Soft polyurethane foam with excellent density distribution

A soft polyurethane and density distribution technology, applied in the field of polyurethane, can solve the problems of uneven foam density distribution, poor cell, unstable foaming process, etc., and achieve excellent density distribution, fine cells, and stable foaming process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 83.5g polysiloxane (its average formula is MD 90 D' 6.0M) and 182.0 g of an allyl-initiated, ester-terminated polyoxyalkylene having an average molecular weight of 4000, containing 40% by weight of ethylene oxide groups and 60% by weight of propylene oxide groups (in Here, referred to as polyether A); 34.5 g of an allyl-initiated, ester-terminated polyoxyalkylene having an average molecular weight of 550, containing 40% by weight of oxirane groups and 60% by weight The propylene oxide group (herein, referred to as polyether B).

[0040] Add 80 μL of dibutylaminoethanol through a pipette gun, and stir, heat the mixture to 90-95°C, and stir for about 10min, add 8ppm of Pt (ethanol solution of chloroplatinic acid), and maintain the mixture in the bottle at 90-95°C, after one hour, measure the Si-H content of the mixture to be less than 0.2mL / g, vacuum remove low molecular weight products, add 3.9g hydrogen peroxide after two hours, stir for half an hour, heat up to 9...

preparation Embodiment 6~12

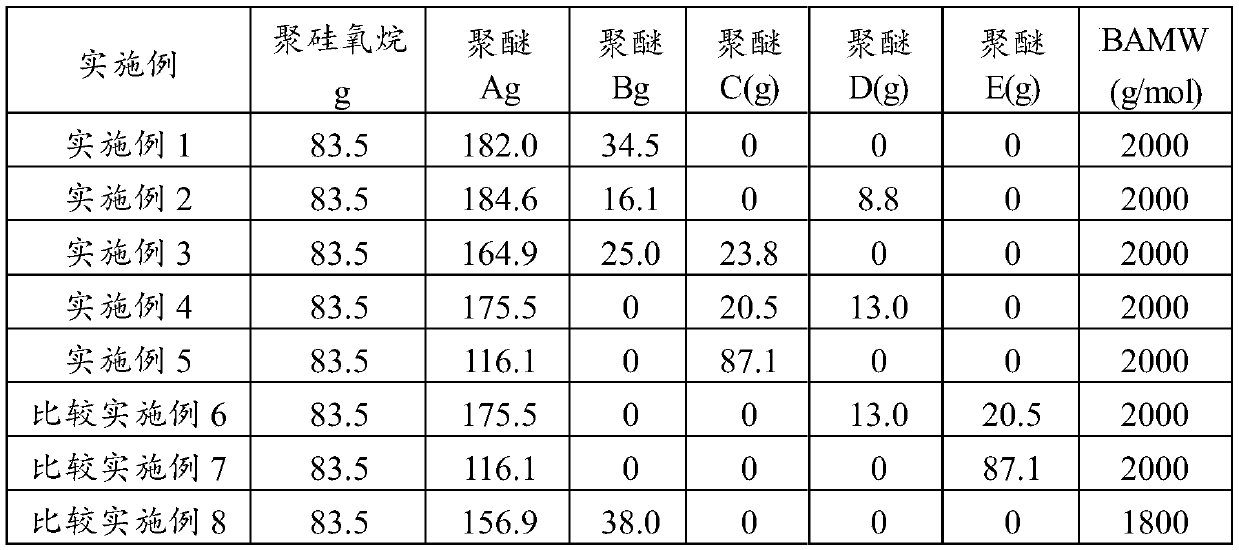

[0042] Table 1 Different polyether combinations Preparation Examples 6-12 and Comparative Examples 2-5

[0043]

[0044] Polyether A:

[0045] CH 2 =CH-CH 2 (C 2 h 4 ) a (C 3 h 6 O) b OC(O)CH 3 ;

[0046] EO / POwt%=2:3; Mn4000g / mol;

[0047] Polyether B:

[0048] CH 2 =CH-CH 2 (C 2 h 4 ) a' (C 3 h 6 O) b' OC(O)CH 3 ;

[0049] EO / POwt%=2:3; Mn550g / mol;

[0050] Polyether C:

[0051] CH 2 =CH-CH 2 (C 2 h 4 ) a″ (C3H6O) b″ OC(O)CH 3 ;

[0052] EO / POwt%=2:3; Mn1200g / mol;

[0053] Polyether D:

[0054] CH 2 =CH-CH 2 (C 2 h 4 ) a' (C 3 h 6 O) b' OC(O)CH 3 ;

[0055] EO / POwt%=2:3; Mn300g / mol;

[0056] Polyether E:

[0057] CH 2 =CH-CH 2 (C 2 h 4 ) a″ (C 3 h 6 O) b″ OH;

[0058] EO / POwt%=2:3; Mn1200g / mol;

[0059] The examples were mixed with different solvents in different weight ratios, specifically using different solvent combinations as shown in Table 2.

[0060] Table 2 Different Solvent Combinations

[0061]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com