Manufacturing method for large-size high-density high-uniformity CuCr alloy

A manufacturing method and high-density technology are applied in the manufacturing field of copper-based vacuum contact materials to achieve the effects of improving current density distribution, simple process and accelerating gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The large-size CuCr alloy of this embodiment is carried out as follows:

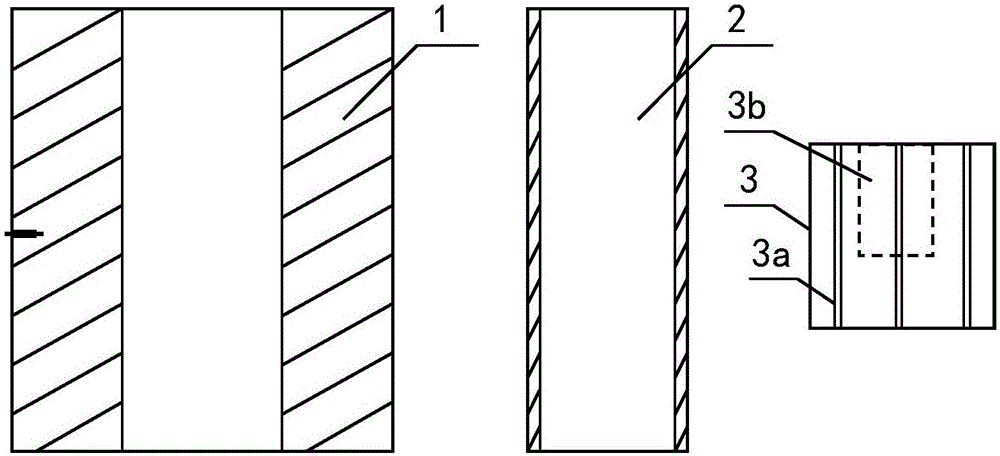

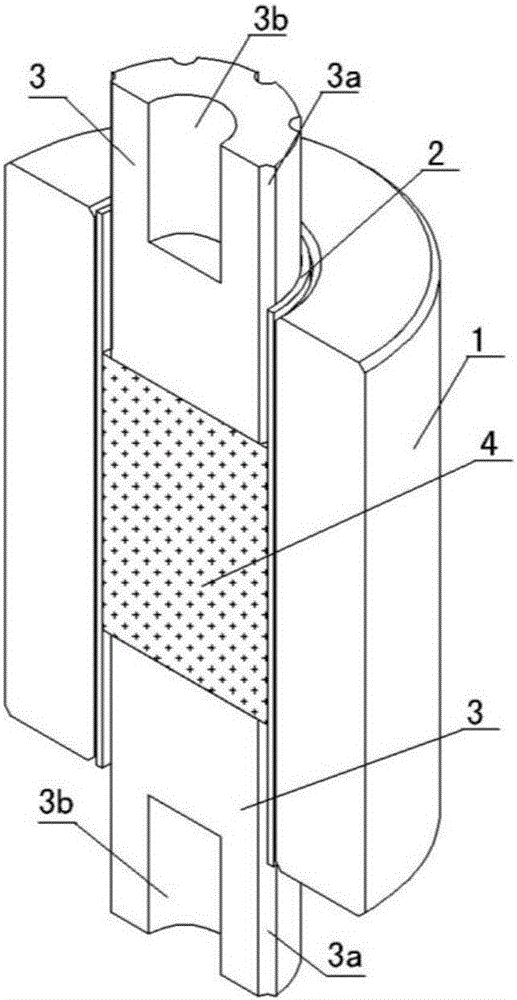

[0034] Step 1. Weigh 7.0 kg of Cu powder and 3.0 kg of Cr powder, and mix for 10 hours by mechanical mixing to obtain uniform CuCr mixed powder; weigh 3.35 kg of CuCr mixed powder for sintering;

[0035] Step 2. Fill the weighed CuCr mixed powder into the graphite mold; use a manual hydraulic press to pre-press the graphite mold with the CuCr mixed powder, and the pressure is ~10MPa;

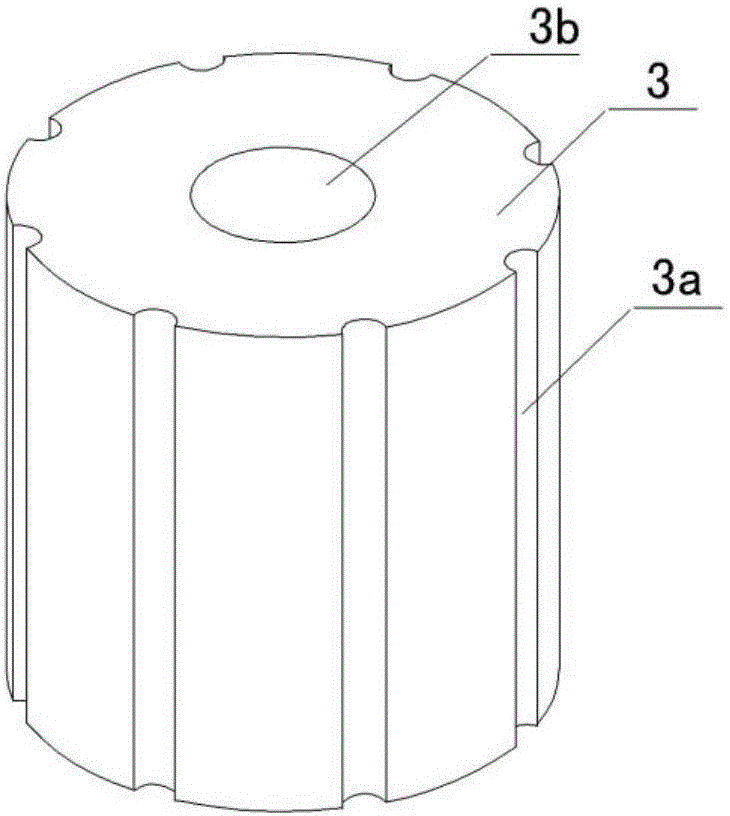

[0036] Step 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold with CuCr mixed powder, then place it in the hearth of the spark plasma sintering system, evacuate it to below 5Pa, pass a DC pulse current, and mix the CuCr The powder is consolidated and formed, and the process conditions are:

[0037] The axial pressure is 30MPa;

[0038] The heating rate is 15℃ / min(≤300℃) and 35℃ / min(> 300℃);

[0039] The sintering temperature is 850℃;

[0040] Holding time is 5min;

[0041] After cooling in the furnace, a CuCr...

Embodiment 2

[0043] The large-size CuCr alloy of this embodiment is carried out as follows:

[0044] Step 1. Weigh 14.0kg of Cu powder and 6.0kg of Cr powder, and mix for 10h by mechanical mixing method to obtain uniform CuCr mixed powder; Weigh 5.66kg of CuCr mixed powder for sintering;

[0045] Step 2. Fill the weighed CuCr mixed powder into the graphite mold; use a manual hydraulic press to pre-press the graphite mold with the CuCr mixed powder, and the pressure is ~10MPa;

[0046] Step 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold with CuCr mixed powder, then place it in the hearth of the spark plasma sintering system, evacuate it to below 5Pa, pass a DC pulse current, and mix the CuCr The powder is consolidated and formed, and the process conditions are:

[0047] The axial pressure is 60MPa;

[0048] The heating rate is 10℃ / min(≤300℃) and 30℃ / min(> 300℃);

[0049] The sintering temperature is 800℃;

[0050] Holding time is 8min;

[0051] After cooling in the furnace, a cyli...

Embodiment 3

[0053] The large-size CuCr alloy of this embodiment is carried out as follows:

[0054] Step 1. Weigh 7.0kg of Cu powder and 3.0kg of Cr powder, and mix for 10h by mechanical mixing method to obtain uniform CuCr mixed powder; Weigh 655g CuCr mixed powder for sintering;

[0055] Step 2. Fill the weighed CuCr mixed powder into the graphite mold; use a manual hydraulic press to pre-press the graphite mold with the CuCr mixed powder, and the pressure is ~10MPa;

[0056] Step 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold with CuCr mixed powder, then place it in the furnace of the spark plasma sintering system, evacuate to below 5Pa, and then pass a DC pulse current to CuCr The mixed powder is consolidated and formed, and the process conditions are:

[0057] The axial pressure is 10MPa;

[0058] The heating rate is 20℃ / min(≤300℃) and 50℃ / min(> 300℃);

[0059] The sintering temperature is 880℃;

[0060] Holding time is 2min;

[0061] After cooling in the furnace, a CuCr al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com