Patents

Literature

32results about How to "Uniform coating structure" patented technology

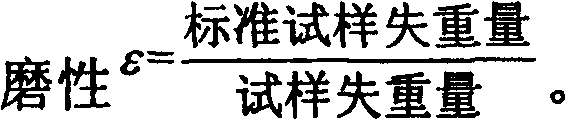

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

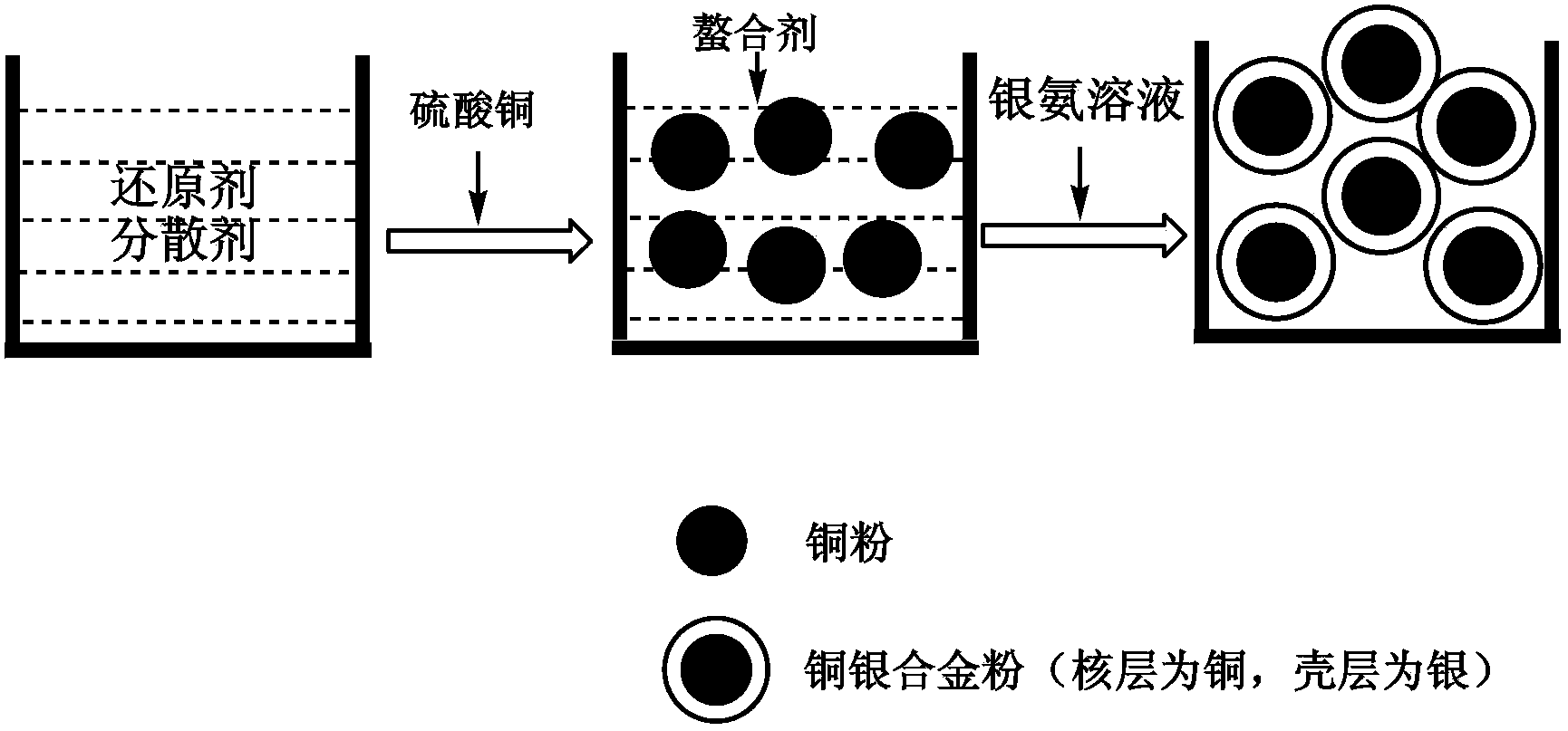

Conductive polymer-carbon coated silicon oxide composite material and preparation method thereof

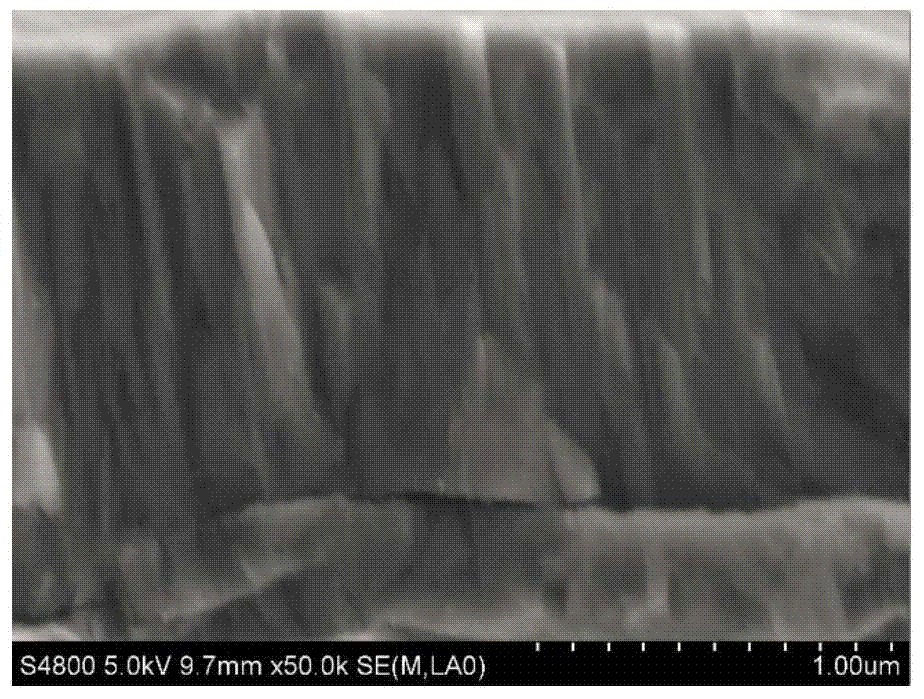

ActiveCN107658455AWide range of temperature selectionUniform covering structureCell electrodesSecondary cellsSilane couplingCarbon source

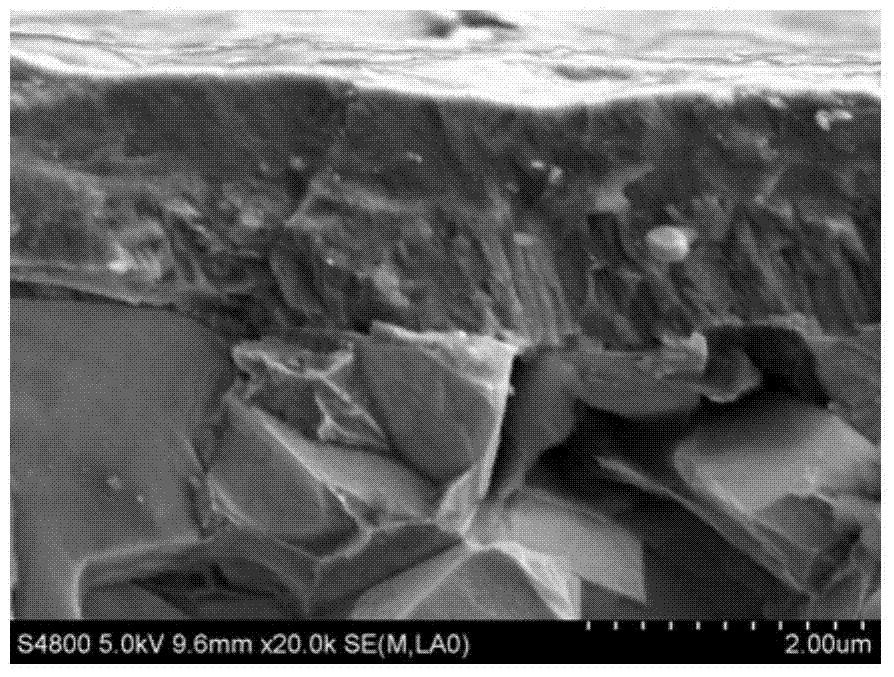

The invention discloses a conductive polymer-carbon coated silicon oxide composite material and a preparation method thereof. The conductive polymer-carbon coated silicon oxide composite material comprises a conductive polymer, a silane coupling agent, carbon and silicon oxide, wherein the carbon is directly coated on a surface of a silicon oxide particle, the silane coupling agent is absorbed toa surface of the carbon, and the conductive polymer is embedded into carbon gaps and also is uniformly coated on the surface of the carbon by a bridge chain effect of the silane coupling agent. The preparation method of the conductive polymer-carbon coated silicon oxide composite material comprises three steps of highly mixing the silicon oxide and a carbon source, performing high-temperature sintering (curing and carbonization) and coating the polymer. The prepared composite material is very uniform in coating structure and has relatively low volume expansion effect and excellent electrochemical performance, the initial charge-discharge efficiency can be obviously improved, and particularly, relatively poor cycle property of a silicon oxide negative electrode material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

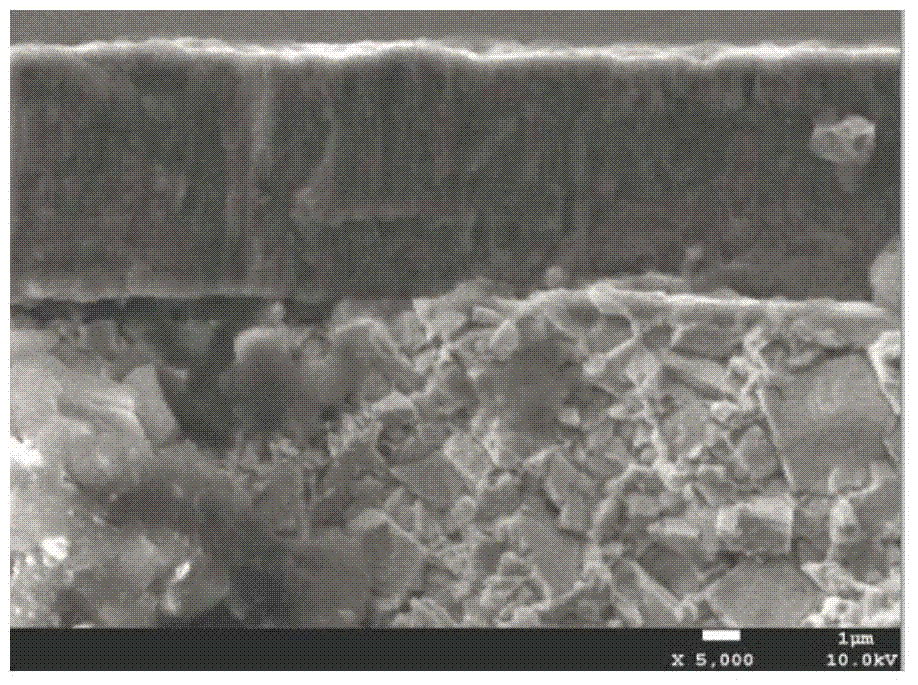

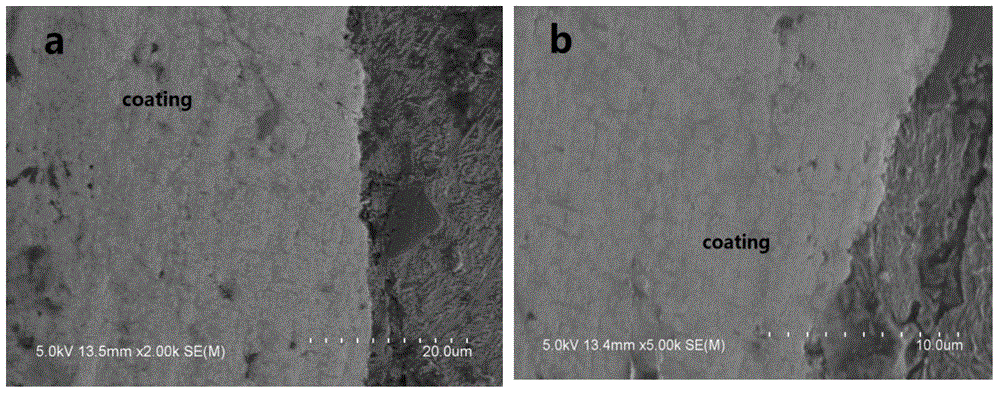

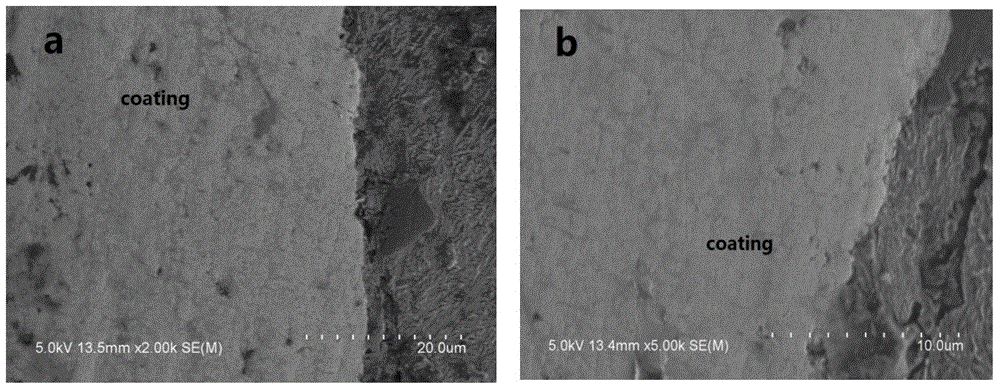

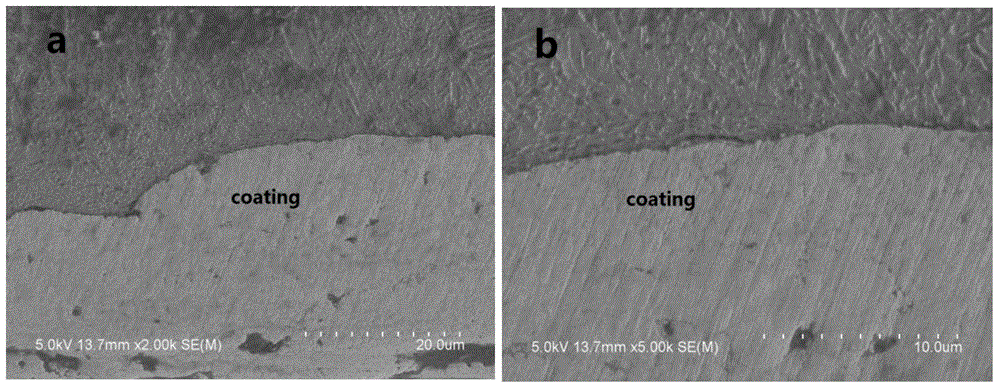

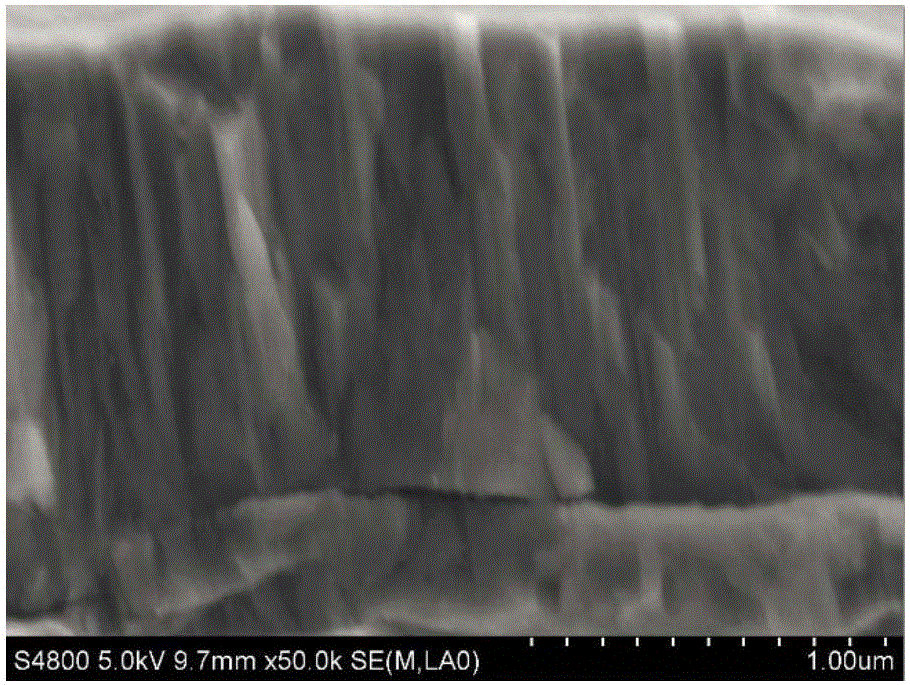

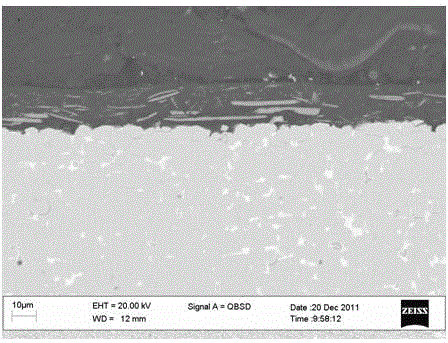

Cr/CrN/(Ti, Al, Si, Cr)N composite hard coating and preparation method thereof

InactiveCN103789723AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

Resin-combined tundish light coating and preparation method thereof

The invention discloses a resin-combined tundish light coating and a preparation method thereof. The tundish light coating is composed of the following components in parts by weight: 85-95 parts of magnesia and / or forsterite with the particle size being larger than 0mm and less than or equal to 0.5mm, 0.3-6.0 parts of resin powder, 0.01-2.5 parts of organic acid, 0.1-3 parts of hollow organic fiber, 0.5-3 parts of paper fiber, 0.1-0.3 parts of magnesian sintering aid and 0.01-0.2 part of sodium salt dispersant. The preparation method comprises steps of preparing raw materials, mixing and stirring the raw materials in sequence, adding water and stirring. The tundish light coating is small in volume density, high in strength, good in liquidity, high in hardening rate, uniform in coating structure and the like.

Owner:YINGKOU PUNAI MAGNESIUM MATERIALS CO LTD

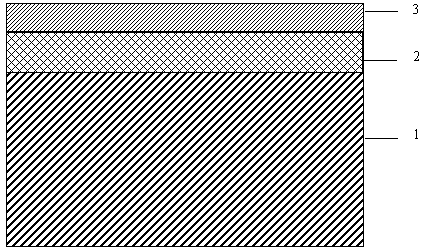

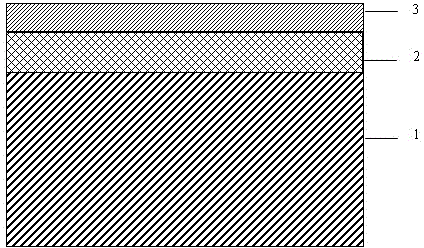

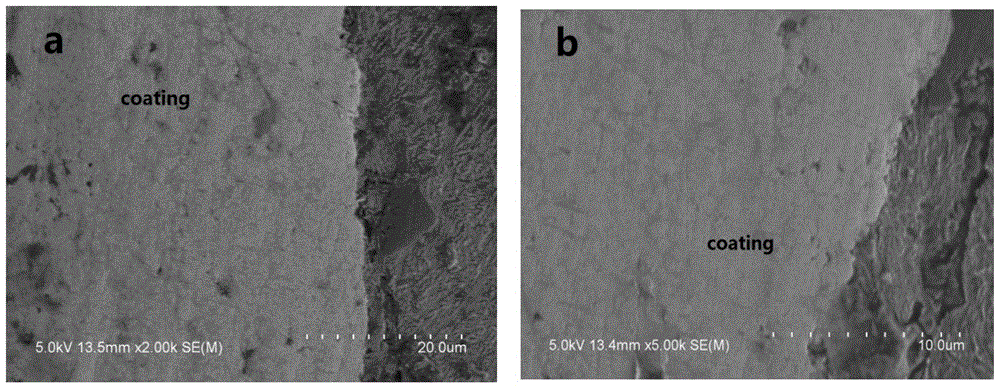

Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

ActiveCN102936455AControl thicknessImprove protectionPretreated surfacesAnti-corrosive paintsAcrylic resinRare earth

The invention belongs to the technical field of surface treatment and particularly relates to a neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and a preparation method thereof. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating is composed of a bottom coating and a top coating, the thickness of the bottom coating is in a range from 10mum to 25mum, the chemical components of the bottom coating comprise 55% to 65% of one or two types of metals of zinc and aluminum, 0% to 5% of one or a plurality of types of metals of nickel, chromium, molybdenum, neodymium, praseodymium, cobalt and titanium and 34% to 40% of neutral resins, the thickness of the top coating is in a range from 5mum to 15mum, and the chemical components of the top coating comprise 55% to 65% of one or a plurality of types of metals of zinc, aluminum, titanium, molybdenum, nickel, cobalt and chromium and 35% to 45% of phenolic resins or acrylic resins. The preparation method includes that firstly the surface of a permanent magnet is preprocessed, a centrifugal immersion tossing is utilized to prepare the bottom coating, and a rolling spraying process is utilized to prepare the top coating. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and the preparation method thereof have the advantages that by means of double layers of coatings, the corrosion resistance is high, the surface binding force is high, the usage temperature is higher than 200 DEG C, the magnetic property of the neodymium iron boron rare earth permanent magnet is improved, the service life is prolonged, and the service environment is widened.

Owner:SHENYANG GENERAL MAGNETIC

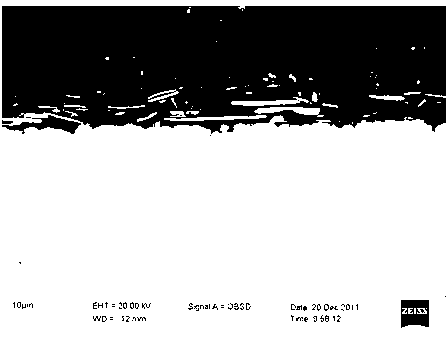

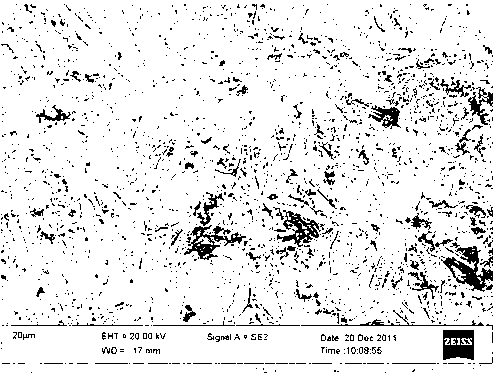

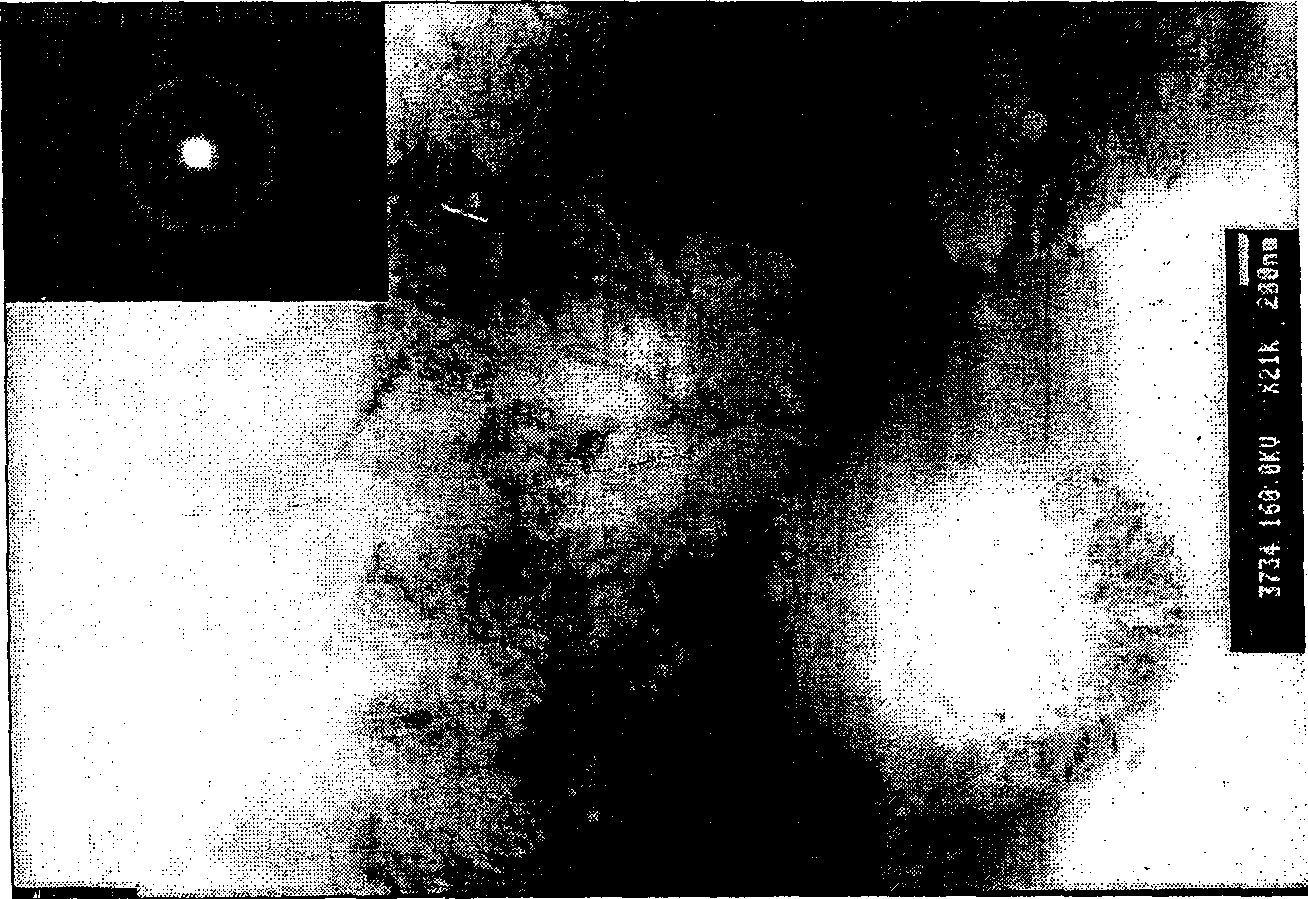

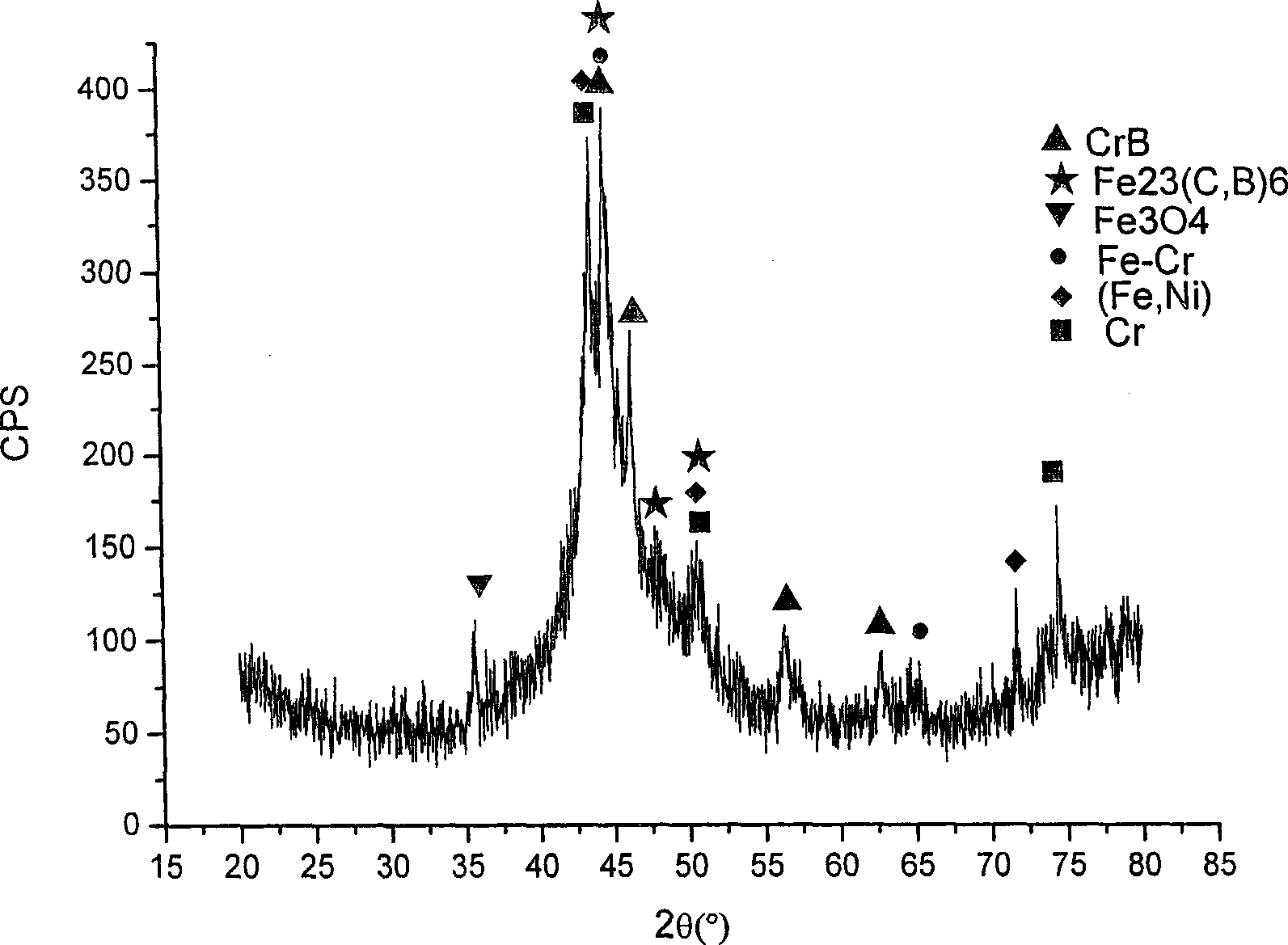

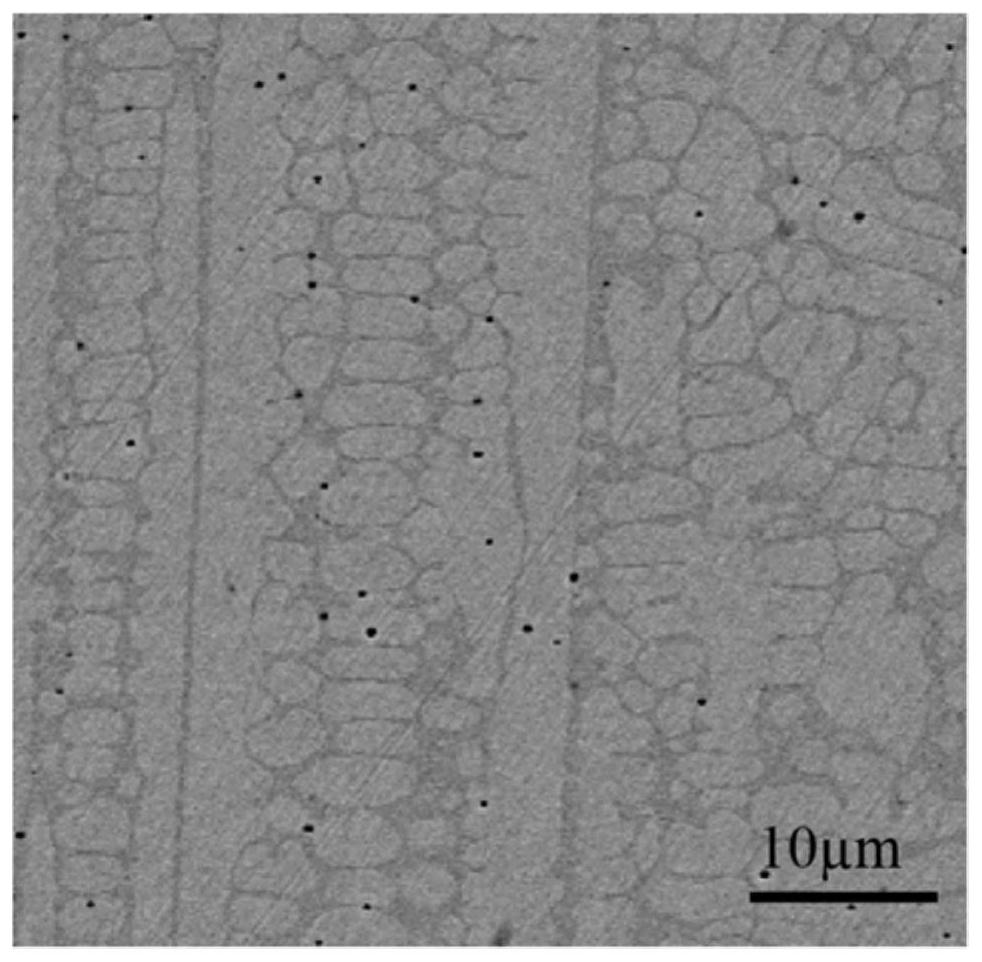

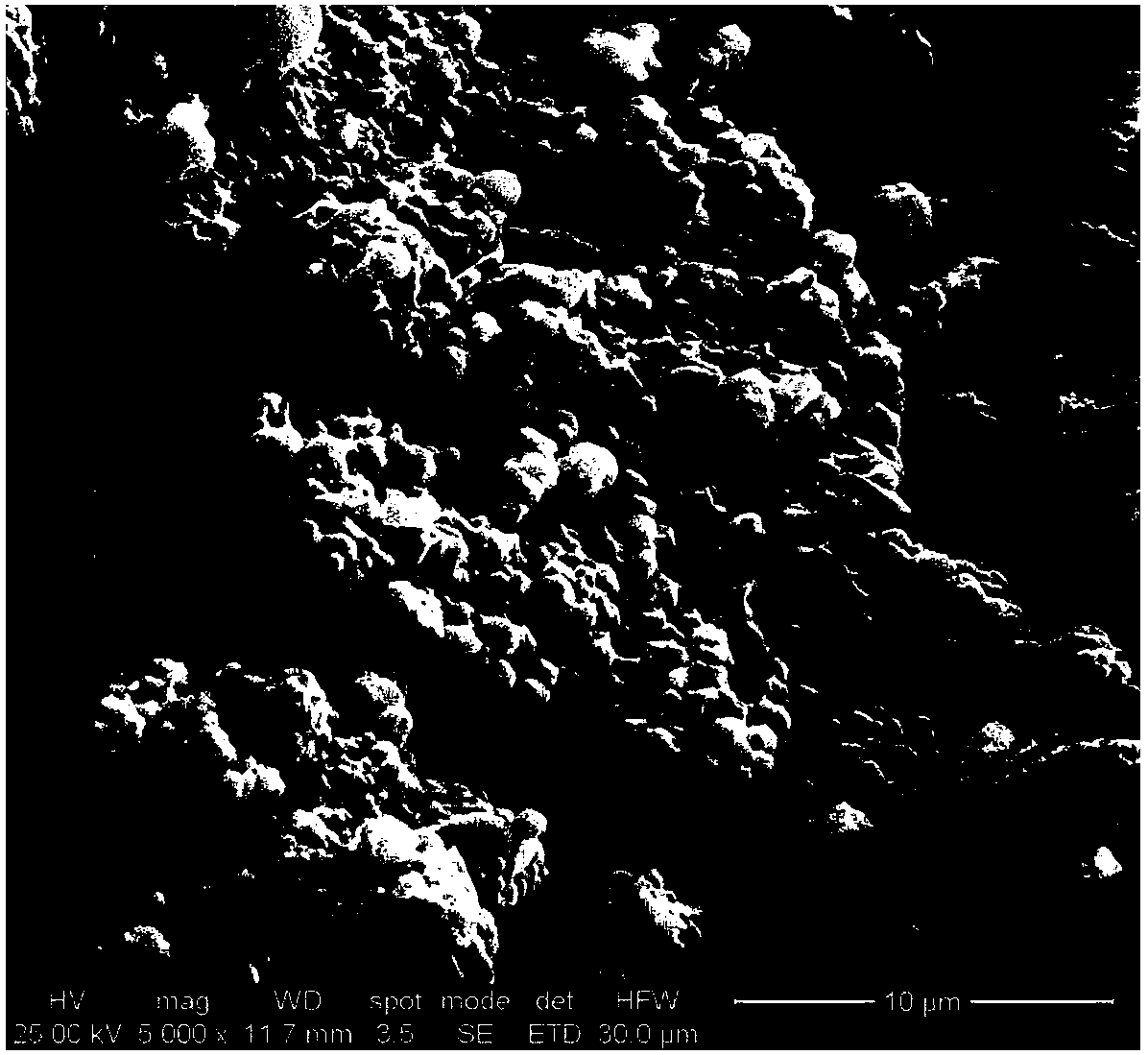

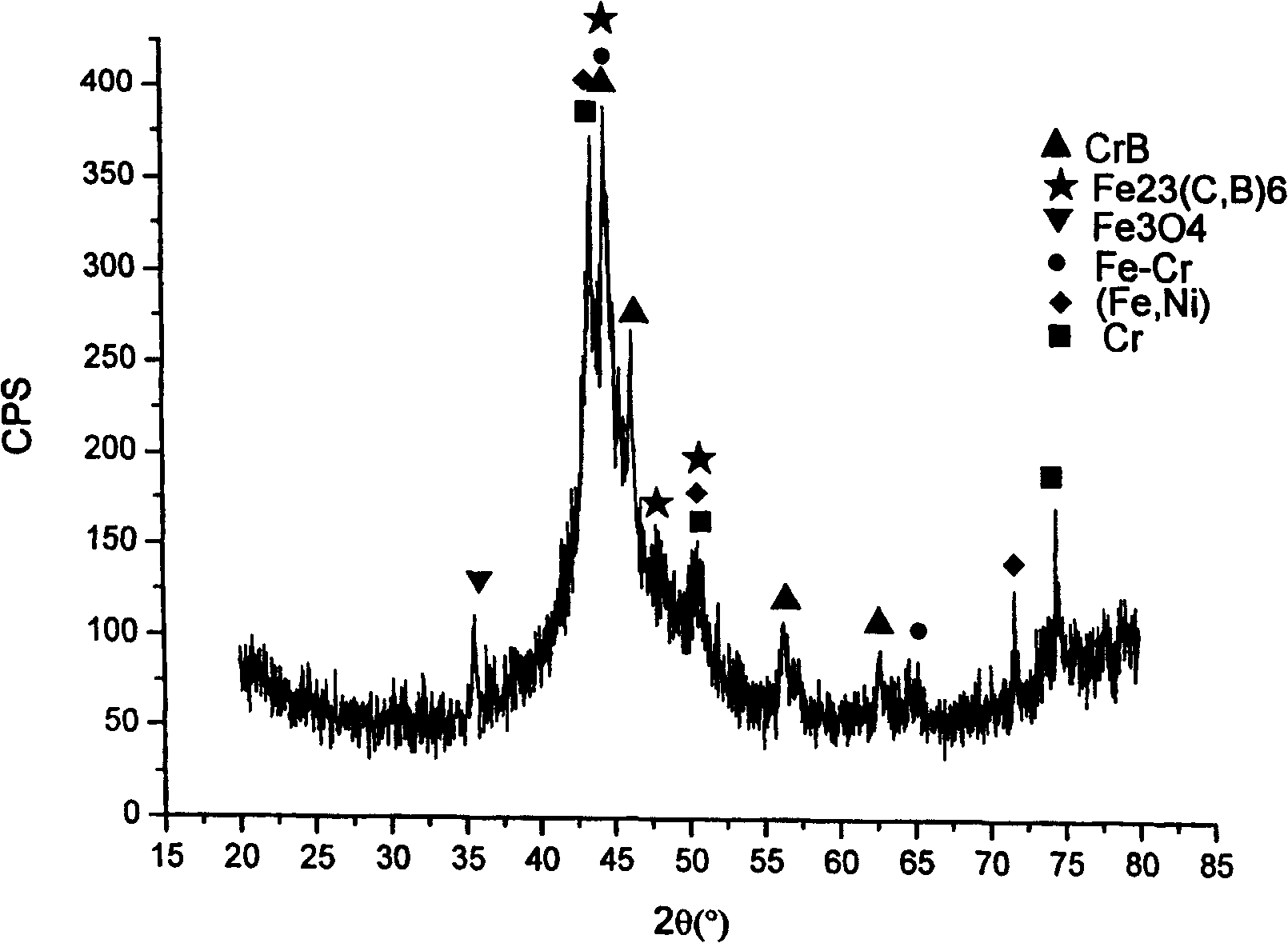

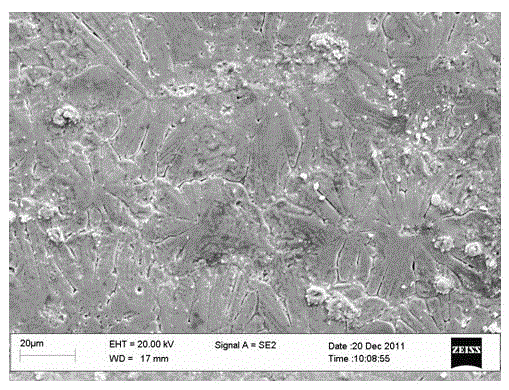

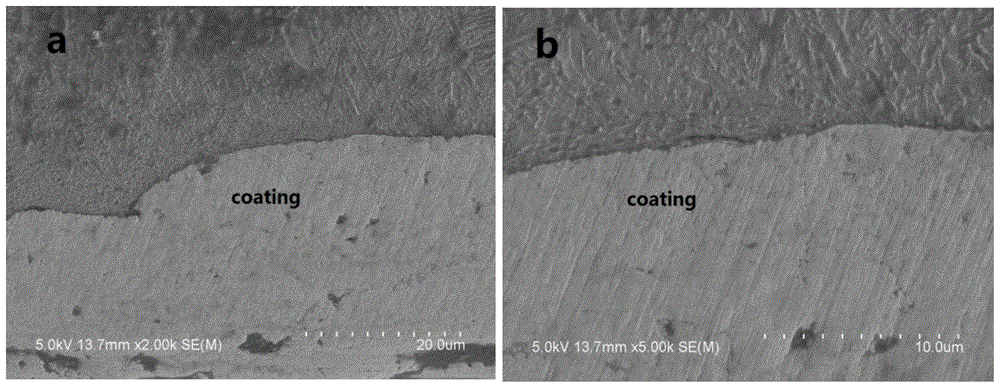

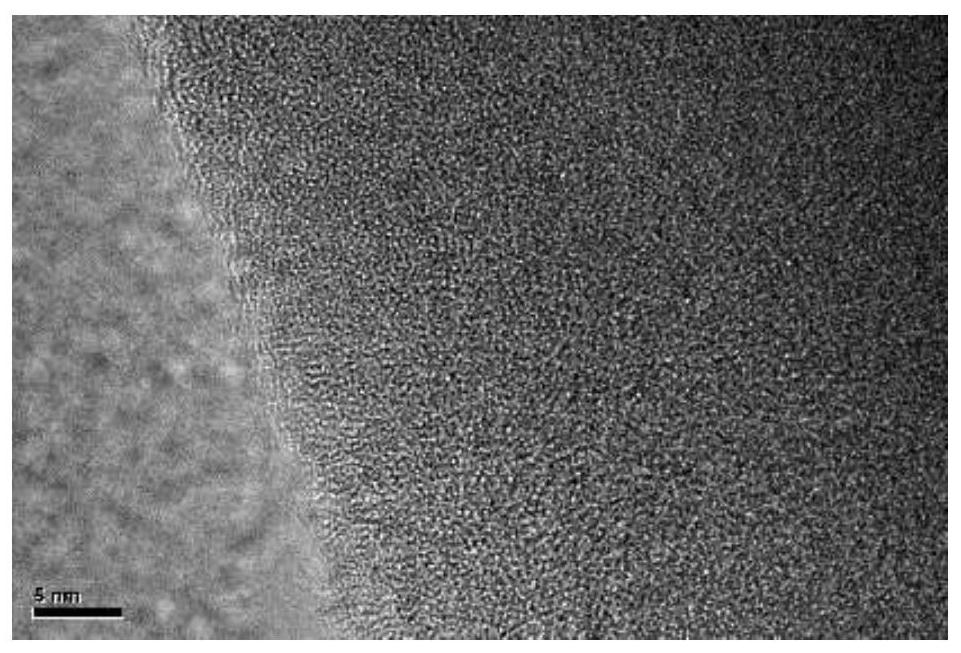

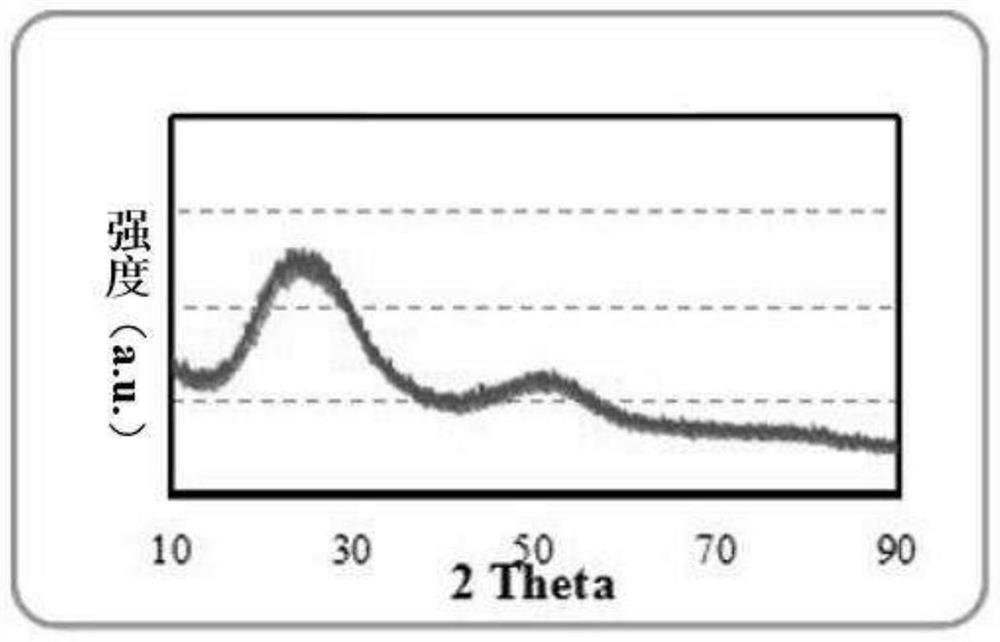

Powder cored wire for CrB-containing amorphous coating prepared by electric arc spraying

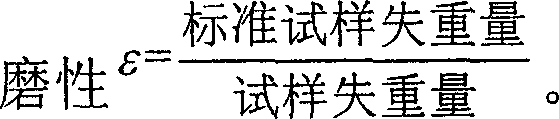

An electrical arc spraying method for preparing amorphous-coating dust core wire containing CrB belongs to hot spraying domain in material processing project and is mainly used in various industrial domains including anticorrosive domain and wearable domain. The amorphous alloy is association of high strength, hardness, tenacity, abradability and noncorrosibility, but there is no patent report about the electrical arc spraying method for preparing iron-base amorphous-coating dust core wire both at home and abroad. The invention is about an electrical arc spraying method for preparing amorphous-coating dust core wire containing CrB and is characterized in that the mass percentage content range of the said dust core components is as follows: 60-80 % boron- chromium, 5-20 % Cr3C2, 5-10 % WC and the residue is iron dust. The covering prepared with the invented dust core contains a good deal of amorphous carborundum, the coating formation is even and has high rigidity with HV0.1 of more than 1190, and has good abradability and the relative abradability is 15.8 times than the Q235 steel.

Owner:BEIJING UNIV OF TECH

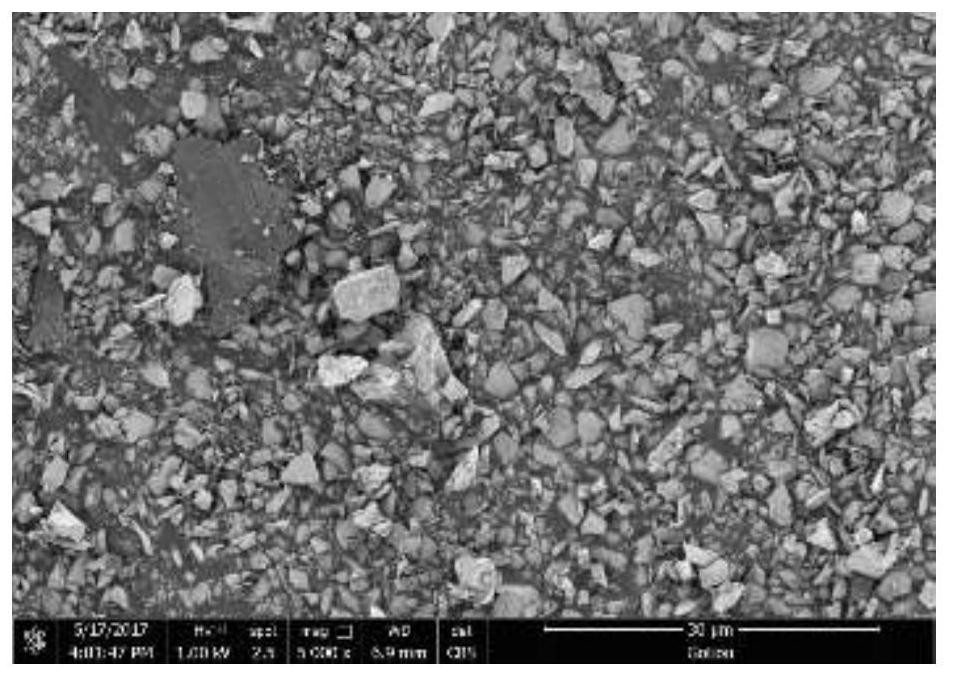

Method for preparing wear-resistant coating of ball mill lining plate

ActiveCN105063539ABroaden your optionsHigh bonding strengthMolten spray coatingWear resistanceBall mill

The invention discloses a method for preparing a wear-resistant coating of a ball mill lining plate, and belongs to the field of remanufacturing of engineering machines. The wear-resistant coating comprises a base and a coating layer. The base comprises, by weight, 0.30%-0.44% of C, 1.50%-2.0% of Si, 0.8%-1.40% of Mn, 2.0%-2.8% of Cr, equal to or less than 0.3% of Mo, equal to or less than 0.3% of Ni, 0.02% of Re, 0.04% of P and S, and the balance Fe. The coating layer comprises, by volume fraction, 95%-98% of WC-Co powder and 2%-5% of Cr. The weight ratio of Cr to Co is 0.2-0.5. The method enables a part to have wear resistance, corrosion resistance and other special performance, the reliability of the part is improved, the service life of the part is prolonged, and especially the wear resistance of the working surface of the ball mill lining plate is improved.

Owner:ANHUI POLYTECHNIC UNIV

Surface coating part for reproduction of ball mill liner plate and manufacturing method for surface coating part

ActiveCN105063499ABroaden your optionsHigh bonding strengthMolten spray coatingGrain treatmentsBall millMaterials science

The invention discloses a surface coating part for reproduction of a ball mill liner plate and a manufacturing method for the surface coating part, and belongs to the field of reproduction of engineering machines. The surface coating part comprises a substrate and a coating layer. The substrate comprises, by weight, 0.30-0.44% of C, 1.50-2.0% of Si, 0.8-1.40% of Mn, 2.0-2.8% of Cr, 0.3% of Mo or less, 0.3% of Ni or less, 0.02% of Re, 0.04% of P and S and the balance Fe. The coating layer comprises, by volume, 95-98% of WC-Co powder and 2-5% of Cr, and the weight ratio of Cr to Co is 0.2-0.5. The surface coating part for reproduction of the ball mill liner plate and the manufacturing method for the surface coating part can give the special properties like abrasion resistance and corrosion resistance to parts, improve the reliability of the parts, prolong the service life of the parts and especially improve the abrasion resistance of a work surface of the ball mill abrasion-resistant liner plate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

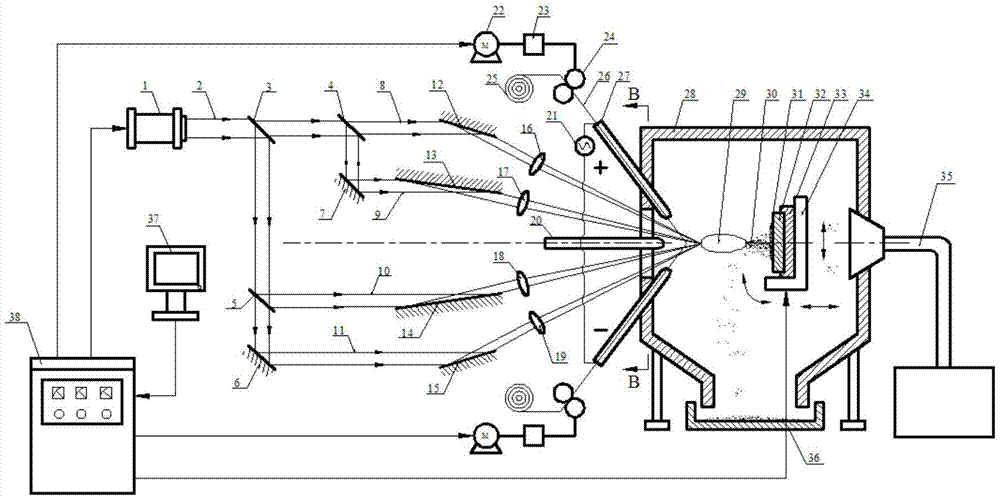

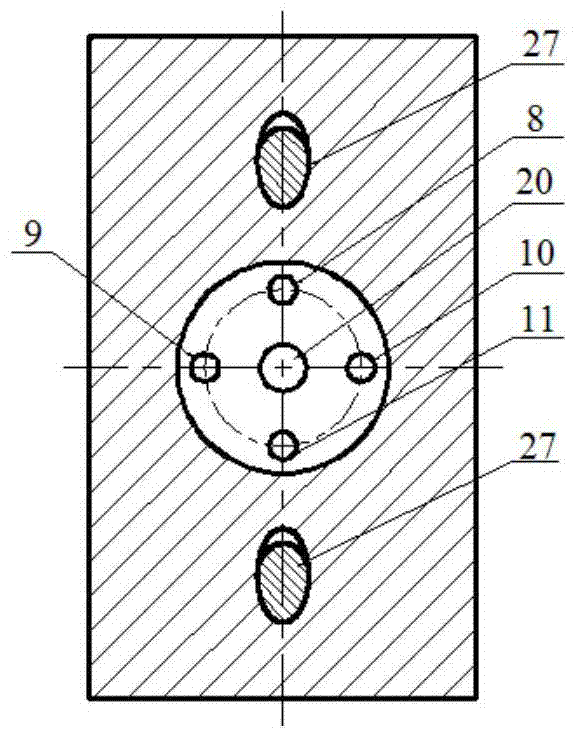

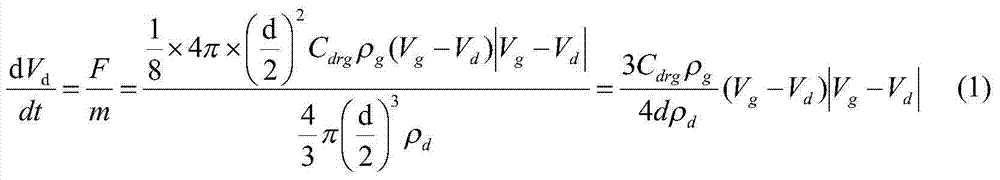

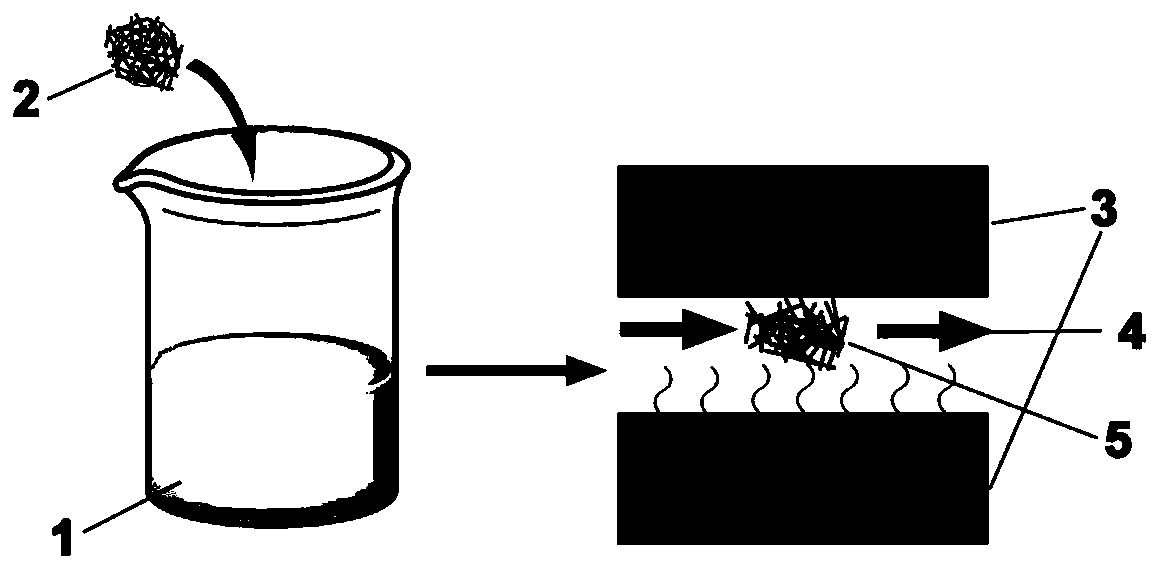

Directional ultrahigh-velocity spraying method and device based on laser induced shock wave technology

The invention discloses a directional ultrahigh-velocity spraying method and device based on a laser induced shock wave technology, belonging to the technical field of part processing and remanufacturing. According to the spraying method, a high-temperature electric arc generated by an electrode is firstly used for heating and melting spray wires of a coating material to form molten drops and the molten drops fall off and are atomized into a microdrop stream; then a laser pulse beam is used for irradiating the surface of the microdrop stream; a part of microdrops on the surface absorb laser energy and are instantly gasified and ionized into high-pressure plasma; the high-pressure plasma further absorbs laser energy and expands and blows up to form high-pressure shock waves at GPa grade; the high-pressure shock waves drive the corpuscular stream to jet onto the surface of a workpiece at a high velocity to form a coating. The spraying device comprises a laser generator, a beam guiding and splitting system, an electric arc liquid making system, a workpiece clamp system, a recycling system and a control system. The spraying device can be used for realizing high-velocity high-efficiency spraying; the combination strength of the coating and a substrate is good; the coating has high density and low void content and also has relatively high thermal fatigue resistance and mechanical fatigue resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

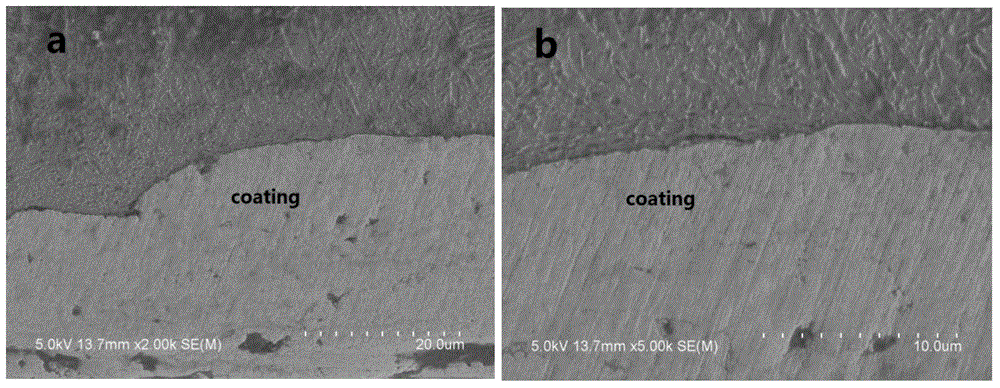

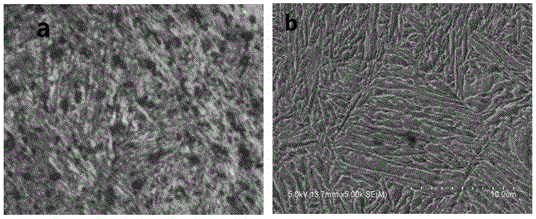

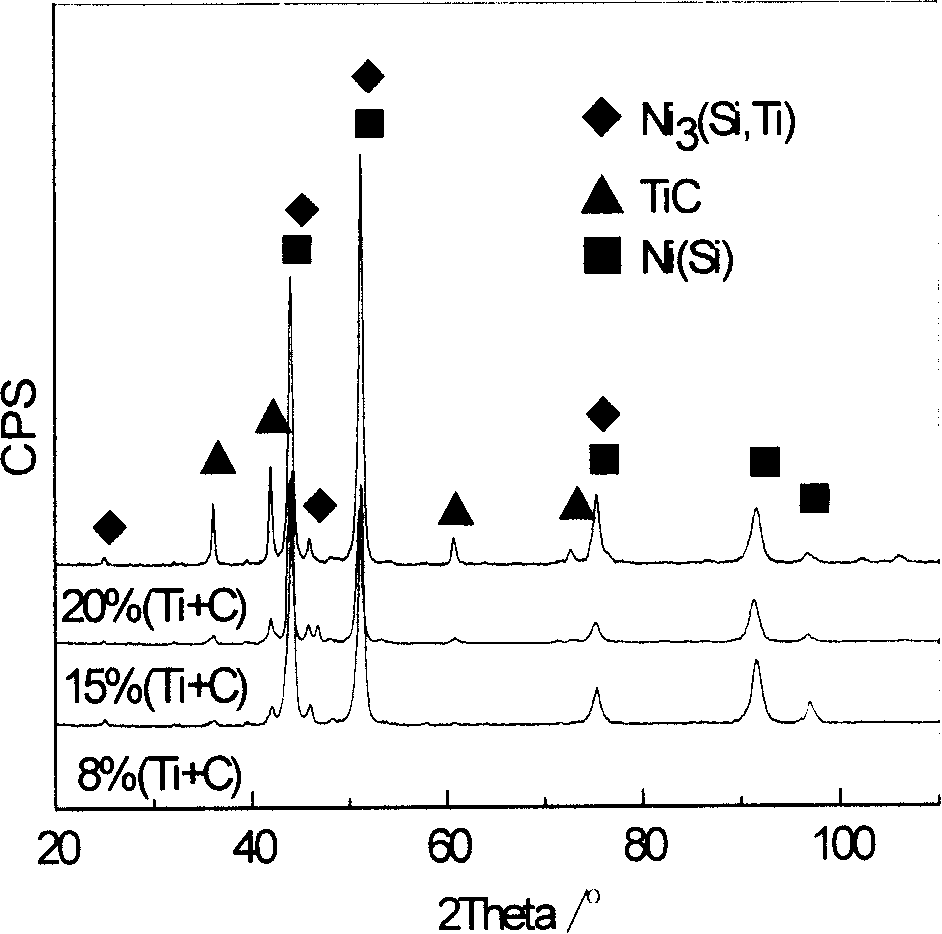

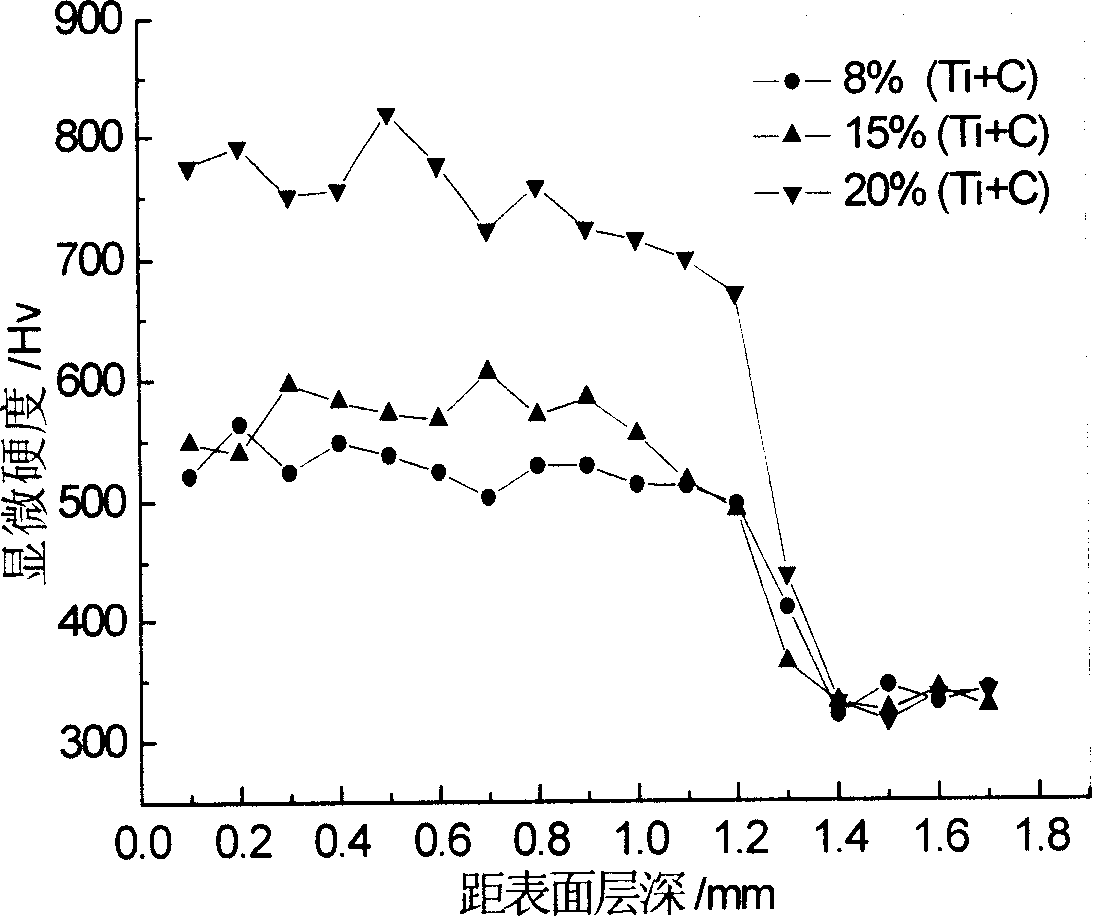

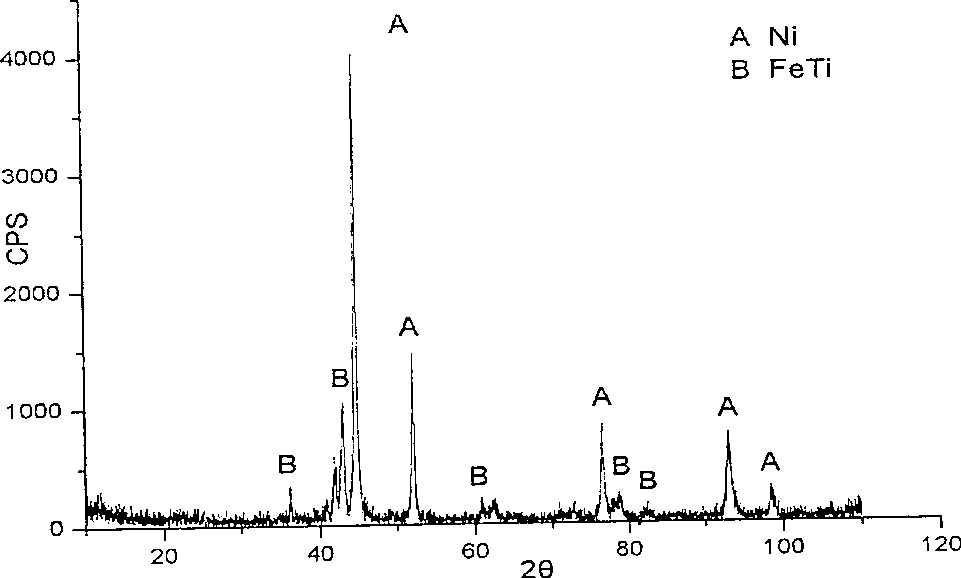

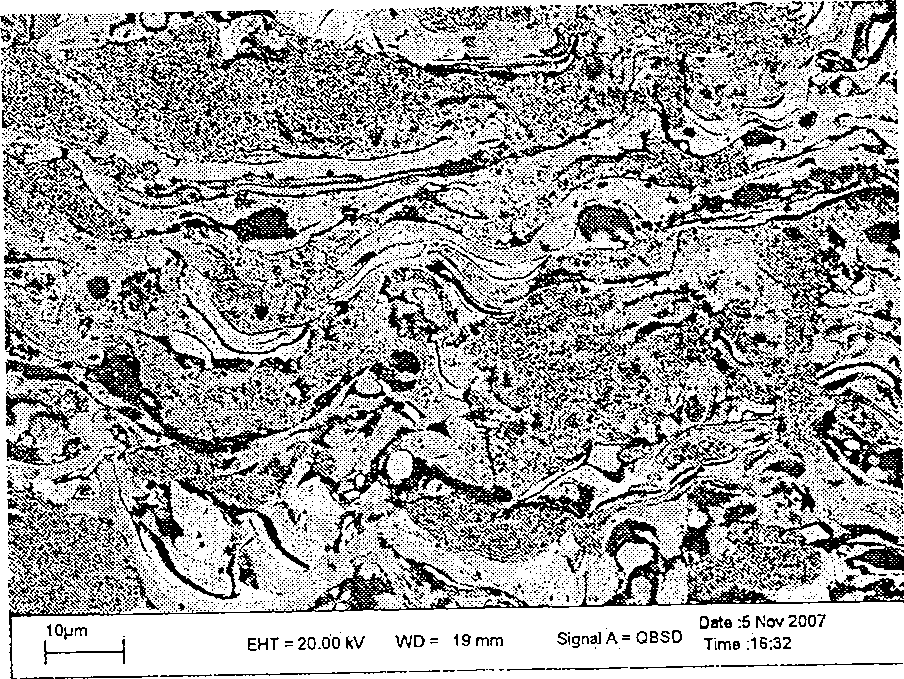

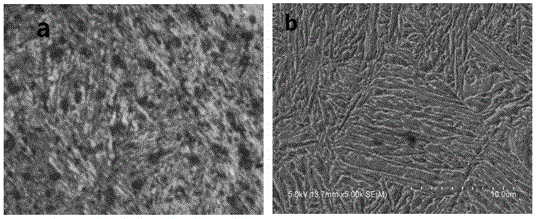

Ni3(Si,Ti)-TiC composite coating material and preparation method thereof

InactiveCN101161865AUniform coating structureHigh hardnessMetallic material coating processesLaser beam welding apparatusThermal sprayingChemical composition

The present invention relates to a nickel trisilicon titanium intermetallic compound-titanium carbide composite coating material and a method for preparing the same; a composite coating mainly consisting of Ni3(Si, Ti) intermetallic compound and TiC ceramic is made on a high-temperature ultratek substrate by laser cladding in situ; the coating material mainly comprises four elements: Ni, Si, Ti and C; the chemical components of the four elements have the following weight percentages: 8 percent to 20 percent Ti powder plus C powder; 78 percent Ni, 13 percent Si and 9 percent Ti; the preparation method adopts the laser to clad and has the following parameters: the output power is between 1000 W and 1500 W; the scanning speed is 4-6 mm / s. the spot diameter is 4 mm; the protective gas is Ar gas in cladding; the cladding substrate material is high-temperature ultratek; the invention has the following procedures: according to the mixture ratio, the coating material is mixed uniformly and pre-coated or hot-sprayed on the surface of the high-temperature ultratek substrate; the thickness is between 1 mm and 1.2 mm; the laser is adopted to have multilayer and multi-path cladding; each channel has related joint of 1.8 mm, thereby achieving the cladding layer with different thickness.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

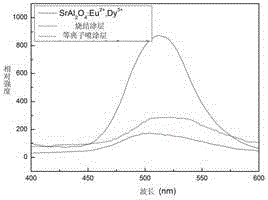

Powder sintering phosphorescence particle indication composite coating

InactiveCN104607630AImprove carrying capacityImprove anti-friction performanceWear resistanceLuminescence

The invention discloses a method for preparing a wear-proof and anti-corrosion concomitant composite sintering coating on a powder sintering function indication coating incorporated with phosphorescence incandescent particles and an indication coating prepared through incorporating phosphorescence incandescent particles. By means of the composite sintering coating, the wear resistance of part surfaces, the wear resistance of a corrosion-resistance coating, and the corrosion self-sensitive luminescence detection or the anti-counterfeiting of equipment assembly parts are achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

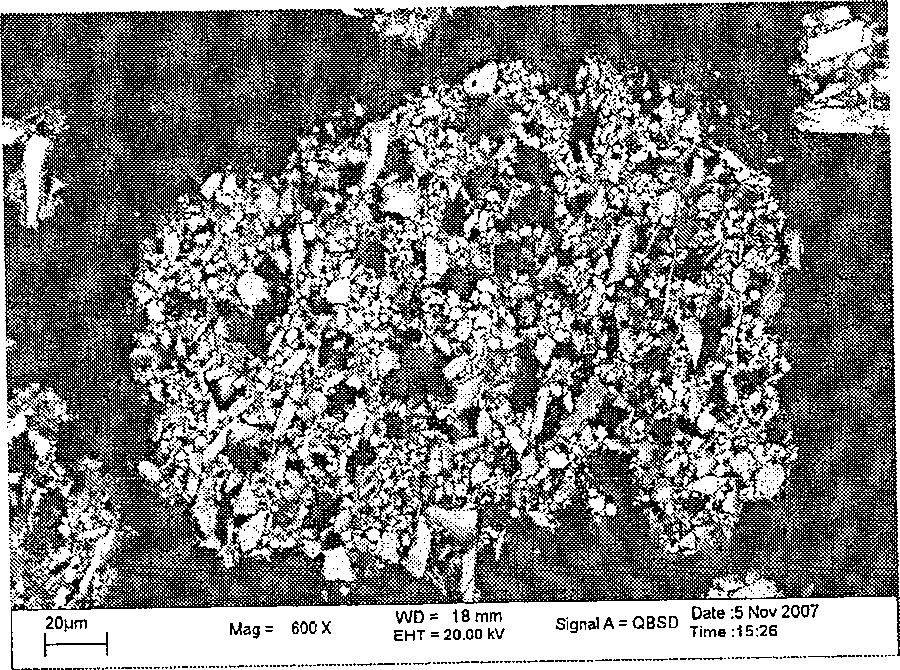

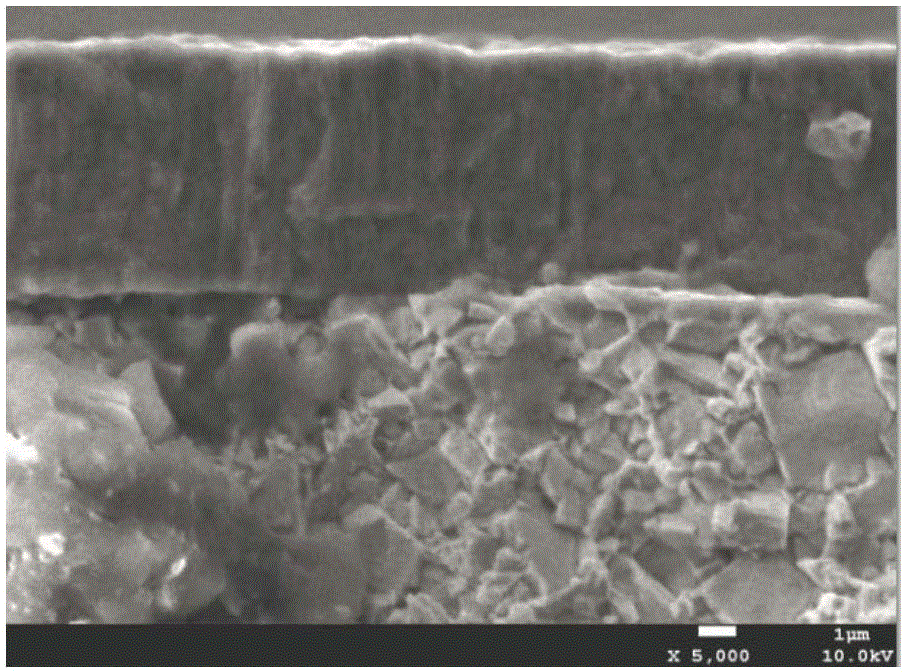

Ti-Fe-Ni-C series reaction thermal spraying composite powder and preparation technique thereof

InactiveCN100510155CHigh bonding strengthAvoid easy separationMolten spray coatingPorosityThermal spraying

The present invention is one kind of composite hot sprayed Ti-Fe-Ni-C powder capable of forming composite TiC / Fe-Ni alloy coating and its preparation process. The composite Ti-Fe-Ni-C powder containing Ni in the amount of 32-45 wt% of Fe+Ni content and Ti+C in over 70 wt% is prepared with sucrose as the precursor of C. The TiC / Fe-Ni alloy coating formed through hot spraying with Fe-Ni alloy as the adhering phase has the advantages of small stress, low porosity, high bonding strength between the Fe-Ni alloy and TiC, excellent high temperature antiwear and anticorrosion performance and small TiC grain size.

Owner:UNIV OF SCI & TECH BEIJING

A kind of cr/crn/(ti, al, si, cr) n composite hard coating and preparation method thereof

InactiveCN103789723BIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

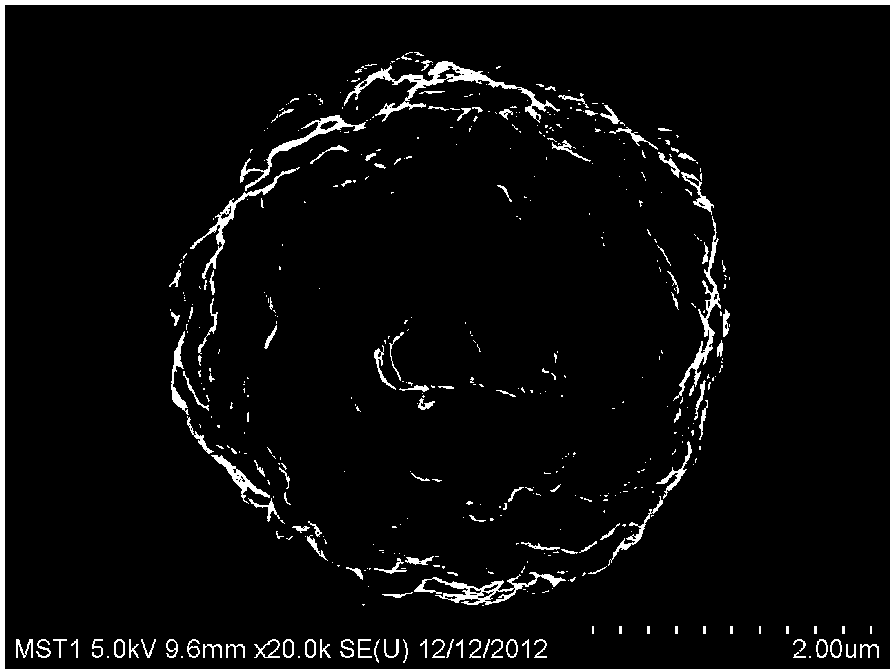

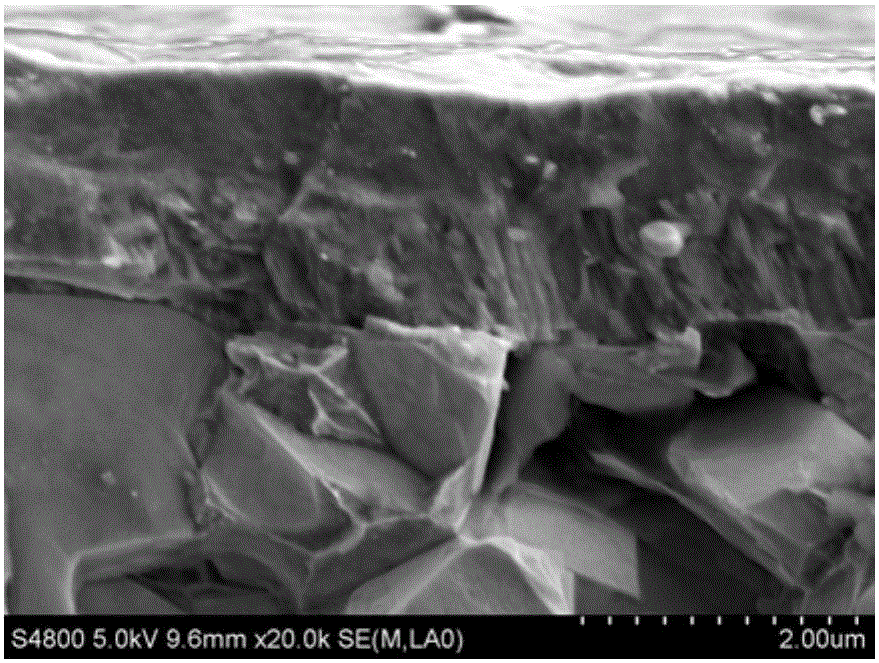

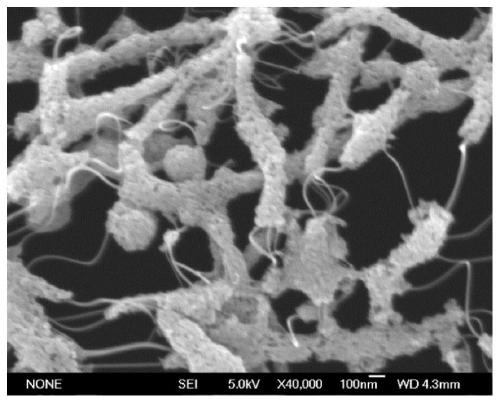

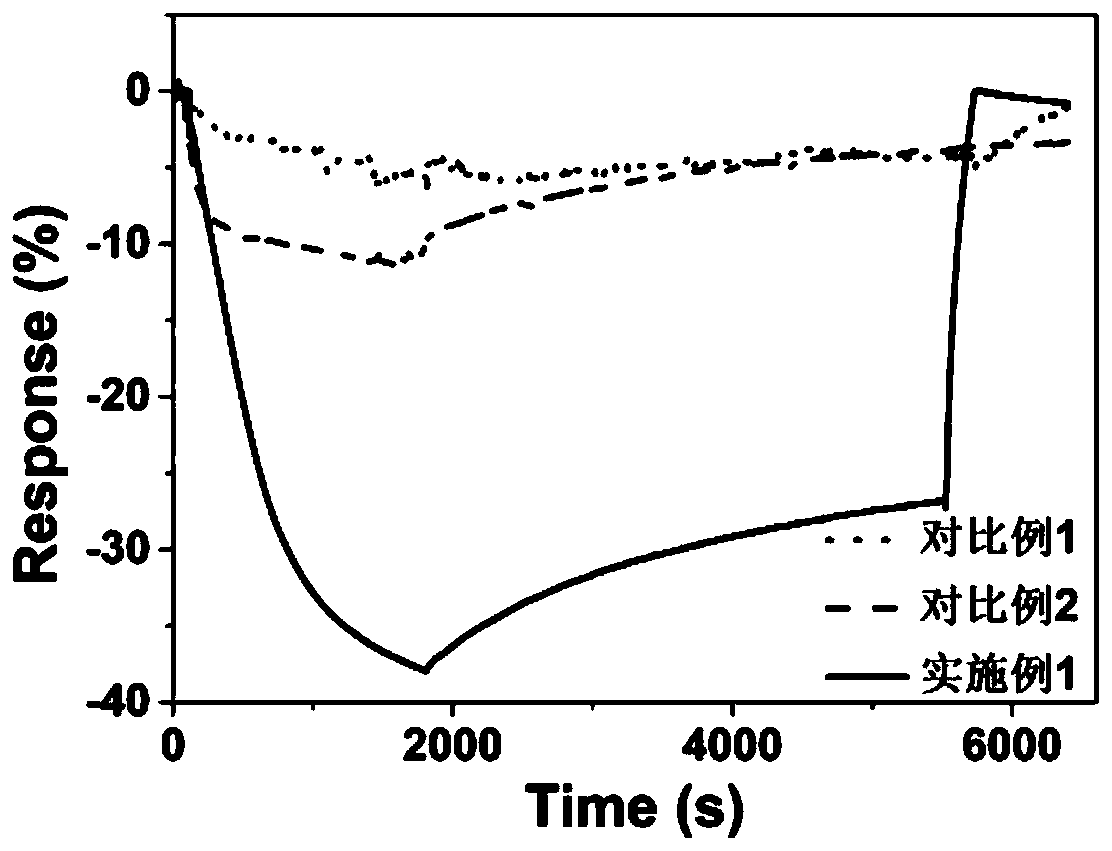

Carbon nanotube/titanium dioxide composite film and preparation method and application thereof

ActiveCN111389365AAvoid destructionImprove conductivityGas treatmentOther chemical processesComposite filmThin membrane

The invention provides a carbon nanotube / titanium dioxide composite film and a preparation method and application thereof. The carbon nanotube / titanium dioxide composite film comprises a single-walledcarbon nanotube film, the single-walled carbon nanotube film is of a network structure composed of staggered carbon nanotubes, the surfaces of the carbon nanotubes are coated with a coaxial titaniumdioxide layer, and the titanium dioxide layer is composed of a plurality of nano titanium dioxide spheres. The flexible carbon nanotube titanium dioxide composite film is assembled through in-situ hydrolysis and high-temperature calcination and has high sensitivity and excellent selectivity to NO at room temperature and simplifies the preparation process and can realize rapid recovery and completerecovery and has good stability.

Owner:ZHENGZHOU UNIV +1

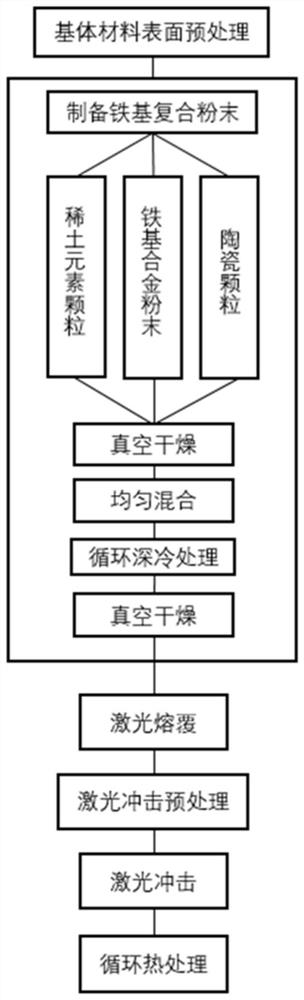

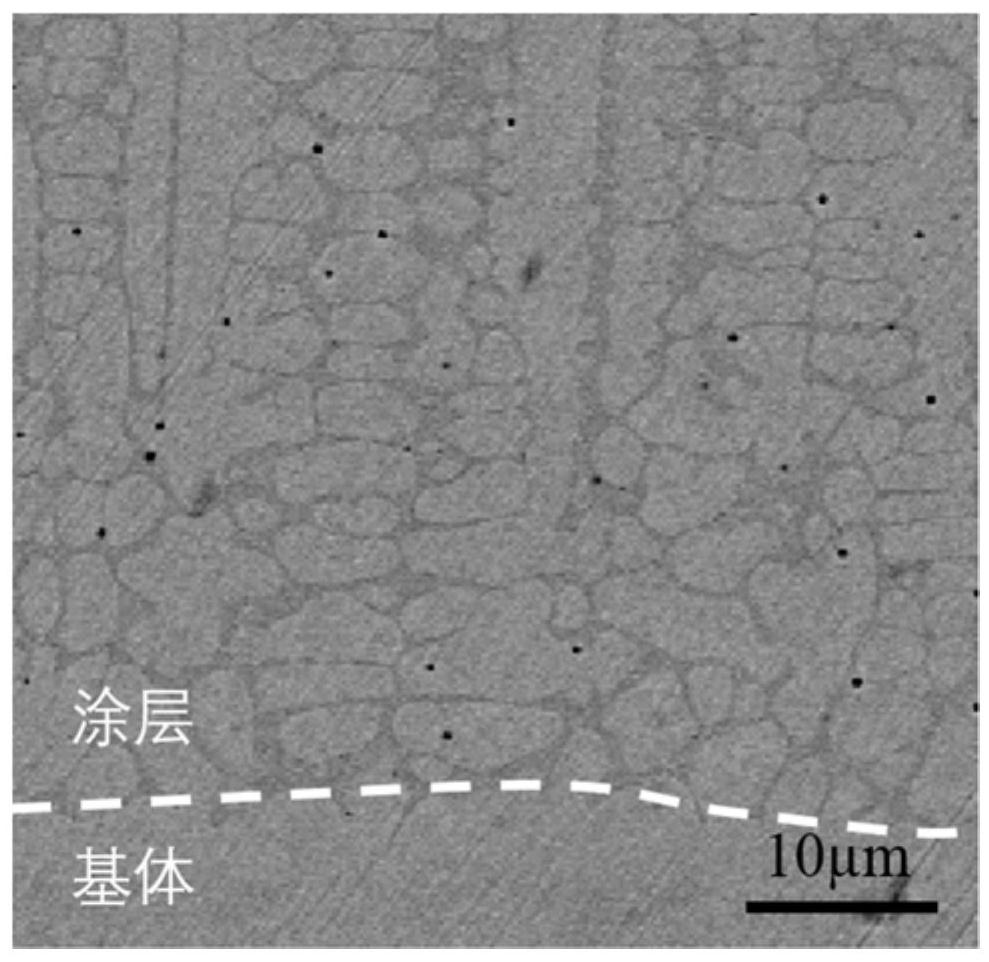

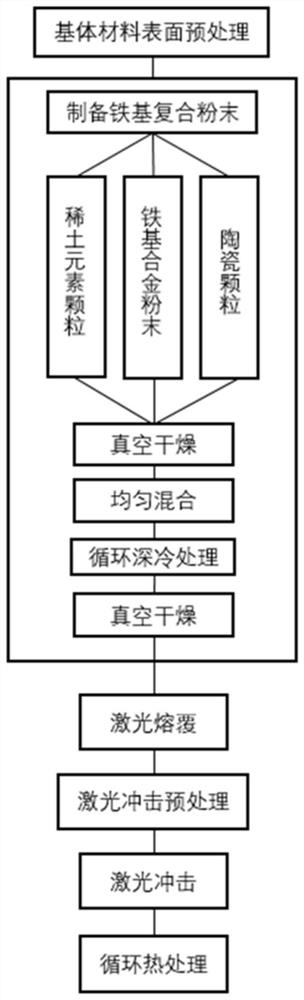

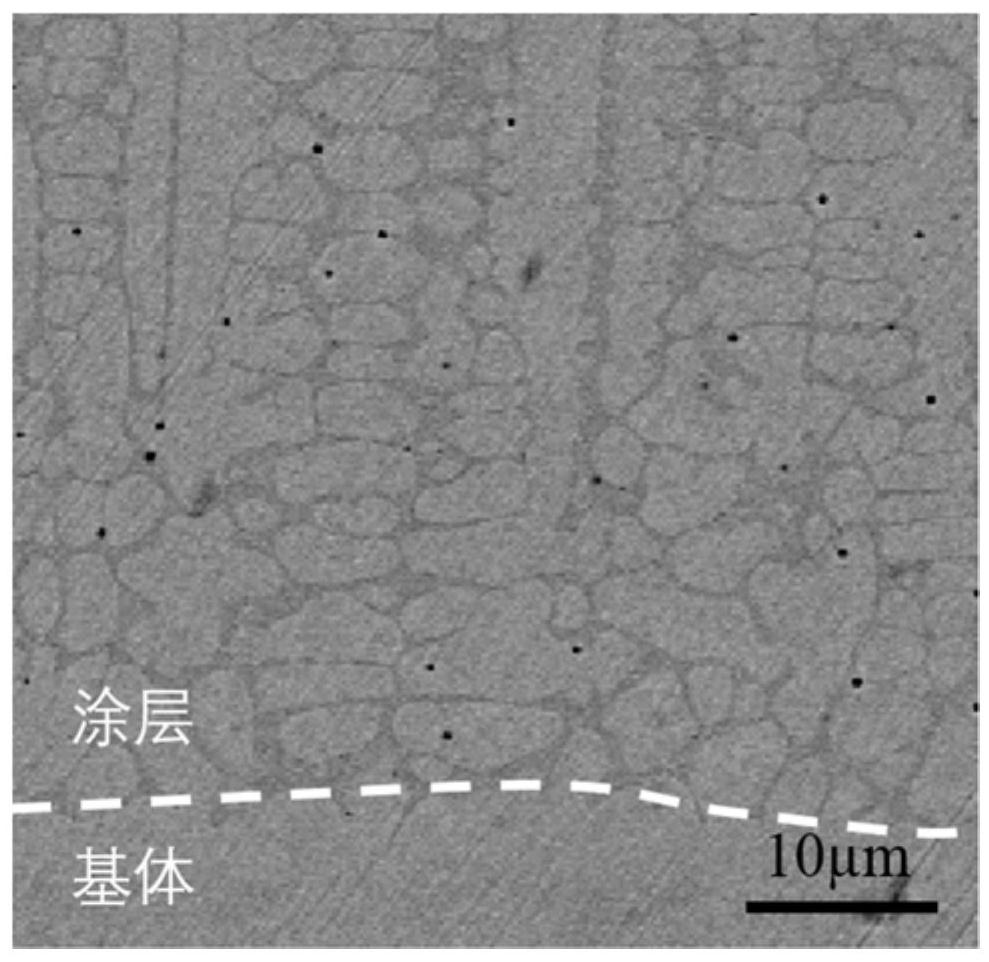

Iron-based wear-resistant composite material and preparation method thereof

ActiveCN113215564AHigh densityImprove refinementTransportation and packagingMetal-working apparatusCoated surfaceHeat treated

The invention discloses an iron-based wear-resistant composite material and a preparation method thereof. The preparation method comprises the following steps: preparing an iron-based wear-resistant composite coating on the surface of an iron-based alloy matrix material by using iron-based composite powder by using a laser cladding method to obtain a composite body; polishing and cleaning the surface of the composite body; then carrying out laser shock, and surface enhancement treatment of the iron-based wear-resistant composite coating is achieved; performing cyclic heat treatment on the composite with the surface subjected to laser shock to eliminate residual stress; and the iron-based composite powder is obtained by uniformly mixing micron La2O3 powder, micron Al2O3 powder and micron FeCrNiSiB powder, carrying out liquid nitrogen circulation subzero treatment and drying, and the iron-based composite powder contains the following components in percentage by mass: 0.05%-10% of the micron La2O3 powder, 0.1%-45% of the micron Al2O3 powder and 50%-95% of the micron FeCrNiSiB powder. According to the iron-based wear-resistant composite material and the preparation method thereof provided by the invention, the composite coating with good performance is prepared on the surface of an iron-based alloy material, the service life of an iron-based alloy matrix is prolonged, and the preparation method has great significance in repairing and reconstruction of engineering machinery.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of high-purity fine-grained zirconia ceramic bar for flame spraying

InactiveCN108558396AImprove deposition efficiencyLow content of impurity elementsPolyvinyl alcoholSpherical shaped

The invention discloses a preparation method of a high-purity fine-grained zirconia ceramic bar for flame spraying, belonging to the technical field of material surface protection. The method comprises the following steps: (1) carrying out spray granulation on high-purity nano zirconia powder to obtain spherical zirconia powder raw material; (2) dissolving polyvinyl alcohol in distilled water, adding a stabilizer, and stirring uniformly to obtain a polyvinyl alcohol aqueous solution binder; (3) adding the spherical zirconia powder raw material into the polyvinyl alcohol aqueous solution binder, adding a lubricant and a plasticizer, and mixing by using a vacuum mixer for pugging; (4) placing zirconia mud pellets into a vacuum extruder, and extruding for molding to obtain a green body; (5) sequentially removing water and organic matters from the green body to obtain a mature blank body; (6) sintering the mature blank body to obtain the zirconia ceramic bar. The high-purity fine-grained zirconia ceramic bar prepared by the method is low in impurity element content and small in grain size, and can be used for preparation of a zirconia coating on the surface of a graphite crucible or anextrusion die.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

A coating method for coating composite ceramic coating on the surface of refractory metal parts

ActiveCN109554702BIncrease surface tensionImprove wettabilityHeat inorganic powder coatingOrganic solventComposite ceramic

The invention discloses a coating method for coating composite ceramic coating layers on the surfaces of refractory metal parts. Firstly, the surfaces of the refractory metal parts are modified; then,a thickening agent and a dispersing agent are added in organic solvent, and composite ceramic coating layer powder is added for ball milling to prepare suspension pulp; the solid content of compositeceramic coating layer powder in the suspension pulp is controlled within 40-65%; the viscosity of the suspension pulp is 10-30 mm2 / s; then, the suspension pulp is uniformly sprayed on the modified surfaces of the refractory metal parts to obtain coating layer blanks; and finally, the coating layer blanks are sintered to form the composite ceramic coating layers on the surfaces of the refractory metal parts. The coating method improves the bonding performances between the composite ceramic coating layers and refractory metal, improves the uniform coating property of the composite ceramic coating layers, and realizes uniform coating of the composite ceramic coating layers on the surfaces of the refractory metal parts with large sizes, multiple dimensions and complicated shapes.

Owner:长沙微纳坤宸新材料有限公司

Powder cored wire for CrB-containing amorphous coating prepared by electric arc spraying

InactiveCN100427634CUniform coating structureHigh hardnessMolten spray coatingThermal sprayingCore component

An electrical arc spraying method for preparing amorphous-coating dust core wire containing CrB belongs to hot spraying domain in material processing project and is mainly used in various industrial domains including anticorrosive domain and wearable domain. The amorphous alloy is association of high strength, hardness, tenacity, abradability and noncorrosibility, but there is no patent report about the electrical arc spraying method for preparing iron-base amorphous-coating dust core wire both at home and abroad. The invention is about an electrical arc spraying method for preparing amorphous-coating dust core wire containing CrB and is characterized in that the mass percentage content range of the said dust core components is as follows: 60-80 % boron- chromium, 5-20 % Cr3C2, 5-10 % WC and the residue is iron dust. The covering prepared with the invented dust core contains a good deal of amorphous carborundum, the coating formation is even and has high rigidity with HV0.1 of more than 1190, and has good abradability and the relative abradability is 15.8 times than the Q235 steel.

Owner:BEIJING UNIV OF TECH

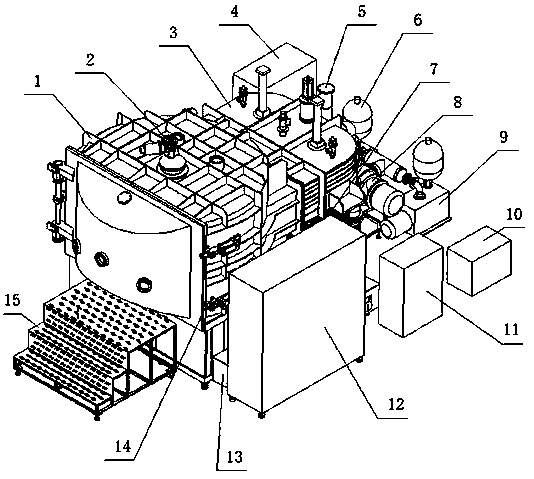

Electron beam evaporative vacuum coating equipment

InactiveCN109628895ASimple organizationUniform coating structureVacuum evaporation coatingSputtering coatingCooling coilEngineering

The invention relates to electron beam evaporative vacuum coating equipment which comprises a cavity assembly, an umbrella frame assembly, a high valve assembly, a copious cooling system, a pipeline system, a diffusing pump, a roots pump, a mechanical pump, an ion source pump, an electron gun assembly, an electric control cabinet assembly, a linear slot assembly and a door clamping assembly. The umbrella frame assembly is fixed to the cavity assembly, the high valve assembly is connected to the cavity assembly, the high valve assembly, the diffusing pump, the roots pump and the mechanical pumpare connected together through a pipeline system, and the door clamping assembly is mounted on the cavity assembly. An electron gun part of the electron gun assembly and an ion source part of the ionsource assembly are mounted in the cavity assembly. The copious cooling system comprises two copious cooling coils, one of which is mounted in the cavity assembly while the other one of which is mounted in the high valve assembly. The electron beam evaporative vacuum coating equipment has the characteristics of being simple in mechanism, high in uniform repeatability of coating structure and highin coating efficiency, and the cavity dimension can reach 2700 mm and the like.

Owner:湖南宇诚精密科技有限公司

Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

ActiveCN102936455BControl thicknessImprove protectionPretreated surfacesAnti-corrosive paintsAcrylic resinRare earth

The invention belongs to the technical field of surface treatment and particularly relates to a neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and a preparation method thereof. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating is composed of a bottom coating and a top coating, the thickness of the bottom coating is in a range from 10mum to 25mum, the chemical components of the bottom coating comprise 55% to 65% of one or two types of metals of zinc and aluminum, 0% to 5% of one or a plurality of types of metals of nickel, chromium, molybdenum, neodymium, praseodymium, cobalt and titanium and 34% to 40% of neutral resins, the thickness of the top coating is in a range from 5mum to 15mum, and the chemical components of the top coating comprise 55% to 65% of one or a plurality of types of metals of zinc, aluminum, titanium, molybdenum, nickel, cobalt and chromium and 35% to 45% of phenolic resins or acrylic resins. The preparation method includes that firstly the surface of a permanent magnet is preprocessed, a centrifugal immersion tossing is utilized to prepare the bottom coating, and a rolling spraying process is utilized to prepare the top coating. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and the preparation method thereof have the advantages that by means of double layers of coatings, the corrosion resistance is high, the surface binding force is high, the usage temperature is higher than 200 DEG C, the magnetic property of the neodymium iron boron rare earth permanent magnet is improved, the service life is prolonged, and the service environment is widened.

Owner:SHENYANG GENERAL MAGNETIC

A kind of preparation method of wear-resistant coating of liner of ball mill

ActiveCN105063539BBroaden your optionsHigh bonding strengthMolten spray coatingWear resistantWear resistance

The invention discloses a preparation method of a wear-resistant coating for a liner of a ball mill, belonging to the field of engineering machinery remanufacturing. It includes a substrate and a coating layer, and the mass percentage of the substrate composition is C0.30~0.44wt%, Si1.50~2.0wt%, Mn0.8~1.40wt%, Cr2.0~2.8wt%, Mo≦0.3wt %, Ni≦0.3wt%, Re0.02wt%, P and S total 0.04wt%, and the rest is Fe; the coating layer contains WC-Co powder with a volume fraction of 95-98% and 2-5% Cr , the Cr / Co weight ratio is 0.2-0.5. The invention can endow the parts with special properties such as wear resistance and corrosion resistance, improve the reliability of the parts and prolong the service life of the parts, especially the wear resistance of the working surface of the wear-resistant liner of the ball mill.

Owner:ANHUI POLYTECHNIC UNIV

ZnAlMgTiSiB anticorrosive coating for steel structure and preparation method of ZnAlMgTiSiB anticorrosive coating

ActiveCN108893698ALow corrosion rateClog micro poresMolten spray coatingPre treatmentUltimate tensile strength

The invention discloses a ZnAlMgTiSiB anticorrosive coating for the steel structure. The ZnAlMgTiSiB anticorrosive coating is composed of, by weight, 41%-73% of Zn, 15%-55% of Al, 0.5%-2% of Mg, 0.5%-5% of Ti, 0.7%-3% of Si and 1%-2% of B. The corrosion products of Ti, Si and B in the ZnAlMgTiSiB anticorrosive coating are insoluble in water, so that coating corrosion rate is lowered, and anti-corrosion life of the steel structure is prolonged. The invention further discloses a preparation method of the ZnAlMgTiSiB anticorrosive coating for the steel structure. The method includes: 1, pretreating the surface of the steel structure to Sa2.5 above; 2, spraying the spraying material onto the surface of the pretreated steel structure by an arc spraying method to form the ZnAlMgTiSiB anticorrosive coating. With the method, pores in the coating are reduced, and binding strength between the coating and the steel structure is improved.

Owner:SINOADDITIVE MFG EQUIP CO LTD

A ball mill liner remanufactured surface coating part

ActiveCN105063499BBroaden your optionsHigh bonding strengthMolten spray coatingGrain treatmentsWear resistanceBall mill

The invention discloses a ball mill liner remanufactured surface coating part and a manufacturing method thereof, which belong to the field of construction machinery remanufacture. It includes a substrate and a coating layer, and the mass percentage of the substrate composition is C0.30~0.44wt%, Si1.50~2.0wt%, Mn0.8~1.40wt%, Cr2.0~2.8wt%, Mo≦0.3wt %, Ni≦0.3wt%, Re0.02wt%, P and S total 0.04wt%, and the rest is Fe; the coating layer contains WC-Co powder with a volume fraction of 95-98% and 2-5% Cr , the Cr / Co weight ratio is 0.2-0.5. The invention can endow the parts with special properties such as wear resistance and corrosion resistance, improve the reliability of the parts and prolong the service life of the parts, especially the wear resistance of the working surface of the wear-resistant liner of the ball mill.

Owner:ANHUI POLYTECHNIC UNIV

Znalmgtisib anti-corrosion coating for steel structure and preparation method thereof

ActiveCN108893698BLow corrosion rateClog micro poresMolten spray coatingUltimate tensile strengthBonding strength

Owner:SINOADDITIVE MFG EQUIP CO LTD

A preparation method of conductive polymer-carbon coated silicon oxide composite material

ActiveCN107658455BUniform coating structureHigh technical requirementsCell electrodesSecondary cellsConductive polymerSilicon oxide

The invention discloses a conductive polymer-carbon coated silicon oxide composite material and a preparation method thereof. The conductive polymer-carbon coated silicon oxide composite material comprises a conductive polymer, a silane coupling agent, carbon and silicon oxide, wherein the carbon is directly coated on a surface of a silicon oxide particle, the silane coupling agent is absorbed toa surface of the carbon, and the conductive polymer is embedded into carbon gaps and also is uniformly coated on the surface of the carbon by a bridge chain effect of the silane coupling agent. The preparation method of the conductive polymer-carbon coated silicon oxide composite material comprises three steps of highly mixing the silicon oxide and a carbon source, performing high-temperature sintering (curing and carbonization) and coating the polymer. The prepared composite material is very uniform in coating structure and has relatively low volume expansion effect and excellent electrochemical performance, the initial charge-discharge efficiency can be obviously improved, and particularly, relatively poor cycle property of a silicon oxide negative electrode material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of iron-based wear-resistant composite material and preparation method thereof

ActiveCN113215564BHigh densityImprove refinementTransportation and packagingMetal-working apparatusCoated surfaceAlloy substrate

The invention discloses an iron-based wear-resistant composite material and a preparation method thereof. The preparation method includes the following process: using a laser cladding method to prepare an iron-based wear-resistant composite coating on the surface of an iron-based alloy base material with iron-based composite powder. layer to obtain the composite body; the surface of the composite body is polished and cleaned; then laser shock is carried out to realize the surface enhancement treatment of the iron-based wear-resistant composite coating; the composite body subjected to laser shock on the surface is subjected to cyclic heat treatment to eliminate residual stress; The iron-based composite powder is micron La 2 o 3 Powder, Micron Al 2 o 3 The powder and micron FeCrNiSiB powder are uniformly mixed, cryogenically treated with liquid nitrogen circulation, and dried. In terms of mass percentage, the iron-based composite powder contains: 0.05% to 10% of micron La 2 o 3 Powder, 0.1%~45% micron Al 2 o 3 powder and 50% to 95% micron FeCrNiSiB powder. The invention improves the service life of the iron-based alloy matrix by preparing a composite coating with good performance on the surface of the iron-based alloy material, and has great significance for the repair and reconstruction of engineering machinery.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

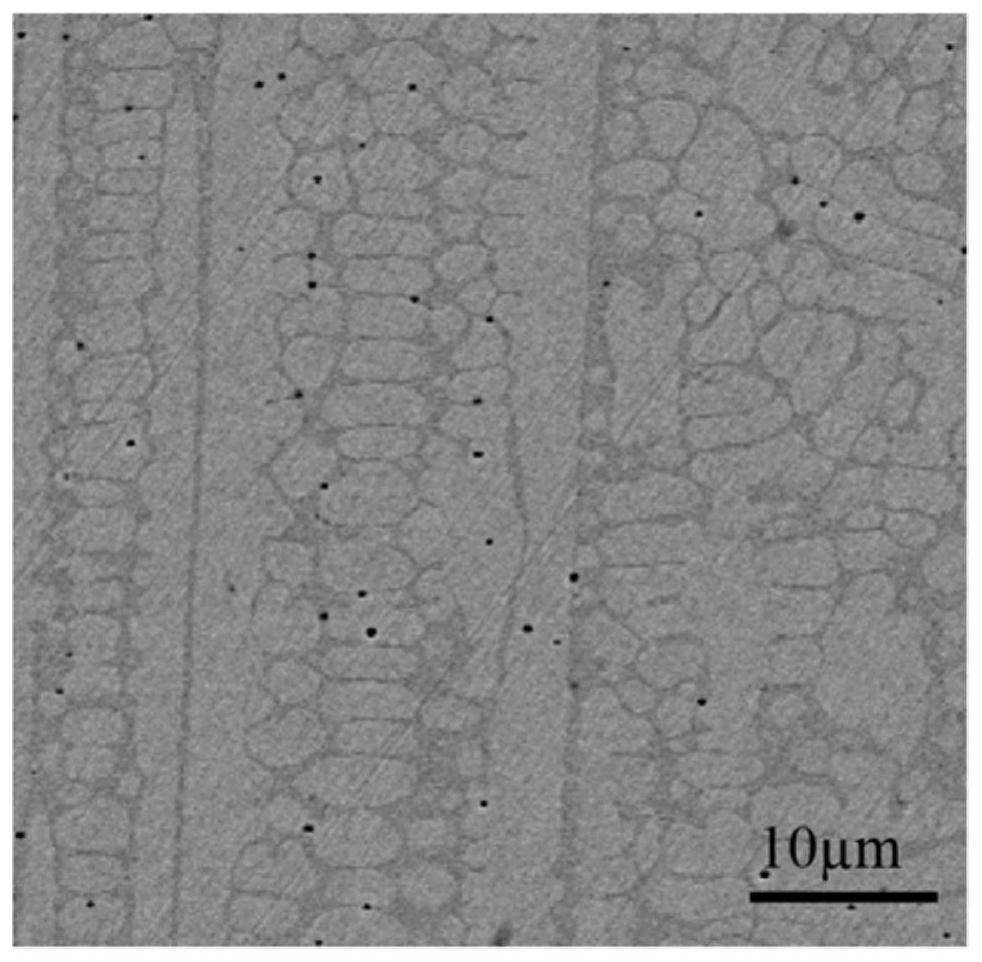

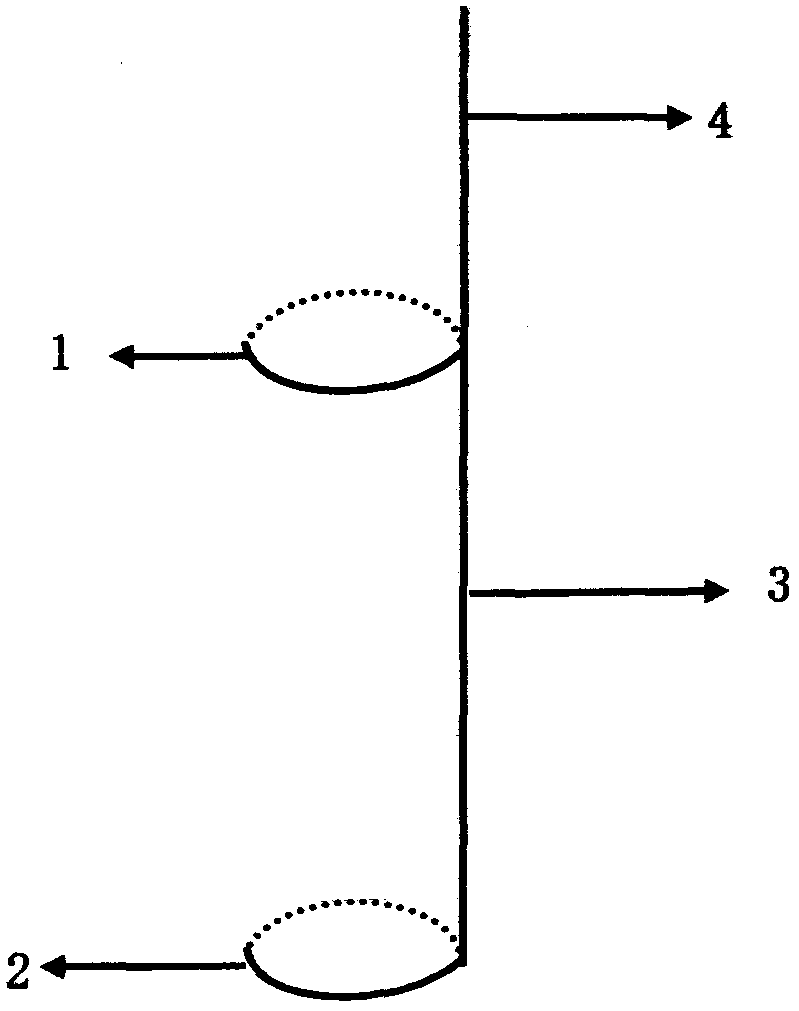

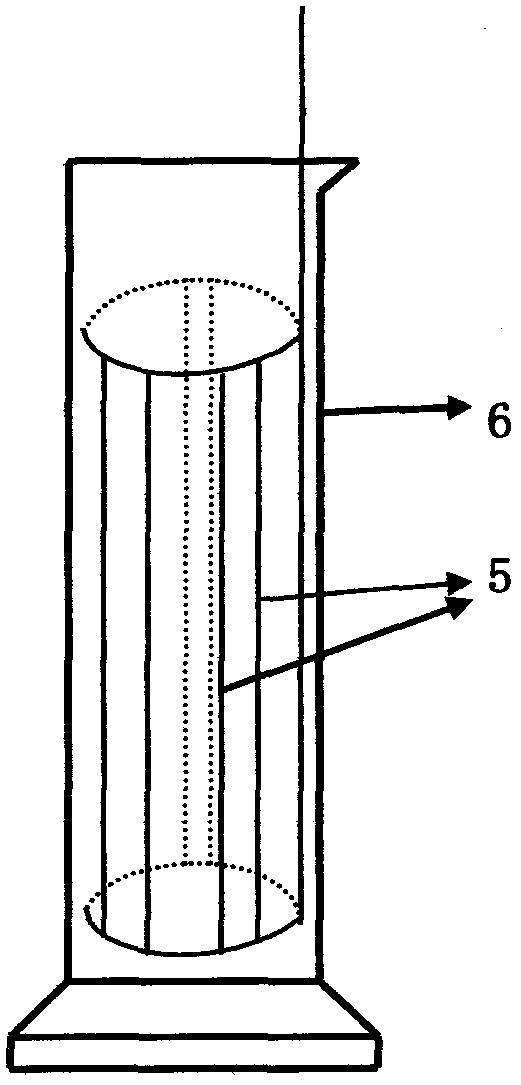

Simple hollow fiber membrane coating tool

PendingCN109201421ASimple structureEasy to manufactureLiquid surface applicatorsCoatingsGraduated cylinderHollow fiber membrane

The invention provides a simple hollow fiber membrane coating tool, which comprises a hollow fiber membrane fixing part, a support part, and a handle. The hollow fiber membrane fixing part fixes a hollow fiber membrane; a user can hold the handle to soak the tool in a graduated cylinder filled with coating liquid; the support part is tightly pressed against the inner wall of the graduated cylinder; and the hollow fiber membrane is evenly painted.

Owner:TIANJIN POLYTECHNIC UNIV

Coating method for coating composite ceramic coating layers on surfaces of refractory metal parts

ActiveCN109554702AImprove adhesionIncrease binding areaHeat inorganic powder coatingOrganic solventComposite ceramic

The invention discloses a coating method for coating composite ceramic coating layers on the surfaces of refractory metal parts. Firstly, the surfaces of the refractory metal parts are modified; then,a thickening agent and a dispersing agent are added in organic solvent, and composite ceramic coating layer powder is added for ball milling to prepare suspension pulp; the solid content of compositeceramic coating layer powder in the suspension pulp is controlled within 40-65%; the viscosity of the suspension pulp is 10-30 mm2 / s; then, the suspension pulp is uniformly sprayed on the modified surfaces of the refractory metal parts to obtain coating layer blanks; and finally, the coating layer blanks are sintered to form the composite ceramic coating layers on the surfaces of the refractory metal parts. The coating method improves the bonding performances between the composite ceramic coating layers and refractory metal, improves the uniform coating property of the composite ceramic coating layers, and realizes uniform coating of the composite ceramic coating layers on the surfaces of the refractory metal parts with large sizes, multiple dimensions and complicated shapes.

Owner:长沙微纳坤宸新材料有限公司

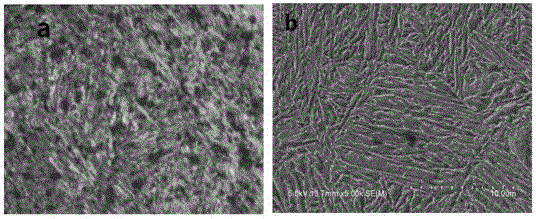

Special high-temperature fly ash wear resistant arc spraying wire for amorphous nanocrystal

The invention relates to a hot spraying material, and particularly relates to a special high-temperature fly ash wear resistant arc spraying wire for an amorphous nanocrystal and a coating prepared therefrom, belonging to the technical field of wear resistant materials. The wire comprises the following components in percentage by mass: 20.0-22.0% of Cr, 4.0-6.0% of Mo, 3.0-5.0% of B, 3.0-5.0% of Nb, 1.0-2.0% of C, 1.0-2.0% of Mn, 0.5-1.0% of Si and the balance of iron. After the wire developed by the invention is applied onto a metal matrix subjected to sand blasting and coarsening according to arc spraying process parameters in the prior art, the prepared coating contains a large number of amorphous nanocrystal structures and is uniform in microstructure and extremely high in hardness, the normal-temperature HV0.3 is higher than 1100, and the porosity is lower than 5%; and the wear resistant coating provided by the invention has high bonding strength (higher than 75 MPa at normal temperature) and excellent shock resistance toughness, and the high-temperature hardness HV0.3 at 600 DEG C is higher than 350.

Owner:JIANGXI HENGDA HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com