Silver-containing fluorhydroxyapatite coating, and preparation method and application of coating

A fluorohydroxyapatite and coating technology, which is applied in coating, medical science, prosthesis and other directions to achieve the effect of improving treatment effect, facilitating bone ingrowth and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Electrodeposition of Ag-containing FHA coating on the surface of high-purity magnesium screws.

[0040] The first step is to prepare the electrodeposition solution so that its ion concentration is: 0.04mol / L Ca 2+ , 0.02mol / L of H 2 PO 4 - , 2×10 -3 mol / L of fluoride ion F - and 6×10 -4 mol / L AgNO 3 , the pH was adjusted to 4.4.

[0041] In the second step, at a current density of 4mA / cm 2 1. Electrodeposit high-purity magnesium bone screws for 30 minutes at a temperature of 60°C.

[0042] In the third step, the coated bone nail obtained by electrodeposition was soaked in 0.05 mol / L AgNO3 aqueous solution for 20 minutes, and the Ag-containing fluorohydroxyapatite coating was finally obtained.

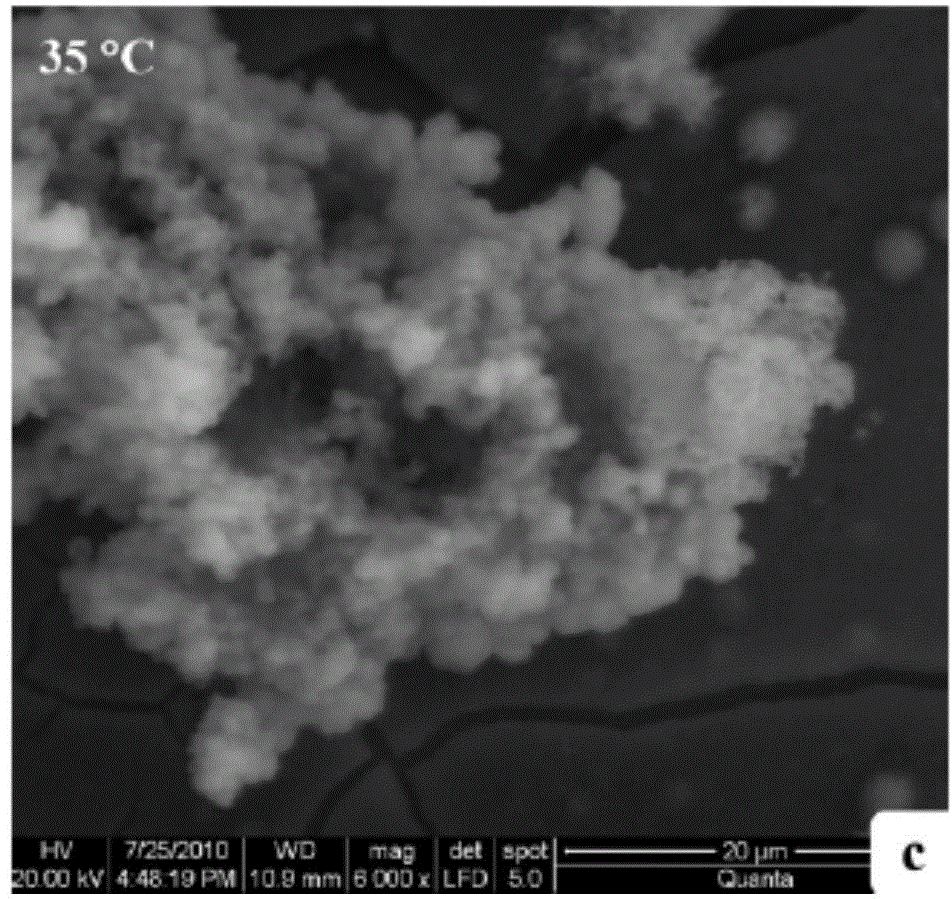

[0043] figure 2 It is a photograph of the microstructure of Ag-containing FHA taken by a scanning electron microscope. It can be seen that its structure is composed of rod-like or needle-like crystals, forming a coating structure with a certain surface porosity.

[00...

Embodiment 2

[0049] Ag-containing FHA coating was prepared on the surface of AZ31 magnesium alloy bone plate.

[0050] The first step is to prepare the electrodeposition solution, the concentration is: 0.03mol / L Ca 2+ , 0.01mol / L of H 2 PO 4 - , 1×10 -3 mol / L of fluoride ion F - and 5×10 -4 mol / L AgNO 3 , pH adjusted to 4.0.

[0051] In the second step, at a current density of 0.3mA / cm 2 , Electrodeposition for 20 minutes at a temperature of 50°C.

[0052] In the third step, soak the AZ31 bone plate obtained by electrodeposition in 1×10 -4 mol / L AgNO3 aqueous solution, the immersion time is 1 minute, and the Ag-containing fluorohydroxyapatite coating is finally obtained.

[0053] After testing its chemical composition, the molecular formula of the coating is Ag 2 Ca 8 (PO 4 ) 6 (OH) 1.99 f 0.01 , porosity 10%, thickness 2 microns. And after XRD diffraction analysis, the main peak (the first strong peak) of XRD diffraction has a diffraction angle (2θ angle) greater than 25°...

Embodiment 3

[0056] Preparation of Ag-containing FHA coating on ZK60 alloy processed spinal intervertebral fusion cage.

[0057] The first step is to prepare the electrodeposition solution, the concentration is: 0.05mol / L Ca 2+ , 0.03mol / L of H 2 PO 4 - , 3×10 -3 mol / L of fluoride ion F - and 8×10 -4 mol / L AgNO 3 , pH adjusted to 5.0.

[0058] In the second step, at a current density of 6mA / cm 2 , Electrodeposition for 40 minutes at a temperature of 70°C.

[0059] In the third step, the coated intervertebral fusion cage obtained by electrodeposition was soaked in 2mol / L AgNO3 aqueous solution for 60 minutes, and the Ag-containing fluorohydroxyapatite coating was finally obtained.

[0060] After testing its chemical composition, the molecular formula of the coating is Ag 8 Ca 2 (PO 4 ) 6 (OH) 0.2 f 1.8 , porosity 70%, thickness 2 microns. And after XRD diffraction analysis, the main peak (the first strong peak) of XRD diffraction has a diffraction angle (2θ angle) greater th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diffraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com