Preparation method of fluorescent ceramic containing aluminum oxide matrix and related fluorescent ceramic

A technology of fluorescent ceramics and alumina, which is applied in the preparation of fluorescent ceramics and related fluorescent ceramics, can solve the problems of low luminous efficiency and low thermal conductivity of fluorescent ceramics, achieve high luminous efficiency, high thermal conductivity, and improve thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

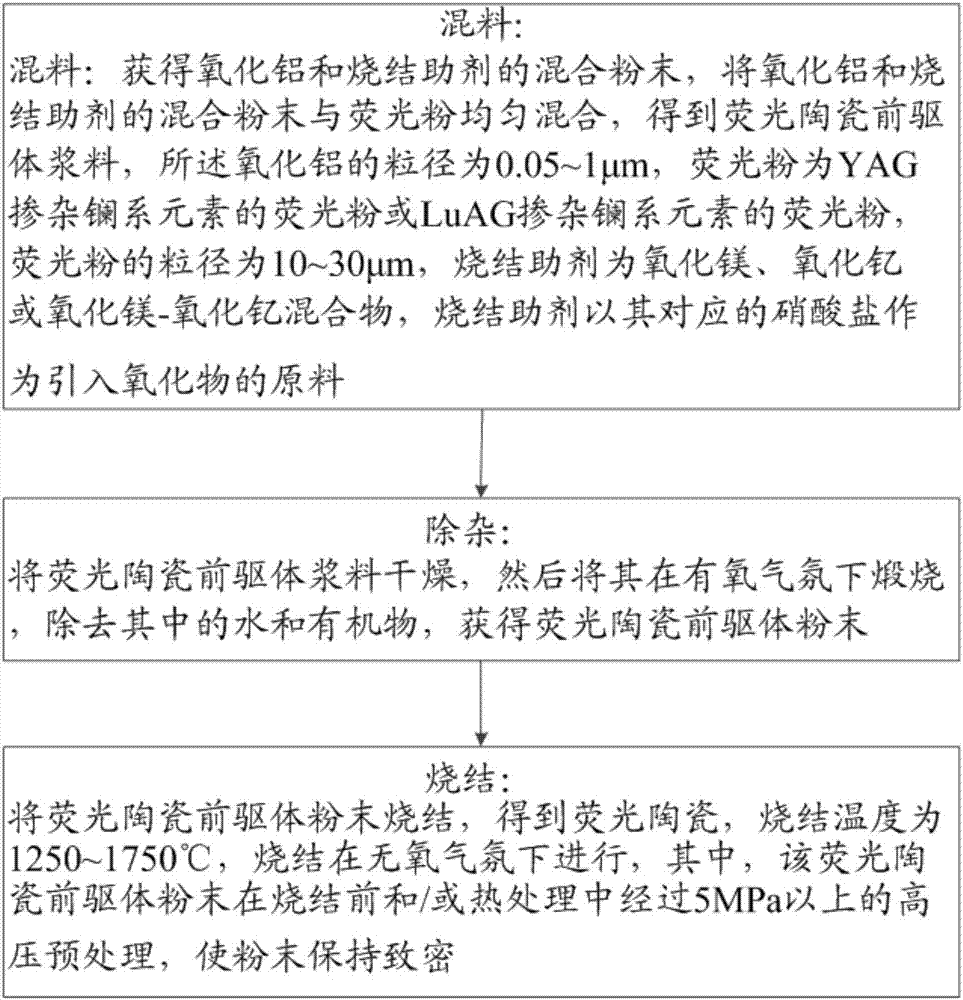

[0026] Such as figure 1 It is a flowchart of a method for preparing fluorescent ceramics according to an embodiment of the present invention. As shown in the figure, the preparation method includes the following steps in sequence:

[0027] ① Mixing: Obtain the mixed powder of alumina and sintering aid, and evenly mix the mixed powder of alumina and sintering aid with phosphor powder to obtain fluorescent ceramic precursor slurry;

[0028] ② Removal of impurities: drying the fluorescent ceramic precursor slurry to remove water and organic matter to obtain fluorescent ceramic precursor powder;

[0029] ③Sintering: The fluorescent ceramic precursor powder is sintered to obtain fluorescent ceramics. The sintering temperature is 1250-1750°C, and the sintering is carried out in an oxygen-free atmosphere. The powder stays compact.

[0030]In the mixing step, the first is the selection of raw materials. In this embodiment, ultra-fine alumina powder with a small particle size is sel...

Embodiment 1

[0044] The raw material is high-purity ultra-fine alumina nanopowder with a particle size of 0.06-0.2μm, and 1wt% PEG aqueous solution is prepared, an appropriate amount of alumina nanopowder is mixed with PEG aqueous solution, and the alumina PEG aqueous solution is ultrasonically prepared for use.

[0045] Considering that magnesium oxide accounts for 0.5 wt% of the total fluorescent ceramic powder, the corresponding mass of magnesium nitrate hexahydrate is weighed to form a magnesium nitrate solution with a concentration of 0.01-1mol / L.

[0046] Mix the PEG aqueous solution of alumina and the magnesium nitrate solution to obtain a mixed suspension, which is placed on a magnetic stirrer and continuously stirred, and the temperature is set at 60°C.

[0047] Use ammonium bicarbonate as a precipitating agent to prepare an aqueous solution of about 0.1 mol / L, and slowly drop into the mixed suspension that is stirred continuously until the pH value of the mixed suspension is contr...

Embodiment 2

[0052] The raw material is high-purity ultra-fine alumina nanopowder with a particle size of 0.06-0.2μm, and 3wt% PEG aqueous solution is prepared, an appropriate amount of alumina nanopowder is mixed with PEG aqueous solution, and the alumina PEG aqueous solution is ultrasonically prepared for use.

[0053] According to the fact that yttrium oxide accounts for 3wt% of the total fluorescent ceramic powder, the corresponding mass of yttrium nitrate hexahydrate is weighed to prepare a yttrium nitrate solution with a concentration of 0.01-1mol / L.

[0054] Mix the PEG aqueous solution of alumina and the yttrium nitrate solution to obtain a mixed suspension, which is placed on a magnetic stirrer and continuously stirred, and the temperature is set at 60°C.

[0055] Use ammonia water as a precipitating agent to prepare an aqueous solution of about 0.02mol / L, and slowly drop into the mixed suspension that is stirred continuously until the pH value of the mixed suspension is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com