A box-type foaming combined polyether and polyurethane foam and its preparation method

A combination of polyether and box-type foaming technology, applied in the field of materials, can solve the problems of high fluidity and density distribution of polyurethane raw materials, poor foam products, shrinkage of products, etc., to achieve excellent density distribution, performance balance, foam The effect of fine and uniform holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

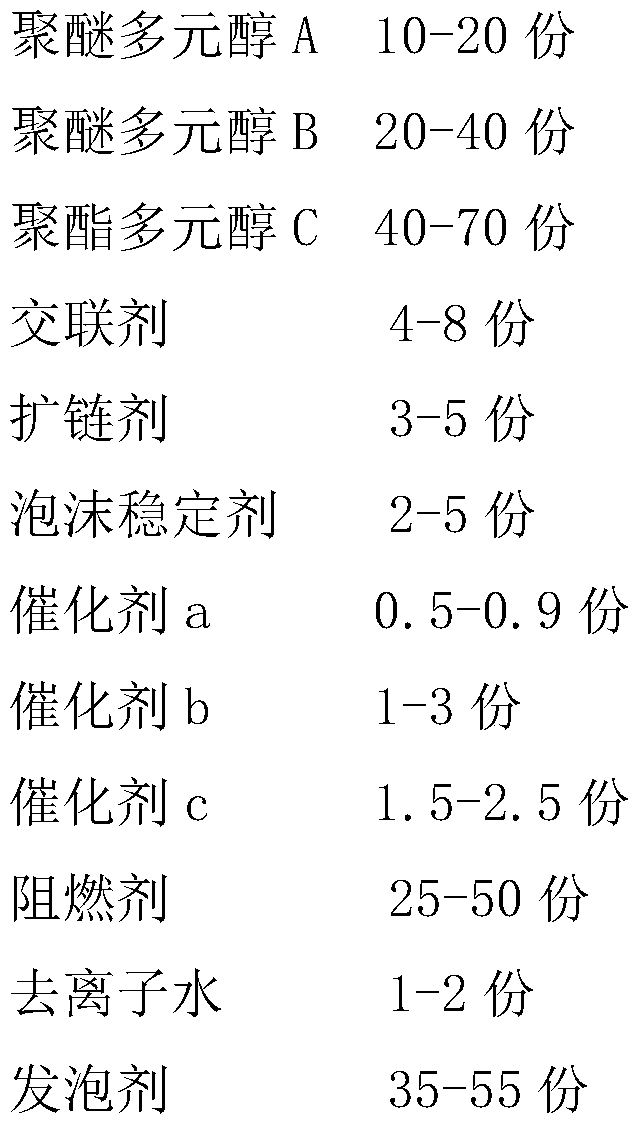

Method used

Image

Examples

Embodiment 1

[0058] Prepare the first component according to the ingredients in the table below

[0059] raw material name Mass parts / parts PN400 10 Ixol B251 20 CF-8240 70 PP30 8 TCD tricyclic diol 4 B8462 4 Dabco DMDEE 0.8 Dabco TMR-31 1.7 Dabco TMR-35 2.5 TCPP 50 Deionized water 2 HCFC-141b 35

[0060] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make the first component; then pour the first component and the second component into the container according to the weight ratio of 1:1.6 , then use an electric mixer to stir for 8 seconds, pour the evenly mixed liquid into a mold with a constant temperature of 45-50°C, close the mold, place it at a constant temperature of 45°C for 6 hours, and then open the mold to obtain the Polyurethane slabstock foam.

Embodiment 2

[0062] Prepare the first component according to the ingredients in the table below

[0063] raw material name Mass parts / parts PN400 20 Ixol B251 20 CF-8240 60 PP50 6 Dodecyl cycloalkanediol 4 AK8809 2 Jeffcat ZF-10 0.9 Dabco BDMA 1 PC CAT NP40 2.3 DEEP 25 Deionized water 1.5 HFC-365mfc 47

[0064] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make the first component; then pour the first component and the second component into the container according to the weight ratio of 1:1.8 , then use an electric mixer to stir for 8 seconds, pour the evenly mixed liquid into a mold with a constant temperature of 45-50°C, close the mold, place it at a constant temperature of 45°C for 6 hours, and then open the mold to obtain the Polyurethane slabstock foam.

Embodiment 3

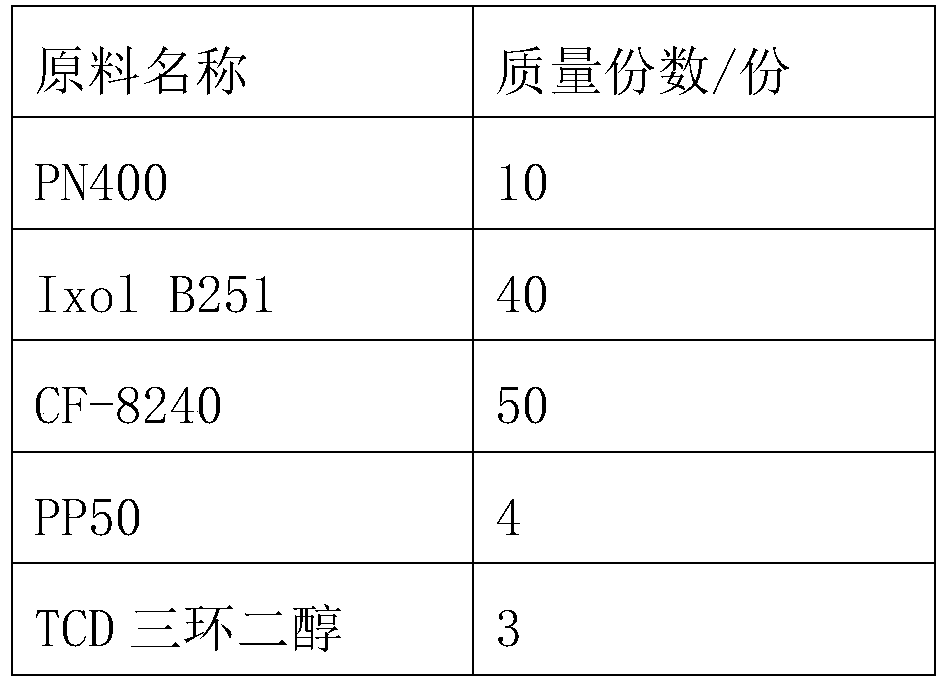

[0066] Prepare the first component according to the ingredients in the table below

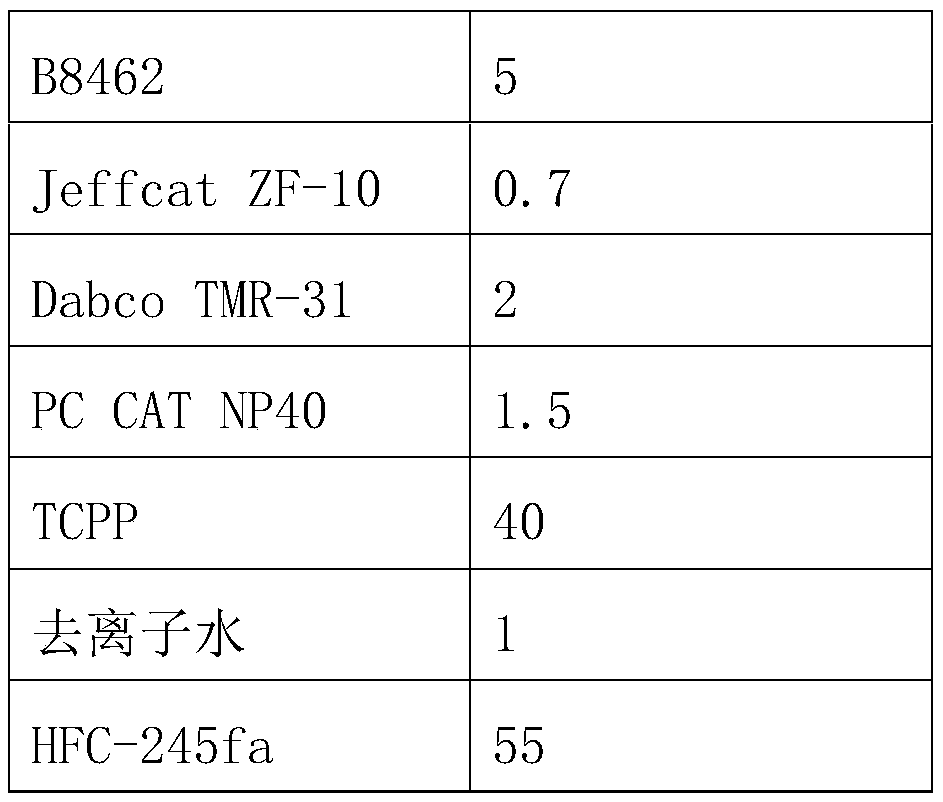

[0067]

[0068]

[0069] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make the first component; then pour the first component and the second component into the container according to the weight ratio of 1:1.9 , then use an electric mixer to stir for 8 seconds, pour the evenly mixed liquid into a mold with a constant temperature of 45-50°C, close the mold, place it at a constant temperature of 45°C for 6 hours, and then open the mold to obtain the Polyurethane slabstock foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com