Outer conical surface type electrostatic spinning sprayer assisted by airflow

An electrospinning, outer cone technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of uneven distribution of fiber diameter, reduce fiber diameter, fiber disturbance, etc. Diameter, increasing distribution density, effect of increasing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

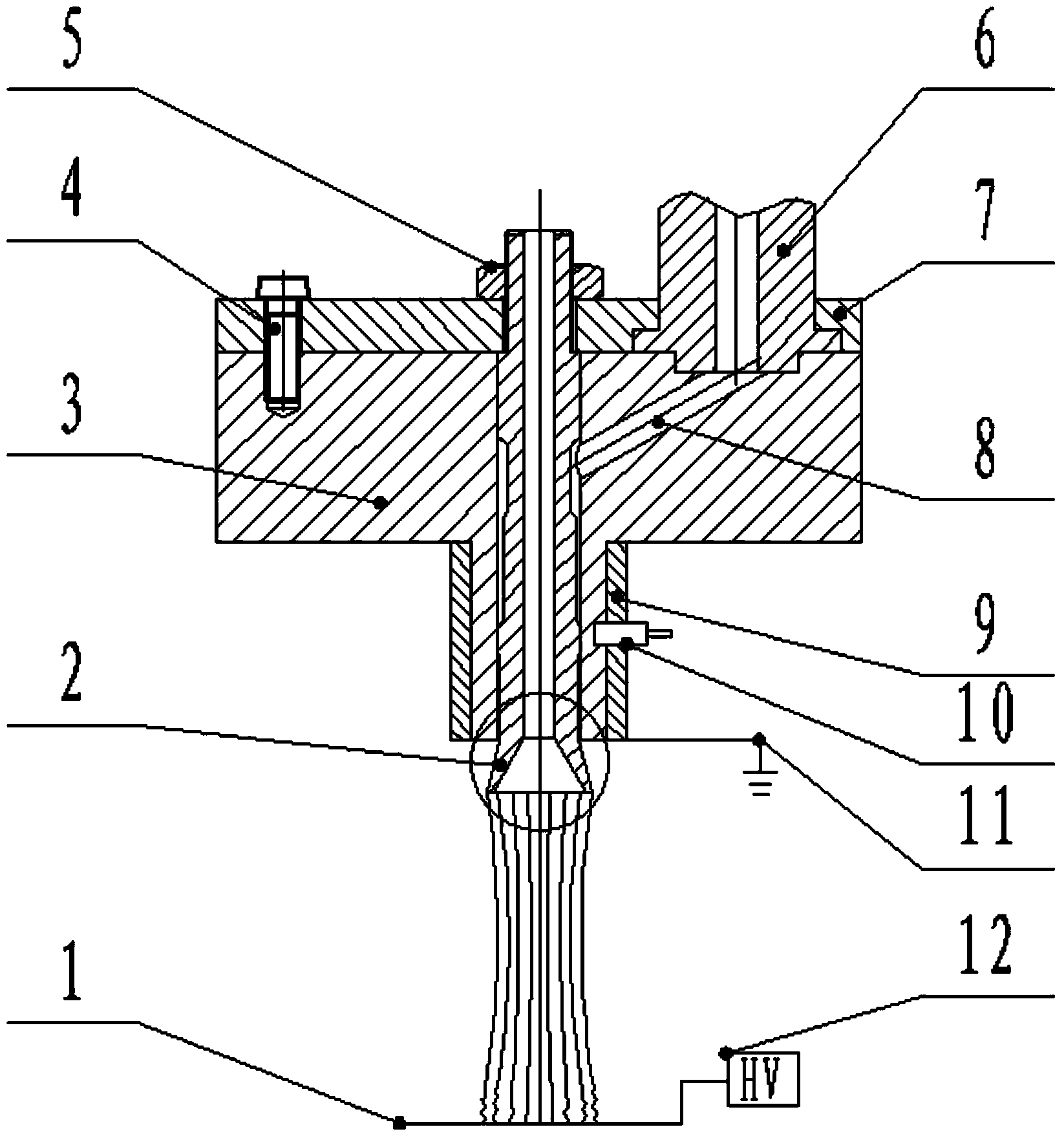

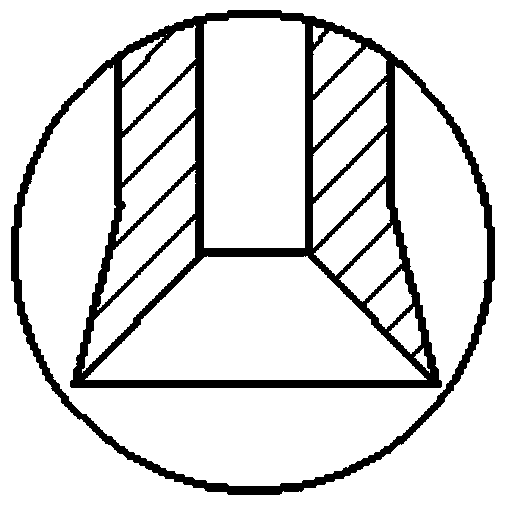

[0021] The present invention proposes an airflow-assisted outer cone type electrospinning nozzle, such as figure 1 and figure 2 As shown, it mainly includes: fiber receiving plate 1, outer cone airflow duct 2, machine head 3, screw 4, material barrel 6, material barrel fixing block 7, machine head flow channel 8, heating ring 9, temperature sensor 10, grounding The electrode 11 and the high-voltage electrostatic generator 12, the fiber receiving plate 1 are fixed at a distance of 12 cm below the outer cone airflow conduit 2, the positioning point on the outer cone airflow conduit 2 is tightly connected to the inner cylindrical hole of the machine head 3, and the barrel 6. The lower end is installed on the flow channel 8 of the machine head 3, and fixed on the machine head 3 through the barrel fixing block 7. The lower end of the machine head 3 is connected to the ground electrode 11, and the fiber receiving plate 1 is connected to the high-voltage electrostatic generator 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com