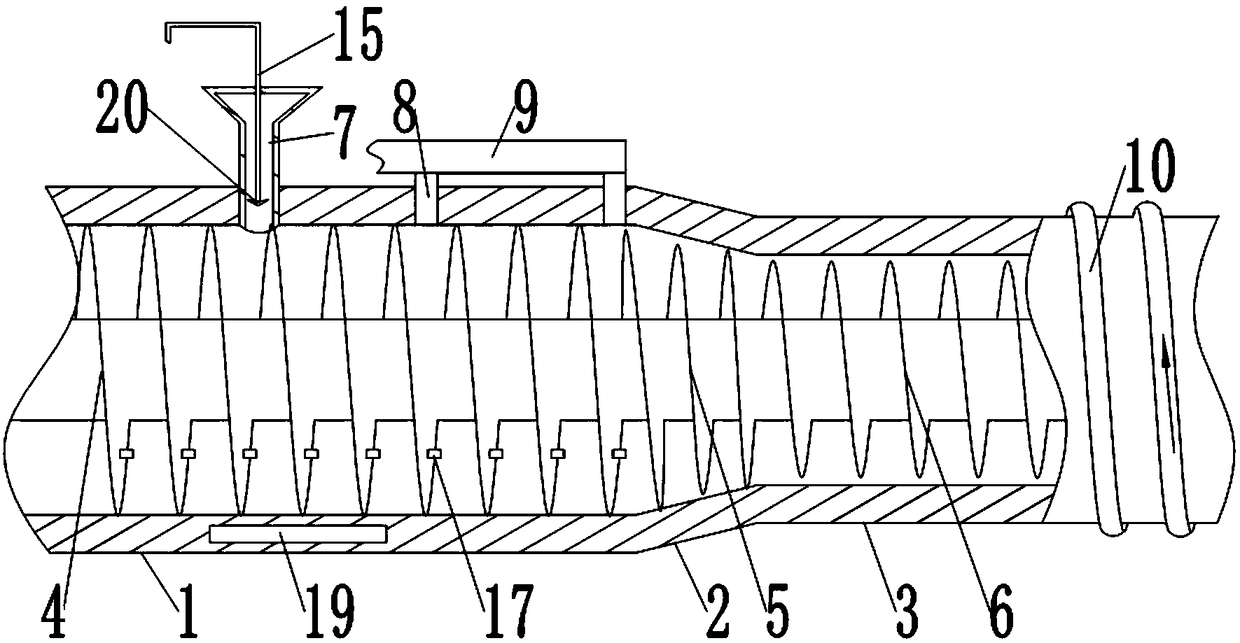

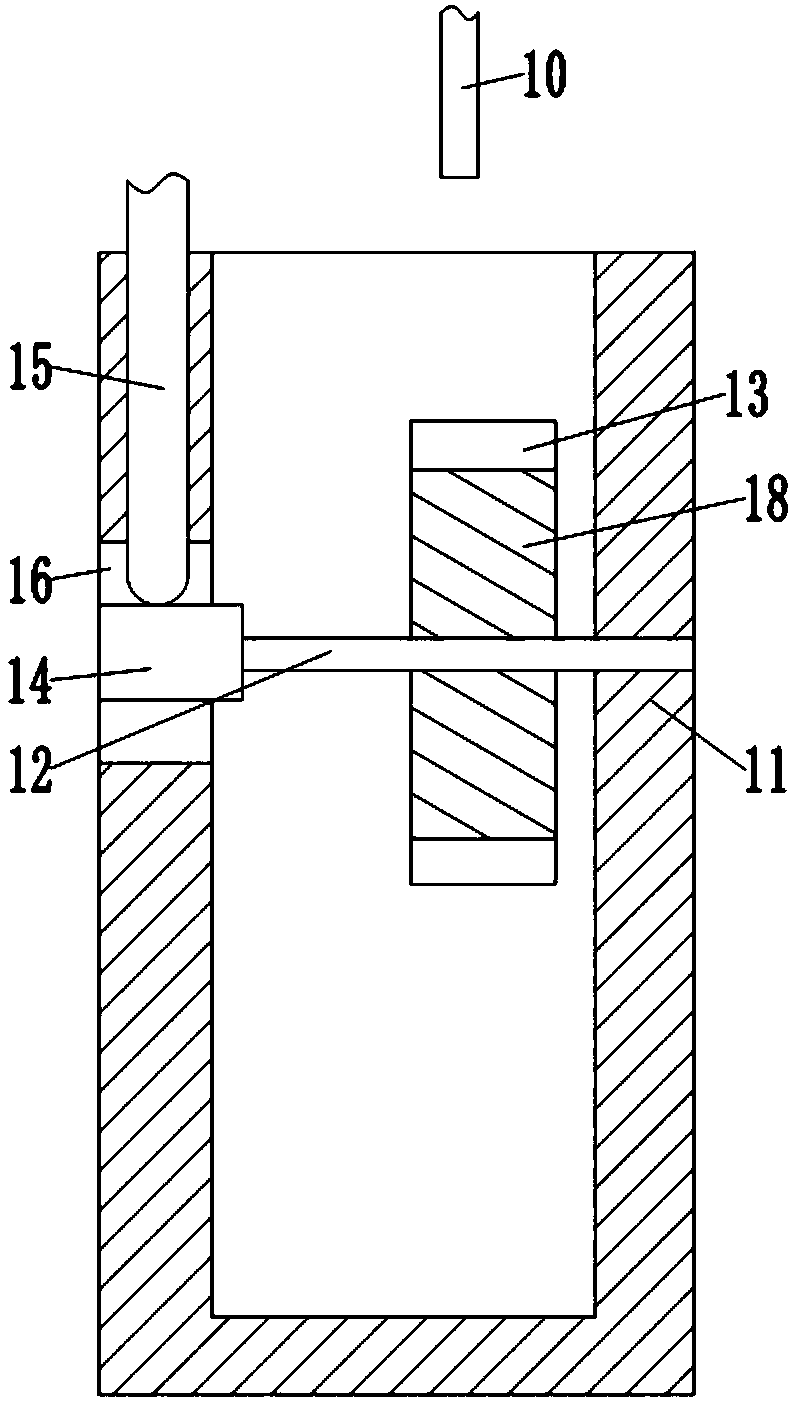

PE wood plastic particle processing device

The invention relates to the technical field of industry manufacturing, in particular to a PE wood plastic particle processing device. The PE wood plastic particle processing device comprises a material barrel and a screw rotationally arranged in the material barrel. The material barrel comprises a first material barrel body, a second material barrel body and a connecting part used for connectingthe first material barrel body with the second material barrel body. The screw correspondingly includes a first screw body and a second screw body, wherein the first screw body is provided with a highspiral blade, and the second screw body is provided with a low spiral blade. The first material barrel body is provided with a feeding hopper and an exhaust hole, the exhaust hole communicates with an exhaust pipe, and the exhaust pipe is arranged on the feeding hopper. The exterior of the second material barrel body is provided with a cooling water pipe, a water collecting box is further arranged below the cooling water pipe, a rotation shaft is rotationally connected in the water collecting box, the rotation shaft is provided with a wood board in a radial manner, and the rotation shaft is coaxially and fixedly connected with a rectangular prism. The water collecting box is further in sliding connection with a sliding rod. One end of the sliding rod is in sliding connection with the circumferential face of the rectangular prism. By adoption of the scheme, PE wood plastic particle extruded products are uniform in organization component, and the product inner stress is small.

Owner:贵州荣兴新型建材科技有限公司

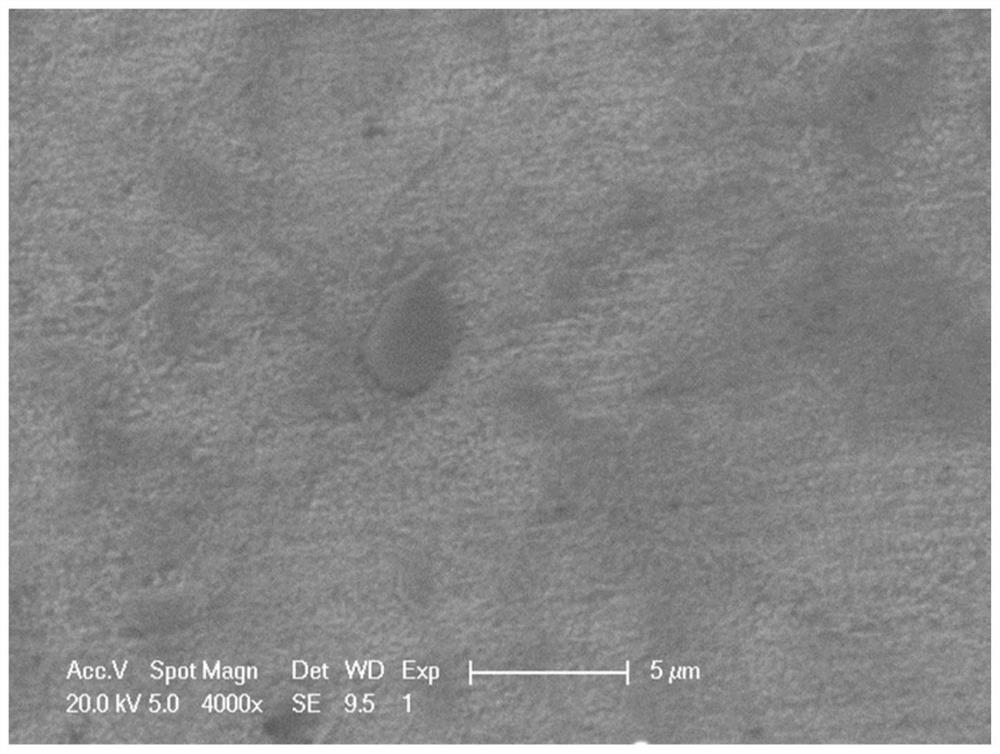

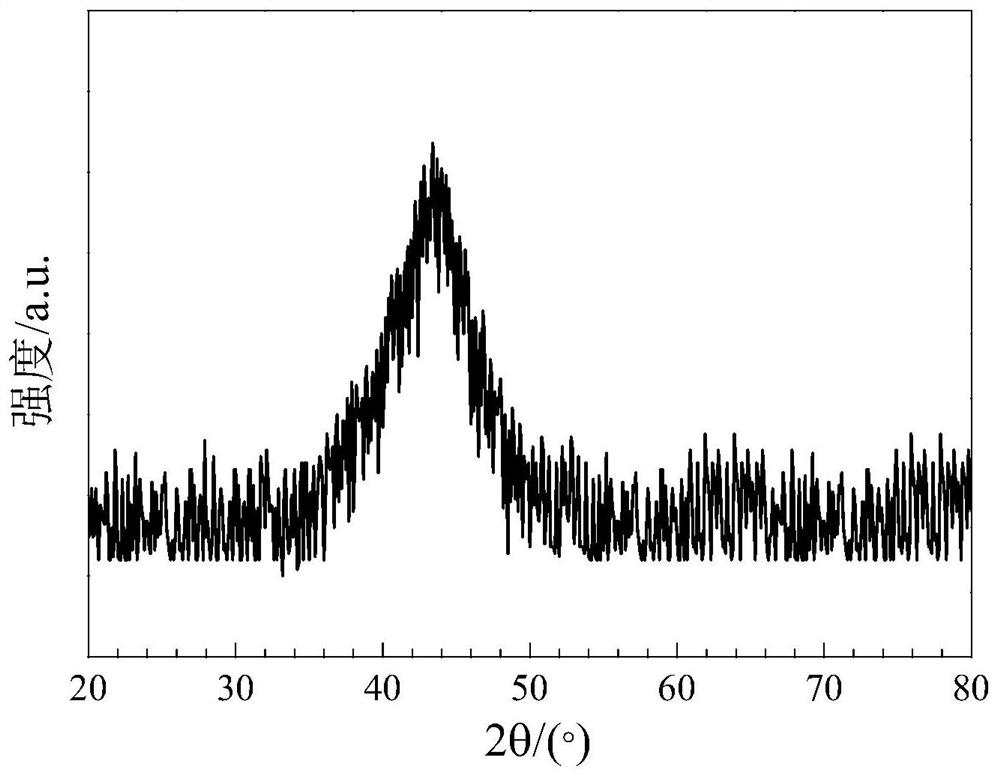

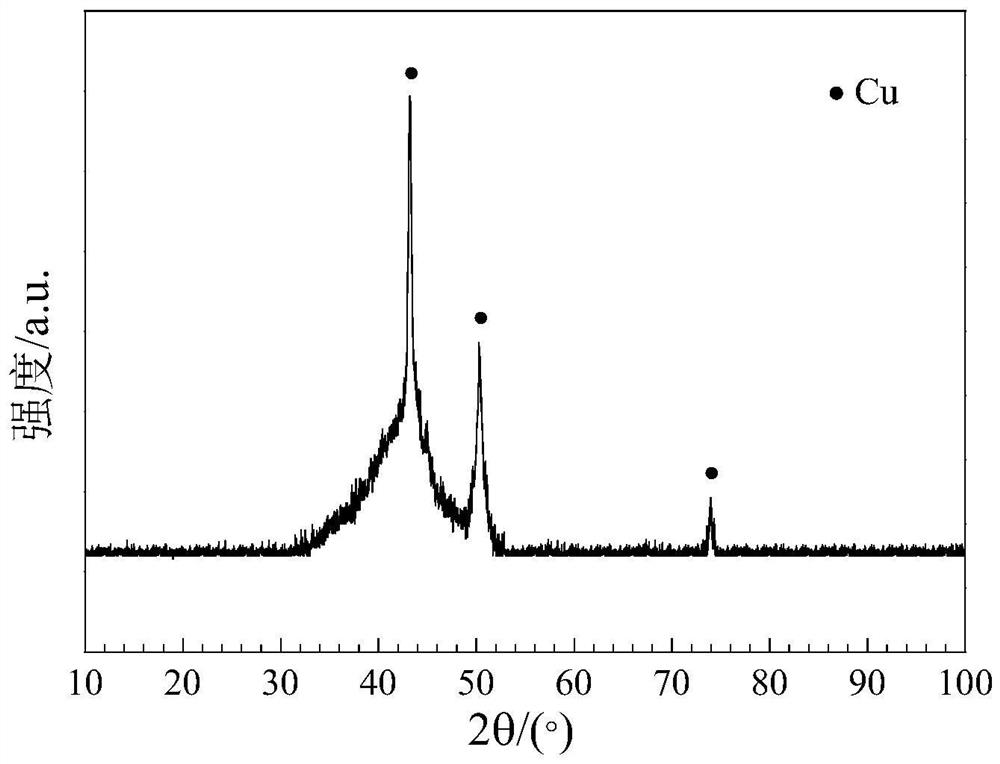

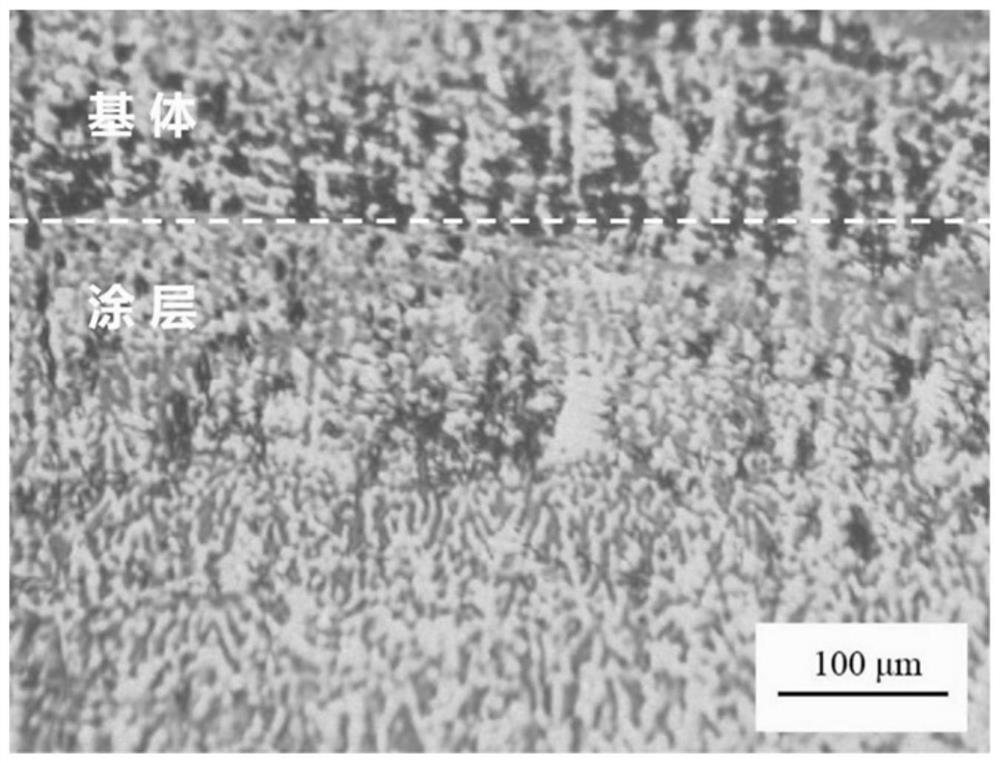

Copper-based amorphous composite coating and preparation method thereof

Owner:YANSHAN UNIV

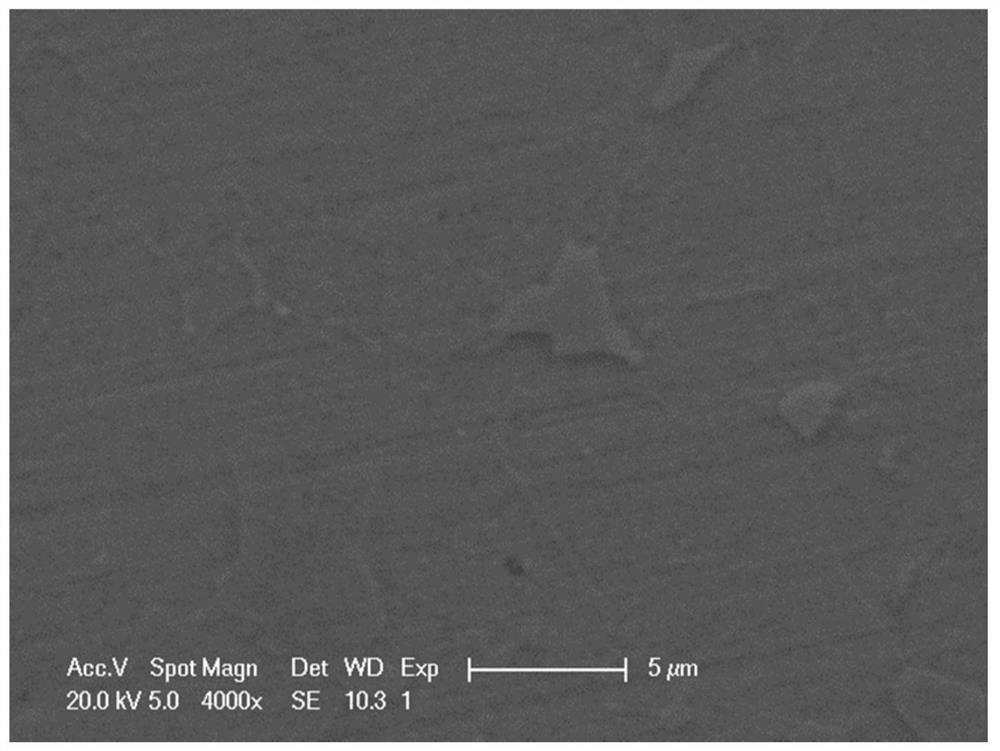

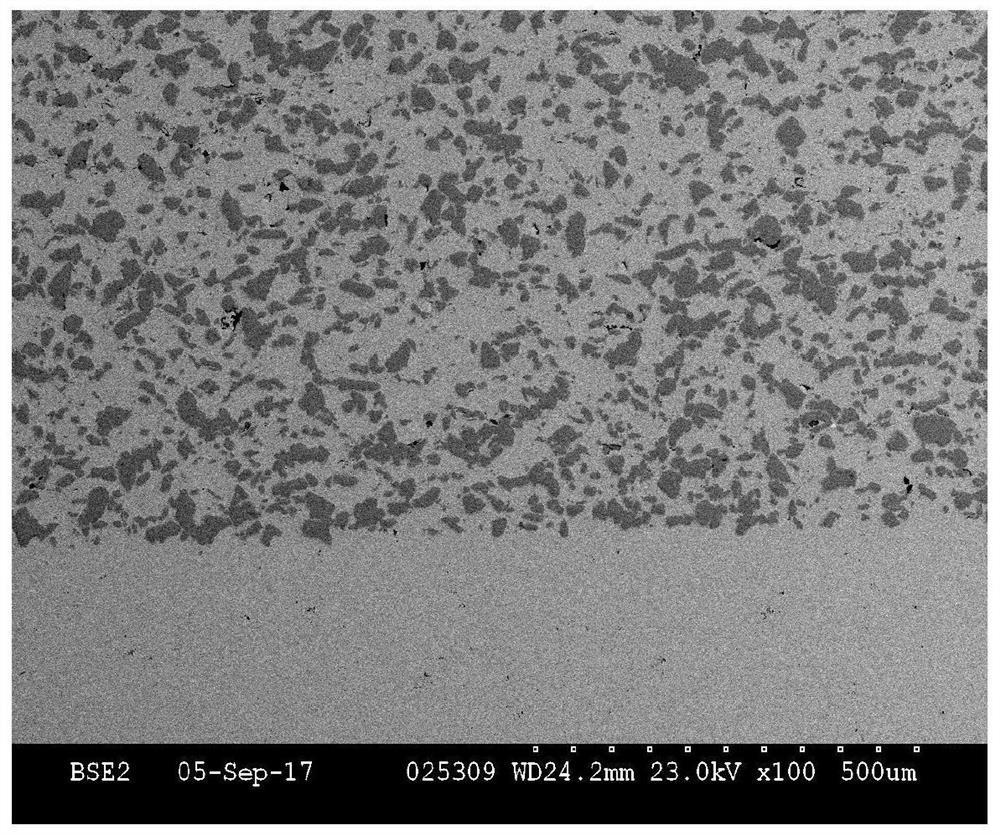

Preparation method of copper-chromium composite coating

PendingCN112195462AImprove deposition efficiencyImprove mechanical propertiesPressure inorganic powder coatingWear resistanceCopper substrate

The invention discloses a preparation method of a copper-chromium composite coating. The preparation method comprises the following steps of: mixing copper powder and chromium powder, and drying to obtain a cold spraying raw material; spraying the cold spraying raw material on a copper substrate by using cold spraying equipment to obtain a sample with a Cu-Cr composite coating; and annealing the Cu-Cr composite coating, and then performing post-treatment on the sample to obtain a Cu-Cr composite coating sample. The copper-chromium composite coating with the thickness of about 3.0mm can be obtained, and the copper-chromium composite coating is high in deposition efficiency, excellent in mechanical property and relatively good in wear resistance, and the hardness of the copper-chromium composite coating exceeds 125HV.

Owner:XI'AN POLYTECHNIC UNIVERSITY

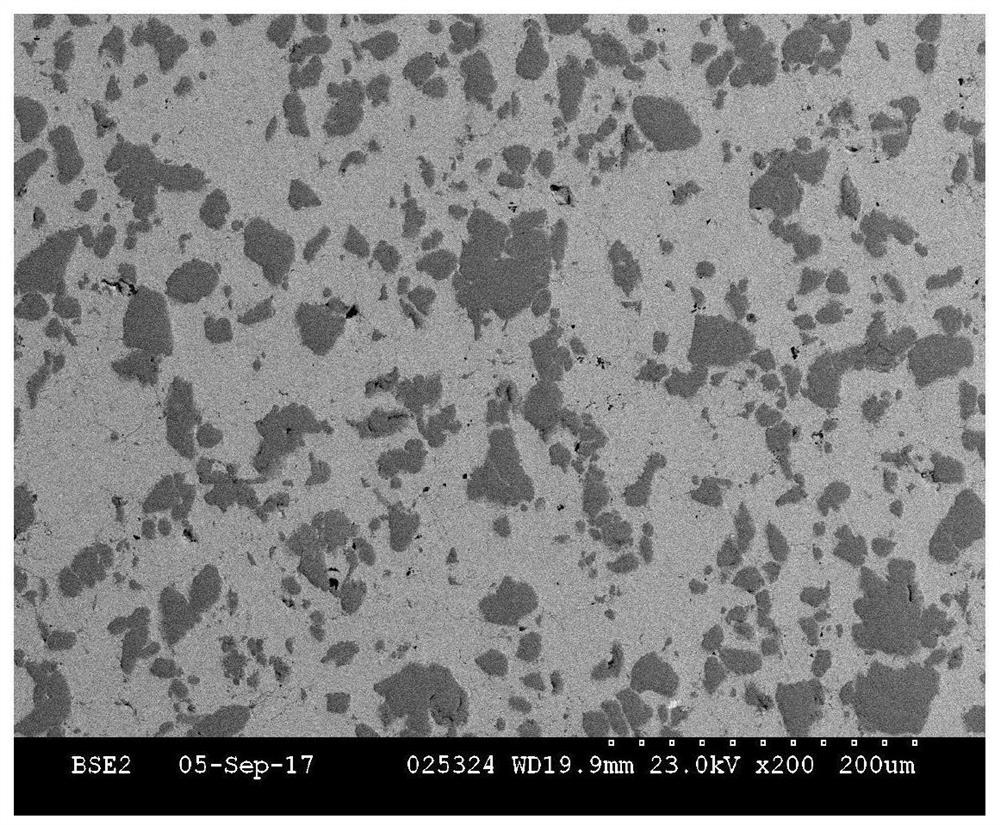

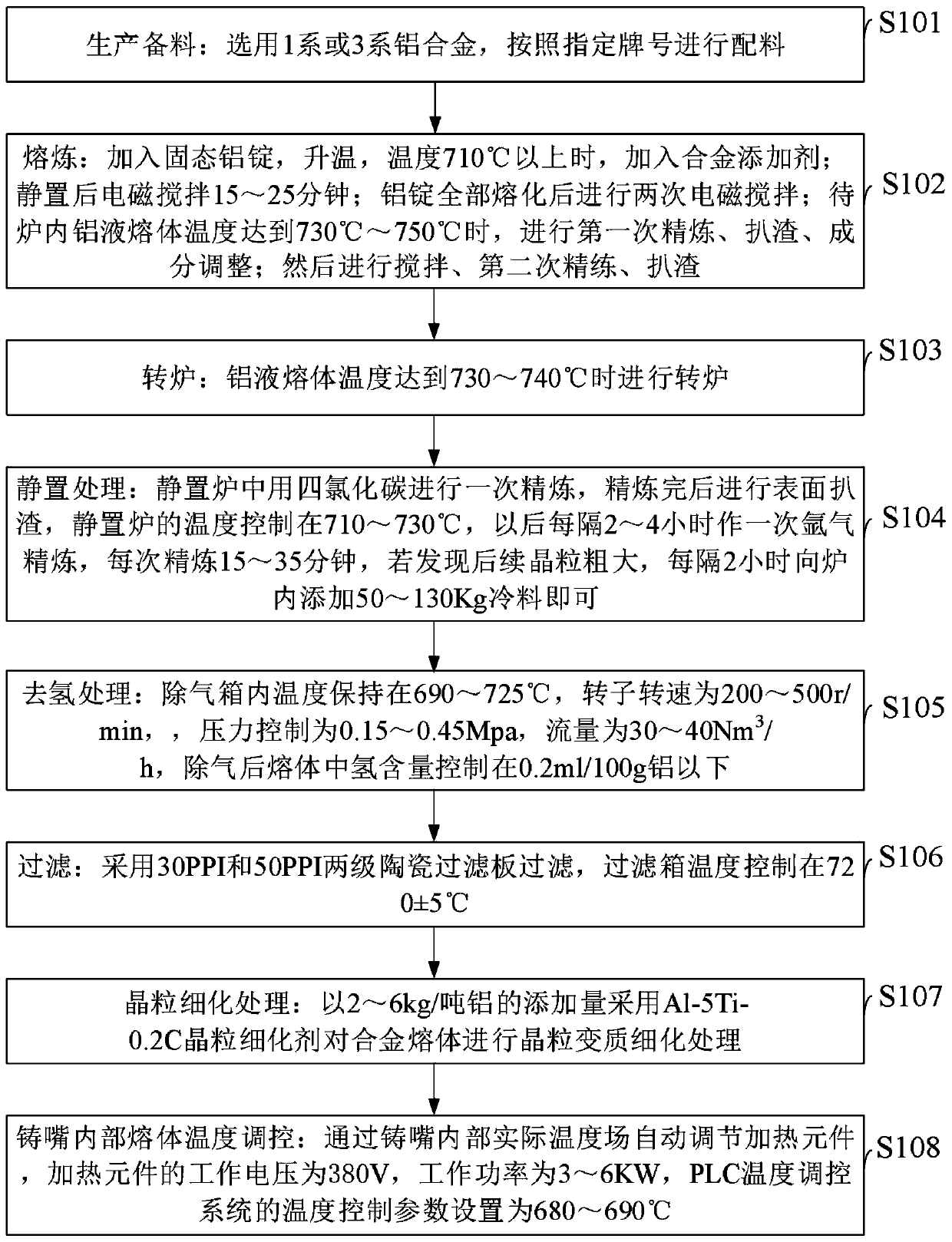

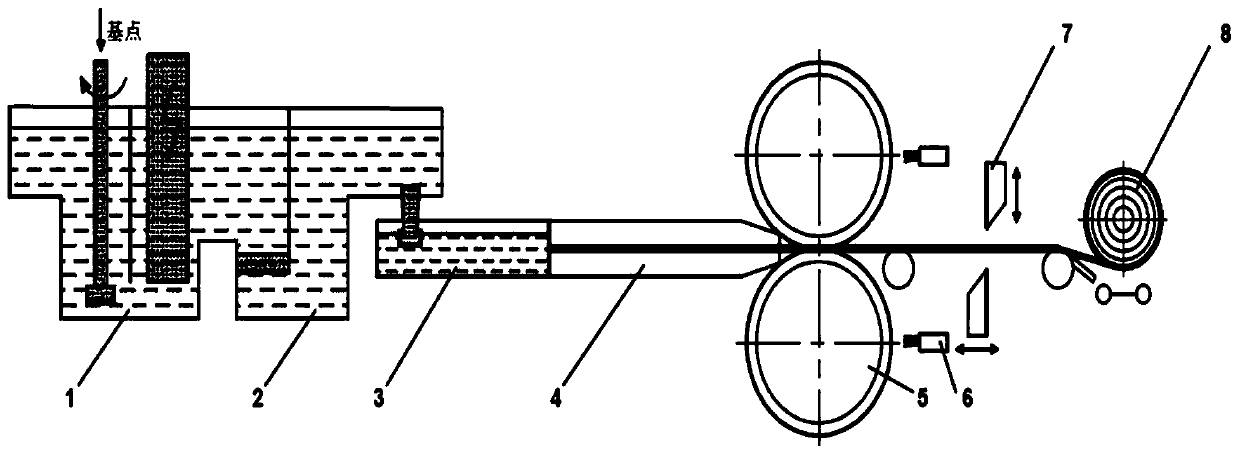

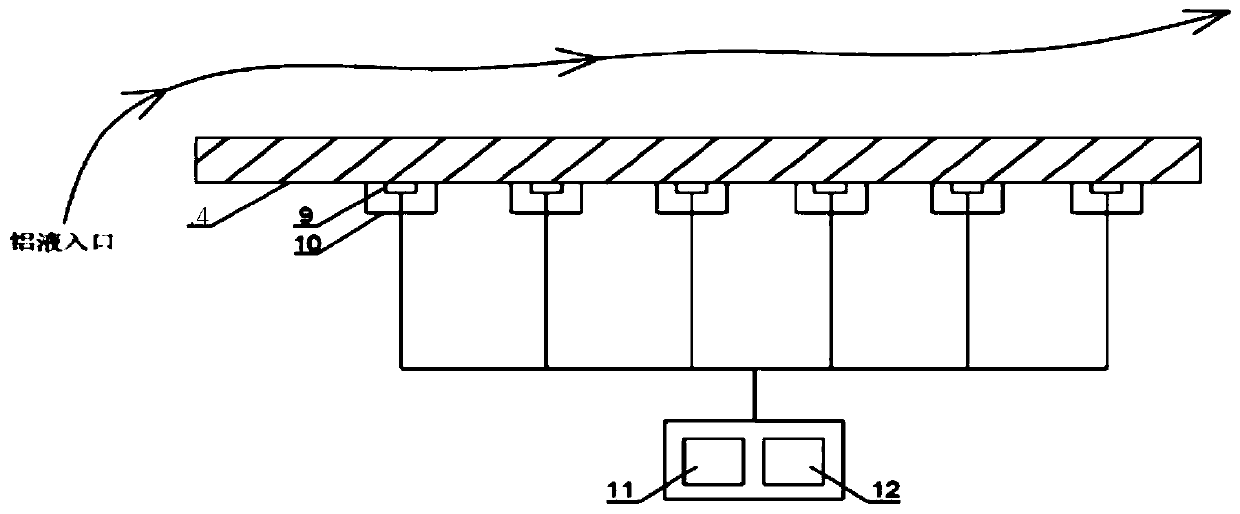

Method for regulating and controlling structure uniformity of cross section of ultra-wide aluminum alloy sheet

ActiveCN109777979AUniform temperature fieldHomogeneous tissue compositionCrystalliteTemperature control

The invention belongs to the technical field of aluminum alloy sheet machining, and discloses a method for regulating and controlling the structure uniformity of a cross section of an ultra-wide aluminum alloy sheet. The method comprises the following steps: producing ingredients, specifically, 1-series or 3-series aluminum alloy is selected and blending is performed according to a specified grade; performing smelting; performing a converter operation when the temperature of a molten aluminum melt reaches 730 to 740 DEG C; performing standing treatment; performing dehydrogenizing treatment; performing filtering by adopting two stages of ceramic filtering plates, namely, 30PPI and 50PPI, specifically, the temperature of a filtering box is controlled at 720+ / -5 DEG C; performing grain refining treatment; and regulating and controlling the temperature of the melt in a casting nozzle. According to the method for regulating and controlling the uniformity of the cross section structure of the ultra-wide aluminum alloy sheet, by introducing a temperature regulating and controlling device at the tail part of the casting nozzle and regulating and controlling the temperature automatically, the temperature field uniformity of the ultra-wide aluminum alloy sheet in the direction of the width of the casting nozzle in a casting-rolling process can be ensured; a uniform plate blank cross section structure is obtained; a 3-mm aluminum alloy sheet with uniform structure components, fine grain size and uniform second phase distribution is produced; and the casting-rolling of a high-quality ultra-wide aluminum alloy sheet is achieved.

Owner:CENT SOUTH UNIV

Cyanide-free composite electroplating method for plating RE-TiO2-Ag layer on surface of steel substrate

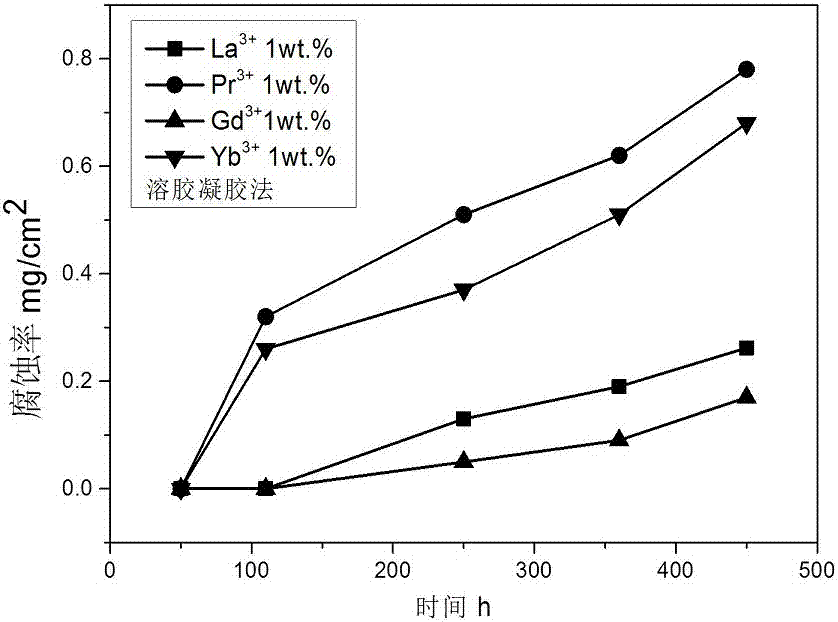

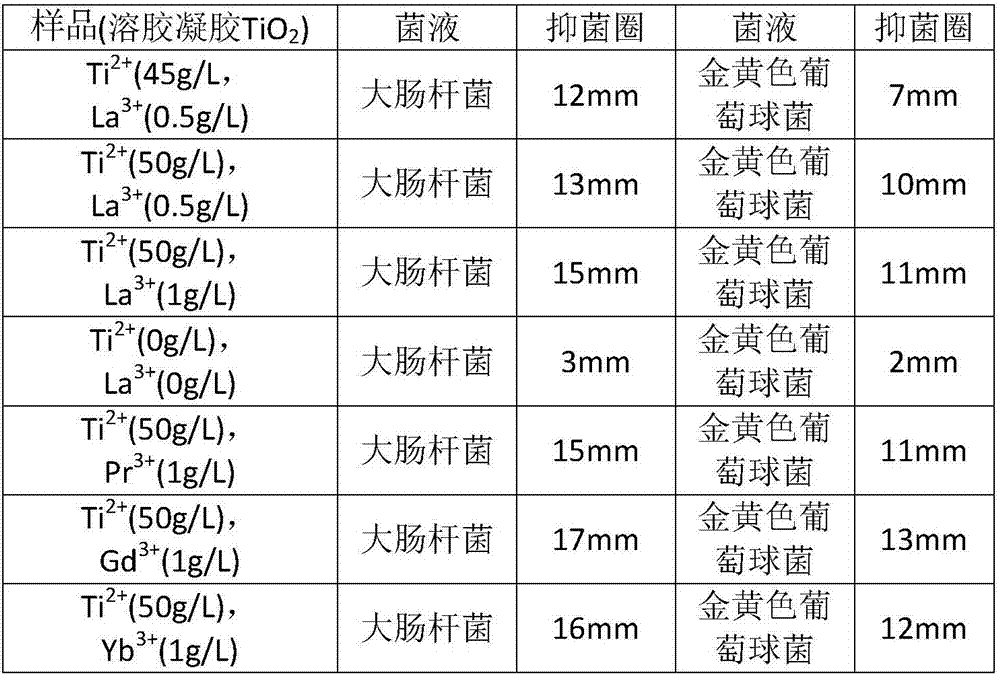

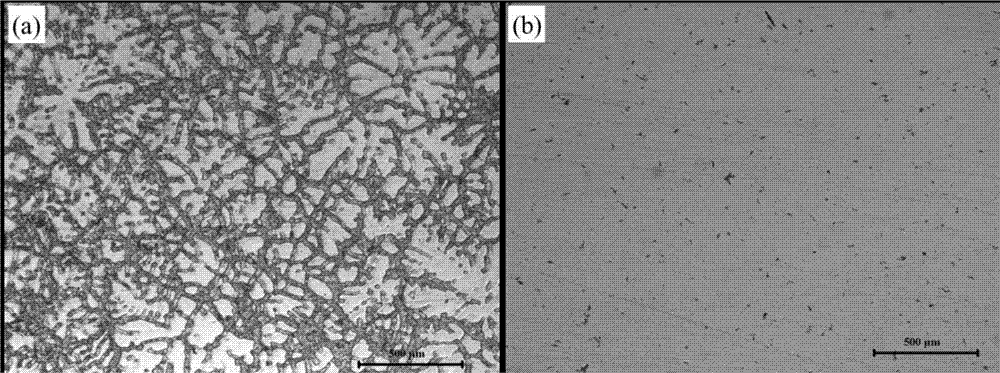

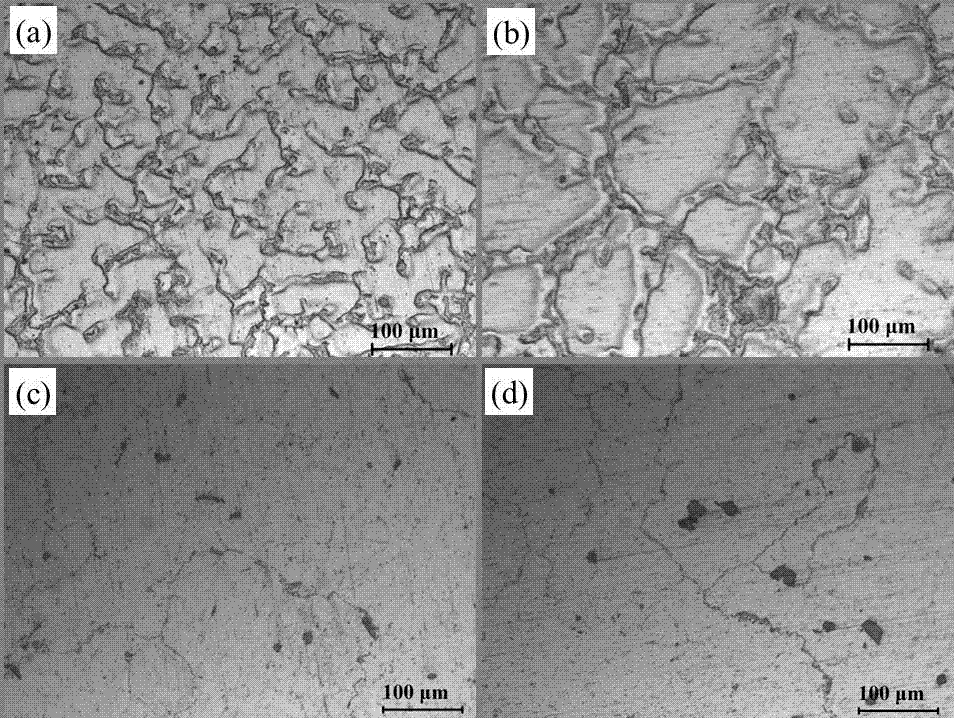

ActiveCN107299368AThe electroplating process is simpleHigh plating effect of electroplating solutionElectrolytic coatingsRare-earth elementCyanide

The invention provides a cyanide-free composite electroplating method for plating a RE-TiO2-Ag layer on the surface of a steel substrate. RE rare earth element is selected from La<3+>, Pr<3+>, Gd<3+> or Yb<3+>, and titanium oxide is from titanium oxide powder with the size of 20-100nm or a titanium oxide sol solution. The electroplating method is safe and environment-friendly, the preparation process is simple, and an obtained electroplated layer is uniform, compact, strong in corrosion resistance and strong in oxidation resistance and has relatively good antibacterial and bactericidal properties.

Owner:长江润发(江苏)薄板镀层有限公司

Preparation method of tool surface coating and prepared coating

ActiveCN106637077AImprove uniformityImprove bindingVacuum evaporation coatingSputtering coatingDlc coatingSputtering

The invention discloses a preparation method of a tool surface coating and the prepared coating. The preparation method comprises the following steps: 1) cleaning the surface of a tool; 2) sputtering a CrN coating on the surface of the tool, wherein a target material is CrN alloy; 3) sputtering a CrAlSiN coating on the surface of the tool sputtered with the CrN coating, wherein a target material is CrAlSiN alloy, and the sputtering environment is an argon environment; 4) preparing a DLC coating on the surface of the tool treated in the step 3) to obtain a purpose coating. The preparation method of the tool surface coating and the prepared coating, disclosed by the invention, have the benefits that by utilizing a CrN transition layer, the bonding strength between the CrAlSiN coating and a tool substrate is increased; by utilizing an amorphous layer formed between the DLC coating and the CrAlSiN coating, the bonding strength between the DLC coating and the CrAlSiN coating is increased; a gradient coating with high hardness, high wear resistance and high bonding strength is formed on the surface of the hard alloy tool, so that the falling-off problem of the DLC coating in the use process of the tool is effectively solved , the friction between the tool and a workpiece material is reduced, and the service life of the coated tool is prolonged.

Owner:SHANDONG UNIV

Multi-heat treatment process for AQ80M magnesium alloy heavy ingot billet composition homogenization

ActiveCN107022689AEliminate overheating and overburningAvoid overheatingSolution treatmentRoom temperature

The invention discloses a multi-heat treatment process for AQ80M magnesium alloy heavy ingot billet composition homogenization. An aimed alloy is prepared from the components in percentage by mass: 7.5 to 9.0 percent of Al, 0.02 to 0.80 percent of Ag, 0.35 to 0.55 percent of Zn, 0.05 to 0.30 percent of Mn, 0.01 to 0.10 percent of RE, and 0.001 to 0.020 percent of Ca. The multi-heat treatment process comprises the steps of firstly placing a large-size ingot billet in an annealing furnace, then heating to 240 to 260 DEG C, and heat-insulating for 4 to 10h; heating the annealing furnace to 410 to 420 DEG C, and heat-insulating for 32 to 48h; and finally stopping heat-insulating the annealing furnace, rising a furnace door, cooling the ingot billet to 250 to 300 DEG C along with the furnace, then pushing out of a hearth, and air cooling to the room temperature. The multi-heat treatment process for AQ80M magnesium alloy heavy ingot billet composition homogenization provided by the invention adopts a multi-homogenization process, so that the problems of excessive heat stress and heat crack occurred during the solution treatment of the large-size ingot billet are solved, a thick and big second phase is promoted to be fully dissolved in a matrix, and alloying elements are promoted to distribute uniformly.

Owner:CENT SOUTH UNIV

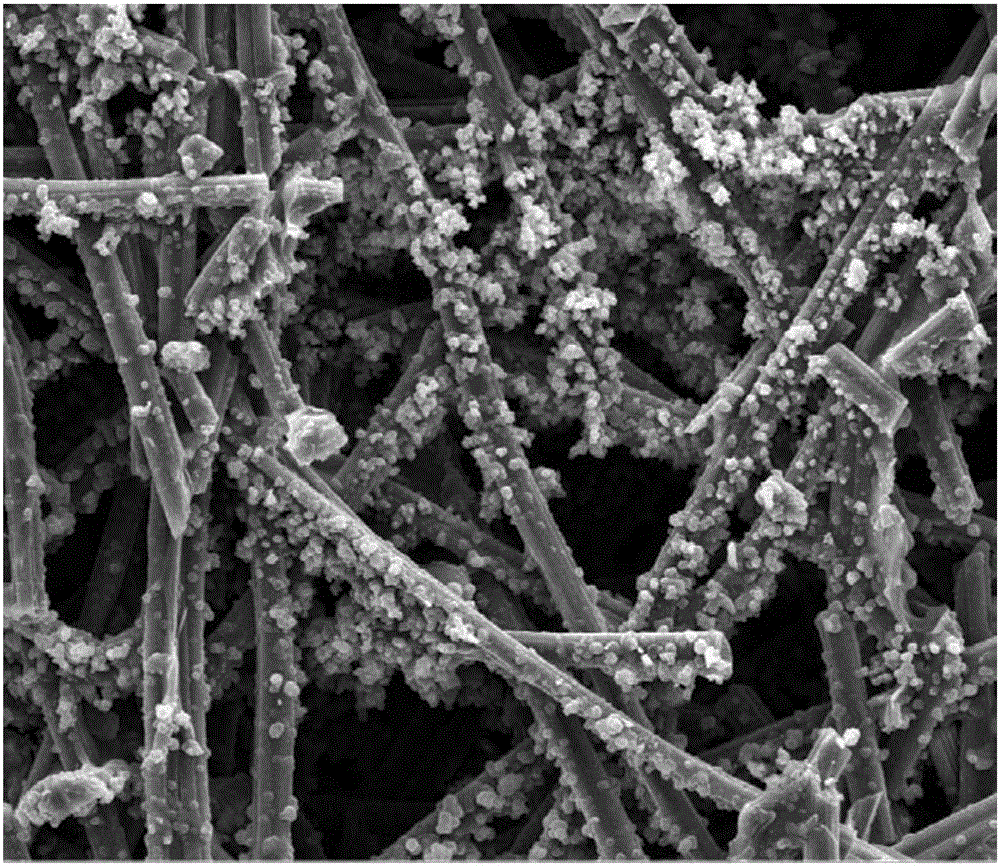

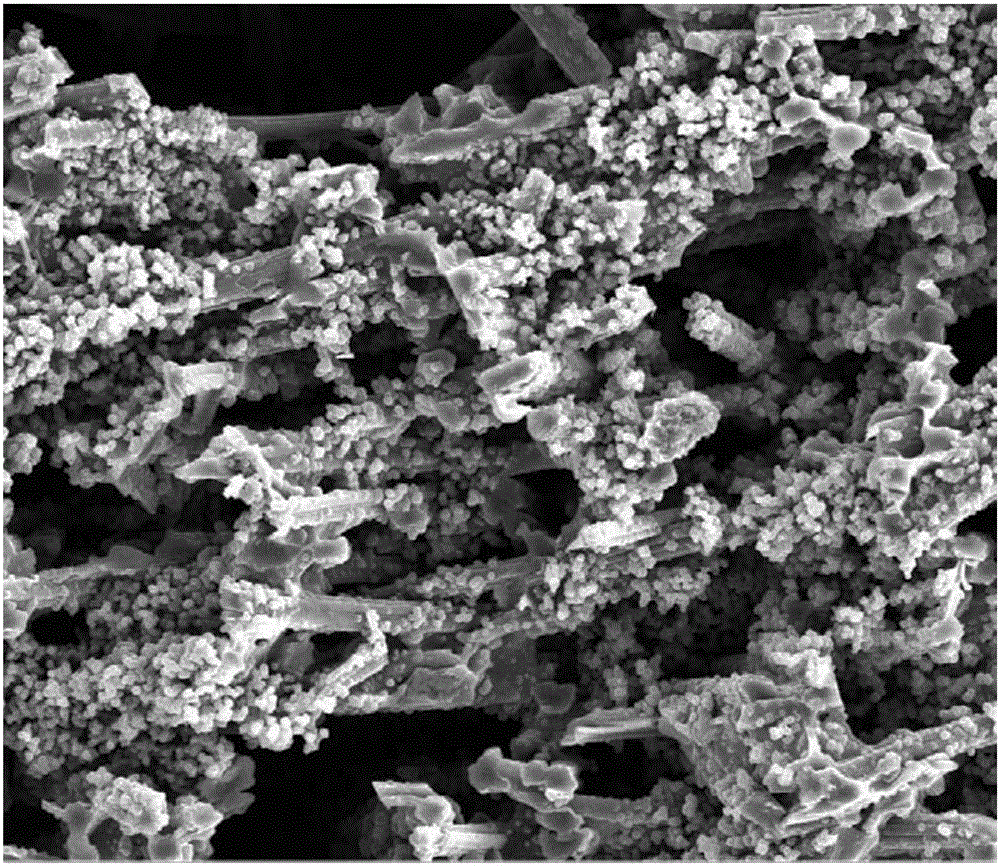

Layered distribution short-fiber reinforced porous phenolic composite material and preparation method thereof

ActiveCN105086348ALayered distribution enhancementHomogeneous tissue compositionInjection mouldingThermal conductivity

The invention provides a layered distribution short-fiber reinforced porous phenolic composite material and a preparation method thereof, and relates to a phenolic resin composite material and a preparation method thereof. The material and the method solve the problem of high heat conductivity and large density of current phenolic resin and a composite material thereof. The porous phenolic composite material consists of phenolic resin and short fibers. The preparation method comprises the steps of (1) preparing a phenolic resin solution; (2) adding the short fibers to obtain a sizing agent; (3) injection moulding and pressing; (4) solidifying. The layered distribution short-fiber reinforced porous phenolic composite material provided by the invention has the characteristics of low density and low heat conductivity.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com