Patents

Literature

66results about How to "Improve density distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

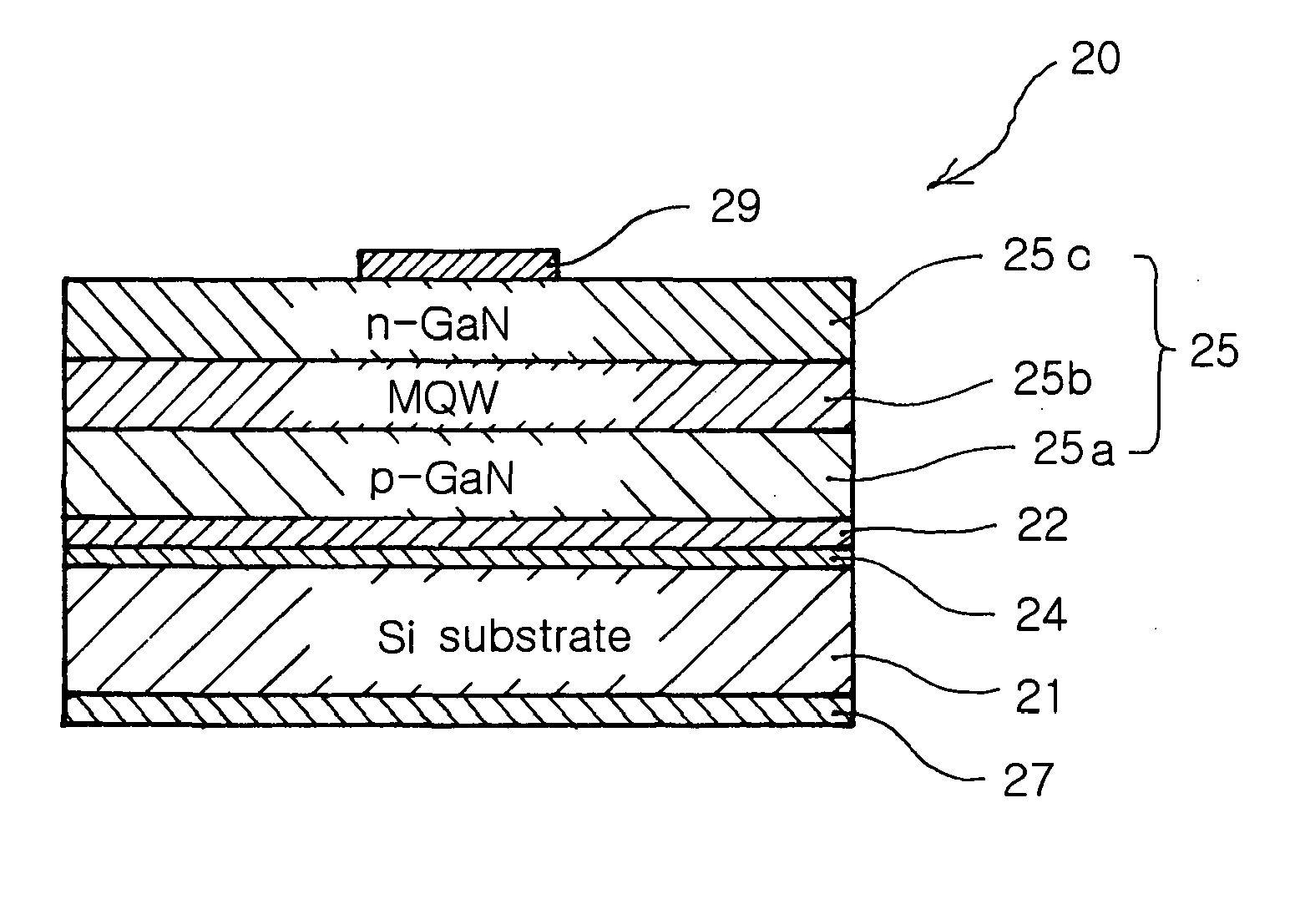

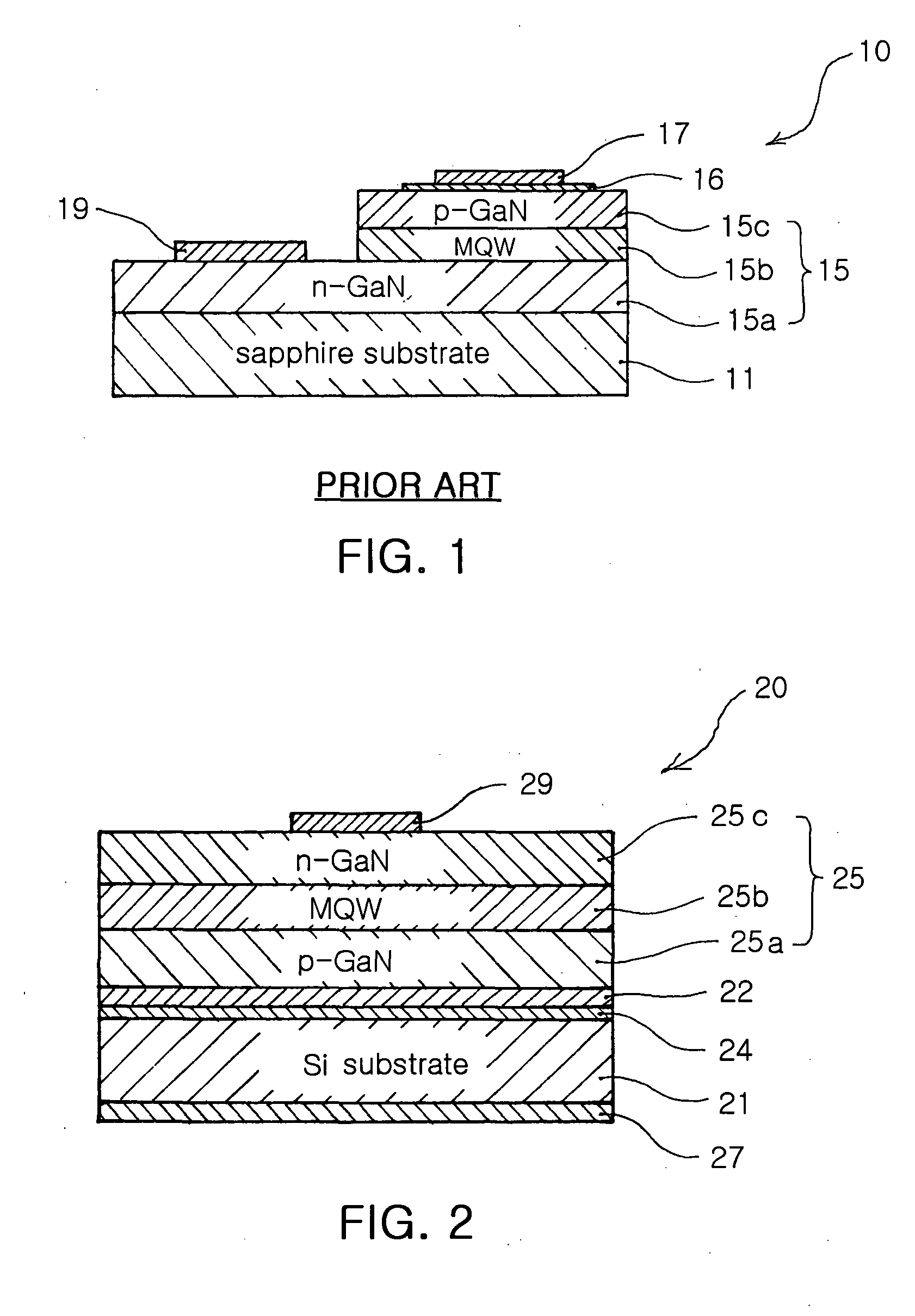

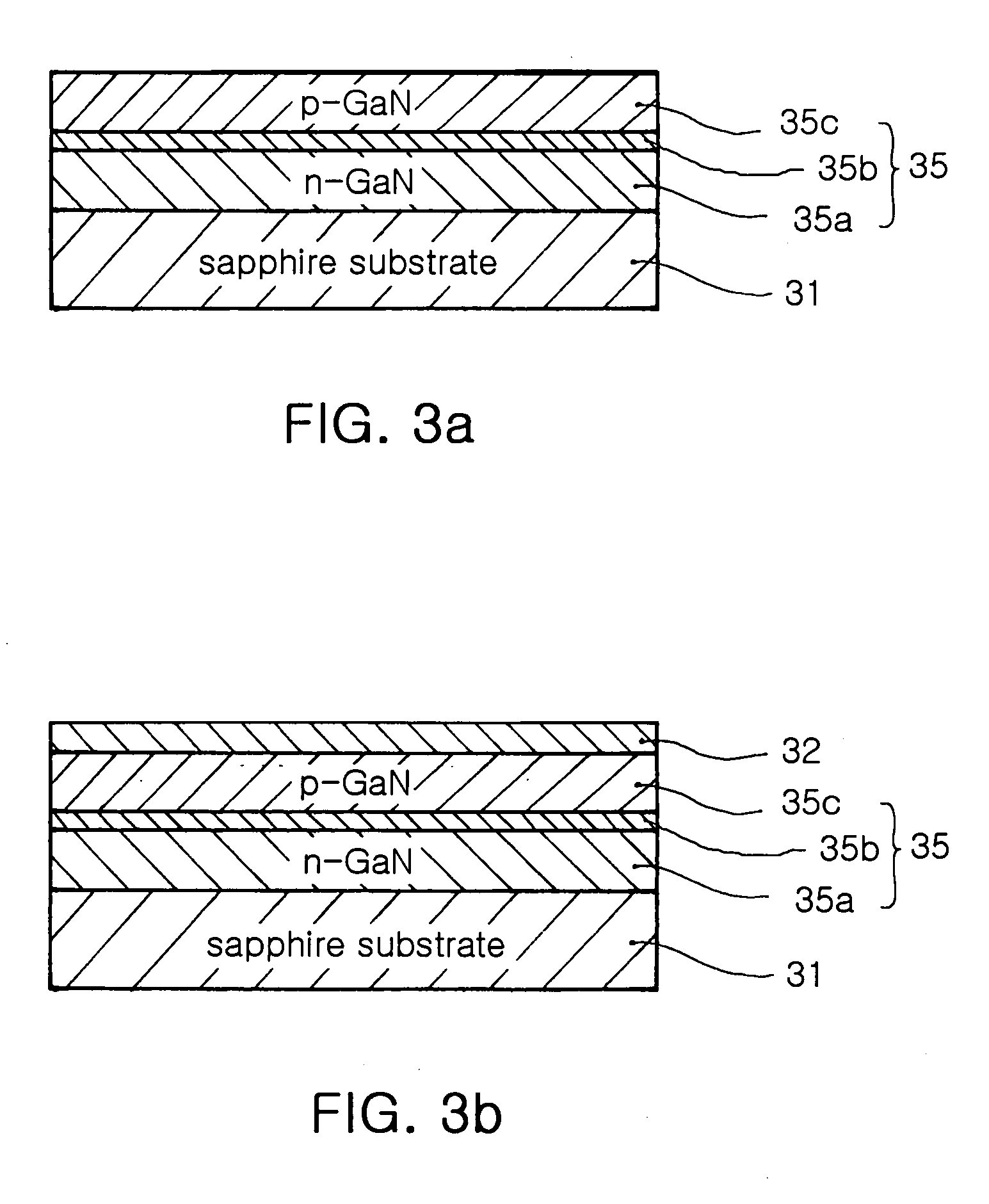

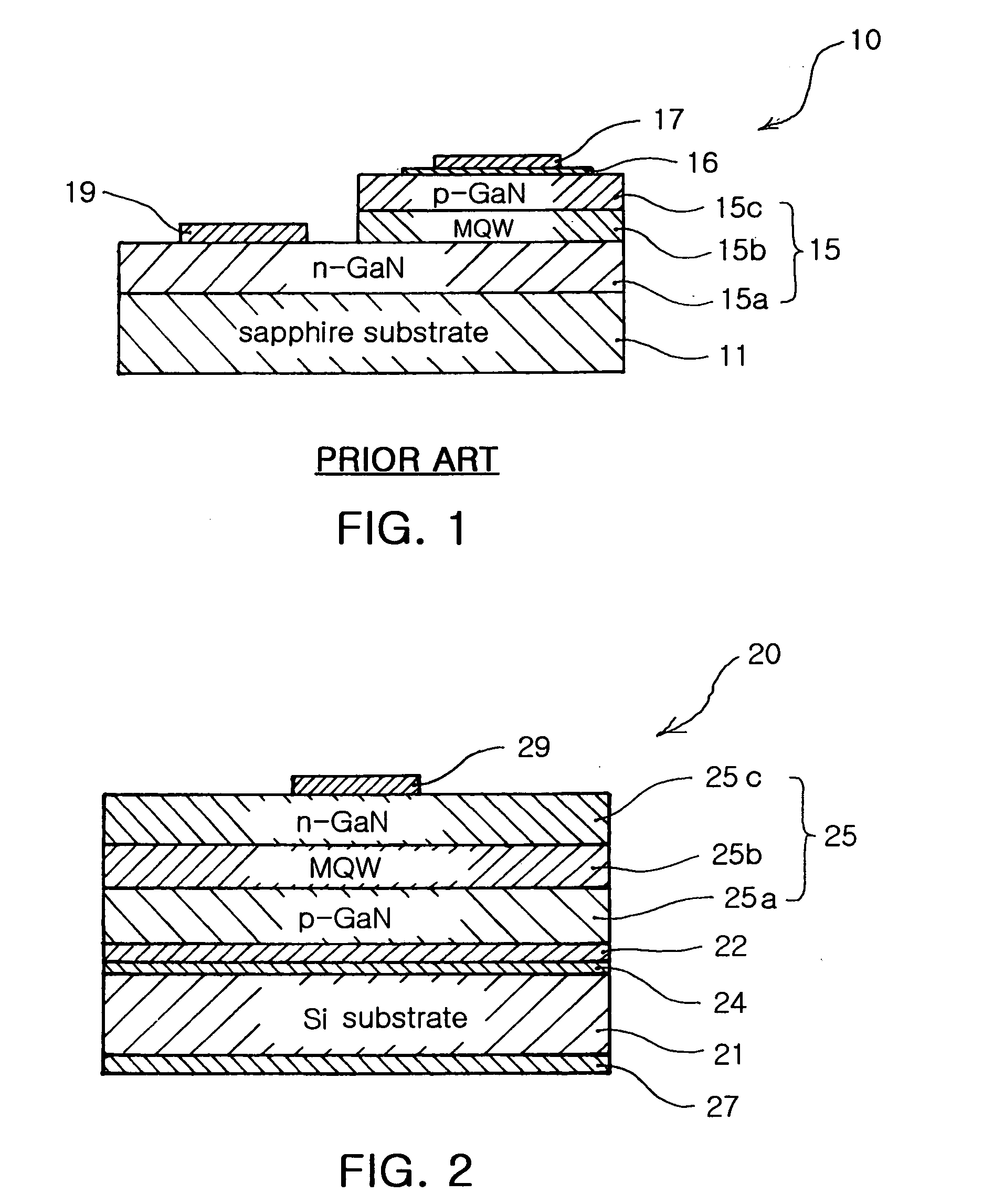

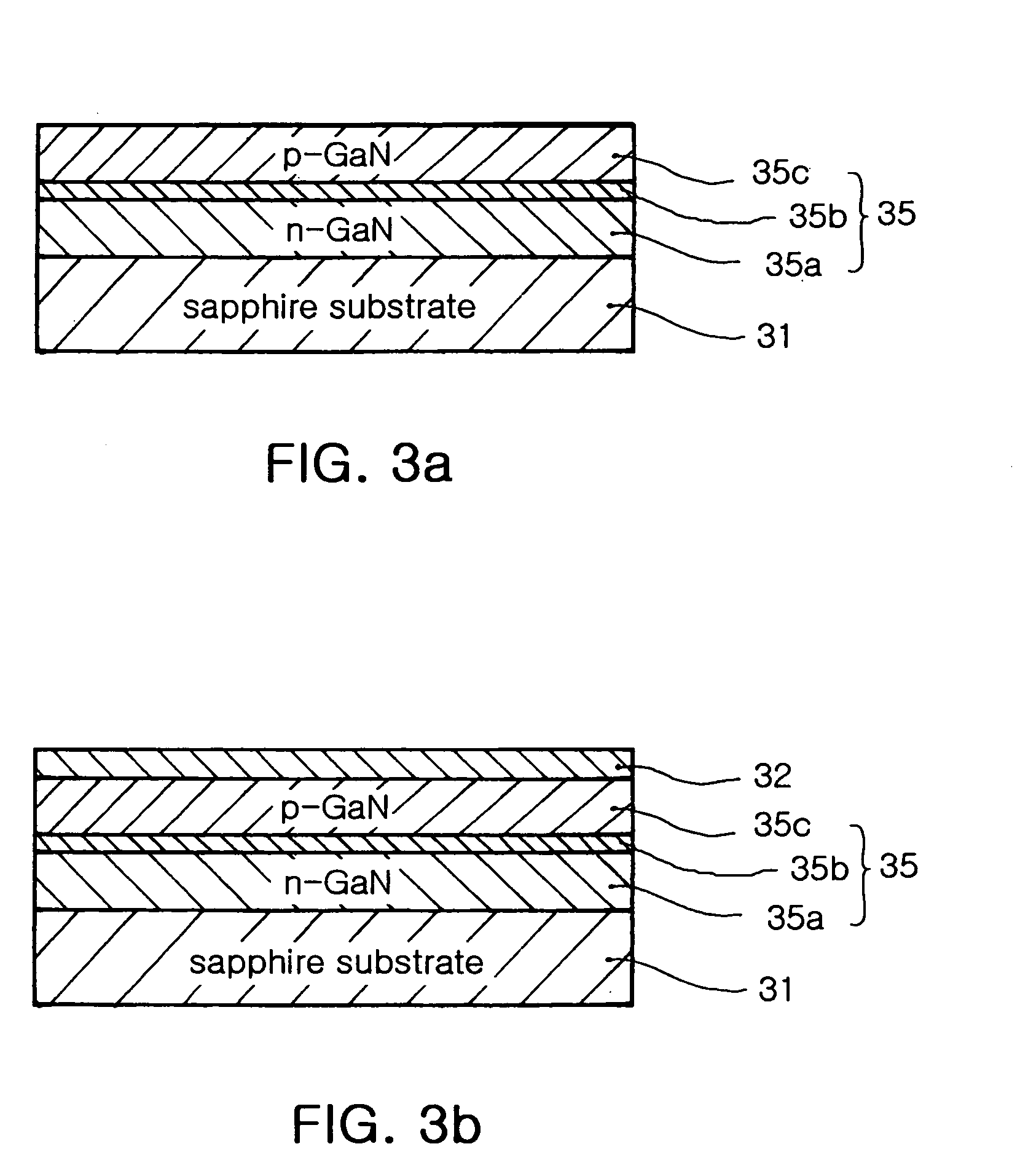

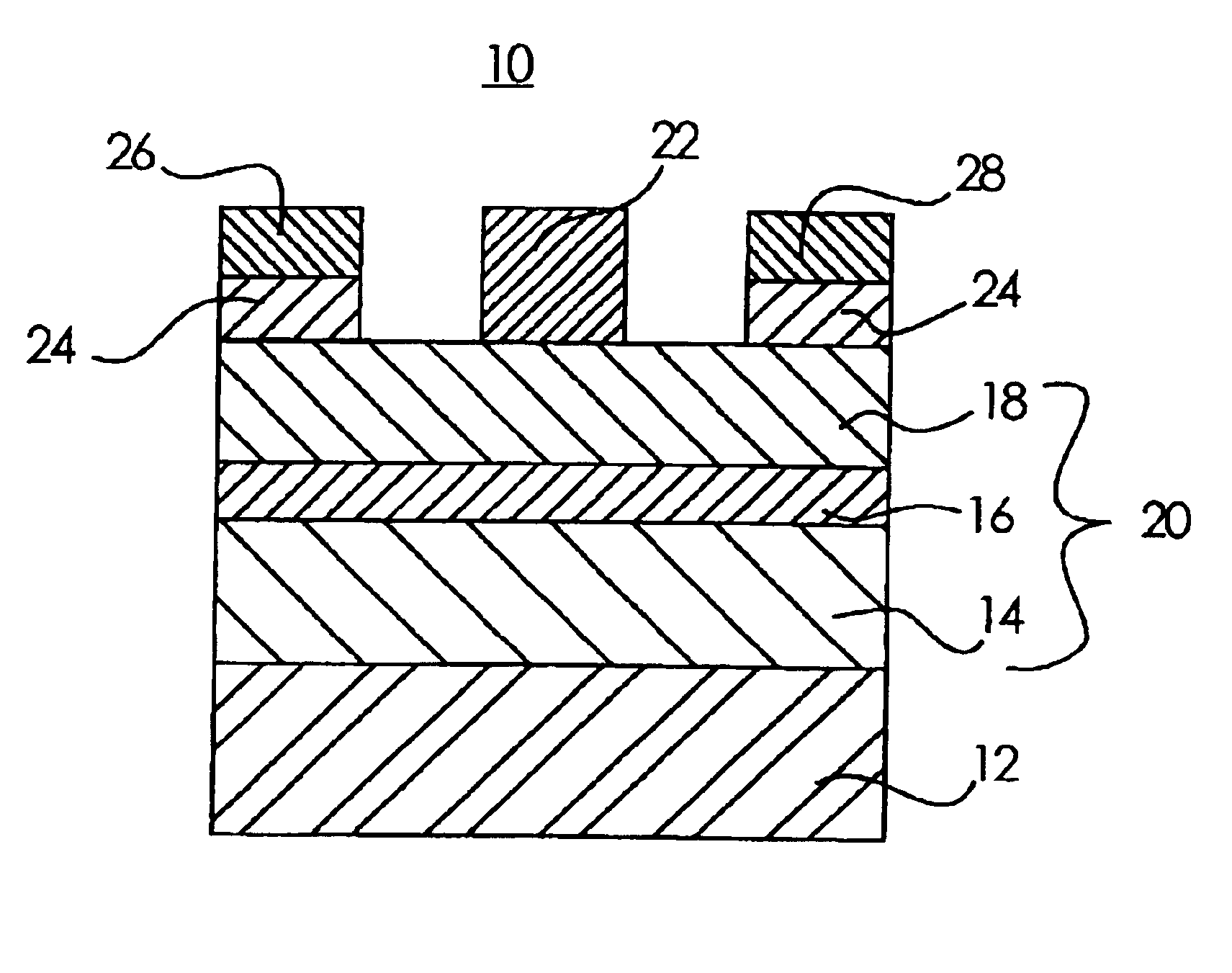

Vertical GaN light emitting diode and method for manufacturing the same

InactiveUS20050173692A1Improved current density distributionIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalActive layer

Disclosed are a vertical GaN light emitting diode and a method for manufacturing the same. The vertical GaN light emitting diode comprises a first conductive GaN clad layer with an upper surface provided with a first contact formed thereon, an active layer formed on a lower surface of the first conductive GaN clad layer, a second conductive GaN clad layer formed on a lower surface of the active layer, a conductive adhesive layer formed on the second conductive GaN clad layer, and a conductive substrate, with a lower surface provided with a second contact formed thereon, formed on a lower surface of the conductive adhesive layer. The method for manufacturing the vertical GaN light emitting diodes comprises the step of removing the sapphire substrate from the light emitting structure so as to prevent the damages on a GaN single crystal plane of the structure.

Owner:SAMSUNG ELECTRONICS CO LTD

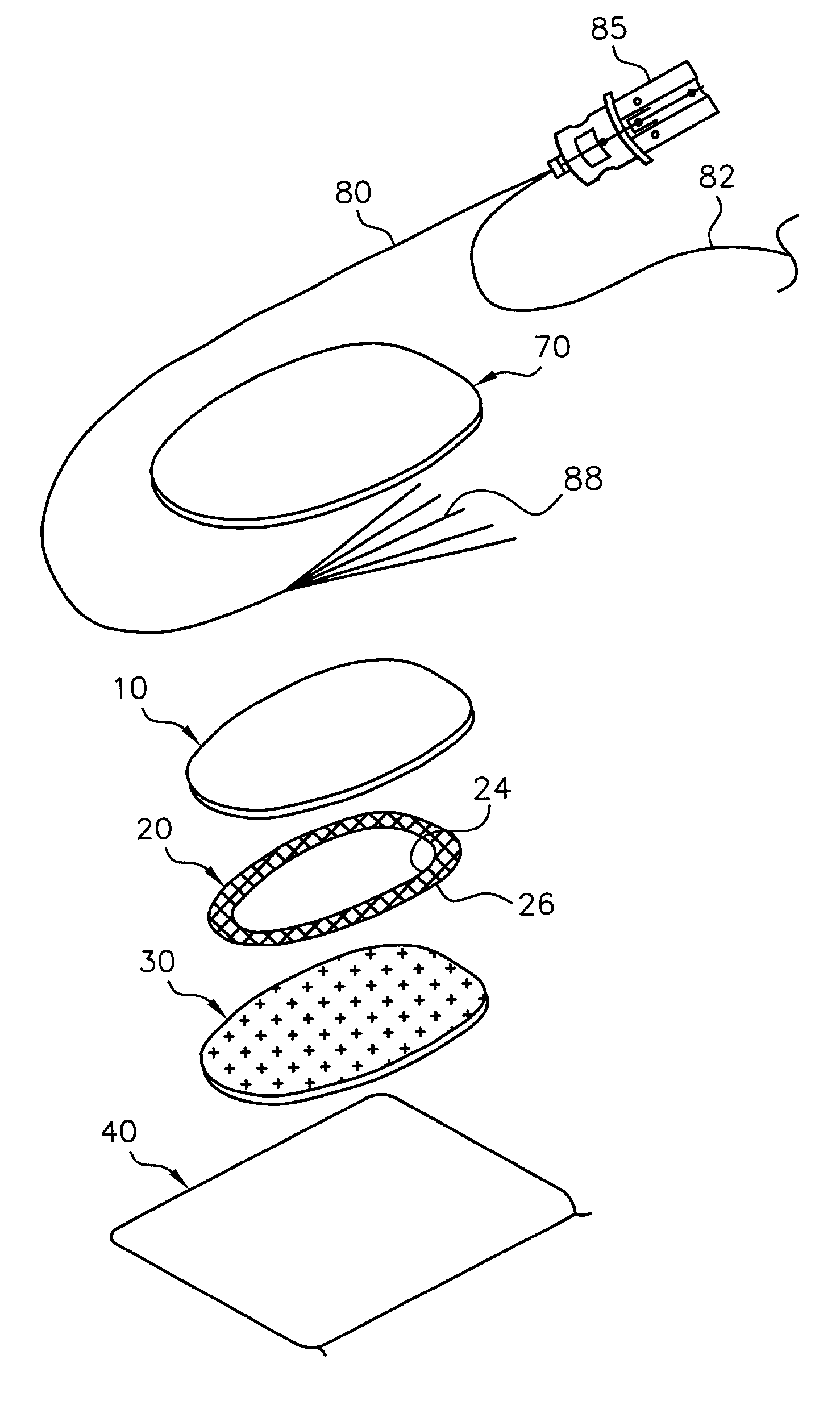

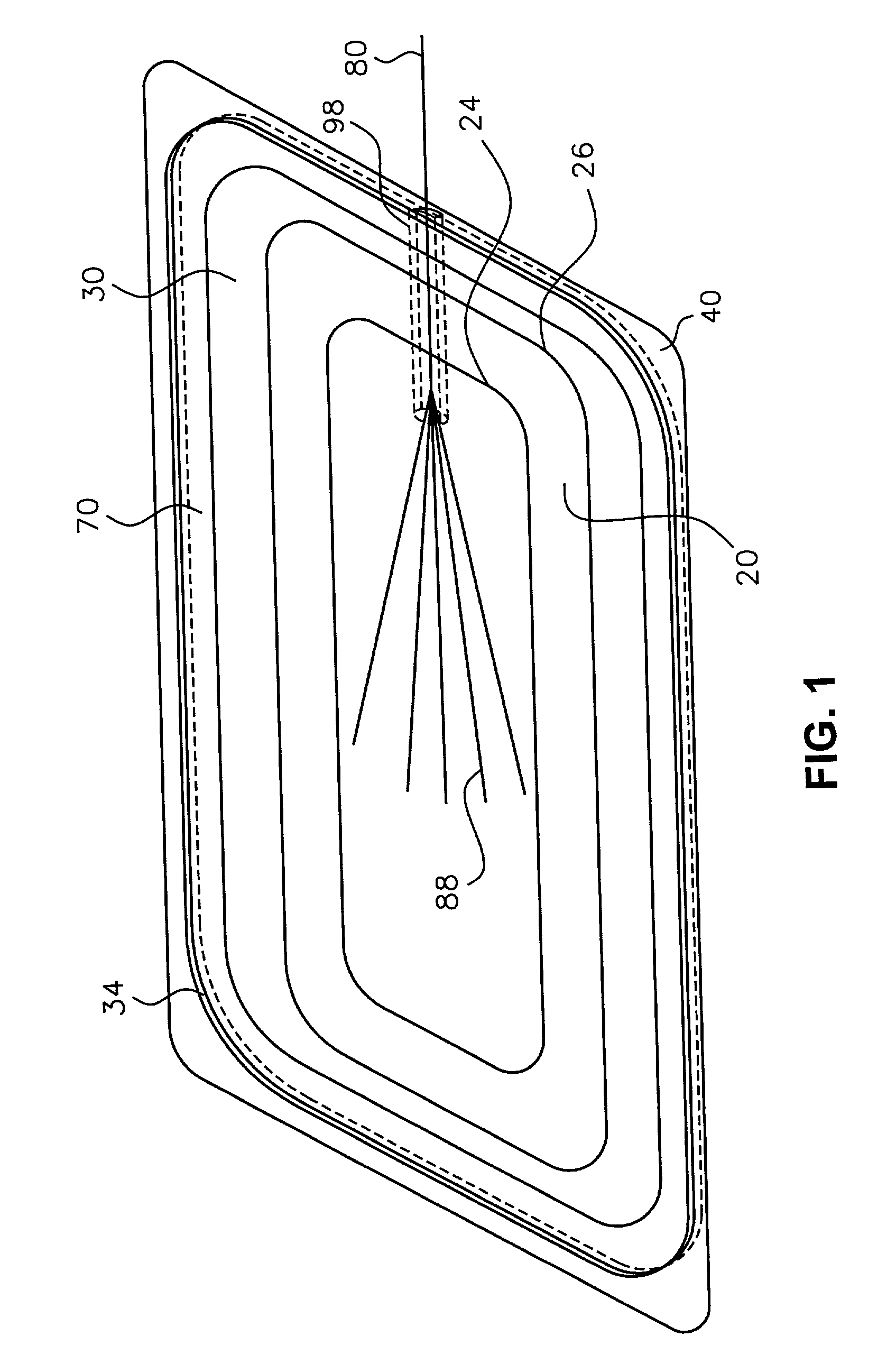

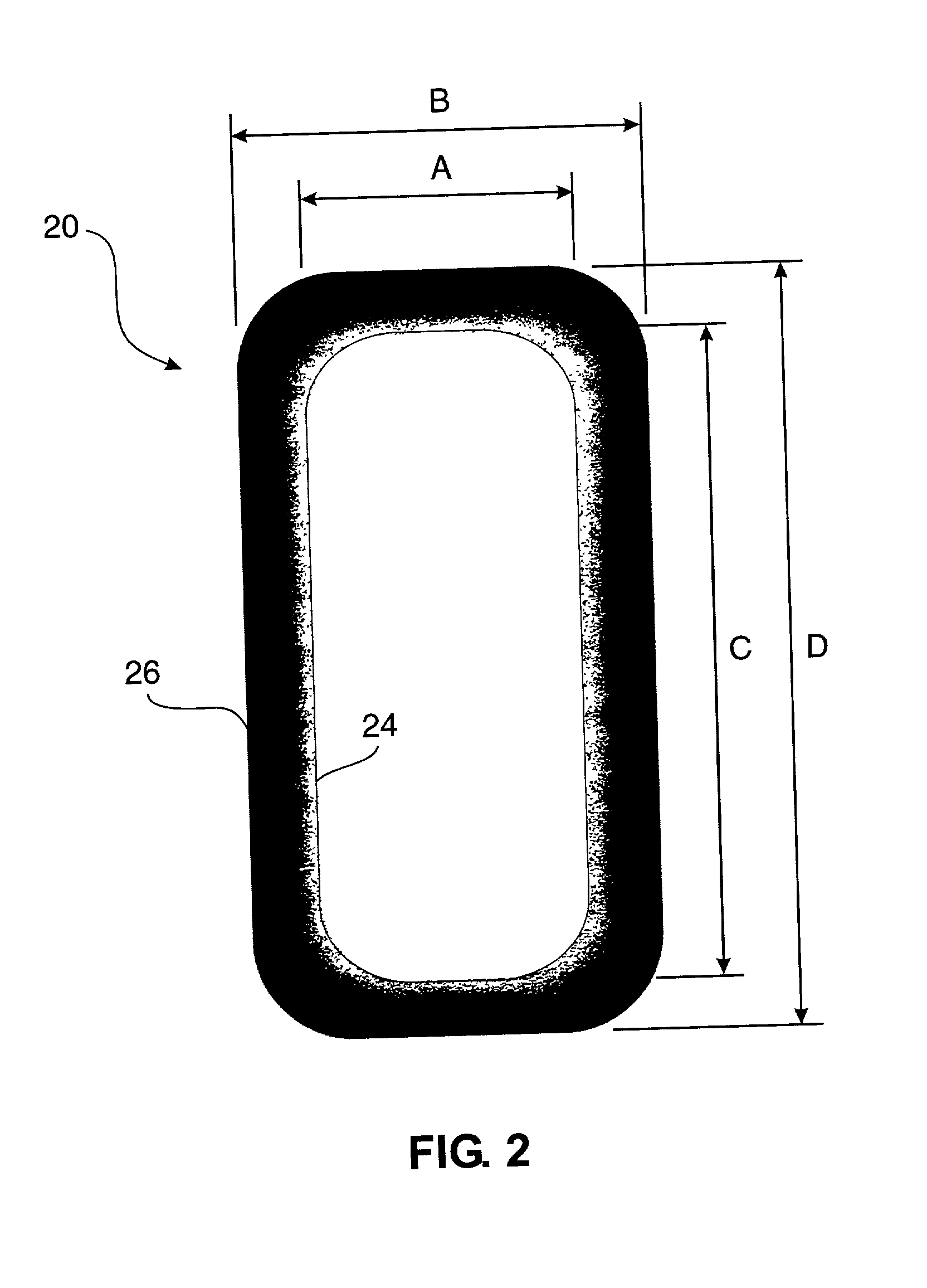

High-energy disposable medical stimulation electrode

InactiveUS20030004558A1Conducting energy sufficientImprove density distributionExternal electrodesBiomedical engineeringContact electrode

A disposable medical electrode for delivering high-energy defibrillation or pacing stimulation and having energy dispersion characteristics. A fanned wire contacts the top of an electrode member for delivering energy to and transmitting energy from the electrode. A hydrogel is disposed on the bottom of the electrode member and an electrically conductive metal / metal chloride ink coating underlies the hydrogel. The ink coating has (a) a center with a first amount of ink, (b) an inner edge defining the terminus of the center and a step at which the ink content of the ink coating drops from the first amount of ink to a lesser second amount of ink, (c) an outer edge defining the terminus of the ink, and (d) a predetermined gradient disposed between the inner edge at which the ink coating has the second amount of ink and the outer edge at which the ink is substantially absent.

Owner:KPR U S LLC

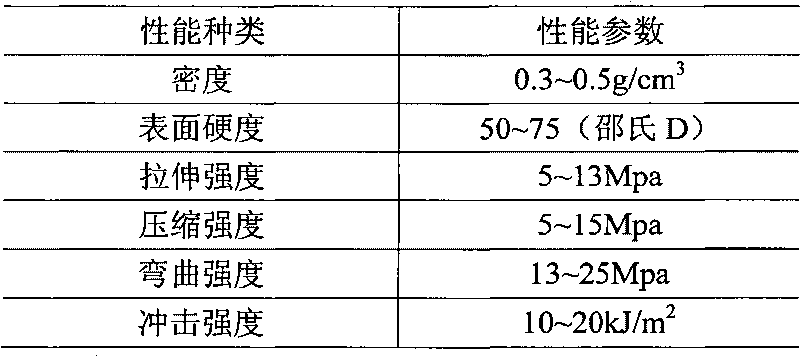

Wood powder reinforced polyurethane wood-imitation material for furniture and production method thereof

The invention discloses a wood powder reinforced polyurethane wood-imitation material for furniture and a production method thereof. The mixture of polyether glycol, foaming agent, catalyst, stabilizing agent and fire retardant serves as a white material, polyisocyanate serves as black material, and wood powder filler with 80-100 meshes serves as the stabilizing agent, wherein, the mass ratio of white material to black material to wood powder is 112:112:7. The production method is as follows: respectively mixing the white material according to ratio to prepare composite polyether; adding wood powder to prepare wood powder / composite polyether mixture; then, adding the black material to prepare foaming mixture; and after injection molding and curing for 20 minutes, demolding to prepare the wood powder reinforced polyurethane wood-imitation material. The invention has the advantages that the compression strength and the shock resistance of the produced wood-imitation material and products are strengthened, wood texture effect is obvious, and density distribution is improved; the produced wood-imitation material and the product have stable size, small deformation and favorable heat insulation and sound insulation performance and are hard and ageing-resistant; flame retardant property can reach construction B2 grade, the product is environmentally-friendly and has low cost as well as favorable handling characteristics, such as sawing, digging, drilling, nailing, rubbing, sticking, coloring, coating and the like.

Owner:德华兔宝宝装饰新材料股份有限公司

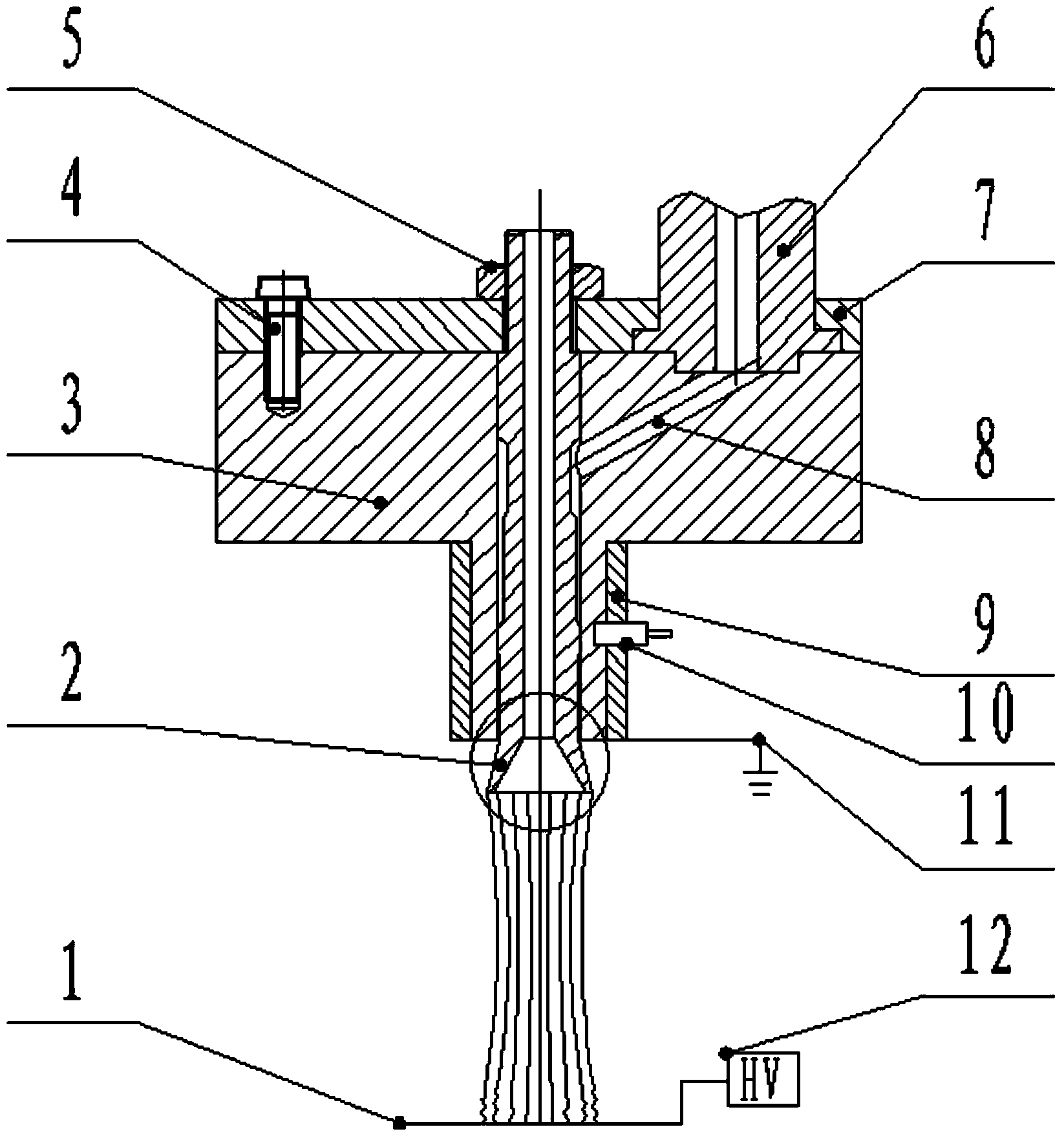

Outer conical surface type electrostatic spinning sprayer assisted by airflow

ActiveCN103668486ASmall diameterAvoid disturbing influenceFilament/thread formingHigh pressureGuide tube

The invention discloses an outer conical surface type electrostatic spinning sprayer assisted by airflow, and belongs to thee field of electrostatic spinning. The device comprises a fiber receiving plate, an outer conical surface airflow guide tube, a machine head, a screw, a positioning nut, a material barrel, a material barrel fixing block, a heating ring, a temperature sensor, a grounding electrode, a high-voltage electrostatic generator and the like, flux is evenly distributed to the conical surface sprayer through a flow channel on the outer wall of the airflow guide tube, a flux film naturally thins in the forming process under the action of gravity and adhesive power, the flux forms a Taylor cone at the tip end of the outer conical surface under the action of high-voltage static, and therefore jet flow spinning is formed. Due to the fact that the flux film thins, the diameters of fibers can be effectively reduced, the fibers are further stretched under the action of high-speed airflow, fiber bundles are made to converge inwards due to internal and external pressure difference formed by the high-speed airflow, the density distribution of the fibers is effectively improved, the device can also be used for eliminating interference of the high-speed airflow on the flux film, and the diameters of the fibers can be more uniform.

Owner:BEIJING UNIV OF CHEM TECH

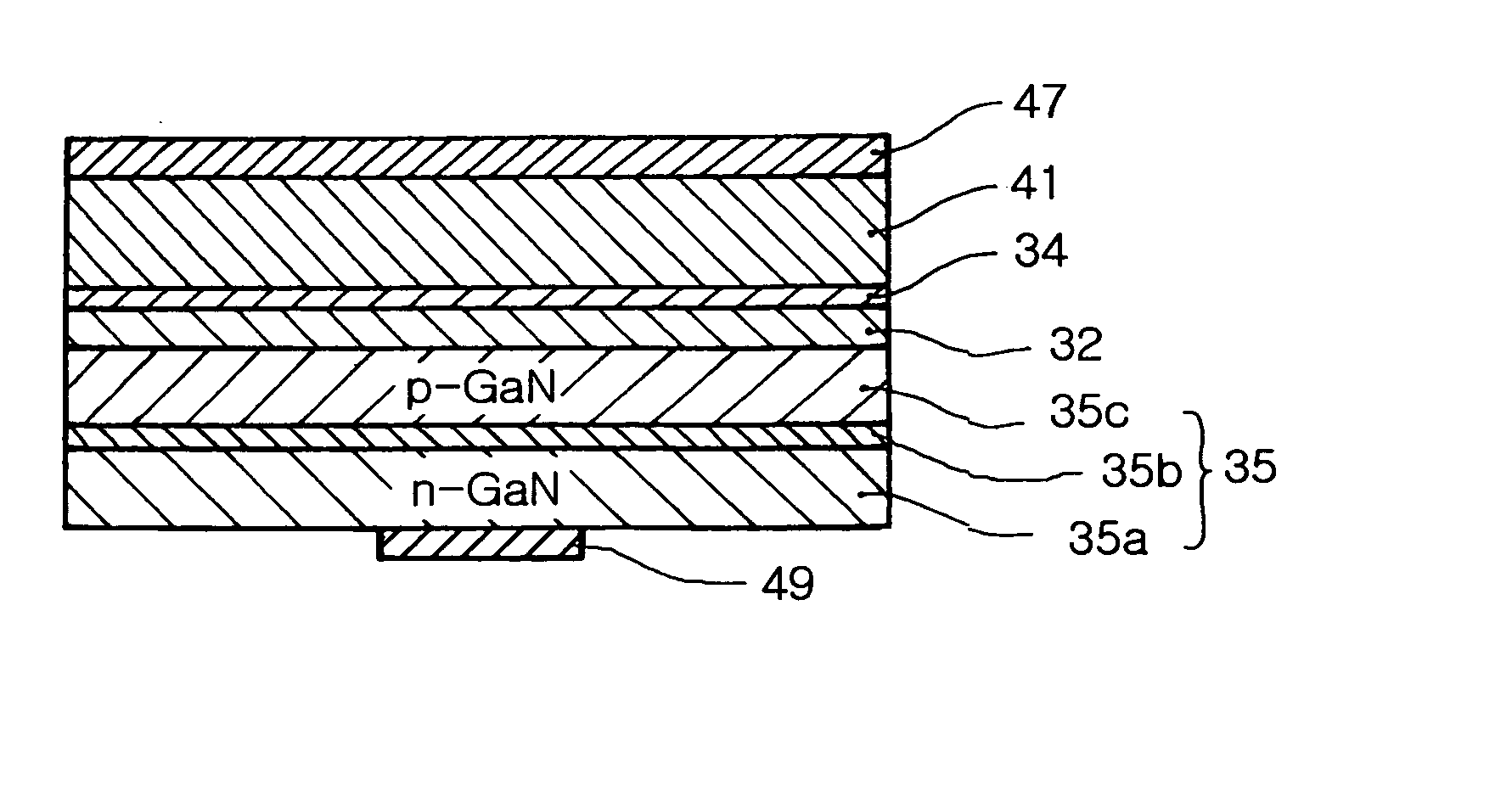

Vertical GaN light emitting diode and method for manufacturing the same

InactiveUS20050214965A1Increase brightnessImprove density distributionSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalActive layer

Owner:SAMSUNG ELECTRONICS CO LTD

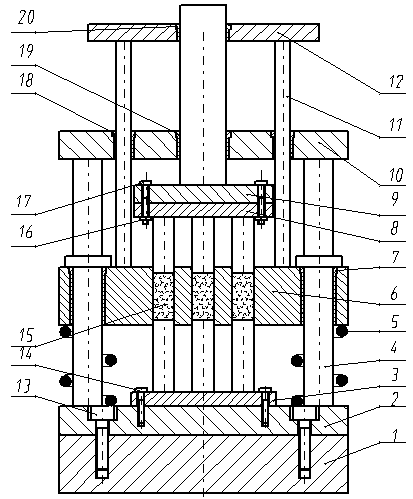

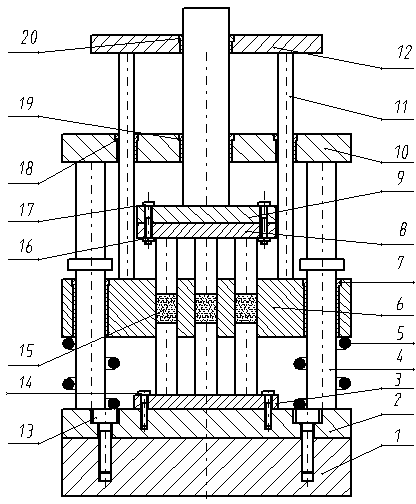

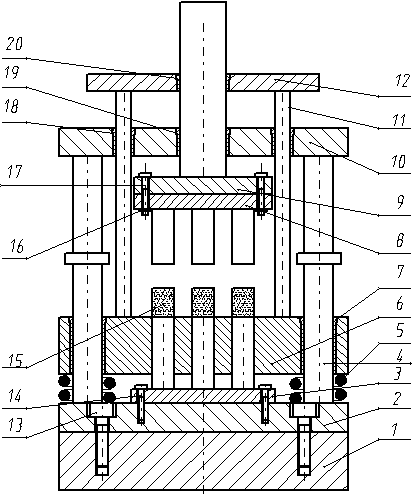

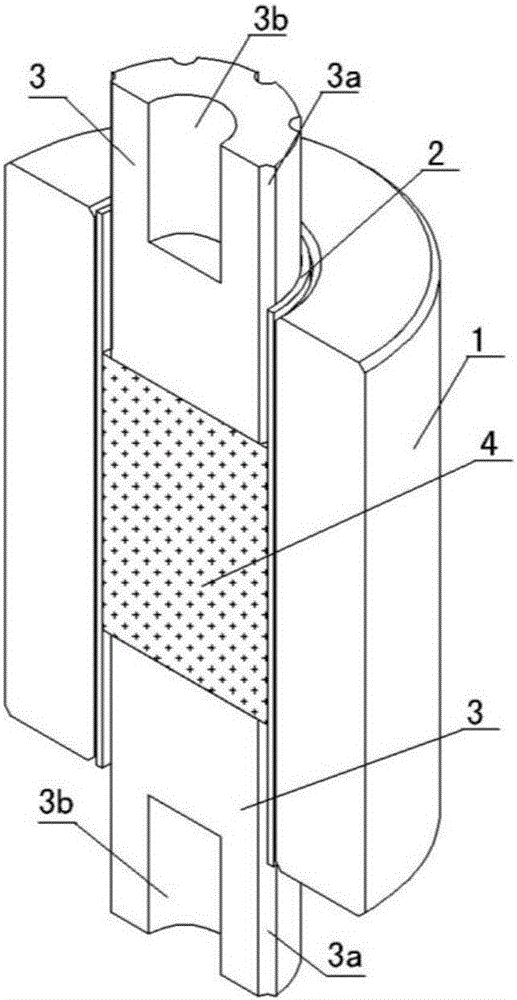

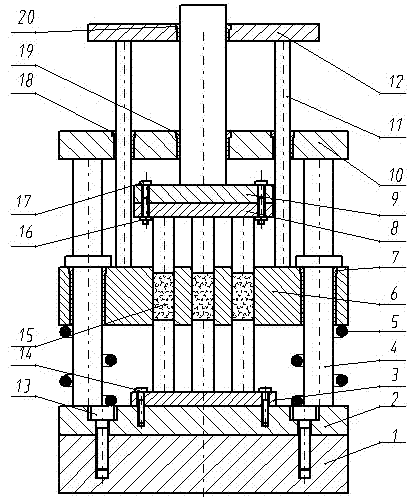

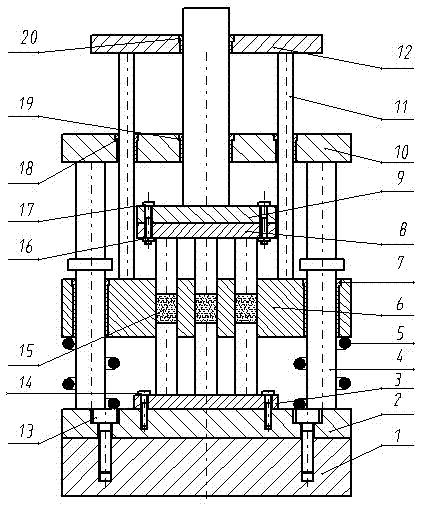

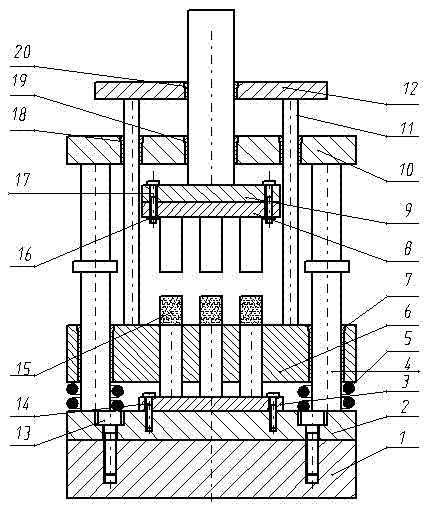

Bi-directional powder pressing forming device capable of demoulding automatically

InactiveCN103273678AImprove density distributionIncrease production speedShaping pressHydraulic cylinderDensity distribution

The invention discloses a bi-directional powder pressing forming device capable of demoulding automatically. An upper mould frame is connected with a lower mould frame through guide columns; and the lower mould frame is fixed on the base board. An upper mould stamping is connected with an upper mould connecting rod which is connected with a first hydraulic cylinder. A lower mould stamping is fixed on the lower mould frame. Female moulds are mounted on the corresponding guide columns through four holes on two sides. Springs are sleeved on the corresponding guide columns of the lower faces of the females moulds and the upper face of the lower mould frame. The female moulds can float on the springs, and each is provided with a heating bar and a thermoelectric couple internally. One ends of four ejection rods are fixed on an ejection rod fixing plate, and the other ends of the ejection rods penetrate the upper mould frame and is located above the female mould. The ejection rod fixing plate is connected with a second hydraulic cylinder. By the aid of the spring floating female mould and the ejection rod structure, bi-directional pressing and automatic demoulding are achieved accurately, density distribution of a workpiece is improved, and production speed is increased. With a multi-punch and multiple-moulding-chamber structure, multiple workpieces can be produced by pressing at one time, mass production can be realized, and device utilization rate and working efficiency are increased.

Owner:ZHEJIANG UNIV

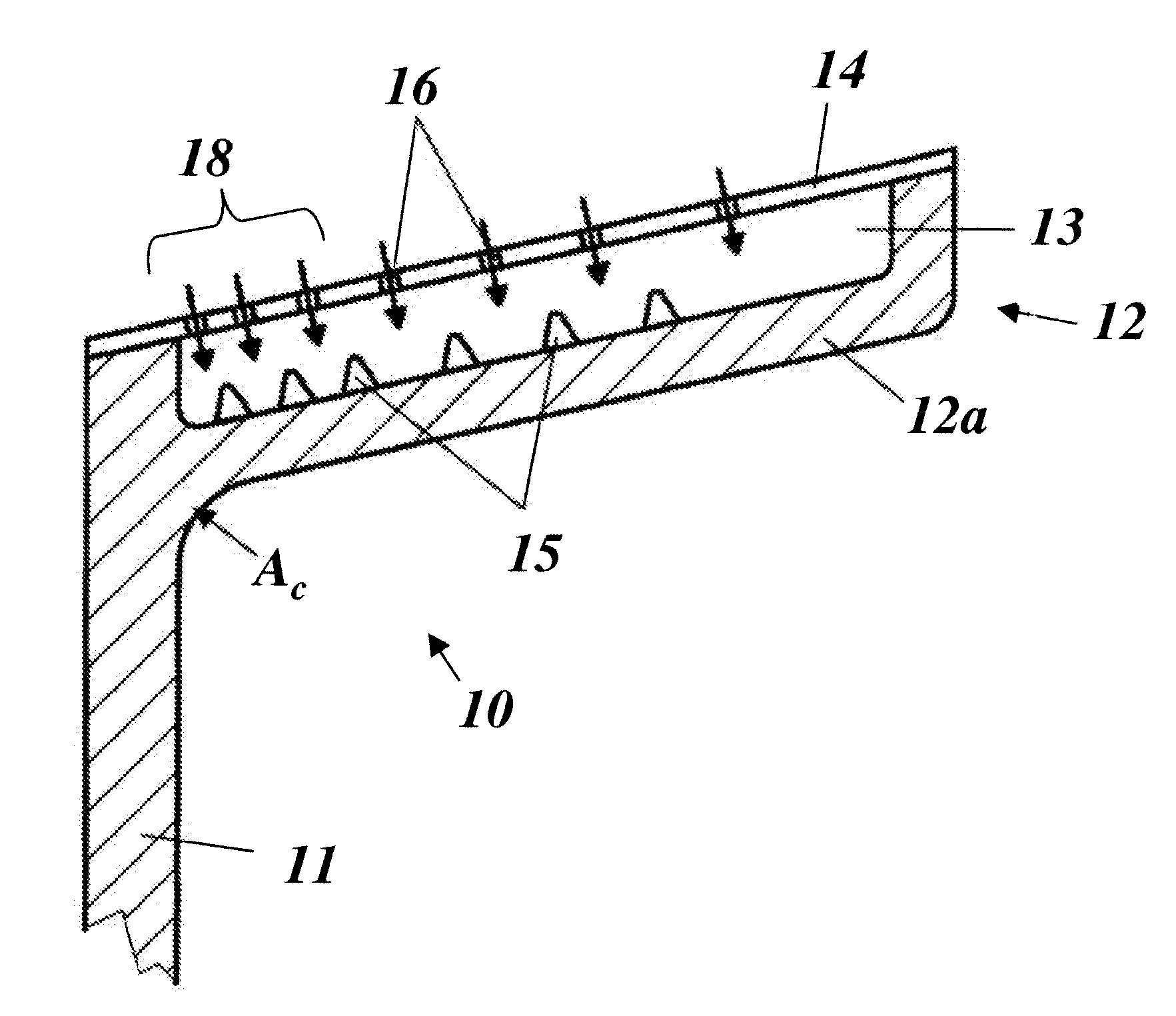

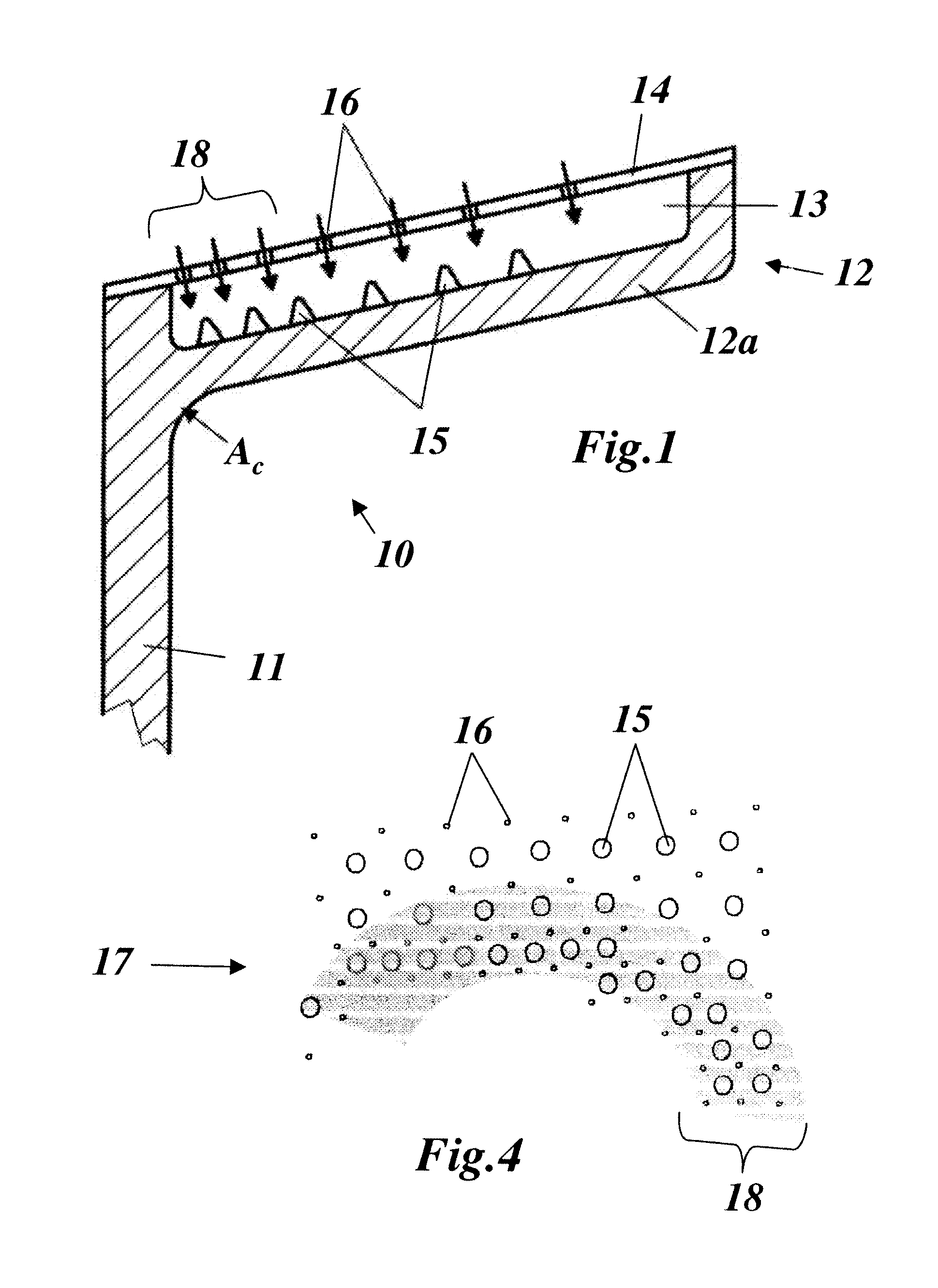

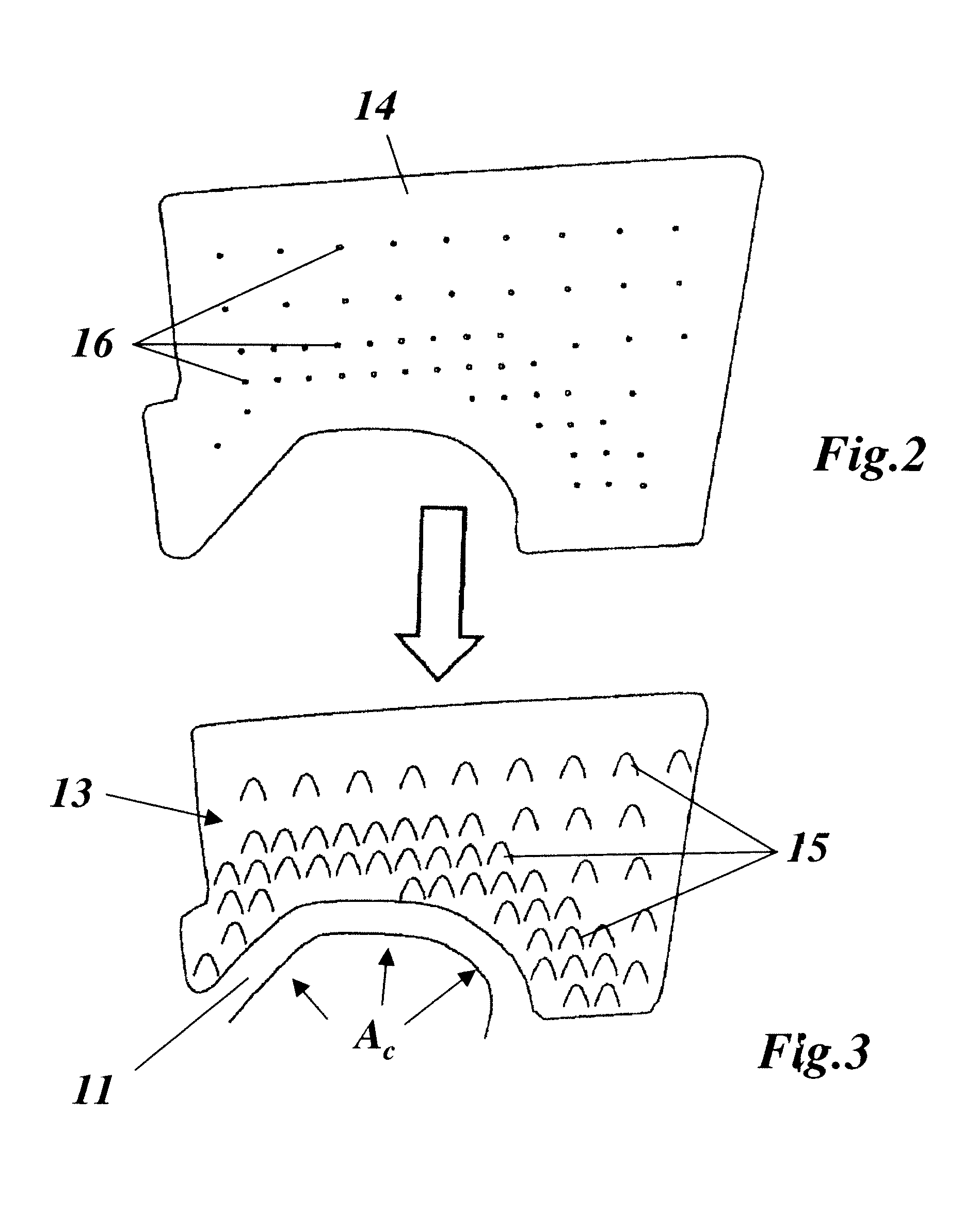

Cooled constructional element for a gas turbine

InactiveUS20120020768A1Improve density distributionPump componentsEngine fuctionsHigh densityDensity distribution

A cooled constructional element for a gas turbine includes a wall having a front and a rear side. The front side is configured to be thermally loaded during operation of the turbine, and the rear side has a plurality of pins projecting therefrom in a two-dimensional distribution, the two-dimensional distribution including a higher density distribution of pins in a critical zone of the cooled constructional element than in the remaining regions of the cooled constructional element. A device is configured to create jets of a cooling medium that are directed onto the rear side of the wall in a region of the plurality of pins so as to cool the rear side of the wall by impingement.

Owner:ANSALDO ENERGIA IP UK LTD

Manufacturing method for large-size high-density high-uniformity CuCr alloy

The invention discloses a manufacturing method for a large-size high-density high-uniformity CuCr alloy. The manufacturing method is characterized in that CuCr mixed powder is solidified and formed through discharge plasma sintering, by optimizing a sintering die structure, the temperature is increased to 800 DEG C to 880 DEG C through a step heating manner at 10 DEG C / min to 50 DEG C / min and then kept for 2 minutes to 8 minutes while axial mechanical pressure is applied, and a sintered cylinder ingot with the diameter not smaller than 50 mm, the long diameter ratio of 0.04-1.0, the density larger than 99.0%, axial and radial fluctuation less than 1% and an uniform component structure can be obtained. According to the manufacturing method, different sintering conditions can be selected according to the size demand of the CuCr alloy, the process is simple, the period is short, the production efficiency is high, and the obtained CuCr alloy can be made into a finished product through a small amount of subsequent machining and then used as a part of a vacuum circuit breaker in large-power transmission and transformation equipment.

Owner:HEFEI UNIV OF TECH +1

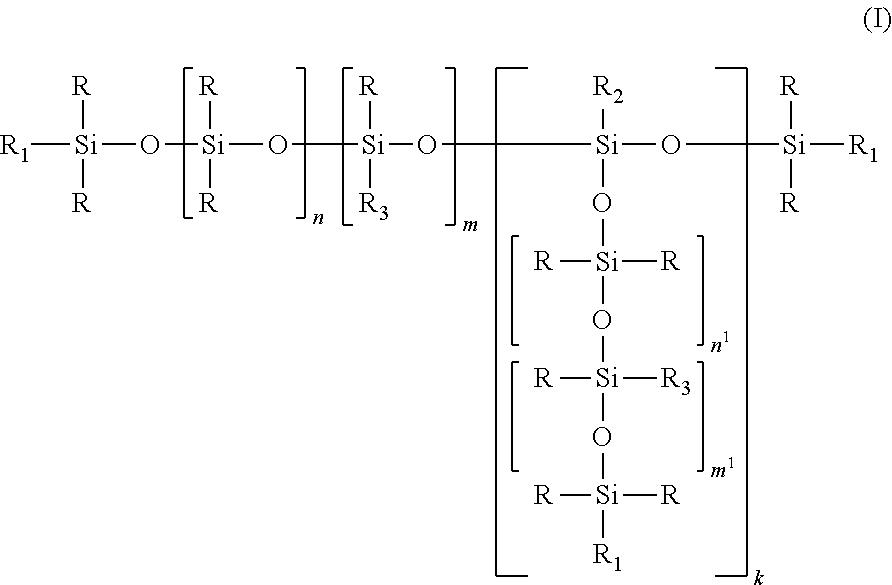

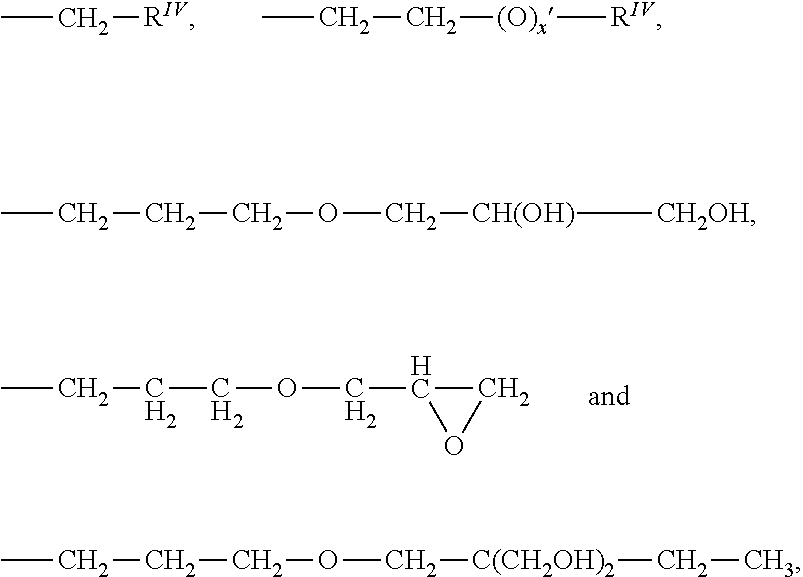

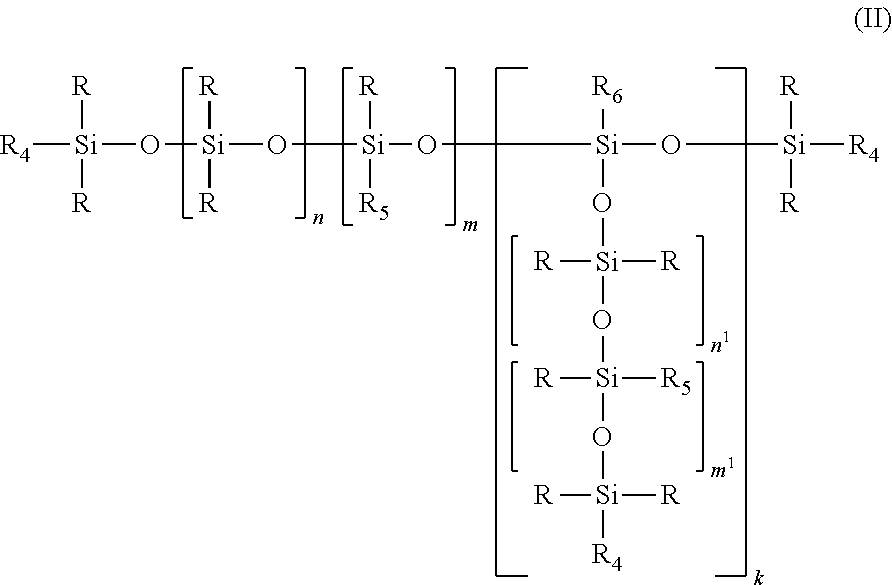

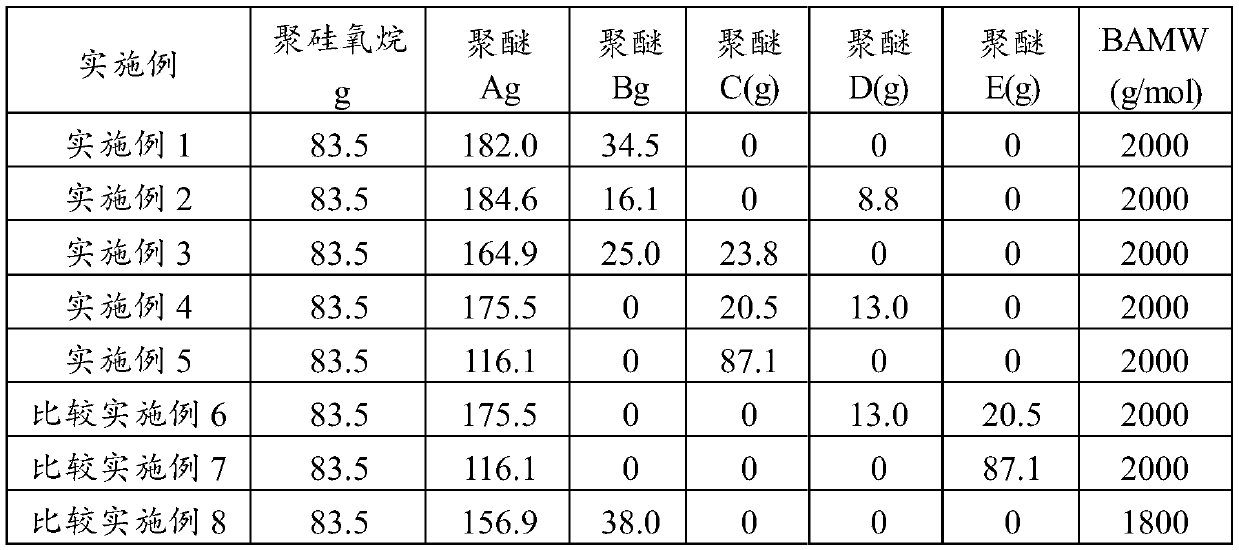

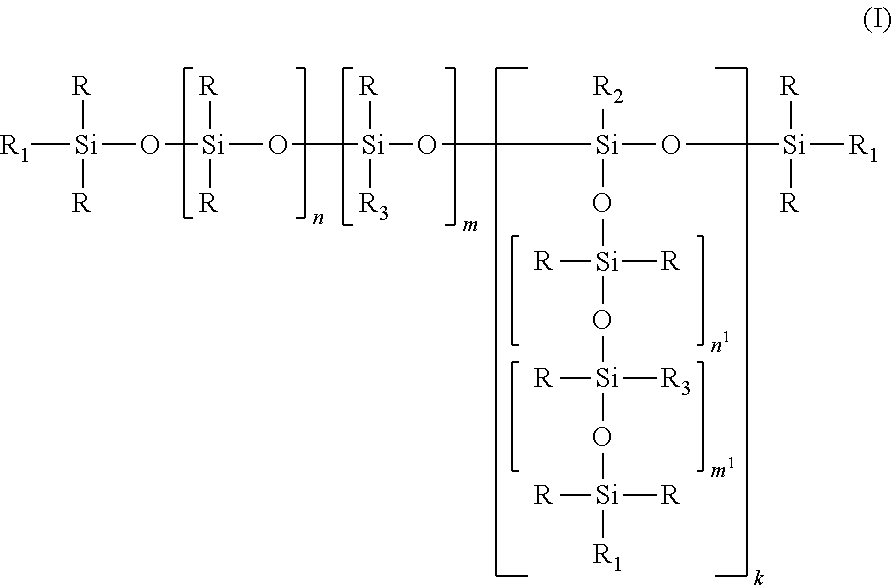

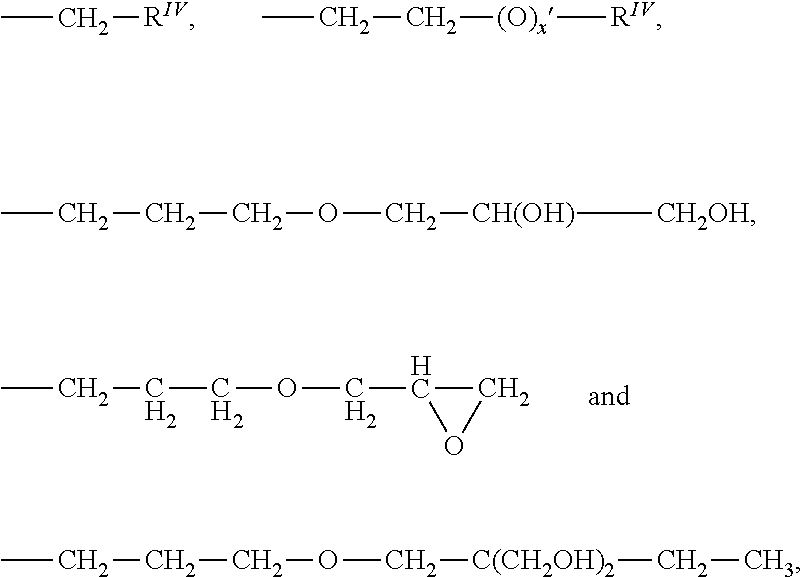

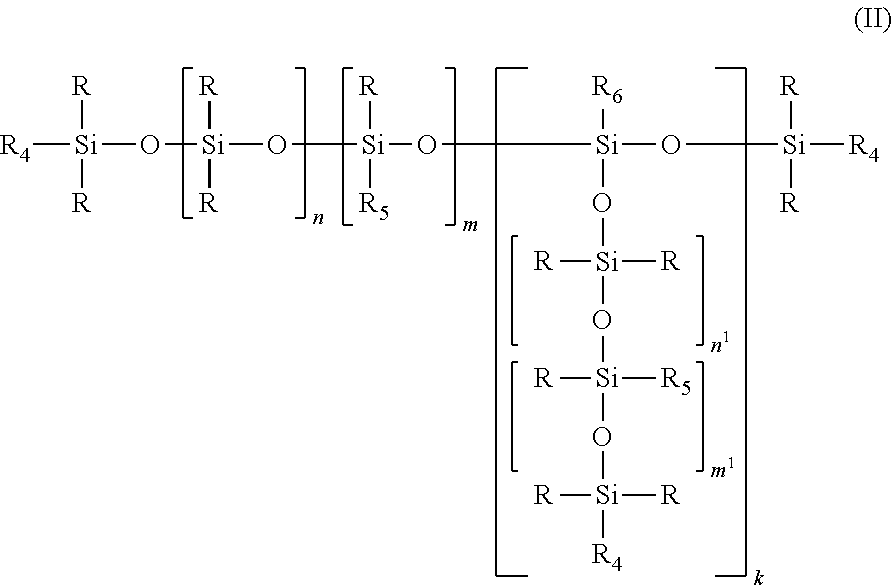

Polysiloxane polyether copolymers having (polyether)moieties comprising carbonate groups and their use as stabilizers for the production of polyurethane foams

InactiveUS20130035409A1Improve distributionBalanced property profileSilicon organic compoundsCopolymerCarbonate

The present invention relates to polysiloxane polyether copolymers which comprise at least one (polyether) moiety which comprises at least one unit —O—C(O)—O—, to a process for the production of the polysiloxane polyether copolymers, and also to the use of the polysiloxane polyether copolymers as stabilizers in the production of polyurethane foams, and also to polyurethane foams and items therefrom which are obtainable through the process.

Owner:EVONIK OPERATIONS GMBH

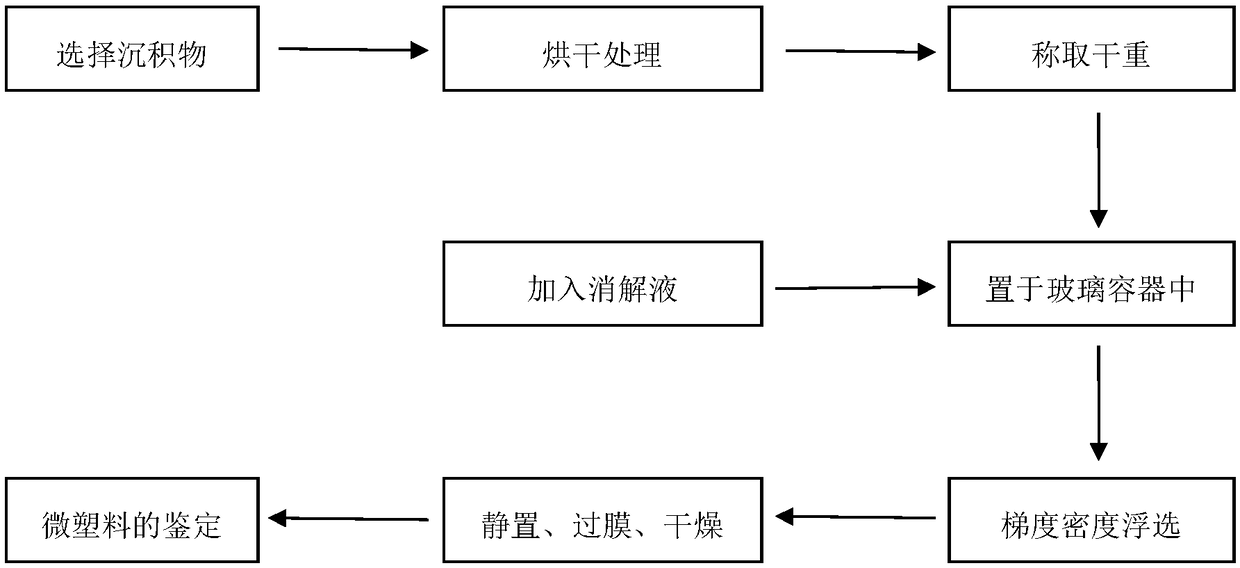

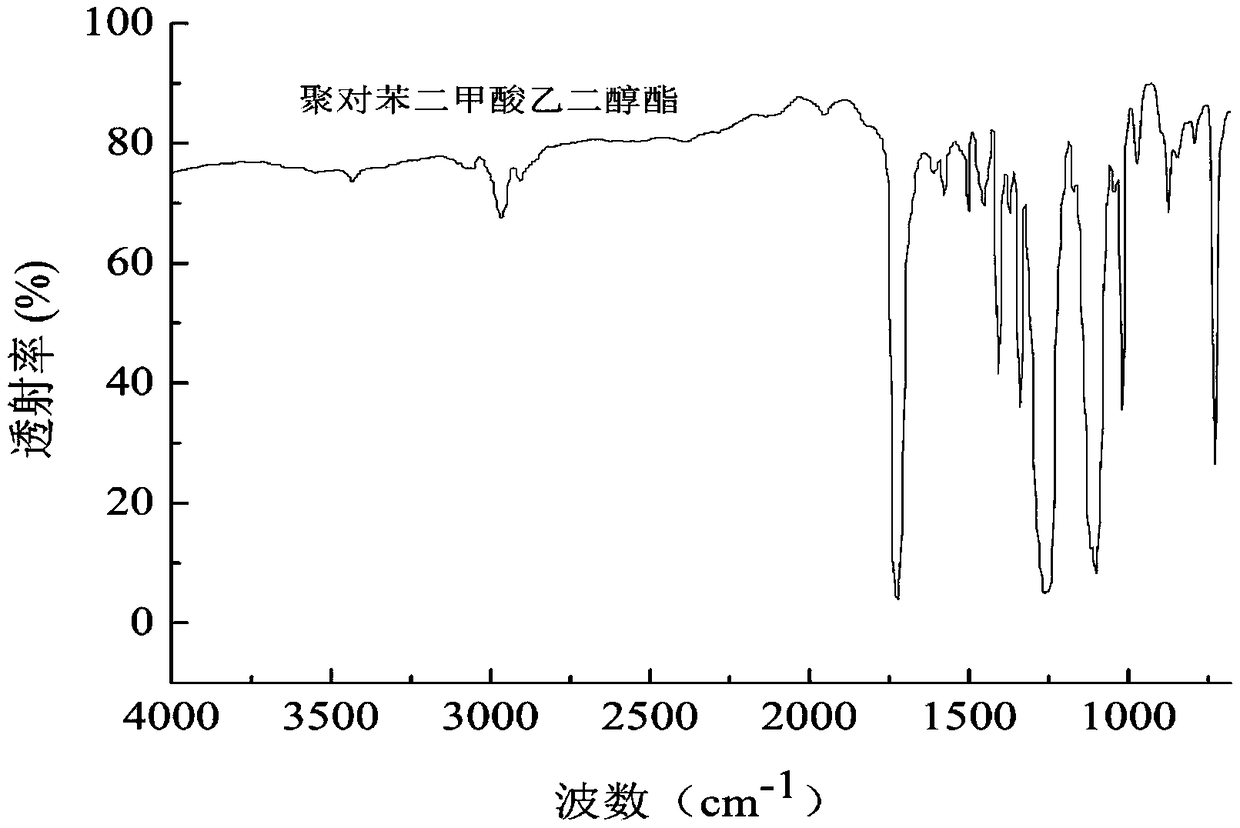

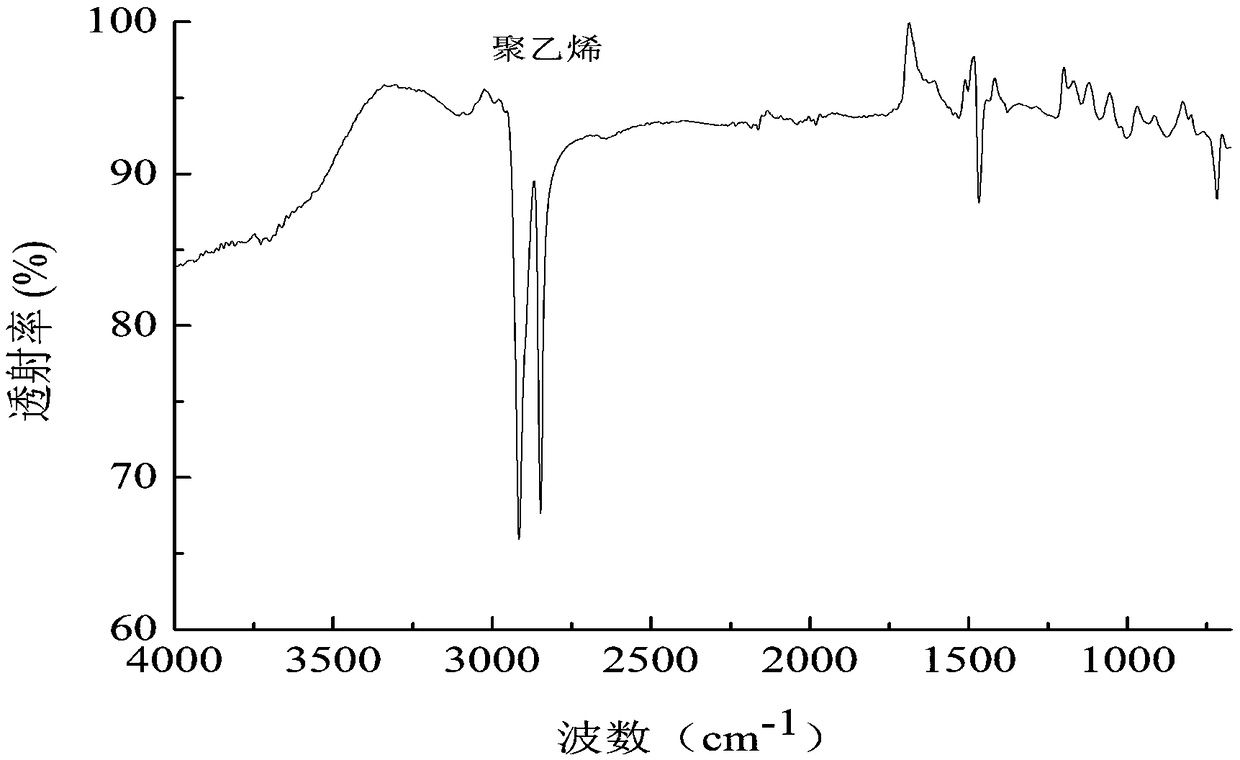

Method for detecting density distribution of micro-plastics in water environment sediments

ActiveCN109238948AImprove density distributionImprove accuracyPreparing sample for investigationIndividual particle analysisHigh densityDensity distribution

The invention provides a method for detecting density distribution of micro-plastics in marine sediments, belongs to the field of detecting micro-plastics in sediment samples. The invention provides amethod for detecting density distribution of micro-plastics in water environment sediments. The invention remedies the limitations of single flotation fluid on the separation type of microplastics and the cost of pretreatment for high density flotation by using 0.9 to 1.2 g / cm3 of NaCl and 1.20 to 1.55 g / cm3 of KI solution to perform a flotation processing on samples separately, and can separatehigh density microplastics; The invention visually detects suspected micro-plastic particles through a microscope, and then performs a micro-Fourier infrared analysis to improve the accuracy of singleidentification. The calculation of the density distribution of microplastics is highly accurate and simple, and can be applied to the study of density distribution characteristics in a variety of water environment sediments.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

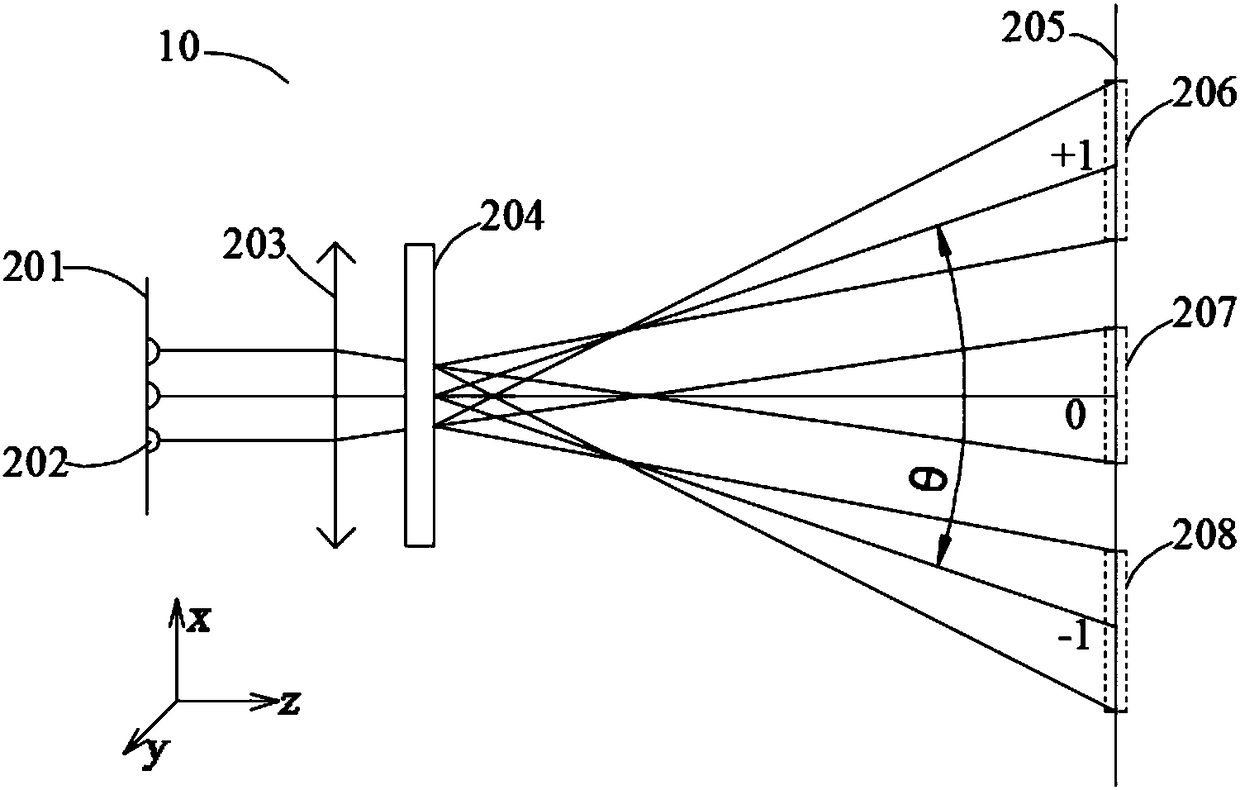

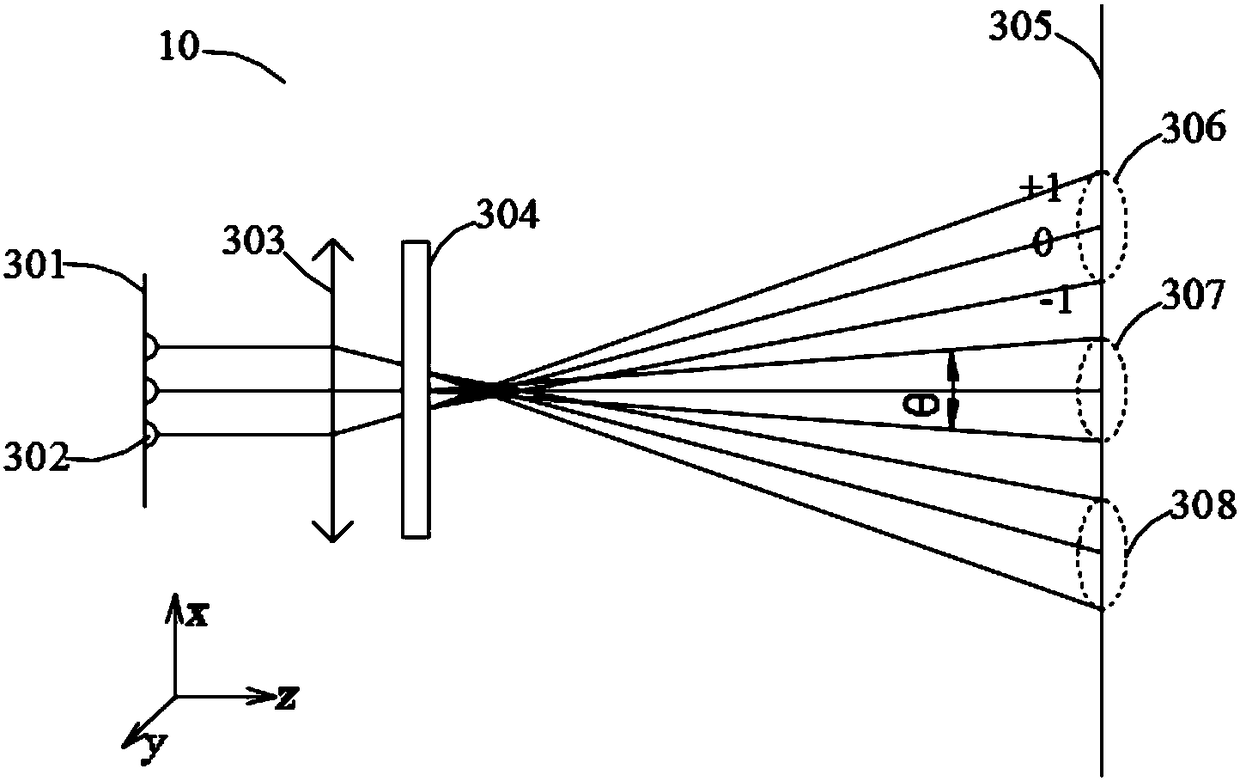

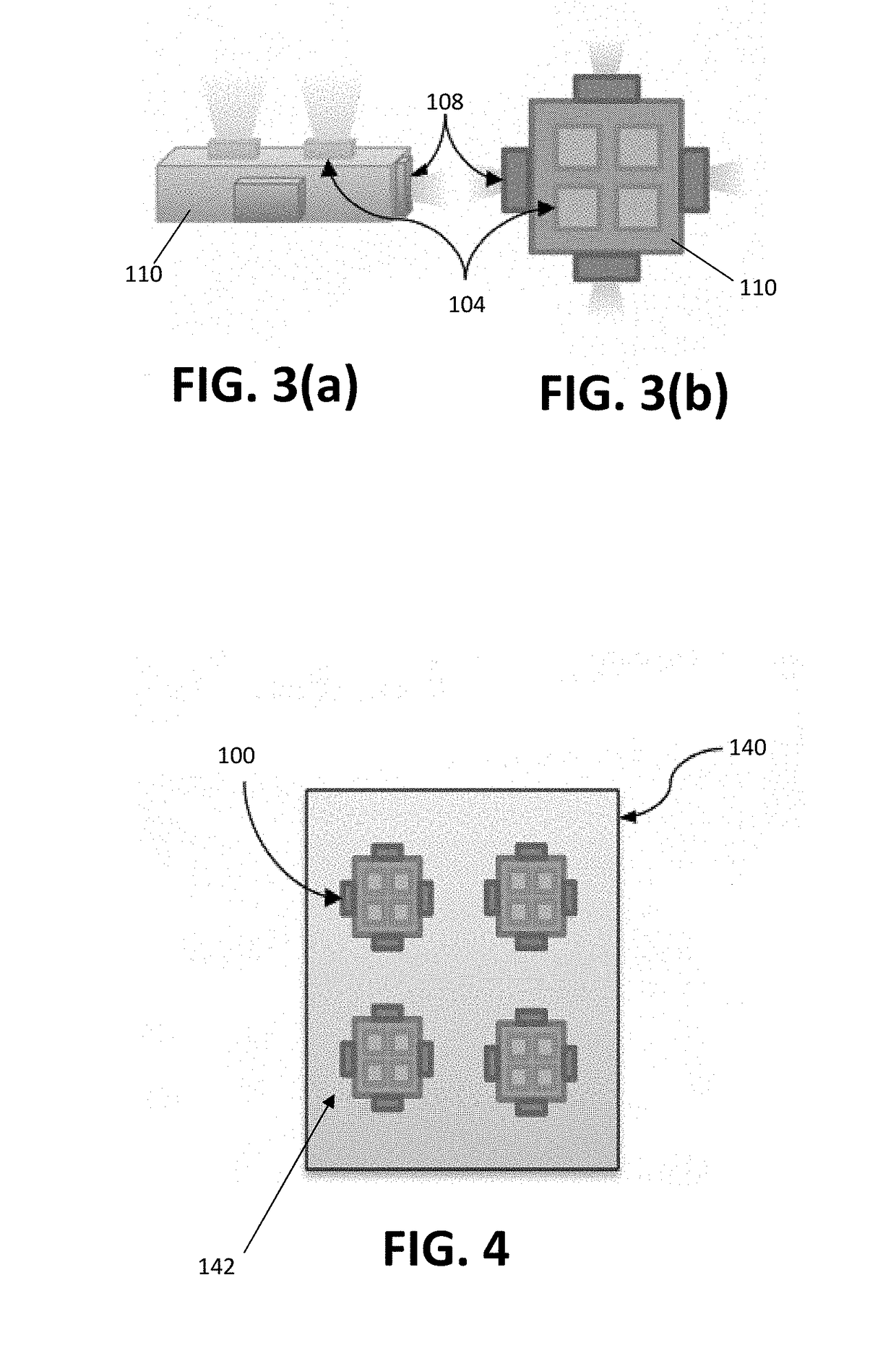

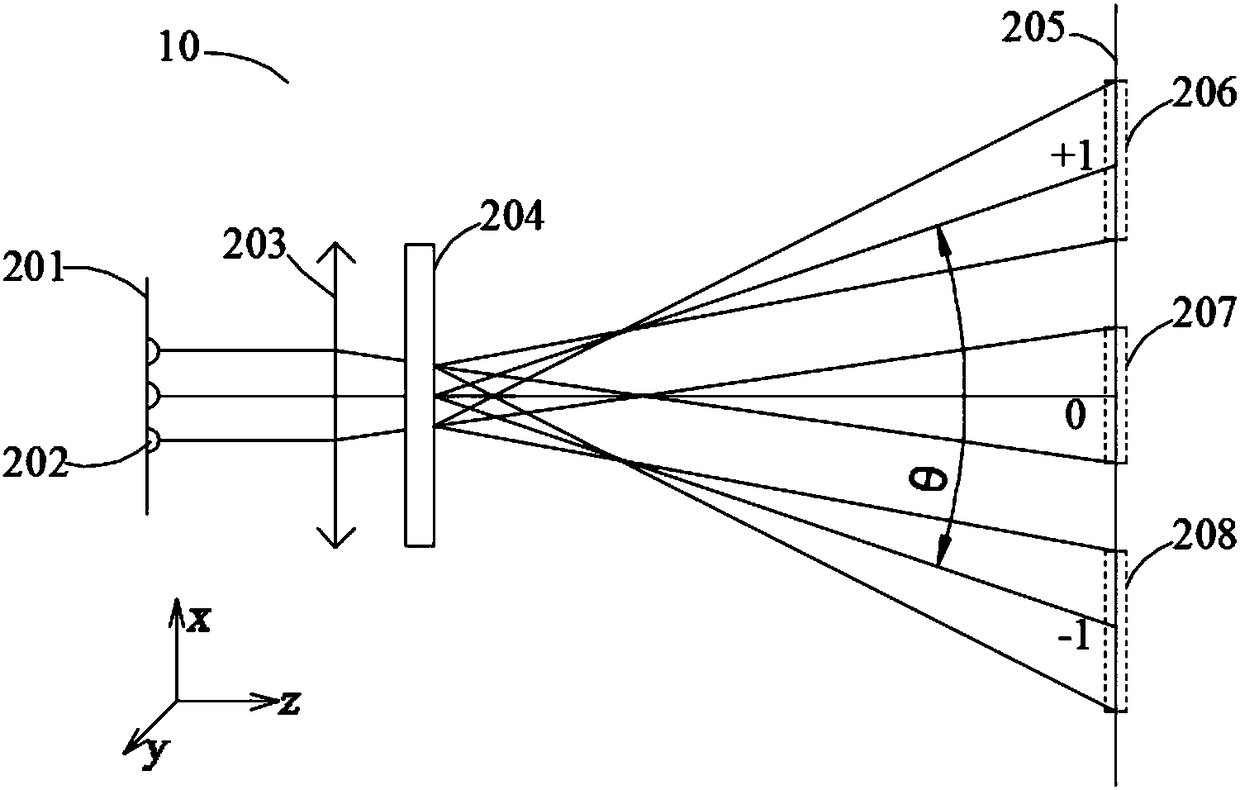

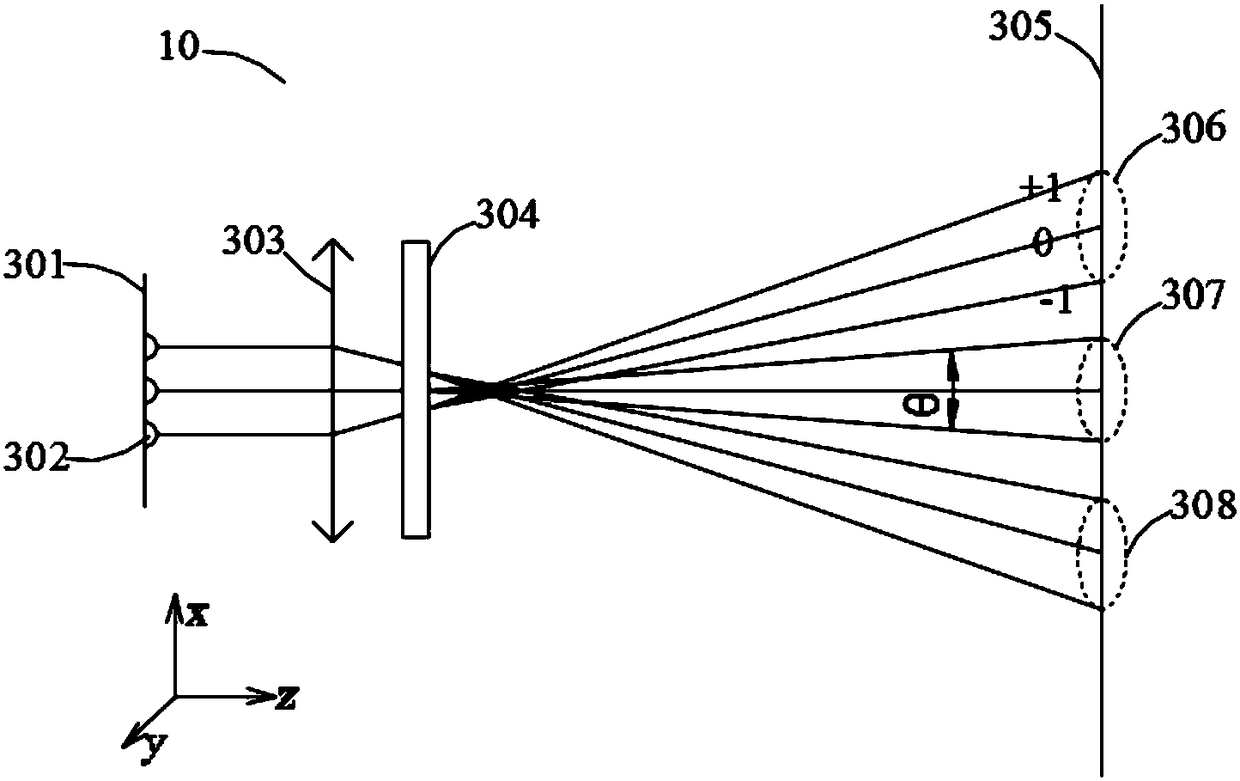

Structured light projection module group and depth camera

ActiveCN108490634AEvenly distributedImprove density distributionUsing optical meansOptical elementsDensity distributionOptoelectronics

The invention provides a structured light projection module group and a depth camera. The structured light projection module group comprises a light source array which comprises multiple sub-light sources arranged in the form of two-dimensional patterns and is used for transmitting array beams corresponding to the two-dimensional patterns; a lens which receives and converges the array beams; and adiffractive optical component which receives the array beams emergent after convergence of the lens and projects the structured light spot patterned beams, wherein the structured light spot patternsinclude at least two sub-structured light spot patterns which are staggered and superposed, the sub-structured light spot patterns are formed by multiple spot blocks through paying and arrangement, and the spot blocks are formed by the spots of the same diffraction grade formed by at least partial sub-light sources of multiple sub-light sources through diffraction of the diffractive optical component. According to the scheme, the density distribution of the structured light spot patterns can be enhanced on the basis of guaranteeing uniform distribution of the structured light patterns and theirrelevance is quite high.

Owner:SHENZHEN ORBBEC

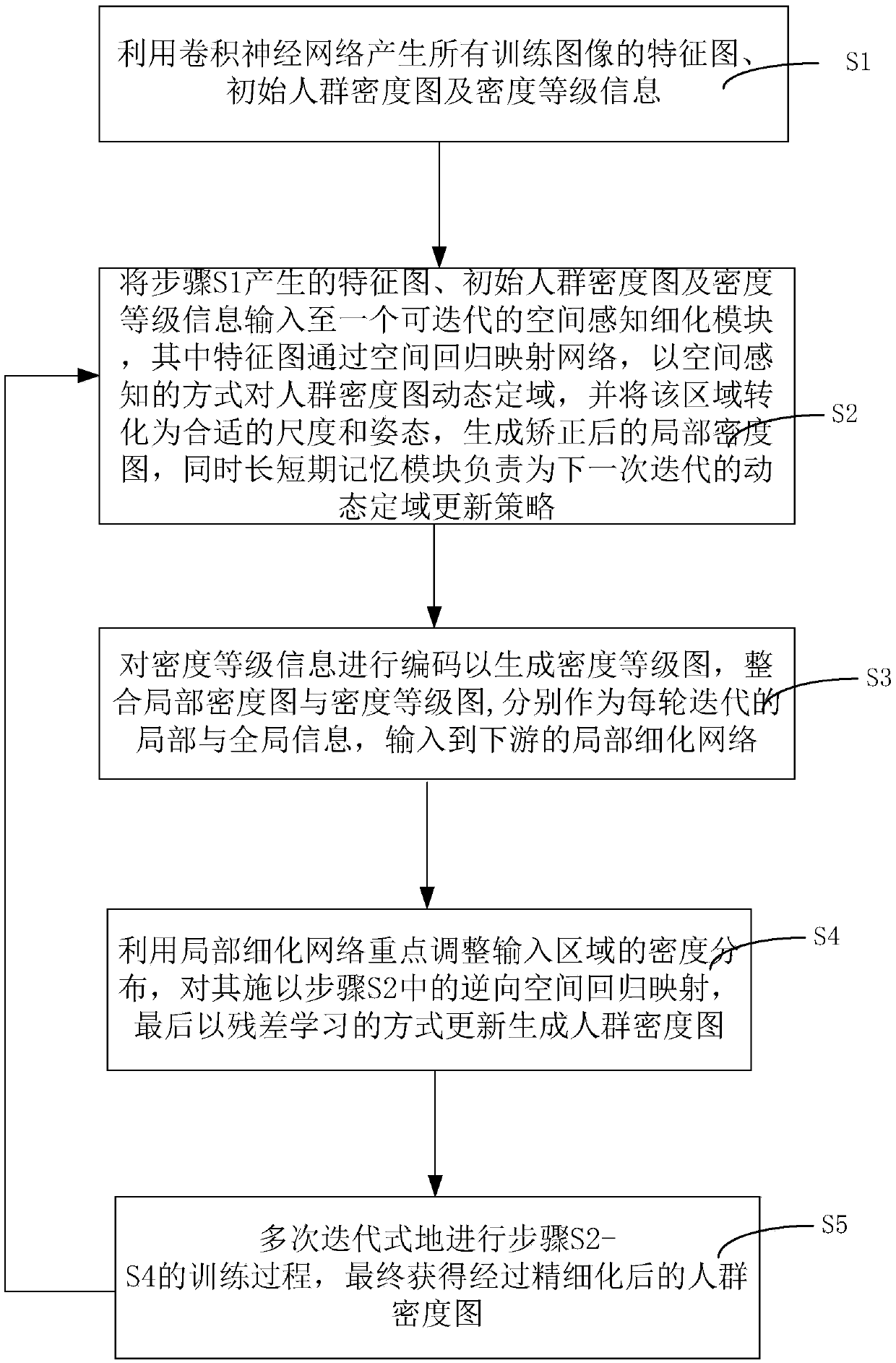

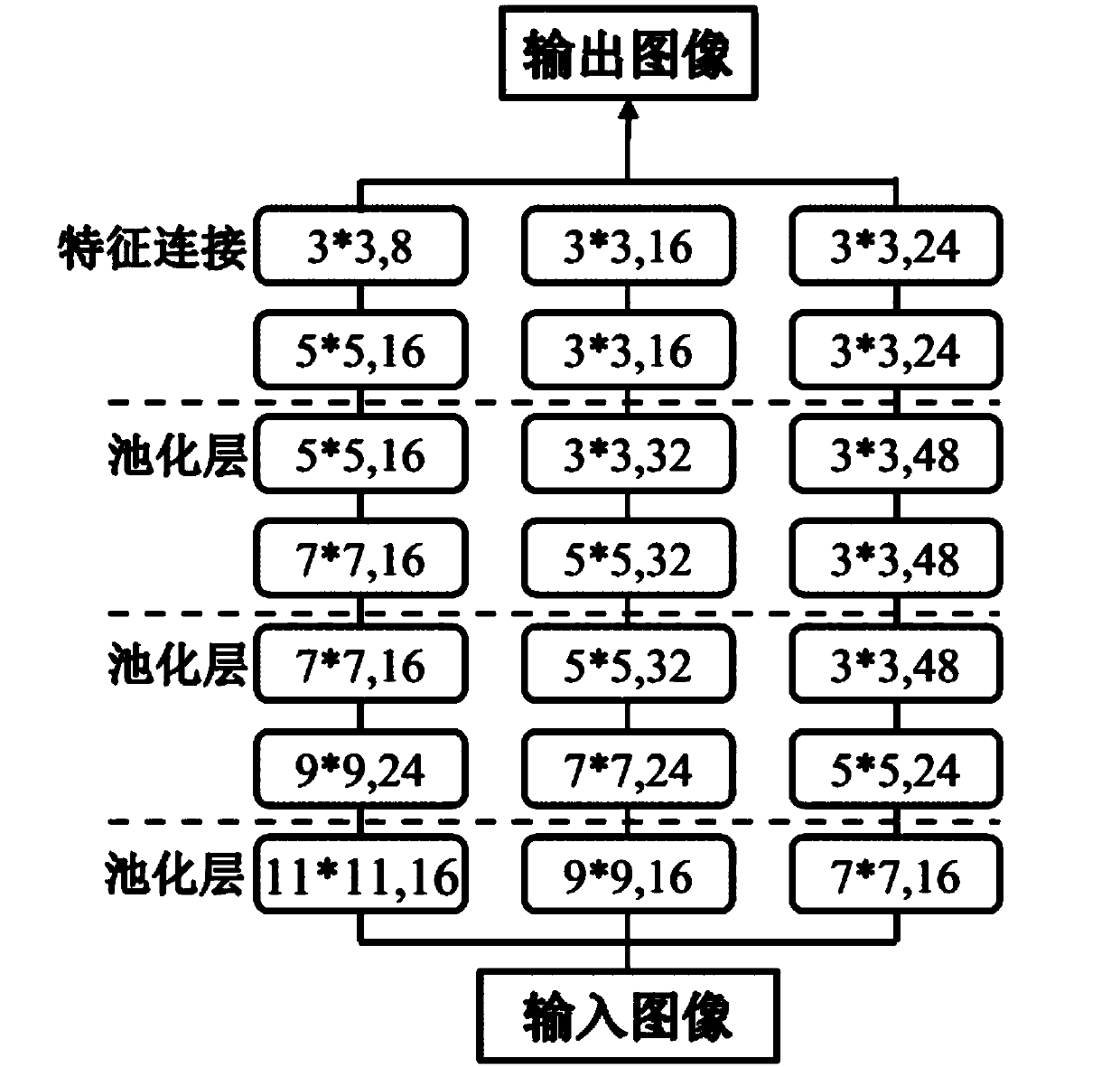

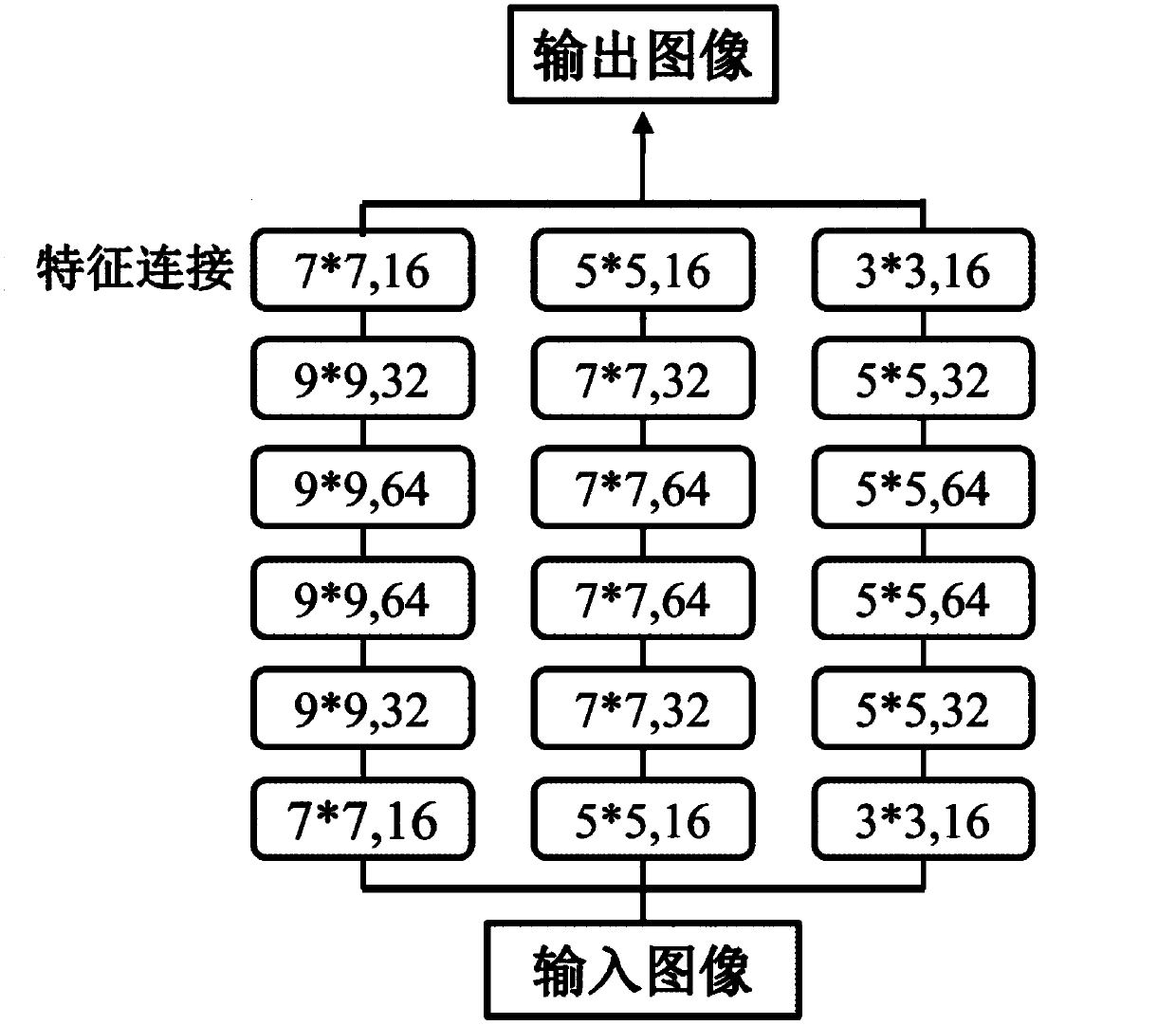

A crowd counting method and system based on a spatial perception attention refinement framework

PendingCN109558862AImprove density distributionCharacter and pattern recognitionInternal combustion piston enginesSpatial regressionDensity distribution

The invention discloses a crowd counting method and system based on a spatial perception attention refinement framework. The method comprises the following steps: generating feature maps, initial crowd density maps and density grade information of all training images by utilizing a convolutional neural network; inputting the information into an iterative spatial perception refining module, carrying out dynamic localization on the crowd density map in a spatial perception mode by utilizing a spatial regression mapping network, generating a corrected local density map, and carrying out a dynamiclocalization updating strategy for next iteration by combining a long-short-term memory module; Encoding the density level information to generate a density level graph, integrating the local densitygraph with the density level graph to serve as local and global information of each round of iteration, and inputting the local and global information into a local refining network; the local refinement network adjusts the density distribution of the input area, performs reverse space regression mapping on the input area, and updates and generates a crowd density map in a residual error learningmode; and iteratively carrying out the training process for multiple times to obtain a refined crowd density map.

Owner:拓元(广州)智慧科技有限公司

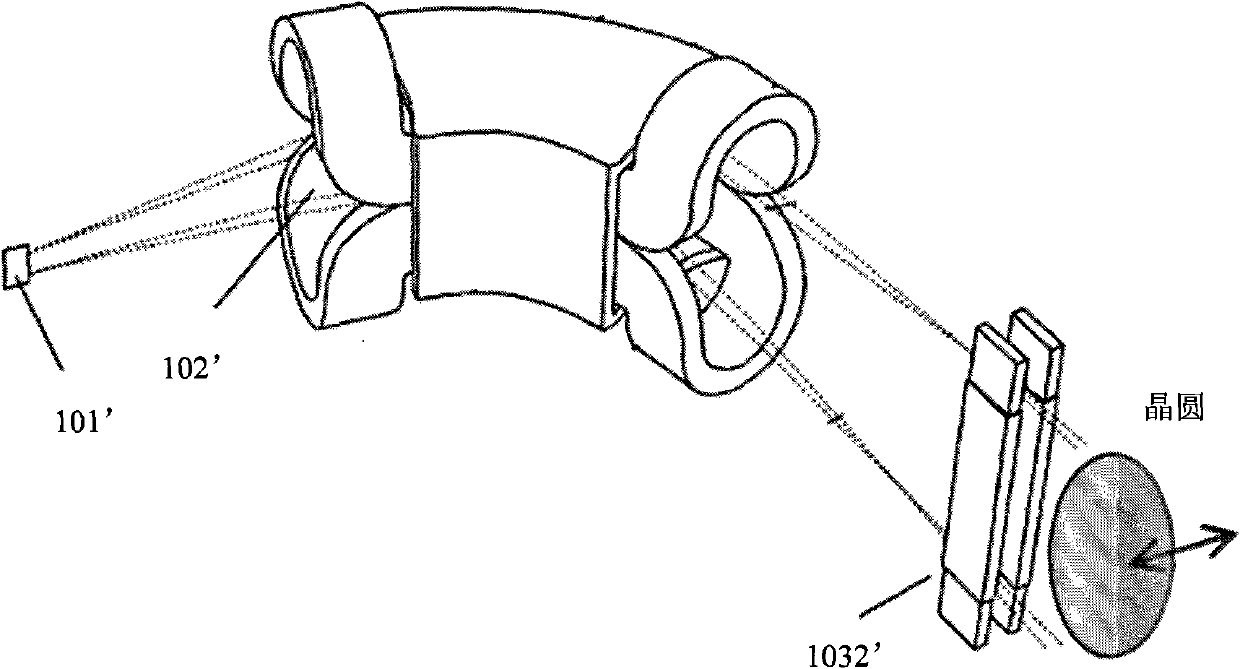

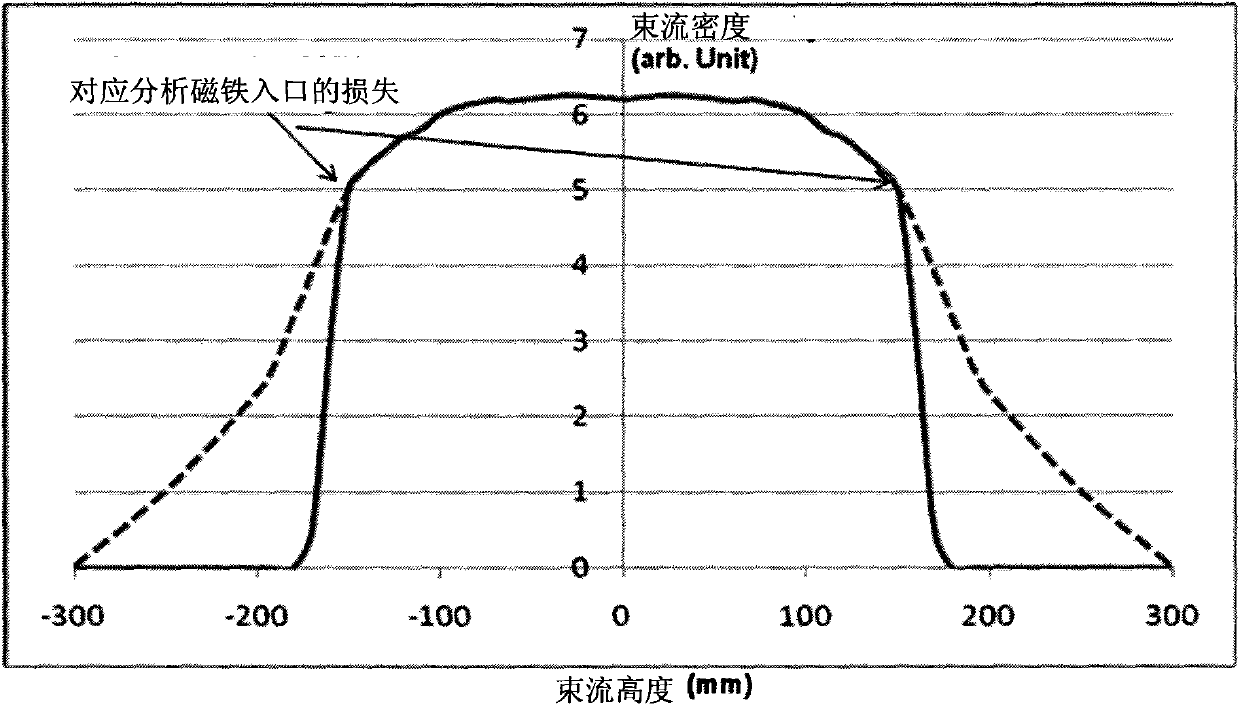

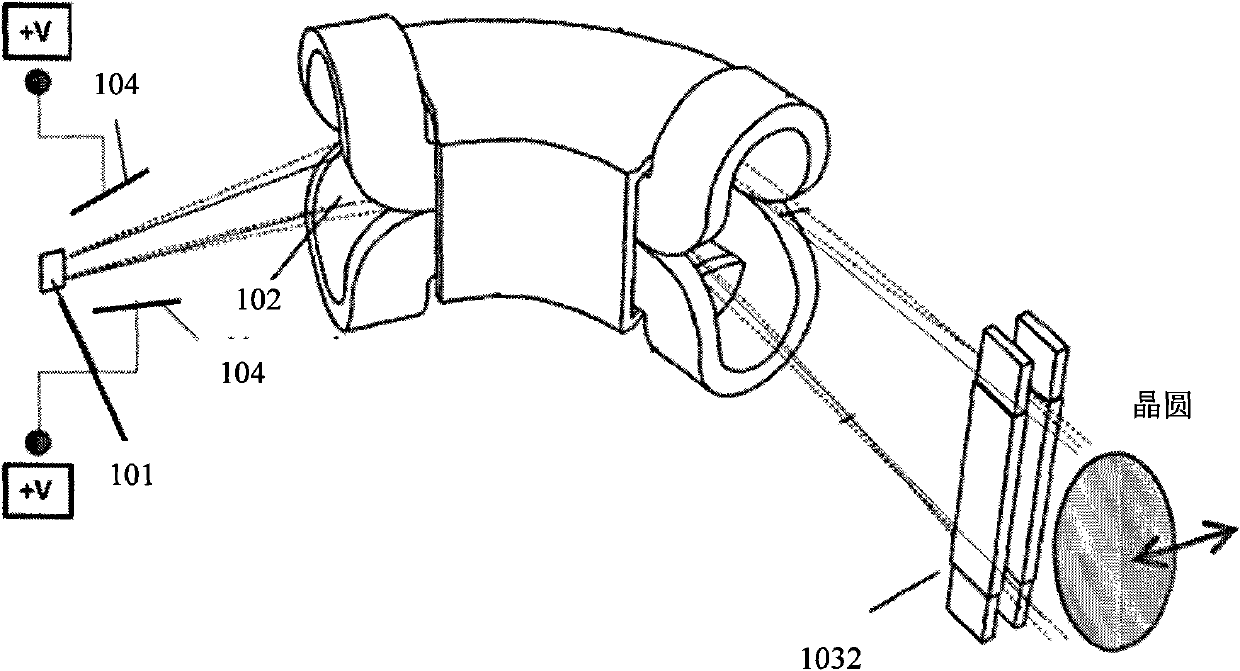

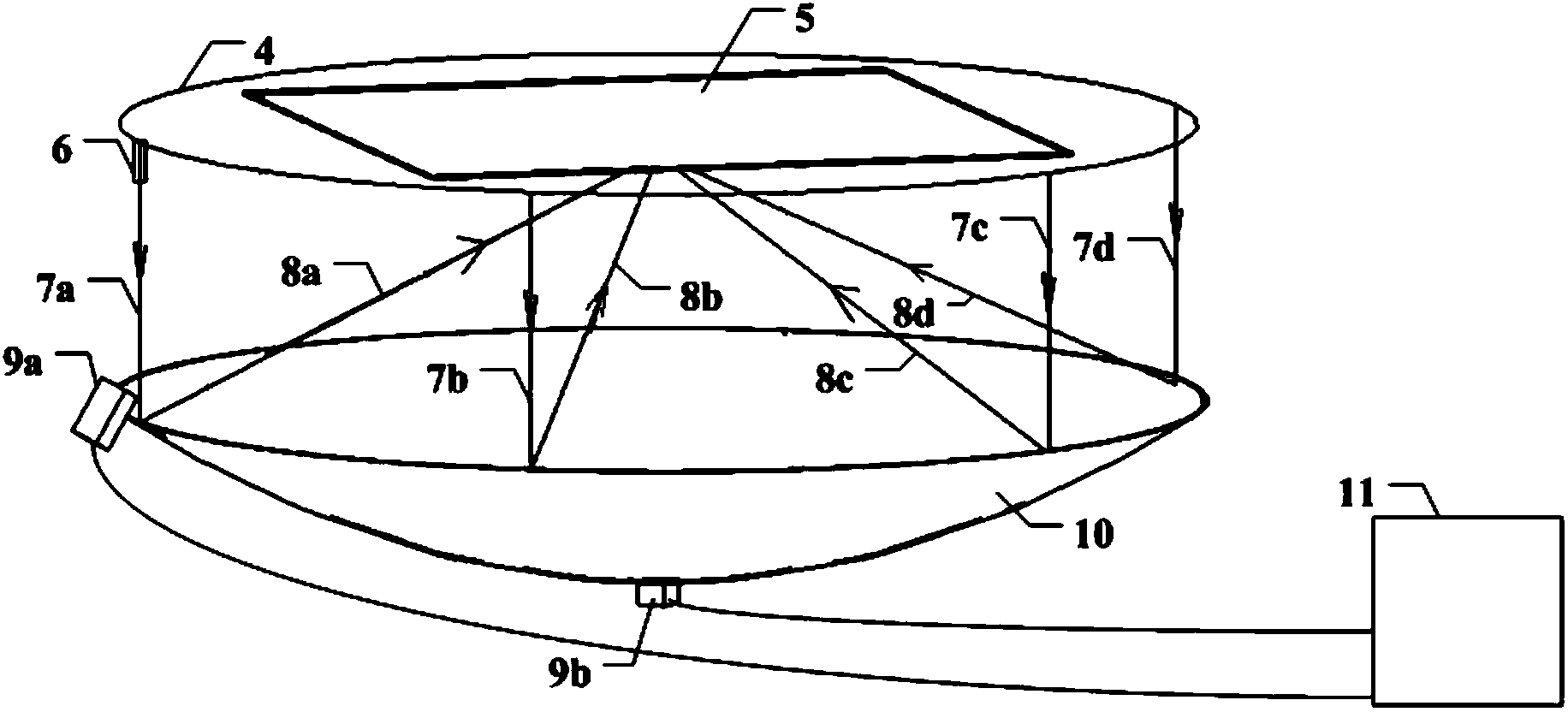

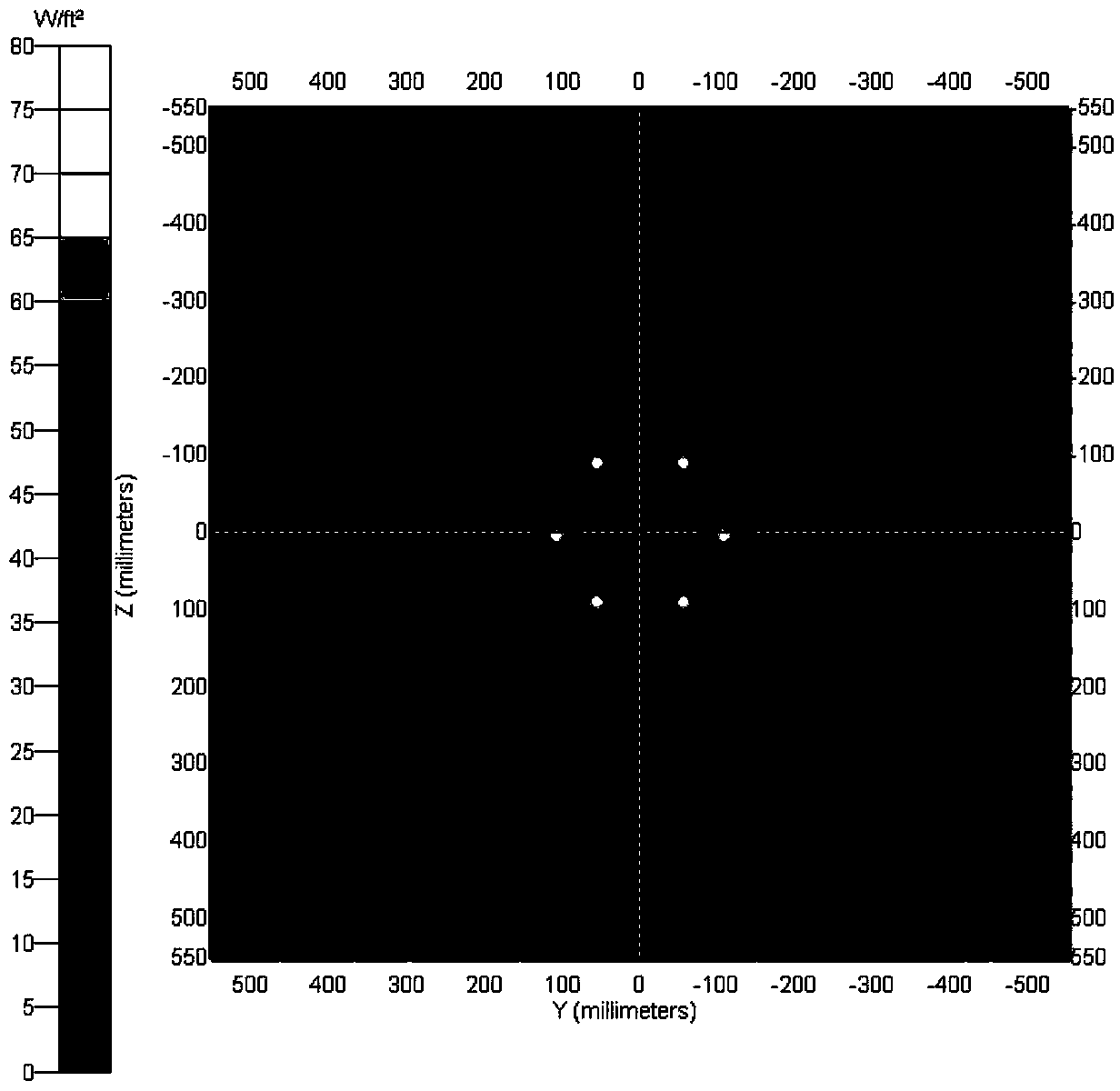

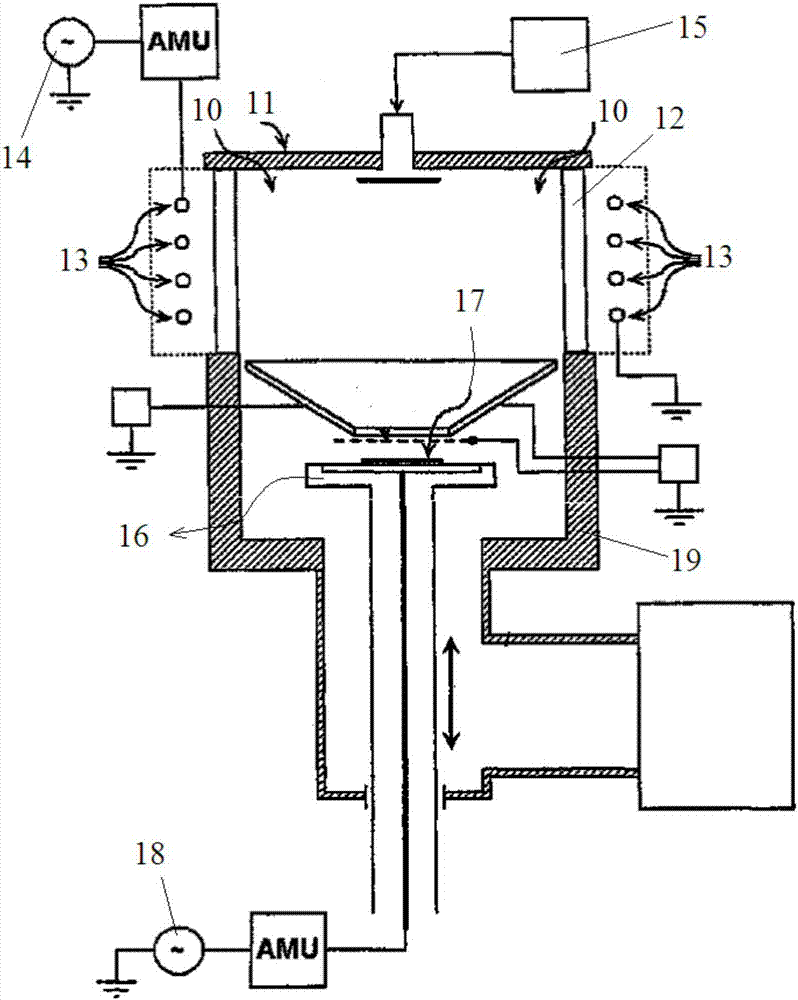

System and method for improving beam current intensity distribution after leading ion beam out

ActiveCN102024656AImprove density distributionReduce beam lossElectric discharge tubesDensity distributionIon beam

The invention discloses a system and a method for improving beam current intensity distribution after leading an ion beam out. A positive bias current-conducting plate is added between the top part and the bottom part of a beam current path between a beam current leading-out system and a mass analysis magnet, wherein the positive bias current-conducting plate can generate an electric field so that part beam current is pressed to the middle part; a bias voltage can modulate beam current intensity to increase the beam current intensity, so that the beam current loss caused by the mass analysis magnet is compensated; and simultaneously, some nonlinear angle changes caused by the positive bias current-conducting plate is independently corrected by utilizing an angle controller. By using the system and the method, the beam current loss caused by an analysis magnet inlet can be reduced; high beam current transmission efficiency is achieved by greatly improving the beam current of an analysis magnet; and the density distribution of the beam current can be optimized more conveniently when the beam current uniformity distribution is adjusted.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

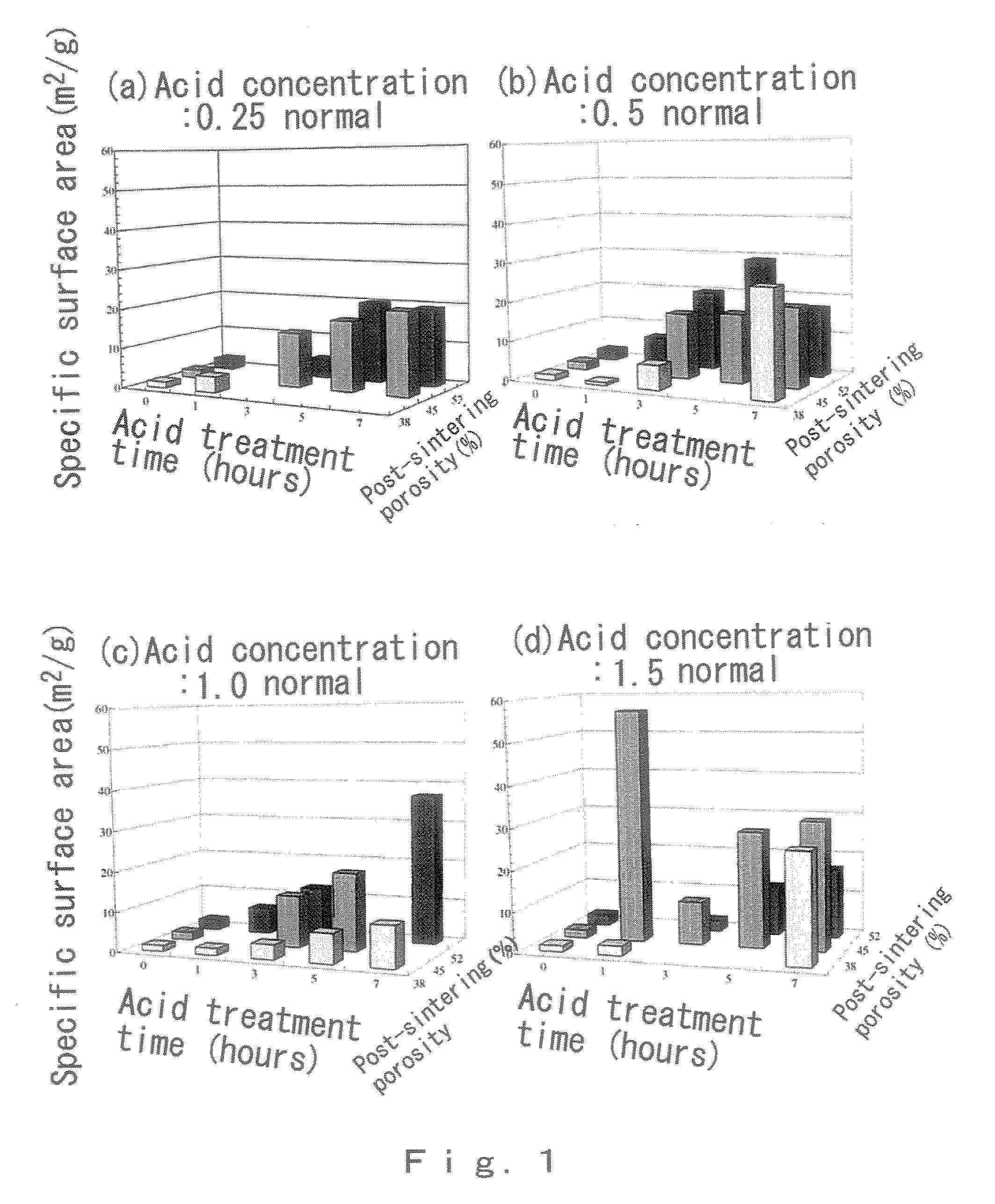

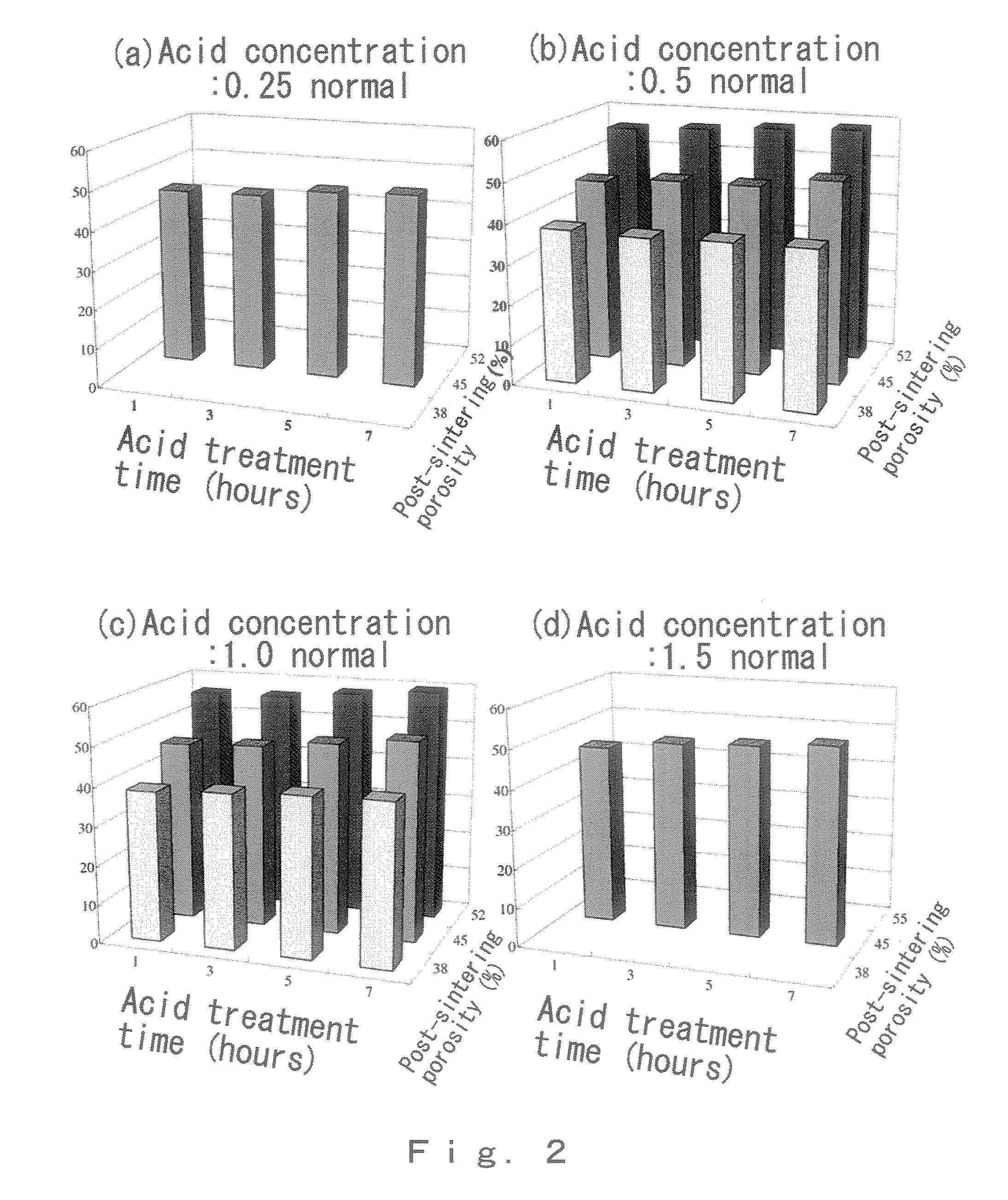

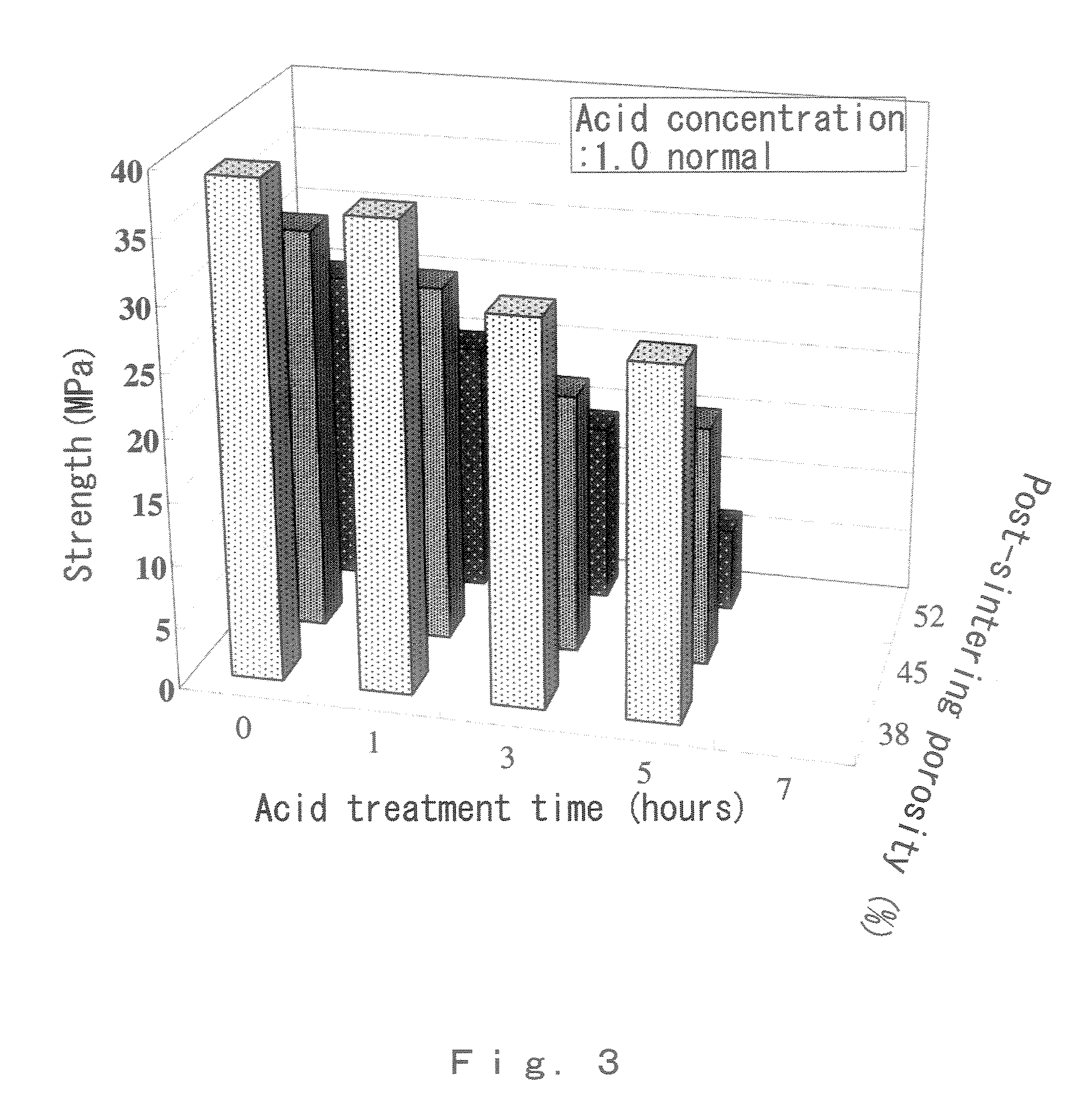

Needle-shaped ceramic body, needle-shaped ceramic catalyst body and method for producing same

InactiveUS20070254804A1Problem is exacerbatedEasy to produceCatalyst carriersOther chemical processesPorosityMetallurgy

The present invention provides a needle-shaped ceramic body and needle-shaped ceramic catalyst body in which a case material is a high specific surface area porous cordierite body that is stable at high temperatures, and also provides methods of producing this needle-shaped ceramic body and needle-shaped ceramic catalyst body. The present invention relates to a needle-shaped ceramic body and needle-shaped ceramic catalyst body in which a base material is a high temperature-stable, high specific surface area porous cordierite body comprising a porous structure having a prescribed porosity and formed of a needle-shaped cordierite crystal phase and further relates to methods of producing this needle-shaped ceramic body and needle-shaped ceramic catalyst body, and by using porous cordierite constituted of needle-shaped crystals as a catalyst-supporting honeycomb structure, the present invention is able to inhibit sintering-induced reduction in the specific surface area. Since a honeycomb can be directly produced as the cordierite sinter itself, an inexpensive product can be provided through the simplifying the prior-art step of coating the interior of the honeycomb.

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

Testing method and testing platform for light spot patterns of solar light condenser

InactiveCN103822772AHigh dimensional accuracyImprove test efficiencyUsing optical meansTesting optical propertiesTest efficiencyPoint light

The invention provides a testing method for light spot patterns of a solar light condenser. The testing method comprises the following steps: firstly, generating light rays which are vertically incident on a solar light condensing lens by utilizing simulation point light sources; then acquiring geometric information about the position and the shape of condensed light on a receiver by utilizing an image detecting technique, and reconstructing and recognizing on a computer; then moving the simulation point light sources fixed on a guide rail along the outer diameter of the solar light condensing lens in parallel by utilizing the electric guide rail with a servo stepping motor, reconstructing and storing the position and the shape of the condensed light after each moving, and automatically analyzing the shape and the position of a light spot on the receiver by testing software after the simulation point light sources move for a cycle, thereby obtaining the accurate light receiving patterns. The invention also provides a testing platform for light spot patterns of the solar light condenser. The testing method and the testing platform provided by the invention can directly measure the actual light spot size after light condensation, and moreover, the obtained light spot is high in size accuracy; additionally, the testing process is automatic, so that the testing efficiency is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Polyester polyurethane sole stoste and preparation method thereof

InactiveCN102417588AImprove conversion rateShort synthesis cycleSolesPolyesterOrganometallic catalysis

The invention discloses polyester polyurethane sole stoste, which comprises a component A and a component B, wherein the component A comprises the following compositions: polyester polyol, chain extender, foaming agent, composite catalyst A, foam stabilizer and compound additive, wherein the compositions are mixed according to the following mass ratio: 100 parts of the polyester polyol, 6-12 parts of the chain extender, 0.4-2.1 parts of the foaming agent, 0.1-0.5 parts of the composite catalyst A, 0.5-1.2 parts of the foam stabilizer and 0.1-0.3 parts of the compound additive; the component Bis prepared by the prepolymerization reaction of isocyanate and polyester polyol according to the mass ratio of 100:(60-70); and the polyester polyol in the component A or the component B is preparedin a way that dibasic acid and polyhydric alcohol carry out polyesterification reaction at the temperature of 140-220DEG C under the action of composite catalyst B. In the polyester polyurethane solestoste, acetate, amine-type catalyst, organic metal catalyst and the like are mutually compounded to form the composite catalyst. The composite catalyst is adopted in the new technology to improve the percent conversion of the polyester polyol, the synthesis cycle is greatly shortened, energy consumption is lowered, and cost is reduced.

Owner:WENZHOU UNIVERSITY

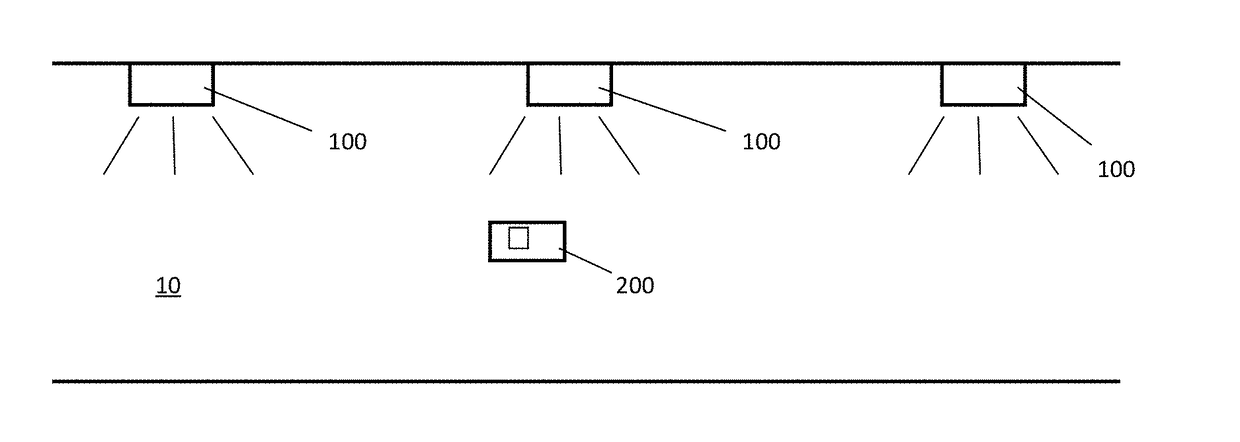

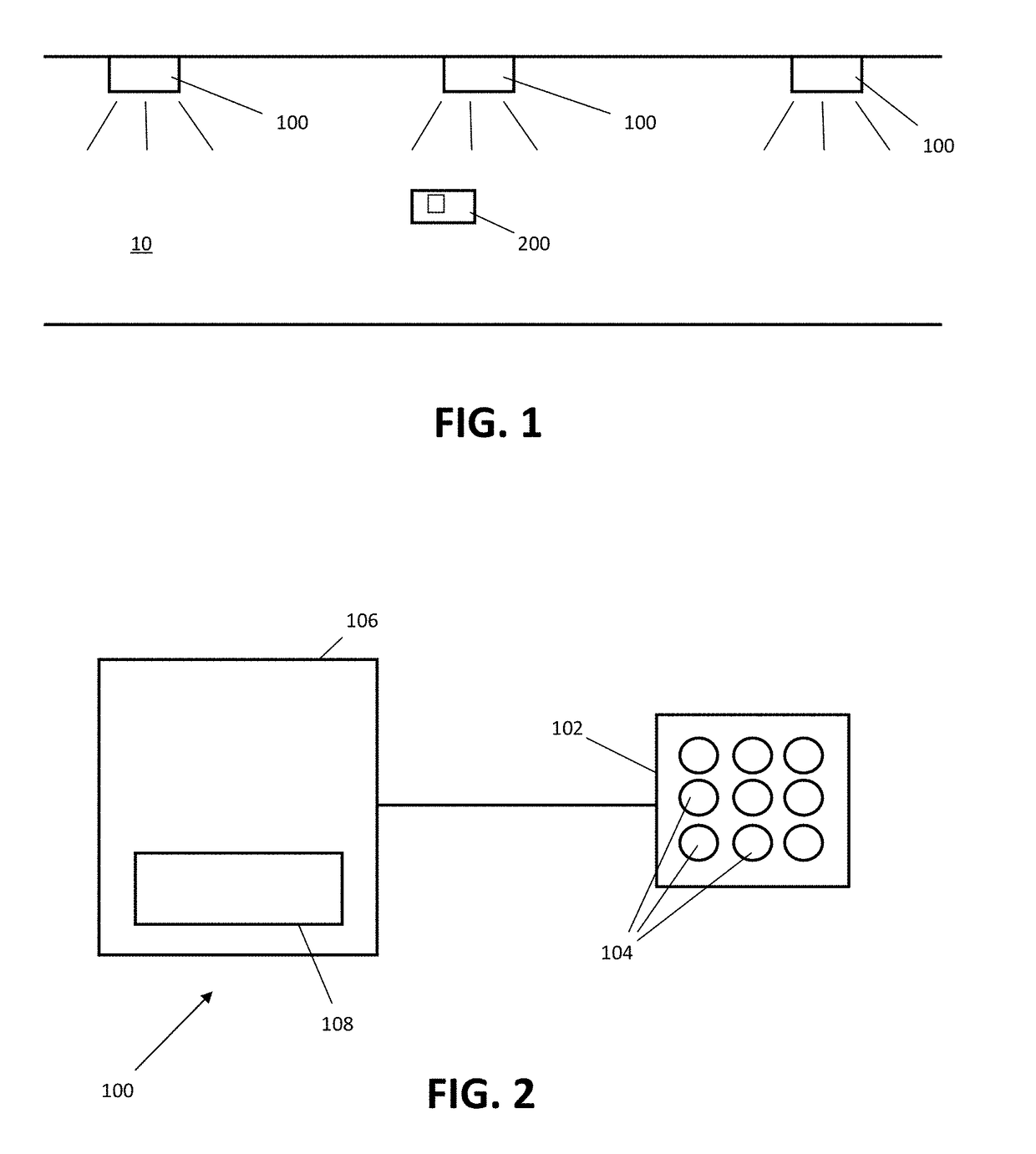

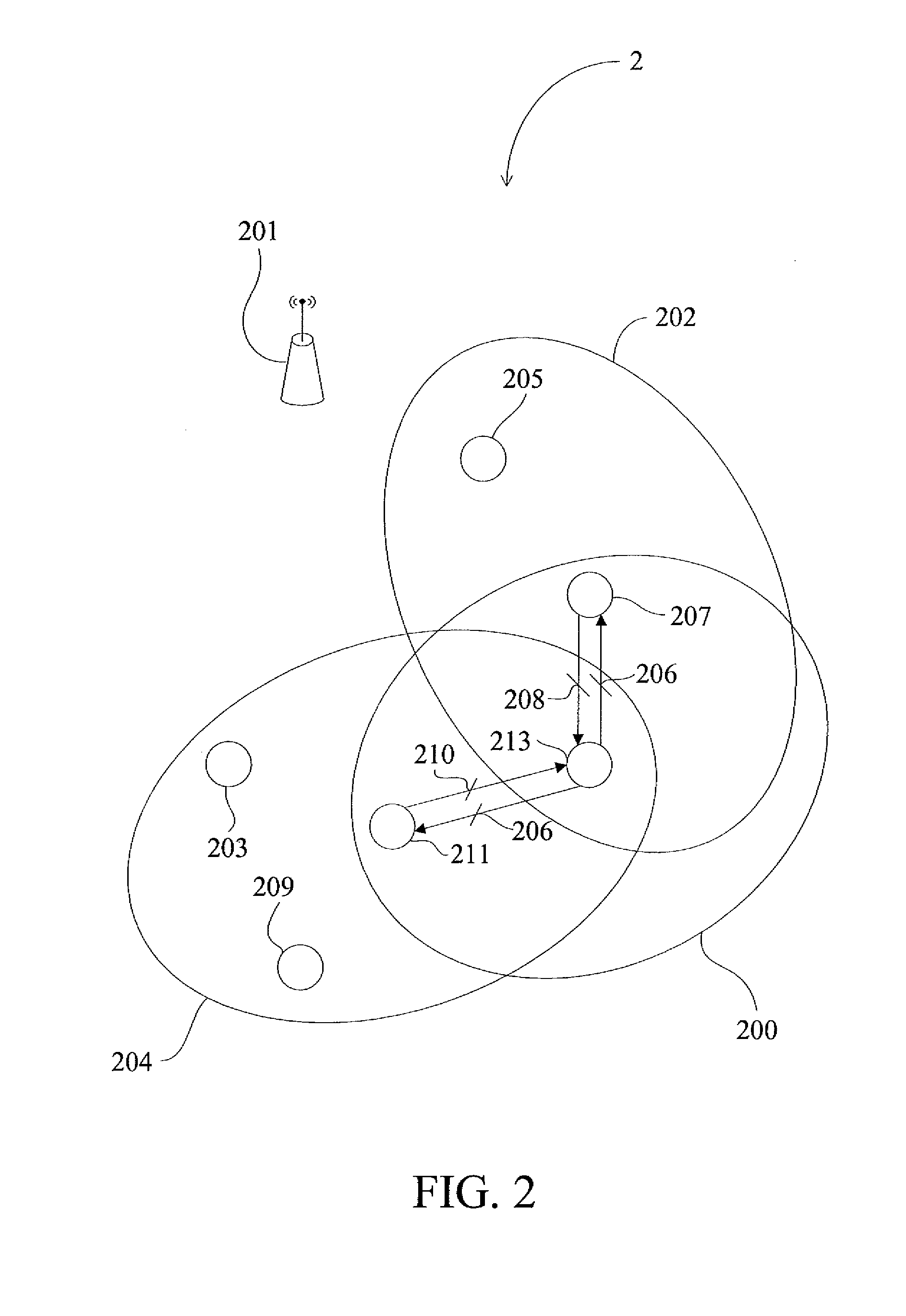

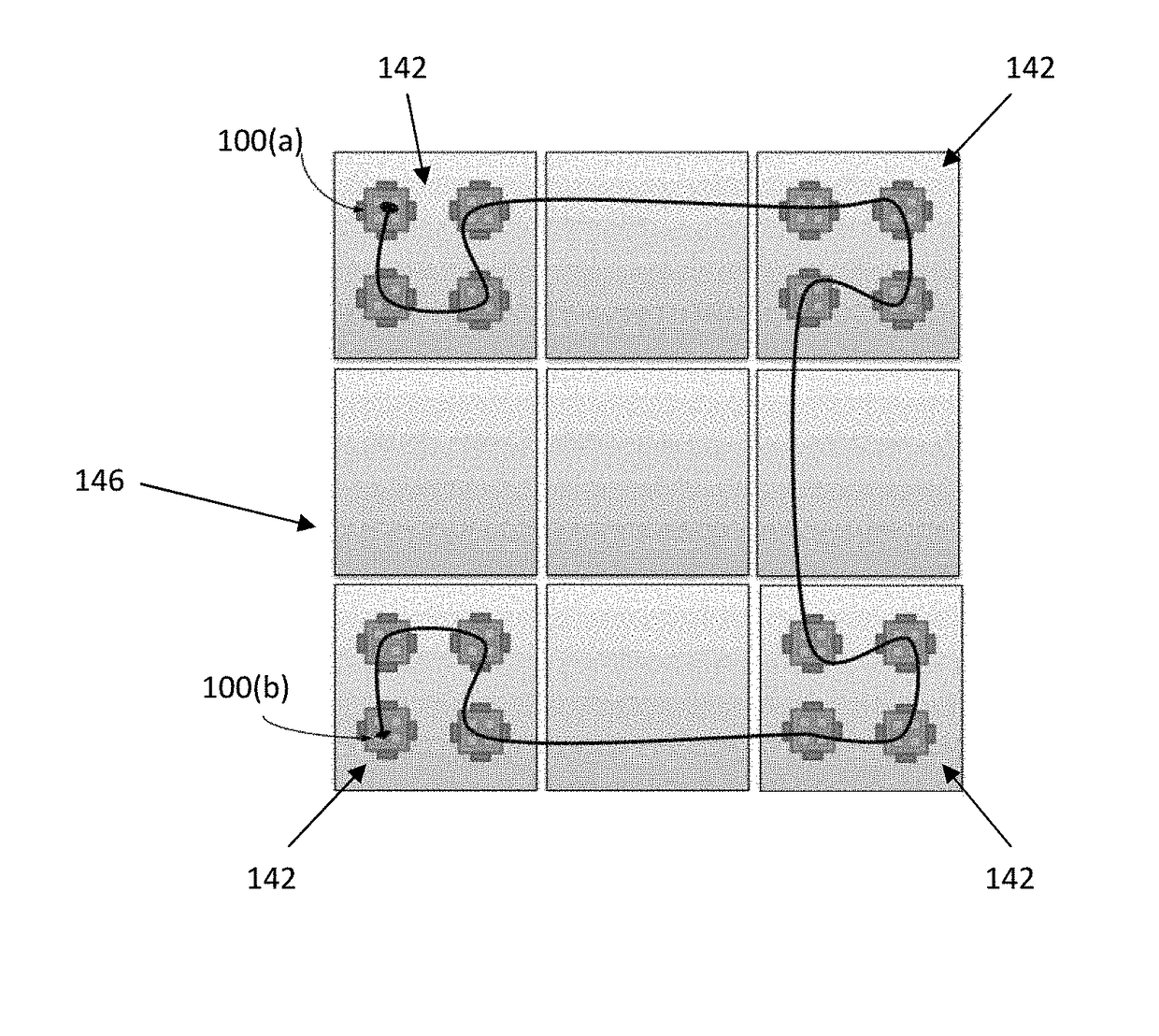

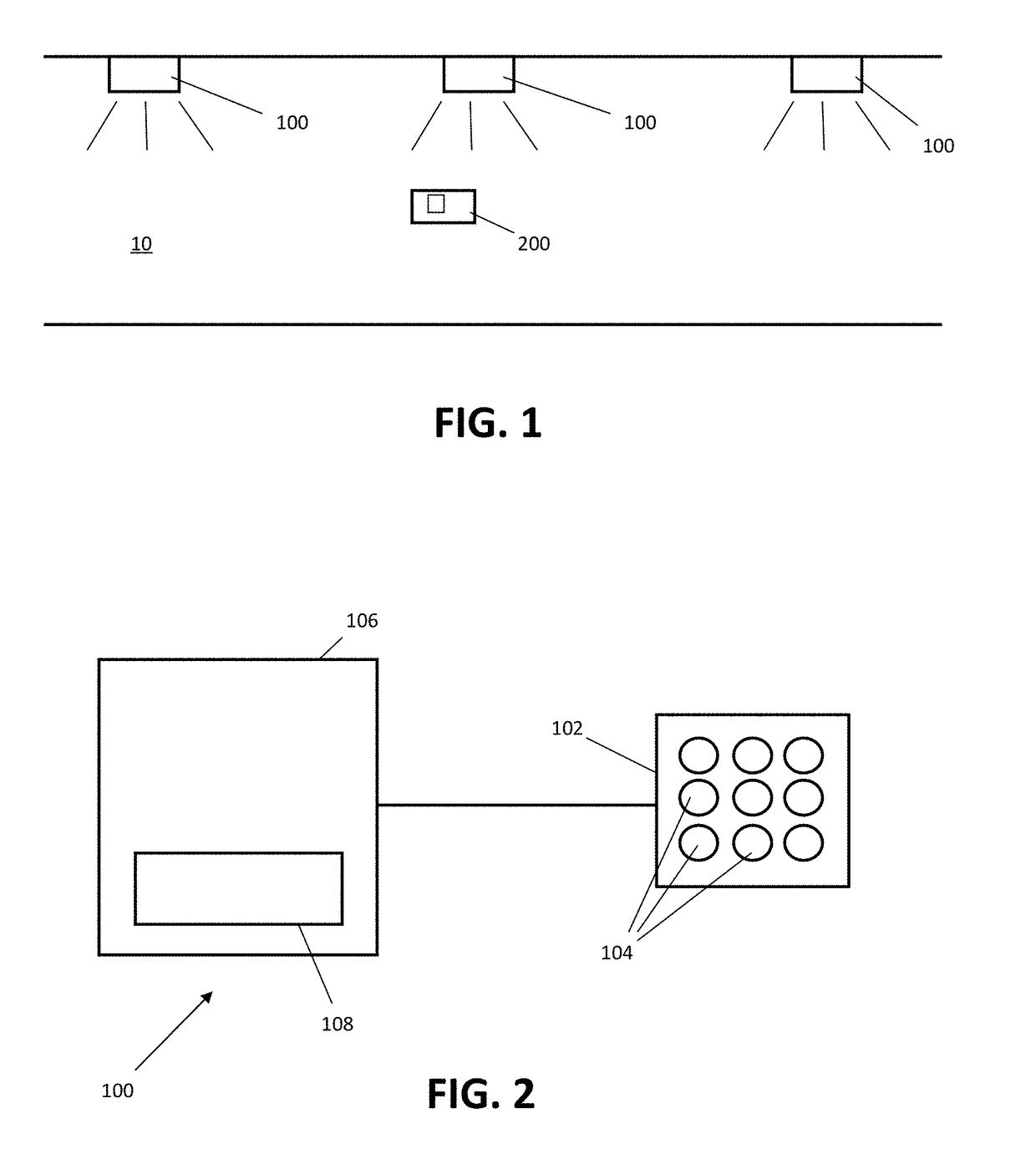

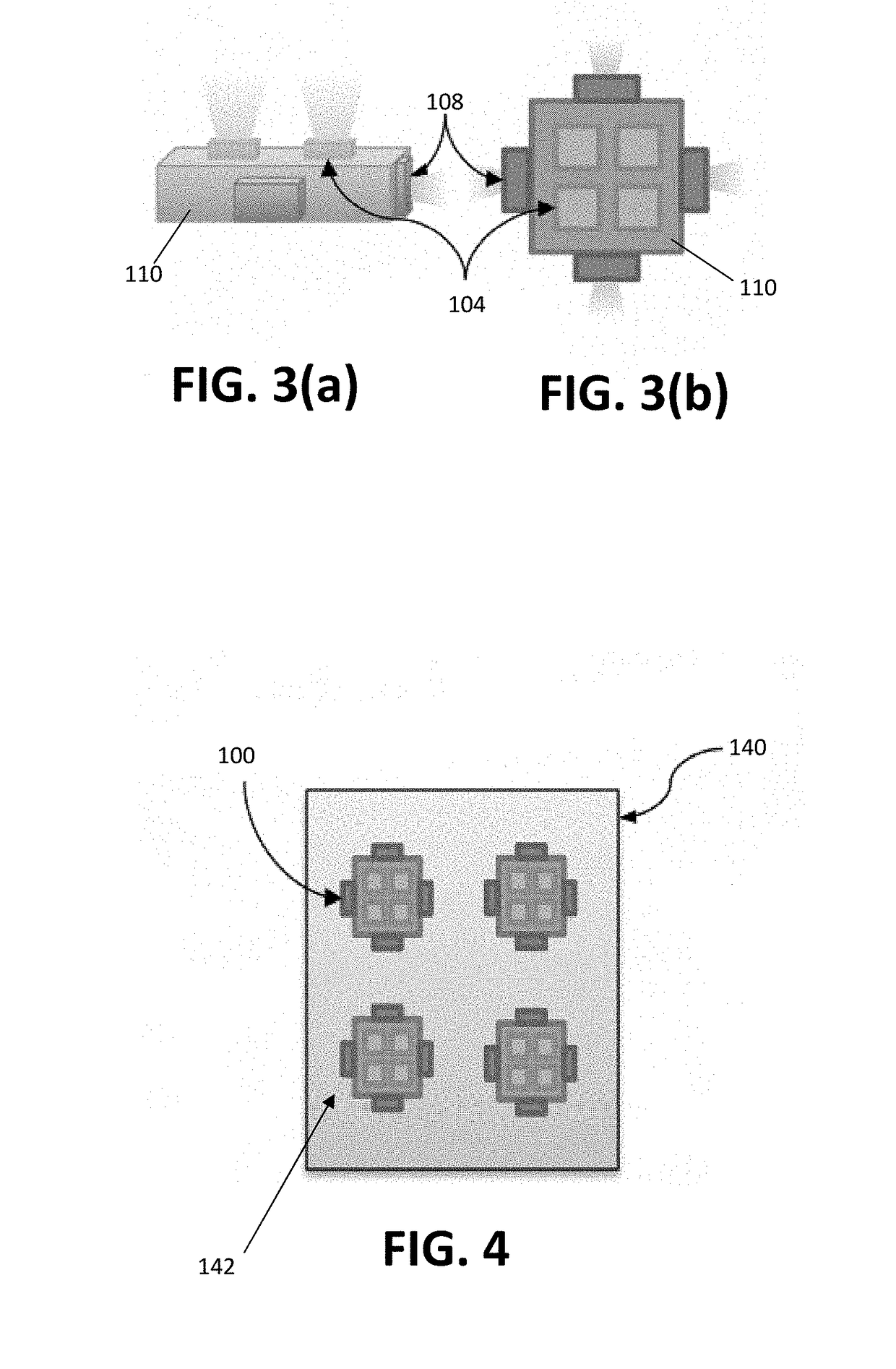

System and method for lighting and building occupant tracking

ActiveUS20170237487A1Less-costly to implementLow costService provisioningParticular environment based servicesComputer moduleComputer science

Disclosed is a system and method for using visible light communication (“VLC”) to perform indoor position location. Through use of a system and method configured as set forth herein, the position of any appropriately marked person or item may be found indoors using data interconnected modules that communicate with one another via RF and visible light. A mobile receiver in the form of a tag or badge attached to the person or item to be tracked receives a VLC signal from a plurality of lighting modules, and transmits back to a processor the data it received so that the processor is able determine the tag's or badge's physical position with respect to the individual network modules.

Owner:MORGAN STATE UNIVERSITY

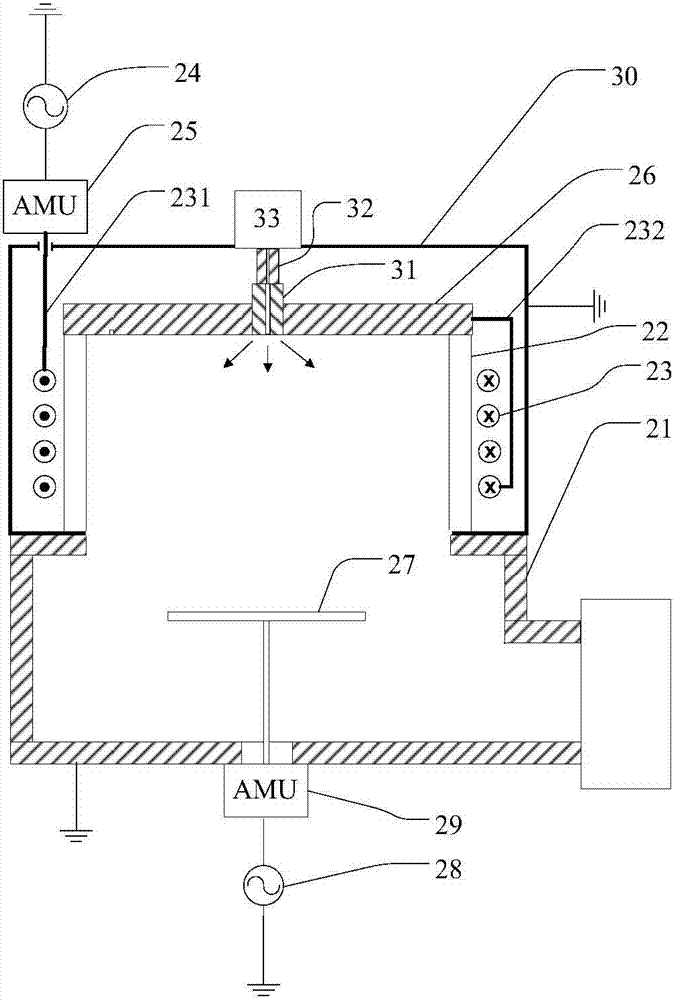

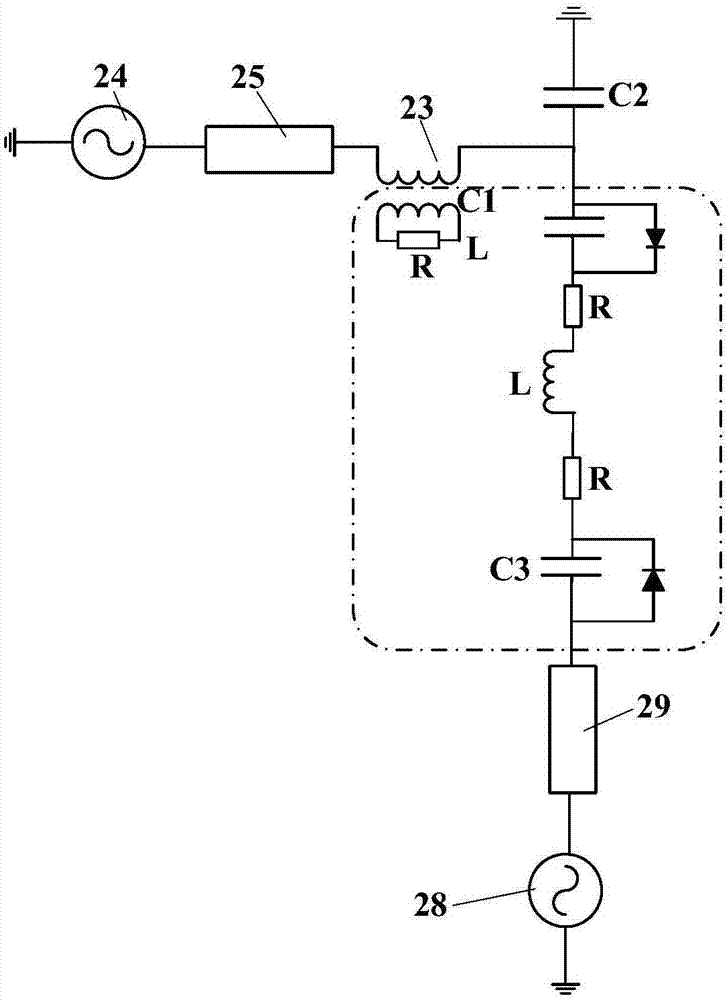

Reaction cavity and semiconductor processing device

ActiveCN107369604AReduce phase differenceUniform density distributionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention provides a reaction cavity and a semiconductor processing device. The reaction cavity comprises a top electrode device and a bottom electrode device, and the bottom electrode device is arranged in the reaction cavity and configured to bear a wafer. The top electrode device comprises a medium cylinder, a coil, a top power source and a top electrode module, and the medium cylinder is arranged at the top of the reaction cavity; the coil is around and arranged at the periphery of the medium cylinder; the top electrode device comprises a top electrode plate, and the top electrode plate is arranged at the top of the medium cylinder; and the top power source is configured to load excitation power to the top electrode plate and the coil at the same time. The reaction cavity can reduce the voltage difference between the output end and the input end of the coil and can weaken the influence generated by a nonuniform electric field so as to improve the plasma density distribution uniformity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

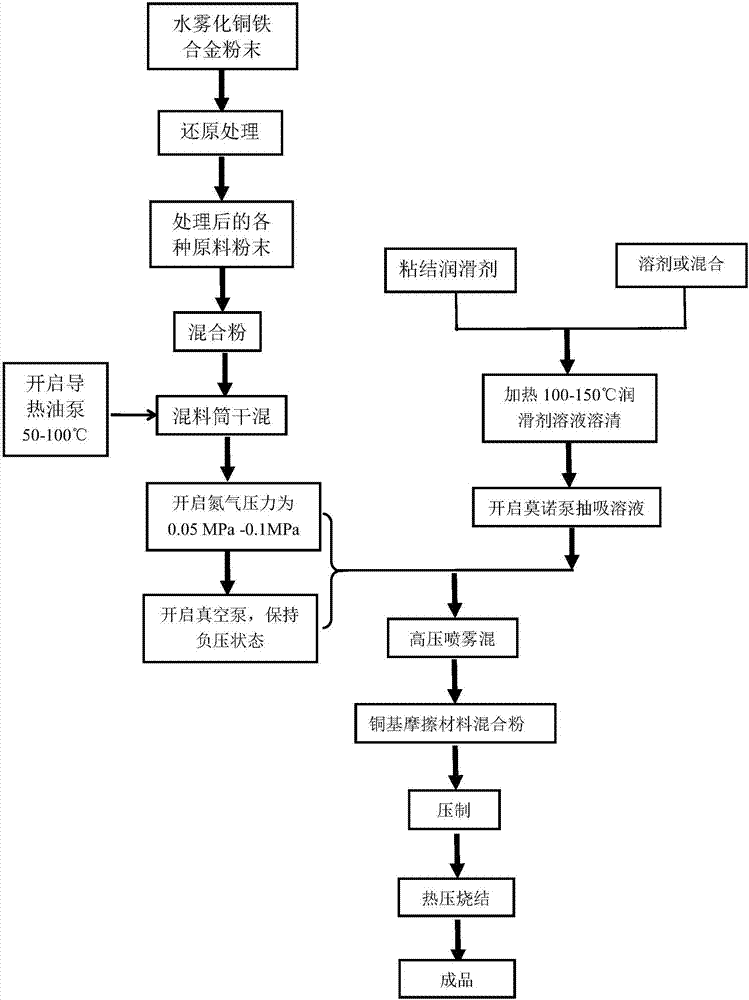

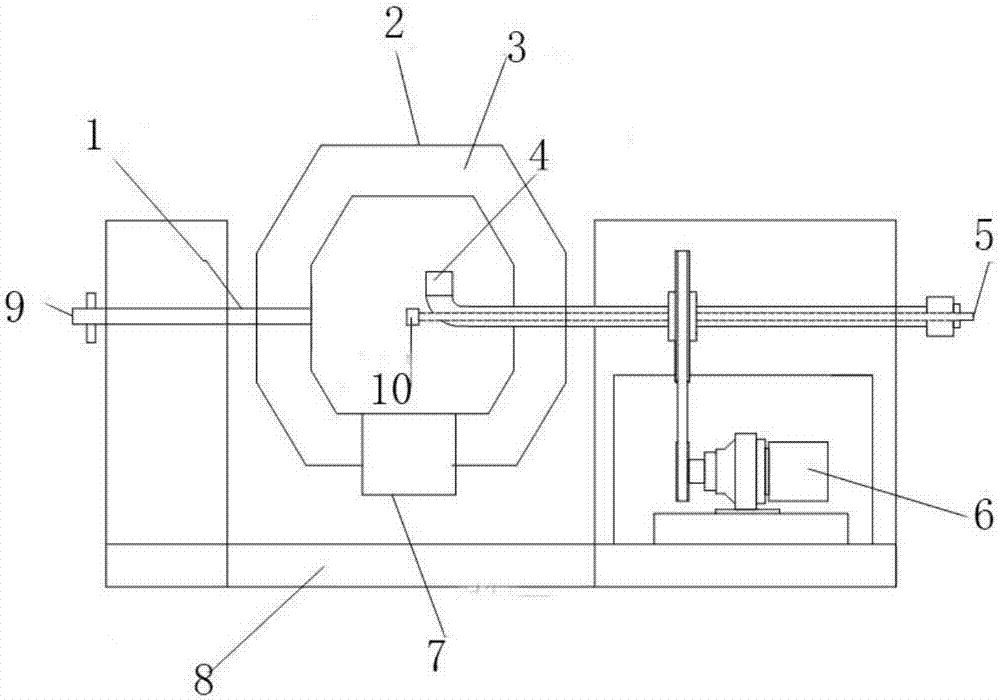

Method for preparing powder metallurgy copper-based friction material through adhesion process

ActiveCN107326205AImprove uniformityUniform compositionTransportation and packagingMetal-working apparatusMaterials scienceTin

The invention discloses a method for preparing a powder metallurgy copper-based friction material through an adhesion process, and belongs to the technical field of preparation of a copper-based high-speed train brake block through a powder metallurgy process. The mass fraction of copper powder in the raw material powder is 60-75%, the grain size of the copper powder is 100-150 [mu]m, the grain size of iron powder is 10-25 [mu]m, the grain size of nickel powder is 10-25 [mu]m, the grain size of tin powder is 10-25 [mu]m, and the grain size of SiO2 is 10-25 [mu]m. Adhesion lubricating agents are added in the mixing process, double-cone spray adhesion treatment is conducted, and accordingly the surfaces of large-granularity copper powder particles are evenly wrapped with fine iron powder, the powder is mixed evenly in proportion and then subjected to cold compression molding, and after hot pressed sintering, the copper-based powder metallurgy brake block prepared by the adhesion process is obtained. Compared with a traditional brake block preparation process, the adhesion process can enhance the powder mixing uniformity, the pressure gradient on the powder in the filling process is reduced, the shrinkage uniformity of the material in the sintering process is improved, and therefore the material component and density distribution are more uniform, and the prepared powder metallurgy copper-based friction material can have the better frictional wear performance.

Owner:山东鲁银新材料科技有限公司

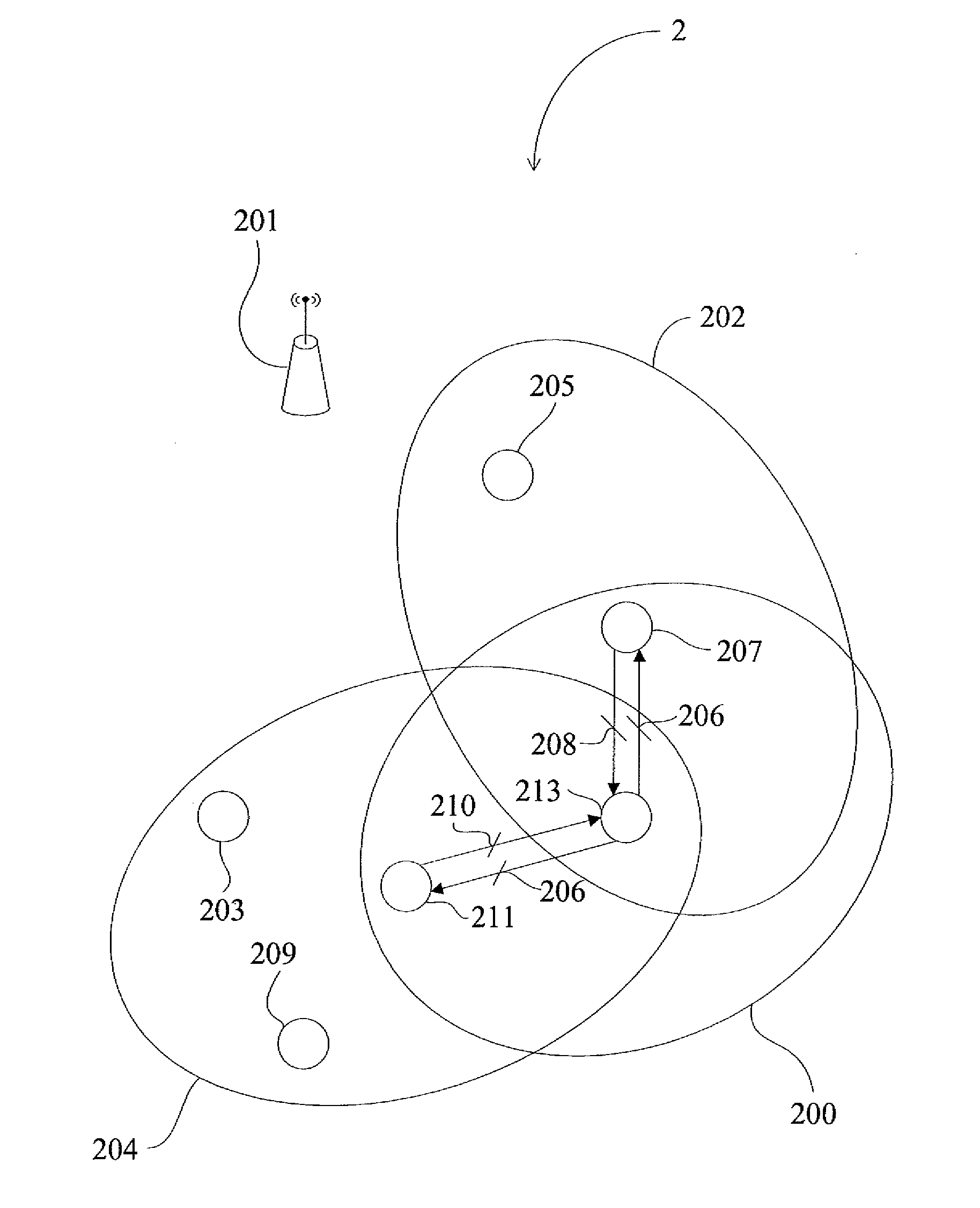

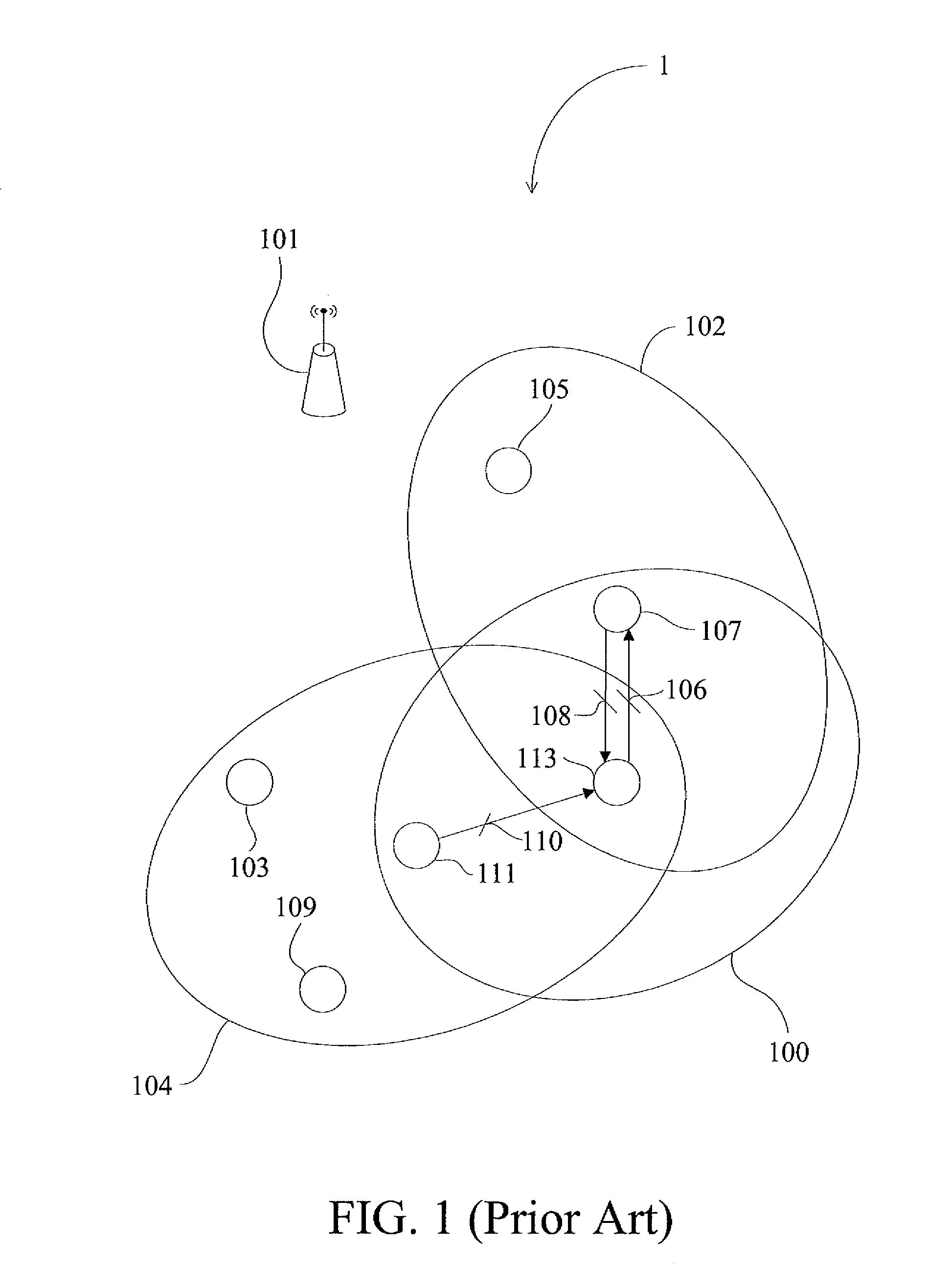

Connection node, method, and computer readable medium thereof for recalculating a transmission opportunity when an apparatus requests to enter a wireless network

InactiveUS20080130552A1Increase usability and efficiencyHigh density distributionAssess restrictionRadio/inductive link selection arrangementsMesh networkingTransmission opportunity

A connection node, a method, a computer program, and a computer readable medium thereof for recalculating a transmission opportunity when an apparatus requests to enter a wireless network are provided. A receiving module receives a mesh network entry message transmitted from the apparatus. A memory stores an identification of a sponsor node. A processing module determines whether an original neighboring node list comprises the identification. If no, the processing module updates the original neighboring node list according to the identification, and recalculates a transmission opportunity of a mesh network configuration message of the connection node. Finally, a transmission module transmits the mesh network configuration message according to the transmission opportunity in order to solve the problem that mesh network configuration messages of nodes collide with each other of the prior art.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

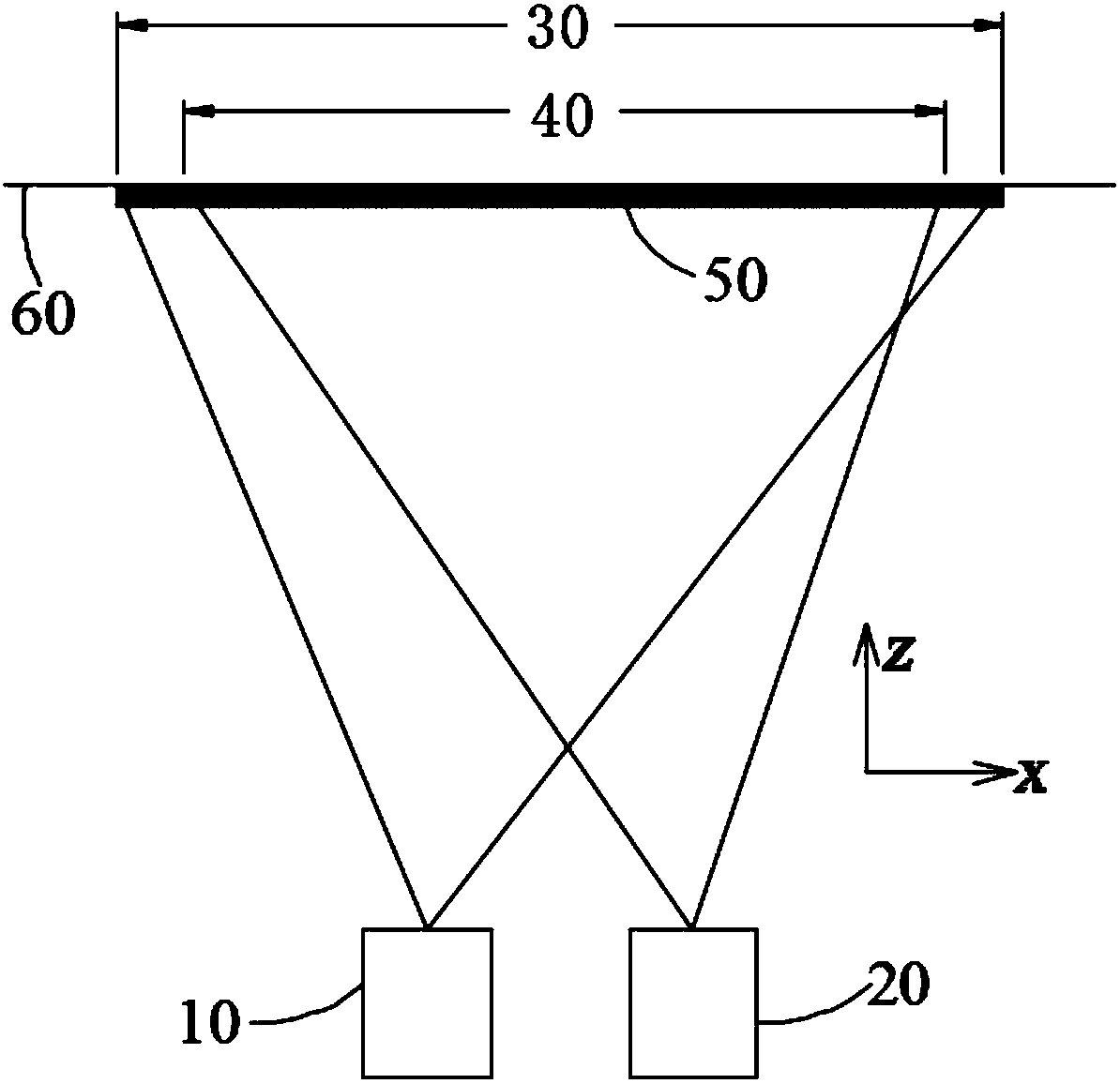

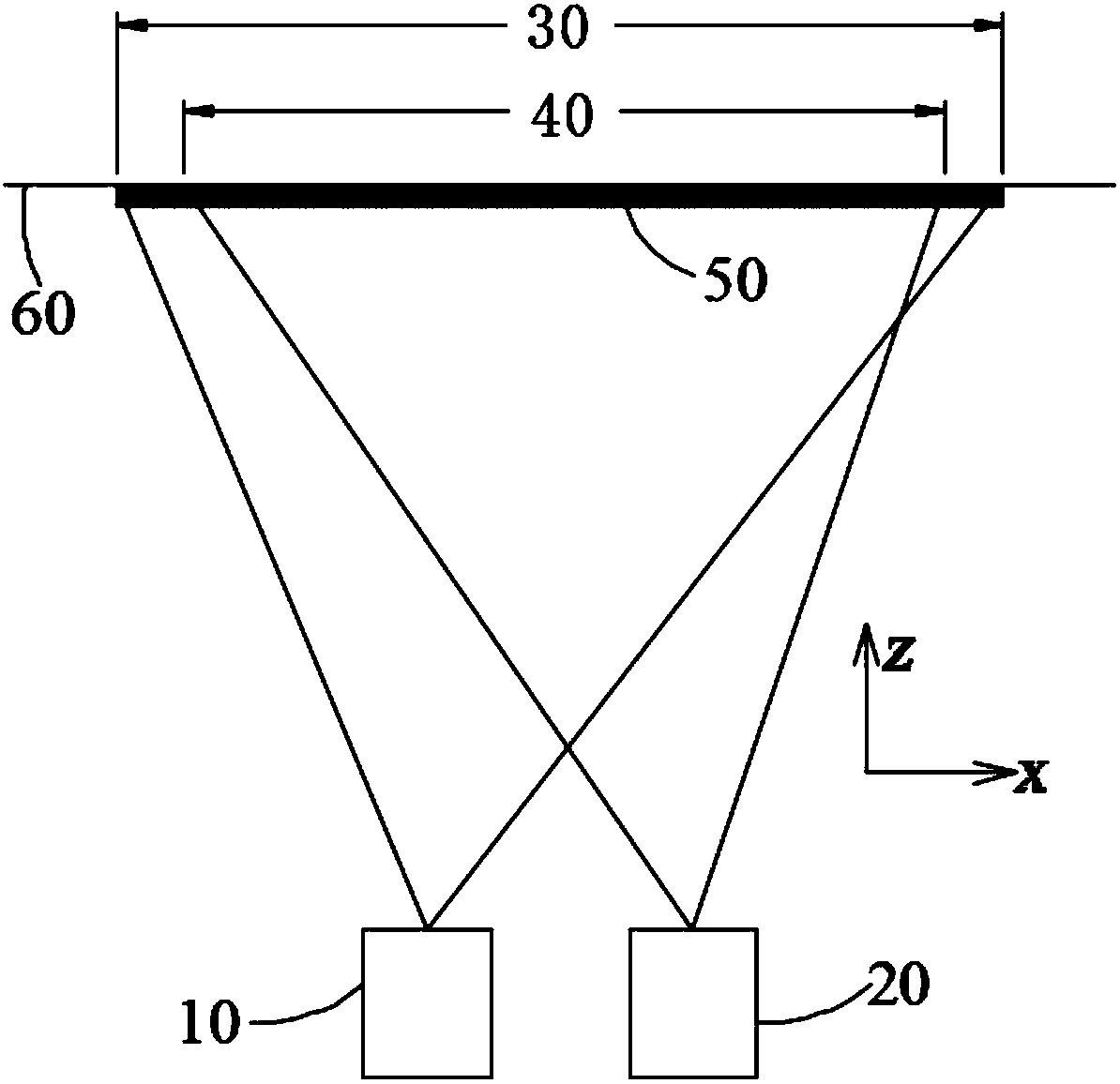

Structured light projection module and depth camera

ActiveCN108594454AEvenly distributedImprove density distributionProjectorsUsing optical meansDiffraction orderDensity distribution

The invention provides a structured light projection module and a depth camera. The structured light projection module comprises a light source array, a lens, and a diffraction optical element, the light source array includes a plurality of sub-light sources arranged in a two-dimensional pattern mode for emitting array light beams corresponding to the two-dimensional pattern; the lens is used forreceiving and converging the array light beams; the diffraction optical element is used for receiving the array light beams which are emitted after being converged by the lens and projecting a structured light spot patterned light beam. The structured light spot pattern is formed by at least two sub-structure light spot patterns through staggering and overlapping; the sub-structure light spot pattern is formed by spreading and arranging a plurality of sub-spot patterns generated by a part of light sources in the plurality of sub-light sources, and each sub-spot pattern is composed of spots ofdifferent diffraction orders formed by diffraction of a single sub-light source through the diffraction optical element. According to the invention, on the basis that the distribution of the structured light patterns is uniform, the density distribution of the structured light patterns is improved, and meanwhile, the structure has very high non-correlation.

Owner:SHENZHEN ORBBEC CO LTD

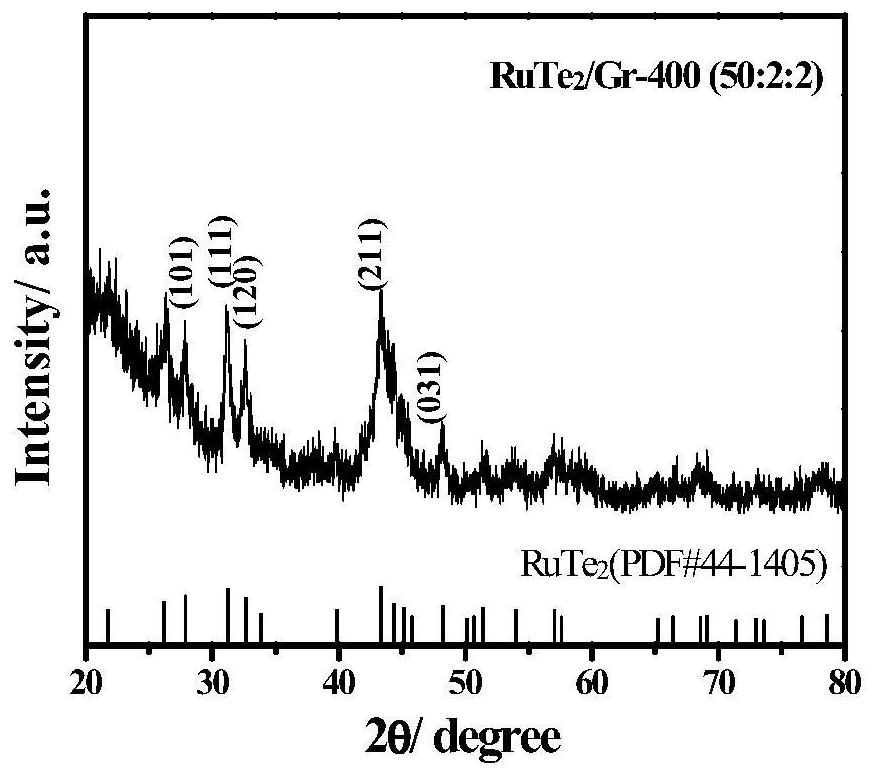

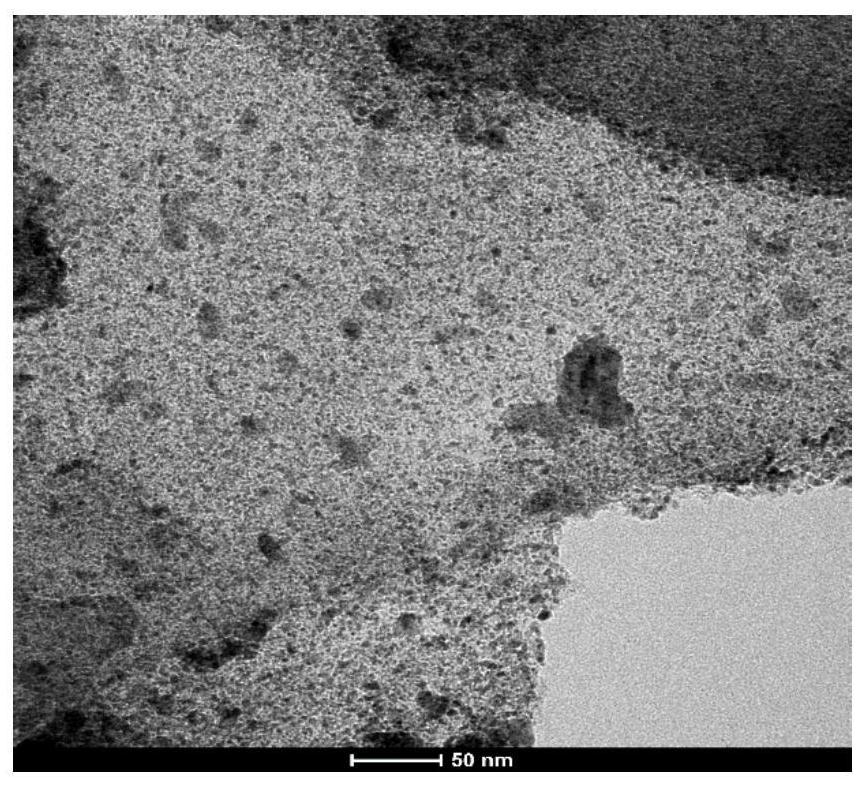

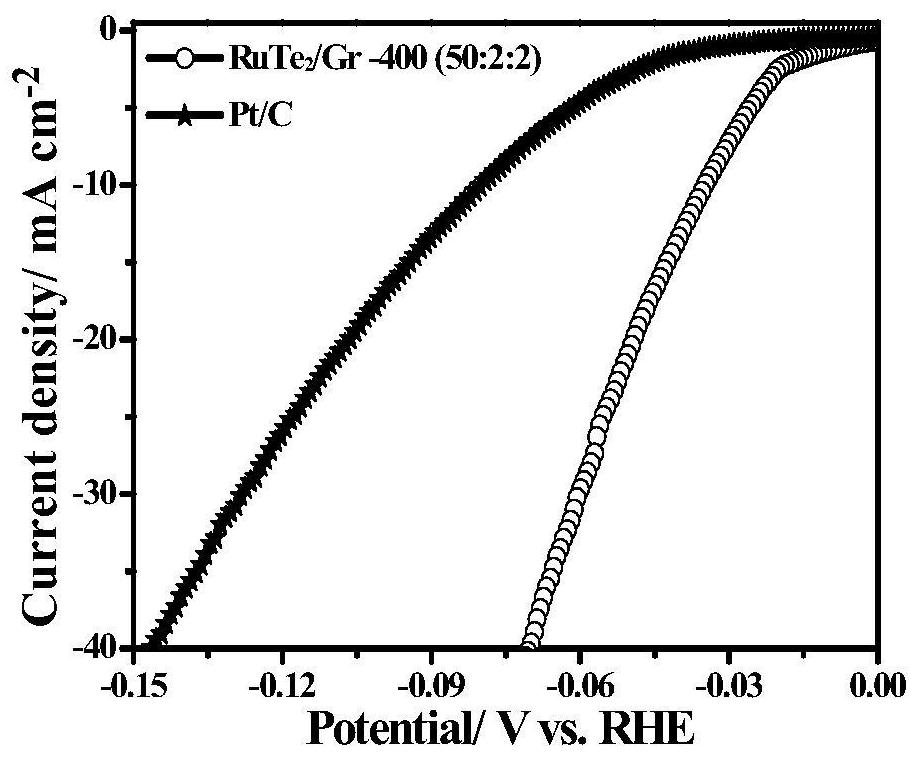

Water electrolysis catalyst based on high catalytic activity and crystallinity RuTe2 and preparation method thereof

ActiveCN111715245AImprove density distributionHigh catalytic activityPhysical/chemical process catalystsElectrodesElectrolytic agentPtru catalyst

The invention discloses a preparation method of a water electrolysis catalyst based on high catalytic activity and crystallinity RuTe2. A carbon material is used as a substrate of the water electrolysis catalyst, and high-crystallinity RuTe2 nano particles are loaded on the substrate. A microwave method and a heat treatment process are adopted; under the action of thermally induced crystallization; the crystallinity of RuTe2 is enhanced along with the rise of the heat treatment temperature; metal Ru and semiconductor Te are coordinated to form the water electrolysis catalyst with high catalytic activity, the water electrolysis catalyst shows excellent HER and OER performances in electrolytes with different pH values, the catalyst can be assembled into a two electrode system, and the performance of the system is superior to that of Pt / C-RuO2. The catalyst has the advantages of simpleness, easy application, and low production cost, is suitable for batch production, and can be widely applied to the fields of water electrolysis industry, solar water electrolysis hydrogen production, fuel cells, organic synthesis and the like.

Owner:YANGZHOU UNIV

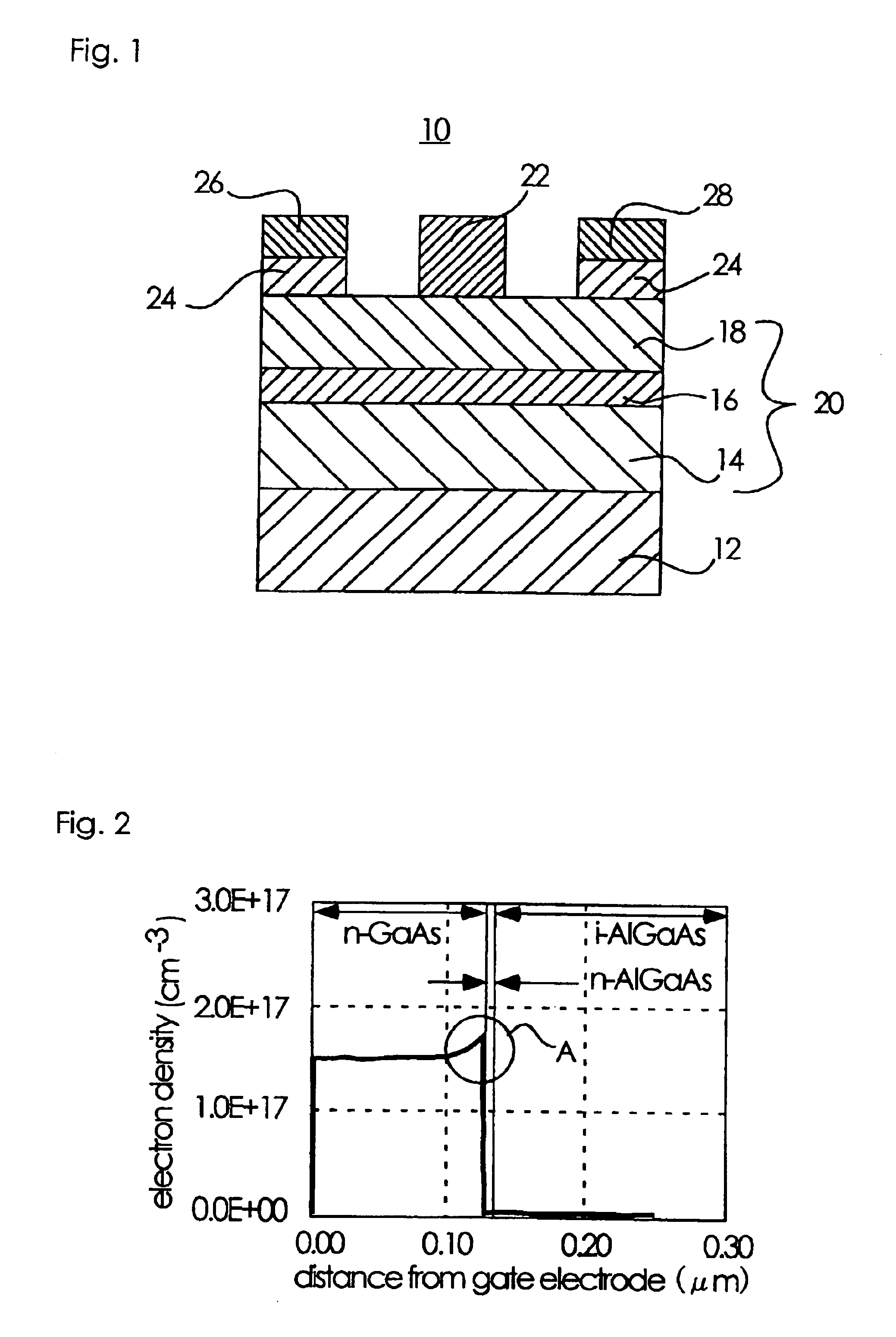

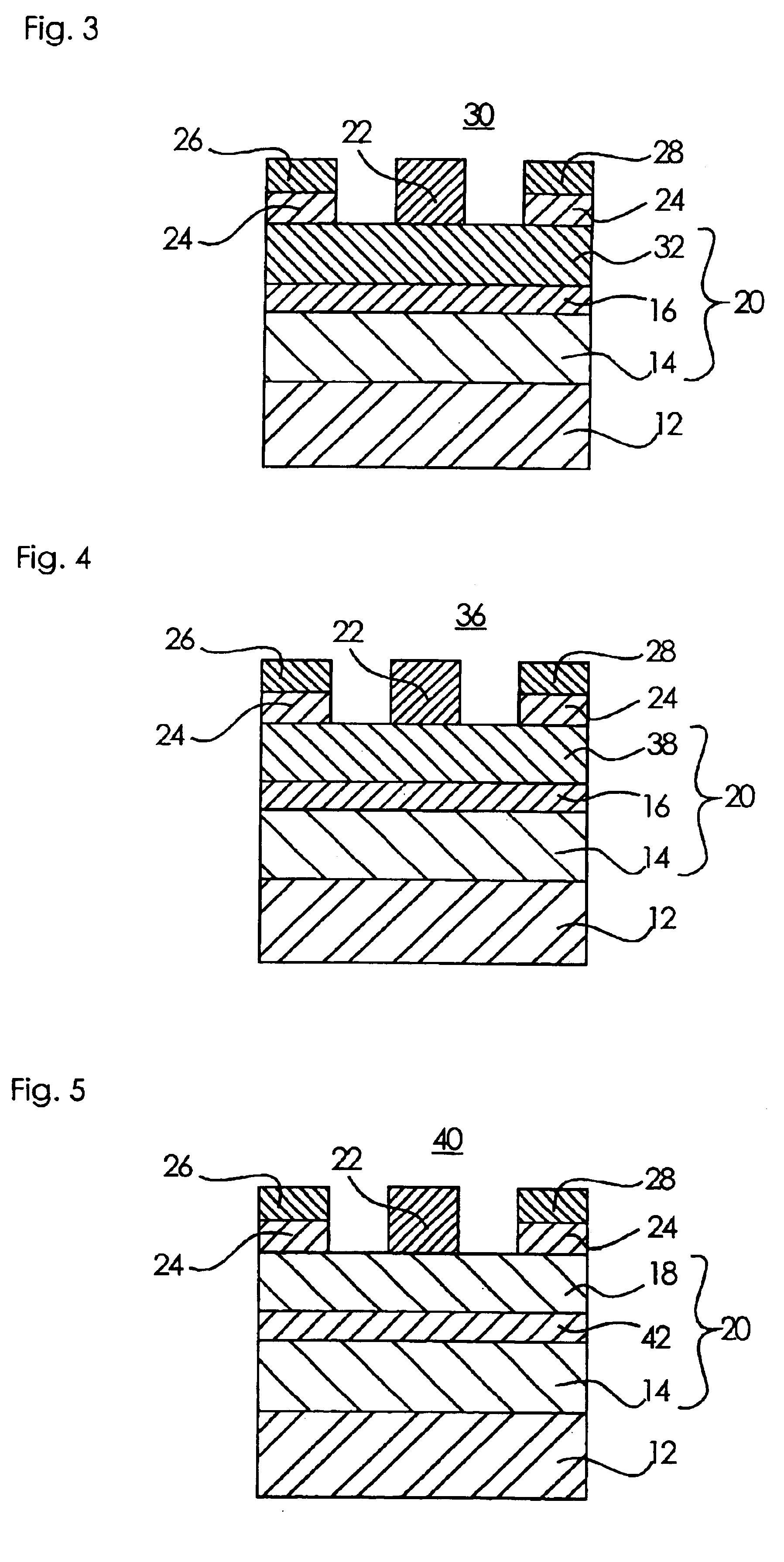

Field effect transistor

ActiveUS6946691B2Prevent degradationSatisfactory drain conductance (gd)Watering devicesSemiconductor/solid-state device manufacturingImpurity dopingMESFET

An MESFET is configured wherein a semiconductor layer structure including an i-AlGaAs buffer layer, an n-AlGaAs electron supply layer having an impurity doping density ranging from 1×1017 cm−3 to 1×1018 cm−3 and a layer thickness ranging from 1 nm to 10 nm, and an n-GaAs channel layer, all of which are sequentially deposited from the semi-insulating GaAs substrate side, is disposed on the semi-insulating GaAs substrate, a gate electrode is provided on the n-GaAs channel layer, and a source electrode and a drain electrode opposite to each other with the gate electrode interposed therebetween are provided.

Owner:MITSUBISHI ELECTRIC CORP

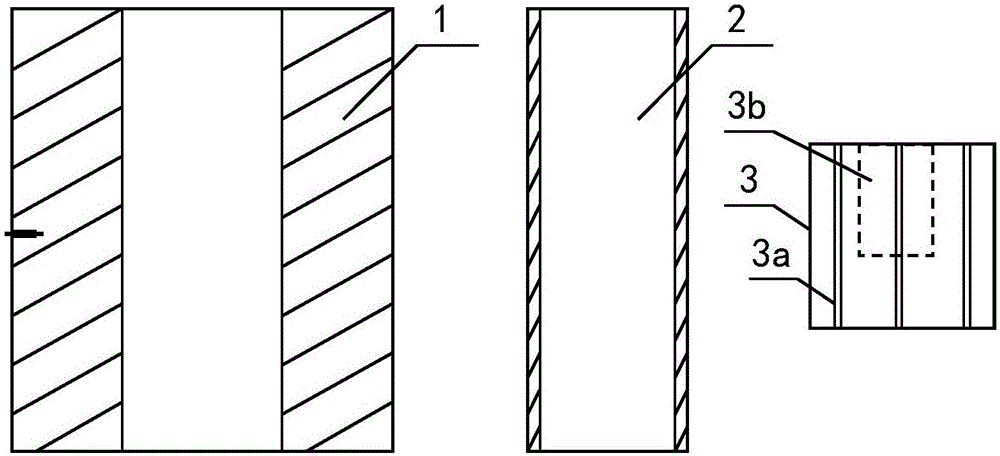

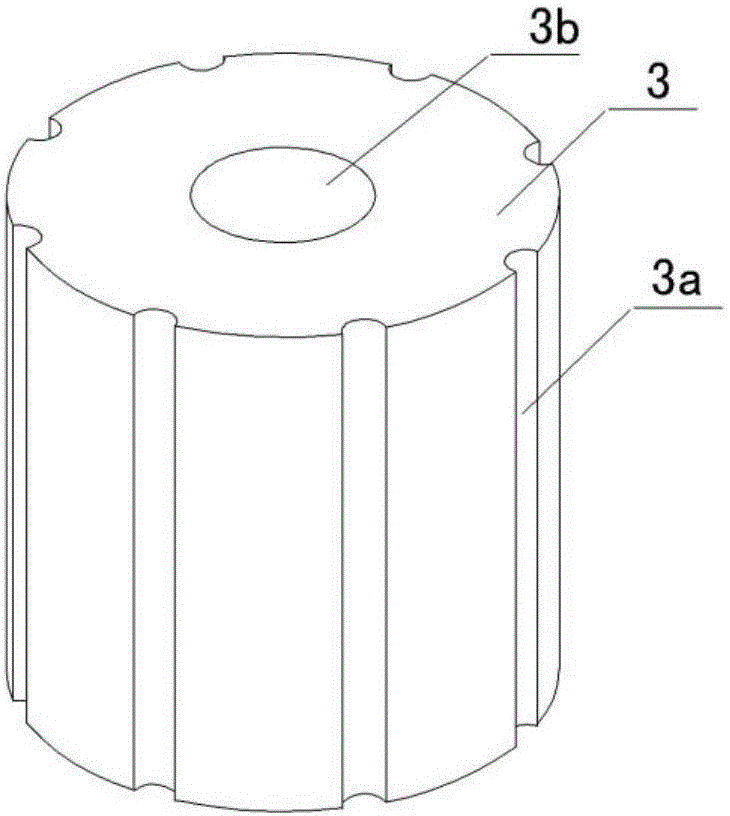

Bi-directional powder pressing forming device capable of demoulding automatically

InactiveCN103273678BImprove density distributionIncrease production speedShaping pressHydraulic cylinderDensity distribution

The invention discloses a bi-directional powder pressing forming device capable of demoulding automatically. An upper mould frame is connected with a lower mould frame through guide columns; and the lower mould frame is fixed on the base board. An upper mould stamping is connected with an upper mould connecting rod which is connected with a first hydraulic cylinder. A lower mould stamping is fixed on the lower mould frame. Female moulds are mounted on the corresponding guide columns through four holes on two sides. Springs are sleeved on the corresponding guide columns of the lower faces of the females moulds and the upper face of the lower mould frame. The female moulds can float on the springs, and each is provided with a heating bar and a thermoelectric couple internally. One ends of four ejection rods are fixed on an ejection rod fixing plate, and the other ends of the ejection rods penetrate the upper mould frame and is located above the female mould. The ejection rod fixing plate is connected with a second hydraulic cylinder. By the aid of the spring floating female mould and the ejection rod structure, bi-directional pressing and automatic demoulding are achieved accurately, density distribution of a workpiece is improved, and production speed is increased. With a multi-punch and multiple-moulding-chamber structure, multiple workpieces can be produced by pressing at one time, mass production can be realized, and device utilization rate and working efficiency are increased.

Owner:ZHEJIANG UNIV

Soft polyurethane foam with excellent density distribution

ActiveCN109851843AExcellent density distributionUniform density distributionDensity distributionChemistry

The invention discloses soft polyurethane foam with excellent density distribution, and belongs to the technical field of polyurethane. The problems that in the prior art, density distribution of foamis not uniform, foam holes are poor and a foaming process is not stable are solved. According to the invention, an synthesized organic silicon surfactant with a relatively low density and a relatively low density gradient is firstly applied to preparation of the polyurethane foam, so that the density distribution of the synthesized polyurethane foam is more uniform, foam holes are more excellent,emulsification performance is better, and the foaming process is more stable.

Owner:南京美思德新材料有限公司

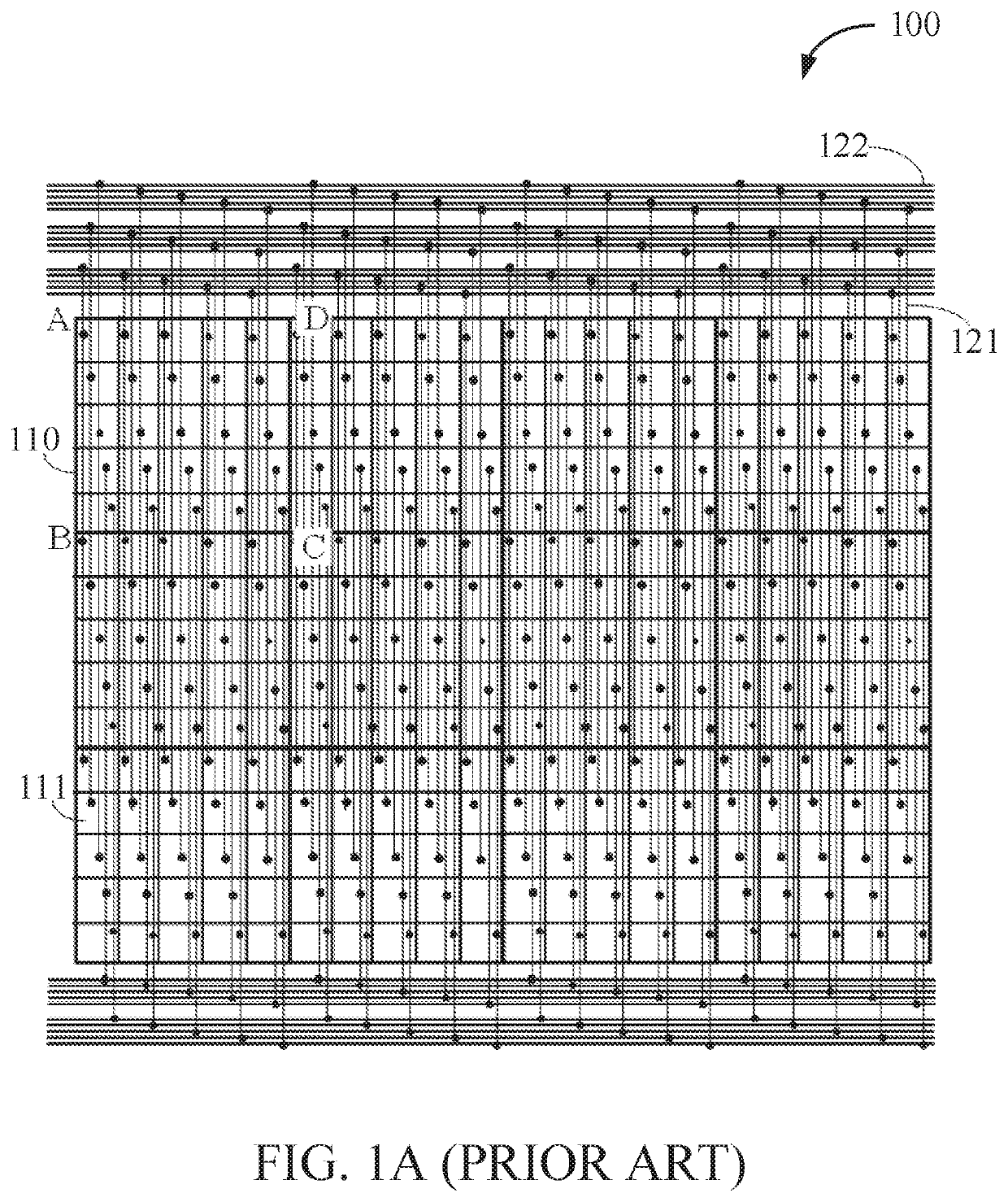

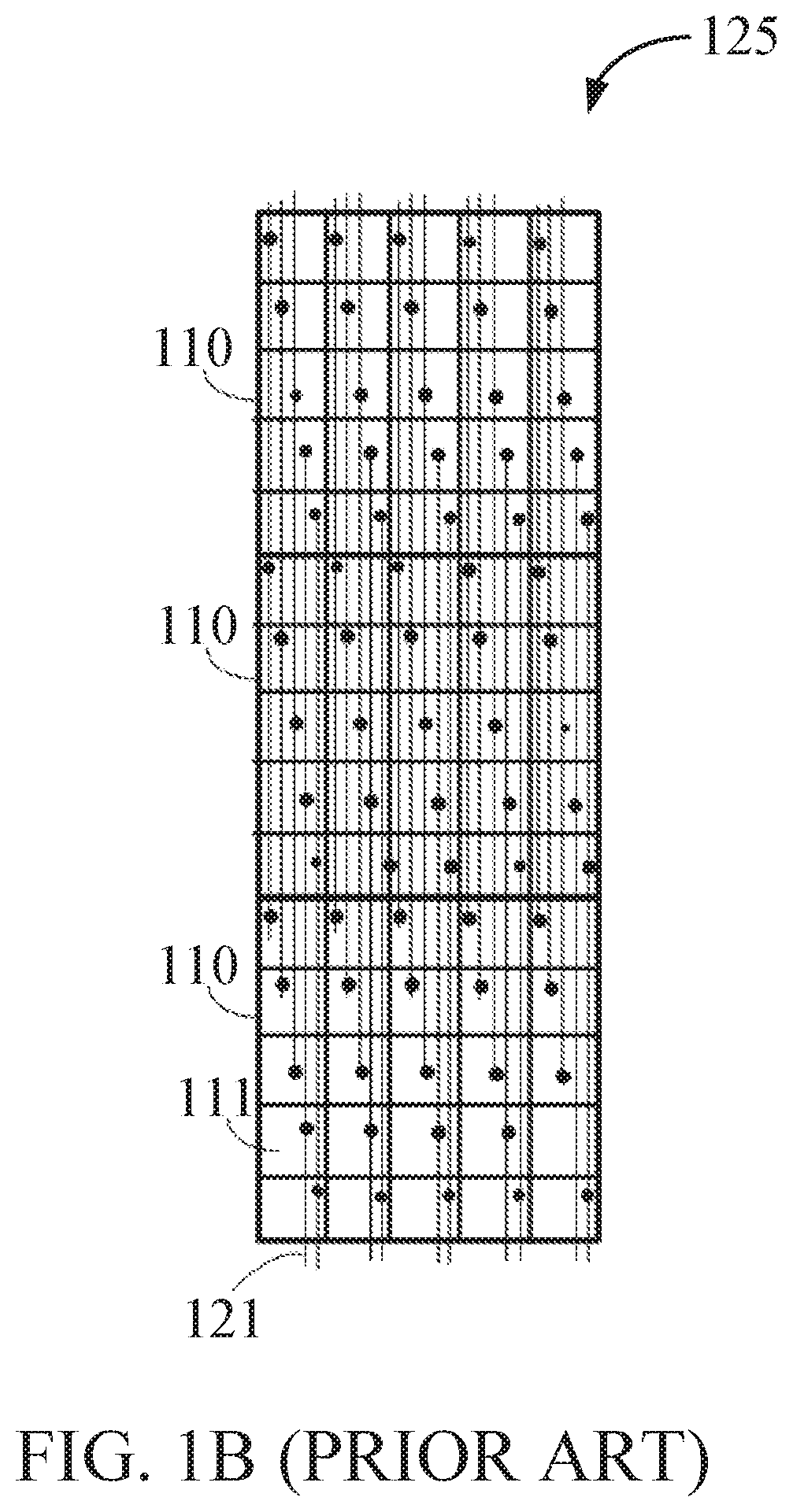

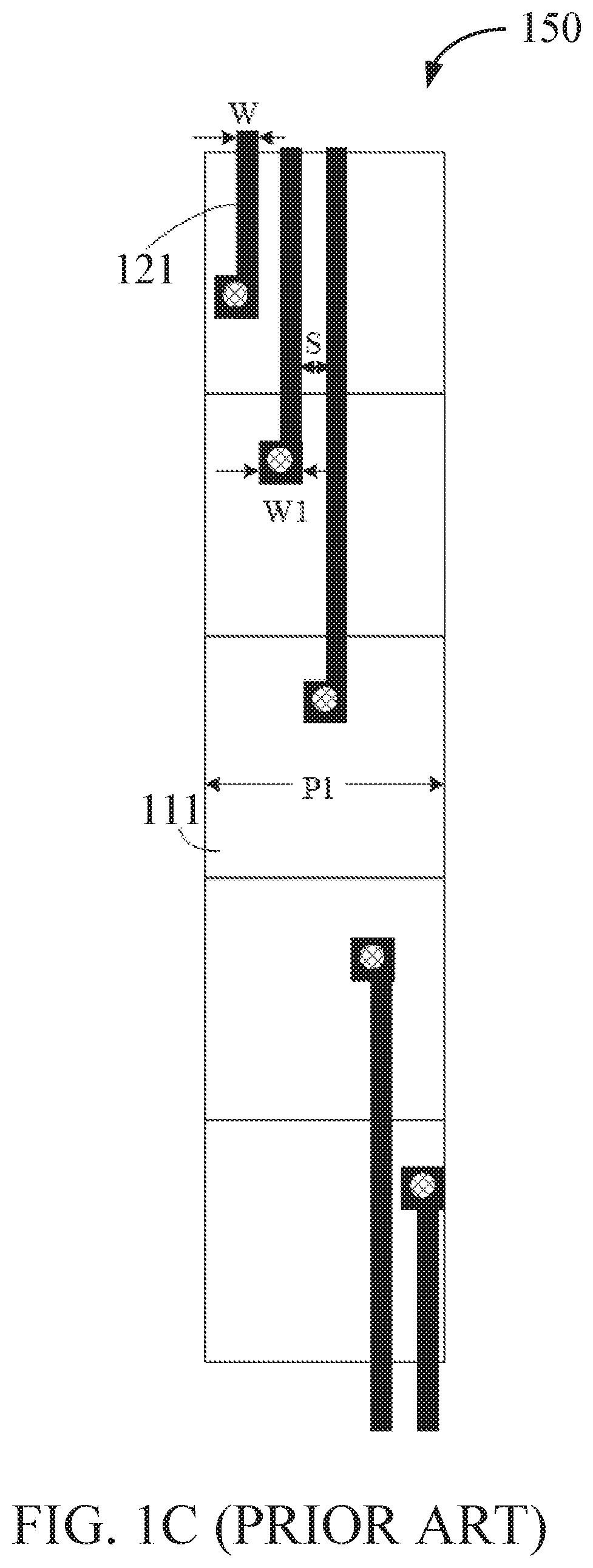

Array substrate and light field display device with overlapping signal lines

ActiveUS11398540B2Improve density distributionSmall sizeStatic indicating devicesSolid-state devicesDisplay deviceEngineering

An array substrate is provided, including a substrate, wherein the substrate is provided with a plurality of electrodes and a plurality of first signal lines, each of the electrodes being correspondingly connected with a first signal line. In some examples, the first signal lines extend in the same direction. In some examples, at least two of the plurality of first signal lines are located in different layers of an insulating spacer from each other. In some examples, orthographic projections on the substrate of at least two of the first signal lines in the different layers at least partially overlap. Accordingly, a light field display device comprising the array substrate is also provided. The array substrate can reduce a light-emitting point size and increase a density distribution of light-emitting points.

Owner:BOE TECH GRP CO LTD

Powder metallurgical material, production method and application thereof

This invention relates to power metallurgical material, production method and application thereof. A metallurgy powder material with pressure-proof & good compactness, satisfactory to the component content requirements for 316 stainless steel, wherein, 5˜9% (by weight) of Fe3P (or Fe3PO4). The powder metallurgical material has properties of pressure resistance and corrosion resistance, and excellent compactness.

Owner:SHANGHAI XINGLUO SPECIAL SEALS

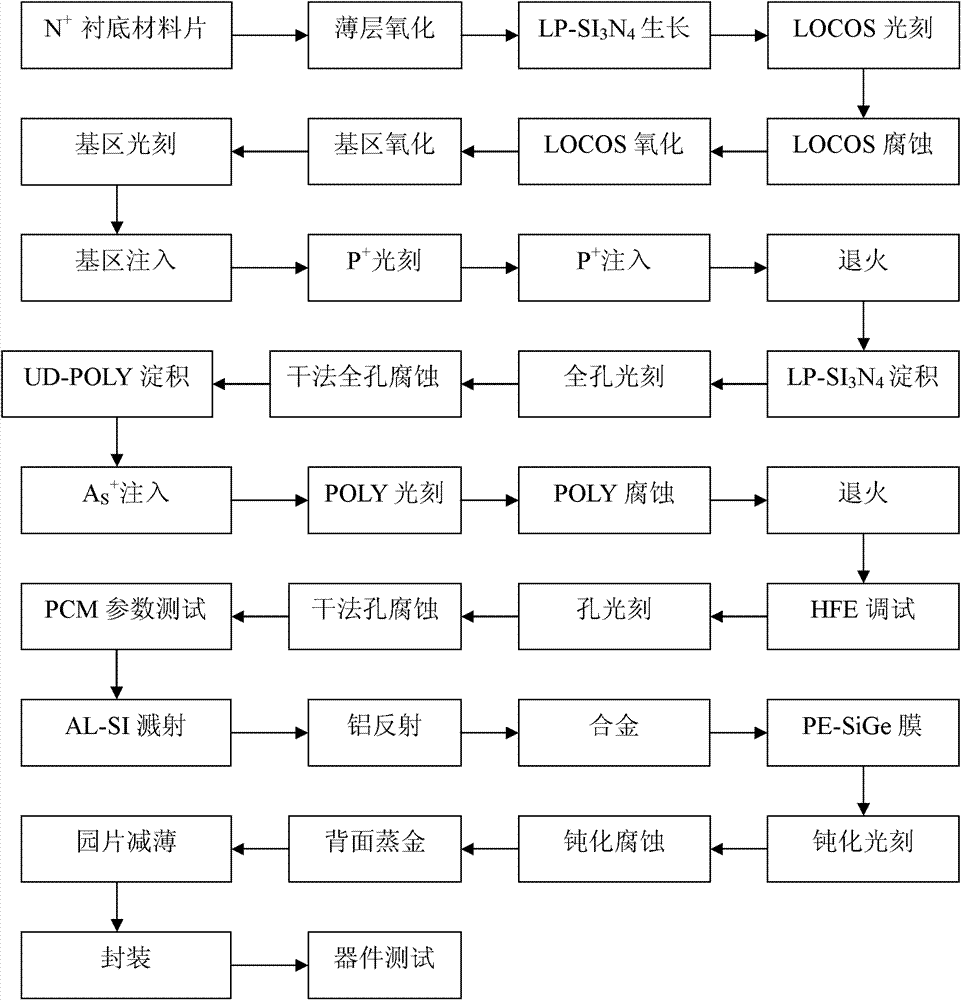

Low-capacitance high-speed transmission semiconductor surge protection device

InactiveCN102769026AImprove density distributionEven transient heat distributionThyristorEmergency protective arrangements for limiting excess voltage/currentCapacitanceMicrometer

The invention discloses a low-capacitance high-speed transmission semiconductor surge protection device. The PN (P-type / N-type) junction is a flat PN junction equilibrium junction. Transmitting areas of the semiconductor surge protection device are filled for two times; the thickness of the P-area is increased by 10-20%; the thickness of the N-area is reduced by 10-20%; the N+substrate is a silicon wafer of which the two sides are polished; the thickness of the wafer ranges from 200-300 micrometers; and the resistivity is 20-22%. By adopting a flat PN junction equilibrium junction structure, the density distribution of the current is improved; by adopting the technology of increasing the thickness of the P-area, filling the transmitting area for two times, adopting a field plate and the like, a reverse breakdown voltage of a control tube EB (electron beam) is increased, and the contradiction between the reverse breakdown voltage of an EB junction and beta is solved; through the control to the beta of NPN (N-P-N type) of a quadruple structure thyristor, the problem of controlling the maintaining current and the breakover current is solved; and by decreasing the contact voltage and thinning the N-area, the minor carrier lifetime is increased.

Owner:江苏锦丰电子有限公司

System and method for lighting and building occupant tracking

ActiveUS9973275B2Less-costly to implementLow costService provisioningBeacon systems using electromagnetic wavesEffect lightComputer science

Disclosed is a system and method for using visible light communication (“VLC”) to perform indoor position location. Through use of a system and method configured as set forth herein, the position of any appropriately marked person or item may be found indoors using data interconnected modules that communicate with one another via RF and visible light. A mobile receiver in the form of a tag or badge attached to the person or item to be tracked receives a VLC signal from a plurality of lighting modules, and transmits back to a processor the data it received so that the processor is able determine the tag's or badge's physical position with respect to the individual network modules.

Owner:MORGAN STATE UNIVERSITY

Polysiloxane polyether copolymers having (polyether)moieties comprising carbonate groups and their use as stabilizers for the production of polyurethane foams

InactiveUS9657144B2Improve distributionBalanced property profileSilicon organic compoundsCopolymerCarbonate

The present invention relates to polysiloxane polyether copolymers which comprise at least one (polyether) moiety which comprises at least one unit —O—C(O)—O—, to a process for the production of the polysiloxane polyether copolymers, and also to the use of the polysiloxane polyether copolymers as stabilizers in the production of polyurethane foams, and also to polyurethane foams and items therefrom which are obtainable through the process.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com