Two-dimensional material as well as preparation method, preparation device and application thereof

A two-dimensional material and preparation process technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve uneven distribution of crystals, insufficient uniformity of crystal material distribution, unsuitable for large-area uniform distribution, etc. problem, to achieve the effect of uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

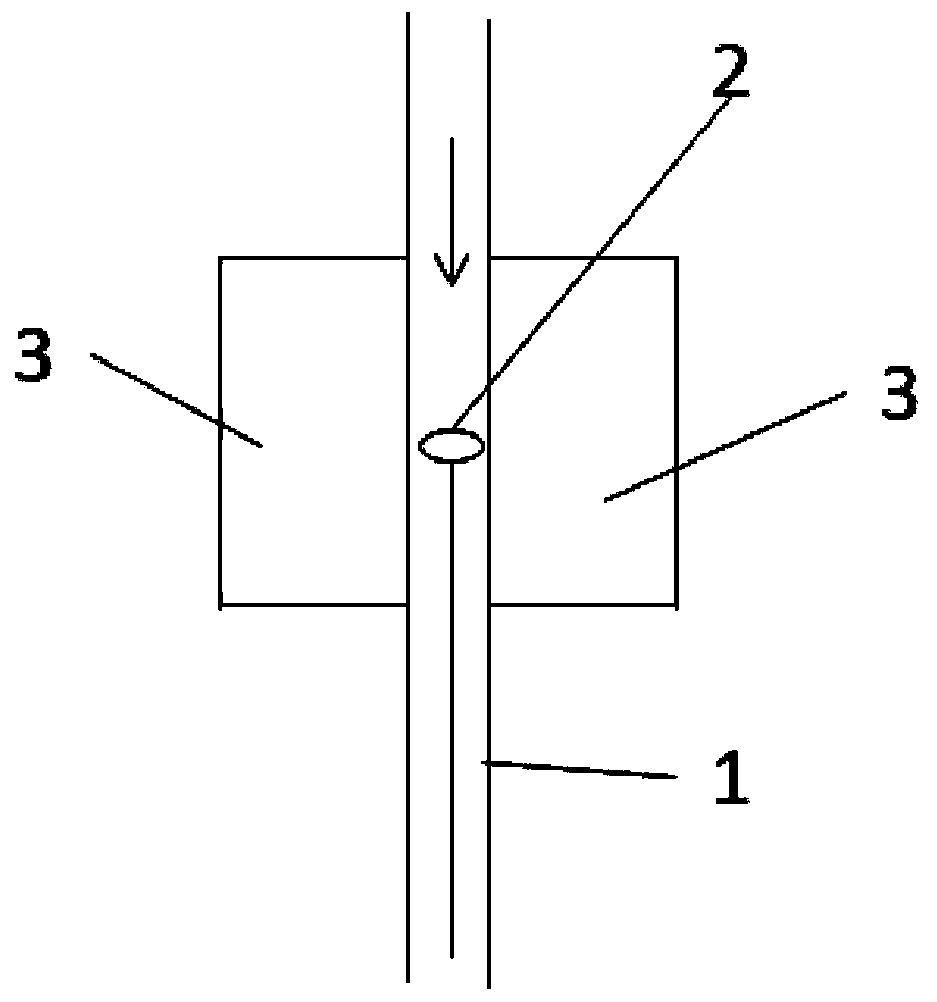

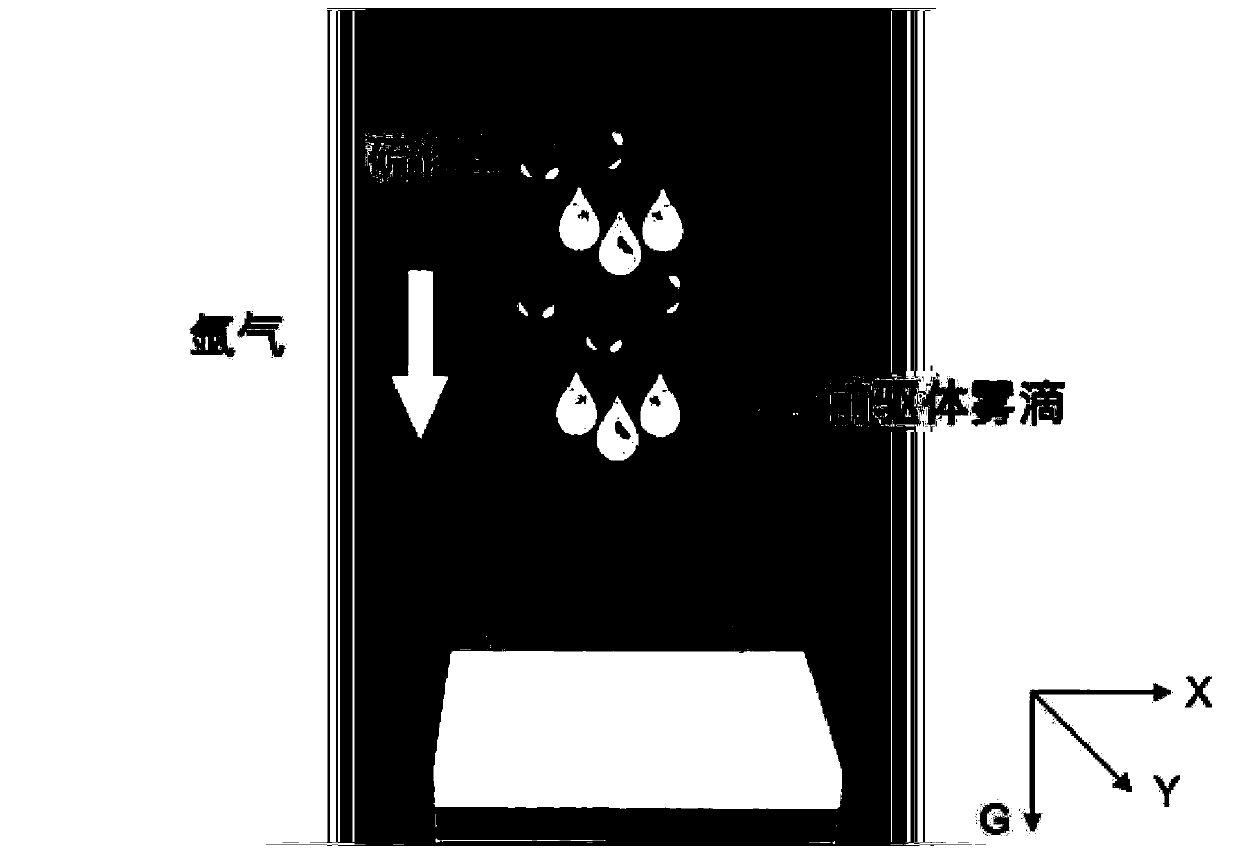

Method used

Image

Examples

Embodiment 1

[0090] This embodiment provides a two-dimensional WS 2 The preparation method:

[0091] (1) Heating stage: Utilize argon to discharge the air in the vertical pipeline of the device, the flow rate of the argon is 800sccm, the time of feeding is 30min, then heat up, enter the heating stage, the heating rate of the heating stage 30°C / min;

[0092] (2) Heat preservation stage: After the temperature is stabilized, the gaseous precursor is introduced along the upper opening of the vertical pipe, and passes through the substrate in the vertical direction to react; the temperature of the heat preservation stage is 850°C; the reaction The time is 30min; the gaseous precursors include gaseous precursors and gas bubbling precursors, and the gaseous precursors are H 2 S, the gas bubbling precursor is obtained by bubbling argon gas into a dispersion liquid containing a tungsten source, the rate of introduction of the argon gas is 20 sccm, and the concentration of the dispersion liquid is...

Embodiment 2

[0101] This embodiment provides a two-dimensional MoS 2 The preparation method:

[0102] In this example, the tungsten source suspension in the gas bubbling precursor in step (2) in Example 1 is replaced by the molybdenum source suspension, and other conditions are completely the same as those in Example 1.

[0103] The two-dimensional MoS prepared in this example 2 Its morphology is triangular flakes, and its crystal system is hexagonal.

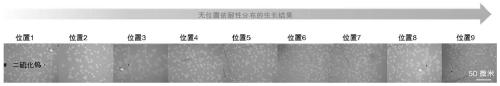

[0104] The two-dimensional MoS prepared in this example 2 Optical microscope pictures of Figure 9 As can be seen from the figure; the two-dimensional MoS prepared in this example 2 The triangular flakes are uniform in thickness and evenly distributed on the substrate.

Embodiment 3

[0106] This embodiment provides a two-dimensional WS 2 Preparation method of continuous film:

[0107] In this example, compared with Example 1, the sample holder of the device used in Example 1 was replaced by a sample holder with a mesh number of 200, and the sample holder was rotated at a speed of 200 rpm. The time of carrying out reaction in the step (2) is replaced as 90min, and other conditions are compared with embodiment 1 and are identical.

[0108] The two-dimensional WS prepared in this example 2 The morphology of the film is a single-layer continuous film, and the crystal system is hexagonal, which is evenly distributed on the surface of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com