Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

A rare-earth permanent magnet and anti-corrosion coating technology, which is applied in anti-corrosion coatings, devices for coating liquid on the surface, coatings, etc., can solve the problem of affecting the bonding force between the coating and the NdFeB substrate, different electrochemical potentials, and electroplating problems. Low layer density and other problems, to achieve high density, strong corrosion resistance, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

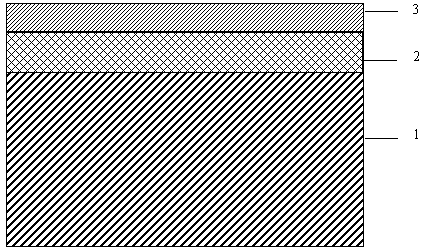

[0039] The anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet in this embodiment is composed of a bottom coating and a top coating, wherein the thickness of the bottom coating is 10 μm, and its chemical composition is: zinc 63%, chromium 2% , 35% polyimide resin; the thickness of the top coating is 15 μm, and its chemical composition is: aluminum 55%, phenolic resin 45%.

[0040] The preparation method of the anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet is carried out according to the following steps:

[0041] (1) Pretreatment: Ultrasonic degreasing is performed on the surface of 1kg NdFeB rare earth permanent magnet with a size of 15*15*50mm at 60°C in a degreasing solution with a concentration of 4% degreasing agent for 2 minutes, and then in dilute nitric acid Washing in acid for 10s, then phosphating the surface of the magnet in a phosphating solution, and drying at normal pressure at 80°C;

[0042] (2) Prepare...

Embodiment 2

[0054] The anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet in this embodiment is composed of a bottom coating and a top coating, wherein the thickness of the bottom coating is 15 μm, and its chemical composition is: aluminum 57%, molybdenum 3% , 40% polyurethane resin; the thickness of the top coating is 10 μm, and its chemical composition is: titanium 58%, acrylic resin 42%.

[0055] The preparation method of the anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet is carried out according to the following steps:

[0056] (1) Pretreatment: Ultrasonic degreasing was performed on the surface of 5kg NdFeB rare earth permanent magnets with a size of 16*8*2mm in a degreasing solution at 70°C with a concentration of 5% degreasing agent for 2 minutes, and then in dilute nitric acid Washing for 15s, then phosphating the surface of the magnet in the phosphating solution, and drying at -133KPa, 30°C under vacuum conditions;

[0...

Embodiment 3

[0069] The anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet of this embodiment is composed of a bottom coating and a top coating, wherein the thickness of the bottom coating is 20 μm, and its chemical composition is: aluminum 60%, nickel 4% , 36% polyurethane resin; the thickness of the top coating is 10 μm, and its chemical composition is: aluminum and titanium 65%, acrylic resin 35%.

[0070] Wherein, the weight ratio of aluminum and titanium is 2:1.

[0071] The preparation method of the anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet is carried out according to the following steps:

[0072] (1) Pretreatment: Ultrasonic degreasing is performed on the surface of 1kg NdFeB rare earth permanent magnet with a size of 15*15*50mm at 60°C in a degreasing solution with a mass concentration of 5% degreasing agent for 2 minutes, and then in dilute nitric acid Washing treatment for 15s, then phosphating the surface of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com