Patents

Literature

169results about How to "Porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing spongy graphene oxide by using freeze-drying method

ActiveCN103058179ASimple processEasy to operateMaterial nanotechnologyCarbon compoundsCvd graphenePore distribution

The invention relates to a method for preparing spongy graphene oxide by using a freeze-drying method, which is in a loose and porous type and is in a spongy type in a macro-morphology. The method comprises the steps of: after an improved Hummers process is utilized to prepare graphite oxide, preparing graphite oxide into a solution with water or ethanol, and then carrying out quick-freezing and vacuumizing on the solution, and sublimating a solvent to obtain the graphene oxide. The graphene oxide is different from general blocky, film type or powdery graphene oxide. The obtained loose and porous graphene oxide provided by the invention is in a spongy type, is an excellent precursor for preparing graphene, and has a great application foreground in the field of an anti-flaming composite material, an adsorbent and the like. The method for preparing spongy graphene oxide by using a freeze-drying method is free from environmental pollution, convenient in technology and small damage to graphite oxide sheets, and completely strips graphite oxide; and the porosity of the graphene oxide is 20-90% and the pore distribution is uniform.

Owner:无锡烯创科技有限公司

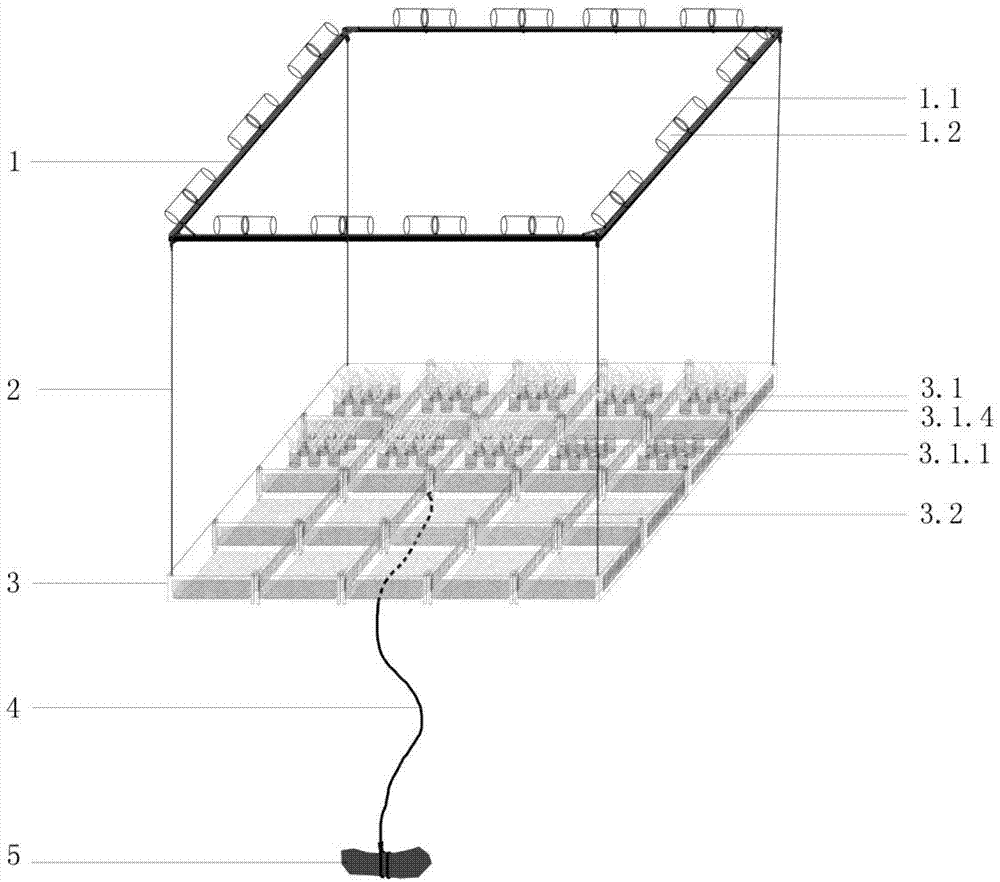

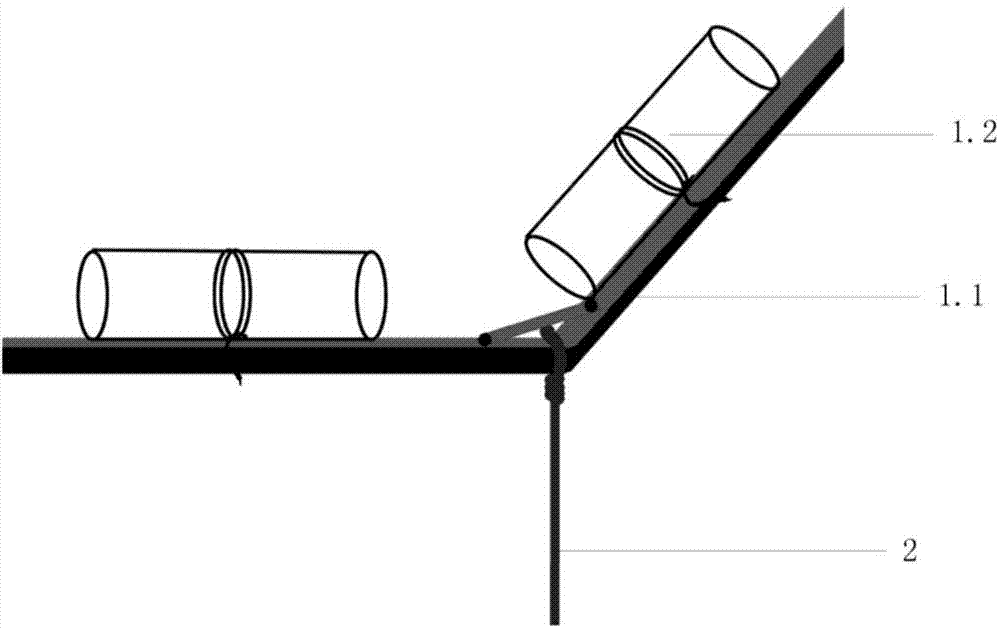

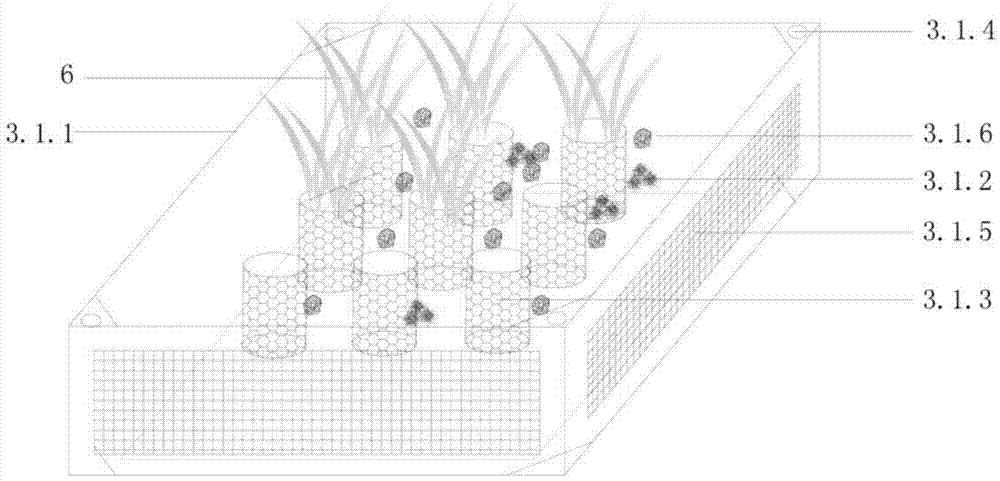

Submerged plant planting device

InactiveCN103936169AFit wellEnlarged surface areaSustainable biological treatmentReceptacle cultivationAgricultural engineeringBiology

The invention discloses a submerged plant planting device, comprising a buoyancy layer, connection ropes, a submerged plant planting layer, a fixed rope an and anchor, wherein the buoyancy layer is formed by a peripheral frame and 12-20 float bowls fixed on the peripheral frame; the submerged plant planting layer is formed by 10-30 planting bricks connected through connecting pegs; each planting brick is formed by a hollow frame and planting matrix filled into the hollow frame, and can adapt to a plurality of submerged plant propagule such as sprouts, clints, seeds and the like; the buoyancy layer is connected with the submerged plant planting layer through four connection ropes; a connecting peg is arranged at the center part of the submerged plant planting layer and connected with the fixed rope; the other end of the fixed rope is connected with the anchor and arranged at the water bottom; the submerged plant planting layer floats up and down along with water-level fluctuation, but the distance to the water level is kept constant all the time. The planting brick structure and the submerged plant root are good to fit, the device is stable in form for a long period of time, the effect on the submerged plant caused by drastic change of water level and stormy waves can be effectively avoided, and the overall device is simple to assemble, and free of labor management in the actual operation process.

Owner:HUBEI NORMAL UNIV

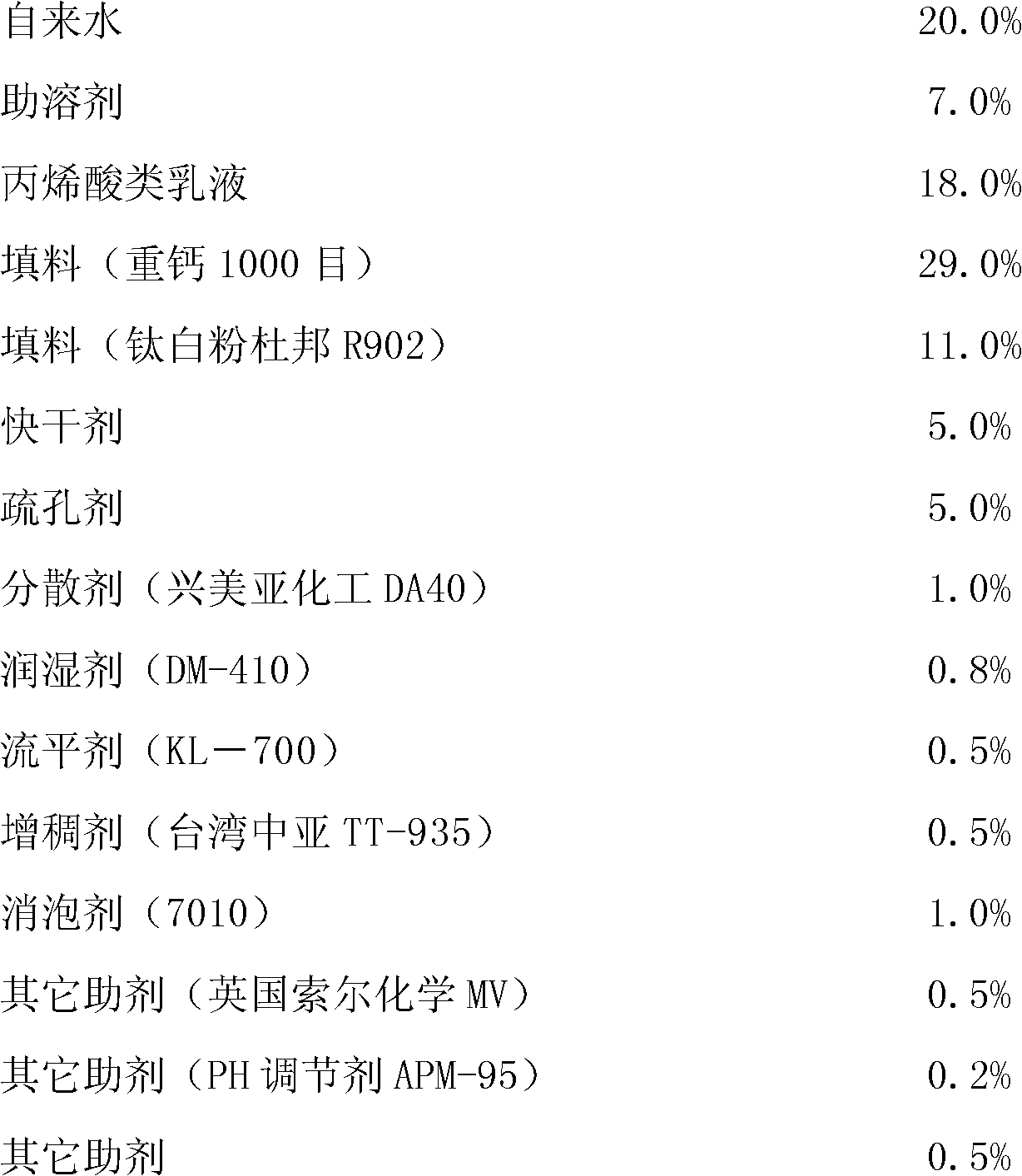

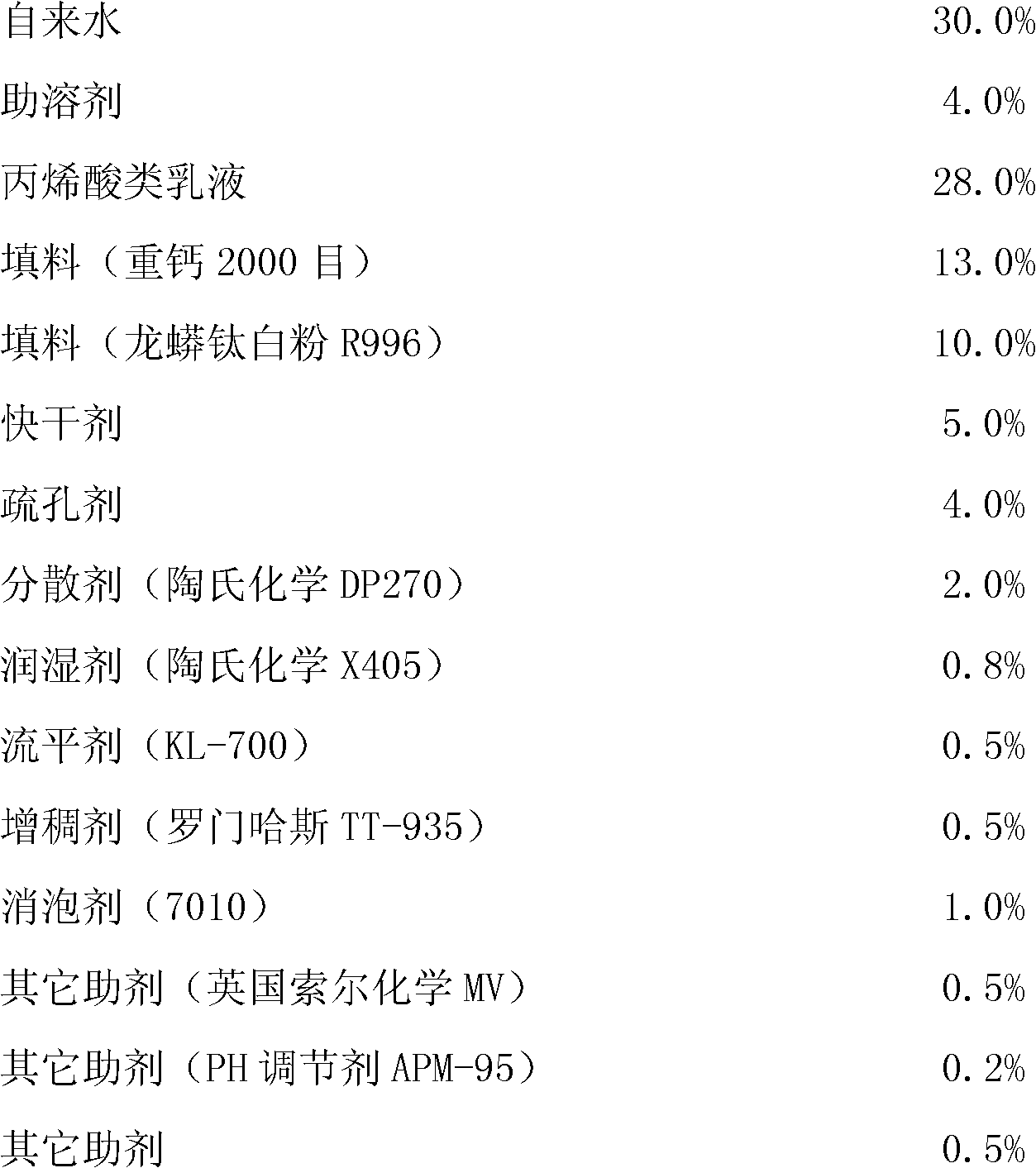

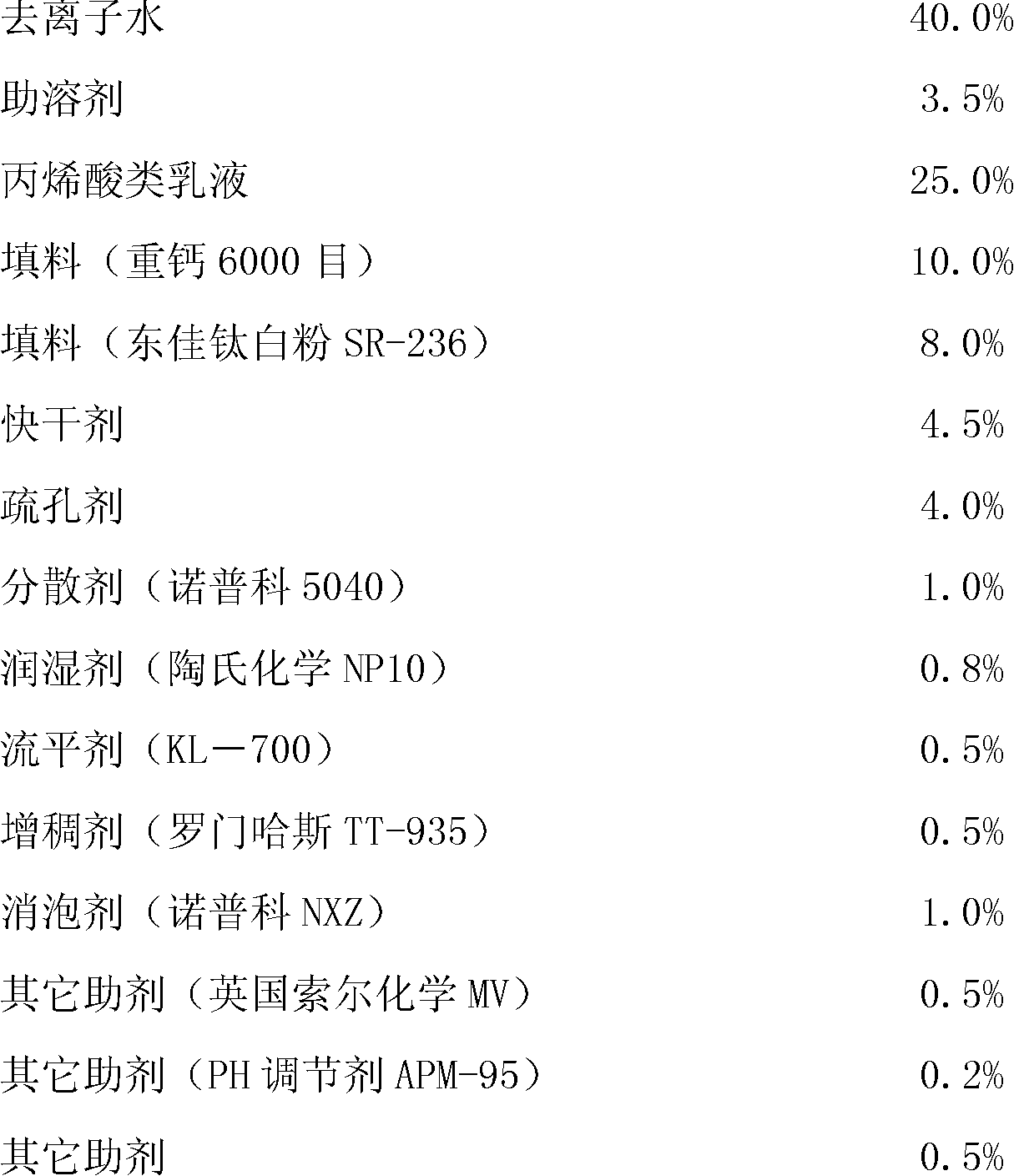

Quick-dry thin acrylic-acid protective coating and HDPE (high-density polyethylene) self-adhesive film waterproof roll protective coating layer

The invention discloses a quick-dry thin acrylic-acid protective coating, which mainly consists of water, cosolvent, acrylic-acid like emulsion, filler, quick dry agent, hole forming agent, dispersing agent, wetting agent, defoamer, flatting agent and thickener and the like. The invention further discloses an HDPE (high-density polyethylene) self-adhesive film waterproof protective coating layer, which is formed after the quick-dry thin acrylic-acid protective coating is sprayed on a HDPE self-adhesive layer uniformly by a reciprocating mechanical spraying method and drying the same. The quick-dry thin acrylic-acid protective coating is environment-friendly and non-toxic and can be dried quickly and has excellent flatting performance, and an HDPE self-adhesive film waterproof roll prepared by the HDPE self-adhesive film waterproof roll protecting layer has excellent pre-paving anti-adhesive effect with post-cast concrete, and the HDPE self-adhesive film waterproof roll protective layer and the post-cast concrete can be guaranteed to be adhered stably and firmly.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

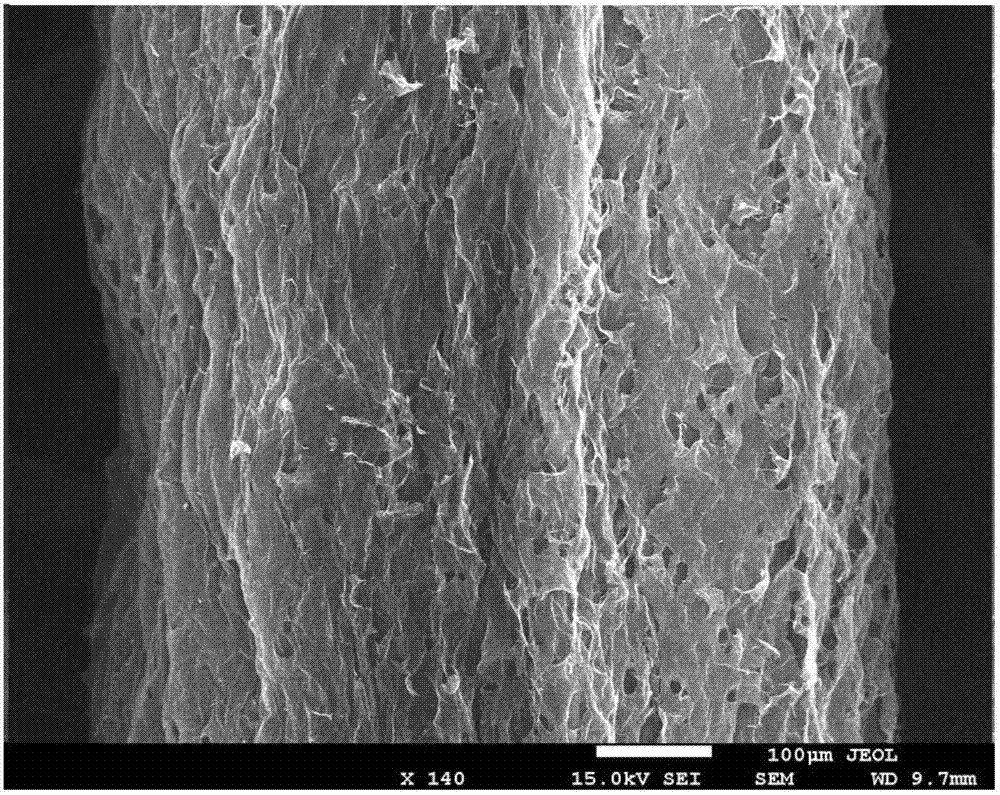

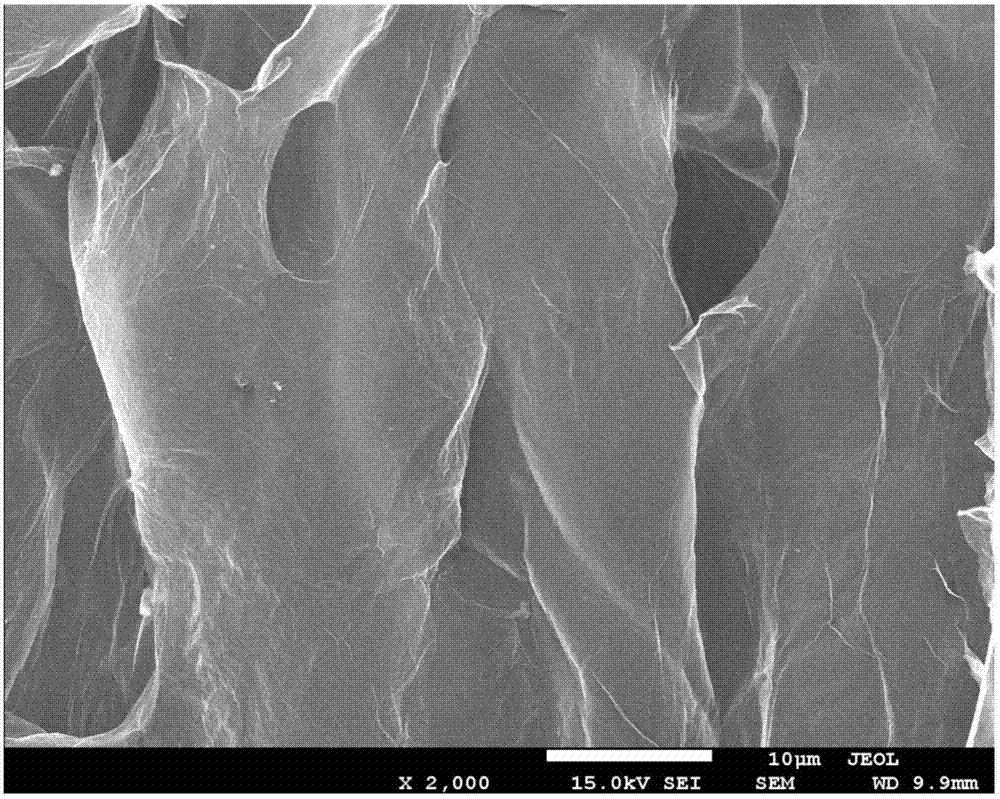

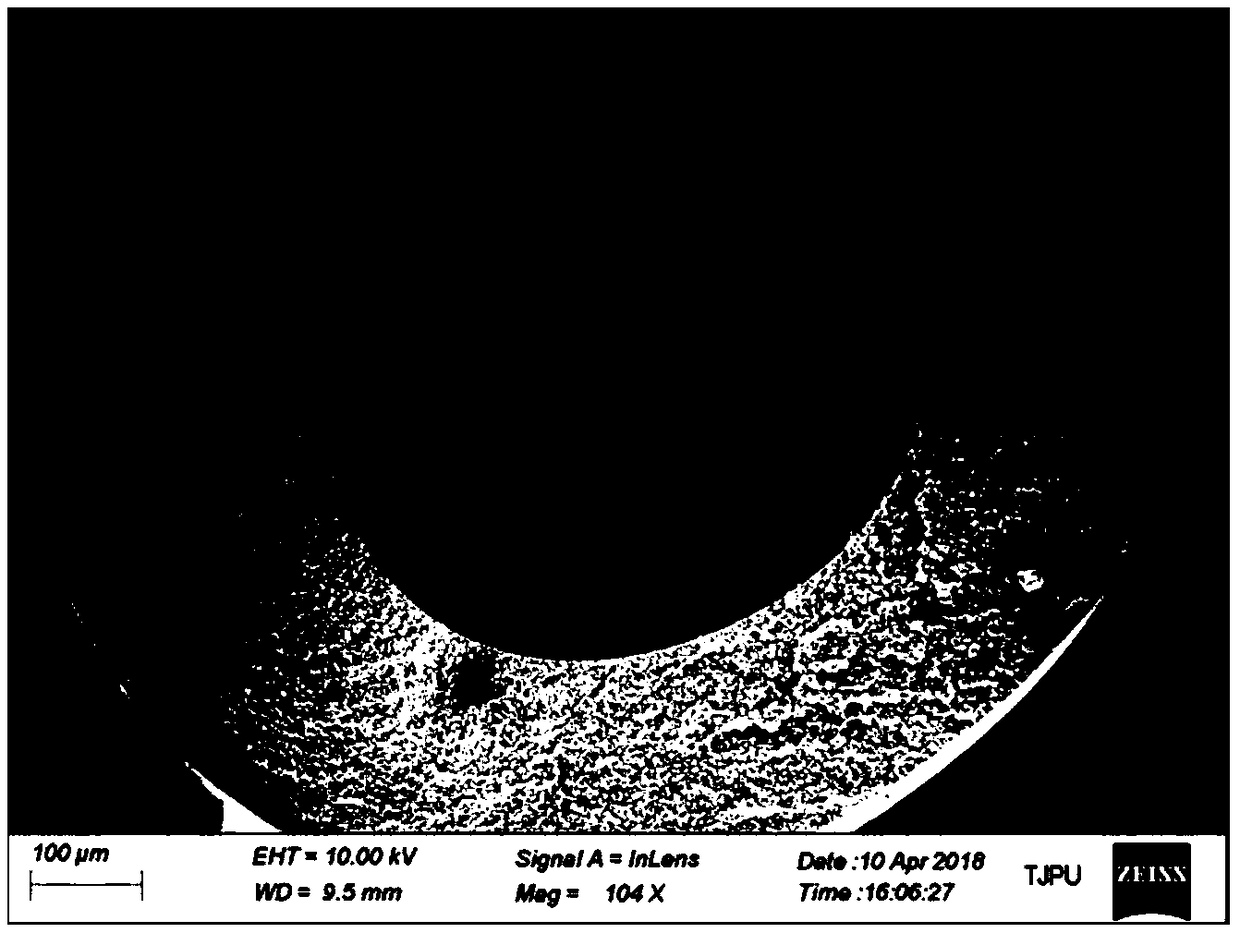

Preparation method of graphene oxide hollow fiber and graphene hollow fiber

ActiveCN103031618AEvenly dispersedStickyInorganic material artificial filamentsHollow filament manufactureMaterials preparationFiber

The invention relates to a preparation method of a graphene oxide hollow fiber and a graphene hollow fiber, and belongs to the technical field of graphene oxide and graphene material preparation. The method comprises the following steps that an outer layer solution and an inner layer solution are respectively input into an outer layer and an inner layer of a coaxial needle head; the outer layer solution is injected into a receiving solution to form an aqueous graphene oxide hollow fiber, and then dried to form a graphene oxide hollow fiber; and the graphene oxide hollow fiber is reduced to a graphene hollow fiber. The outer layer solution is a 20-25mg.mL<-1> graphene oxide solution; the inner layer solution and the receiving solution are methanol solutions of KCL with a mass concentration greater than or equal to 3mol / L; the flow velocity of the inner layer solution is 0.6ml / min; and the flow velocity of the outer layer solution is greater than or equal to 0.1ml / s. According to the preparation method, the graphene oxide hollow fiber and the graphene hollow fiber can be prepared respectively in different steps of one method, the operation is easy and simple, aftertreatment and edulcoration are not required, the cost is low, and mass continuous production can be conducted.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

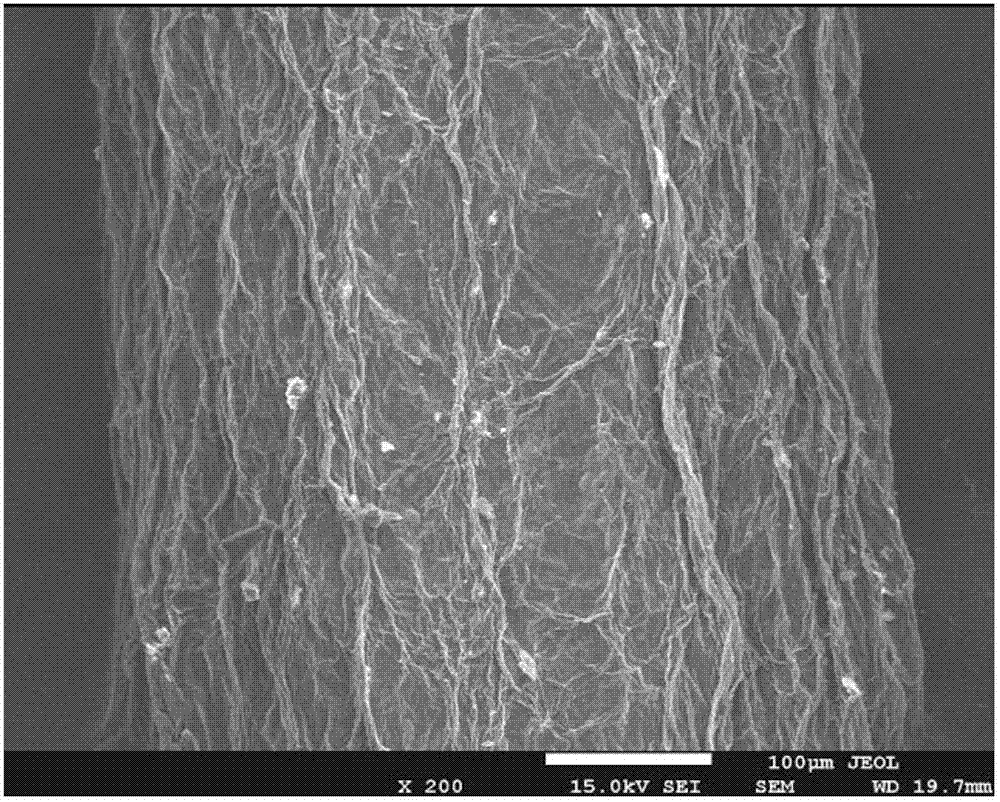

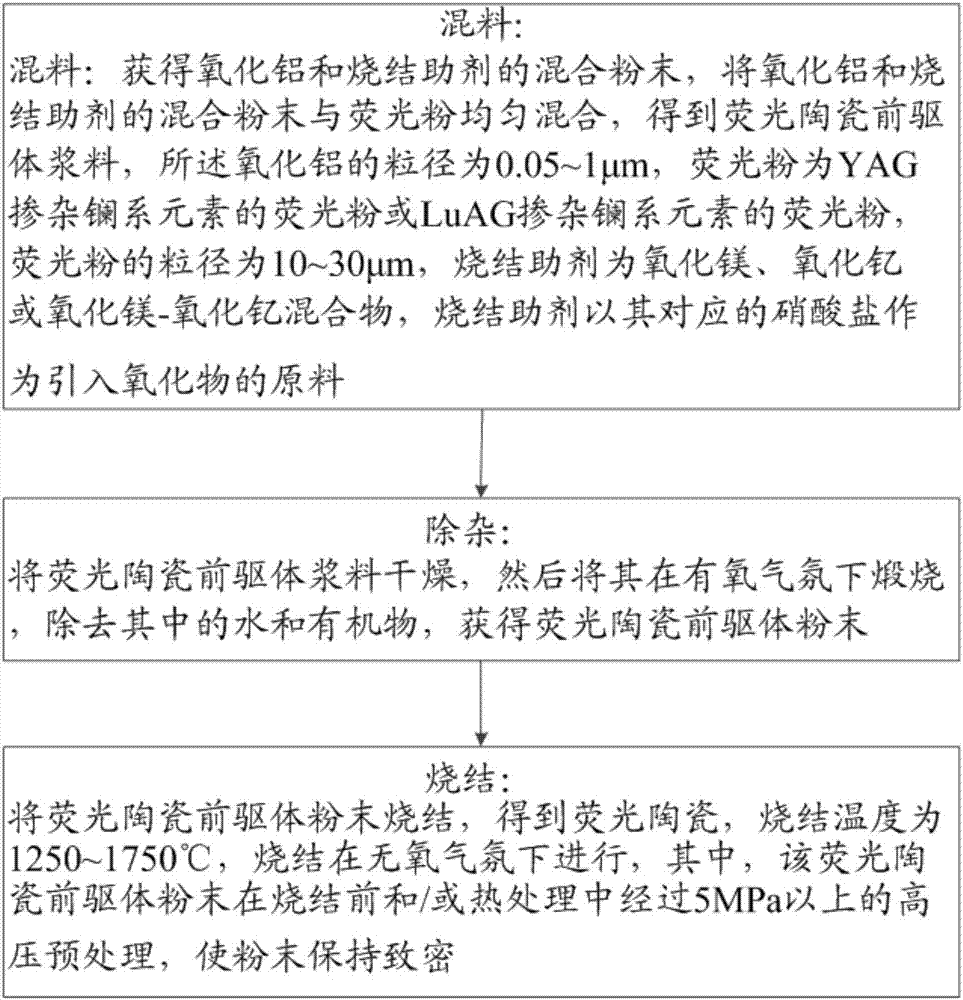

Preparation method of fluorescent ceramic containing aluminum oxide matrix and related fluorescent ceramic

The invention provides a preparation method of fluorescent ceramic containing an aluminum oxide matrix. The preparation method sequentially comprises the following steps: mixing aluminum oxide, fluorescent powder and a sintering additive and removing impurities to obtain fluorescent ceramic precursor powder; then sintering the powder under an oxygen-free atmosphere to obtain the fluorescent ceramic. The grain diameter of each component is selected to be a pre-set size and the fluorescent ceramic precursor powder is subjected to high-pressure treatment in a sintering process; the sintering additive and corresponding nitrate are used as raw materials for introducing oxide. By adopting the preparation method provided by the invention, the aluminum oxide enters a liquid phase at relatively low temperature under the condition that the fluorescent powder has an unchanged crystal new look in a preparation process and the uniform and dense fluorescent ceramic with low porosity is obtained; the heat-conducting performance and luminous efficiency of the fluorescent ceramic are extremely improved.

Owner:APPOTRONICS CORP LTD

Seedling cultivation composite organic matter basis and method of preparing the same

InactiveCN101492322AImprove adsorption performanceGood water absorptionOrganic fertilisersFertilizer mixturesFertilizerDecomposition

The invention particularly relates to a composite organic nursery substrate and a production method thereof. The substrate adopts leftovers of edible fungi and peanut shells as main materials, adopts peat, vermiculite, rice husk ash and attapulgite as accessories and adopts water retention agents, green fertilizers and ferrous sulfate as additives. The volume ratio of the main materials is 40-60:20-30 in sequence, the accessories are 5-20% of the main materials and the additives are in proper quantities. The production process of the substrate is as follows: decomposition pretreatment is carried on the main materials; the accessories and additives are added according to the volume ratio and are stirred evenly until the mixture passes test to be a qualified finished product. The substrate of the invention has good quality, rapid and neat emergence of seedlings, healthy plant growth and good water retention. The fertilizer efficiency can last for 30-50 days, enough for the growing development of the seedling stage, thus simplifying the management of labor power on plug seedling. Meanwhile, with good buffer action, the substrate can be widely applied to seedling culture of various organisms such as vegetables, flowers, cotton, rice, tobacco and nursery stocks, etc.

Owner:JIANGSU XUHUAI DISTRICT HUAIYIN AGRI SCI RES INST

Special PU (polyurethane) plate for automobile roof and prepared by one-step wet method

The invention discloses a special PU (polyurethane) plate for an automobile roof and prepared by a one-step wet method. The special PU plate is prepared by uniformly mixing the following raw materials in parts by weight, namely 100 parts of a mixture of polyether polyol and polyester polyol, 1-3 parts of mixed sillicon oil, 0.1-0.5 part of amine catalyst, 5-20 parts of mixed foaming agent, 0.1-0.3 part of delaying catalyst and 1.0-2.0 parts of pore forming agent, to obtain a material A, performing reaction of the material A and 140-175 parts of modifying material B to obtain a big foamed block, and slicing. The special PU plate is applicable to the automobile roof manufactured by the one-step wet method; and the special PU plate is good in toughness, high in size stability and low in cost.

Owner:YANTAI ZHENGHAI HIGH TECH

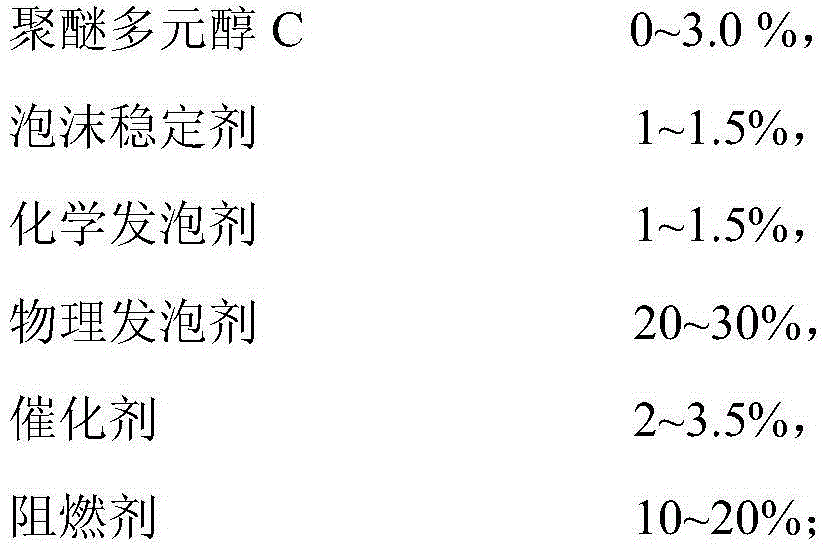

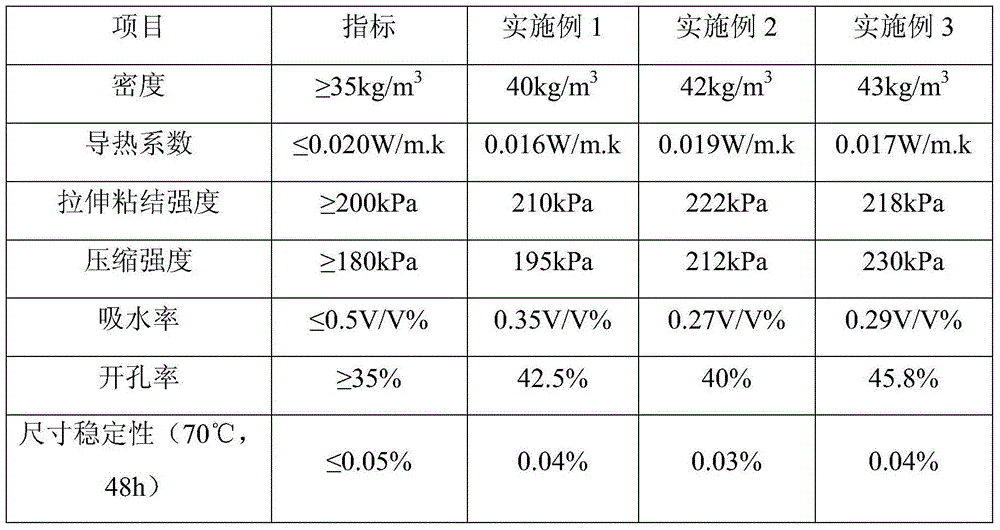

Premixed polyether polyol for polyurethane insulation board for electrothermic floor heating system and application method of premixed polyether polyol

The invention relates to premixed polyether polyol for a polyurethane insulation board for an electrothermic floor heating system and an application method of the premixed polyether polyol and belongs to the technical field of premixed polyether polyol. The premixed polyether polyol, which is disclosed by the invention, for the polyurethane insulation board for the electrothermic floor heating system consists of polyether polyol A, polyether polyol B, polyether polyol C, a foam stabilizer, a chemical foaming agent, a physical foaming agent, a catalyst and a flame retardant. The premixed polyether polyol, which is disclosed by the invention, for the polyurethane insulation board for the electrothermic floor heating system is wide in raw material source and is low in cost; the polyurethane insulation board prepared from the premixed polyether polyol has high low-temperature size stability, the heat conductivity coefficient of the polyurethane insulation board meets the use requirements, compression intensity is high and flame retardance is good; the invention also provides the application method of the premixed polyether polyol for the polyurethane insulation board for the electrothermic floor heating system; and the application method is simple in process and is high in production efficiency.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Regulation and control method of mechanical strength of natural biologic material products

InactiveCN101648035AGood biological activityReduce denaturationProsthesisPorosityVolumetric Mass Density

The invention discloses a regulation and control method of mechanical strength of natural biologic material products. A final product is obtained by the treating steps of freezing and drying, compression, crosslinking and secondary drying on natural biologic material solution. The treating method adopts the controllable compression step for a primary product after freezing and drying, thereby controlling the density of a porous material product, reducing the porosity of the porous material product and controlling the mechanical performance of the final product by the step. Meanwhile, the adopted method does not influence the biologic performance of the initial natural biologic material, thereby still keeping better biologic activity of the final product.

Owner:SOUTH CHINA UNIV OF TECH

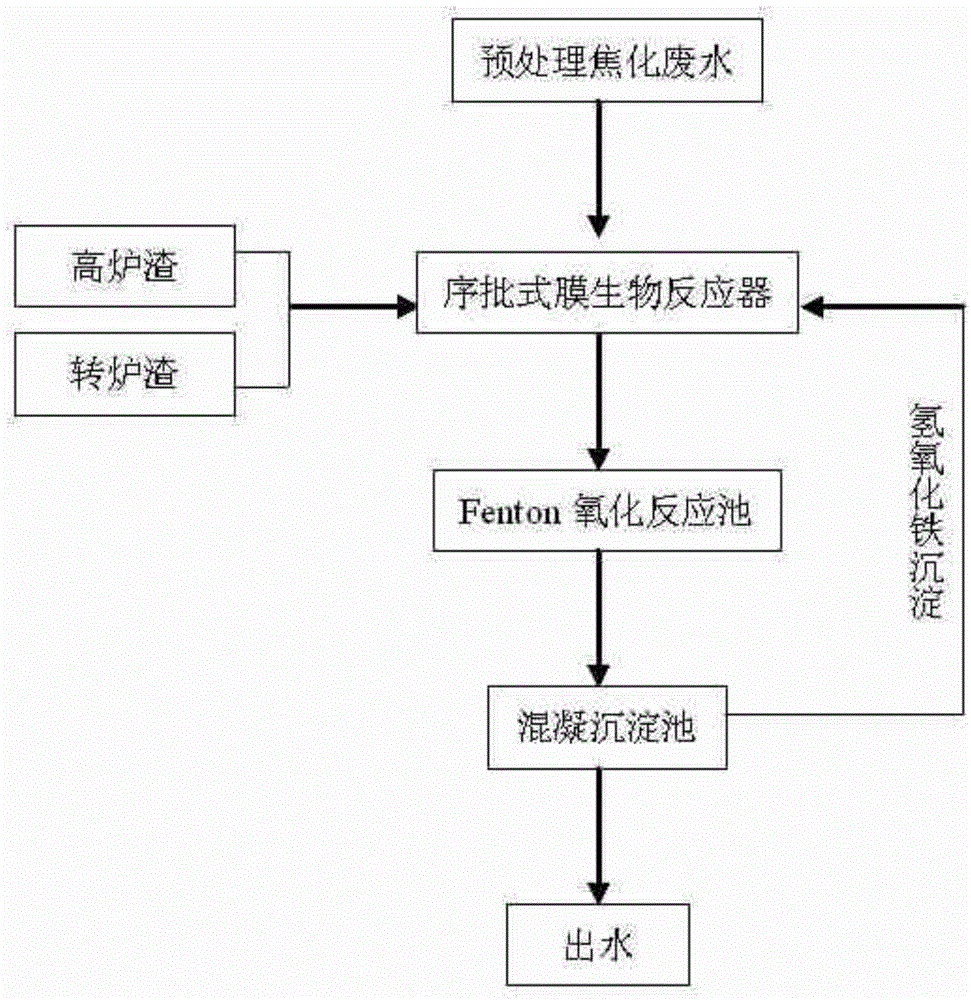

Coking wastewater treatment method

ActiveCN105271606APorosityMitigation capacityMultistage water/sewage treatmentSequencing batch reactorMetallurgical slag

A coking wastewater treatment method is as follows: coking wastewater pretreated by a gravity degreasing tank and an air flotation degreasing tank is treated by collaborative Fenton oxidation and coagulation precipitation by use of a sequencing batch membrane bioreactor, metallurgical slag with 1 / 8 to 1 / 6 of effective volume of the reactor are added into the sequencing batch membrane bioreactor, metallurgical slag accounted for 0.3%-0.8% of the metallurgical slag amount is supplemented into the sequencing batch membrane bioreactor every 10-15 days, iron mud precipitate produced by Fenton reaction is refluxed into the sequencing batch membrane bioreactor every 5-7 days, and the reflux amount is 6% to 8% of the reactor sludge amount; the sequencing batch membrane bioreactor is anoxically stirred for 7-8h in every cycle, aerobic aeration time is 15-17h, and the residence time is 70-73h. According to the method, by use of the flocculation effect of iron hydroxide floc, wastewater treatment effect is strengthened, alkalinity consumed in nitrification process can be mitigated, and the iron mud precipitate produced by the reaction can be recycled, meanwhile by taking advantage of adsorption precipitation performance of the metallurgical slag, purposes of improvement of wastewater treatment effect and reduction of wastewater treatment costs can be realized.

Owner:ANGANG STEEL CO LTD

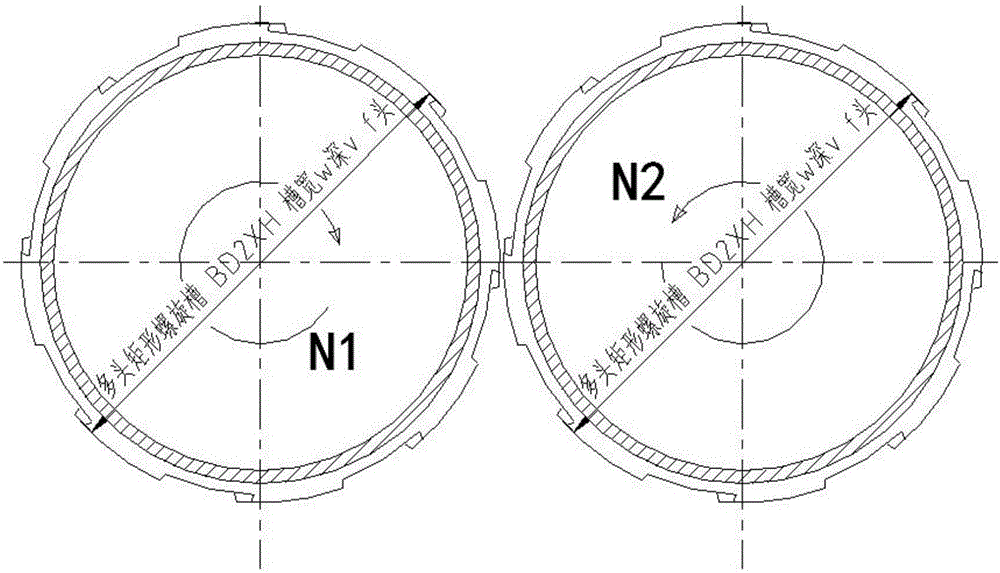

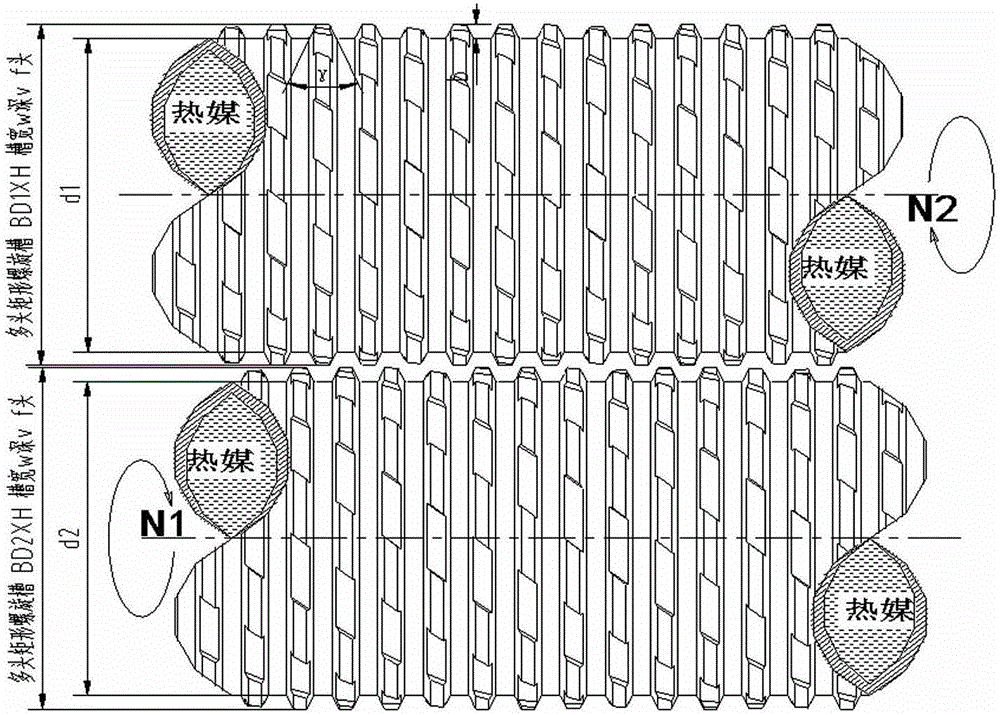

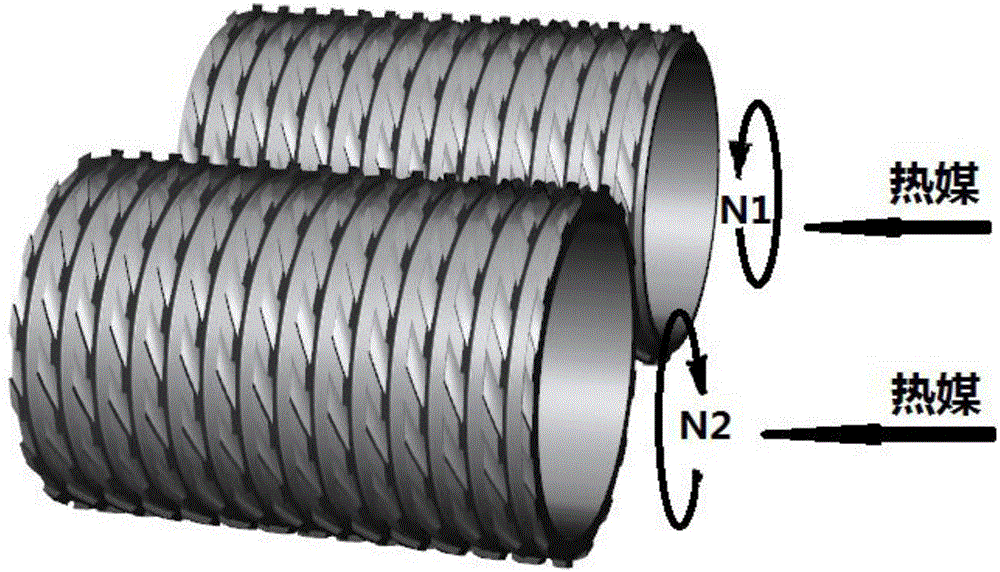

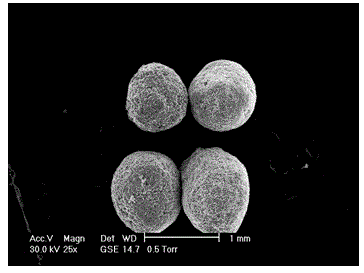

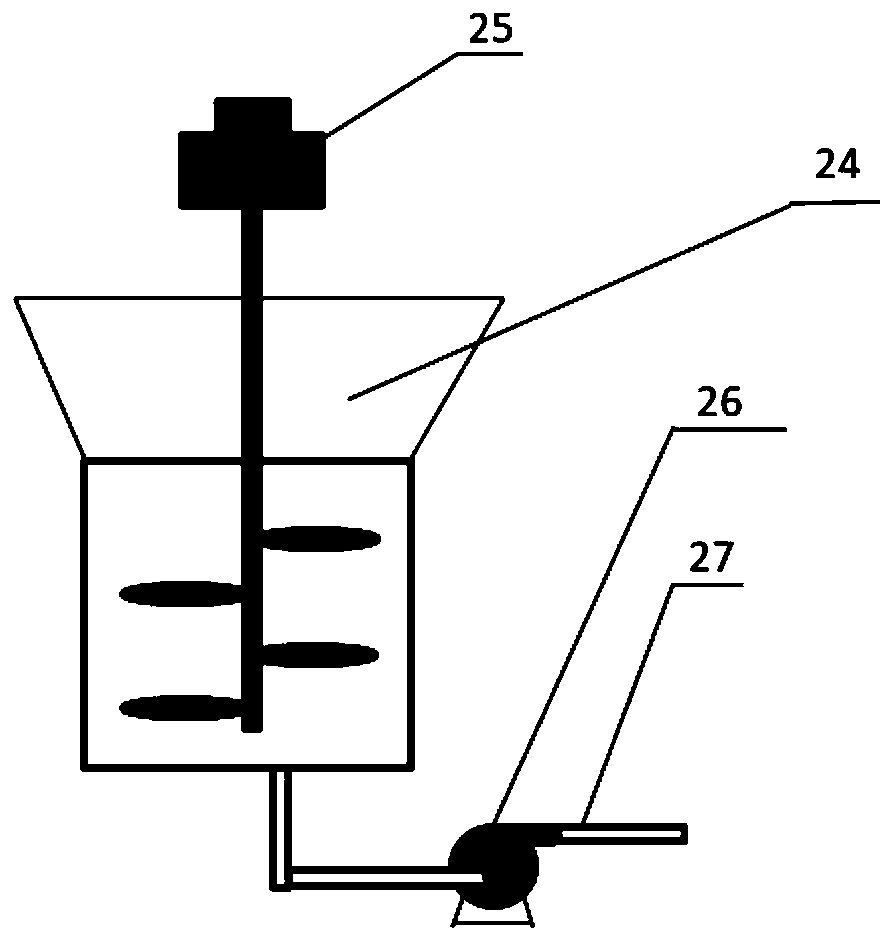

Combined-type granulator

ActiveCN106422974AAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

The invention belongs to a wet material granulation principle and an equipment combination process, and particularly relates to a combined-type granulator. The combined-type granulator comprises a plurality of layers of combined box bodies, a temporary storage feed bin and a plurality of layers and groups of roller mills. Each group of roller mills is equipped with a rotary joint, a cleaning blade, an elastic stripping frame, a material baffle and a guide plate; a waste gas emptying interface is also arranged on each of the box bodies, and an air inlet at a lowest layer of the granulator is arranged on a bracket. The linear velocity of a tooth surface and the flow rate of volume of a rotary drum of each of the roller mills at a second layer are higher than those of a rotary drum of each of the roller mills at a first layer, and the linear velocity of a tooth surface and the flow rate of volume of a rotary drum with a reticular tooth socket or a single radial tooth socket of each of the roller mills at an adjacent lower layer are designed according to the volume properties of materials in the area. According to the granulator disclosed by the invention, hard foreign matters can be stripped, and simple granulation of soft materials in a cream state, a paste state, a slurry state and the like can be realized; meanwhile, caky and blocky materials can be pulled into monomer granules, soft and hard materials can simultaneously enter into the granulator, and granules at an outlet have a plurality of pores and are in an irregular shape.

Owner:张元才

Environmentally-friendly energy-saving polyurethane spraying composite material with ultralow density

InactiveCN102391774ANo damageMeet the requirements of green environmental protectionFireproof paintsPolyurea/polyurethane coatingsPolyolFoaming agent

The invention discloses an environmentally-friendly energy-saving polyurethane spraying composite material with ultralow density, which comprises the following components in part by weight: 20-60 parts of polyether polyol which takes glycerol as an initiator, 3-10 parts of amine catalyst, 0.5-3.0 parts of foam stabilizer, 22-30 parts of water, 30-45 parts of fire retardant and 95-120 parts of isocyanate. In the environmentally-friendly energy-saving polyurethane spraying composite material, pure water is used for replacing the traditional hydro chlorofluorocarbon (HCFC)-141b foaming agent, and the environmentally-friendly energy-saving polyurethane spraying composite material is an environmentally-friendly energy-saving polyurethane spraying foam with the ultralow density. The polyurethane spraying composite material has the ultralow density which can reach 5-10kg / m3. Because the polyurethane spraying composite material has tapping performance, the sound absorption performance can reach 70%. Meanwhile, the oxygen index of the environmentally-friendly energy-saving polyurethane spraying composite material reaches 23 and can pass the Society of Tool and Manufacturing Engineers (ASTME)-84 authentication.

Owner:可利亚多元醇(南京)有限公司

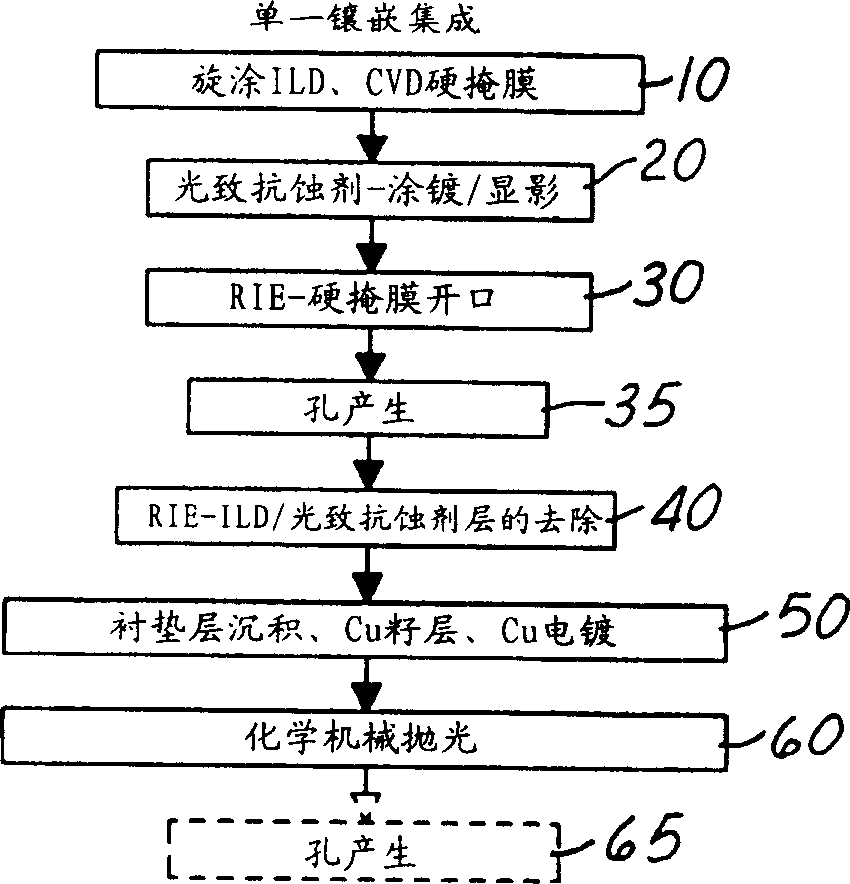

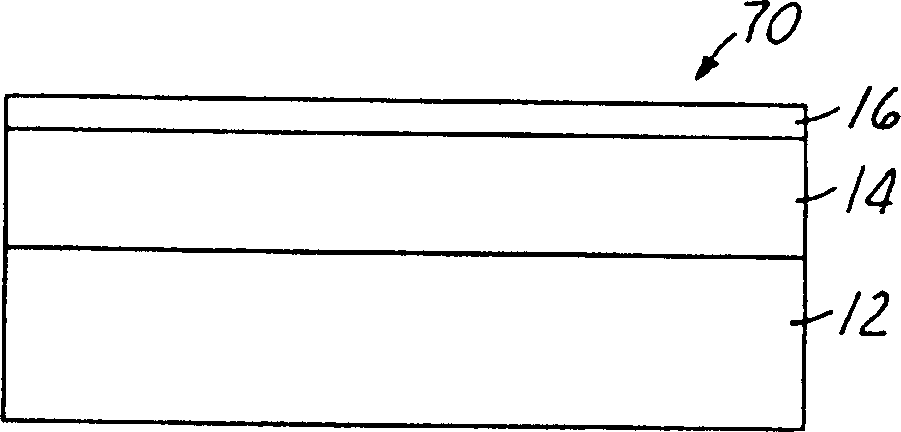

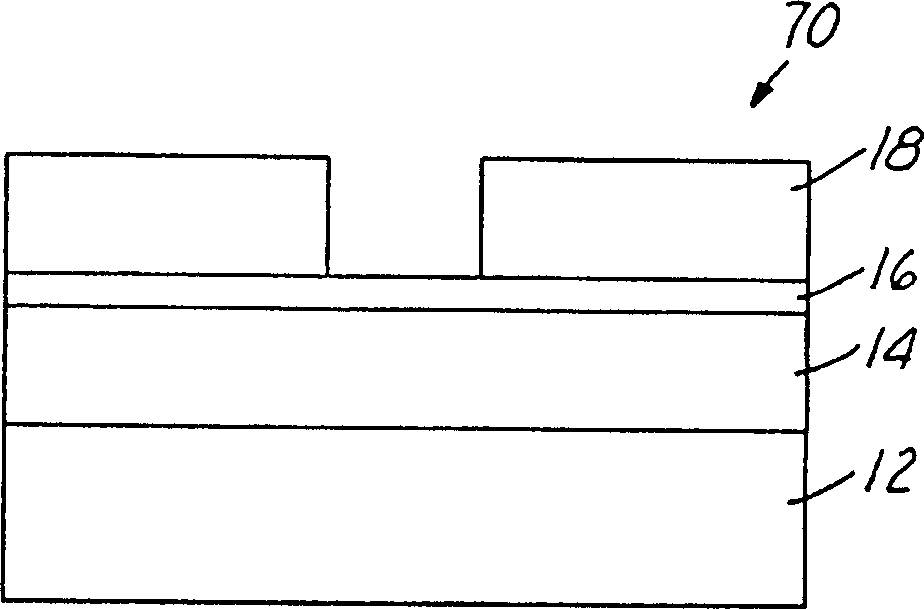

Method for forming porous dielectric material layer on semiconductor device and formed device

InactiveCN1427456ANot subject to erosionPorositySemiconductor/solid-state device detailsSolid-state devicesElectronic structureThermosetting polymer

A method for forming a porous dielectric material layer in an electronic structure and the structure formed are disclosed. In the method, a porous dielectric layer in a semiconductor device can be formed by first forming a non-porous dielectric layer, then partially curing, patterning by reactive ion etching, and final curing the non-porous dielectric layer at a higher temperature than the partial curing temperature to transform the non-porous dielectric material into a porous dielectric material, thus achieving a dielectric material that has significantly improved dielectric constant, i.e. smaller than 2.6. The non-porous dielectric material may be formed by embedding a thermally stable dielectric material such as methyl silsesquioxane, hydrogen silsesquioxane, benzocyclobutene or aromatic thermoset polymers with a second phase polymeric material therein such that, at the higher curing temperature, the second phase polymeric material substantially volatilizes to leave voids behind forming a void-filled dielectric material.

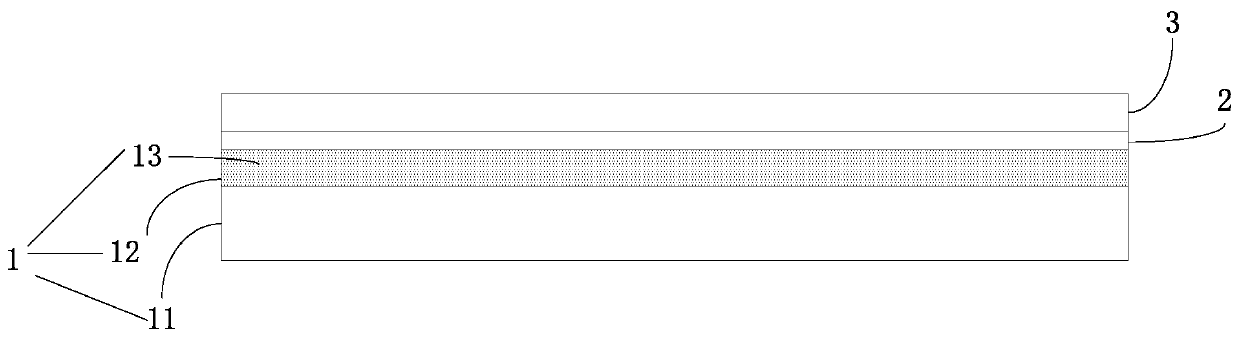

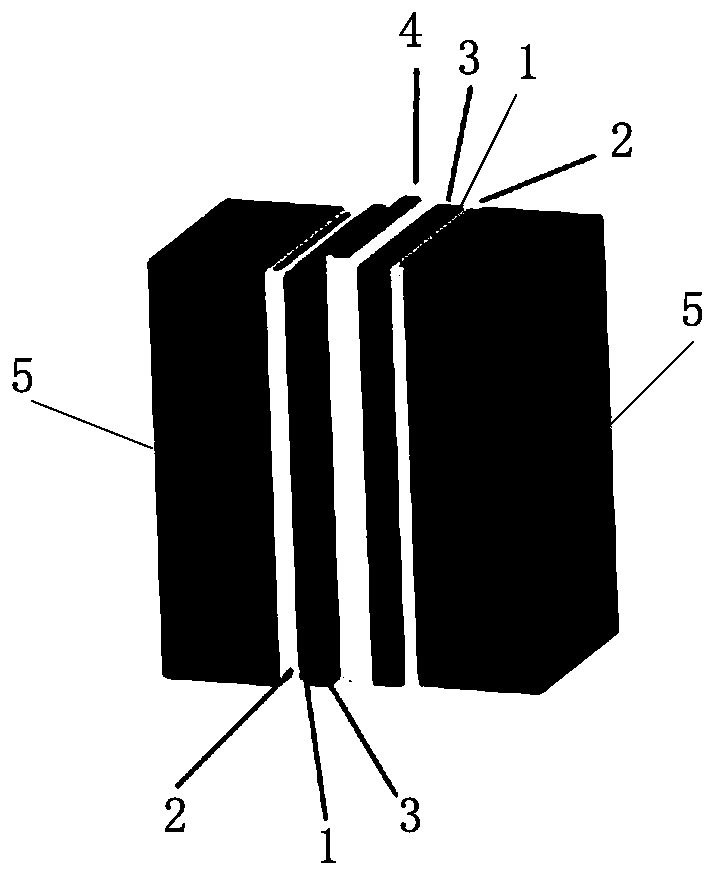

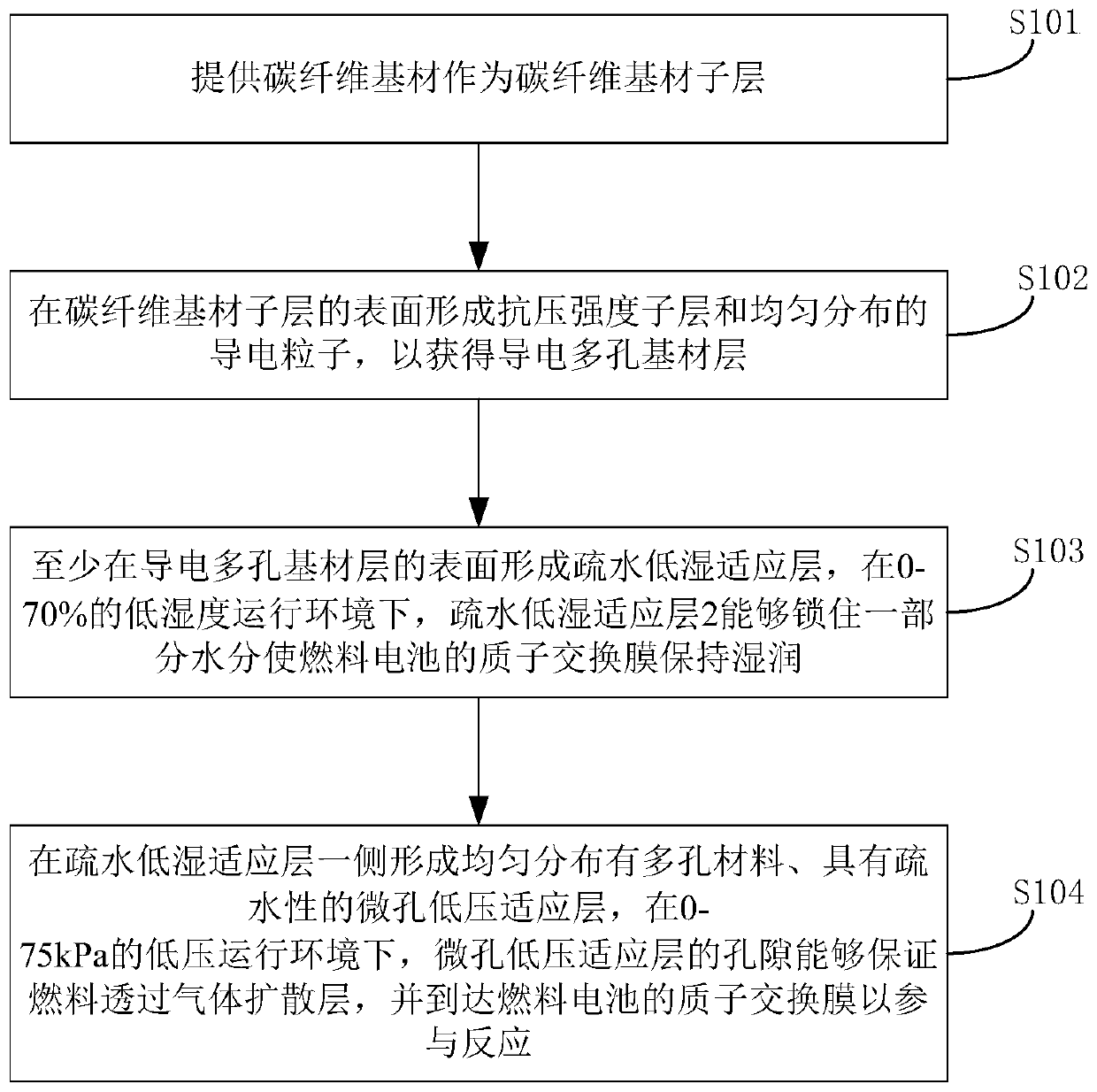

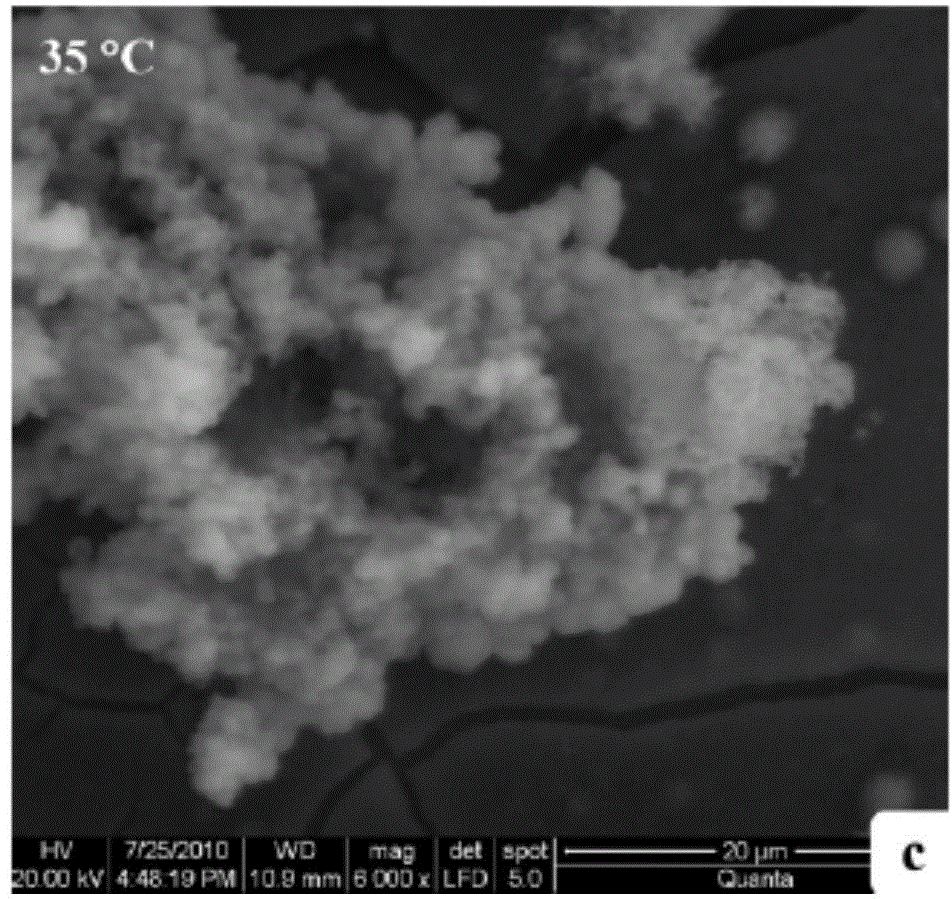

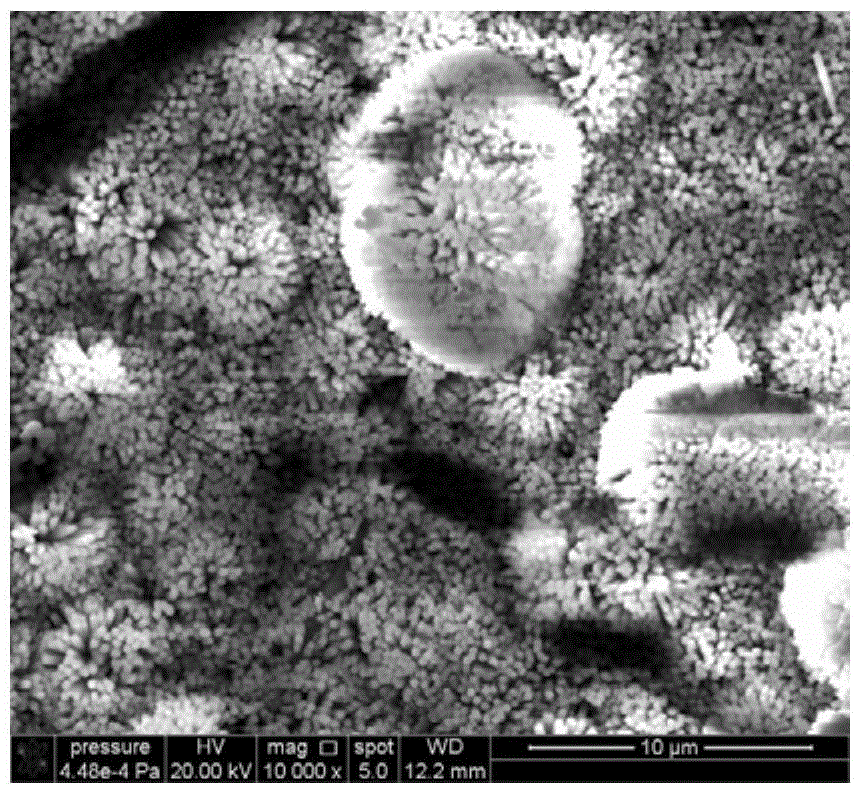

Low-pressure and low-humidity gas diffusion layer for fuel cells, fuel cell and preparation method

The invention discloses a low-pressure and low-humidity gas diffusion layer, a fuel cell and a preparation method. The gas diffusion layer comprises a conductive porous substrate layer, a hydrophobiclow-humidity adaptation layer and a micro-porous low-pressure adaptation layer. The conductive porous substrate layer includes a carbon fiber substrate sub-layer, a compressive sub-layer and uniformlydistributed conductive particles. The hydrophobic low-humidity adaptation layer is at least formed on the surface of the conductive porous substrate layer, and can lock a part of water to keep a proton exchange membrane wet in a low-humidity (0-70%) operation environment. The micro-porous low-pressure adaptation layer includes a porous material which is formed on one side of the hydrophobic low-humidity adaptation layer and uniformly distributed. The micro-porous low-pressure adaptation layer is hydrophobic, and the pores can ensure that the fuel permeates the gas diffusion layer and reachesthe proton exchange membrane to participate in the reaction in a low-pressure (0-75kPa) operation environment. Through the technical scheme, the mechanical strength of the gas diffusion layer can be improved, the gas diffusion layer has excellent gas diffusion performance and drainage performance, the fuel cell is enabled to operate stably in low-pressure and low-humidity environments, and technical support is provided for the adjustment of the bulk resistance.

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

Silver-containing fluorhydroxyapatite coating, and preparation method and application of coating

InactiveCN104857563APrevent proliferationReduce postoperative infection rateElectrolytic coatingsProsthesisPorosityNitrate

The invention provides a silver-containing fluorhydroxyapatite coating, and a preparation method and an application of the coating. A molecular formula of the coating is as shown below: AgxCa10-x(PO4)6(OH)2-yFy, wherein x is greater than 0 and less than or equal to 10; and y is greater than 0 and less than 2. The coating is applied to a medical magnesium metal surface. The method comprises the steps that a component containing a silver ion is added to an electrodeposition solution; the coating is electrodeposited on the magnesium metal surface; and nitrate solution soaking is performed, so that the stability of the coating is further improved and the uniformity of silver content is ensured. According to the coating, the method and the application, the stability of silver-containing fluorhydroxyapatite is adjusted by adjusting F content and hydroxyl content, so that a degradation cycle and a rate of the silver-containing fluorhydroxyapatite are adjusted and controlled, and the coating is applicable to different application positions and requirements; and the surface has certain porosity, so that bone ingrowth is facilitated, and a binding force of an implant is increased. The coating has effects of controlling bacteria of an implantation position and reducing a postoperative infection rate.

Owner:SUZHOU ORIGIN MEDICAL TECH

Dephosphorization and denitrification integrated material prepared based on battering method and preparation method thereof

InactiveCN101693186AAchieve recyclingReduce eutrophicationOther chemical processesAluminium silicatesSlagPulverised fuel ash

A dephosphorization and denitrification integrated material prepared based on a battering method mainly consists of the following materials according to mass ratio: 2 to 4 percent of fly ash, 0.3 to 0.7 percent of steel slag, 0.3 to 0.7 percent of zeolite powder, 1 to 3 percent of binder, and the balance of zeolite particles. Aiming at problems existing in the current sewage and wastewater treatment, the invention provides a composite material with dephosphorization and denitrification functions simultaneously, and a preparation method thereof; and compared with the existing sewage and wastewater treatment materials, the novel composite material not only can protect the environment and realize the reclamation of wastes, but also can obtain good social and economic benefits.

Owner:SOUTHEAST UNIV

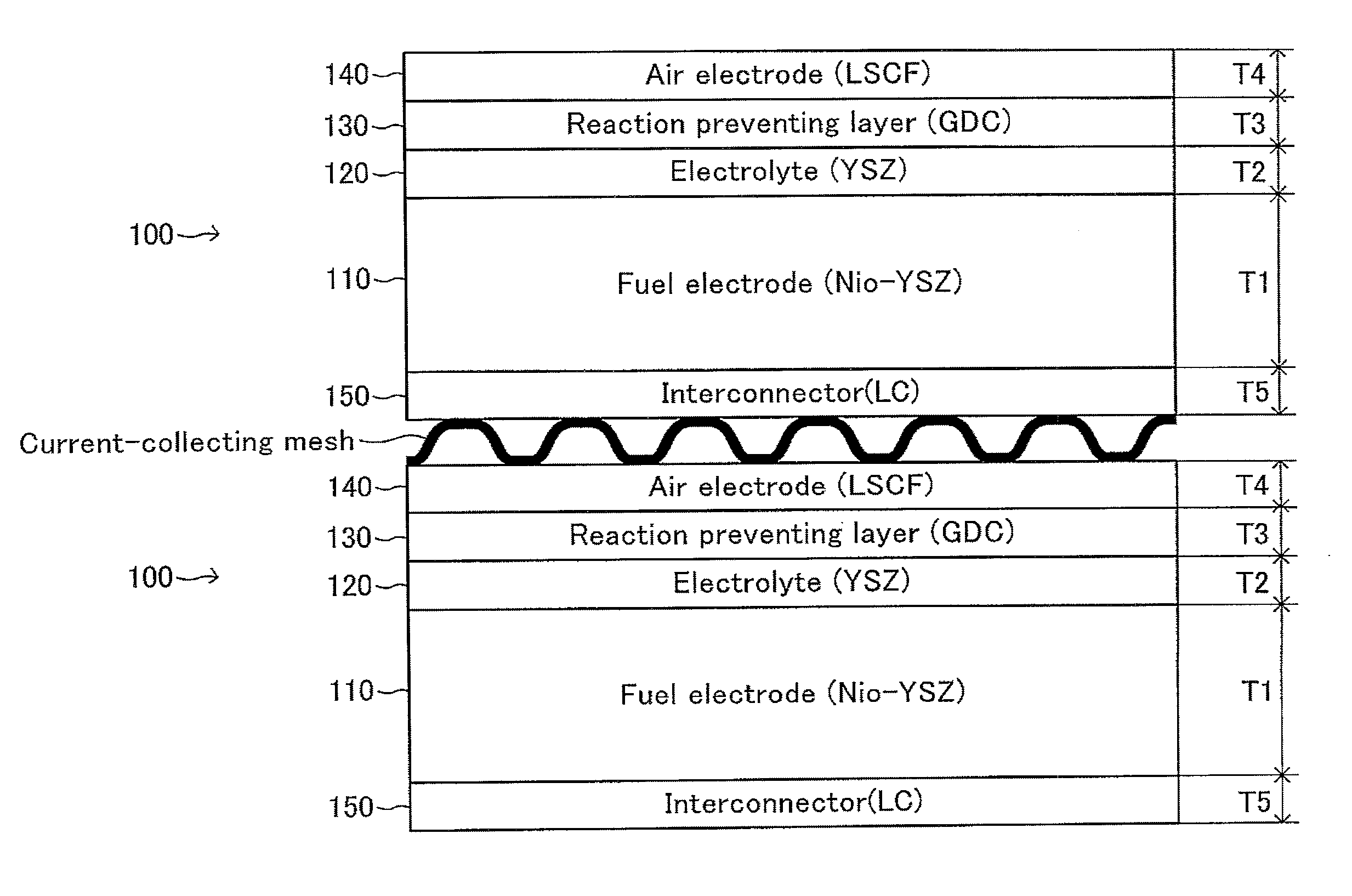

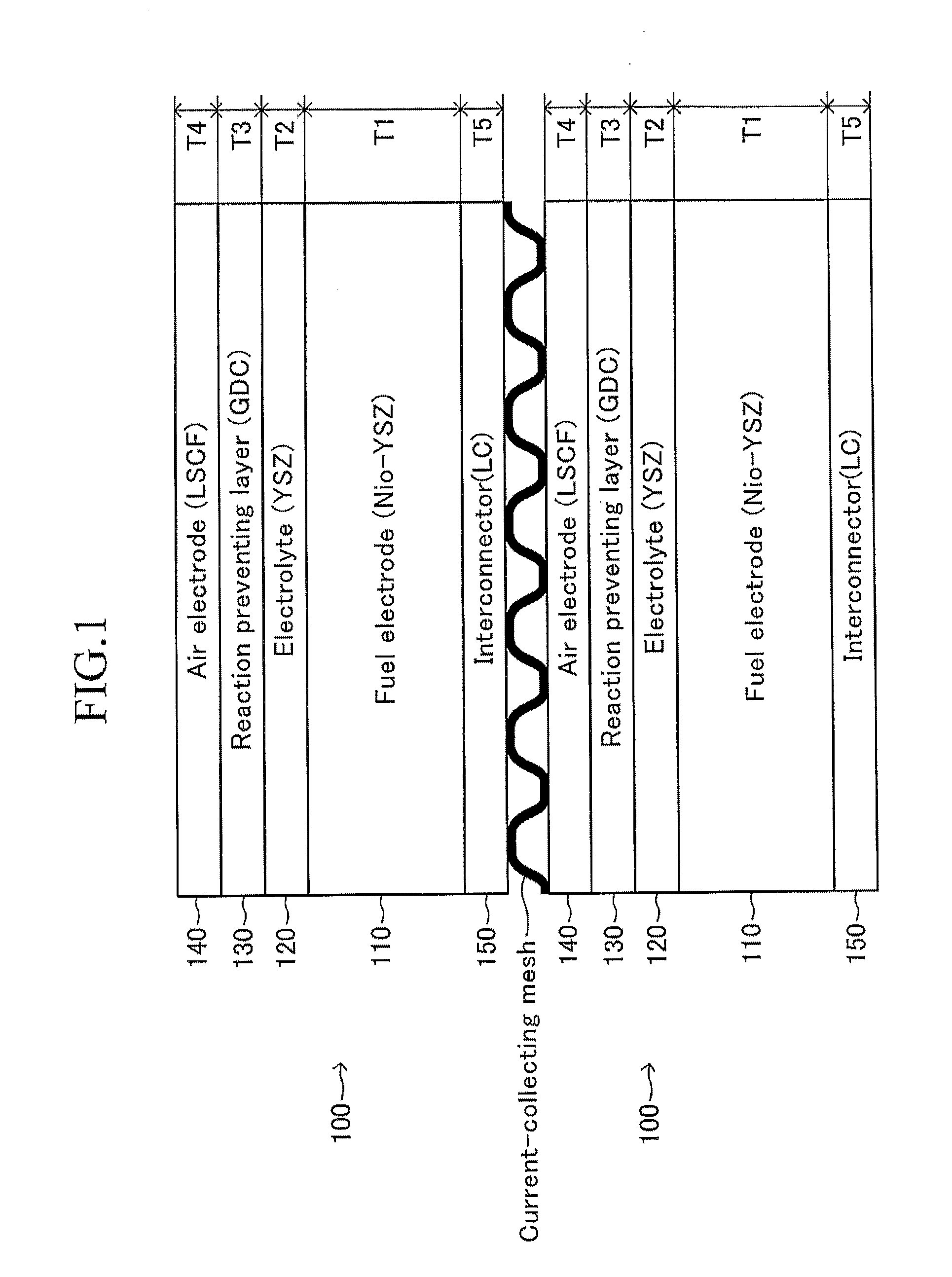

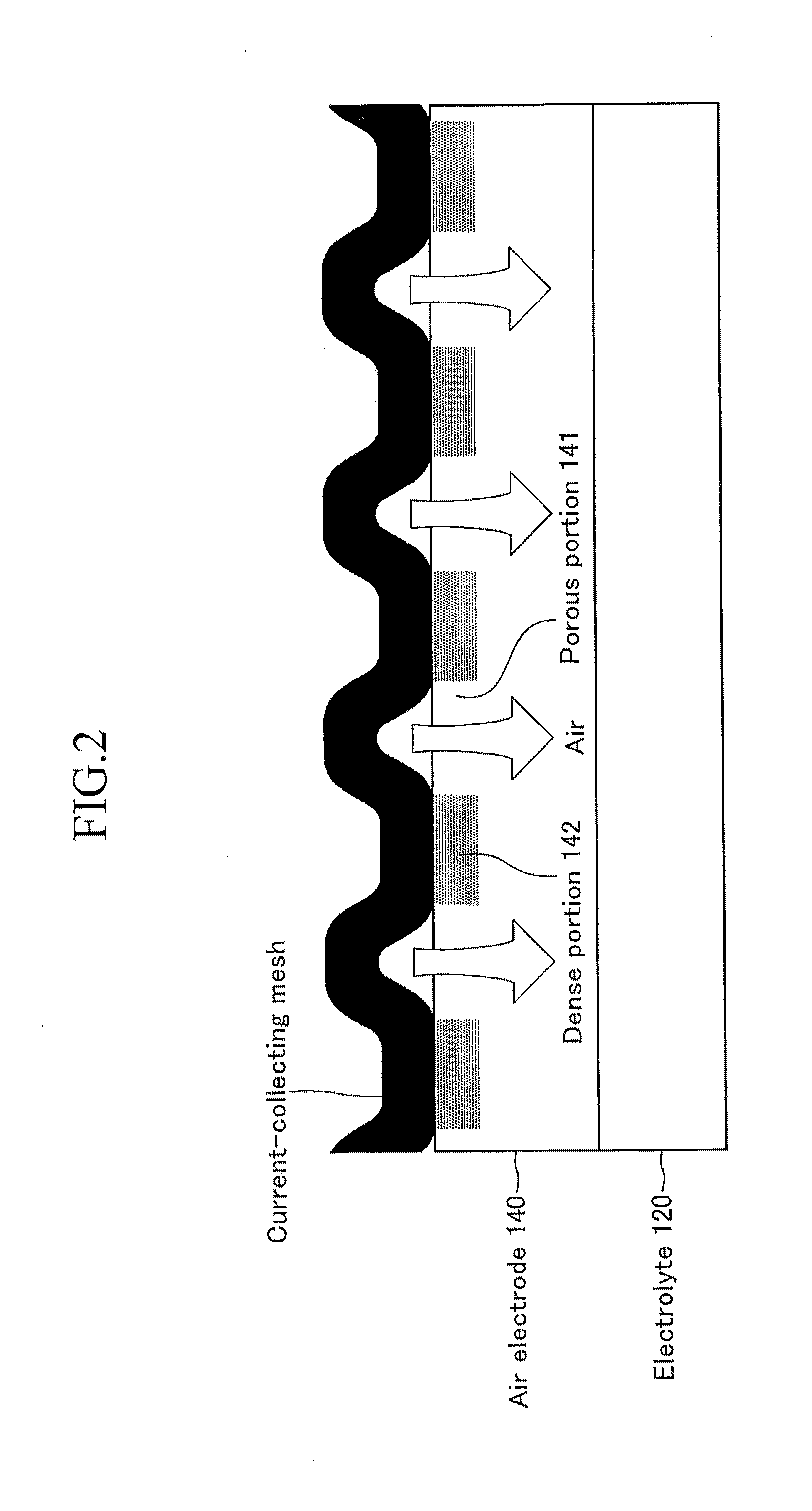

Solid oxide fuel cell

ActiveUS20120164552A1Reduced responseIncrease productionFinal product manufactureElectrode carriers/collectorsPorosityFuel cells

A solid oxide fuel cell having a fuel electrode, a solid electrolyte film, an air electrode, and a conductive current-collecting mesh bonded to an upper surface, opposite to a lower bonding surface with the solid electrolyte film, of the air electrode. Plural bonding portions that are bonded to the current-collecting mesh and plural non-bonding portions that are not bonded to the current-collecting mesh are present on the upper surface of the air electrode. In the air electrode, regions having a porosity smaller than a porosity of the other region are respectively formed on the position in the middle of the thickness of the air electrode from each bonding portion. The average of the porosity of the dense portion is 20% or more and less than 35%, while the average of the porosity of the porous portion is 35% or more and less than 55%.

Owner:NGK INSULATORS LTD

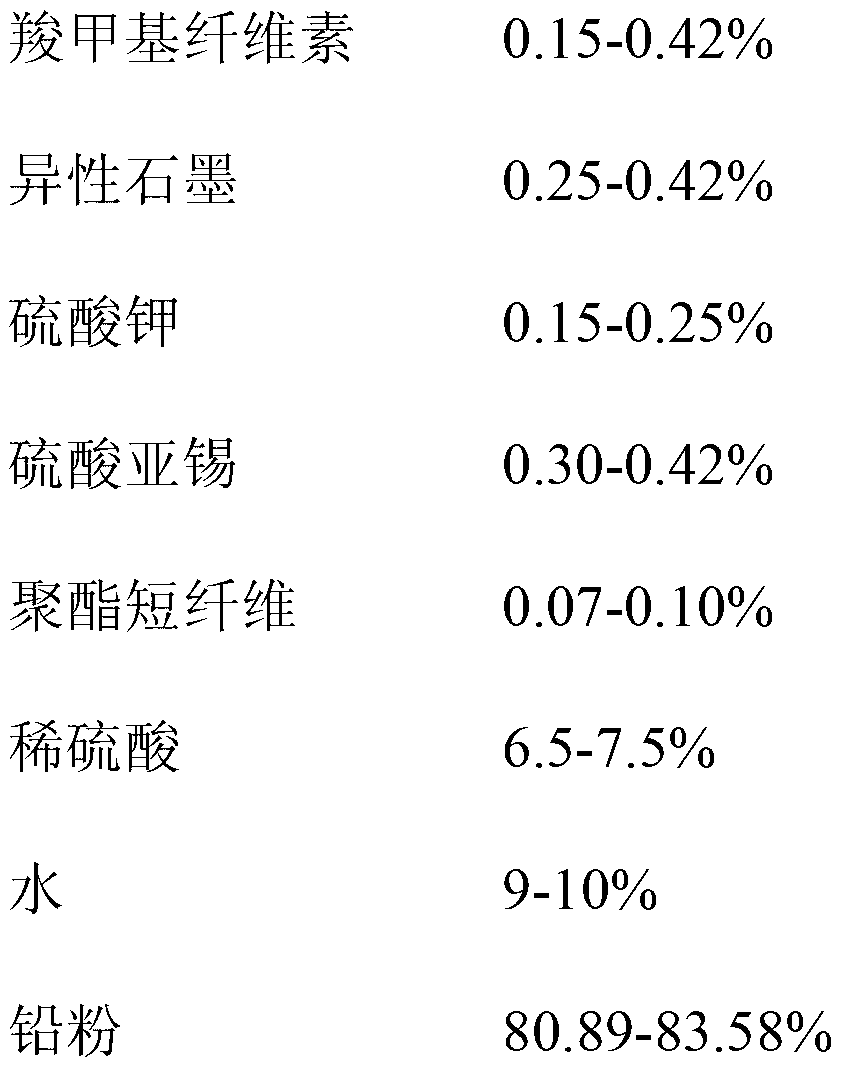

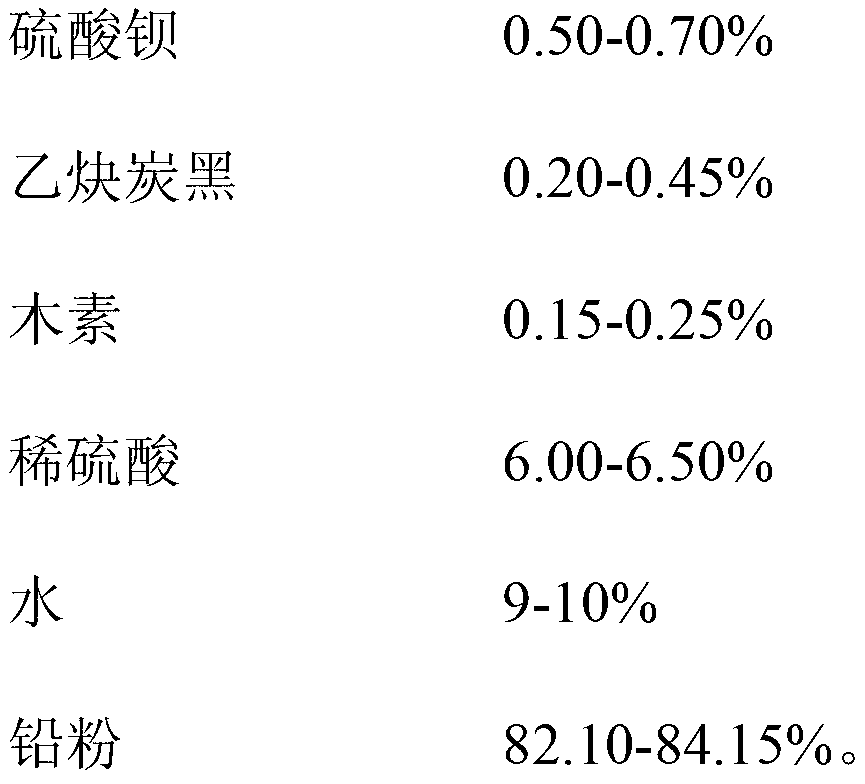

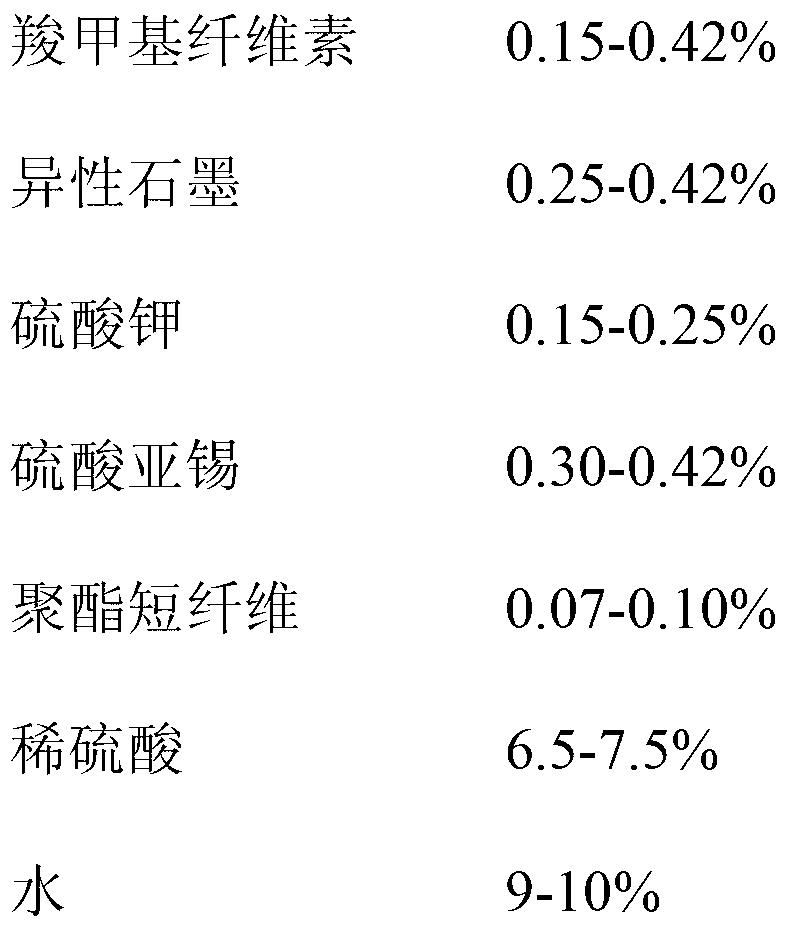

Deep circulation storage battery container formation diachylon

ActiveCN103219512AImprove conductivityImprove charge reception capabilityCell electrodesCarboxymethyl cellulosePolyester

The present invention discloses a deep circulation storage battery container formation diachylon, and is to solve the technical problem of short circulation life of conventional storage batteries. The diachylon of the present invention includes a positive diachylon and a negative diachylon. The positive diachylon includes the components by weight: 0.15-0.42% of carboxymethyl cellulose, 0.25-0.42% of anisotropy graphite, 0.15-0.25% of potassium sulfate, 0.30-0.42% of stannous sulfate, 0.07-0.10% of polyester staple fibers, 6.5-7.5% of dilute sulfuric acid, 9-10% of water, and 80.89-83.58% of a lead powder; and the negative diachylon includes the components by weight: 0.50-0.70% of barium sulfate, 0.20-0.45% of acetylene black, 0.15-0.25% of lignin, 6.00-6.50% of dilute sulfuric acid, 9-10% of water, and 82.10-84.15% of a lead powder.

Owner:CHAOWEI POWER CO LTD

Light thermal insulation sprayed material

The invention discloses a light thermal insulation sprayed material. The sprayed material comprises expanded perlite, light low-aluminum aggregate, raw clay, high-aluminum cement, micro silicon powder, a compound additive and water glass, wherein the compound additive consists of brownmillerite and slaked lime. Compared with the traditional sprayed material, the sprayed material has the advantages that: the rebound rate is reduced from 14 percent to 8 percent, the adhesion rate of the sprayed material is greatly improved, and the utilization rate of the material is improved.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

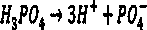

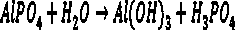

Water glass curing agent and preparation method and application thereof

InactiveCN108083672AIncrease valueControl curing speedPhosphorus compoundsCeramicwarePhosphoric acidALUMINUM PHOSPHATE

The invention provides a water glass curing agent and a preparation method and application thereof. The water glass curing agent comprises aluminum phosphate, zinc oxide modified shell powder, powderysilicic acid / silica fume and barium sulfate according to a mass ratio of aluminum phosphate to zinc oxide modified shell powder of (4-7): (1-2), a mass ratio of aluminum phosphate to powdery silicicacid / silica fume of 7: (1-2) and a mass ratio of aluminum phosphate to barium sulfate of (4-7): (0.5-1). Through loading and sintering, the novel water glass curing agent is prepared. The preparationmethod realizes initial control of a curing speed of water glass and improves the water resistance and toughness after curing.

Owner:广西经正科技开发有限责任公司

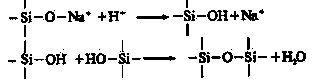

Calcium sulfate spherical particle alveolar bone repair material and preparation method and application thereof

ActiveCN103055345AImprove biological activityFully degradableProsthesisBULK ACTIVE INGREDIENTDrug biological activity

The invention relates to a calcium sulfate spherical particle alveolar bone repair material and a preparation method thereof. The calcium sulfate spherical particle alveolar bone repair material is mainly used for alveolar bone defect repair and also can be used for other bone defect repair, and belongs to the field of biomedical material. The calcium sulfate spherical particle alveolar bone repair material is characterized in that active ingredients are prepared from the following raw materials: (a) calcium sulfate, (b) molding liquid, and (c) surface modification liquid; and the size of the spherical particle is 0.5-2.0mm. The calcium sulfate is alpha type hemihydrate calcium sulfate powder. The surface modification liquid is soluble silicate aqueous solution. The calcium sulfate spherical particle alveolar bone repair material and the preparation method thereof have the following advantages: the provided calcium sulfate spherical particle alveolar bone repair material has the advantages of being excellent in biological activity, being capable of completely being degraded for a controllable period, and the like; good space can be provided for the growth of bone cells through big holes with the diameters of 183-732 microns produced by piling of spherical calcium sulfate particles in specific sizes; and the material is simple in preparation technology, short in preparation period and low in cost.

Owner:KUNMING UNIV OF SCI & TECH

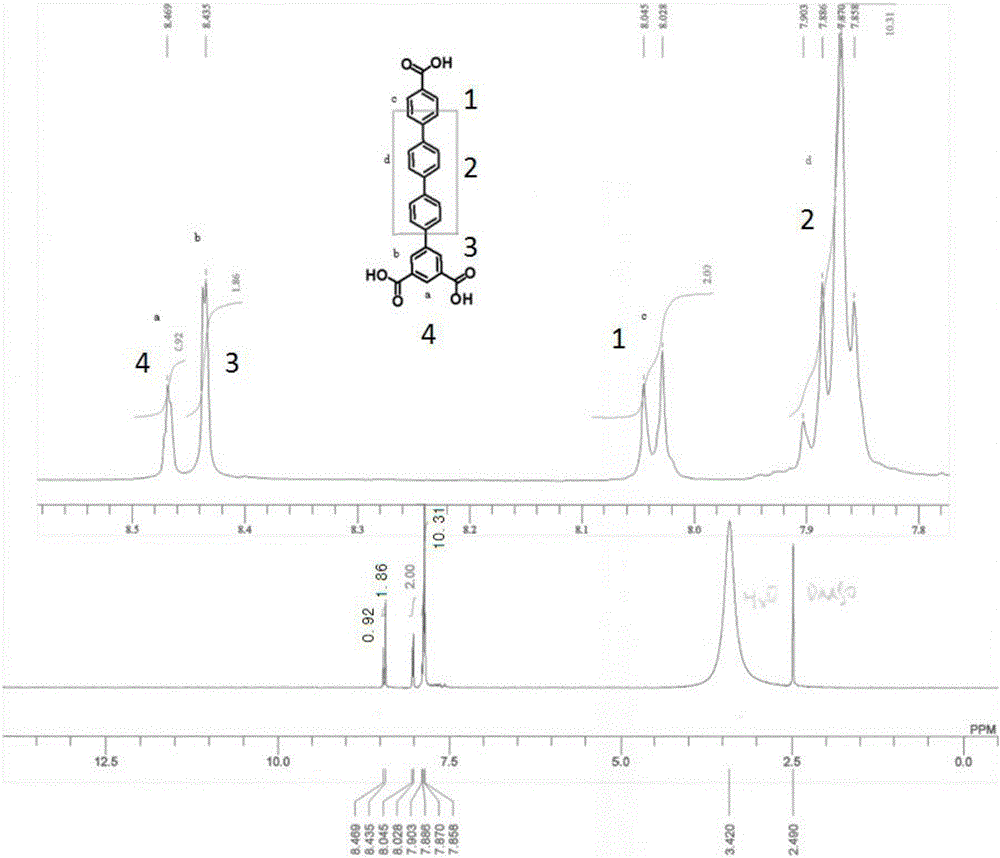

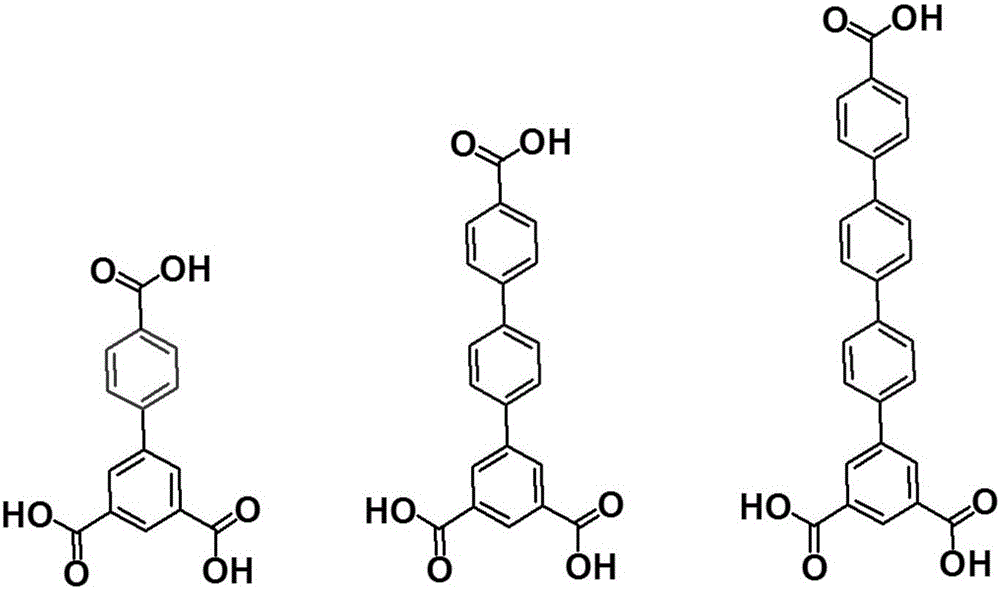

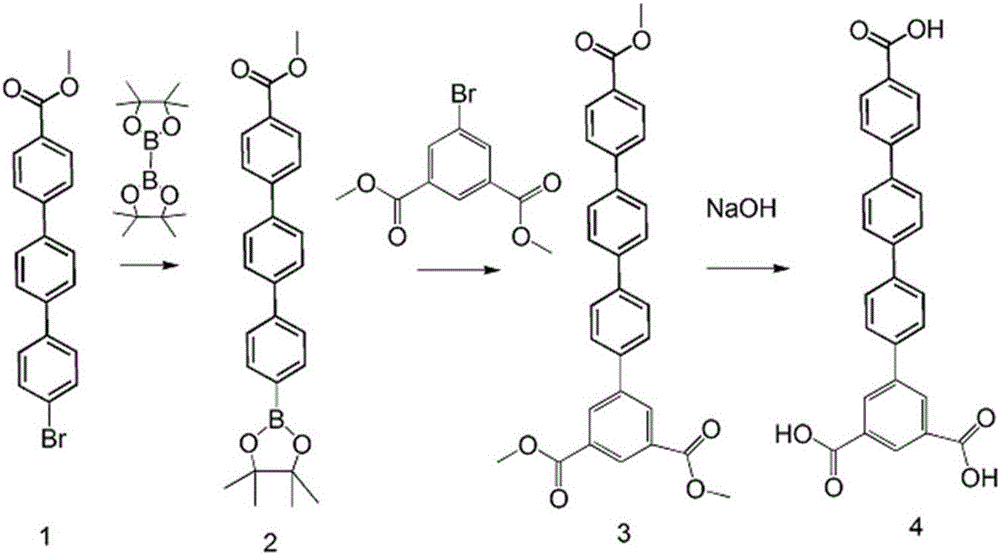

Lanthanum-series porous coordination polymers based on C2v symmetrical ligands, and synthesis method and application thereof

ActiveCN105936639AAchieve precise color adjustmentEasy to operateOther chemical processesGroup 3/13 organic compounds without C-metal linkagesFluorescenceSynthesis methods

The invention belongs to the field of material preparation, and mainly relates to lanthanum-series porous coordination polymers based on C2v symmetrical ligands, and a synthesis method and an application thereof. A series of fluorescent porous coordination polymers based on the C2v symmetrical ligands with gradually increased conjugacy are designed and synthesized, and the synthesis method is simple, convenient and easy to implement. The prepared novel lanthanum-series porous coordination polymers have good fluorescent properties; by adjusting the ligands and lanthanide elements, chrominance between pink and blue light can be adjusted; based on relatively high quenching coefficient, the polymers can be used for molecular recognition. Single crystal X-ray diffraction reveals that the pore size and the pore volume are controlled by the system, and the prepared porous coordination polymers have potential applications in highly-effective adsorption and release of iodine.

Owner:NANJING UNIV OF TECH

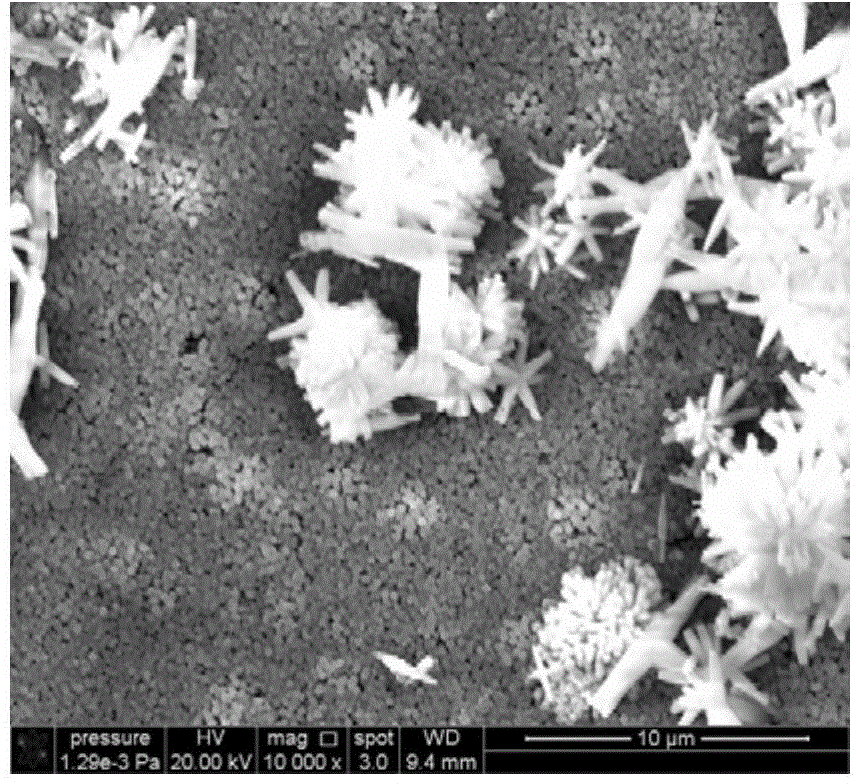

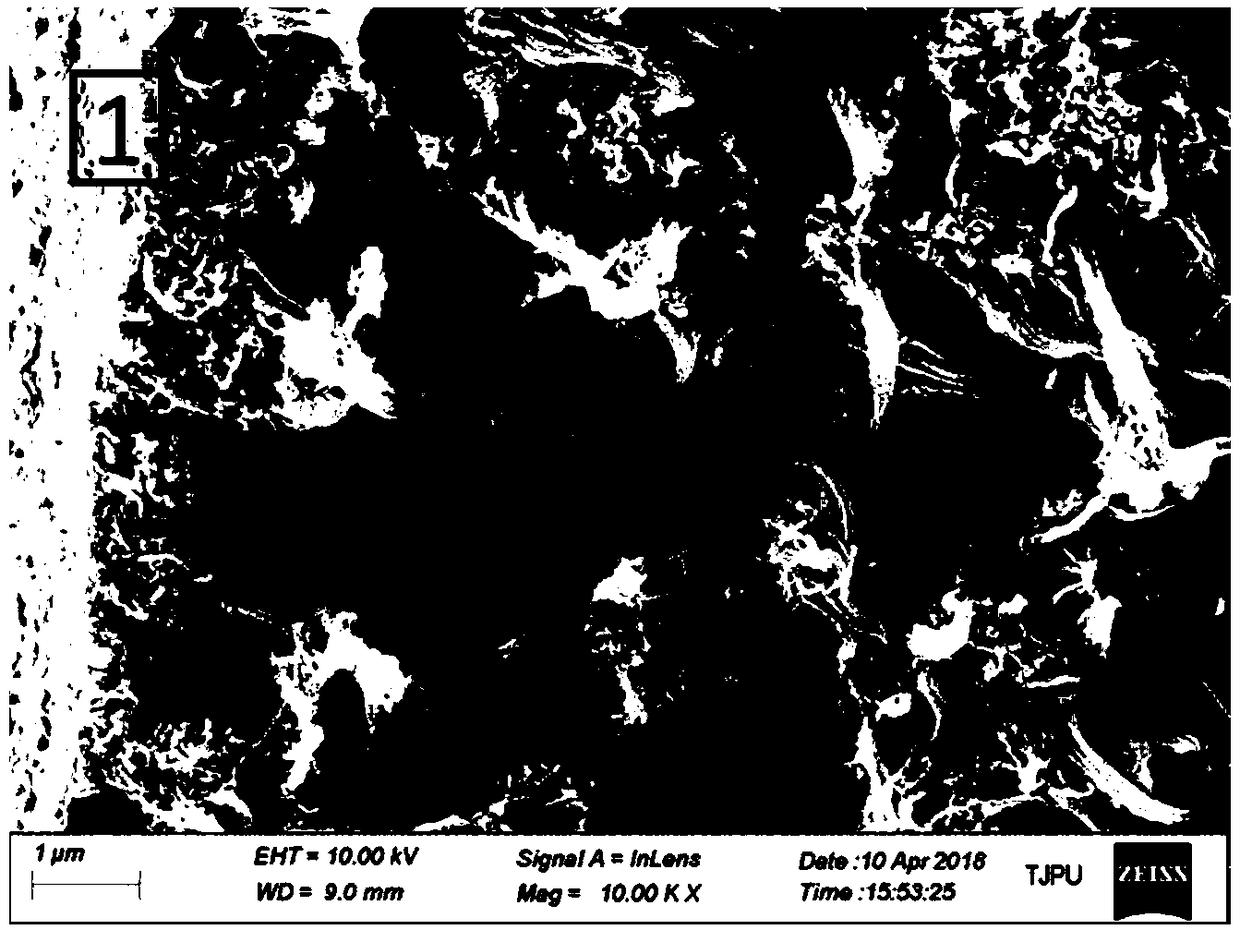

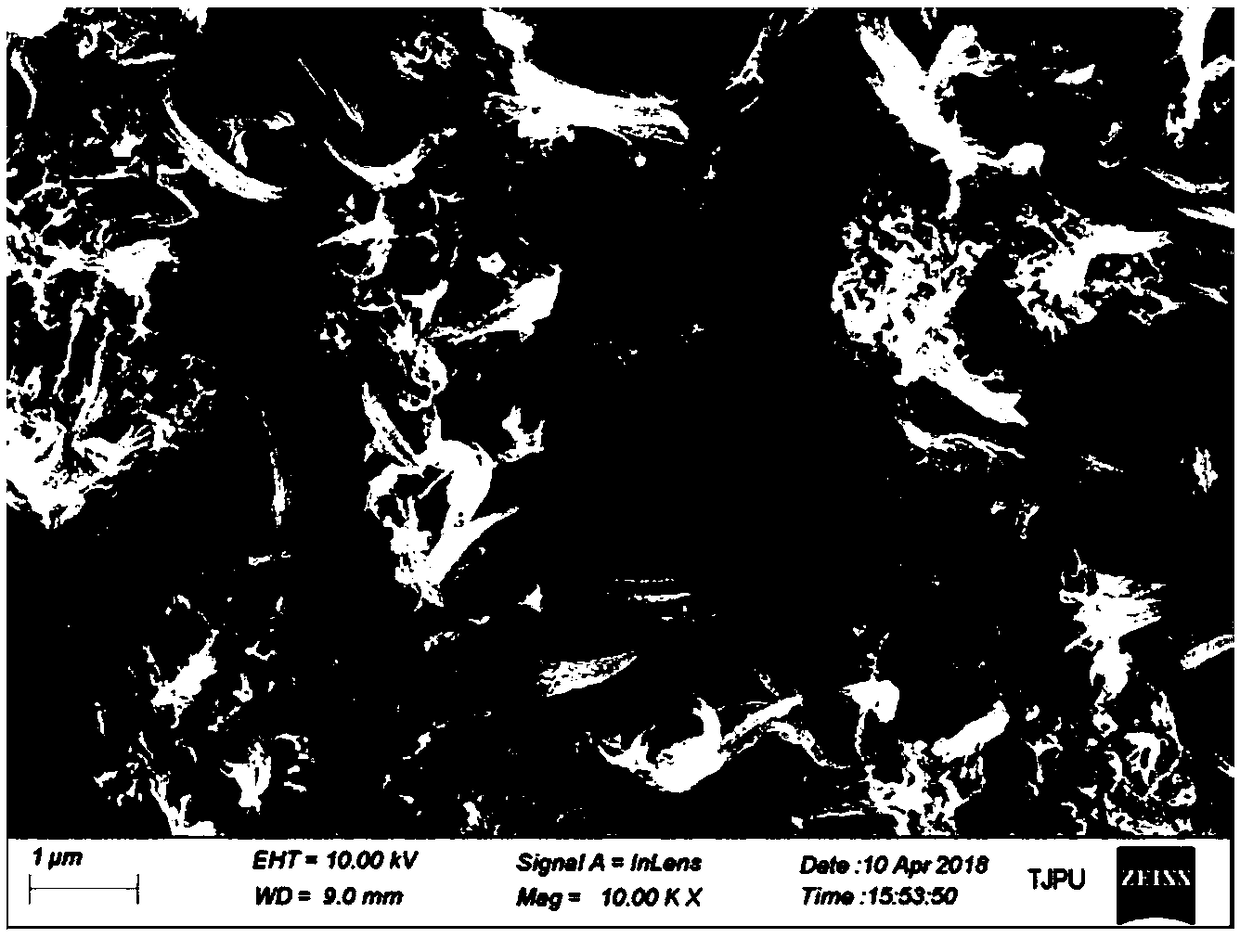

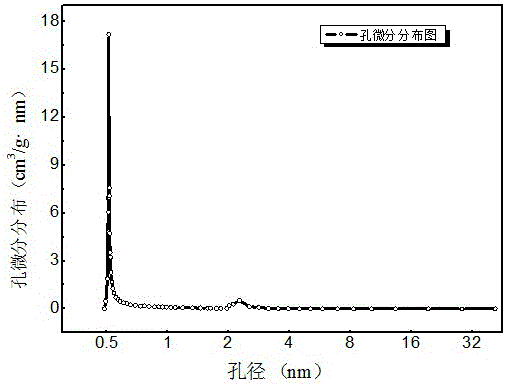

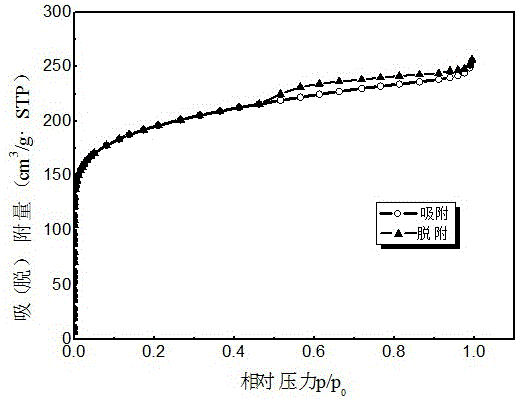

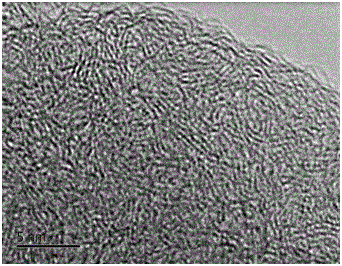

Novel graphene-molecular sieve composite gas purifying material and preparation method thereof

InactiveCN106693893APorousPorosityOther chemical processesDispersed particle separationPorosityMolecular sieve

A preparation method of a novel graphene-molecular sieve composite gas purifying material comprises the following steps: 1) activating a 3A molecular sieve; 2) activating a graphene oxide, and obtaining a graphene suspension through ultrasonic dispersion; 3) adding the activated 3A molecular sieve and the graphene suspension into a hydrothermal reaction kettle according to a mass ratio ranging from (1:5) to (1:20), performing a hydrothermal reaction for 8-12h at 180-220 DEG C, filtering and drying a reaction product, and vacuumizing in a vacuum drying box to obtain the graphene-molecular sieve composite gas purifying material. The graphene-molecular sieve composite gas purifying material prepared according to the preparation method solves the problems in aspects of the specific surface area and the selectivity of the conventional adsorbent material, and has permanent porosity and pore diversity. The invention further provides the novel graphene-molecular sieve composite gas purifying material prepared according to the preparation method.

Owner:GUANGZHOU FENGSHANG ELECTRIC APPLIANCE

Coarse-cell polyurethane foam board produced with wet method

The invention discloses a coarse-cell polyurethane foam board produced with a wet method. The foam board is characterized in that: the foam board is produced from materials of, by weight: 100 parts of a mixture of 2-5 types of polyether glycol or 2-3 types of polyether glycol and 1-2 types of polyester polyol, 1-2 parts of 1-2 types of hard-bubble silicone oil, 0.1-0.5 parts of 2-3 types of aminecatalysts, 5-20 parts of a foaming agent, 0.5-1.5 parts of mixed silicone oil, 0.1-0.3 parts of a delayed action catalyst, 1.0-2.0 parts of an open-cell agent, and 120-160 parts of coarse MDI. The produced polyurethane foam board has cell sizes of 1-1.5mm. With the foam board, molding production efficiency of car inner decorative ceilings is improved by above 30%, and a rejection rate of the car inner decorative ceiling molding production is reduced by above 5%.

Owner:YANTAI ZHENGHAI HIGH TECH

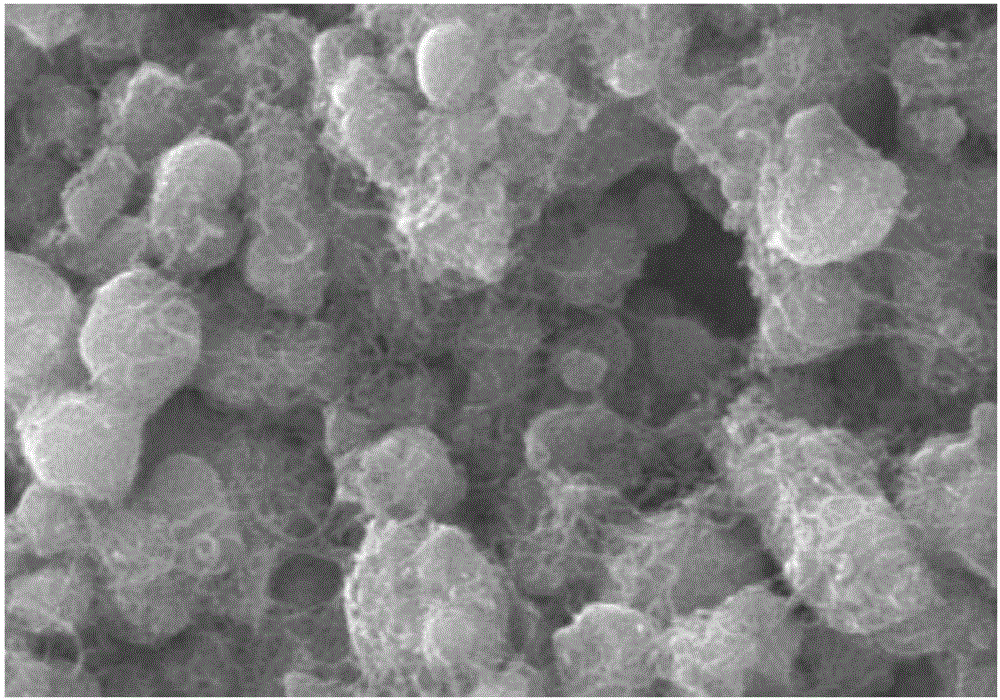

Preparation method for microporous polyphenylene sulfide hollow fiber membrane

The invention discloses a preparation method for a microporous polyphenylene sulfide hollow fiber membrane. The preparation method comprises the following steps of 1) uniformly mixing a diluent, a pore-forming agent, inorganic nanoparticles and polyphenylene sulfide so as to obtain a homogeneous-phase polyphenylene sulfide membrane casting solution; 2) adjusting the feeding rotating speed of a screw machine, the rotating speed of a main engine, the rotating speed of a metering pump and the heating temperature of each part, and then putting the polyphenylene sulfide membrane casting solution obtained in step 1) into the screw machine; 3) setting the gas flow rate or the core liquid flow rate of a nozzle of the screw machine, setting the temperature of a coagulating bath and the receiving distance of the coagulating bath, and carrying out spinning; and 4) immersing membrane yarns obtained in step 3) into a heated extraction agent, and carrying out drying to remove the organic solvent soas to obtain the microporous polyphenylene sulfide hollow fiber membrane. According to the method, the inorganic nanoparticles and the auxiliary diluent are added to regulate and control the crystallization rate and the phase-splitting process of the membrane casting solution; and the diluent is separated out by the aid of extraction liquid, and then the hollow fiber membrane with micro-nano through holes which are formed in the inner surface and the outer surface, enable the outside to be communicated with the inside and are uniformly distributed is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

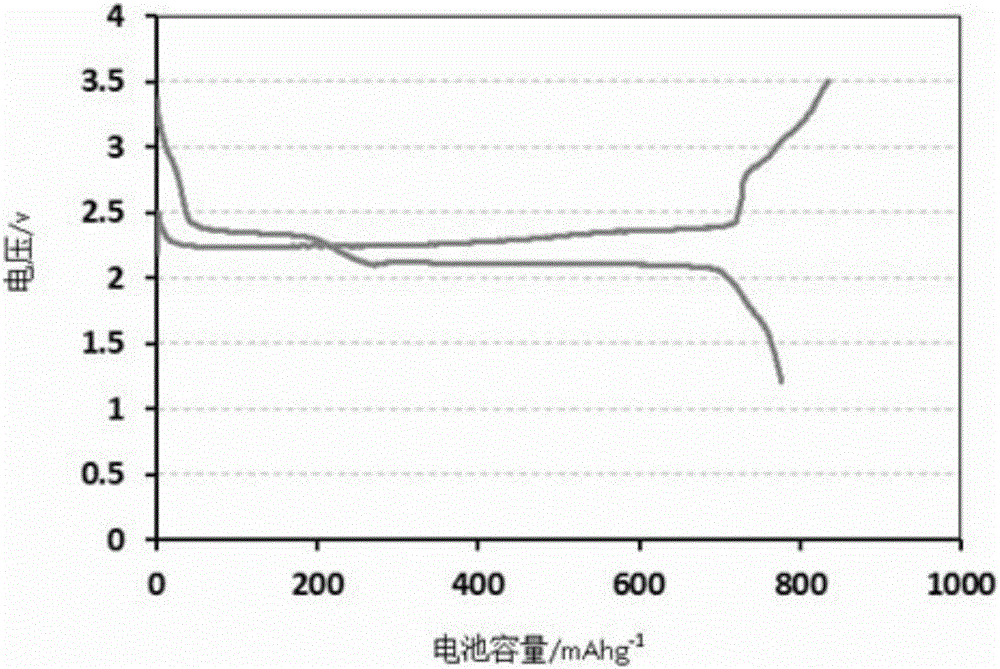

Manganese dioxide sulfur-carbon positive electrode and preparation method

The invention belongs to the field of lithium battery preparation, and specifically relates to a manganese dioxide sulfur-carbon positive electrode and a preparation method. The preparation method comprises the following steps: 1) adopting a vapor deposition method, and uniformly mixing sublimed sulfur powder and conductive agent powder to obtain a sulfur-carbon composite material; 2) mixing the sulfur-carbon composite material obtained in the step 1), powdered sulfur, manganese dioxide, a dispersing agent and a binder, using 1-methyl-2-pyrrolidinone (NMP) as a solvent, sufficiently and uniformly stirring to obtain a mixed sizing agent; 3) uniformly coating the mixed sizing agent on the surface of a positive electrode current collector to form a positive electrode coating layer, then heating and drying at the temperature of 60 to 130 DEG C so as to obtain a primary manganese dioxide sulfur-carbon core-shell structure positive electrode; and 4) heating the pole piece of the primary manganese dioxide sulfur-carbon core-shell structure positive electrode obtained in the step 3) in a nitrogen environment, and carrying out in situ sublimation so that sulfur grows on a sulfur-carbon shell of the primary manganese dioxide sulfur-carbon core-shell structure to complete sulfur fixation, and thus forming a secondary manganese dioxide sulfur-carbon core-shell structure.

Owner:TIANJIN LISHEN BATTERY +1

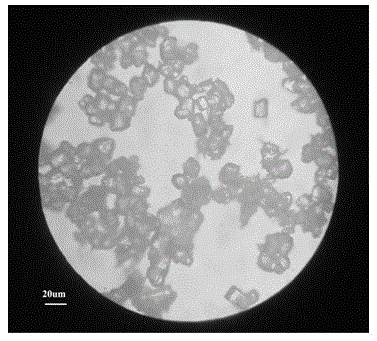

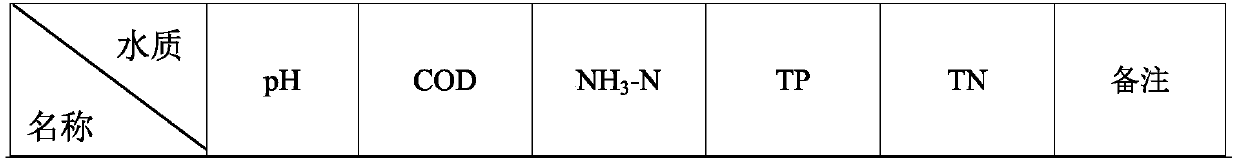

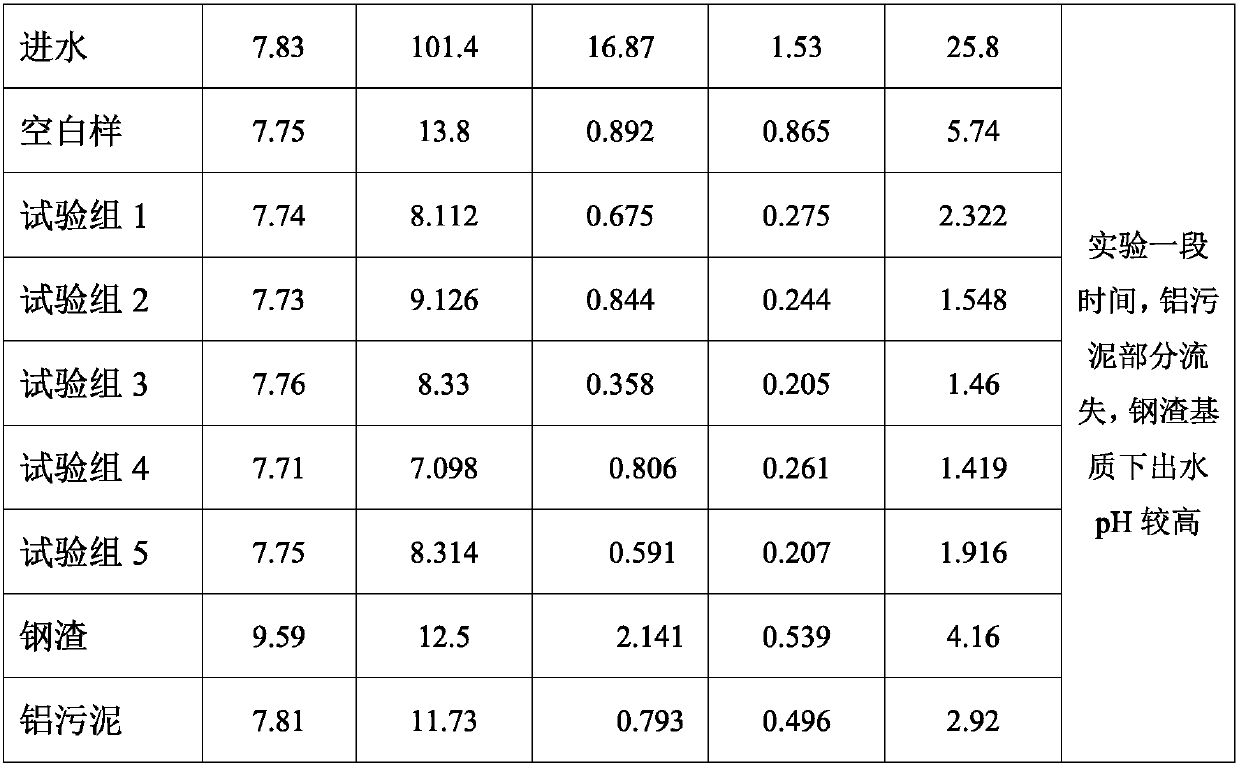

Ecological floating island phosphorous removal composite medium and preparation method thereof

InactiveCN109678249AGood environmental benefitsLow costWater contaminantsBiological treatment apparatusFloating islandAluminium

The invention relates to an ecological floating island phosphorous removal composite medium and a preparation method thereof. The preparation method comprises the following specific preparation processes: S1, respectively carrying out drying pretreatment on aluminum sludge, steel slag and a coconut shell fiber, grinding into powder, and mixing so as to obtain aluminum sludge powder, steel slag powder and coconut shell fiber powder; S2, weighing the following components made in the step S1 in percentage by weight: 40-50% of the aluminum sludge powder, 20-30% of the steel slag powder, 10-20% ofthe coconut shell fiber powder, 5-10% of an adhesive and 5-10% of starch for later use; S3, mixing the aluminum sludge powder, the steel slag powder and the coconut shell fiber powder weighed in the step S2 so as to obtain first mixed powder; S4, sufficiently stirring the adhesive and the starch weighed in the step S2 with the first mixed powder made in the step S3, adding water, carrying out pelletizing and medium / high temperature thermal treatment, and cooling, thereby obtaining ecological floating island phosphorous removal composite medium granules. The ecological floating island phosphorous removal composite medium has the advantages of being low in cost, good in phosphorous removal effect, effective in waste resource recycling, and good in pore structure.

Owner:河南永泽环境科技有限公司

Cordierite compound ceramic filter element and preparation method thereof

ActiveCN103830962AImprove toughnessImprove adsorption capacityOther chemical processesFiltration separationFiltrationHeat stability

The invention discloses a cordierite compound ceramic filter element. The cordierite compound ceramic filter element is characterized by being prepared from the following raw materials in parts by weight: 13-15 parts of cordierite, 9-11 parts of mullite, 6-8 parts of silochrom, 4-7 parts of smectite, 8-10 parts of activated alumina, 3-5 parts of calcium sulfate, 2-3 parts of dimethyl silicon oil, 3-4 parts of sodium alginate, 3-5 parts of palm fibers, 2-3 parts of urea, 5-7 parts of modifying coconut active charcoal, and the defined amount of water. The cordierite compound ceramic filter element provided by the invention has the advantages that the silochrom is added, so that the adsorptive property and heat stability are good, the chemical property is stable, and the mechanical strength is high; the palm fibers are added, so that the tenacity of the filter element is added, meanwhile, the cordierite compound ceramic filter element has a porous property, and the filtering adsorptive property is improved; the modifying coconut active charcoal is added, so that the gap structure is developed, the adsorptive property is good, the intensity is high, the regeneration is easy, and the cordierite compound ceramic filter element is economical and durable, is long in service life, is corrosion-proof and can be used for air adsorption filtration.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

InactiveCN106517189AReduce dosageReduce corrosionHydrogen separation by selective and reversible uptakeCarbon compoundsActivation methodMass ratio

The invention relates to uniform ultra-microporous activated carbon for gas separation and a preparation method of the uniform ultra-microporous activated carbon. According to the technical scheme of the preparation method, mixing semi-coke with KOH in a mass ratio being 1: (0.01-0.2), adding water and an activating aid to impregnate the mixture for 1-36 h; increasing the temperature to 800-950 DEG C in a programmed manner under N2 protection, controlling thermal decomposition, and introducing water for activation of part of steam for 0.5h-1.5h; finally, washing the mixture with acid and water until the mixture is neutral to obtain the uniform ultra-microporous activated carbon. The pore size is distributed centrally between 0.45 and 0.55 nm, the pores belong to ultra-micropores and have microporosity of 70% or more, and the adsorption capacity of hydrogen is 77cm<3> / g or higher. The semi-coke is taken as a raw material, low in price and low in energy consumption and needs not to be carbonized; an activation method integrates KOH impregnation pretreatment and activation of part of steam, little KOH is consumed, and the activation method has the characteristics of being low in cost and pollution, helpful for reducing corrosion of equipment and the like. The activated carbon prepared with the method has the characteristics of uniform pore size distribution, extremely rich ultra-microporous structure and the like, and can be used in gas separation fields such as pressure swing adsorption hydrogen making or hydrogen storage and the like.

Owner:WUHAN UNIV OF SCI & TECH

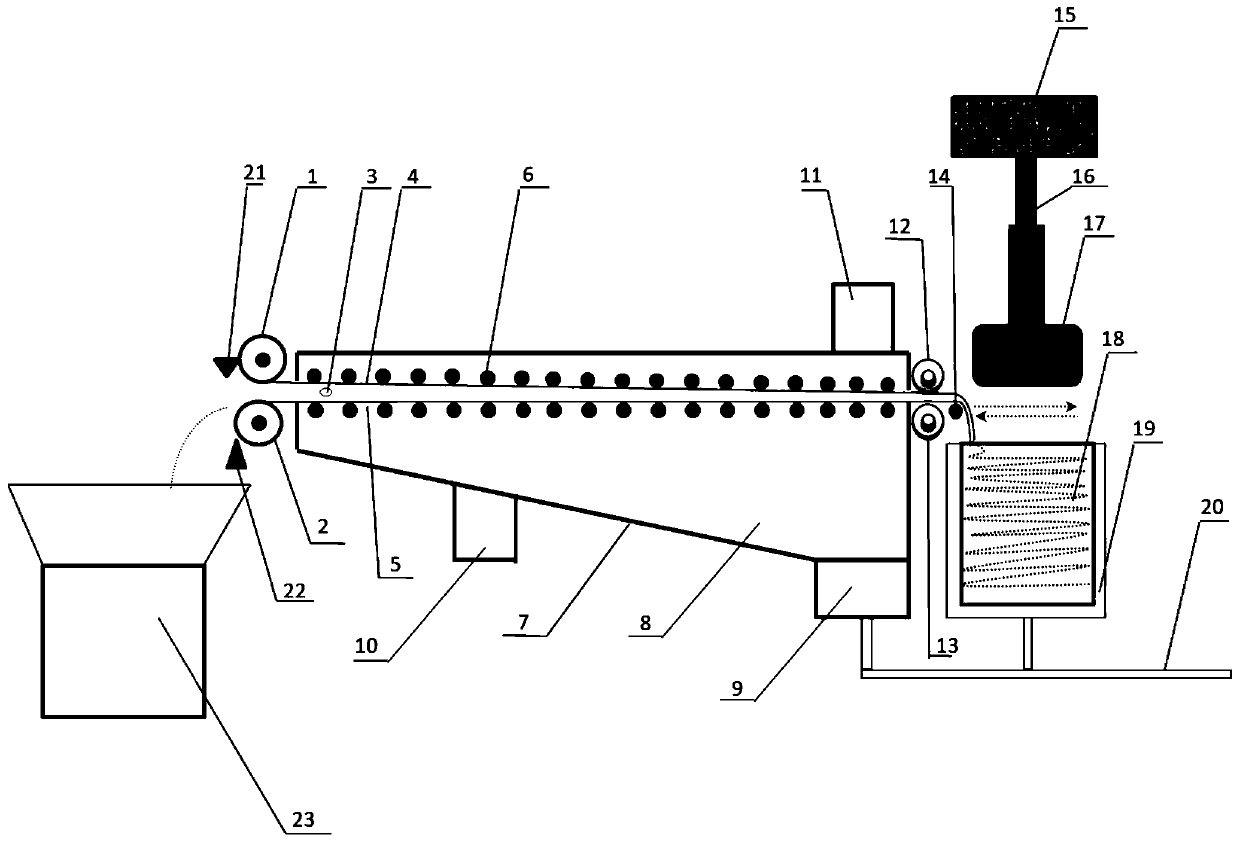

Sludge dewatering and drying device and method

PendingCN111348815AFine particleHigh viscositySludge treatment by de-watering/drying/thickeningHydraulic cylinderFlue gas

The invention discloses a sludge dewatering and drying device and method, and belongs to the technical field of sludge treatment, wherein the device comprises a heating pre-dewatering chamber, upper-layer filter cloth, lower-layer filter cloth and a high-pressure dewatering assembly, the upper-layer filter cloth and the lower-layer filter cloth penetrate through a sludge conveying channel formed by the heating pre-dewatering chamber; the upper-layer filter cloth and the lower-layer filter cloth are fed and collected along the channel; the heating pre-dewatering chamber is provided with a feeding hole for inputting sludge; sliding rollers are arranged on the outer sides of the upper-layer filter cloth and the lower-layer filter cloth; the heating pre-dewatering chamber is provided with a flue gas inlet for heating and conditioning sludge in a filter cloth interlayer on line to realize heating and pre-dewatering; a high-pressure dewatering assembly is arranged at one end of the heating pre-dewatering chamber and comprises a high-pressure dewatering tank and a matched hydraulic cylinder, a circulating material distribution mechanism is arranged on the high-pressure dewatering tank tofold the interlayer filter cloth in the high-pressure dewatering tank in a reciprocating mode, and the hydraulic cylinder presses the multiple layers of filter cloth for high-pressure dewatering. Deepdrying dewatering is achieved, the moisture content of the finally obtained sludge is less than 10%, and the device has the advantages of being high in dewatering efficiency, low in operation cost, high in practicability and the like.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com