Preparation method of copper-chromium composite coating

A composite coating and copper-chromium technology, which is applied in the field of preparation of copper-chromium composite coatings, can solve the problems of thin copper-chromium alloy coating, and achieve the effects of small spray loss, tight bonding and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

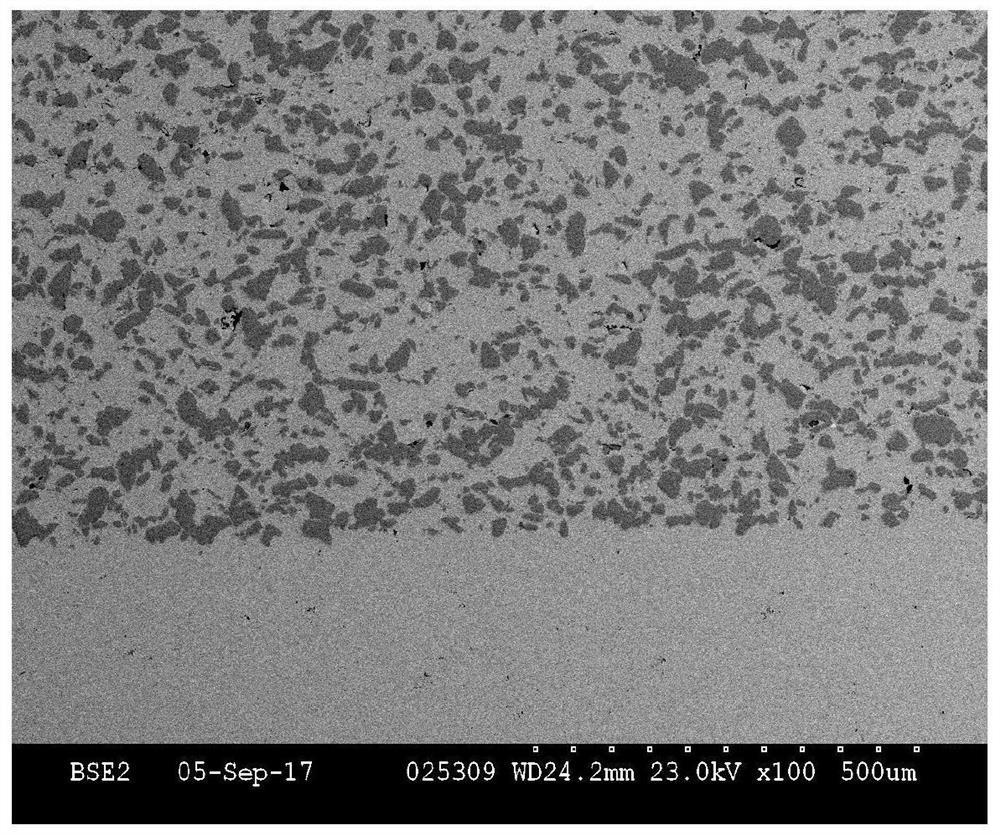

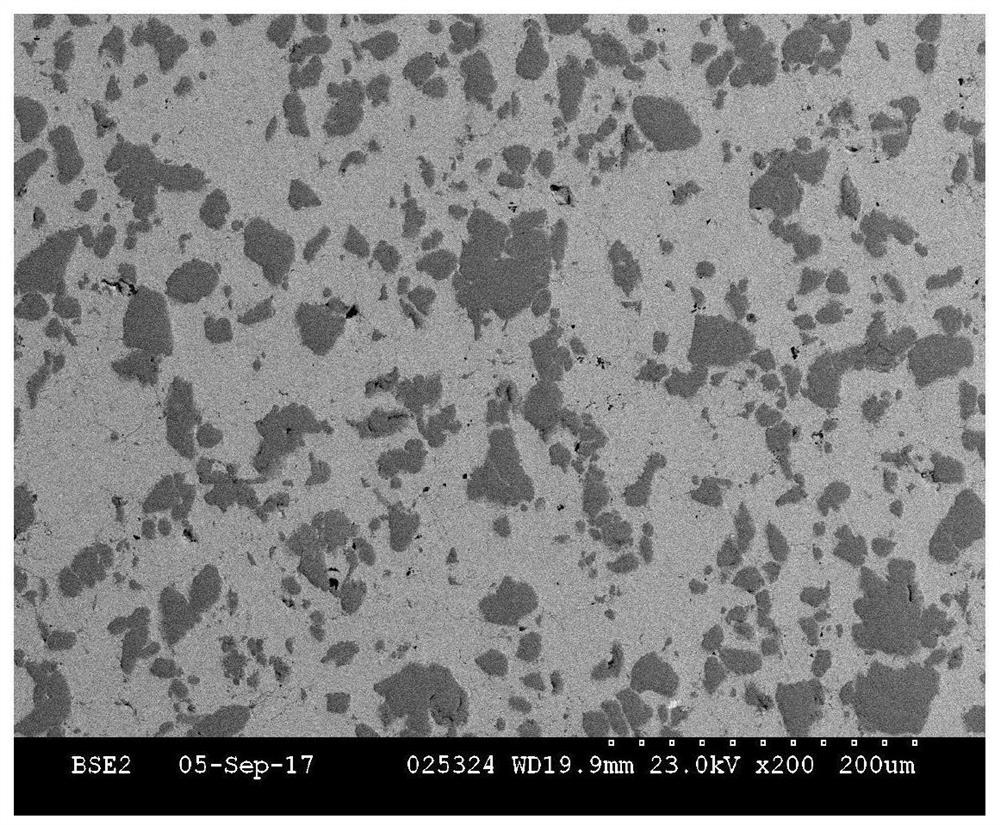

[0019] A preparation method of copper-chromium composite coating, such as figure 1 shown, including the following steps:

[0020] Step 1. The copper powder with a purity of 99.8% and a particle size of 40-50 μm and the chromium powder with a particle size of 30-45 μm are mixed according to a mass ratio of 1:0.8-1 for 1-1.5 hours by high-energy ball milling, and then dried in a vacuum Dry in the oven at a temperature of 80-90°C for 20-30 minutes to obtain raw materials for cold spraying;

[0021] Step 2. Use multi-purpose 110 copper (electrolytic hard pitch (ETP) copper) with a purity of 99.9% as the base material, and polish the copper substrate in advance; use cold spray equipment to spray the cold spray raw materials on the copper substrate, cold spray The process parameters of the equipment are: the distance of cold spraying is 8-12mm, the rate of powder feeding is 0.9-1.2rpm, the pressure of cold spraying is 2.1-2.3MPa, the spraying temperature is 400-500°C, and the gas i...

Embodiment 1

[0027] Step 1. Mix copper powder with a purity of 99.8%, a particle size of 40 μm, and a chromium powder with a particle size of 30 μm at a mass ratio of 1:0.8 for 1 hour by high-energy ball milling, and then dry in a vacuum oven at 80°C for 20 minutes , to obtain the raw material for cold spraying;

[0028] Step 2, using multi-purpose 110 copper (electrolytic hard pitch (ETP) copper) with a purity of 99.9% as the substrate, the size of the copper substrate is 57.2mm*50.9mm*3.2mm, and the copper substrate is polished in advance; The spraying equipment sprays the cold spraying raw materials on the copper substrate. The process parameters of the cold spraying equipment are: the cold spraying distance is 8mm, the powder feeding rate is 0.9rpm, the cold spraying pressure is 2.1MPa, the spraying temperature is 400°C, and the gas is N 2 ; Obtain a Cu-Cr composite coating with a thickness of about 3.0mm on the copper substrate;

[0029] Step 3, annealing the Cu-Cr composite coating ...

Embodiment 2

[0031] Step 1. Mix copper powder with a purity of 99.8% and a particle size of 45 μm and chromium powder with a particle size of 40 μm for 1.2 hours by high-energy ball milling at a mass ratio of 1:0.9, and then dry it in a vacuum oven at a temperature of 85°C 25min, get cold spraying raw material;

[0032] Step 2, using multi-purpose 110 copper (electrolytic hard pitch (ETP) copper) with a purity of 99.9% as the substrate, the size of the copper substrate is 57.2mm*50.9mm*3.2mm, and the copper substrate is polished in advance; The spraying equipment sprays the cold spraying raw materials on the copper substrate. The process parameters of the cold spraying equipment are: the cold spraying distance is 10mm, the powder feeding rate is 1rpm, the cold spraying pressure is 2.2MPa, the spraying temperature is 450°C, and the gas is N 2 ; Obtain a Cu-Cr composite coating with a thickness of about 3.0mm on the copper substrate;

[0033] Step 3, annealing the Cu-Cr composite coating at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com