Powder sintering phosphorescence particle indication composite coating

A luminescent particle, phosphorescent technology, applied in the field of wear and corrosion self-sensitive luminescence detection, can solve the problems of not meeting the requirements of industrial coating applications, quenching luminescence performance, weak binding force and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

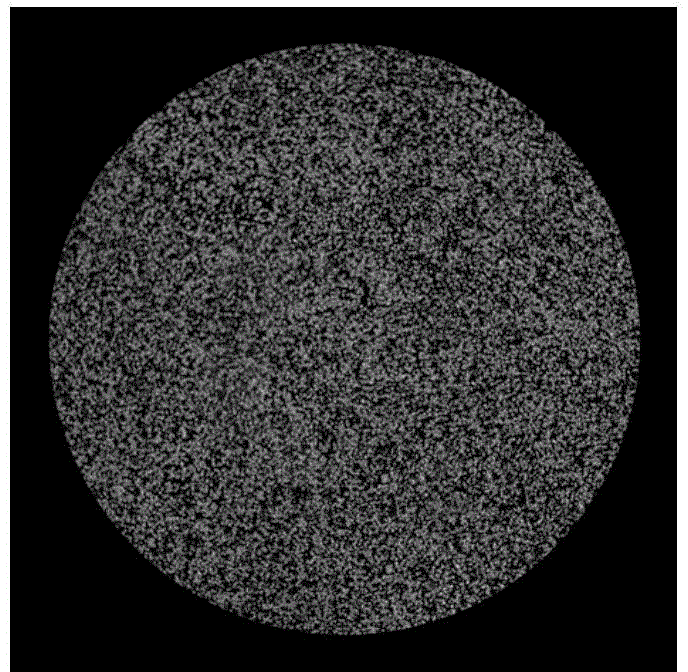

[0021] Preparation of copper-based powder sintered functional indicator coatings incorporated with phosphorescent luminescent particles:

[0022] Aluminum bronze base powder, its chemical composition (mass fraction) is: Cu is 78.00%, Al is 13.00%, Mn is 1.80%, Fe is 4.00%, Co is 1.50%, Ni is 1.50%, Ce is 0.20%. The particle size distribution is (-160~+260) mesh.

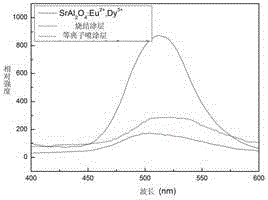

[0023] Phosphorescent particles are selected from SrAl 2 o 4 :Eu 2+ , Dy 3+ Phosphor powder (europium, dysprosium activated strontium aluminate), particle size is 180 mesh.

[0024] The aluminum bronze-based powder is quantitatively taken by volume, the phosphorescent particles are dosed according to 25.0% of the total volume fraction of the aluminum bronze-based powder, and liquid paraffin with a total volume fraction of 1.0% of the ingredients is added as a molding agent, and the three-dimensional vortex mixer (TD-2) Mix in medium for 30 minutes, fill the material according to the thickness of the coating, put...

Embodiment 2

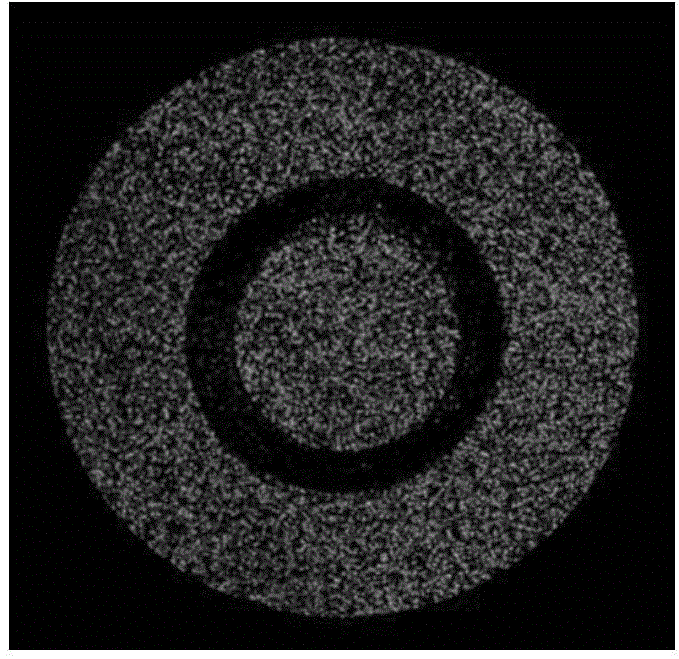

[0026] Preparation of symbiotic composite sintered coatings in which phosphorescent particles are incorporated into the coating as an indicator layer under the wear-resistant and corrosion-resistant functional layer:

[0027]Functional layer aluminum bronze base powder, its chemical composition (mass fraction) is: Cu is 78.00%, Al is 13.00%, Mn is 1.80%, Fe is 4.00%, Co is 1.50%, Ni is 1.50%, Ce is 0.20% . The particle size distribution is (-160~+260) mesh.

[0028] The metal powder of the indicator layer is Ni65G nickel-based alloy powder, and the particle size distribution is (-160~+260) mesh.

[0029] Phosphorescent particles are selected from SrAl 2 o 4 :Eu 2+ , Dy 3+ Phosphor powder (europium, dysprosium activated strontium aluminate), particle size is 150 mesh.

[0030] Quantitatively take the indicator layer Ni65G nickel-based alloy powder by volume, the phosphorescent particles are formulated according to 25.0% of the overall volume fraction of the Ni65G nickel-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com