Combined-type granulator

A granulator and combined technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of heavy cleaning work, affecting normal operation, blockage, etc., and achieve the effects of rapid evaporation, improved material drying power, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

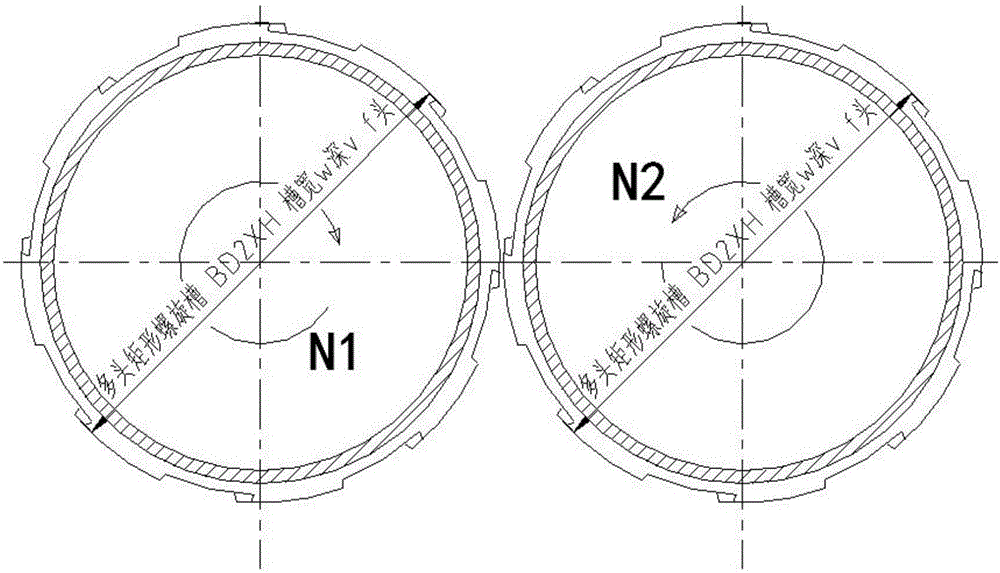

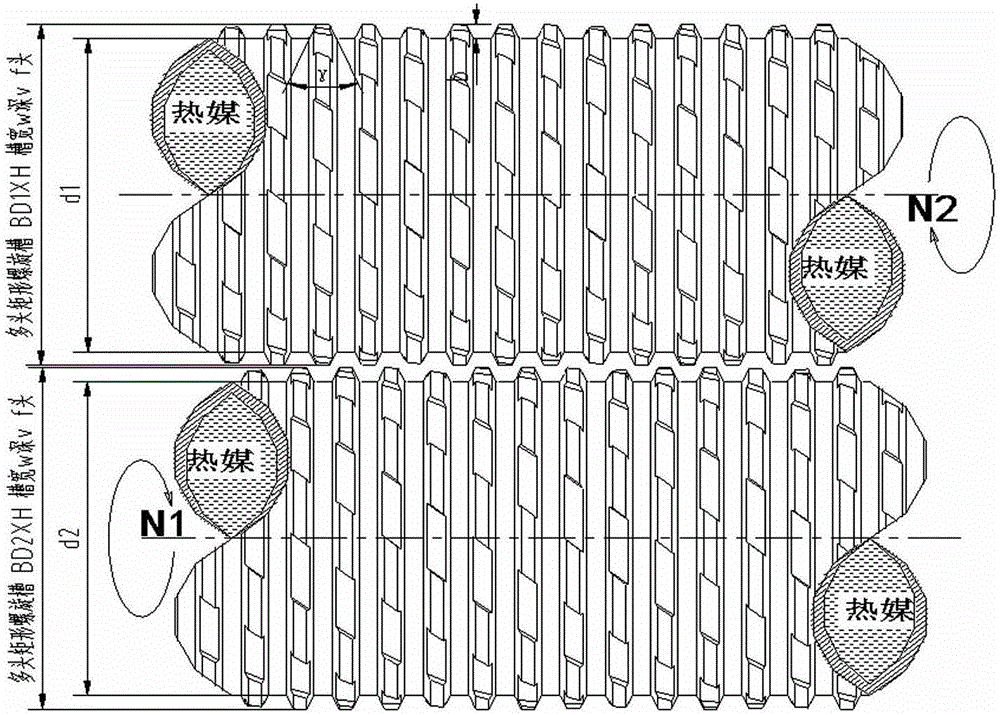

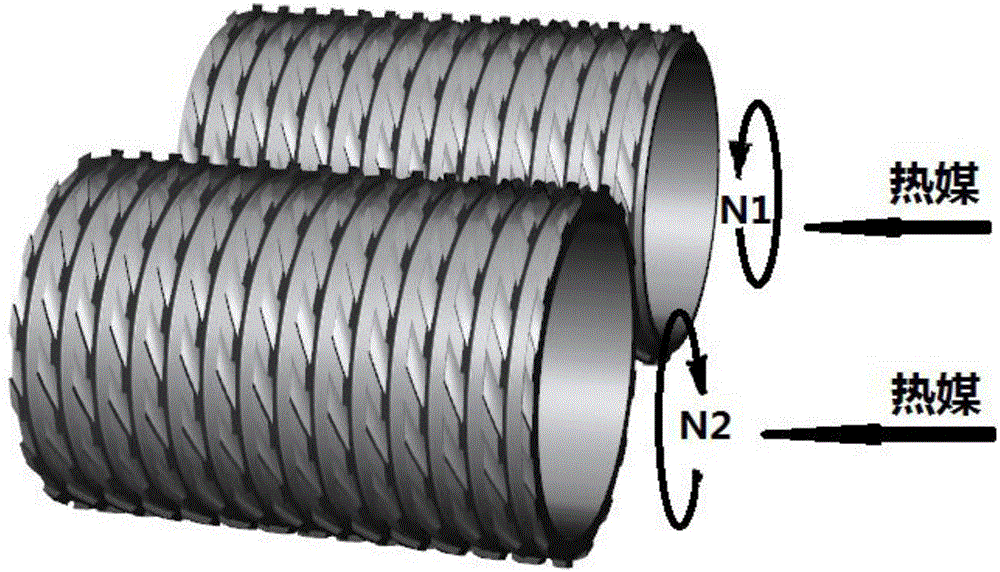

[0058] The present invention is a new type of granulation equipment combined on the basis of a rolling mill with a reticulated spiral groove (or a single radial groove). When the drum of the rolling mill rotates in the forward and reverse directions, the material placed on the edge of the tooth surface is torn by the differential mesh alveolar, which can tear the lumpy and cake-shaped materials into small particles; When the material is soft (such as slurry, paste, paste) material, due to the gravity and the friction force of the local tooth top, it will be pulled into the axial groove of the drum with the rotation of the teeth and continue to move downward. Until it enters the engagement groove and naturally forms strips or particles. According to different materials, the diameter of the drum can be reasonably designed to meet the balance of the vector sum of the suction friction force and the strip forming force, so that the strip or particle forming force is minimized.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com