Structured light projection module group and depth camera

A structured light projection and structured light technology, applied in optics, optical components, optical devices, etc., can solve the problem of uniform density distribution of projection patterns of difficult structured light projection modules, achieve high irrelevance, improve density distribution, Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

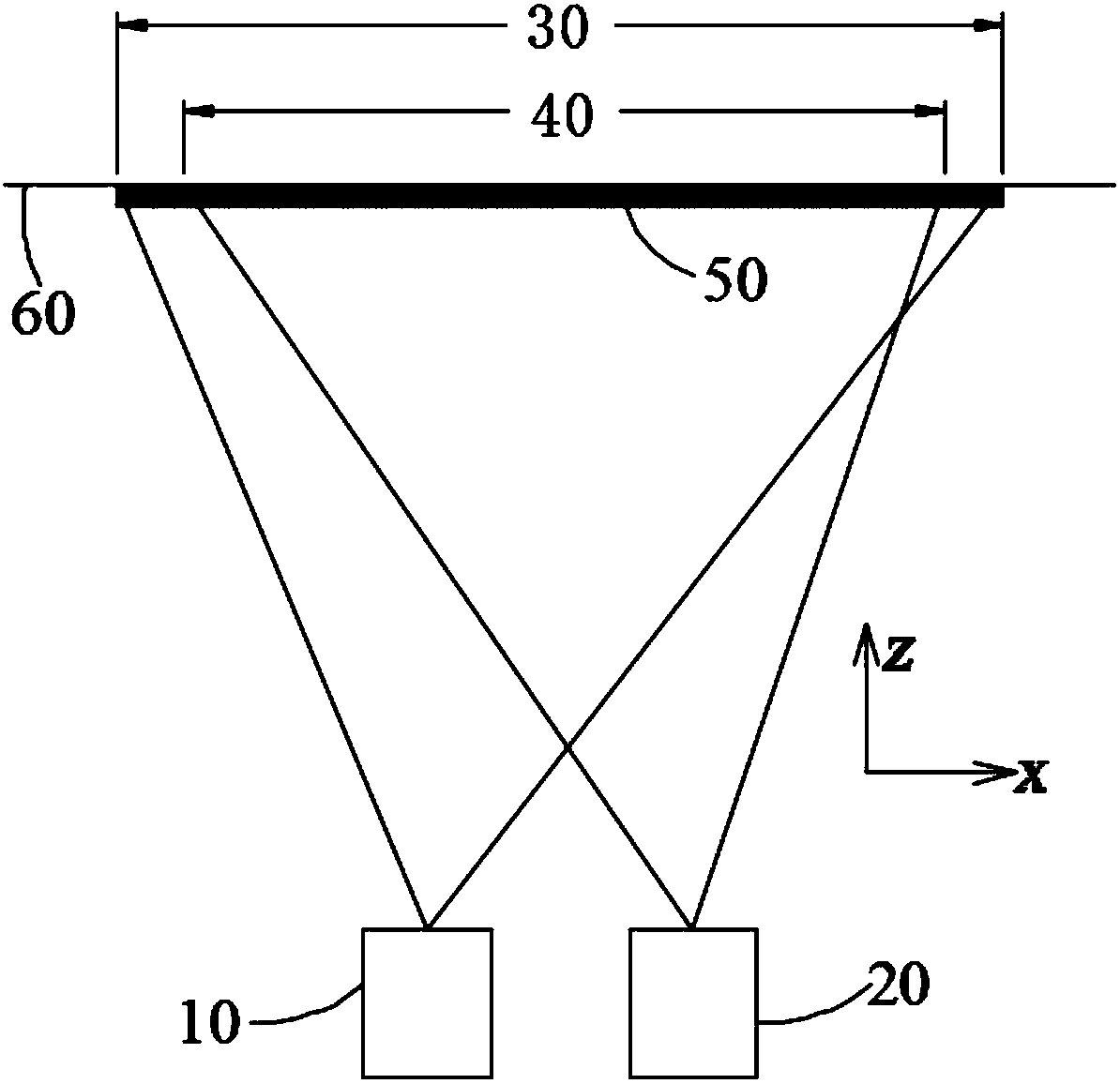

[0033] figure 1 It is a schematic diagram of a structured light depth camera according to an embodiment of the present invention. The depth camera includes a structured light projection module 10 and an acquisition module 20. The structured light projection module 10 is used to project a structured light beam into space. When the structured light beam irradiates on the plane 60, structured light will be generated on the area 30 pattern 50, the collection module 20 is used to collect structured light images on objects in its collection area 40, and generally the projection area 30 is not smaller than the collection area 40, so as to ensure that the objects in the collection area corresponding to the collection module can be structured covered by the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com