Patents

Literature

75results about How to "Improve surface binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper welding paste for automatic brazing and its preparing method

InactiveCN1586795AImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaRare-earth elementOrganic solvent

The copper base welding paste for automatic brazing includes brazing material, brazing agent and paste forming material. The brazing material has Cu as main material and added alloy elements P, Sn, Ni, B, Ti, In and RE; the brazing agent consists of chemically synthesized intermediate polyboride M, potassium fluoroborate N and flux Q; and the paste forming material consists of mixture of polyisobutylene in different molecular weight and organic solvent. The copper base welding paste has good flowability, wetability and gap-filling performance, etc. and is suitable for industrial production.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

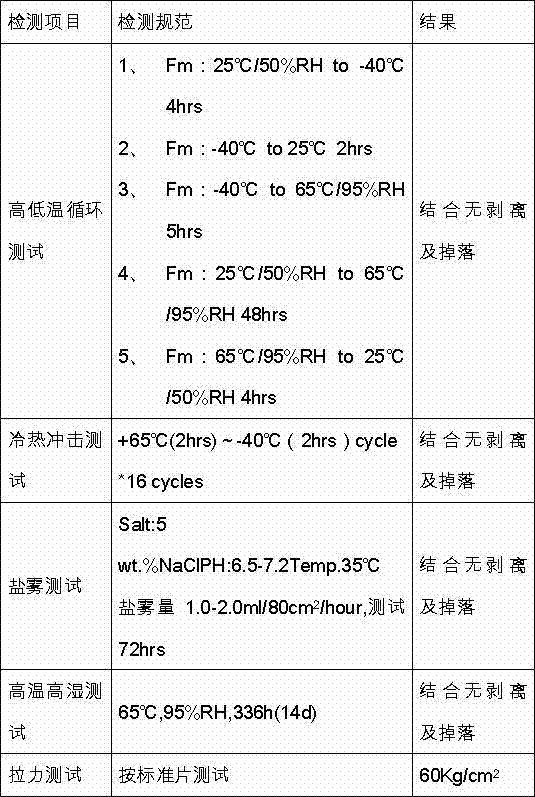

Fluorine-containing metal coating on surface of NdFeB rare-earth permanent magnet and preparation method of fluorine-containing metal coating

The invention discloses a fluorine-containing metal coating on the surface of an NdFeB rare-earth permanent magnet and a preparation method of the fluorine-containing metal coating, and belongs to the technical field of anticorrosion surface treatment. The fluorine-containing metal coating has the thickness of 5-40 microns and is prepared from polytetrafluoroethylene, solid powder and adhesive according to the mass ratio of (1-30):(2-30):(20-40). The preparation method includes the steps of firstly, preprocessing the surface of the NdFeB rare-earth permanent magnet through an oil removal and acid pickling or sand blasting method; secondly, preparing the coating through a centrifugal soaking and throwing or spraying method. Polytetrafluoroethylene contained in paint for preparing the coating has excellent corrosion resistance, and the corrosion resistant capacity of the surface of the NdFeB rare-earth permanent magnet can be improved; in the coating process, no acid bath is used, the fresh surface of the magnet is not damaged after preprocessing, and the surface adhesion force between the coating and the magnet can be effectively improved; no acid waste liquid exists, the environment is not polluted, and the preparation method belongs to the green and environment-friendly coating process.

Owner:NORTHEASTERN UNIV

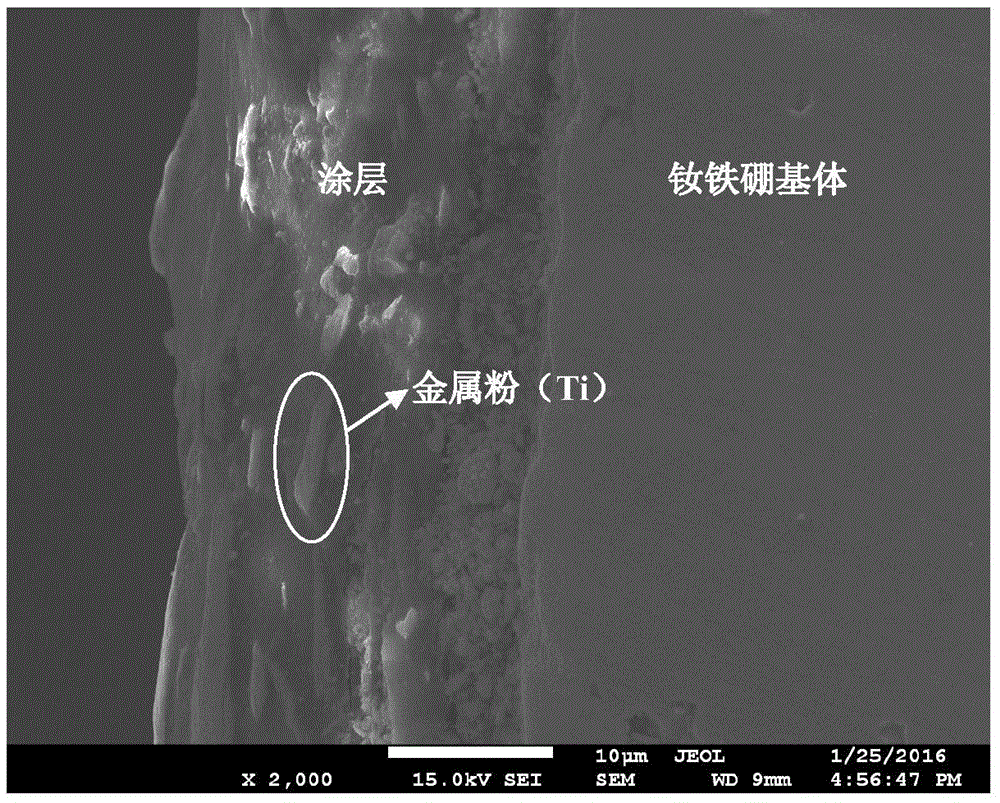

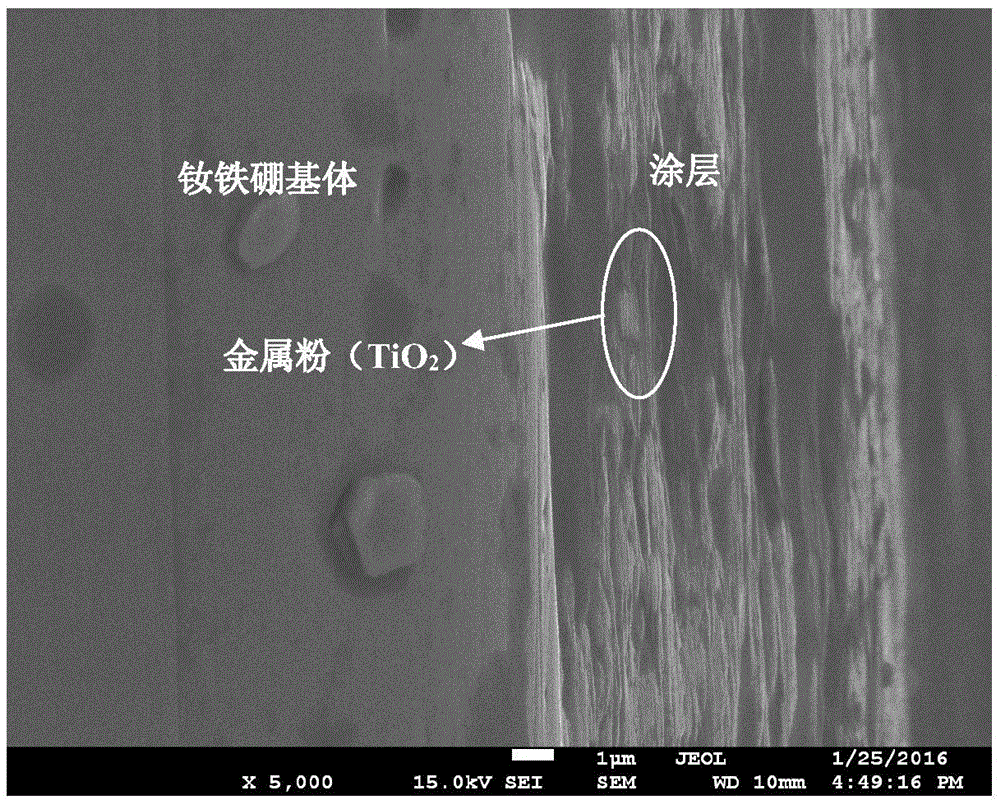

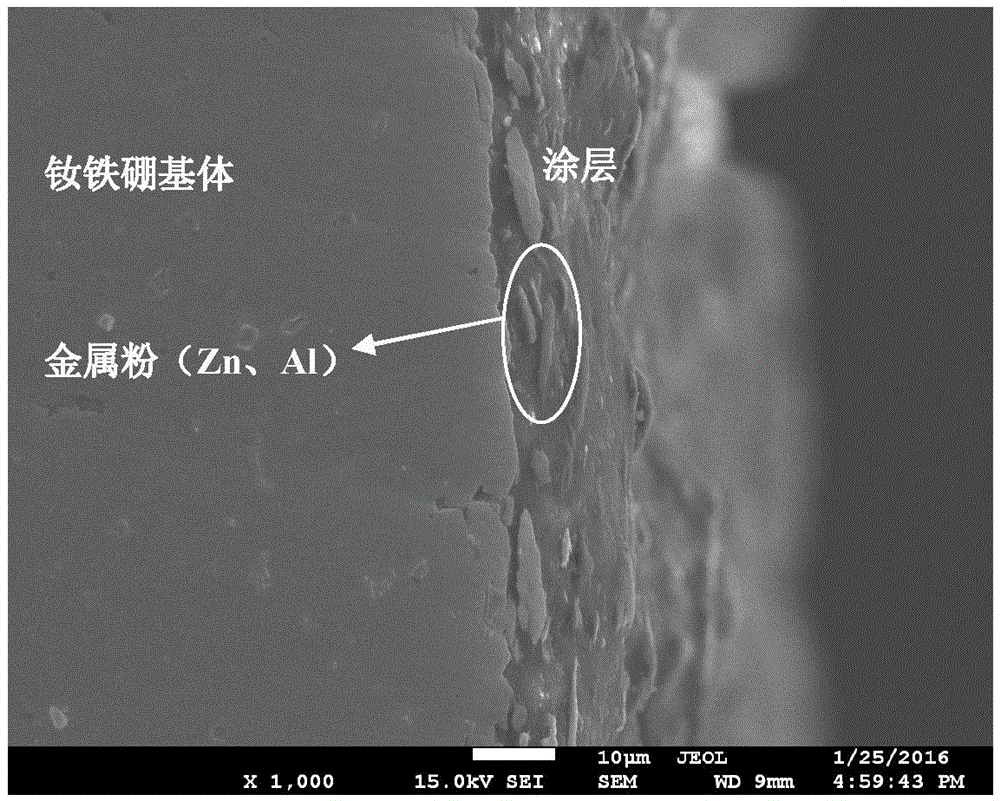

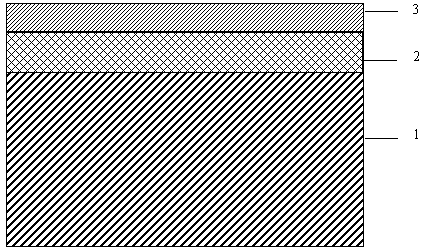

Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

ActiveCN102936455AControl thicknessImprove protectionPretreated surfacesAnti-corrosive paintsAcrylic resinRare earth

The invention belongs to the technical field of surface treatment and particularly relates to a neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and a preparation method thereof. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating is composed of a bottom coating and a top coating, the thickness of the bottom coating is in a range from 10mum to 25mum, the chemical components of the bottom coating comprise 55% to 65% of one or two types of metals of zinc and aluminum, 0% to 5% of one or a plurality of types of metals of nickel, chromium, molybdenum, neodymium, praseodymium, cobalt and titanium and 34% to 40% of neutral resins, the thickness of the top coating is in a range from 5mum to 15mum, and the chemical components of the top coating comprise 55% to 65% of one or a plurality of types of metals of zinc, aluminum, titanium, molybdenum, nickel, cobalt and chromium and 35% to 45% of phenolic resins or acrylic resins. The preparation method includes that firstly the surface of a permanent magnet is preprocessed, a centrifugal immersion tossing is utilized to prepare the bottom coating, and a rolling spraying process is utilized to prepare the top coating. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and the preparation method thereof have the advantages that by means of double layers of coatings, the corrosion resistance is high, the surface binding force is high, the usage temperature is higher than 200 DEG C, the magnetic property of the neodymium iron boron rare earth permanent magnet is improved, the service life is prolonged, and the service environment is widened.

Owner:SHENYANG GENERAL MAGNETIC

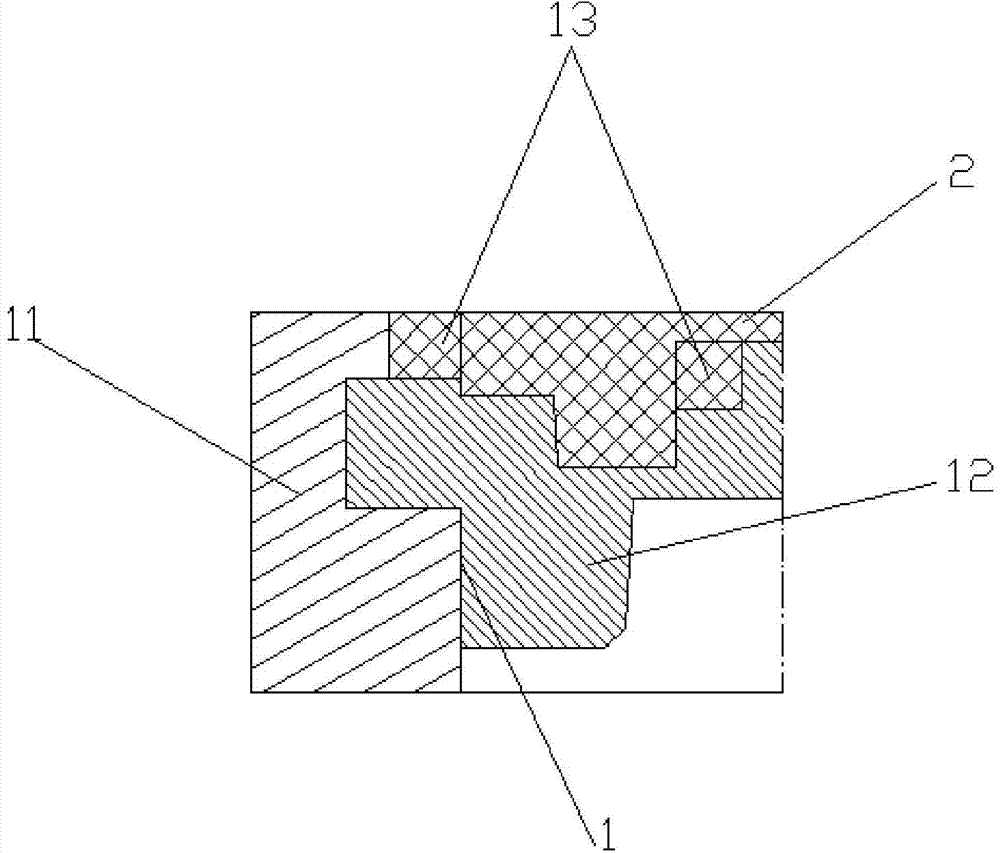

Combination outer shell piece and in-mould injection molding method

InactiveCN104717857AChange material requirementsStrong surface processing abilityCasings/cabinets/drawers detailsPressure castingEngineering

The invention discloses a combination outer shell piece and an in-mould injection molding method. The combination outer shell piece comprises a combination outer shell and plastic components. The combination outer shell comprises appearance aluminum materials and an inner structure piece. Plastic connecting positions are arranged on the combination outer shell. The plastic connecting positions are placed on the inner surface and the side face of the appearance aluminum materials and the upper surface of the inner structure piece. The plastic components are formed on the upper surface of the inner structure piece and the inner surface of the appearance aluminum materials in an injection moulding mode. By using in-mould pressure casting and the in-mould injection molding method, the problem that according to an existing combination outer shell piece, a machining process is complex, and the combining force of an outer shell body and plastic is poor is solved.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

Nickel soldering paste for automatic brazing

InactiveCN1876312ALow melting pointImprove liquidityWelding/cutting media/materialsSoldering mediaActivator 1Polyvinyl acetate

The invention relates to a nickel covered welding paste for automatic braze welding. It comprises following components with percent by weight: solder 91.50-96.5% and paste-forming material 3.50-8.50%, and solder concludes: Cr 5-20%, Fe 0.2-5%, C 0.01-0.1%, Si 0.1-5% and left is Ni. The paste-forming material comprises following components with percent by weight: mixture of polybutene and polyisobutene with molecular weight being 200-9000, 72-92%, or one or several objects among polyvinyl acetate, polyvinyl pyrrolidon, and polyisobutene, polypentene with molecular weight being 10000-100000 6.5-45%, organic solvent 50-80%, surface activator 1.0-12.0% and lubricant 1.0-18.0%. The said nickel covered welding paste is the solder paste that is characterized by good fire resistant and corrosion resistant property and used for stainless steel.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Silver-containing fluorhydroxyapatite coating, and preparation method and application of coating

InactiveCN104857563APrevent proliferationReduce postoperative infection rateElectrolytic coatingsProsthesisPorosityNitrate

The invention provides a silver-containing fluorhydroxyapatite coating, and a preparation method and an application of the coating. A molecular formula of the coating is as shown below: AgxCa10-x(PO4)6(OH)2-yFy, wherein x is greater than 0 and less than or equal to 10; and y is greater than 0 and less than 2. The coating is applied to a medical magnesium metal surface. The method comprises the steps that a component containing a silver ion is added to an electrodeposition solution; the coating is electrodeposited on the magnesium metal surface; and nitrate solution soaking is performed, so that the stability of the coating is further improved and the uniformity of silver content is ensured. According to the coating, the method and the application, the stability of silver-containing fluorhydroxyapatite is adjusted by adjusting F content and hydroxyl content, so that a degradation cycle and a rate of the silver-containing fluorhydroxyapatite are adjusted and controlled, and the coating is applicable to different application positions and requirements; and the surface has certain porosity, so that bone ingrowth is facilitated, and a binding force of an implant is increased. The coating has effects of controlling bacteria of an implantation position and reducing a postoperative infection rate.

Owner:SUZHOU ORIGIN MEDICAL TECH

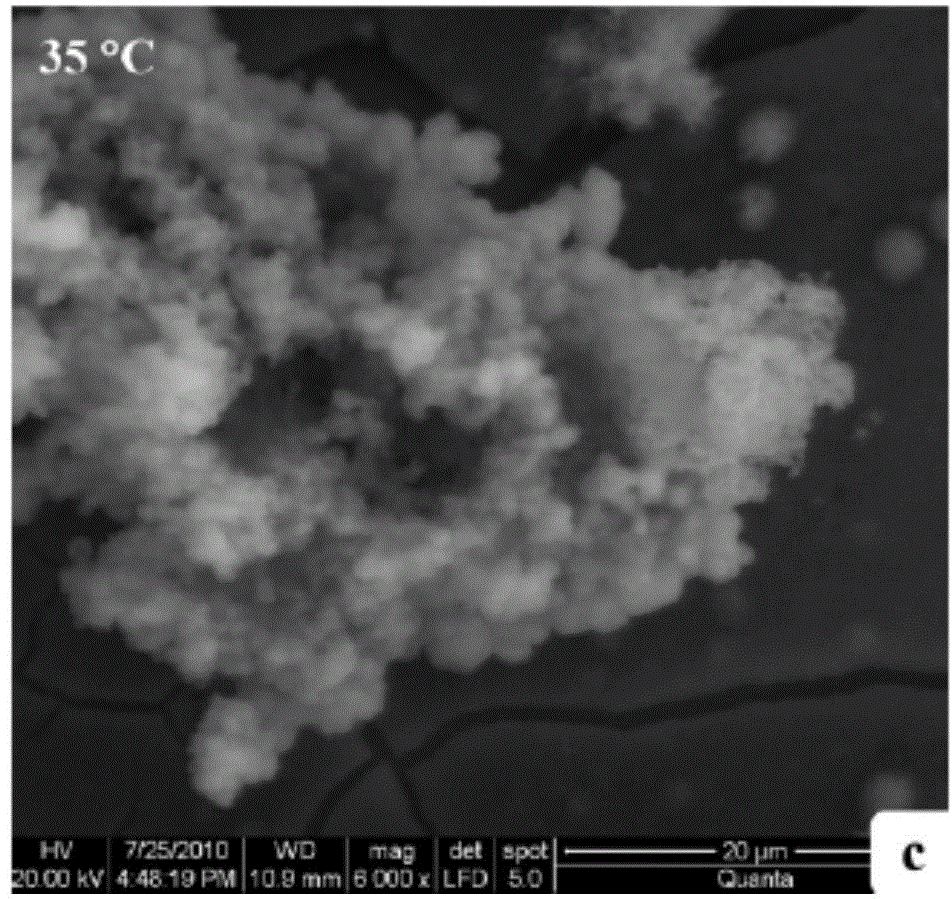

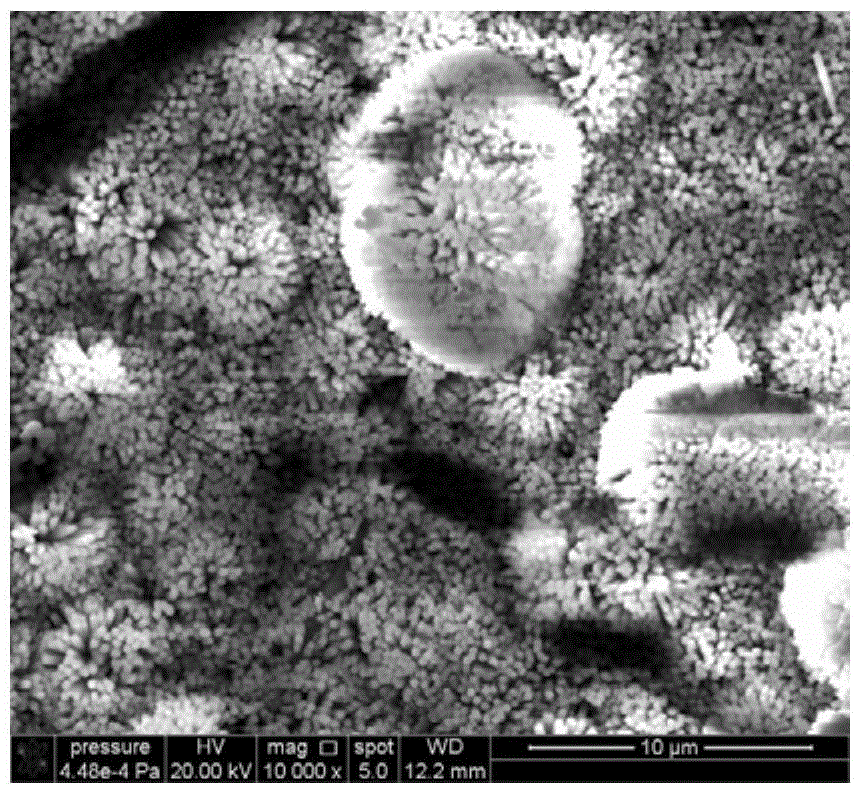

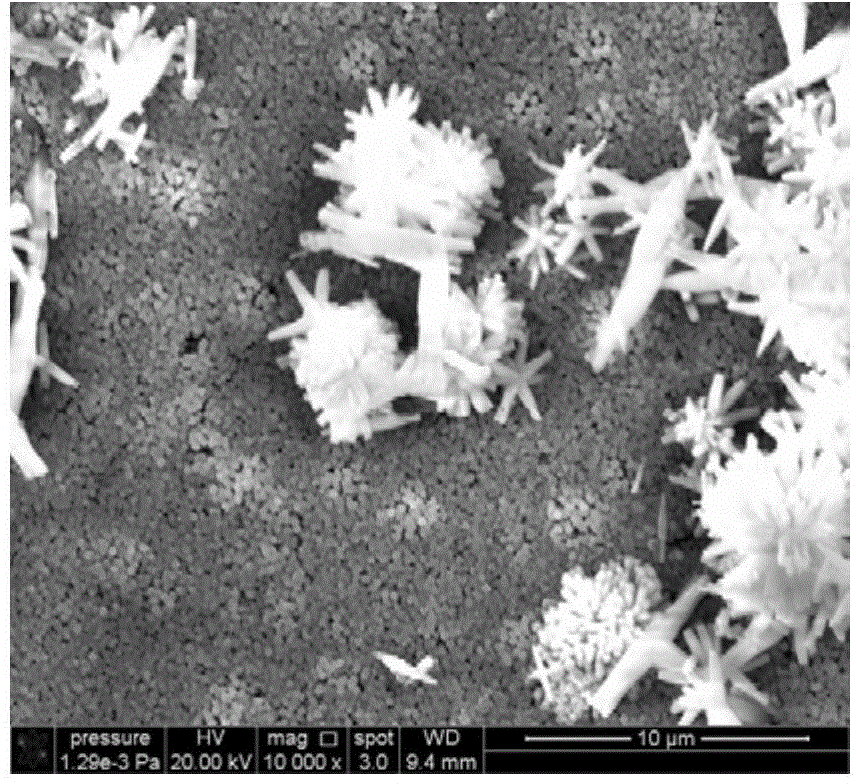

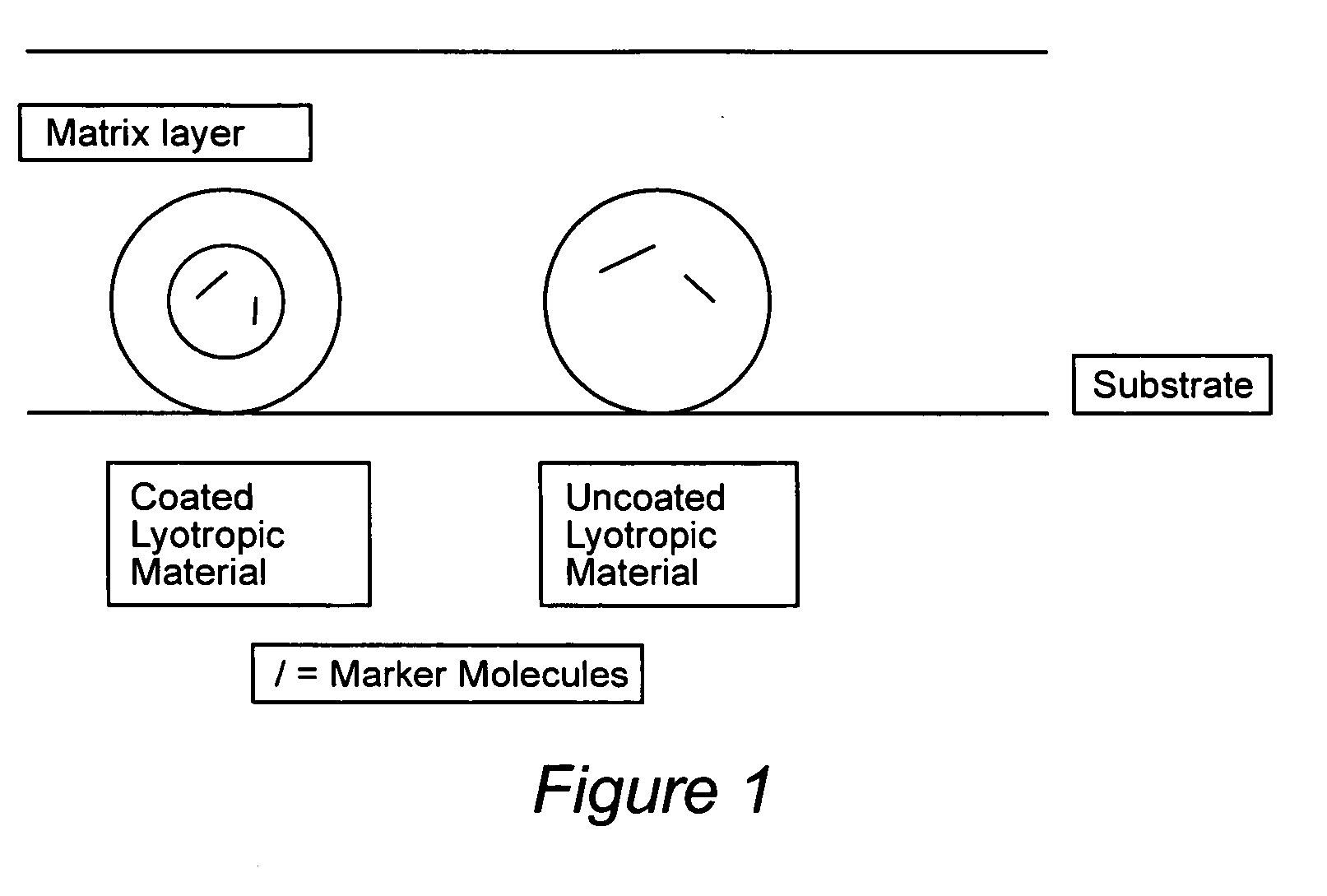

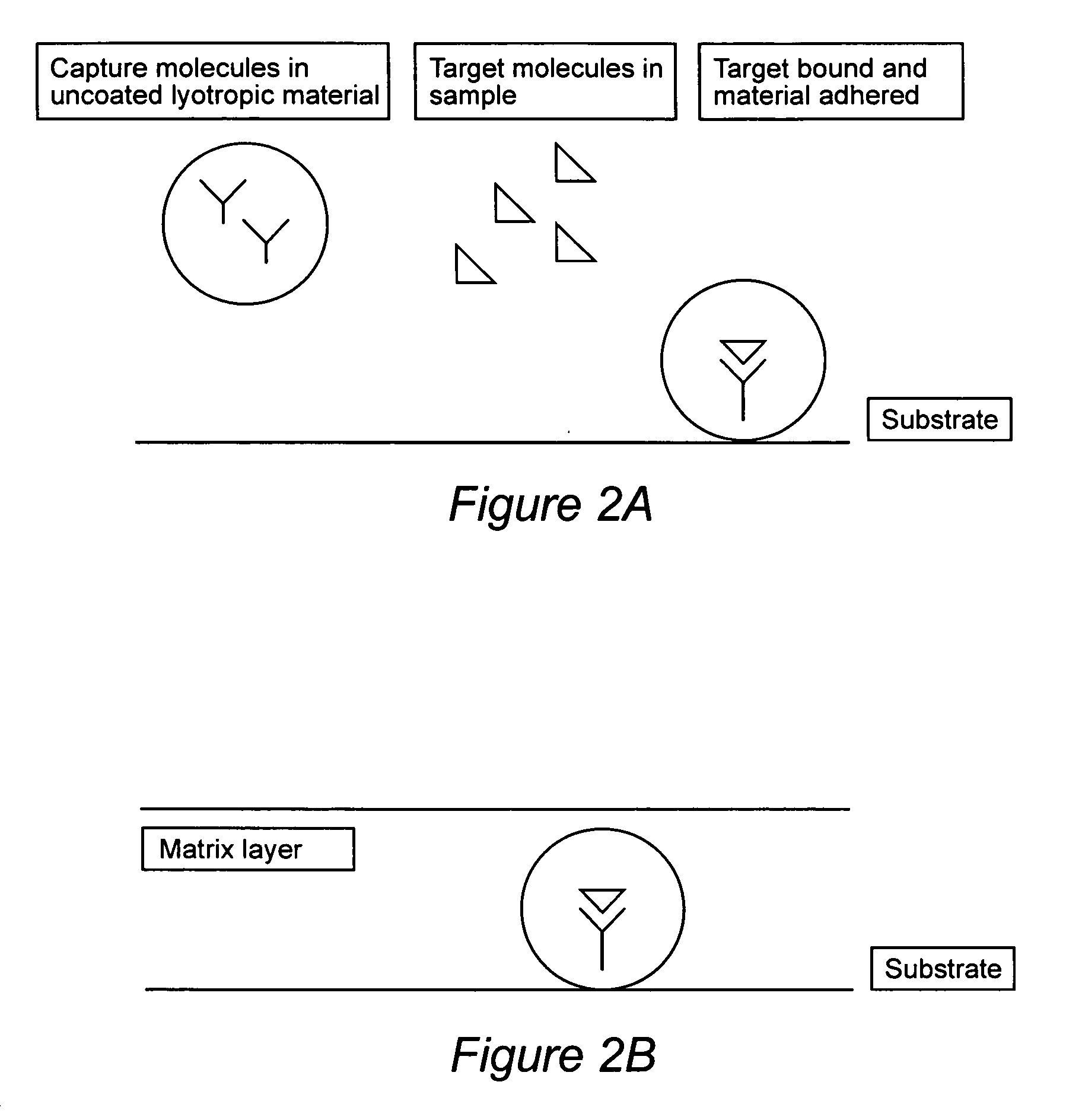

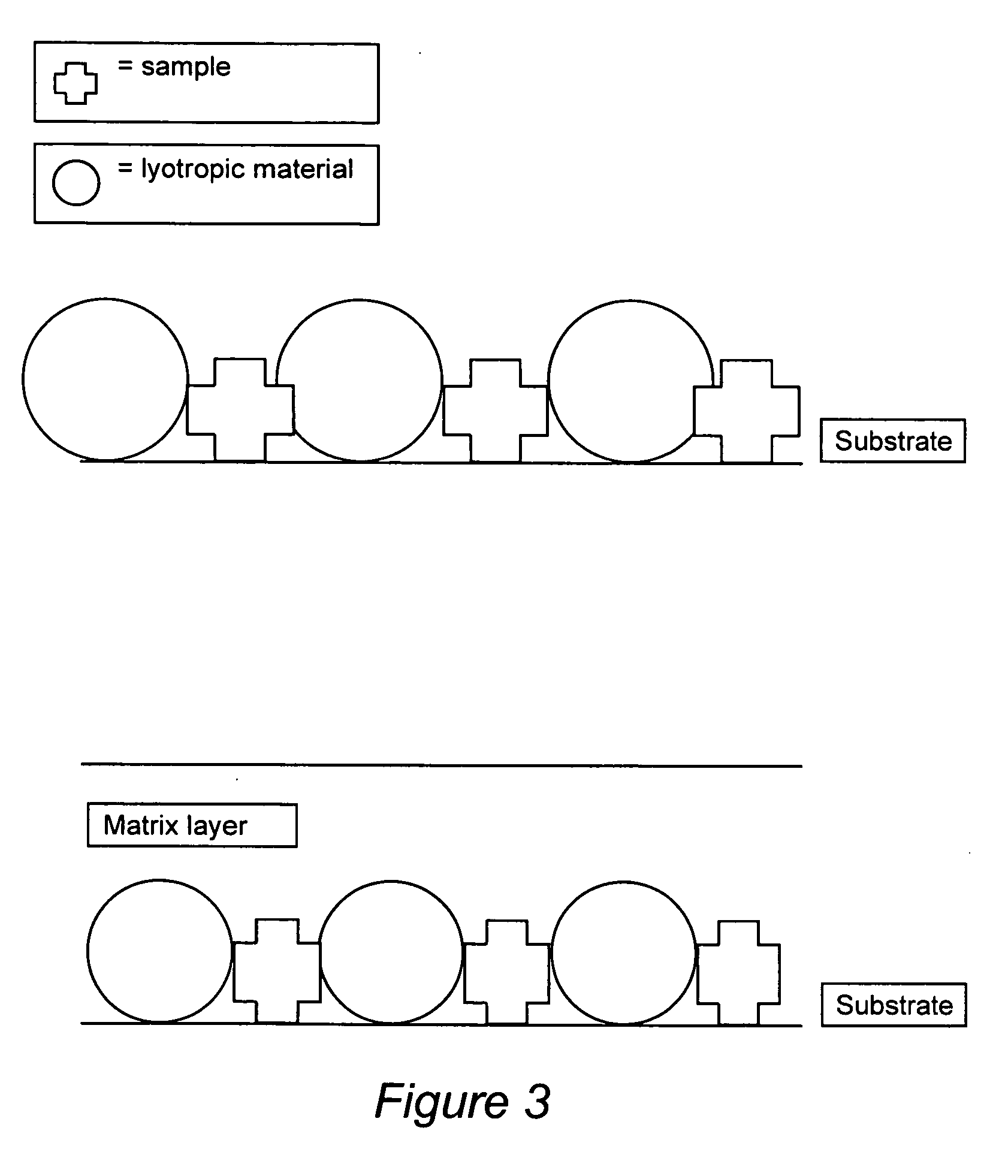

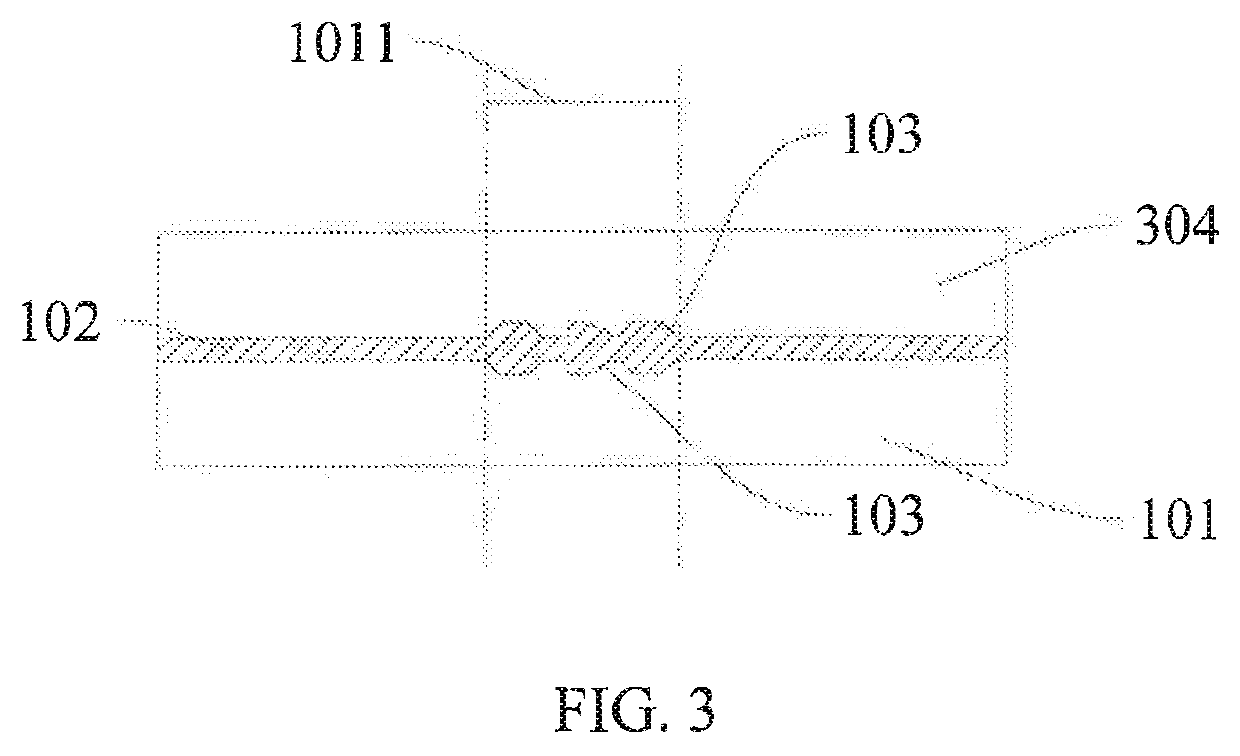

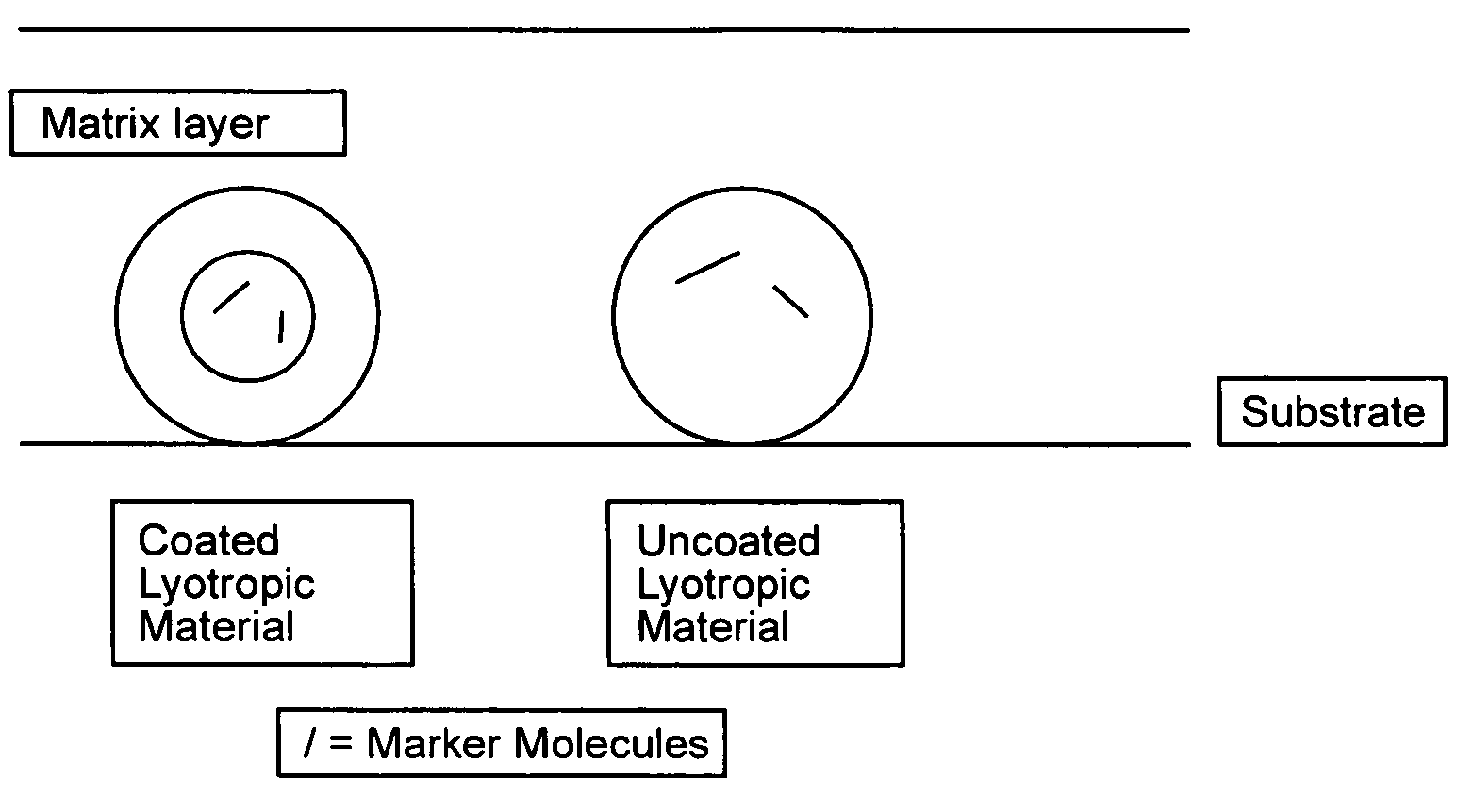

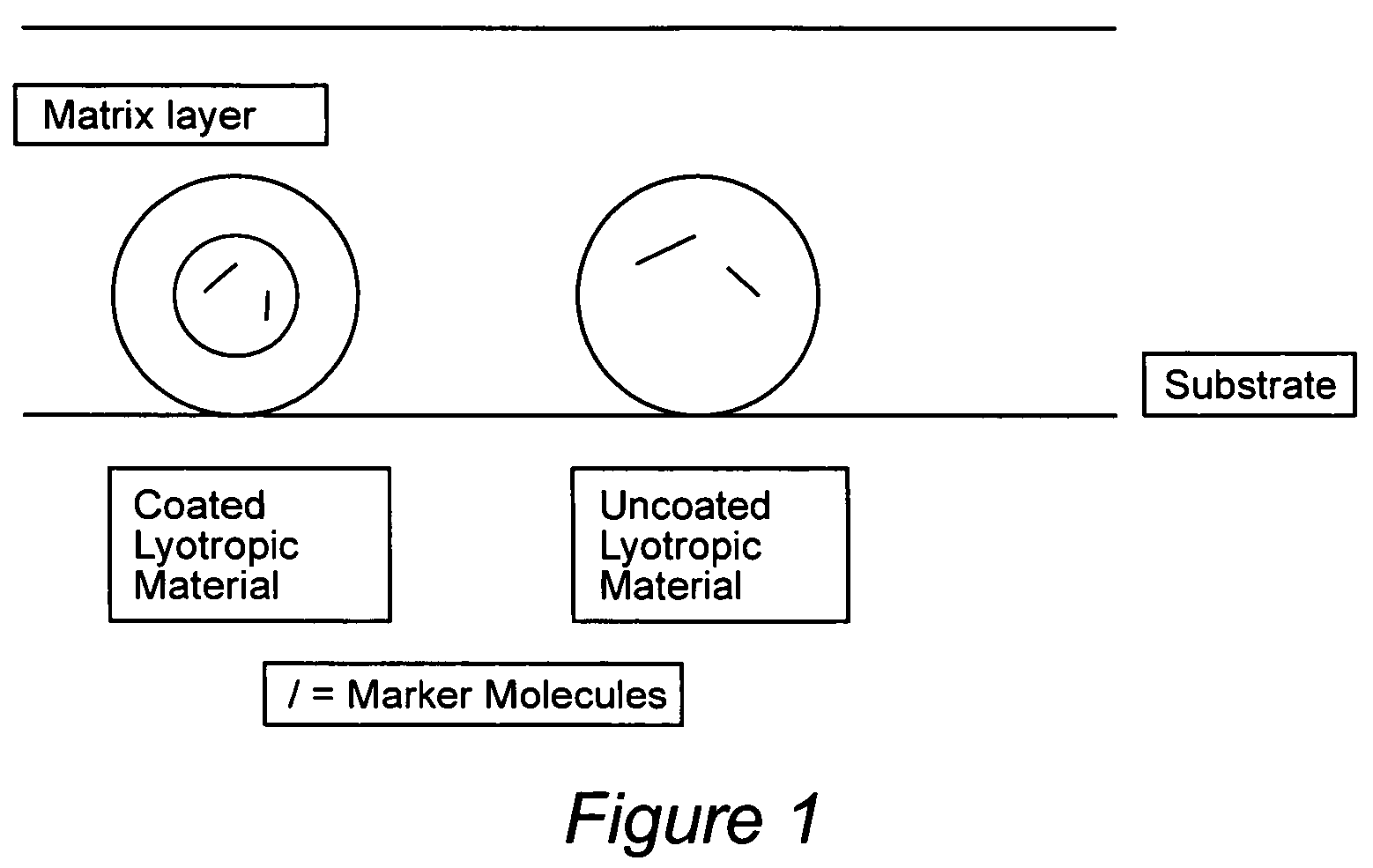

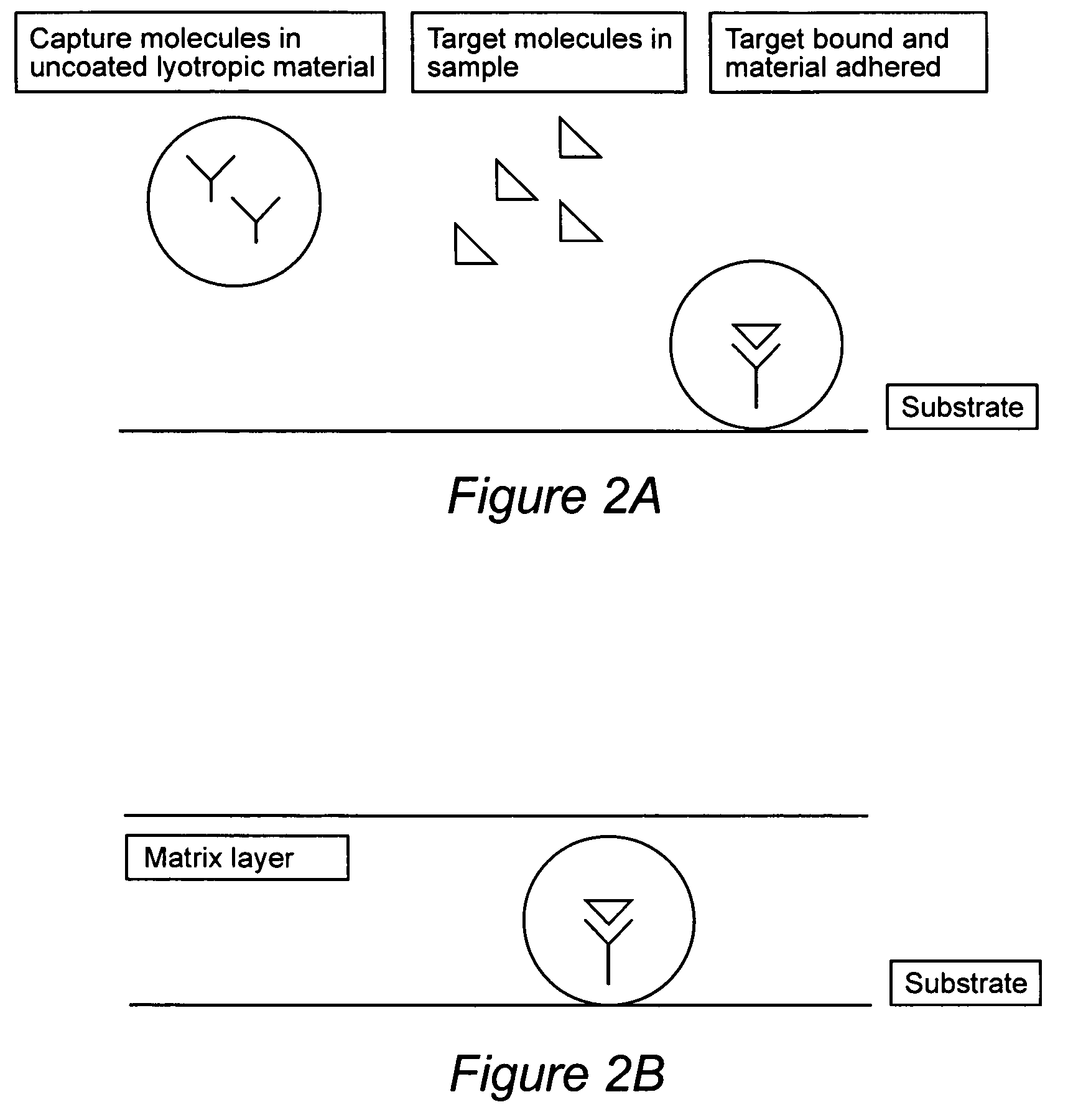

Compositions for binding to assay substrata and methods of using

ActiveUS20060141544A1Reduce run-to-run variabilityHigh measurement accuracyAnalysis by subjecting material to chemical reactionBiological testingSpectroscopyMass spectrometry

Compositions and methods for binding to assay substrata in a stable and protective manner, thereby enhancing assay performance, are provided. The compositions comprise lyotropic materials (for example, lyotropic liquid and / or liquid crystalline materials) and may contain macromolecular standards, markers or capture compounds. The compositions are capable of binding to assay substrata such as that of chips that are employed for MALDI and SELDI mass spectroscopy analyses and plates that are used for ELISA type assays.

Owner:LYOTROPICS THERAPEUTICS INC

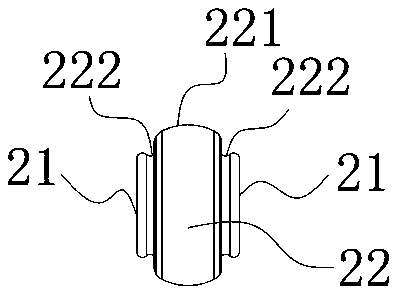

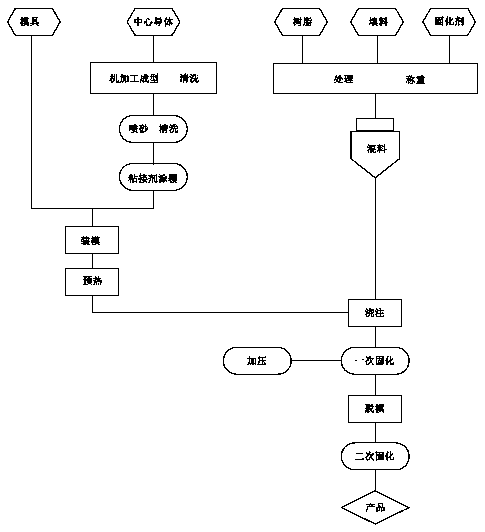

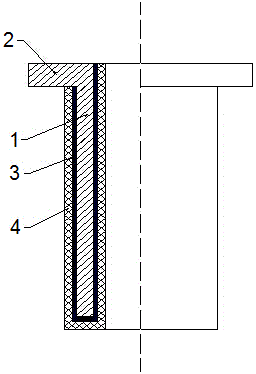

Basin-type insulator and manufacturing process thereof

InactiveCN105513723AImprove the state of the interfaceHigh hydraulic strengthInsulatorsEpoxyElectrical conductor

The invention discloses a basin-type insulator and a manufacturing process thereof. The basin-type insulator comprises a basin body and a center conductor. The center conductor is machined and formed, the outer cylindrical surface is in a shape like a Greek letter 'omega', and the normal bearing area is increased. The manufacturing process mainly includes the two stages of center conductor pretreatment and epoxy resin pouring. The center conductor is subjected to die filling and preheating after machining, washing, sand blasting and epoxy resin adhesive coating, materials obtained after vacuum mixing are poured into a die, and the basin-type insulator is finally formed through two times of curing. By means of the process, due to the fact that shape machining, sand blasting and adhesive coating are additionally carried out on the center conductor, electric field distribution is more reasonable, interface bonding strength is remarkably improved, and the poured and formed basin-type insulator has excellent electrical and mechanical performance.

Owner:MOTIC XIAMEN ELECTRIC GRP

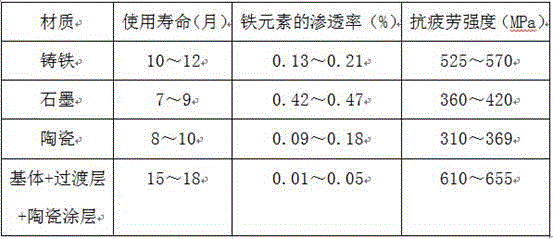

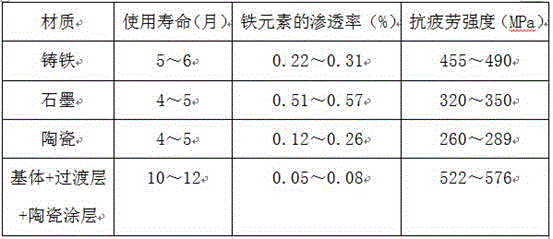

Composite low-pressure casting riser tube and preparation method thereof

ActiveCN105834399AWith metal toughnessExtended service lifeMolten spray coatingThermal sprayingCeramic coating

The invention relates to a composite low-pressure casting riser tube and a preparation method thereof. The composite low-pressure casting riser tube comprises a base body, a transition layer and a ceramic coating coated in sequence from inside to outside. In preparation, firstly, a casting technology is used for preparing the base body of the riser tube, treatment such as deburring and deflashing is performed, and the sand blasting roughening treatment is performed on the base body of the riser tube; then, the transition layer and the ceramic coating are sprayed on the inner and outer surfaces of the base body by use of a thermal spraying technology; and finally, after-treatment such as polishing is performed on the prepared riser tube. The composite low-pressure casting riser tube and the preparation method thereof have the following advantages: the riser tube solves the problems of short life of an existing low-pressure casting riser tube and reduction of casting performance due to pollution of casting materials, has certain metal toughness and the wear and corrosion resistance of ceramic, solves the defects of high brittleness, easy cracking and easy breaking of a ceramic riser tube, and solves the problem of easy corrosion by molten metal and easy pollution to the molten metal of an integral cast iron riser tube through a barrier effect of the ceramic coating

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

High-density fiberboard with high fire resistance and preparation method of high-density fiberboard

ActiveCN113070969AStrong fire resistanceImprove fire and flame retardant performanceWood working apparatusFlat articlesHigh densityMagnesium stearate

The invention belongs to the technical field of fiberboard materials, particularly relates to a high-density fiberboard with high fire resistance and a preparation method of the high-density fiberboard. The problems that in the prior art, a fiberboard can release harmful substances such as formaldehyde, the fiberboard belongs to an inflammable material are solved, and the high-density fiberboard comprises the following raw materials of, in parts by weight, 30-50 parts of wood chips, 30-50 parts of straws, 10-20 parts of light silicon dioxide, 3-5 parts of an adhesive, 3-5 parts of a flame retardant, 1-3 parts of magnesium stearate, 2-4 parts of hexamethyldisiloxane and 2-5 parts of p-hydroxybenzenesulfonic acid. According to the high-density fiberboard with the high fire resistance and the preparation method of the high-density fiberboard, the high-density fiberboard is scientific in formula and rigorous in proportion, the obtained high-density fiberboard has excellent fire-resistant and flame-retardant performance, waterproof and moistureproof performance and physical and mechanical performance, the preparation method of the high-density fiberboard is simple, mild in preparation condition and easy for industrial production, and can be widely applied.

Owner:佳诺威集团股份有限公司

Corrosion-resistance aluminum alloy door/window and preparation method thereof

InactiveCN106475290AImprove qualityImprove surface bindingPretreated surfacesAnti-corrosive paintsPolyvinyl chlorideSurface-active agents

The invention discloses a preparation method of a corrosion-resistance aluminum alloy door / window. The preparation method comprises the following steps: (1) styrene, acetone, isopropanol, urea resins, lauryl sodium sulfate and polyvinyl chloride are mixed to prepare a coating composition; (2) an aluminum alloy door / window basal body is deoiled by alkali liquid and a surface active agent in sequence; (3) the deoiled aluminum alloy door / window basal body is cleaned the surface by ethanol and water; and (4) the coating composition is coated on the cleaned surface of the aluminum alloy door / window basal body, and is heated to prepare the corrosion-resistance aluminum alloy door / window; and corresponding to 2 parts of styrene, 4-8 parts of acetone, 30-40 parts of isopropanol, 40-50 parts of urea resins, 5-9 parts of lauryl sodium sulfate and 3-8 parts of polyvinyl chloride are added. The corrosion-resistance aluminum alloy door / window prepared through the method is excellent in mechanical performance and corrosion resistance.

Owner:ANHUI KATA DOOR & WINDOW

Copper welding paste for automatic brazing and its preparing method

InactiveCN1298493CImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaRare-earth elementOrganic solvent

The copper base welding paste for automatic brazing includes brazing material, brazing agent and paste forming material. The brazing material has Cu as main material and added alloy elements P, Sn, Ni, B, Ti, In and RE; the brazing agent consists of chemically synthesized intermediate polyboride M, potassium fluoroborate N and flux Q; and the paste forming material consists of mixture of polyisobutylene in different molecular weight and organic solvent. The copper base welding paste has good flowability, wetability and gap-filling performance, etc. and is suitable for industrial production.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

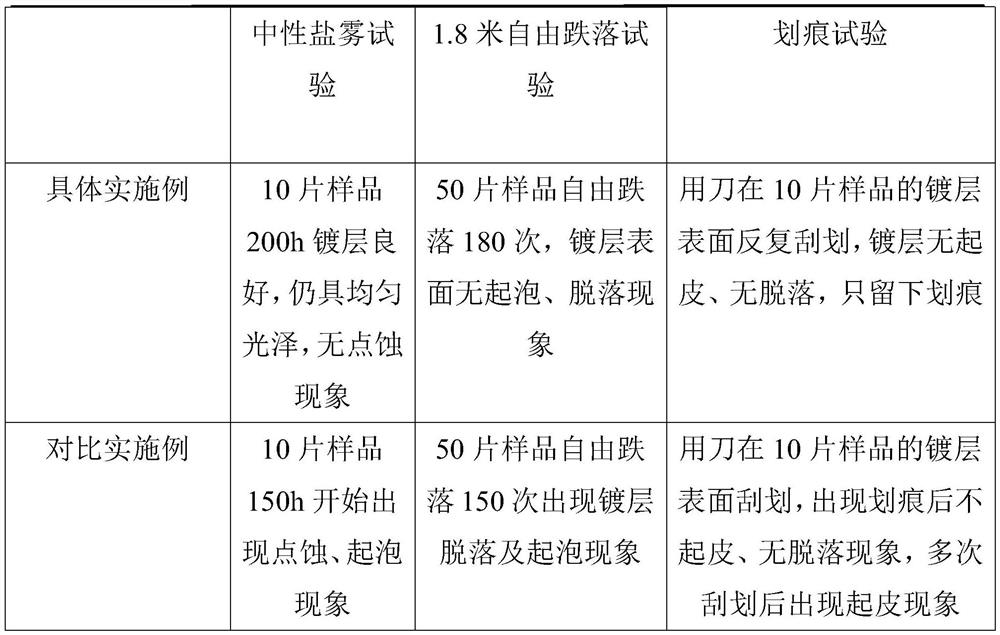

Method for improving binding force of plating layer of neodymium-iron-boron magnet and neodymium-iron-boron magnet electroplating piece

InactiveCN111636084AImprove bindingSimple production processInductances/transformers/magnets manufactureBinding forceCorrosion resistant

The invention discloses a method for improving the binding force of a plating layer of a neodymium-iron-boron magnet and a neodymium-iron-boron magnet electroplating piece. The method comprises the steps that firstly, a neodymium-iron-boron semi-finished product workblank is subjected to multi-thread slicing to obtain neodymium-iron-boron semi-finished product slices, then the neodymium-iron-boronsemi-finished product slices are subjected to chamfering, deoiling, washing, acid pickling, ultrasonic wave washing, excitation and washing, and finally the neodymium-iron-boron semi-finished productslices are subjected to electroplating treatment, so that the neodymium-iron-boron magnet electroplating piece is obtained. The method provided by the invention improves the bonding force of the plating layer of the neodymium-iron-boron magnet and the corrosion resistance of the magnet, has high production efficiency and low production cost, and can be applied to automatic production.

Owner:有研稀土(荣成)有限公司

Scratch-resistant aluminum alloy door window and preparation method thereof

InactiveCN106479308AImprove qualityImprove mechanical propertiesPretreated surfacesCoatingsEpoxyAlcohol

The invention discloses a scratch-resistant aluminum alloy door window and a preparation method thereof. The preparation method includes: (1), mixing, by weight, 5 parts of glycerol, 4-8 parts of carbon black, 30-40 parts of epoxy propane, 40-50 parts of urea formaldehyde resin, 5-9 parts of polyacrylamide and 10-15 parts of polyvinyl chloride to obtain a coating composition; (2), sequentially using alkaline liquid and a surfactant to deoil an aluminum alloy door window matrix; (3), using alcohol and water to clean the surface of the deoiled aluminum alloy door window matrix; (4), coating the surface of the aluminum alloy door window matrix with the surface cleaned with the coating composition, and heating to obtain the scratch-resistant aluminum alloy door window. The scratch-resistant aluminum alloy door window prepared by the method has excellent mechanical performance, wear resistance and scratch resistance.

Owner:ANHUI KATA DOOR & WINDOW

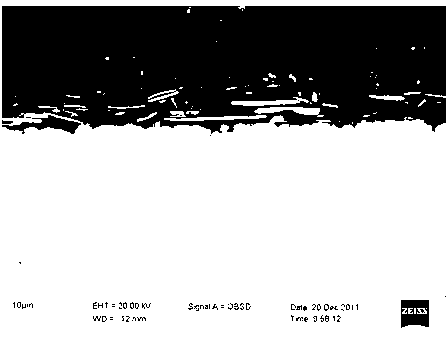

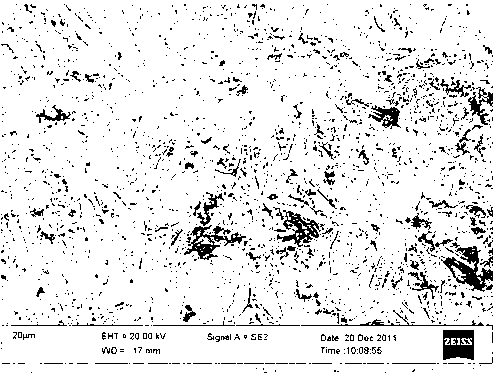

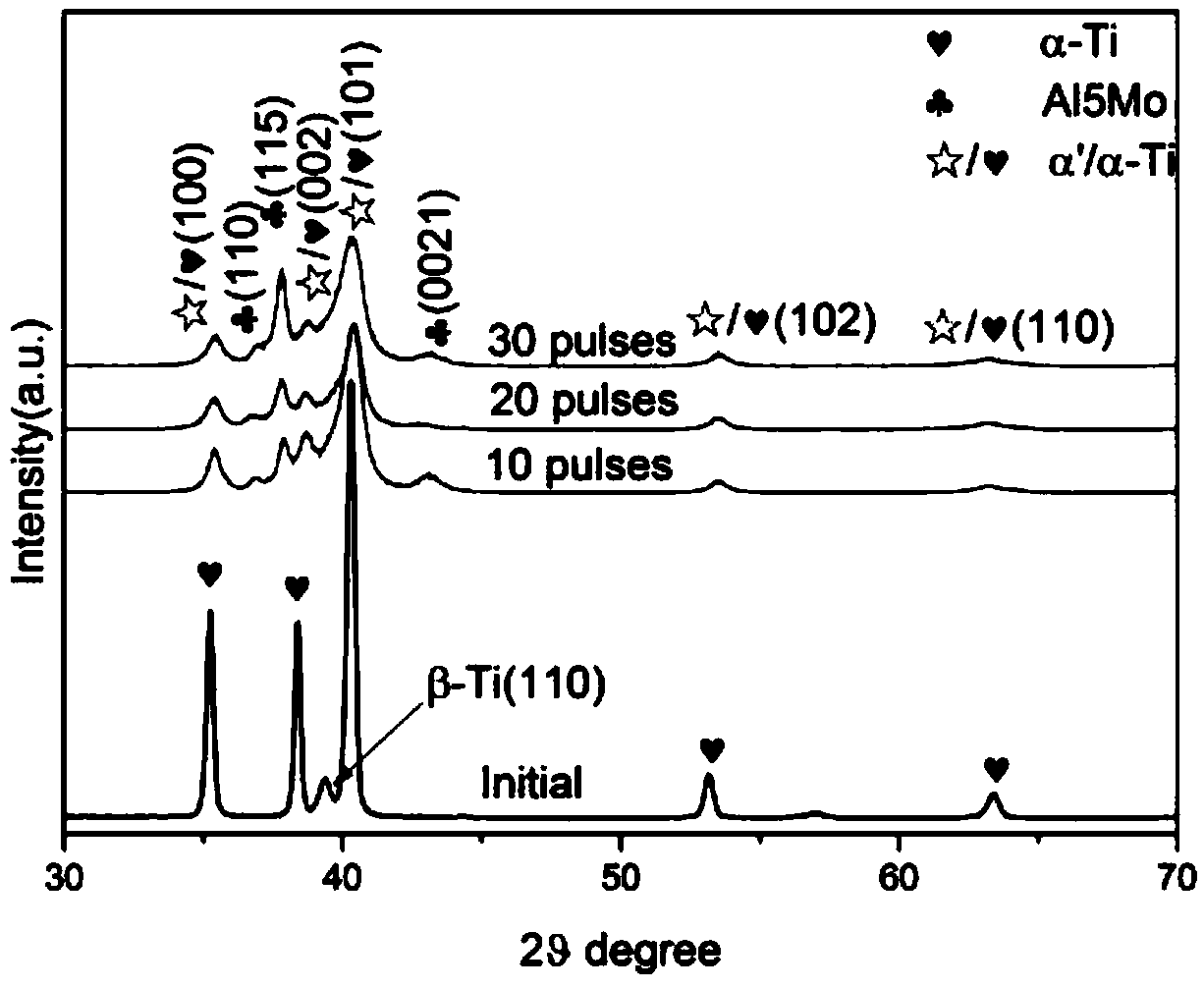

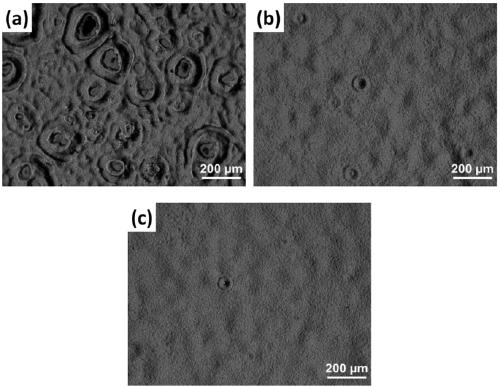

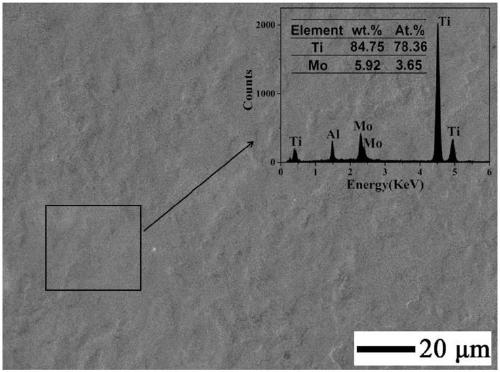

Method for realizing molybdenum alloying of surface through irradiating TC4 titanium alloy by electron beam

The invention relates to the technical field of titanium alloy surface modification, in particular to a method for realizing molybdenum alloying of a surface through irradiating TC4 titanium alloy byan electron beam. Metal powder pre-coating is combined with the high current pulse electron beam irradiating technology to prepare an alloying layer with high hardness and corrosion resistance on thesurface of TC4 titanium alloy.

Owner:JIANGSU UNIV

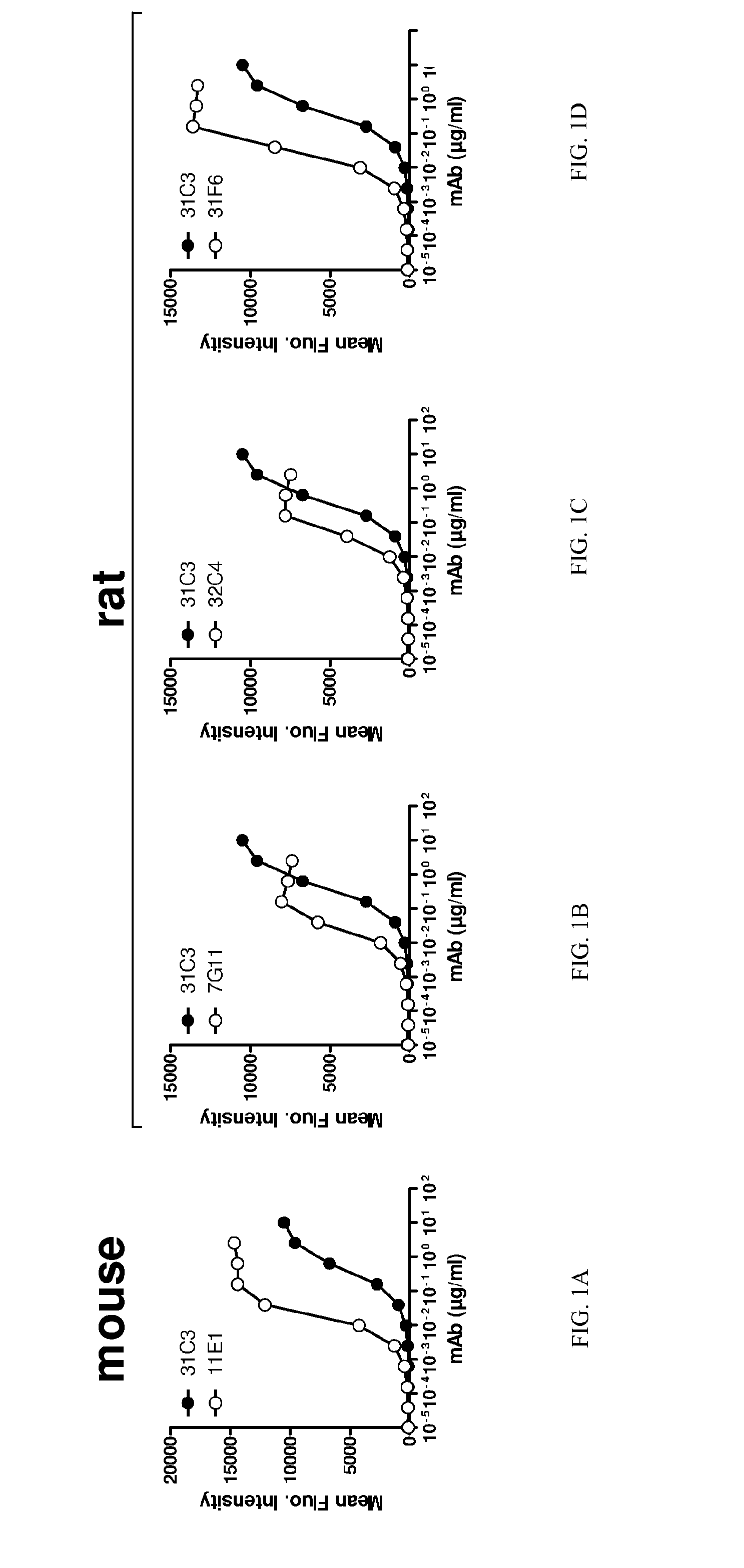

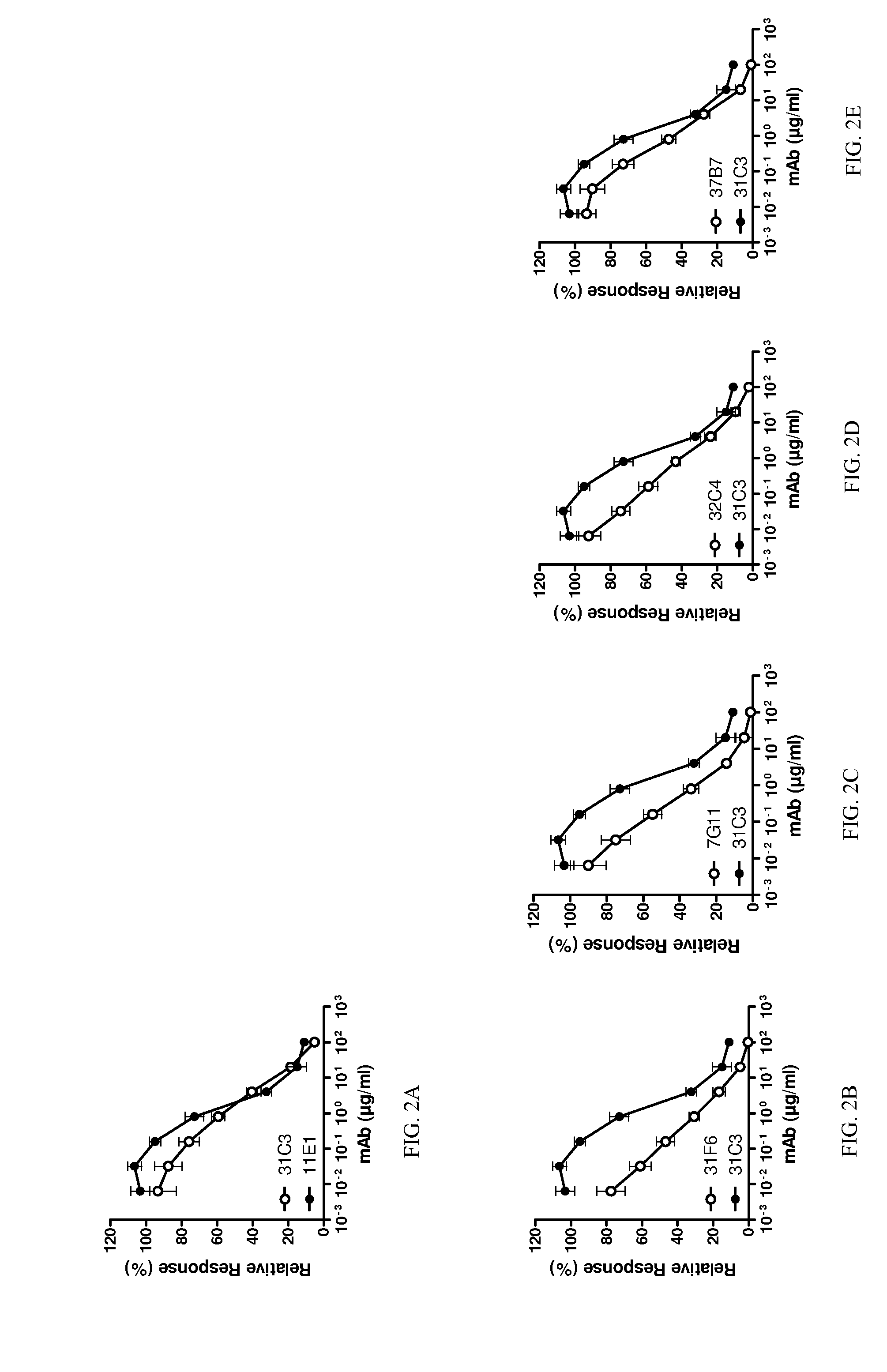

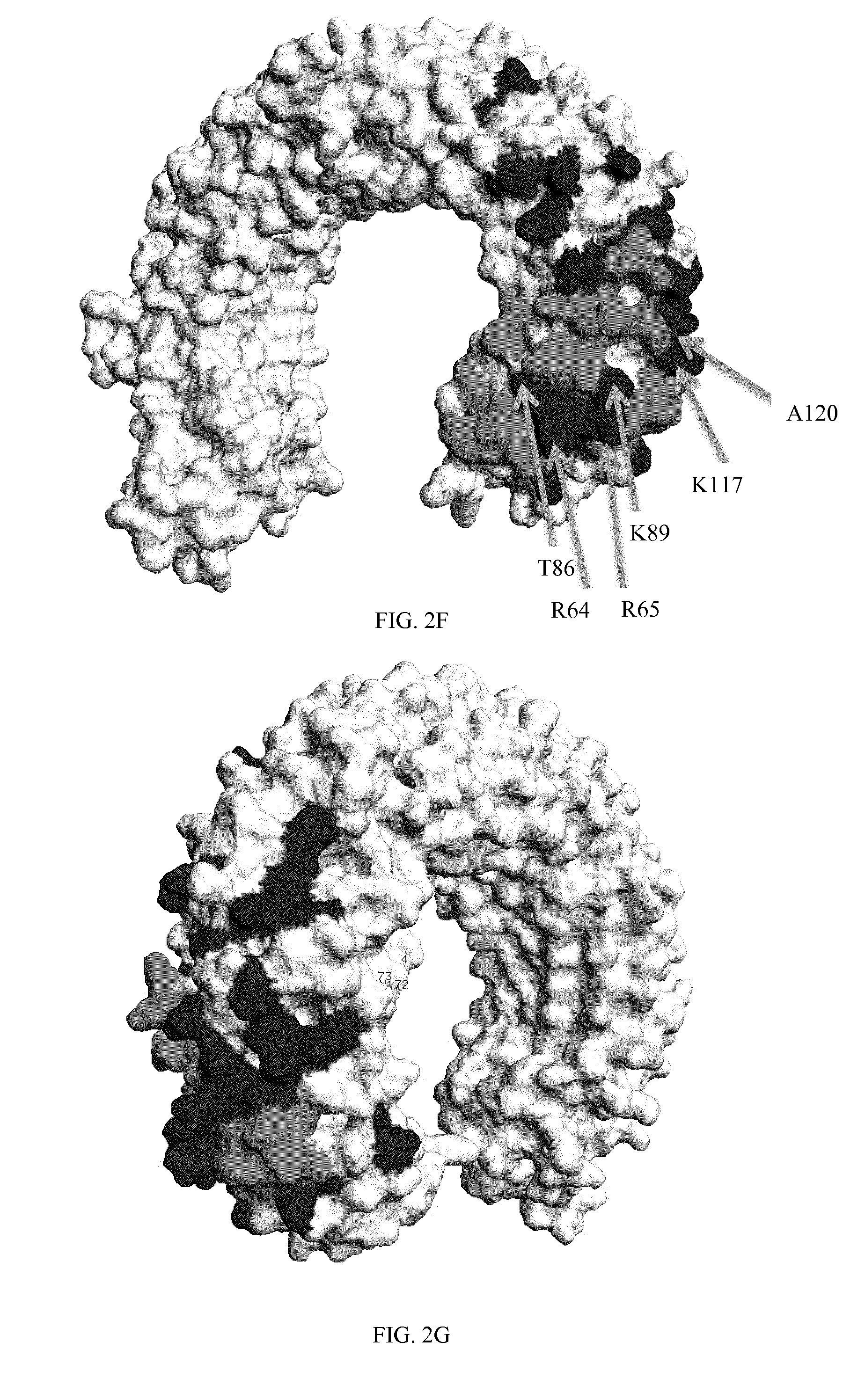

Tlr3 binding agents

Owner:INNATE PHARMA SA

High-toughness wear-resisting cable material

PendingCN110041661ALarge poresImprove mechanical propertiesPlastic/resin/waxes insulatorsCastor oilActive ingredient

The invention discloses a high-toughness wear-resisting cable material and belongs to the technical field of wires and cables. According to the invention, biogas slurry is firstly treated and then shrimp shells are treated in the manner of mixed fermentation, so that chitin is differentiated and degraded, active ingredients can be generated, cross-linking action can be enhanced and overall wear-resisting property can be promoted; aramid fiber pulp has a fluff structure, has an ultra-large contact area with a resin component and is capable of promoting interaction of inner components of the system, improving shock resistance, promoting toughness, increasing degree of orientation, increasing surface roughness, promoting compatibility thereof with a modified resin component and jointly promoting toughness and wearing resistance; due to the addition of castor oil, vibration strength of covalent bonds in the resin component can be reduced, tensile strength can be effectively promoted, and the castor oil and the compound modified resin component can be combined into an interwound firm three-dimensional network so as to promote the inner mechanical properties. The high-toughness wear-resisting cable material is capable of solving the problems of inferior wear-resisting property, low tensile strength, low toughness and inconvenience in processing of the present common cable material.

Owner:北京中科惠景储能材料科技有限公司

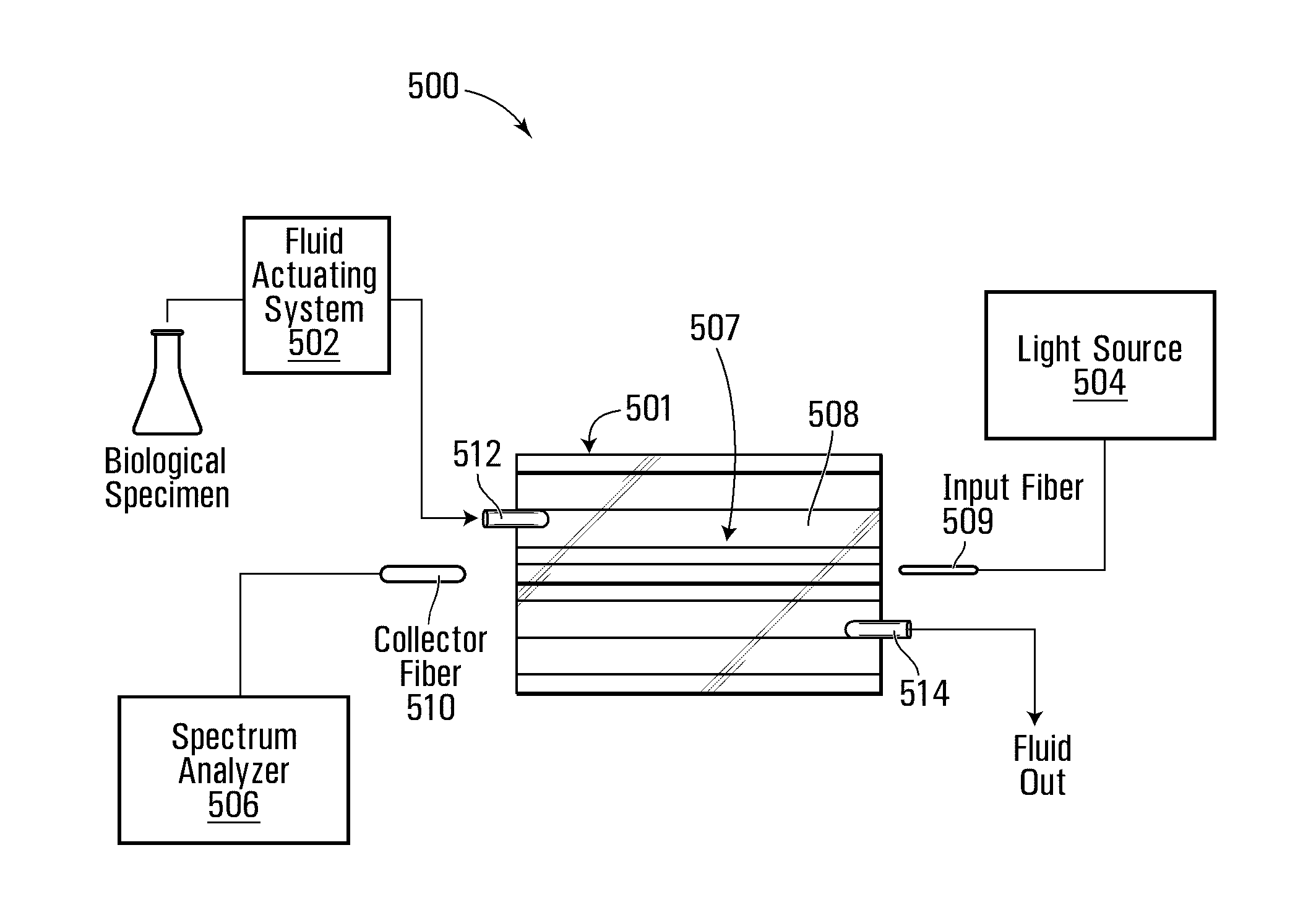

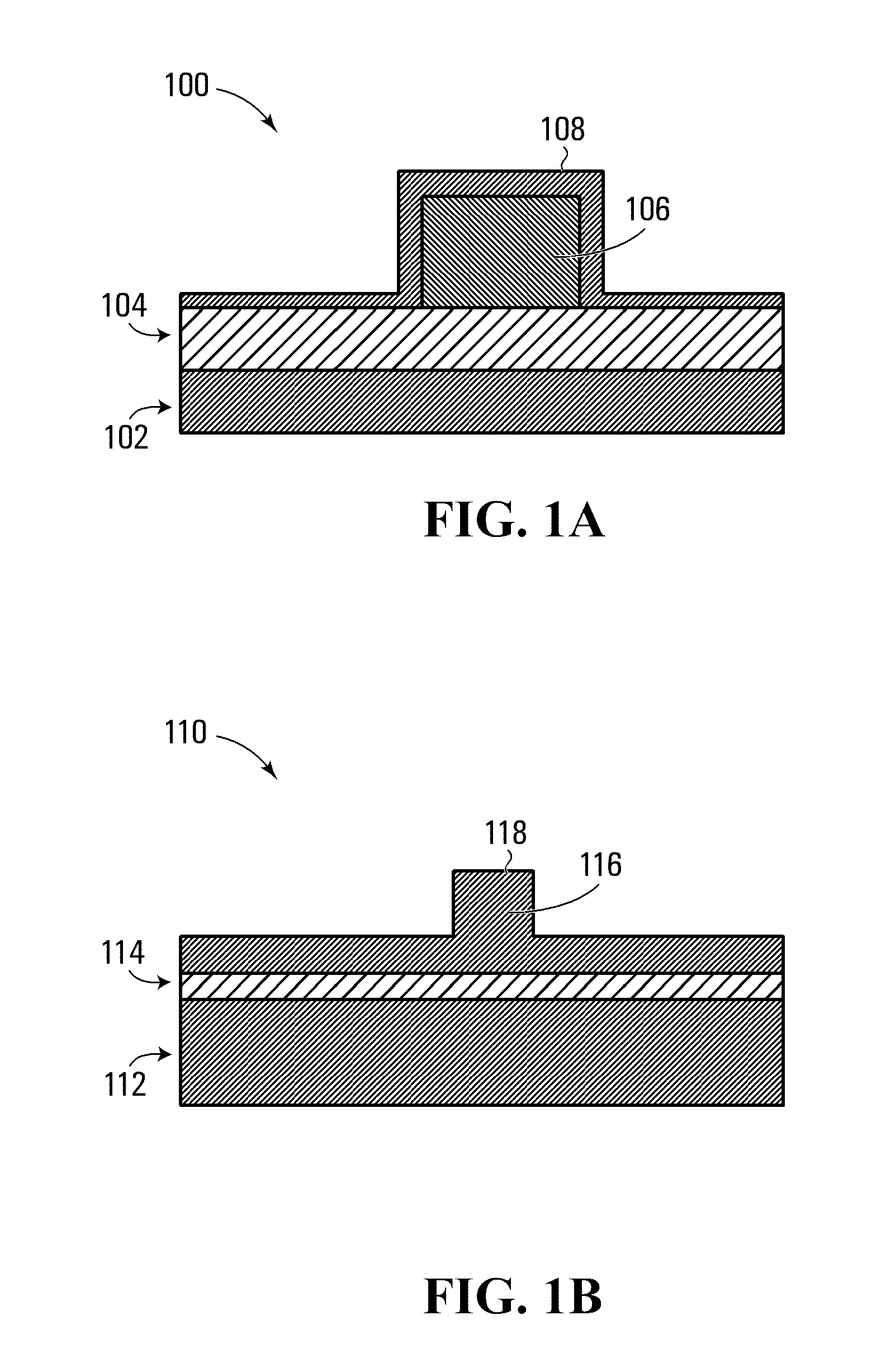

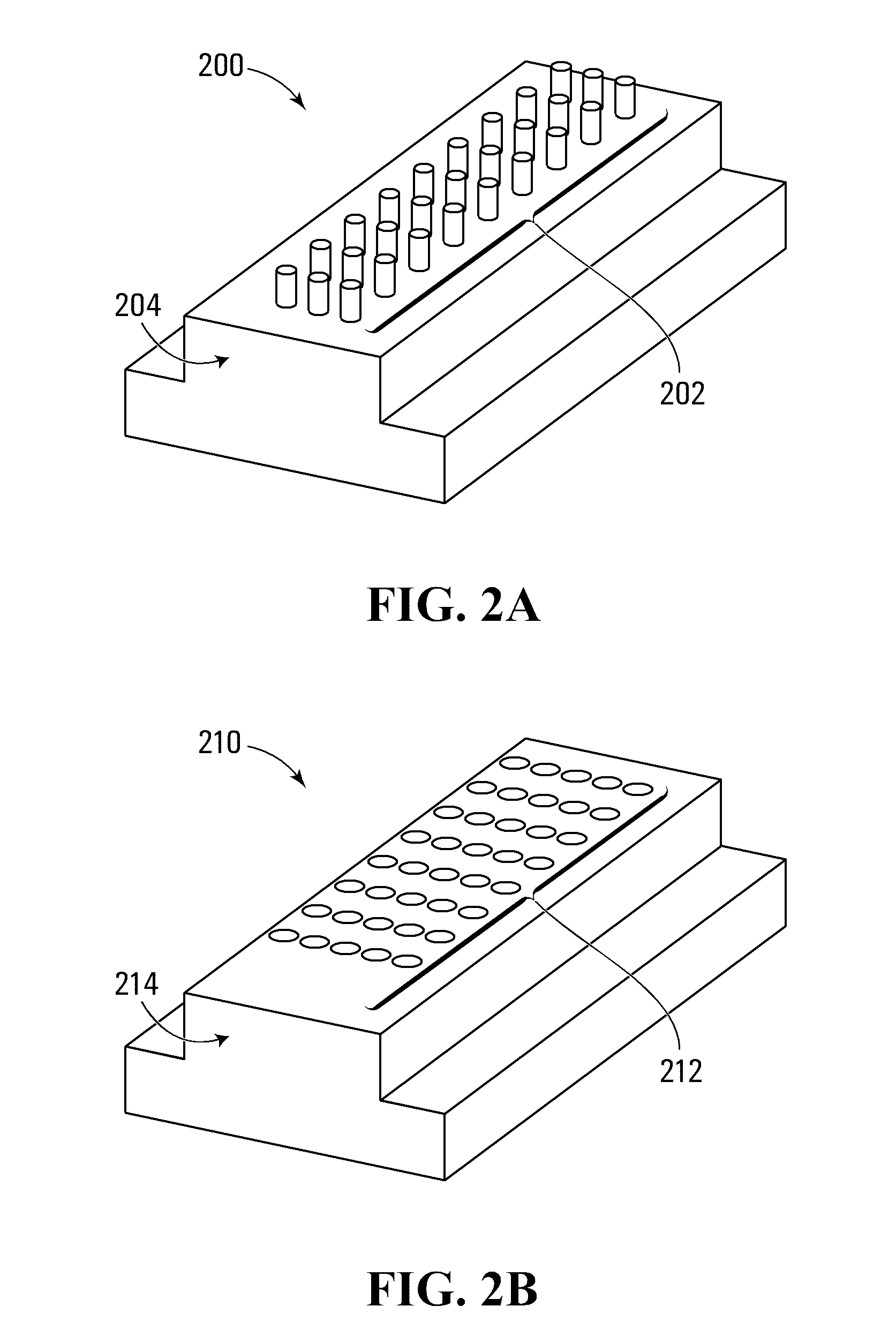

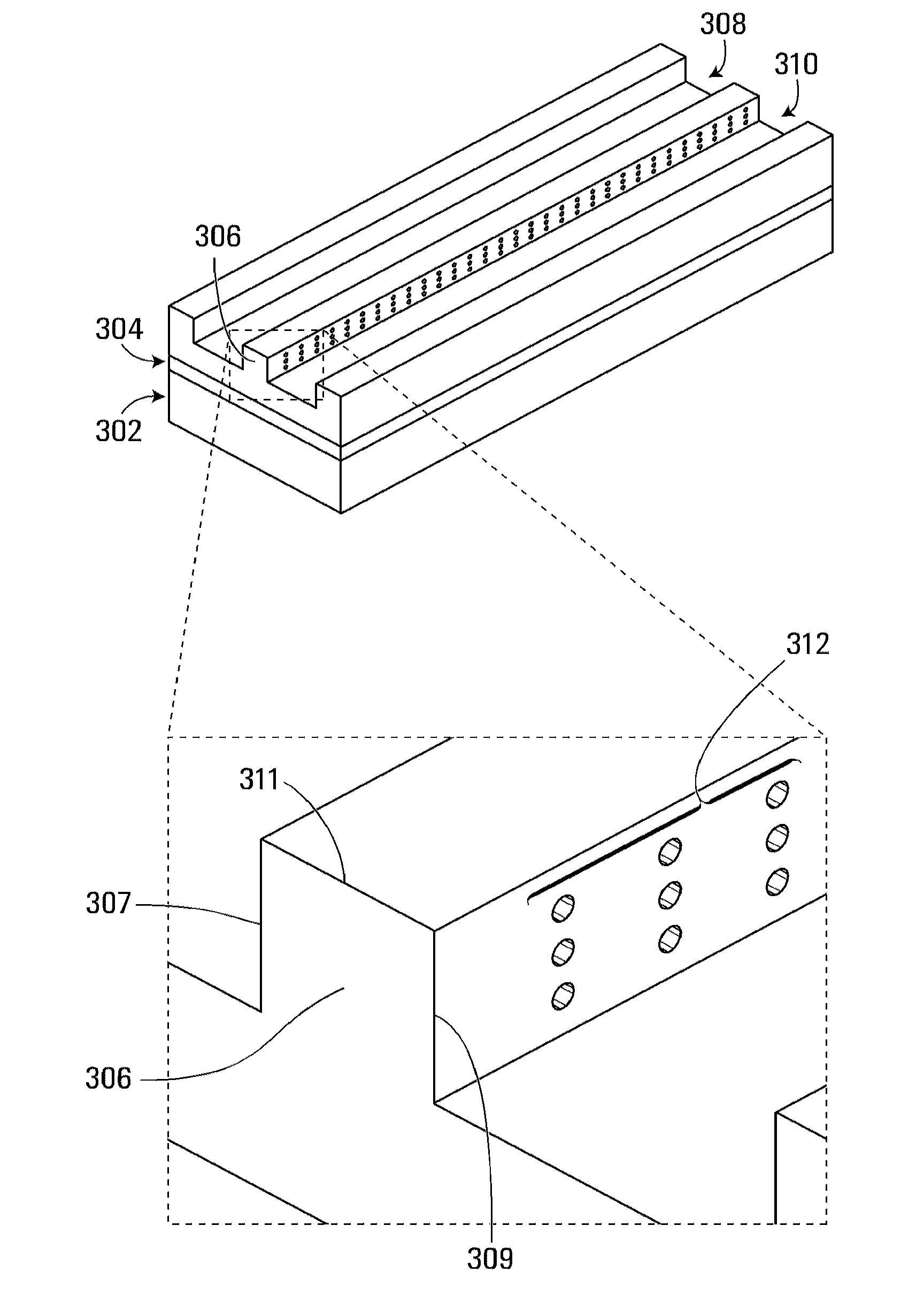

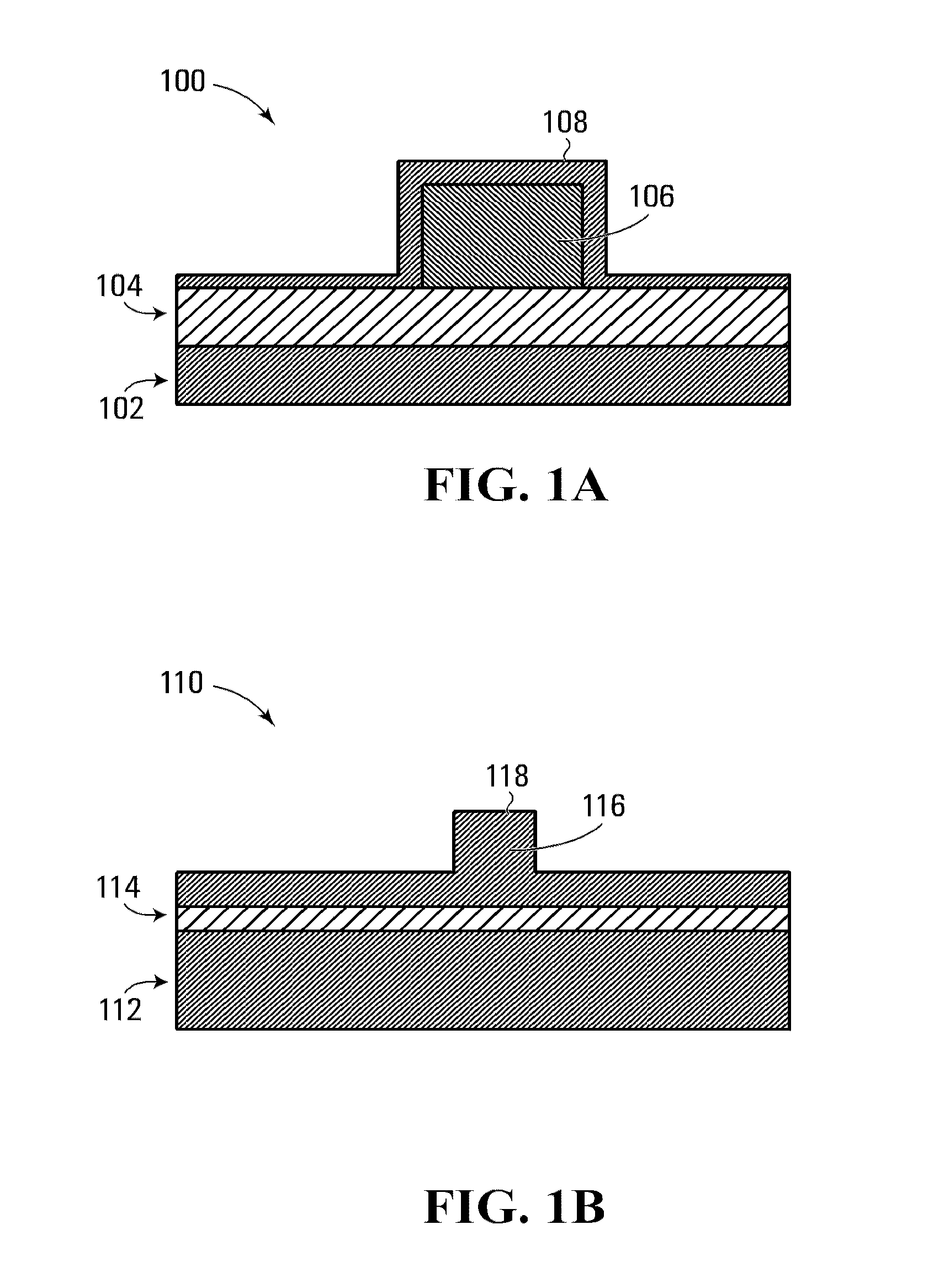

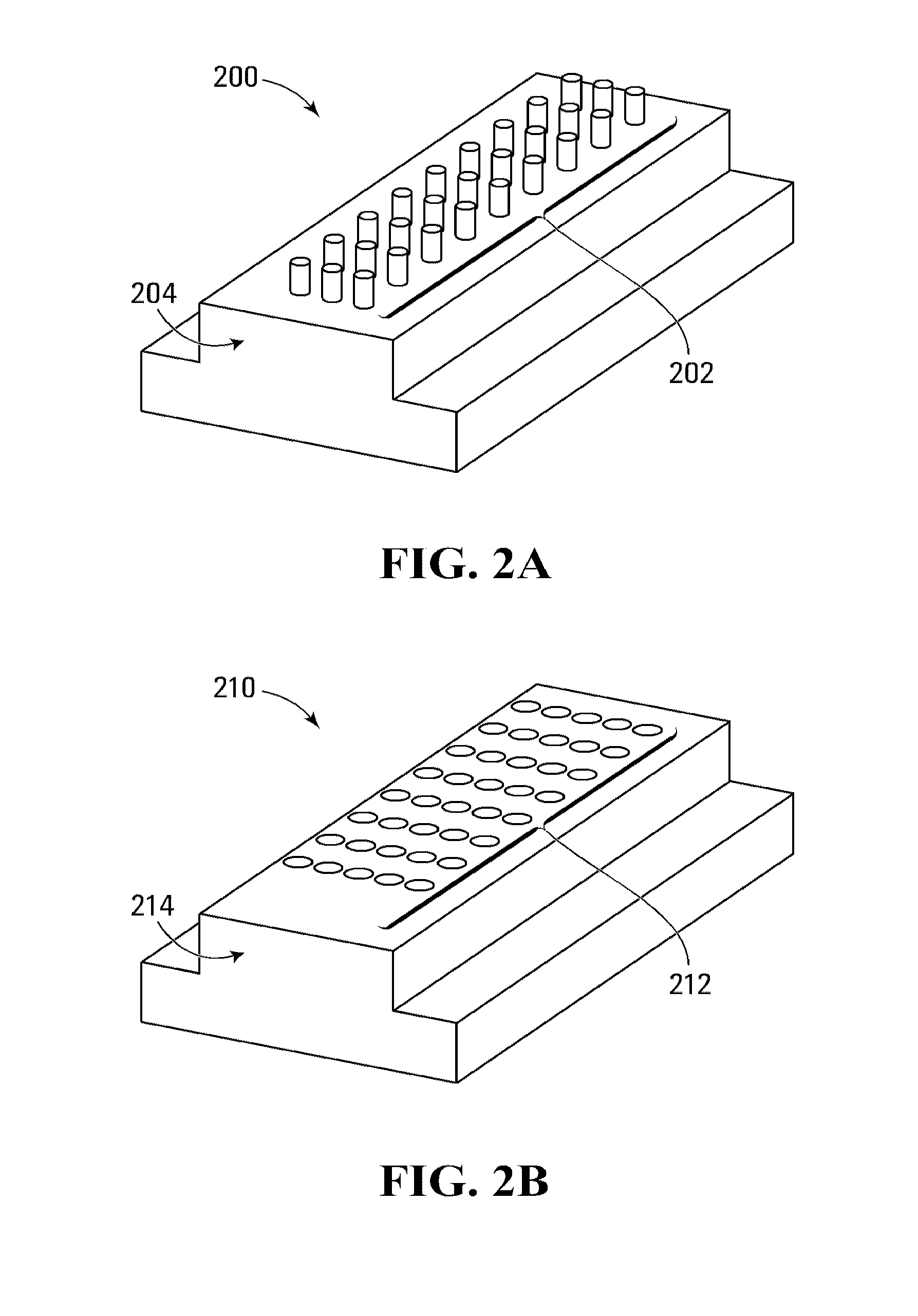

Nano-enhanced evanescence integrated technique (NEET) based microphotonic device and sample analysis system

InactiveUS20120269683A1Improve surface bindingSemiconductor/solid-state device manufacturingNanoopticsCouplingEngineering

A device, a method of fabricating the device and a sample analysis system that includes the device are provided. The device includes an optical waveguide having a plurality of nanofeatures integrated thereon to influence at least one of evanescence and coupling of an optical field of the optical waveguide. The sample analysis system includes a fluidic actuation system for introducing sample specimen fluid into a microfluidic channel of the device for evanescence based detection.

Owner:CONCORDIA UNIVERSITY

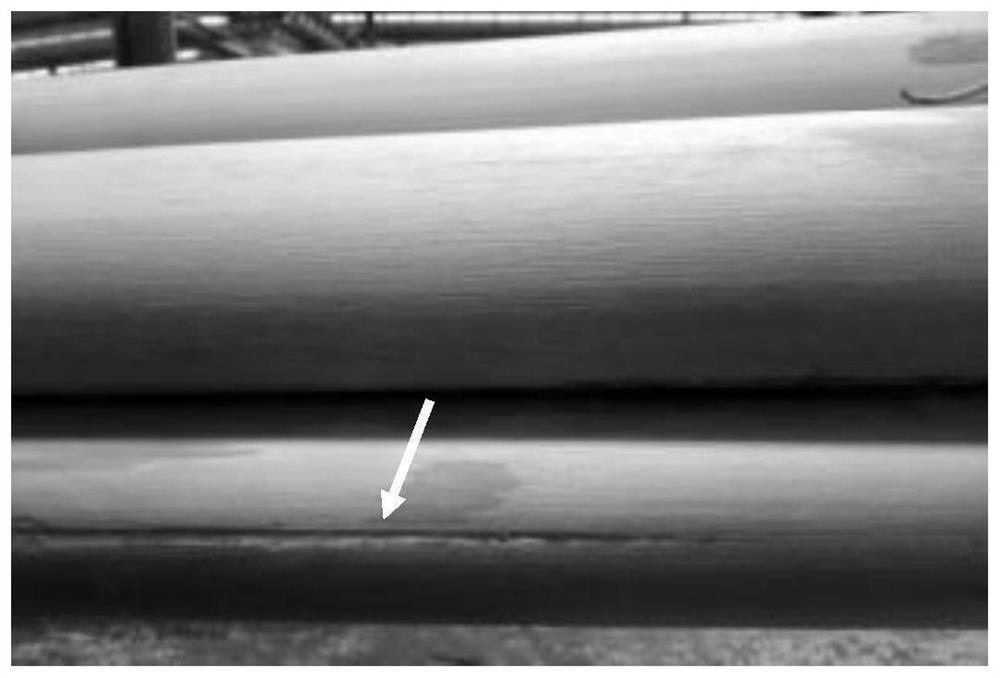

Preparation method of anti-corrosion pipe material

The invention provides a preparation method of an anti-corrosion pipe material. The method comprises the following steps of a, mixing polyvinyl chloride resin, nitrile rubber and polybutylene resin; feeding the mixture into a mixing machine for mixing; obtaining a first material; b, mixing the first material with modified glass fiber, silicon dioxide and compatilizers; guiding the mixture into a stirring machine; performing high-speed stirring; then, adding semi-refined paraffin wax, asbestos powder and antioxidants; performing uniform mixing; then, performing ultrasonic wave processing to obtain a second material; c, mixing modified nanometer carbon fiber and auxiliary filling materials; feeding the mixture into a ball mill for grinding and stirring to obtain a third material; d, mixing the first material, the third material, a toughening agent, a mildew preventive and a lubricating agent into a single-screw extruding machine; performing extrusion to obtain a pre-finished product; e,guiding the pre-finished product into a mold; performing heating and pressurization; then, performing molding and shaping. The prepared pipeline material has the characteristics of good impact performance, good anti-corrosion performance and high pressure-resistant intensity.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

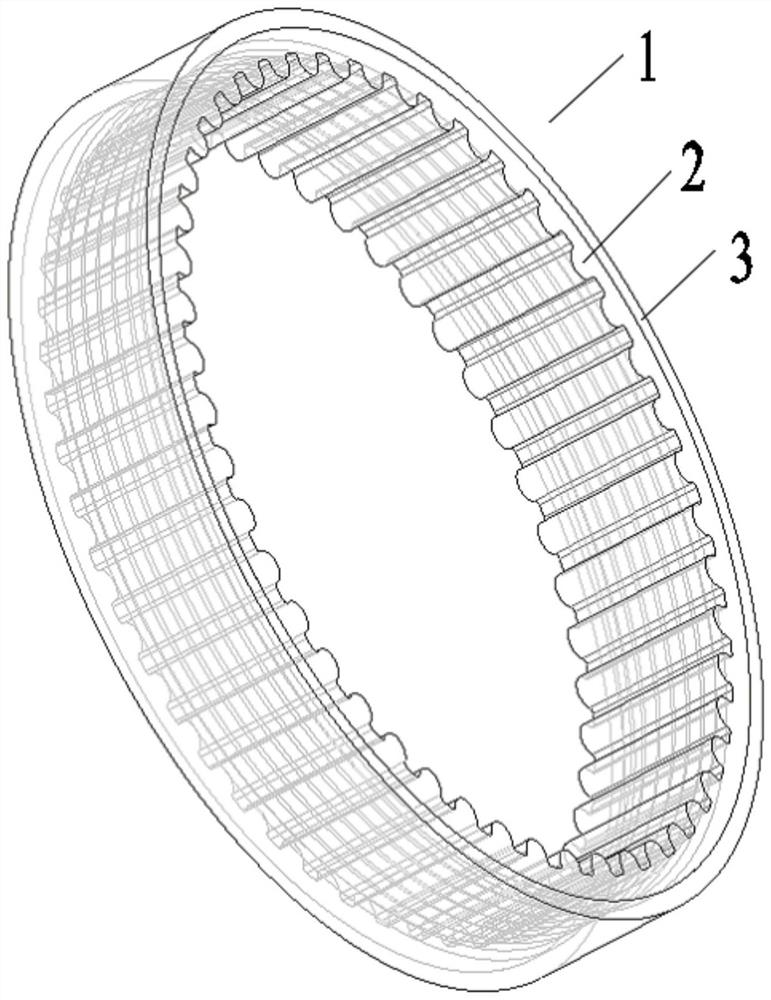

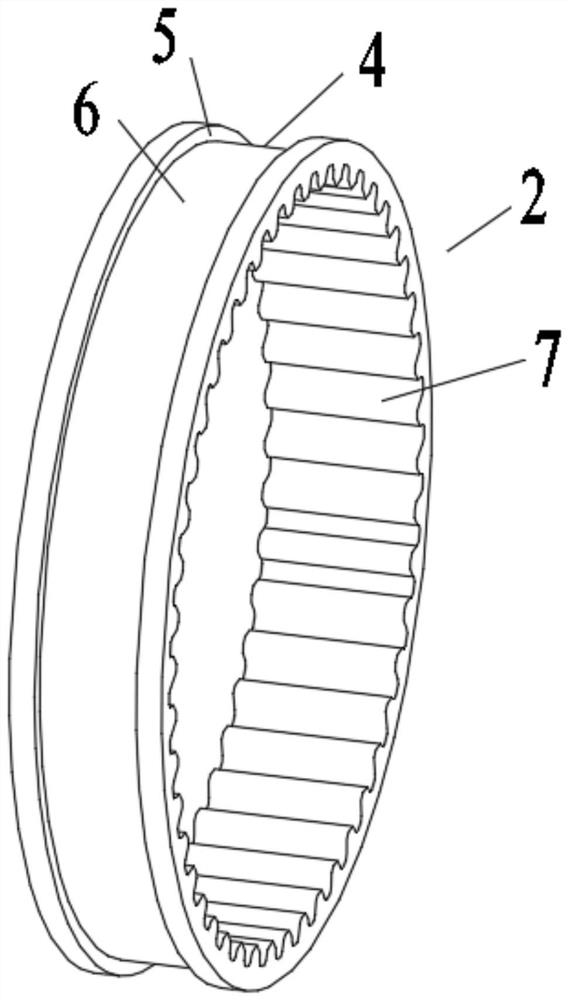

Self-moving robot, synchronous belt and preparation method of synchronous belt

PendingCN113386105AImprove work efficiencyIncrease frictionProgramme-controlled manipulatorGearingControl engineeringHigh wear resistance

The invention provides a self-moving robot, a synchronous belt and a preparation method of the synchronous belt. The self-moving robot comprises a robot body, the synchronous belt is arranged at the bottom of the robot body, the synchronous belt comprises an inner ring and an outer ring, the outer ring is in rolling contact with a walking surface, the inner ring and the outer ring are both made of mixed polyurethane, the shore hardness of the inner ring ranges from 60A to 90A, and the shore hardness of the outer ring ranges from 30A to 60A. According to the self-moving robot provided by the invention, the synchronous belt has good wear resistance, high wear resistance can be kept under the condition of low hardness, the friction force between the self-moving robot and working media such as glass can be effectively improved, the working efficiency of the self-moving robot is improved, the cleaning range of the self-moving robot is widened, and the application range of the self-moving robot is expanded.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Nano-enhanced evanescence integrated technique (NEET) based microphotonic device and sample analysis system

InactiveUS8883080B2Improve surface bindingMaterial analysis by optical meansSemiconductor/solid-state device manufacturingEngineeringMicrofluidic channel

Owner:CONCORDIA UNIVERSITY

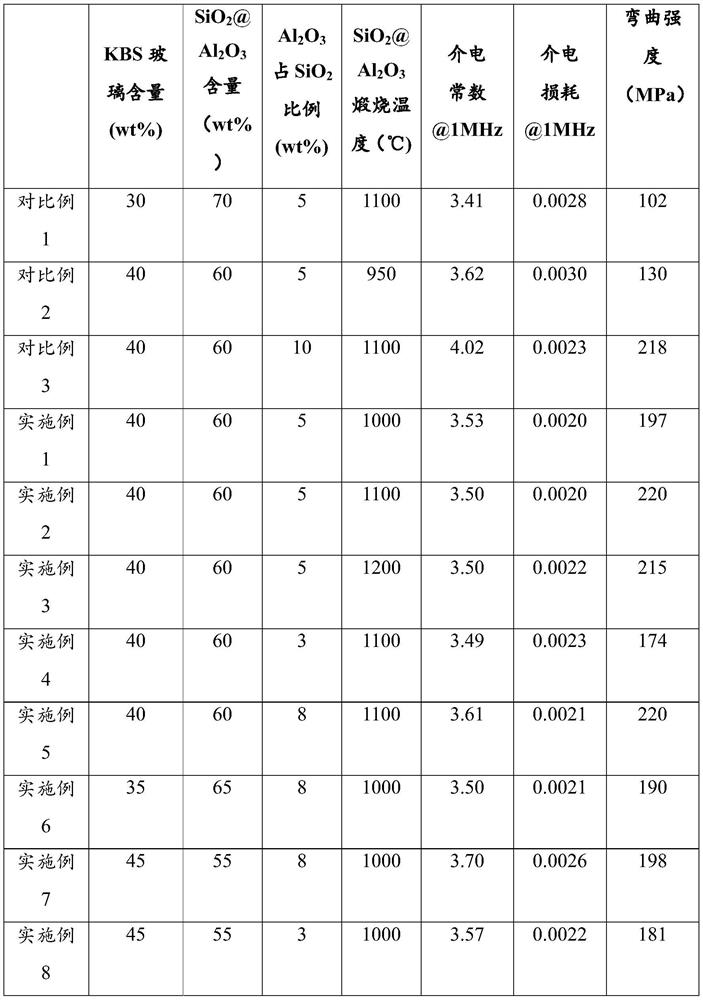

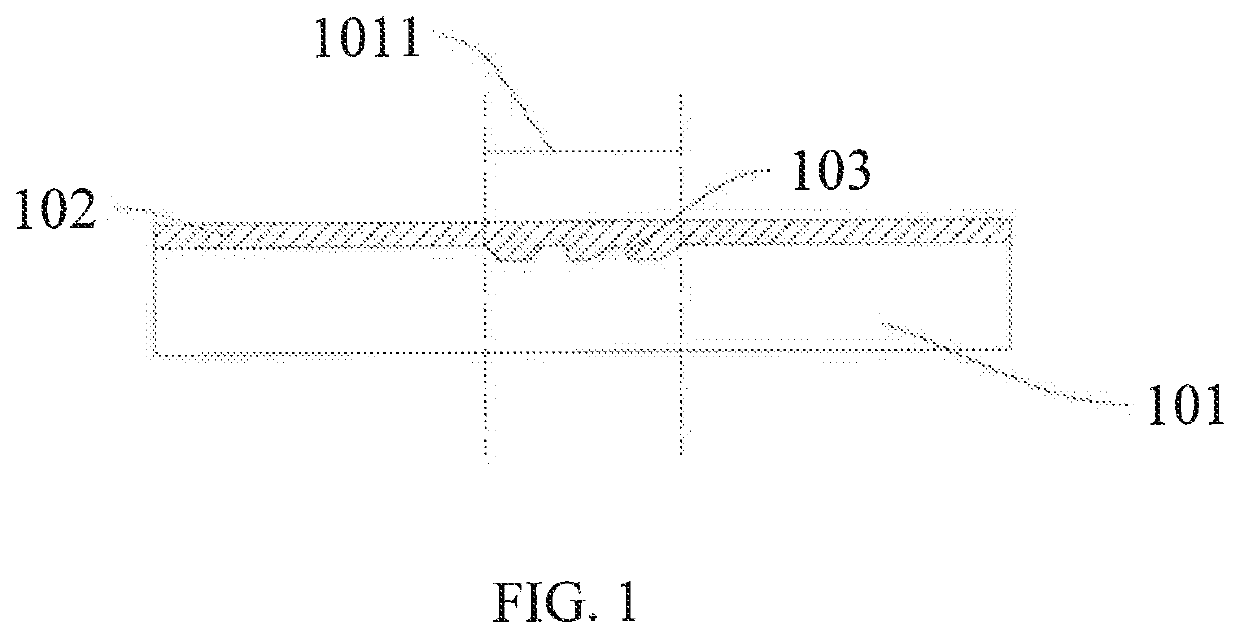

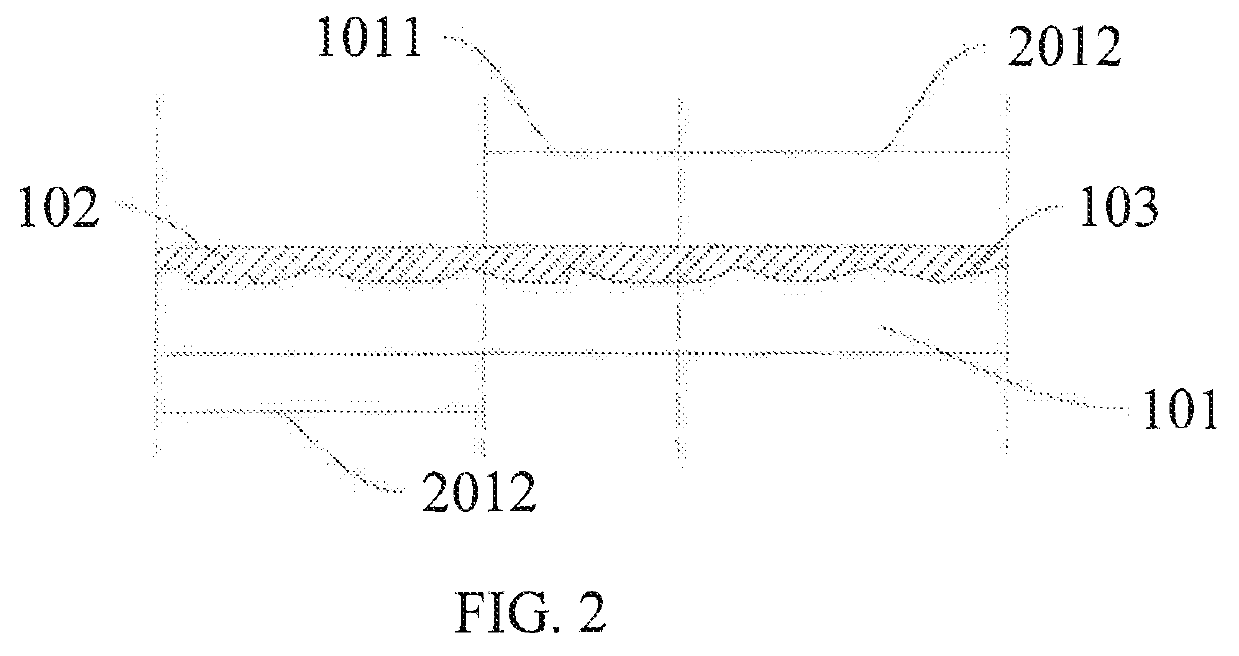

LTCC substrate as well as preparation method and application thereof

InactiveCN113416066ALow dielectric constantReduce dielectric lossGlass furnace apparatusDielectric lossRadio frequency

The invention discloses an LTCC substrate as well as a preparation method and application thereof. The preparation method comprises the following steps: 1) carrying out ball milling on hollow spherical SiO2 and Al2O3, and calcining to obtain SiO2@Al2O3 powder; 2) mixing KBS glass powder, the SiO2@Al2O3 powder and an additive, and carrying out ball milling to obtain ceramic slurry; (3) forming the ceramic slurry, laminating membranes, carrying out isostatic pressing, and cutting into a ceramic blank; and 4) sintering the ceramic blank to obtain the LTCC substrate. By adding the hollow spherical SiO2, the dielectric constant of the LTCC ceramic is reduced, the dielectric constant of the material is as low as 3.5, and the dielectric loss is as low as 0.2%; and the surface of the hollow spherical SiO2 is coated with Al2O3, the surface binding force of glass and SiO2 in the sintering process is improved, the strength of the substrate is improved to 220 MPa, and the ultralow dielectric constant LTCC substrate which is good in compactness and high in bending strength is obtained and is suitable for the fields of high-frequency communication and radio frequency.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

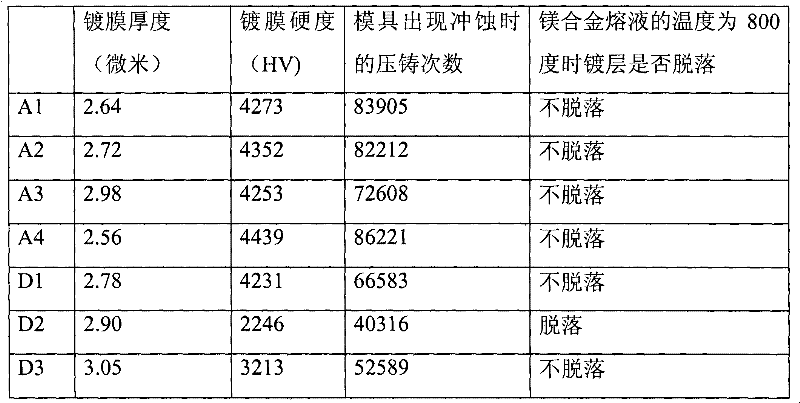

Method for manufacturing die for casting

ActiveCN102453861AHigh hardnessExtend your lifeVacuum evaporation coatingSputtering coatingMetallurgyGas phase

The invention discloses a method for manufacturing a die for casting, comprising the step of forming at least one TiBN layer on the surface of hot die steel after pretreatment by PVD (physical vapor deposition), wherein the pretreatment comprises degreasing and cleaning in order, and degassing and drying are carried out in a vacuum degassing box after cleaning, the degassing and drying is carried out at 100-200 DEG C, the vacuum degassing box is vacuumized at 5-10 Pa, and the degassing time is 30-60 minutes. The bonding force between the obtained coating and a base material is greatly improved, and die surface erosion is retarded, thereby improving the product surface quality and die service life.

Owner:惠州臻富机械电子科技有限公司

Display panel and manufacturing method thereof

PendingUS20210408406A1Improve the bonding force between layersRisk of peelingFinal product manufactureDigital data processing detailsEngineeringMechanical engineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Anti-abrasion aluminum alloy door and window and preparation method thereof

InactiveCN106639768AImprove qualityImprove mechanical propertiesCoatingsDoor leavesAlcoholPolyvinyl chloride

The invention discloses an anti-abrasion aluminum alloy door and window and a preparation method thereof. The preparation method includes the steps that firstly, styrene, carbon black, isopropanol, urea resin, lauryl sodium sulfate and polyvinyl chloride are mixed to prepare a coating composite; secondly, an aluminum alloy door and window base body is subjected to oil removal sequentially with alkaline liquid and a surfactant; thirdly, the surface of the aluminum alloy door and window base body obtained after oil removal is cleaned with ethyl alcohol and water; fourthly, the cleaned surface of the aluminum alloy door and window base body is coated with the coating composition and heated to prepare the anti-abrasion aluminum alloy door and window, wherein the composition is prepared from, by weight, 5 parts of styrene, 4-8 parts of carbon black, 30-40 parts of isopropanol, 40-50 parts of urea resin, 5-9 parts of lauryl sodium sulfate and 10-15 parts of polyvinyl chloride. The anti-abrasion aluminum alloy door and window prepared through the method have excellent mechanical properties and abrasion resistance.

Owner:ANHUI KATA DOOR & WINDOW

Compositions for binding to assay substrata and methods of using

ActiveUS7838307B2Reduce run-to-run variabilityHigh measurement accuracyAnalysis by subjecting material to chemical reactionBiological testingSpectroscopyMass spectrometry

Compositions and methods for binding to assay substrata in a stable and protective manner, thereby enhancing assay performance, are provided. The compositions comprise lyotropic materials (for example, lyotropic liquid and / or liquid crystalline materials) and may contain macromolecular standards, markers or capture compounds. The compositions are capable of binding to assay substrata such as that of chips that are employed for MALDI and SELDI mass spectroscopy analyses and plates that are used for ELISA type assays.

Owner:LYOTROPICS THERAPEUTICS INC

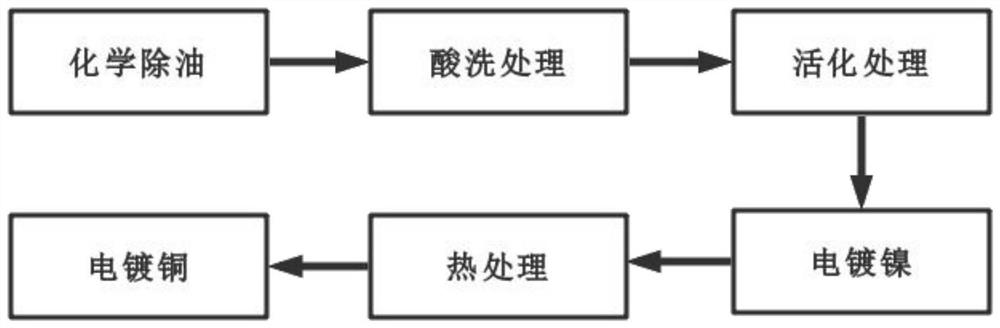

Surface treatment method for titanium alloy ingot blank

The invention relates to the technical field of titanium alloy surface treatment, and provides a surface treatment method of a titanium alloy ingot blank. The titanium alloy ingot blank is sequentially subjected to oil removal, acid pickling, activating treatment, nickel electroplating, heat treatment and copper electroplating. According to the method, the surface of the ingot blank is pretreated through oil removal, acid pickling and activating treatment to improve the binding force of a plating layer and the titanium alloy ingot blank, then the nickel plating layer serves as an inner coating layer to prevent the titanium alloy ingot blank from reacting with copper, the internal stress of the nickel plating layer is eliminated through heat treatment, the ductility of the nickel plating layer is improved, the nickel plating layer and a base body are mutually diffused, and the corrosion resistance of the titanium alloy ingot blank is improved. And finally, the copper plating layer is used as an outer coating layer of the titanium alloy ingot blank, and the copper plating layer plays a lubricating role when the titanium alloy ingot blank is extruded. Compared with a conventional copper sheet coating layer, the obtained lubricating layer is more beneficial to uniform distribution of extrusion stress on an ingot blank, and surface defects during subsequent extrusion preparation of a pipe blank are reduced.

Owner:WESTERN METAL MATERIAL

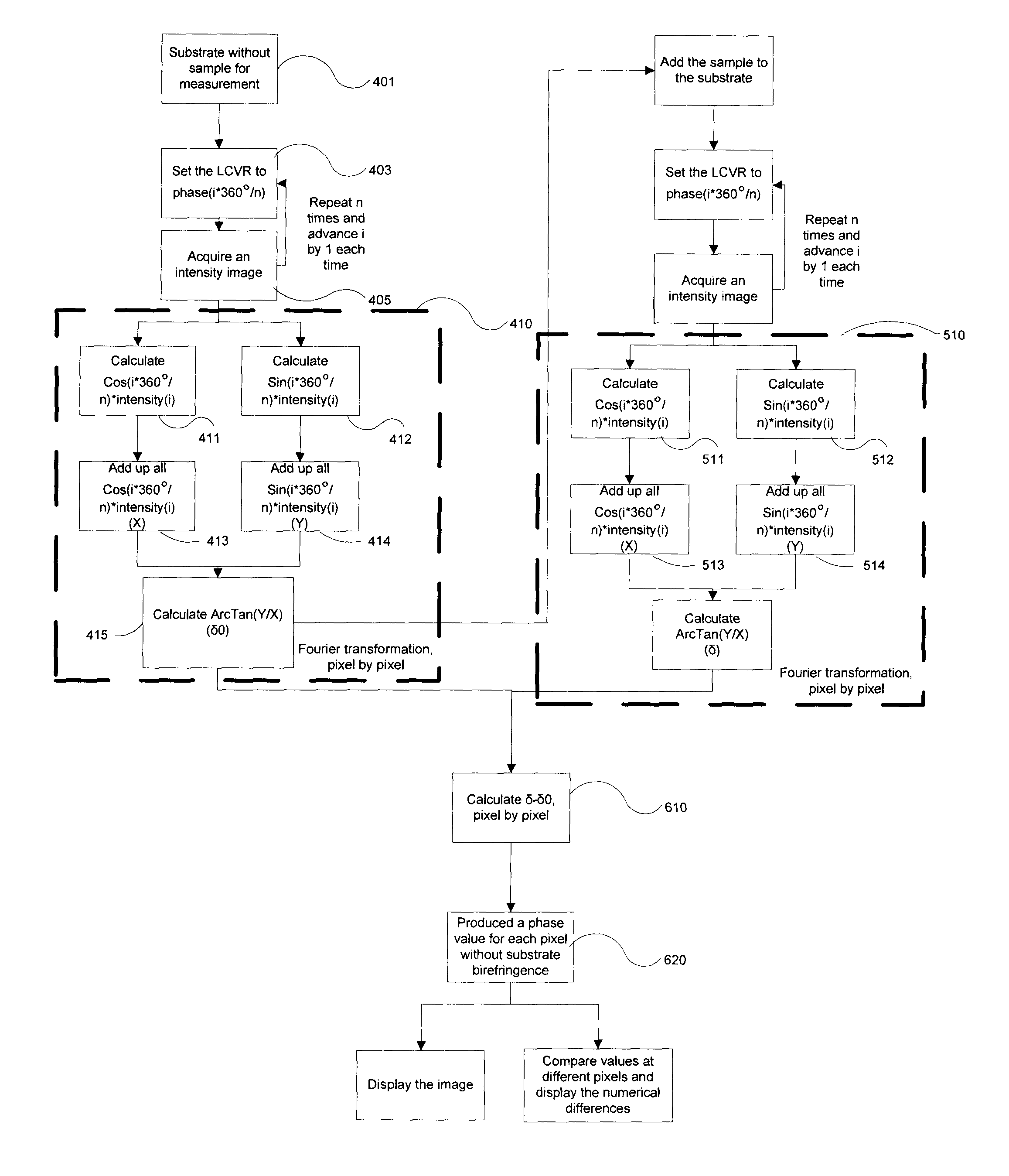

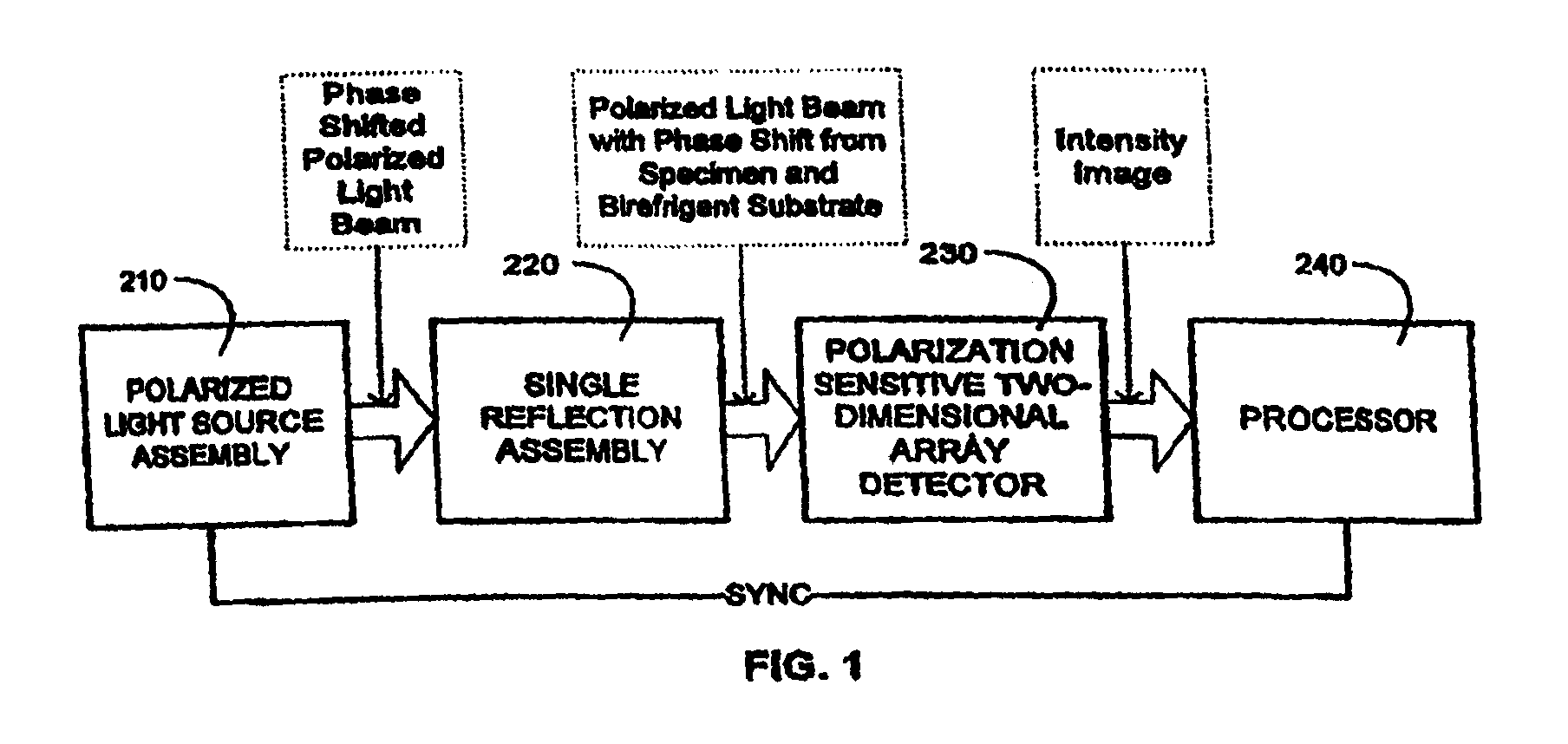

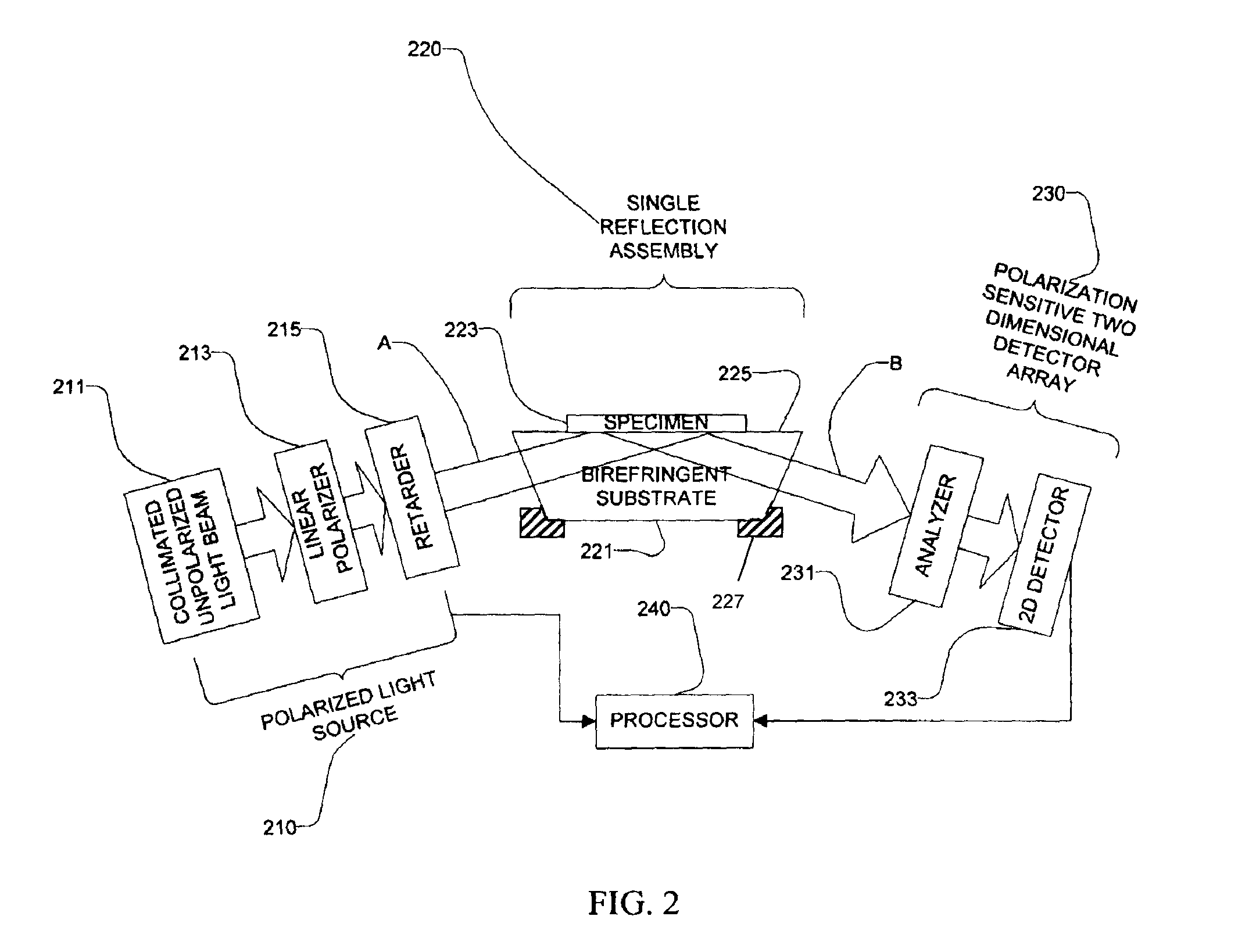

Birefringence correction for imaging ellipsometric bioassay system and method

ActiveUS9063072B1Fast and accurate measurementReduce calculationPolarisation-affecting propertiesScattering properties measurementsDistortionPhysics

A system, apparatus and method for analysis of a specimen using ellipsometric analysis. Polarization distortions caused by the propagation of polarized light within a substrate upon which a specimen is located are reduced by directing light at selected polarizations at the substrate alone and the specimen on the substrate. Image data is collected for each of the selected polarizations and processed to remove errors due to birefringence. Fourier transform processing is used to obtain polarization phase data for correcting polarization caused by any birefringence in the substrate, and optionally amplitude data.

Owner:MAVEN BIOTECH

Graphene modified thermochromic plastic and preparation method and application thereof

The invention discloses graphene modified thermochromic plastic. The graphene modified thermochromic plastic is prepared from, by mass, 60-90 parts of plastic particles, 2-5 parts of surface-treated graphene, 6-13 parts of thermochromic pigment, 0.1-3 parts of a crosslinking agent, 0.1-2 parts of an initiator, 0-0.9 part of a stabilizing agent and 0-2 parts of a plasticizer, wherein graphene and asurface treatment agent are jetted to a reaction chamber by using a jet spreading method at the same time to prepare the surface-treated graphene. The graphene prepared by using the jet spreading technology is high in dispersibility, high in particle size uniformity and capable of improving the heat conductivity of the thermochromic plastic, so that the thermochromic sensitivity is improved, andthe shock-resisting strength and the weather resistance of the thermochromic plastic are effectively improved.

Owner:宁波力达得为高分子科技有限公司

Nickel soldering paste for automatic brazing

InactiveCN100443245CLow melting pointImprove liquidityWelding/cutting media/materialsSoldering mediaActive agentPyrrolidinones

The invention relates to a nickel covered welding paste for automatic braze welding. It comprises following components with percent by weight: solder 91.50-96.5% and paste-forming material 3.50-8.50%, and solder concludes: Cr 5-20%, Fe 0.2-5%, C 0.01-0.1%, Si 0.1-5% and left is Ni. The paste-forming material comprises following components with percent by weight: mixture of polybutene and polyisobutene with molecular weight being 200-9000, 72-92%, or one or several objects among polyvinyl acetate, polyvinyl pyrrolidon, and polyisobutene, polypentene with molecular weight being 10000-100000 6.5-45%, organic solvent 50-80%, surface activator 1.0-12.0% and lubricant 1.0-18.0%. The said nickel covered welding paste is the solder paste that is characterized by good fire resistant and corrosion resistant property and used for stainless steel.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com