Deep circulation storage battery container formation diachylon

A battery, internalization technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of softening of positive active material lead paste, hidden dangers in safety, drying of electrolyte, etc., to reduce the internal resistance of the plate and improve the utilization rate rate, the effect of increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

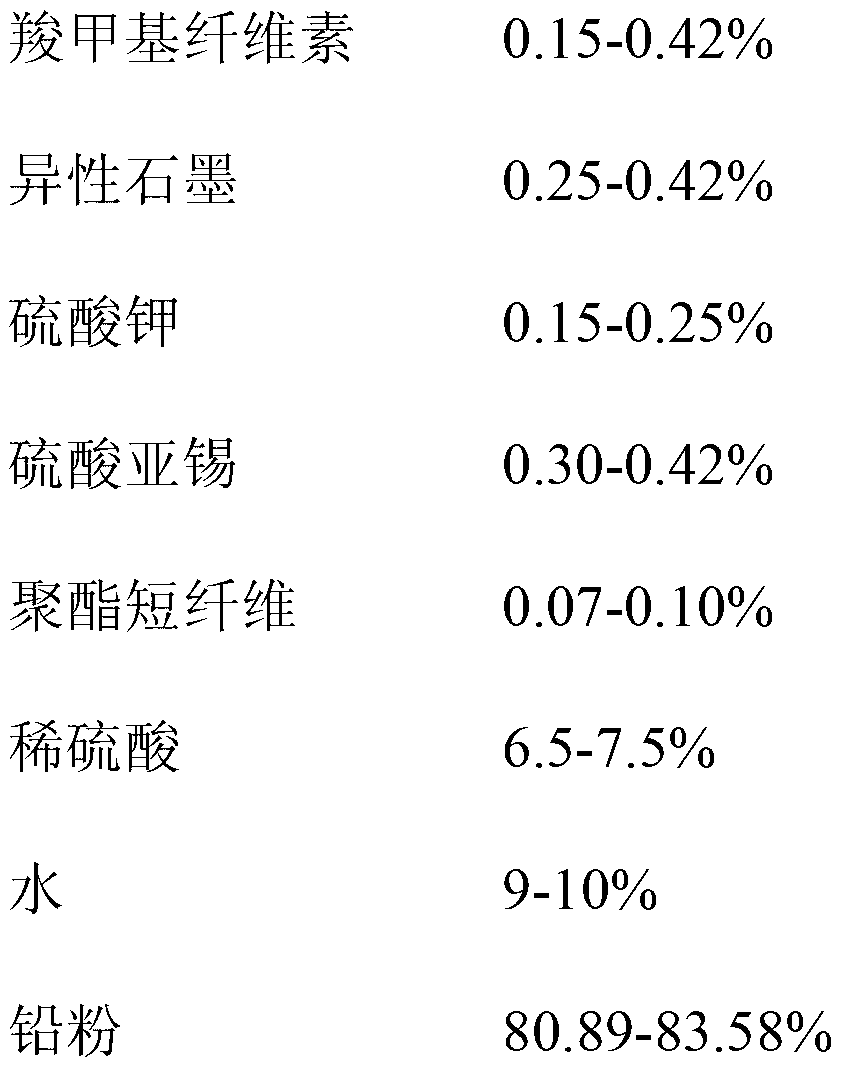

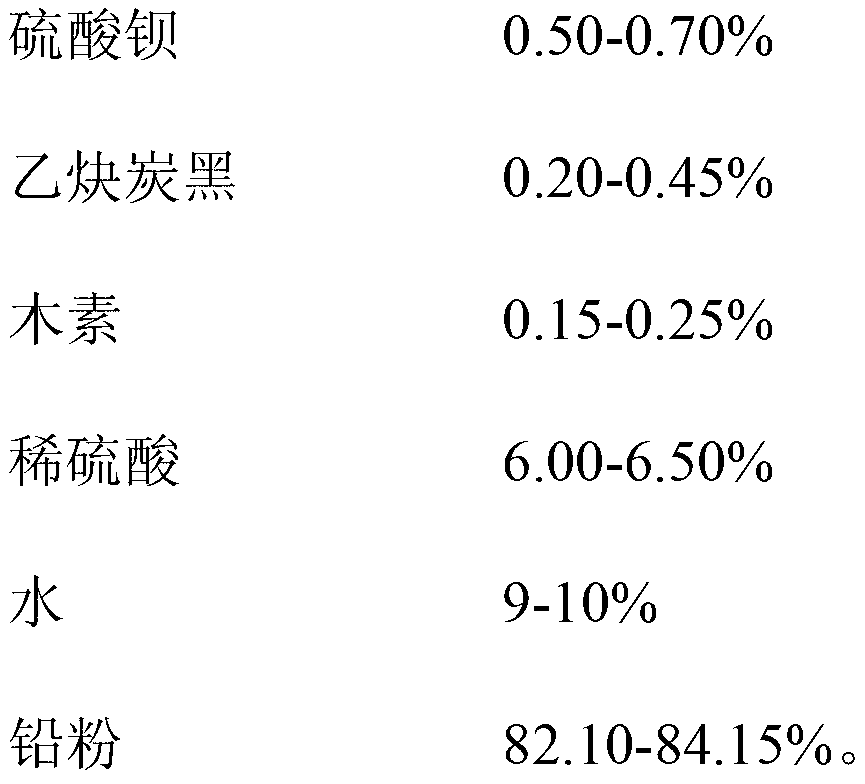

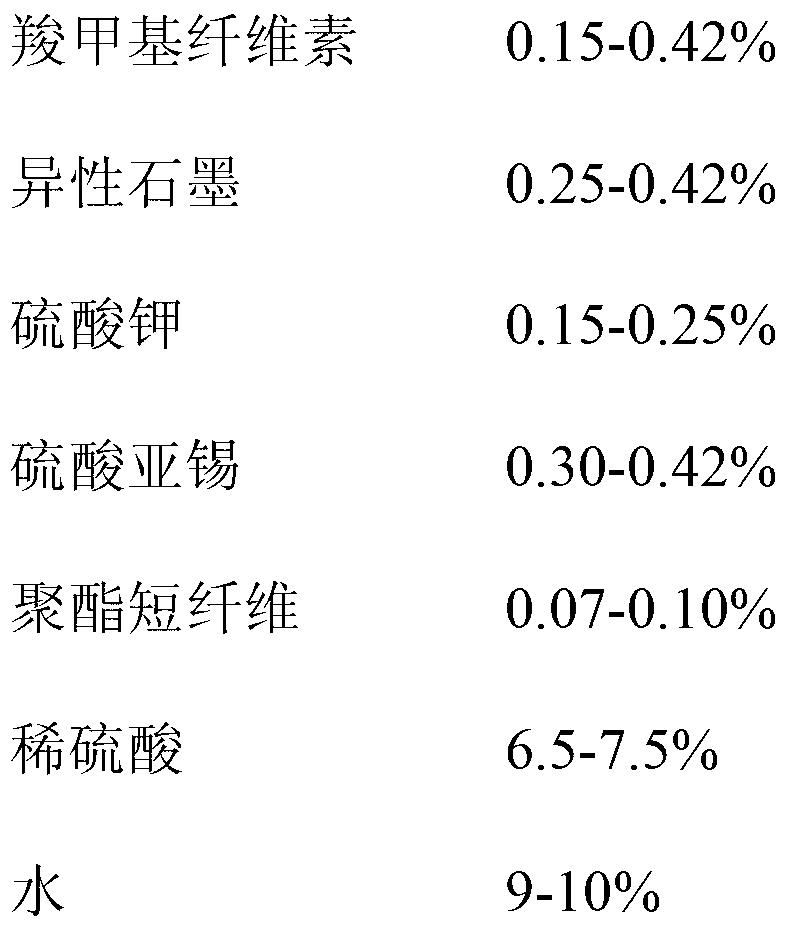

[0019] A deep-cycle storage battery is internally formed into lead paste, including positive electrode lead paste and negative electrode lead paste, wherein the components of the positive electrode lead paste are calculated by mass percentage: 0.15% carboxymethyl cellulose, 0.25% heterosexual graphite, 0.20% potassium sulfate, 0.35% stannous sulfate, 0.08% polyester staple fiber, 6.8% dilute sulfuric acid, 9% water, 83.17% lead powder; the components of negative lead paste are calculated by mass percentage: barium sulfate 0.50%, acetylene carbon black 0.20%, 0.25% lignin, 6% dilute sulfuric acid, 9.5% water, 83.55% lead powder.

[0020] The specific gravity of dilute sulfuric acid used in positive electrode paste and negative electrode paste in this embodiment is 1.400g / ml at 25°C. Before mixing the paste, the dilute sulfuric acid should be fully circulated and stirred to ensure that the paste acid meets the process requirements; The resistivity is not less than 1MΩ to prevent...

Embodiment 2

[0026] A deep-cycle storage battery is internally formed into lead paste, including positive electrode lead paste and negative electrode lead paste, wherein the components of the positive electrode lead paste are calculated by mass percentage: 0.17% carboxymethyl cellulose, 0.35% heterosexual graphite, 0.22% potassium sulfate, 0.38% stannous sulfate, 0.09% polyester staple fiber, 7% dilute sulfuric acid, 9.3% water, 82.49% lead powder; the components of negative lead paste are calculated by mass percentage: barium sulfate 0.55%, acetylene carbon black 0.28%, 0.15% lignin, 6.2% dilute sulfuric acid, 9.2% water, 83.62% lead powder.

Embodiment 3

[0028] A deep-cycle storage battery is internally formed into lead paste, including positive electrode lead paste and negative electrode lead paste, wherein the components of the positive electrode lead paste are calculated by mass percentage: 0.25% carboxymethyl cellulose, 0.4% heterosexual graphite, 0.25% potassium sulfate, 0.42% stannous sulfate, 0.1% polyester staple fiber, 7.5% dilute sulfuric acid, 10% water, 81.08% lead powder; the components of negative lead paste are calculated by mass percentage: barium sulfate 0.70%, acetylene carbon black 0.45%, 0.2% lignin, 6.5% dilute sulfuric acid, 10% water, 82.15% lead powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com