Patents

Literature

147 results about "Composite indicator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wikis > Composite indicator. A composite indicator is formed when Indicators are compiled into a single index, on the basis of an underlying model of the multi-dimensional concept that is being measured (e.g. competitiveness, e-trade or environmental quality).

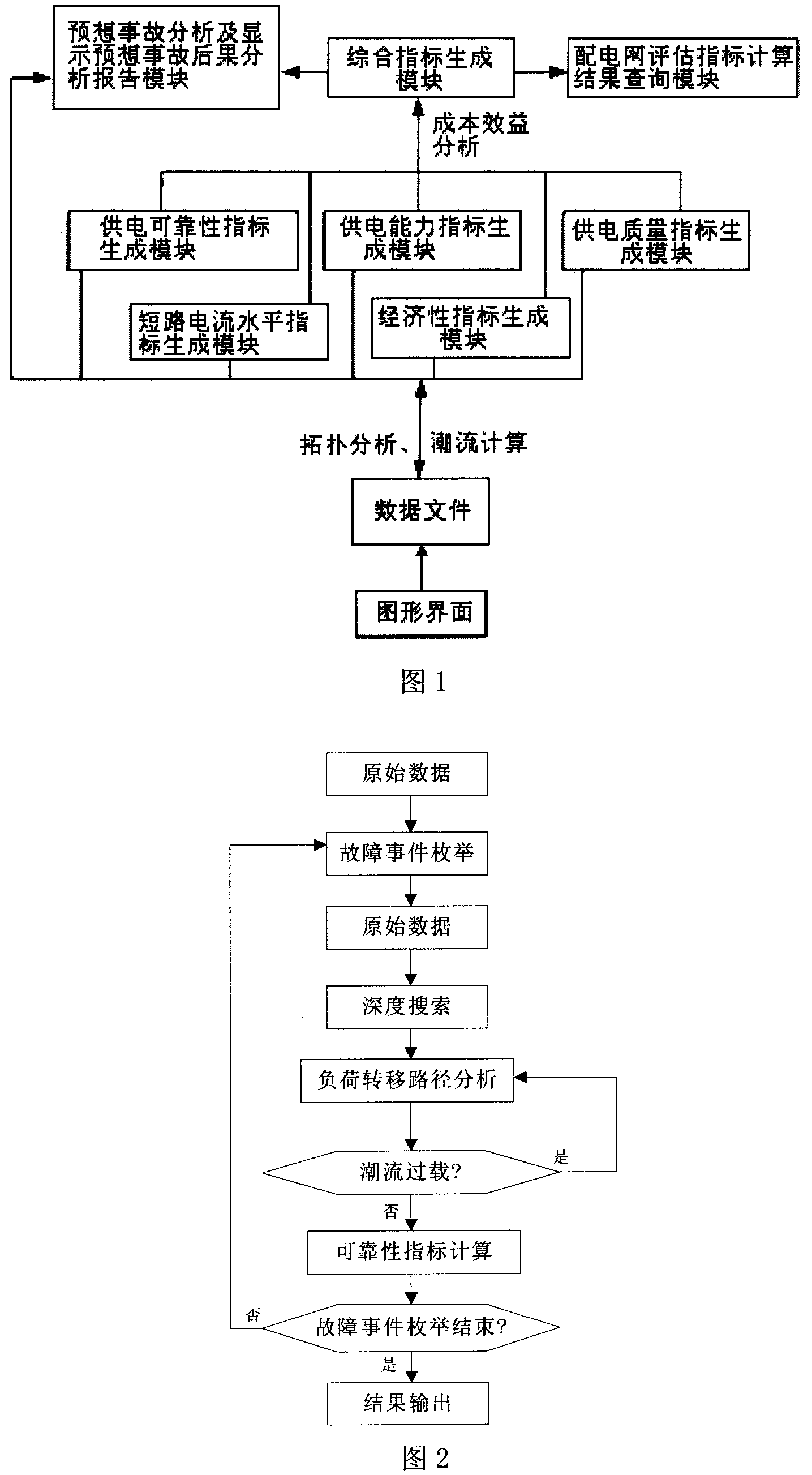

Power distribution network planning scheme assistant decision system

InactiveCN101179195AEasy to editComputationally efficientSpecial data processing applicationsInformation technology support systemProject proposalEngineering

The invention relates to an assistance determination system of a distribution network programming proposal in a electricity technical field, which includes a data input and output module, a power-supply reliability index generation module, a power-supply capacity index generation module, a power-supply quality index generation module, a short-circuit electric-current level index generation module, a projected economy index generation module, an integrated index generation module, a module for analyzing preconceived accident and displaying an analysis report on the preconceived accident consequence and an inquiry module for an calculation result on the assessment index of the distribution network. The data input and output module is used for inputting the data of the distribution network proposal into each index generation module, and outputting the assessment index calculated by each index generation module. Each index is calculated by each index generation module through calling a topology analysis and a power flow calculation, and the analysis reporting module and the inquiry module carry out an analysis and a report to each module respectively. The invention finds out existing problems and weak steps of the projected proposal quickly and accurately, and provides scientific basis for a revise and an execution of the projected proposal.

Owner:SHANGHAI JIAO TONG UNIV

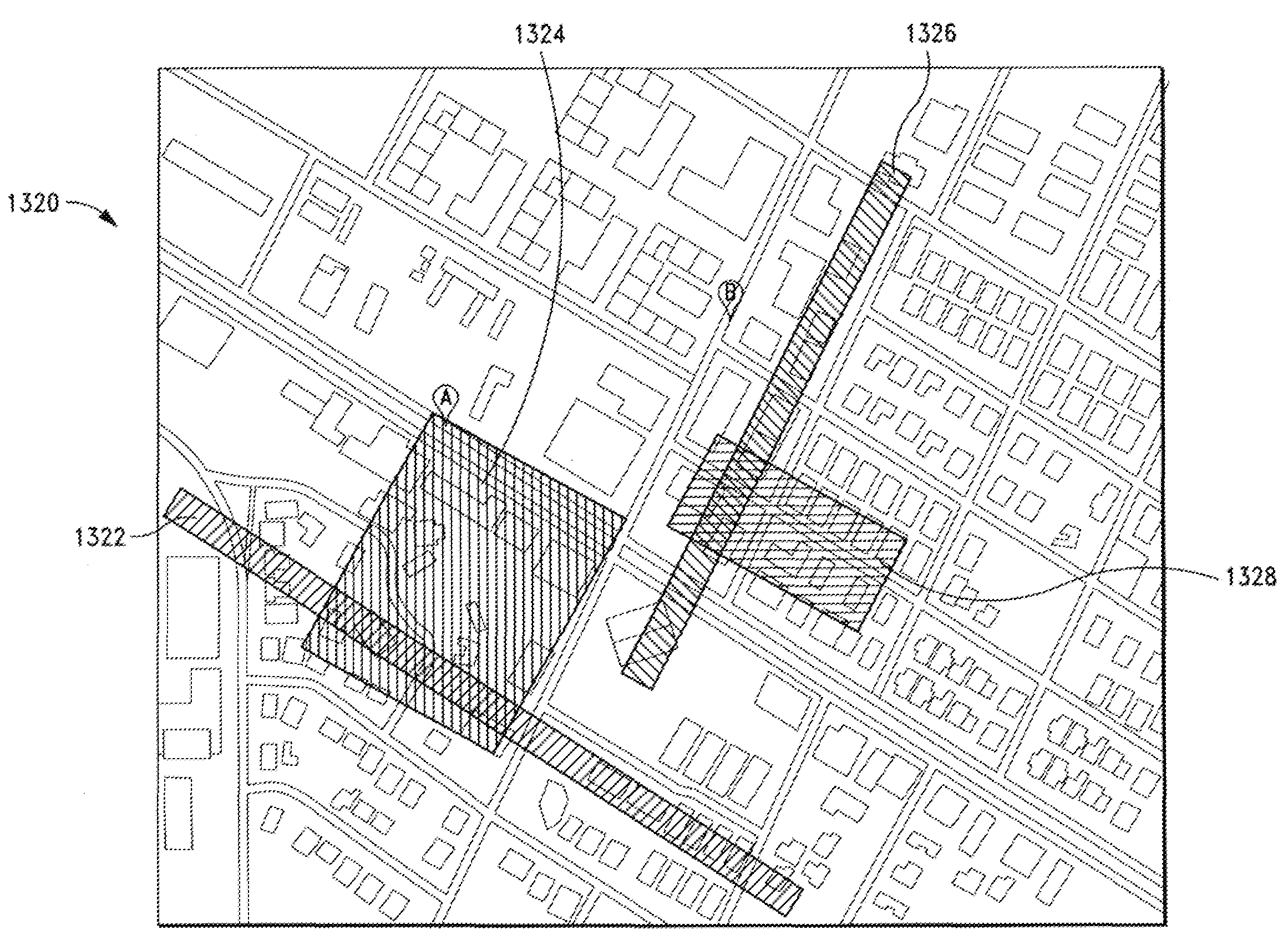

Method and system utilizing online analytical processing (OLAP) for making predictions about business locations

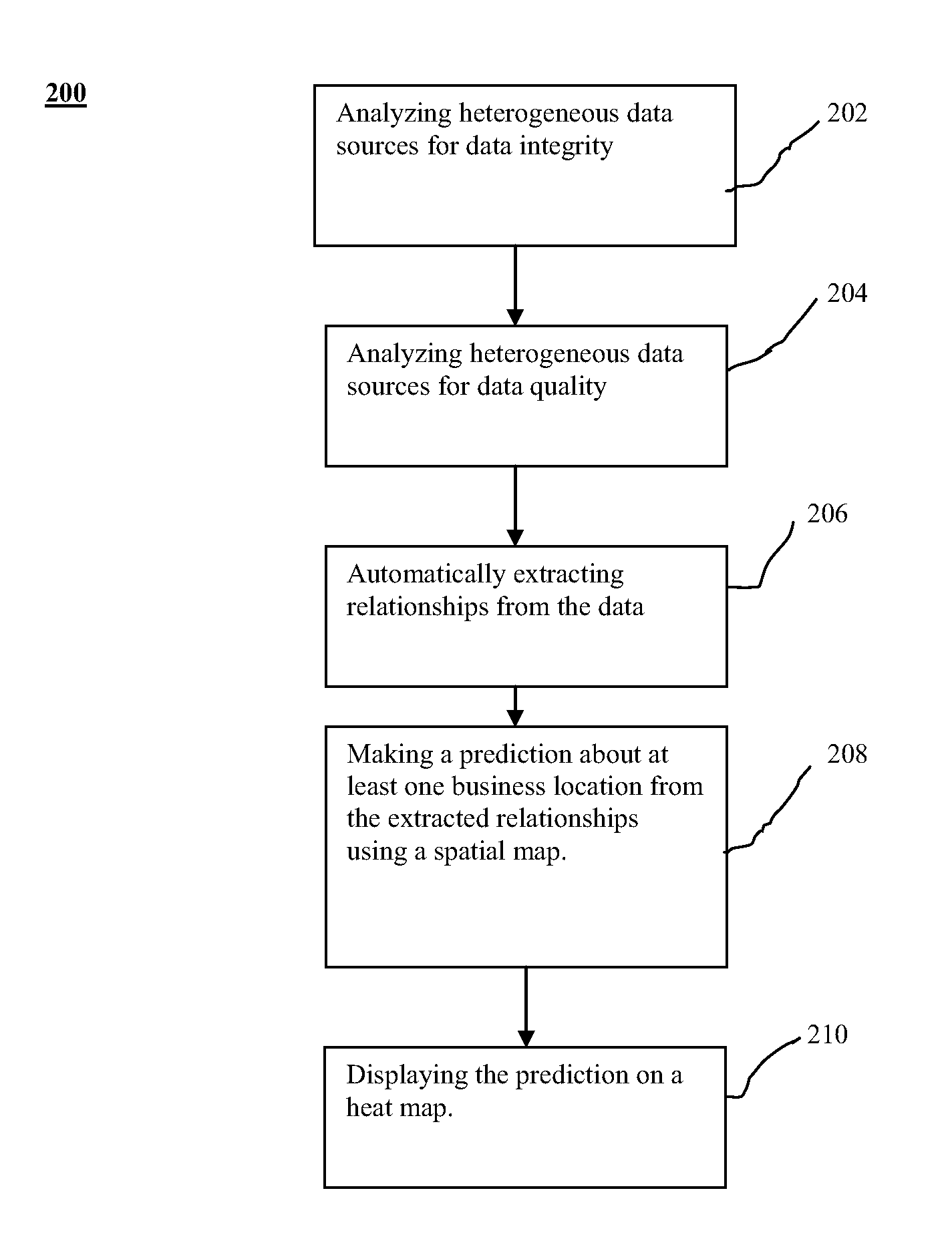

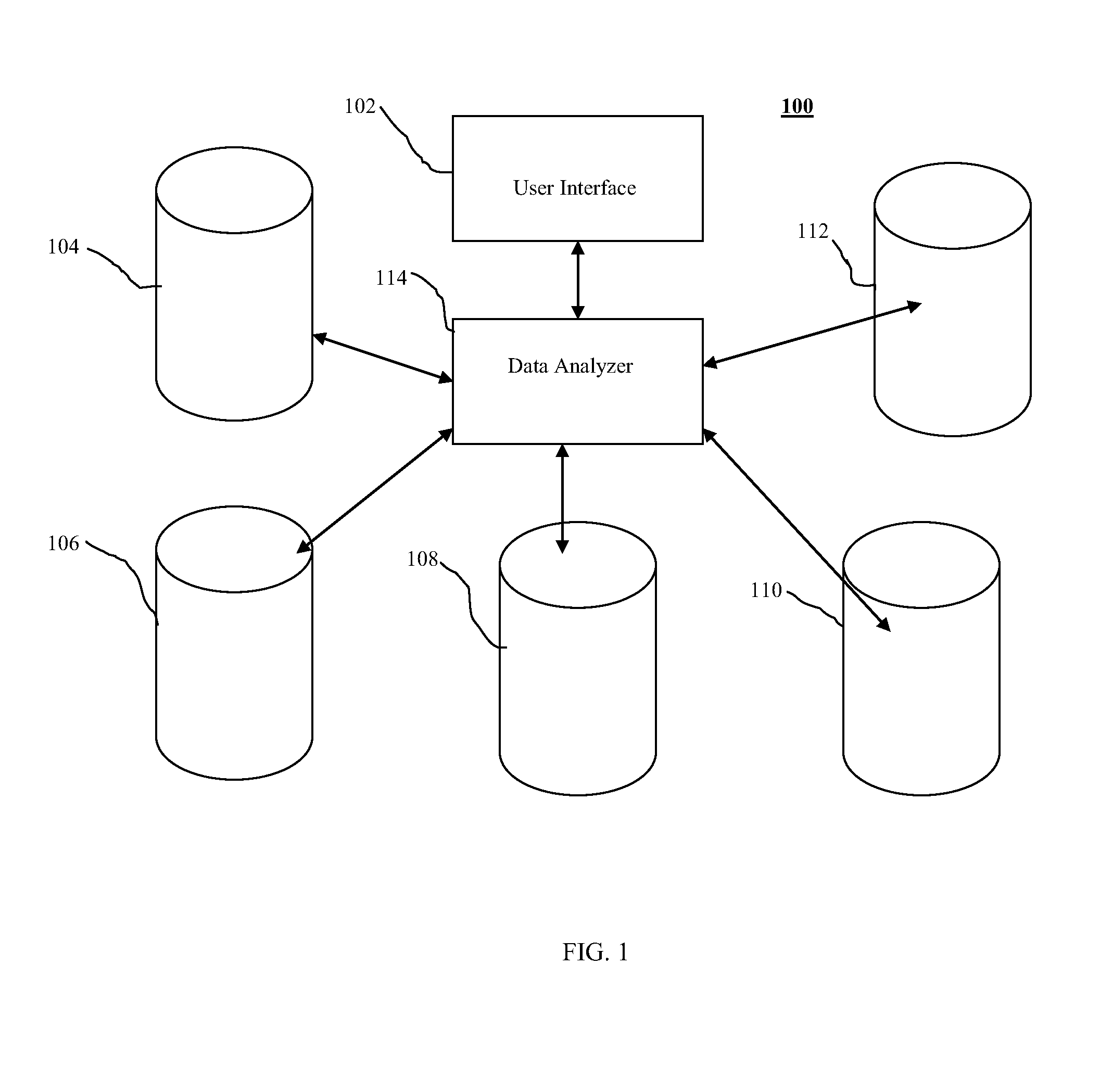

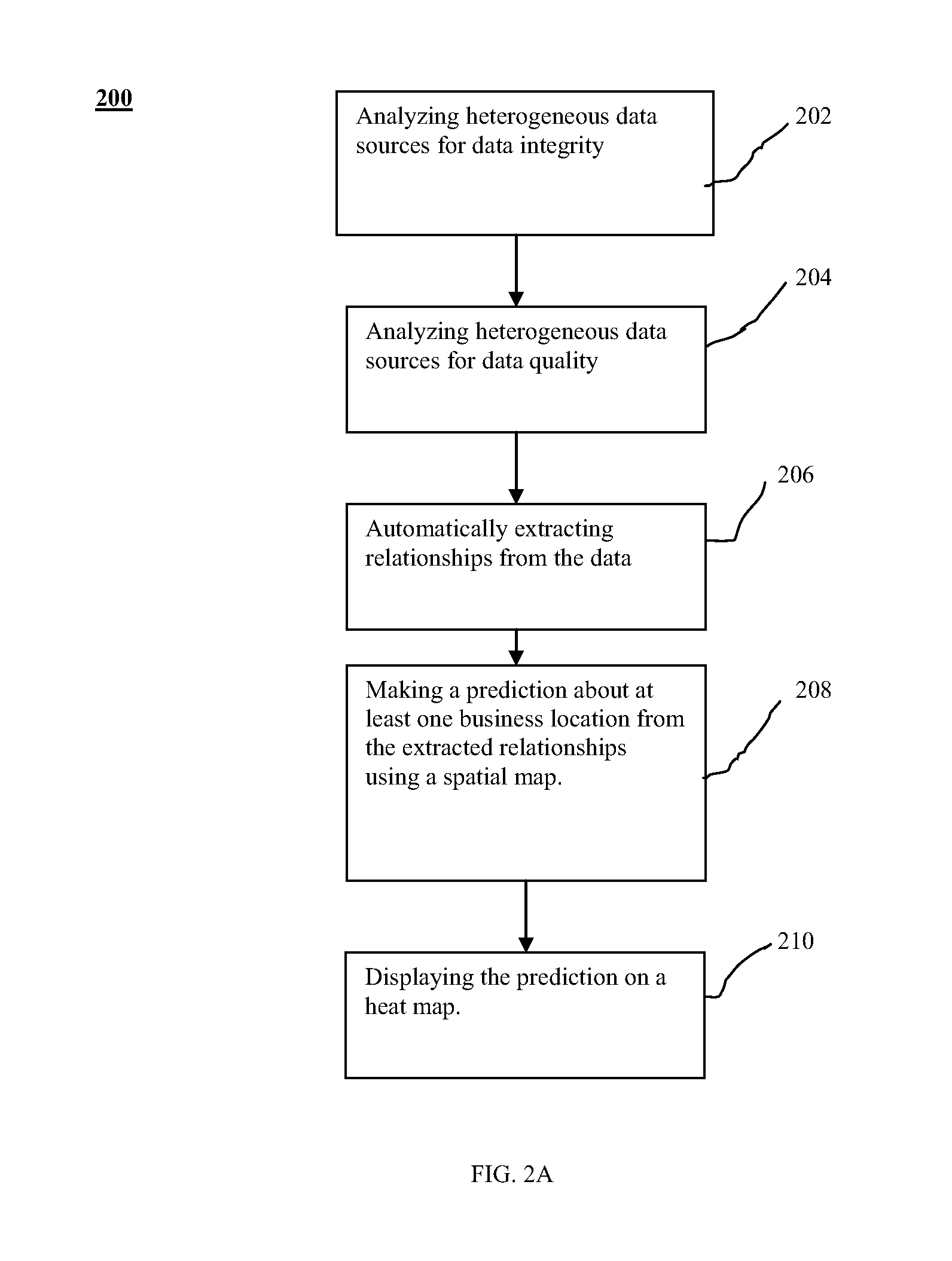

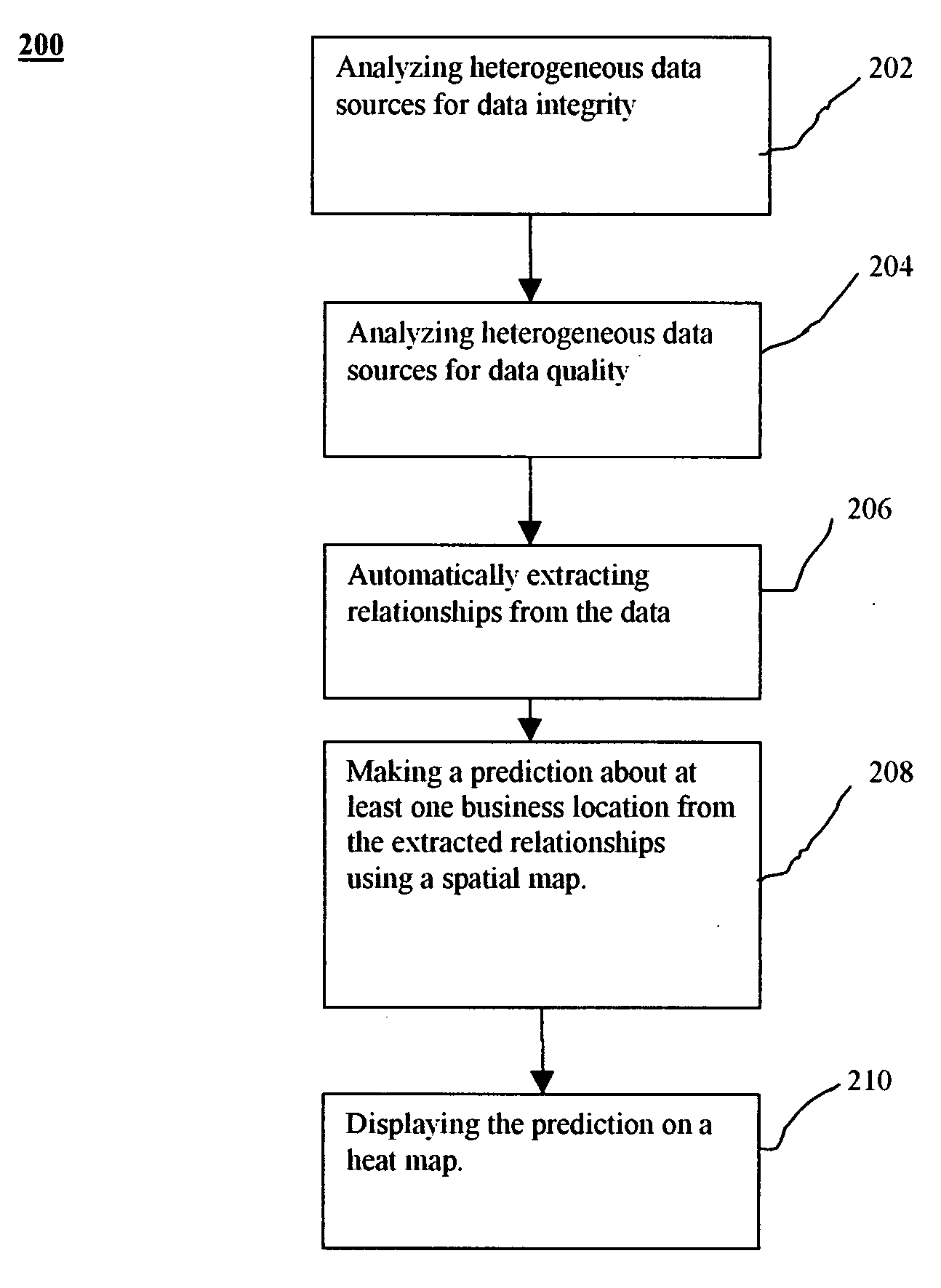

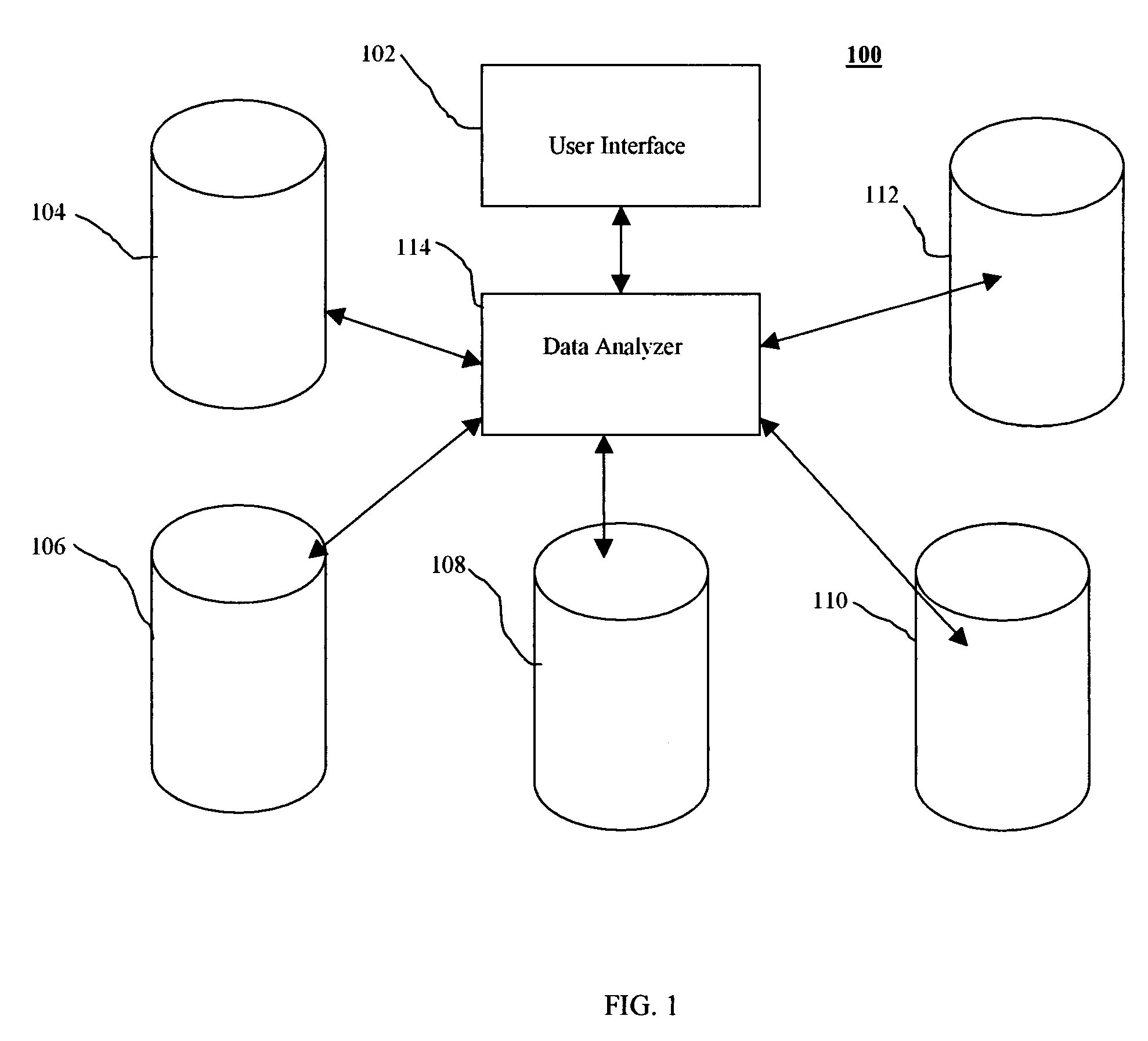

A method and system that utilizes OLAP and supporting data structures for making predictions about business locations. The method includes providing a spatial map and analyzing heterogeneous data having a spatial component to find utilizable data. Relationships are automatically extracted from the utilizable data by employing machine learning. The step of automatically extracting relationships includes generating a composite indicator, which correlates spatial data with unstructured data. The extracted relationships are presented on a spatial map to make a prediction about at least one business location. Preferably, the predictions are presented as a rank-ordered list on the spatial map and a heat map overlays the spatial map to indicate predictions about particular regions.

Owner:SAAMA TECH LLC

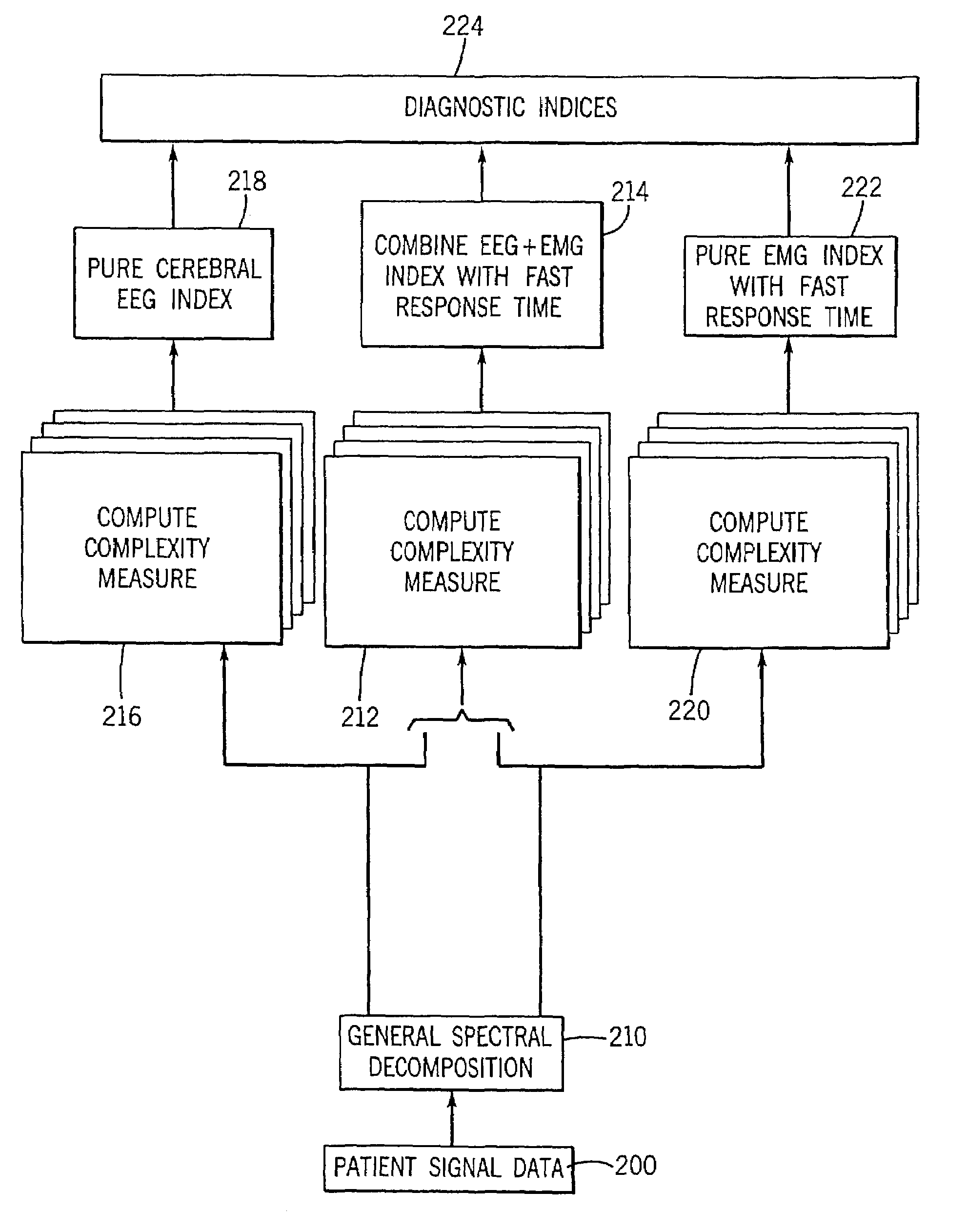

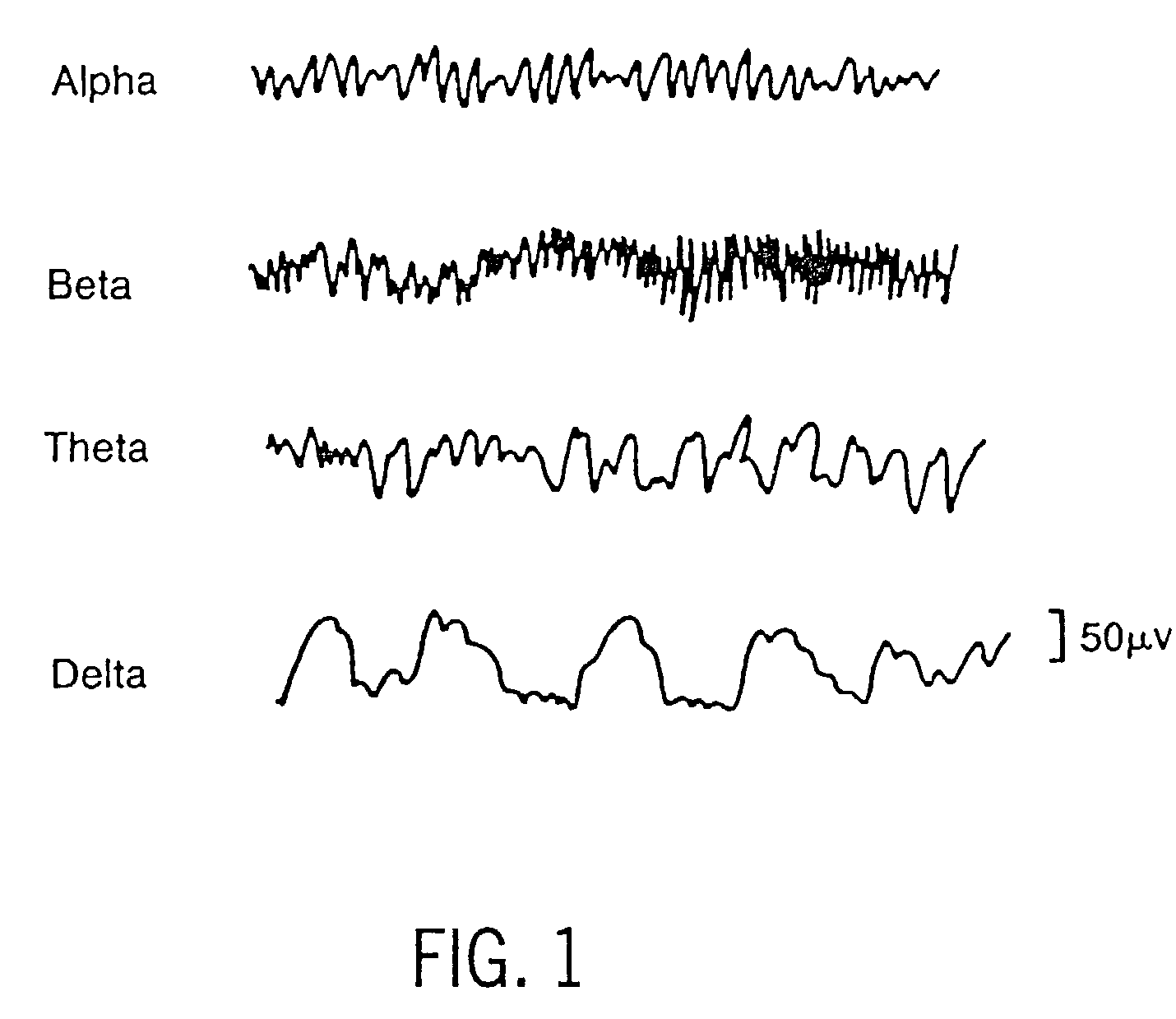

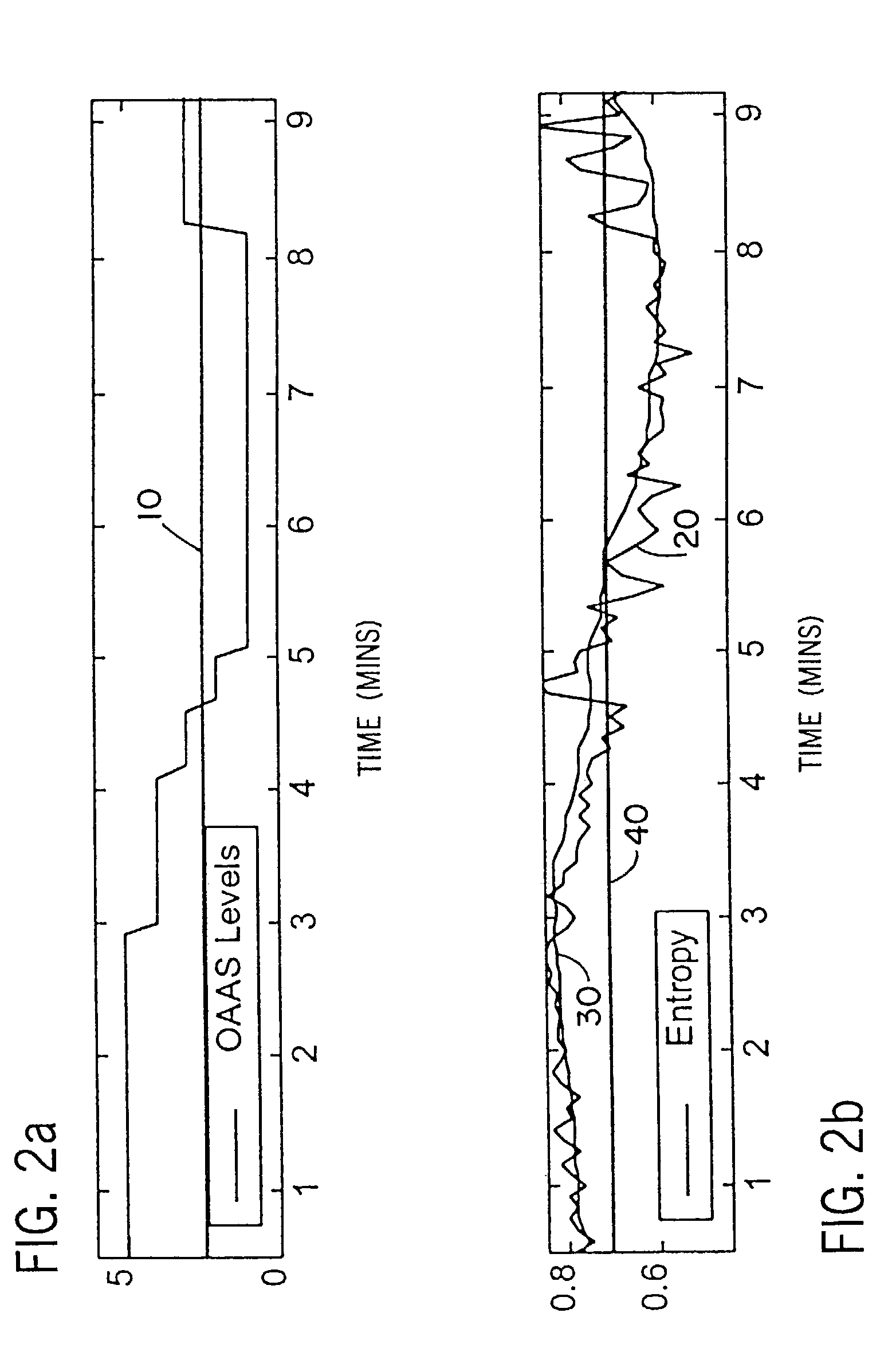

Method and apparatus for determining the cerebral state of a patient with fast response

InactiveUS7228169B2Accurately determineAccurately determinedElectroencephalographyElectromyographyAnesthesiaDepth of anesthesia

Owner:GE HEALTHCARE FINLAND

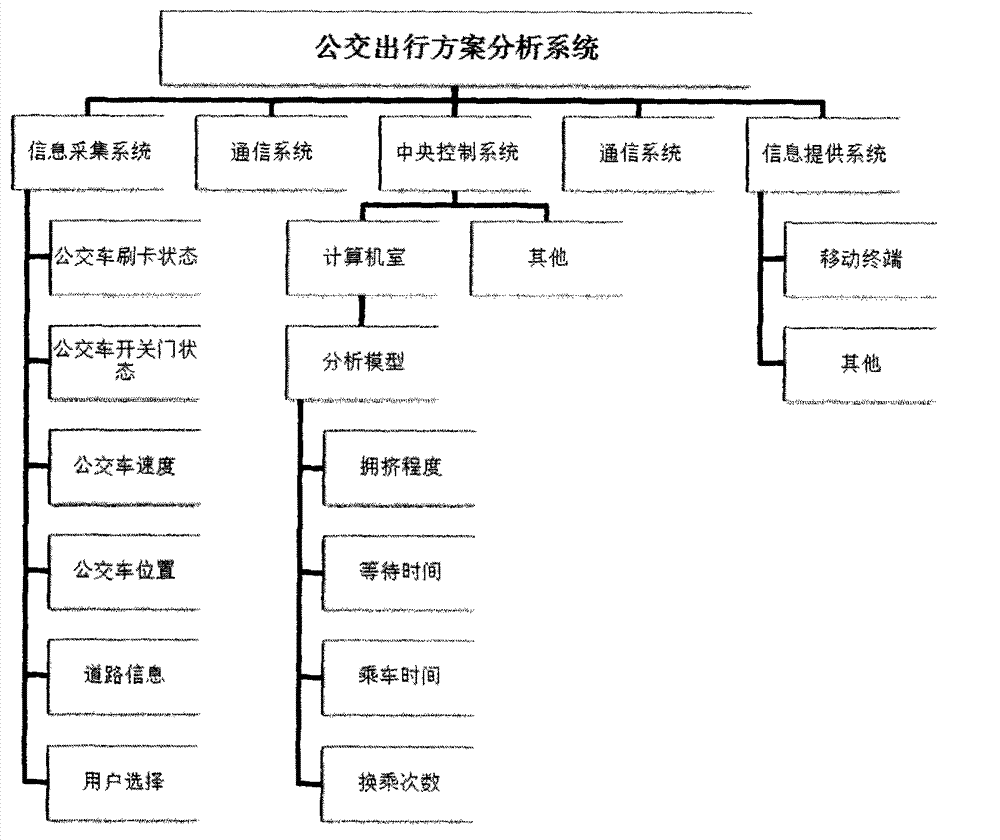

Method and system for selecting bus trip route

InactiveCN102867408AFully reflect the needsHigh precisionRoad vehicles traffic controlLinear regressionComputer science

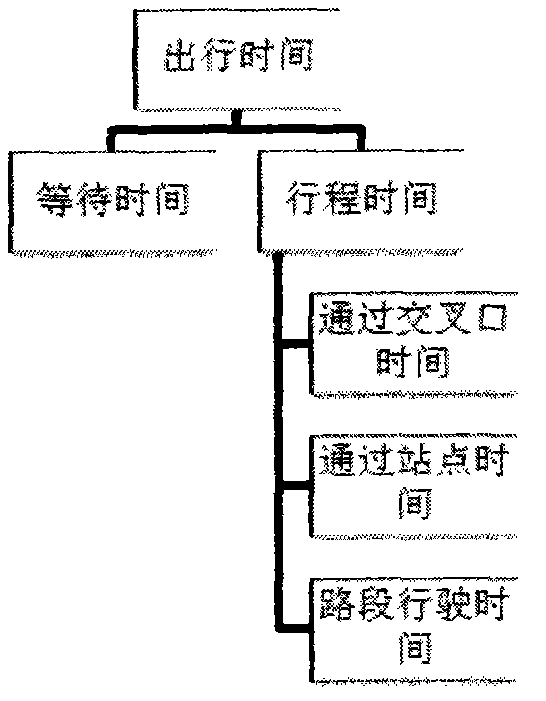

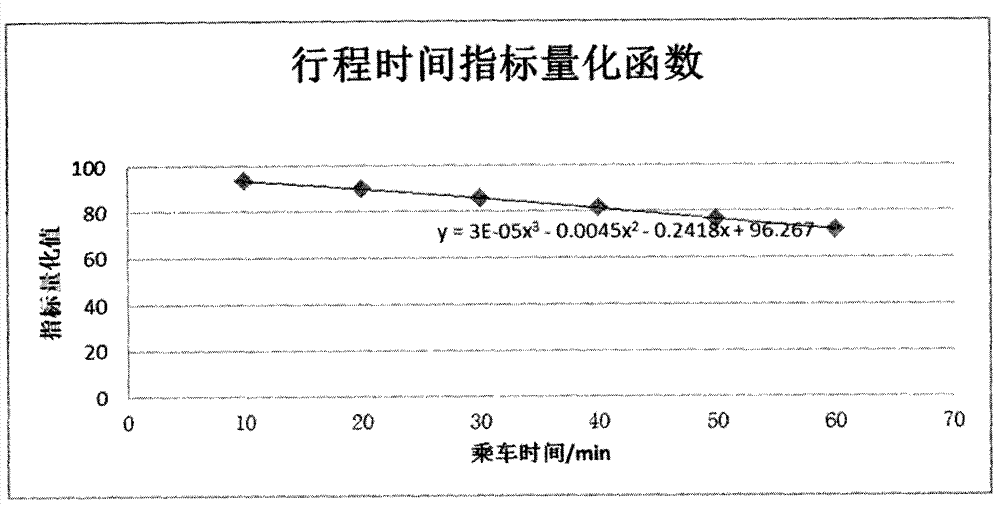

The invention discloses a method and a system for selecting a bus trip route. The method comprises the following steps of: selecting at least one of trip time Trt, waiting time Twt, crowdedness degree c and transfer frequency H as a factor considered in a trip scheme; inputting a starting point and a terminal point, determining possible trip schemes, and calculating the transfer frequency H of each trip scheme; establishing an analytic function of each factor according to collected trip data, and obtaining an index quantification value of each factor by employing a linear regression method; establishing a trip scheme analysis model; acquiring a comprehensive index quantification value F corresponding to each trip scheme; sorting the comprehensive index quantification values F according to a sequence from the highest to the lowest; and determining the highest value F to serve as the trip scheme.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method and system for optimizing business location selection

ActiveUS7797188B2Reducing resourceShorten the timeCharacter and pattern recognitionCommerceUnstructured dataComputer science

A method and system for making predictions about business locations. The method includes providing a spatial map and analyzing heterogeneous data having a spatial component to find utilizable data. Relationships are automatically extracted from the utilizable data. The step of automatically extracting relationships includes generating a composite indicator, which correlates spatial data with unstructured data. The extracted relationships are presented on a spatial map to make a prediction about at least one business location. Preferably, the predictions are presented as a rank-ordered list on the spatial map and a heat map overlays the spatial map to indicate predictions about particular regions.

Owner:SAAMA TECH LLC

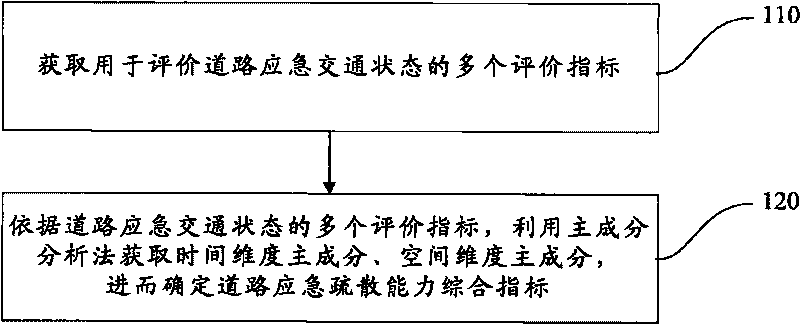

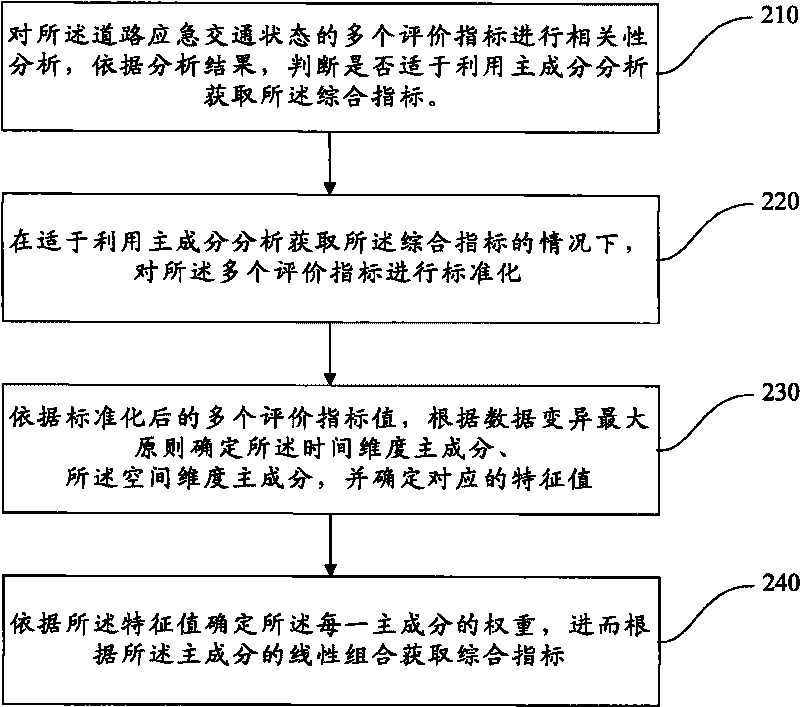

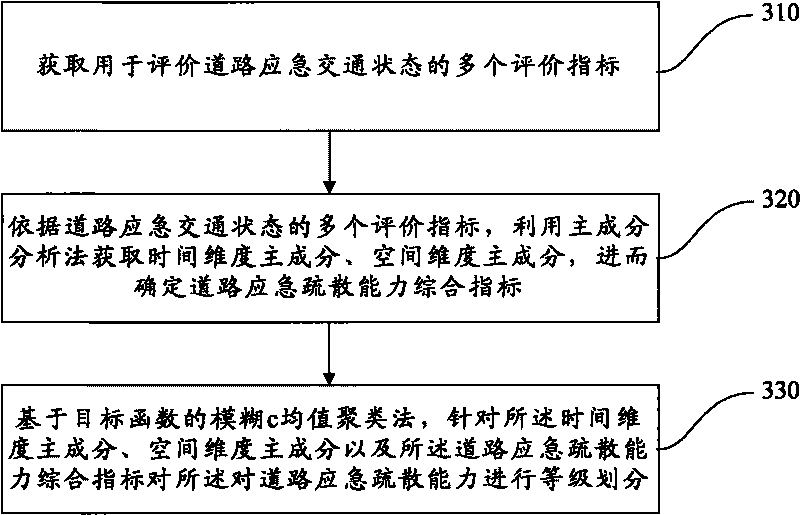

Method and system for evaluating road emergency evacuation capacity and method and system for grading road emergency evacuation capacity

The invention discloses a method and a system for evaluating road emergency evacuation capacity and a method and a system for grading the road emergency evacuation capacity. The method for evaluating includes steps of acquiring a plurality of evaluation indexes used for evaluating road emergency traffic states, acquiring a time dimension principal component and a space dimension principal component by aid of a principal analysis method according to the evaluation indexes of road emergency traffic states, and then determining integrated index of road emergency evacuation capacity. The method for evaluating utilizes the principal component analysis to process mass data and expresses the integrated index of road emergency evacuation capacity in incidents by aid of combination of the time dimension principal component and the space dimension principal component. The higher the integrated index is, the higher the corresponding road emergency traffic service level is, therefore, the method is more adaptable to evacuation and rescue of traffic flow in emergency.

Owner:BEIJING JIAOTONG UNIV

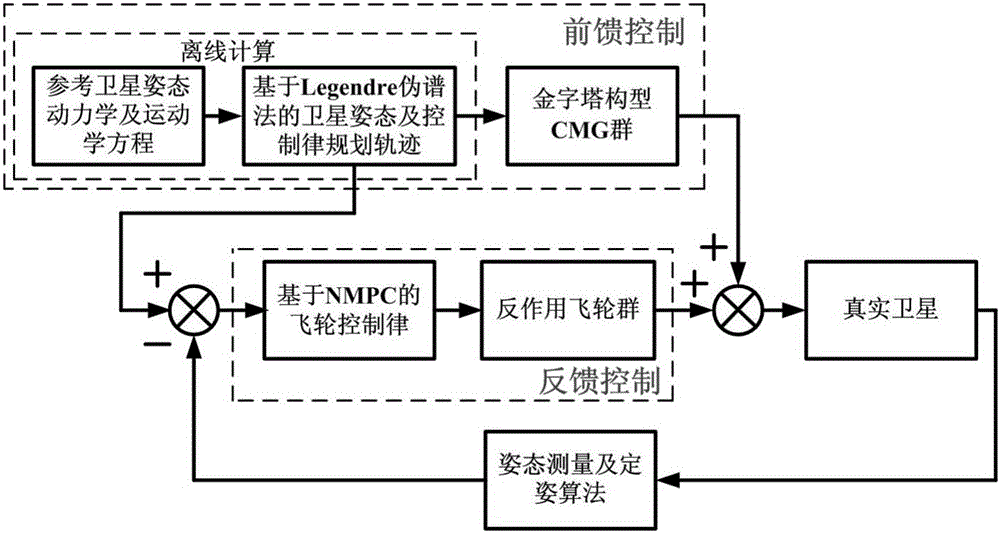

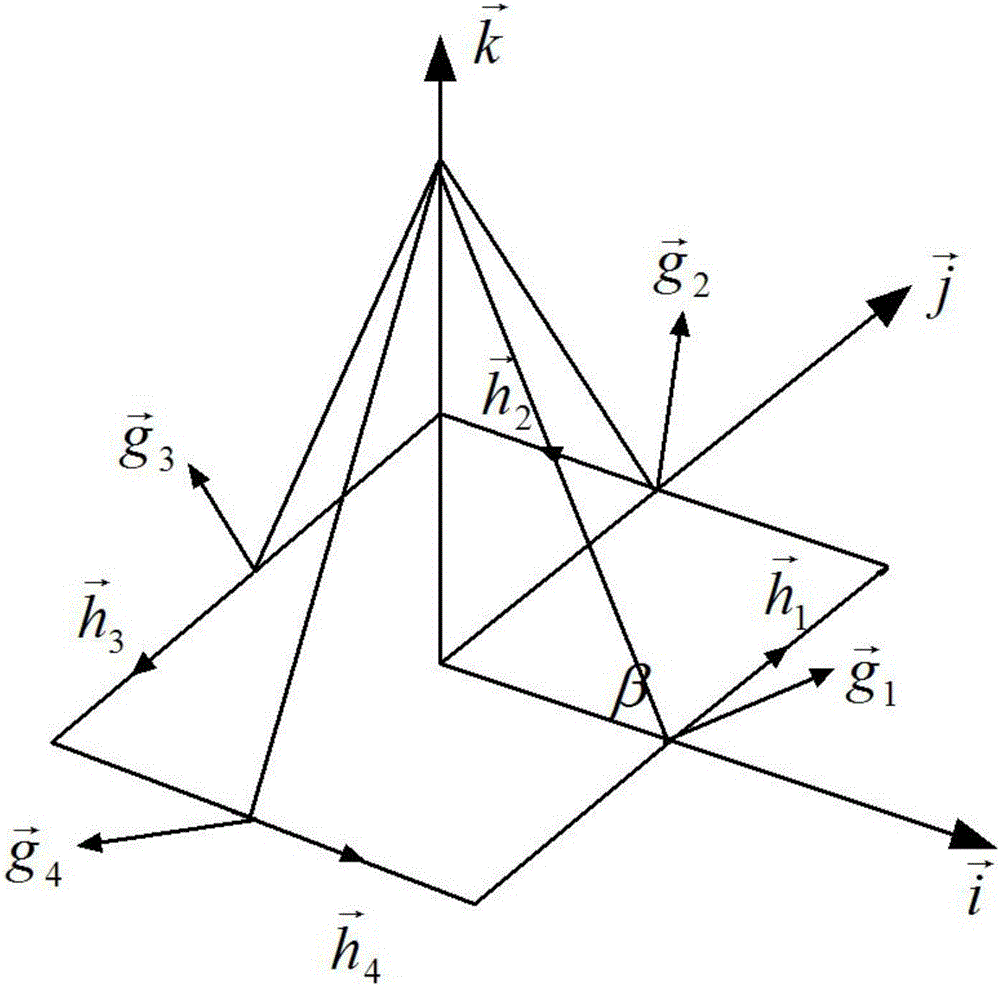

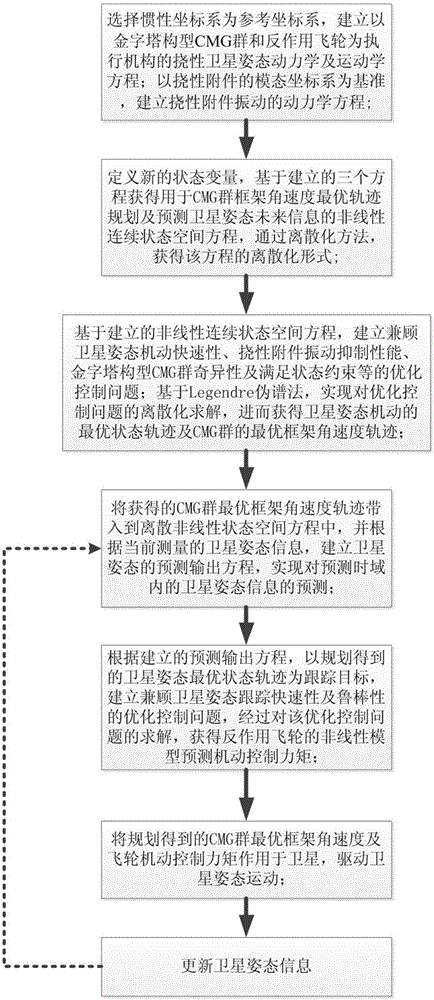

Control method for united actuating mechanism of flexible agile satellite

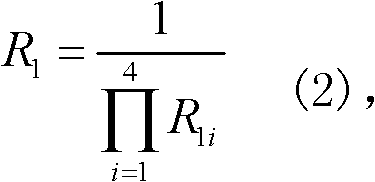

ActiveCN106218922AAccurate predictionCosmonautic vehiclesSpacecraft guiding apparatusSatelliteComposite indicator

The invention relates to a control method for a united actuating mechanism of a flexible agile satellite, relates to the technical field of satellite attitude control, and solves the problems that when rapid maneuver tracking control or high-precision tracking control is performed on the attitude of a conventional flexible satellite, the conventional flexible satellite has the characteristics that the conventional flexible satellite is high in nonlinearity and under multiple limits, and flexible accessories are easy to vibrate, so that control demands are difficult to meet. In accordance with the flexible agile satellite which is used for uniting two actuating mechanisms, and through the combination of the flexible satellite attitude dynamics, the kinematics and vibration equations of the flexible accessories, a nonlinear state-space equation which faces an optimum track programming of the attitude of the satellite and forecasts future attitude information is established; based on that composite indicators including attitude maneuver rapidity, flexible accessory vibration suppression, CMG group singularity and the like are established, and based on a pseudospectral method, the discretization of original continuous optimization problem is realized, and the optimum track of the maneuvering of the satellite attitude and the optimum track of the angular speed of a CMG group framework are calculated; and based on a nonlinear model predictive control technology, the control of a reaction flywheel is designed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

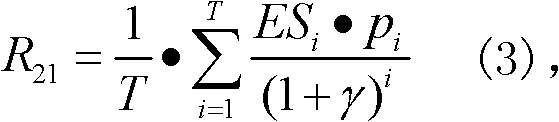

LCC theory-based method of comprehensive evaluation of transmission network planning scheme

InactiveCN102368314AComprehensive evaluationObjective evaluationData processing applicationsPower gridRisk index

The invention relates to an LCC theory-based method of comprehensive evaluation of a transmission network planning scheme. The method is characterized in that the method comprises the following steps that: step 1.1, according to power grid data published by an electric power company, calculation is respectively carried out on risk indexes Rs, efficiency indexes Es and LCC indexes Cs of N transmission network planning schemes by employing different computing methods; step 1.2, the risk indexes Rs, the efficiency indexes Es and the LCC indexes Cs of the N transmission network planning schemes are respectively substituted into a formula (1) to obtain N composite indicators RECs, wherein the formula is: REC= R + E + C (1) and the risk indexes Rs, the efficiency indexes Es and the LCC indexes Cs are obtained by the step 1.2; and step 1.3, comparison is carried out on the N composite indicators RECs that are obtained by the step 1.2; and a scheme that is corresponded to a composite indicator REC with a minimum numerical value is an optimum scheme and a scheme that is corresponded to a composite indicator REC with an infinite numerical value is an ineffective scheme. According to the invention, economy and technique rationality of a transmission network planning scheme as well as an influence on the environment can be evaluated comprehensively; and coordination optimization of the transmission network planning in the aspects of economy, technology and environmental protection can be realized.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER

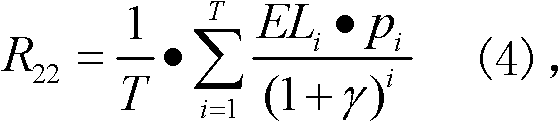

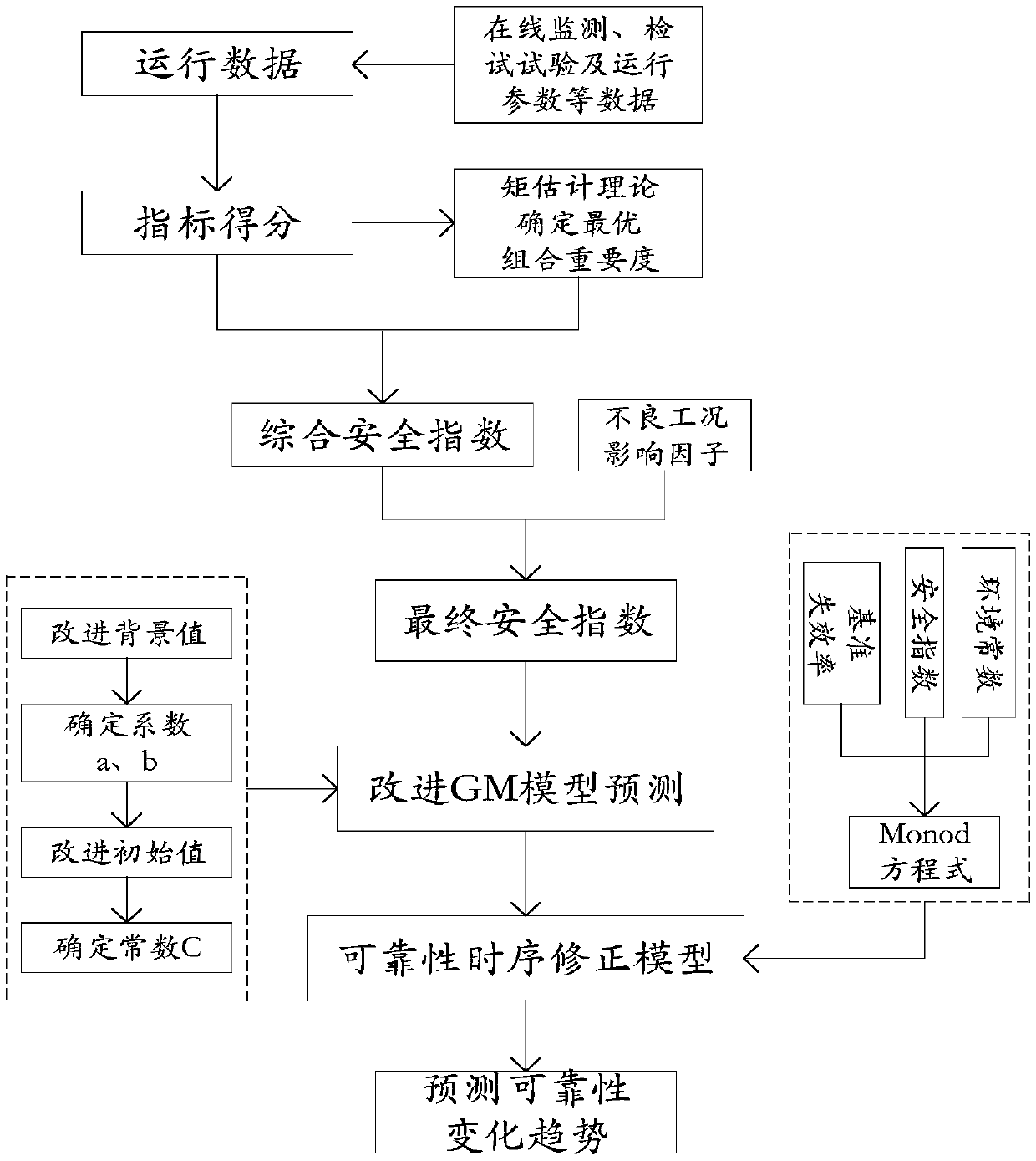

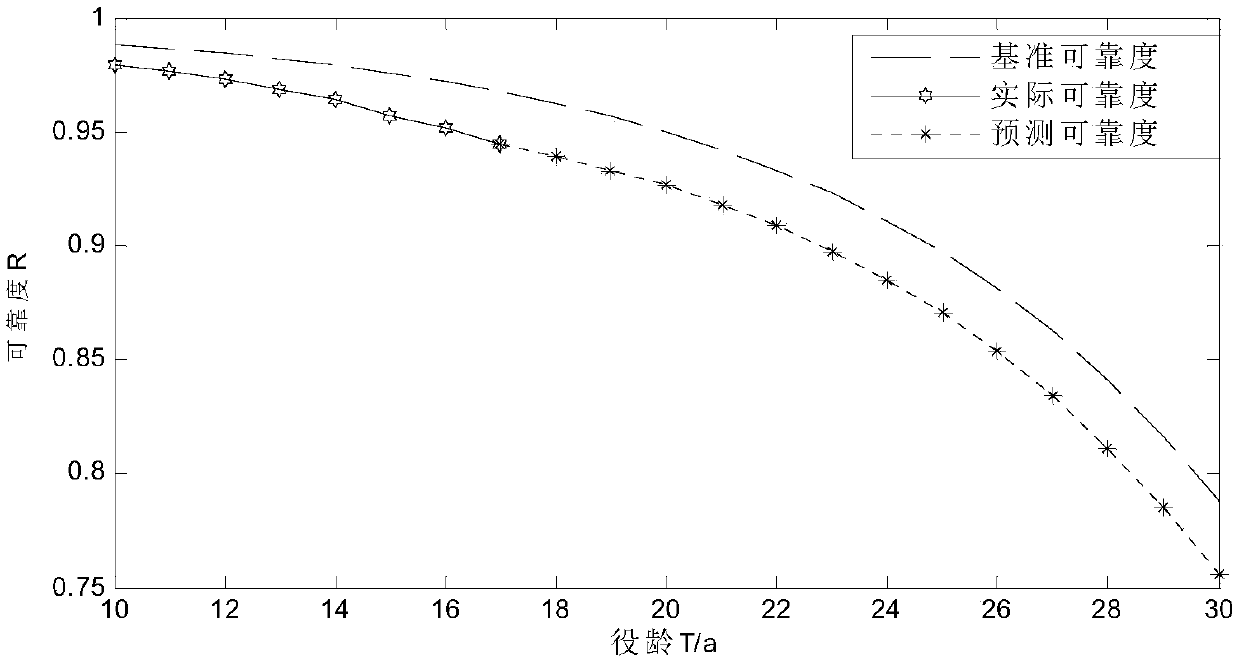

Transformer comprehensive reliability evaluation and prediction method based on operation data

ActiveCN109031014AImprove accuracyThe results have little deviationTransformers testingSafety indexTransformer

The invention provides a transformer comprehensive reliability evaluation and a prediction method based on operation data, and belongs to the technical field of power transformation equipment operation evaluation; According to the evaluation and the prediction method, a final safety index of the transformer operation evaluation model is obtained through establishing an evaluation index system of the operation reliability of the transformer, according to an optimal combination importance degree of the estimated theoretical comprehensive index, and correcting an influence factor of bad working condition; a future safety index of the transformer is predicted based on an improved GM model, and finally a future reliability changing trend of the transformer to be evaluated is predicted. According to the evaluation and the prediction method, a comprehensive and quantitative assessment of the index that affect equipment reliability is conducted by combining the real-time operation data, the deformation diagnosis test and the fault overhaul condition of the transformer,, and influence of timing characteristics of its operating state on reliability parameters is considered. Therefore, the reliability changing trend of the transformer equipment is more truly reflected, and further guidance is provided for maintenance work.

Owner:YICHANG POWER SUPPLY COMPANY OF STATE GRID HUBEI ELECTRIC POWER

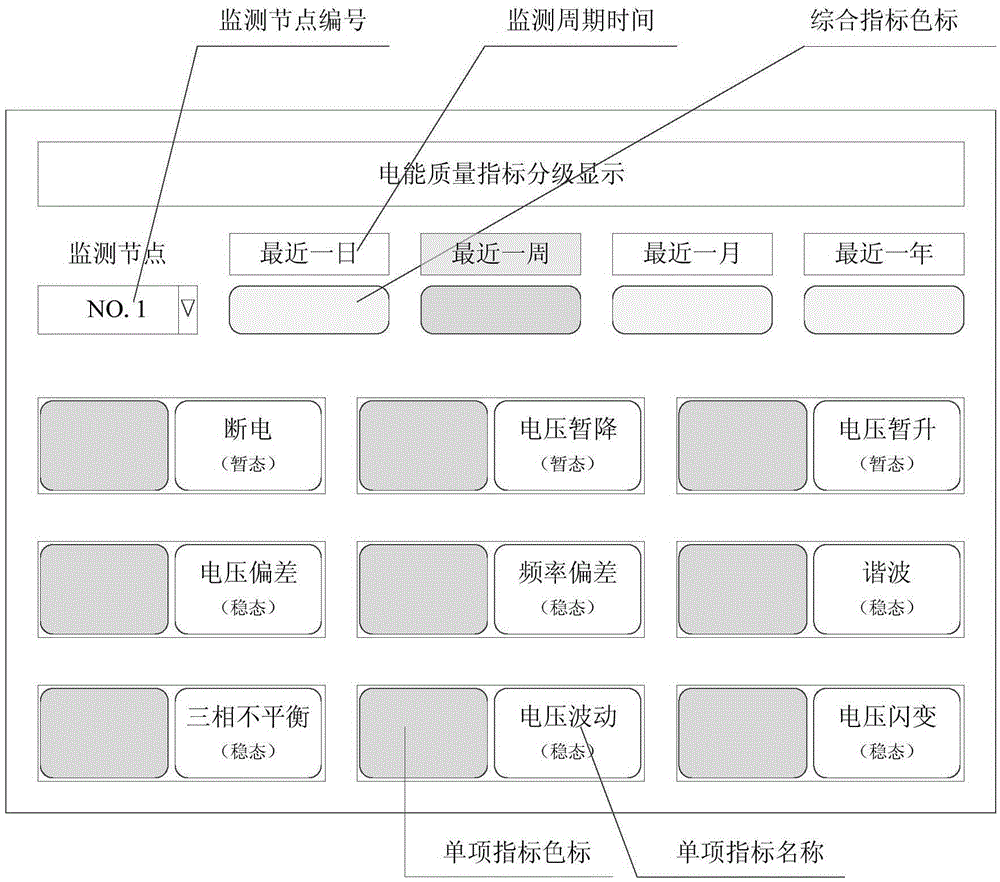

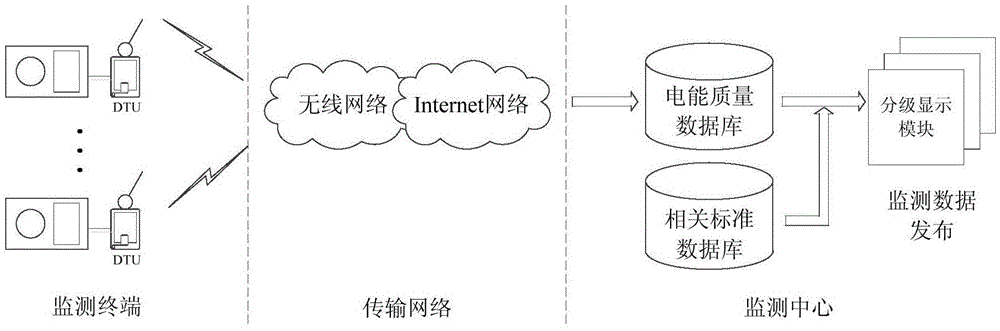

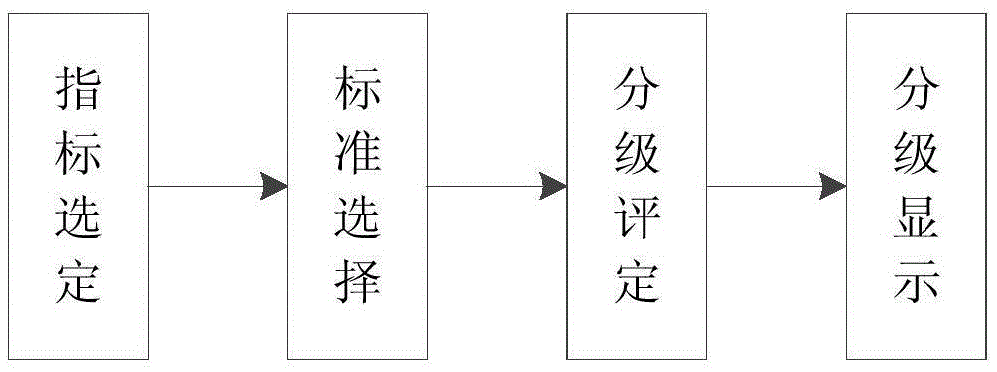

Index graded display method of port power grid electric energy quality monitoring system

The invention belongs to the electric energy quality evaluation technical field and provides an index graded display method of a port power grid electric energy quality monitoring system. According to the index graded display method, an electric energy quality index graded display module is additionally installed in a conventional power grid electric energy quality monitoring system; through digging electric energy quality monitoring data, the module displays the single indexes and comprehensive indexes of electric energy quality in a graded manner with the three colors of green, yellow and red according to the severity degree of the deterioration of the indexes based on reasonable evaluation schemes; when index display color marks are green, it is indicated that the indexes are normal and no adverse consequences will be generated; when the index display color marks are yellow which means warning, it is indicated that the indexes begin deteriorating, and can continue to operate, but the causes for deterioration needs to be checked; when the index display color marks are red which means out-of-limit, it is indicated that the indexes are seriously deteriorated and downtime maintenance is required to exclude faults causing index deterioration. Based on the electric energy quality graded display method of the monitoring system, electrical personnel can accurately understand the electric energy quality condition of each monitoring point of the power grid and influence on operating equipment by using networked computers and in a web form or a smart phone application form, and therefore, a guarantee can be provided for the safe operation of the port equipment and power grid.

Owner:SHANGHAI MARITIME UNIVERSITY

Strip-shaped time series data mining method based on data patterns

ActiveCN103341506AShorten adjustment timeHigh control precisionProfile control deviceOriginal dataAssociation rule hiding

The invention provides a strip-shaped time series data mining method based on data patterns. Data pre-processing is conducted on PDA monitoring data for cold-rolled sheet production, noise data, vacancy data and inconsistent data in original data are excluded; findings of a frequent item set and a plurality of item sets are conducted on data after being processed, and the frequent item set and the item sets are found out; association rule findings are conducted on the found frequency item set in the finding process of the frequency item set, and a potential association rules hidden in the data are found out. According to the method, because an average support degree and an average confidence coefficient threshold value are brought in and used in an Apriori algorithm, a significative frequency item set and association rules can be efficiently mined, insignificant data association can be effectively removed, a data basis can be provided for controlling of a high-precision strip shape, the adjustment time of the strip shape is greatly shortened, the control precision of the strip shape is improved, and the aggregative indicator of the strip shape is stably controlled to be within 5I.

Owner:ANGANG STEEL CO LTD

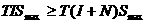

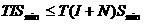

Underwater intelligent self-adapted terrain matching method based on terrain information amount

InactiveCN103743402AReduce utilizationOvercoming the defects of incomplete evaluationNavigational calculation instrumentsTerrainUnderwater navigation

The invention discloses an underwater intelligent self-adapted terrain matching method based on terrain information amount and mainly aims to solve the problems that the terrain information amount of an underwater navigation region is not sufficient or not complete so that the error of an aided navigation system is increased and the long-time accurate navigation and positioning requirements of an underwater vehicle cannot be met. The underwater intelligent self-adapted terrain matching method mainly comprises the following steps: calculating different terrain feature parameter values in the navigation region; calculating a terrain information amount aggregative index based on an intelligent method; and carrying out sampling time calculation and a self-adapted terrain matching algorithm based on a terrain information amount aggregative index value. According to the method, the problems that the terrain information amount of the underwater navigation region is not sufficient so that the error of the aided navigation system is increased and the single terrain feature index can cause the incomplete evaluation on the terrain information amount can be effectively improved; the intelligent method is used for comprehensively considering the influence of each index; the sampling time is adjusted by the terrain information amount in a self-adapted manner, the matching range is enlarged and the matching precision is improved.

Owner:SOUTHEAST UNIV

Method and system for optimizing business location selection

ActiveUS20080205768A1Reducing resourceShorten the timeCharacter and pattern recognitionCommerceUnstructured dataComputer science

A method and system for making predictions about business locations. The method includes providing a spatial map and analyzing heterogeneous data having a spatial component to find utilizable data. Relationships are automatically extracted from the utilizable data. The step of automatically extracting relationships includes generating a composite indicator, which correlates spatial data with unstructured data. The extracted relationships are presented on a spatial map to make a prediction about at least one business location. Preferably, the predictions are presented as a rank-ordered list on the spatial map and a heat map overlays the spatial map to indicate predictions about particular regions.

Owner:SAAMA TECH LLC

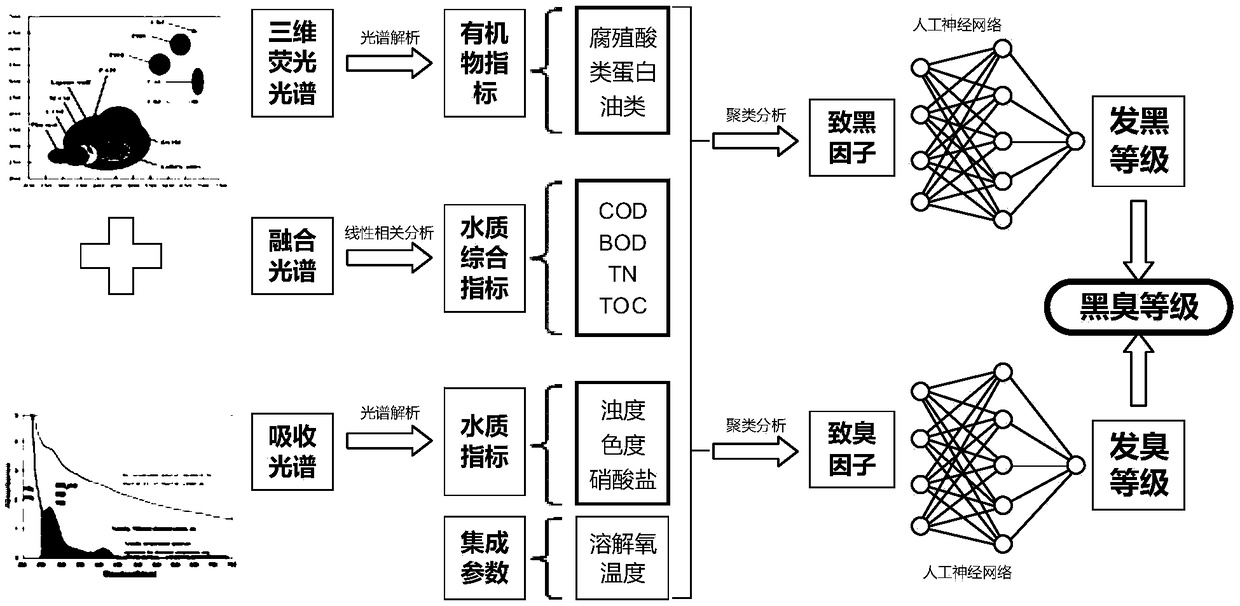

Method for rapidly identifying and determining black and odor of urban water body based on multi-source spectral characteristics

PendingCN109142296AOvercoming single monitoring indicatorsOvercoming the lack of organic indicatorsColor/spectral properties measurementsFluorescence/phosphorescenceTurbidityRapid identification

The invention discloses a method for rapidly identifying and determining the black and odor of an urban water body based on multi-source spectral characteristics. A three-dimensional fluorescence spectrum is used for analyzing concentrations of humic acid, albumin and oil black and odor precursors in the water body, and a UV-visible absorption spectrum is utilized for analyzing and obtaining waterquality parameters of turbidity, chroma and nitrate black and odor and other related parameters, and water quality comprehensive indexes of COD, BOD and TOC are obtained by using fluorescence spectrum and absorption spectrum fusion inversion; combining dissolved oxygen and water temperature parameters, a water body black and odor grade measurement algorithm model is established based on data driving through testing and training of different types of water bodies in a plurality of cities, and the rapid identification and determination of the black odor grade of the water body is achieved. Themethod solves the problems of 'single monitoring index, organic index missing and ammonia nitrogen sampling and off-line measuring' in a water body black and odor monitoring method specified in Guideto Regulation of Urban Black and Odor Water Bodies, has the advantages of no reagent, no need of sample pretreatment, rapid measurement and the like, and is a rapid and effective method for measuringthe black and odor of water bodies.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

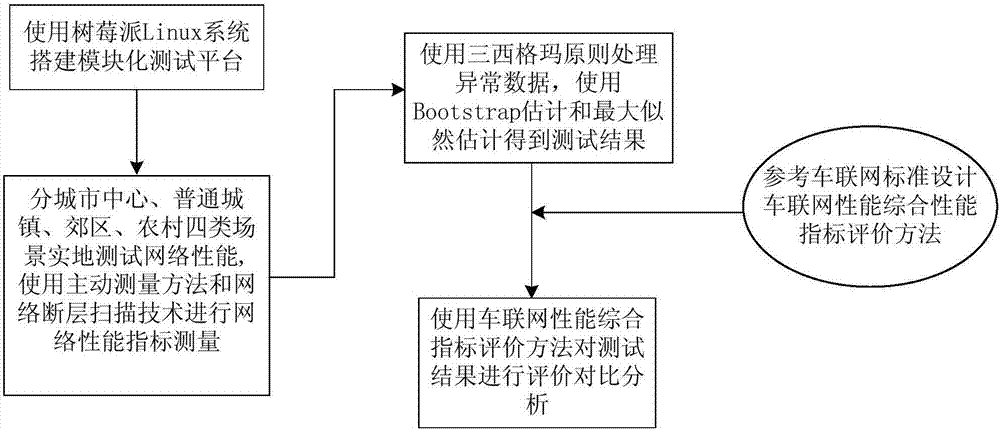

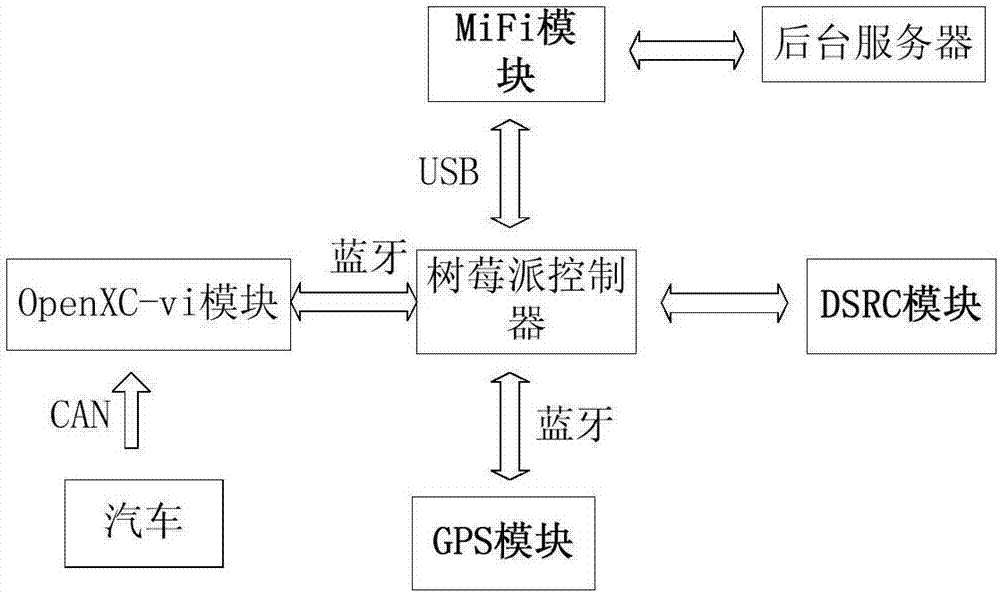

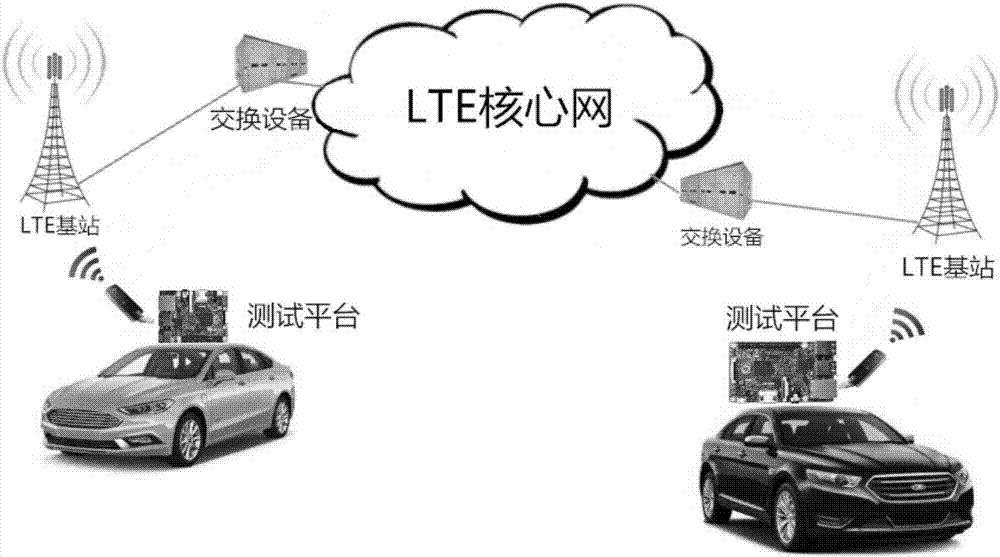

Internet-of-vehicles environment oriented network performance comprehensive testing and evaluating analysis method

ActiveCN106961366AAccurate time delayAccurate Packet Loss RateData switching networksThe InternetTest platform

The invention discloses an Internet-of-vehicles environment oriented network performance comprehensive testing and evaluating analysis method which comprises the following steps of 1, establishing a testing platform which comprises a first testing board, a second testing board and a background server, wherein the first testing board and the second testing board are respectively used for network performance testing and vehicle driving information acquisition, and the background server is used for data storage, analysis and processing; 2, in different testing scenes, testing a network performance index by means of an active measuring method and network tomography; 3, performing abnormal data processing on testing data according to a 3-sigma principle, and obtaining a testing result by means of Bootstrap estimation and maximum likelihood estimation; and 4, performing evaluation and comparative analysis on the testing result by means of an Internet-of-vehicles performance comprehensive index evaluation method. The Internet-of-vehicles environment oriented network performance comprehensive testing and evaluating analysis method can realize comprehensive network performance measurement on the Internet-of-vehicles and can more visually and more effectively reflect network performance and change.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

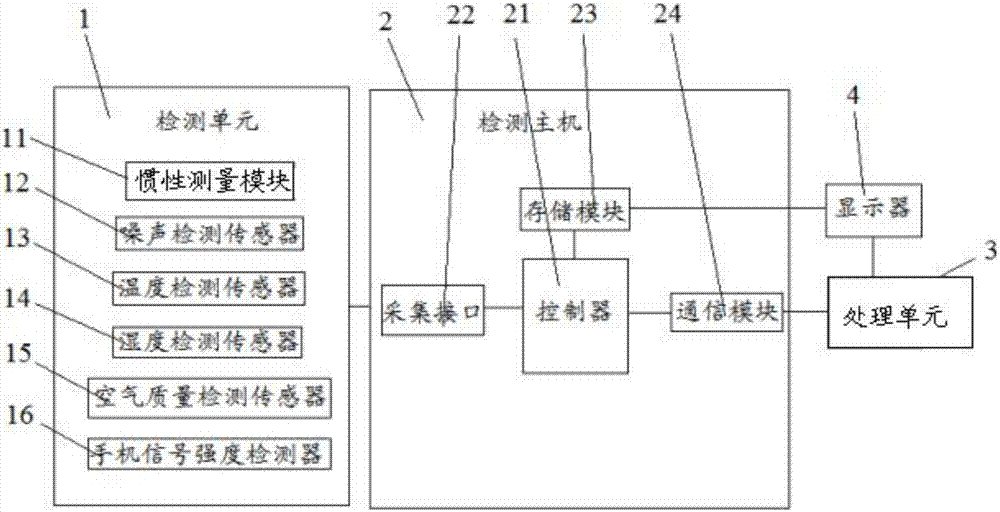

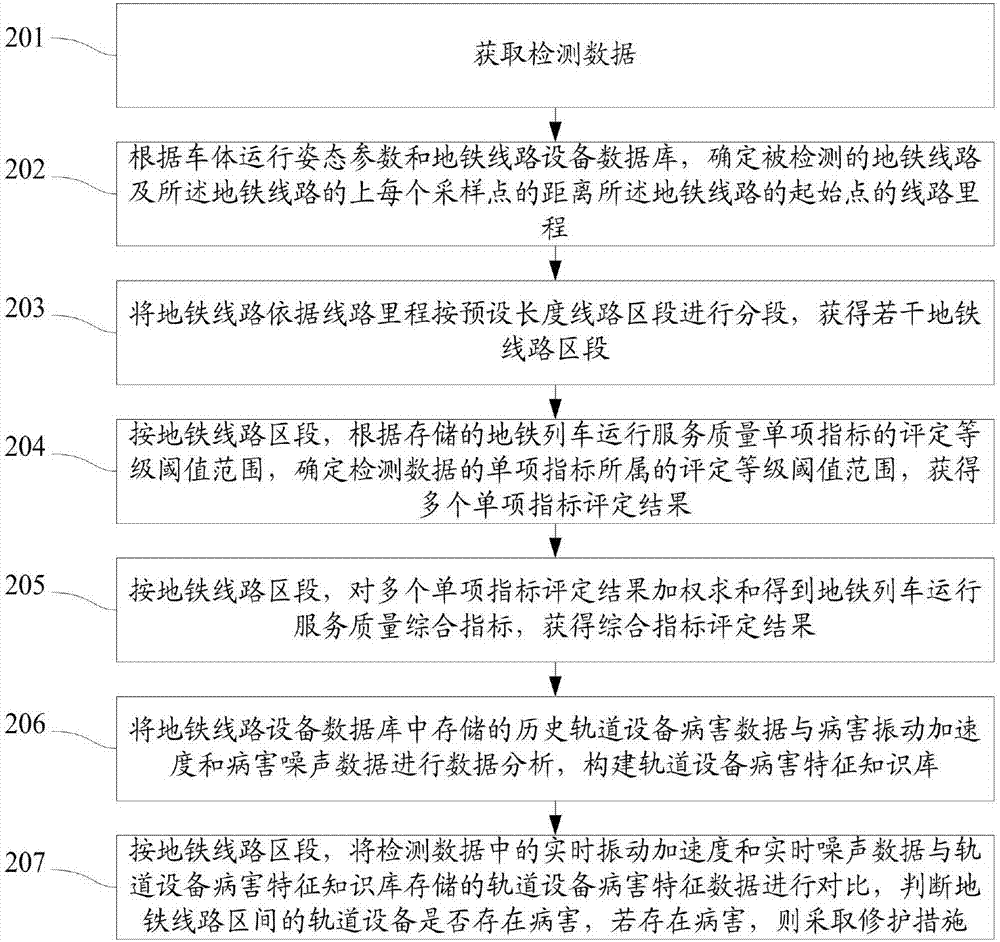

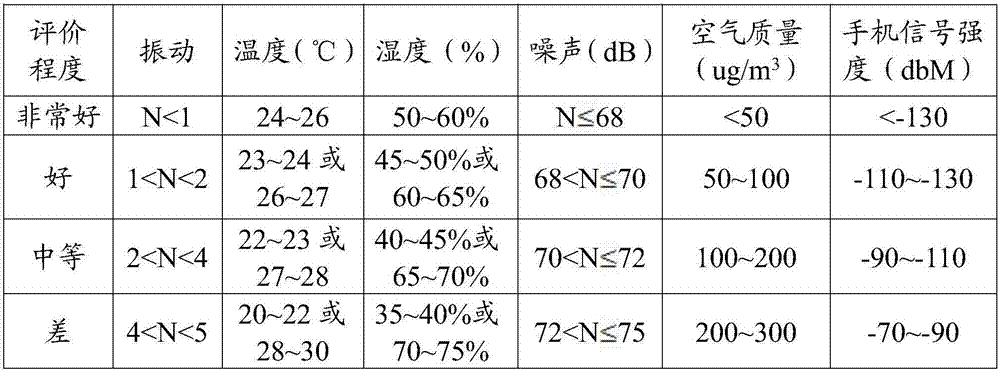

Subway train operation service quality detection apparatus and method thereof

ActiveCN106960285AAchieving Vibration ComfortAchieving Thermal ComfortResourcesSingle measureEngineering

The invention discloses a subway train operation service quality detection apparatus and a method thereof. The apparatus comprises a detection unit, a detection host and a processing unit, wherein the detection unit includes an inertial measurement module and the detection unit is used for collecting a train body operation attitude parameter, a noise in a carriage, a temperature, humidity, air quality and a mobile phone signal intensity; the detection host is connected to the detection unit in a communication connection mode and is used for acquiring data collected by the detection unit; and the processing unit is connected to the detection host in the communication connection mode, and is used for receiving and storing data transmitted by the detection host, calculating a position parameter of a subway line where the detection apparatus is located according to the data, carrying out single index and integration index evaluation on subway train operation service quality, and carrying out data contrast analysis, data trend analysis, space position analysis, line equipment association analysis and subway line track disease analysis. In the invention, space positioning precision of subway train operation service quality analysis evaluation and objectivity of an analysis result are increased, and a convenient technology means is provided for subway train service quality management and monitoring.

Owner:BEIJING JIAOTONG UNIV

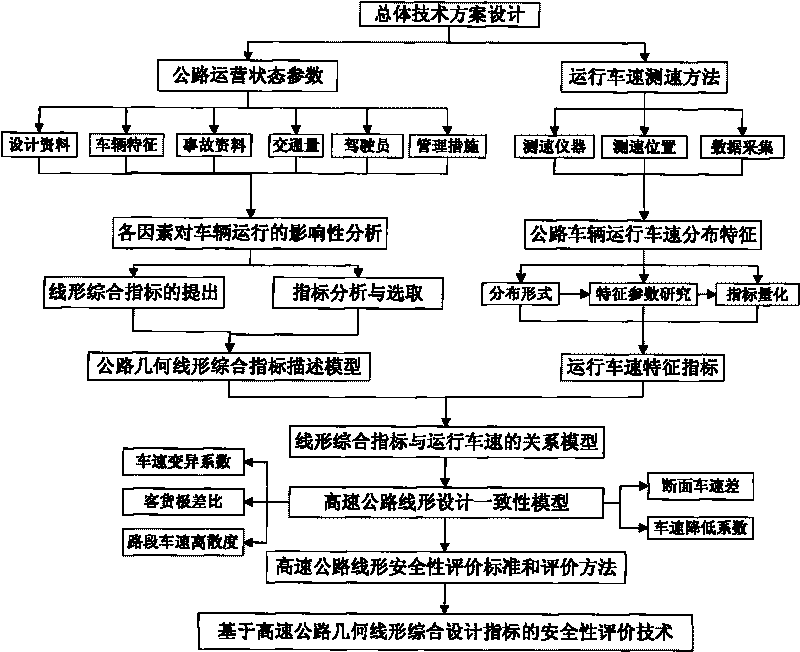

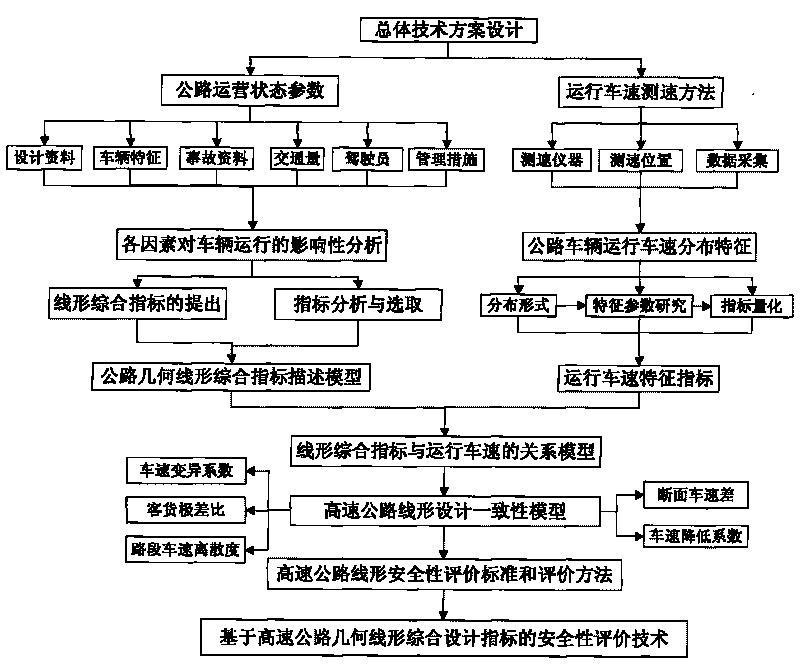

Safety detection method based on freeway geometry linear comprehensive technical indexes

InactiveCN101694745AOvercome limitationsAvoid difficultiesDetection of traffic movementEngineeringFeature parameter

Owner:TONGJI UNIV

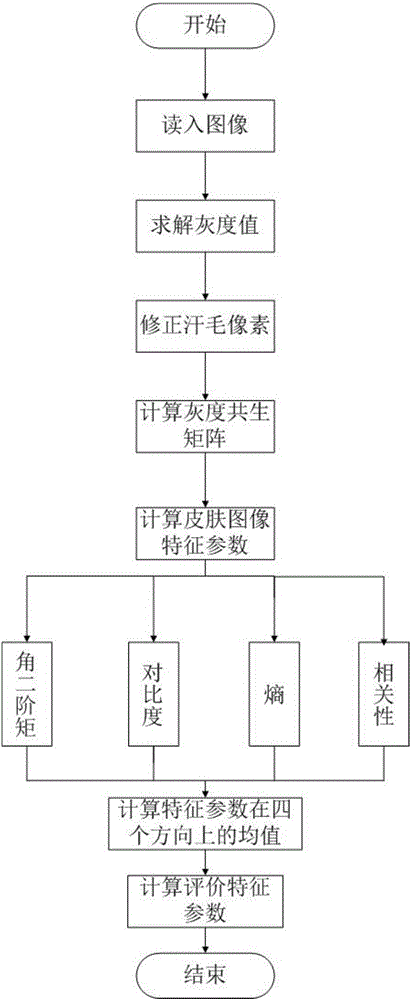

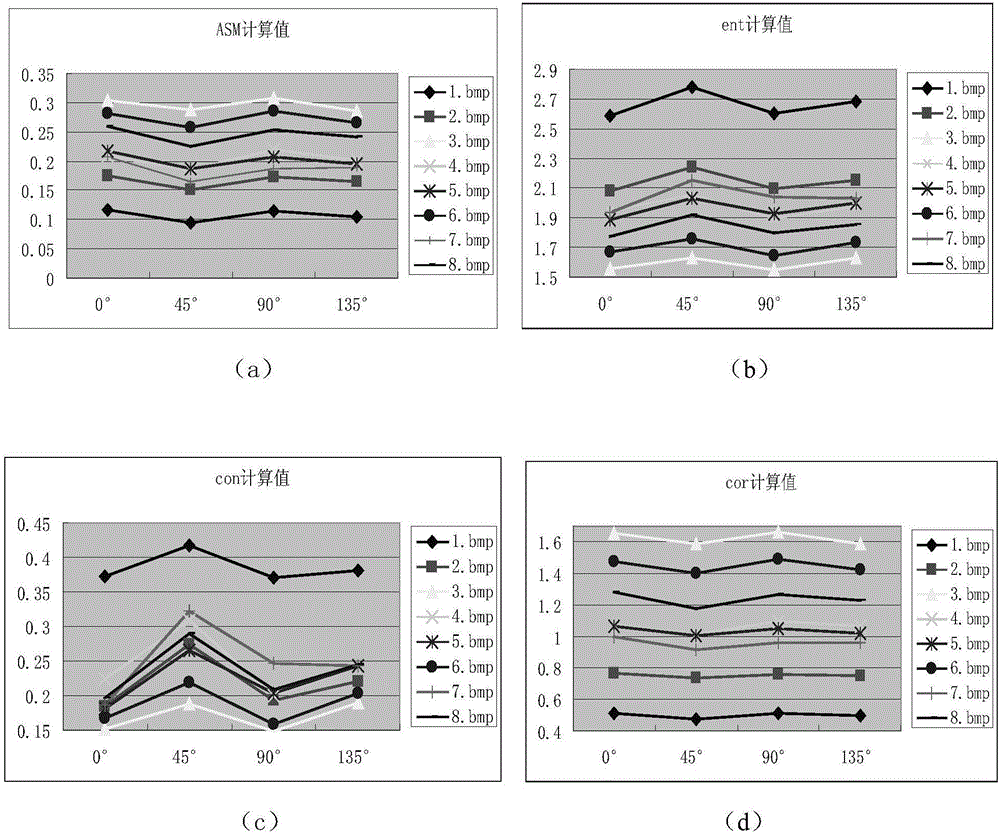

Skin condition quantitative evaluation method based on gray level co-occurrence matrix

InactiveCN106600585AAvoid stimulationAvoid harmImage enhancementImage analysisEvaluation resultSkin texture

The invention discloses a skin condition quantitative evaluation method based on a gray level co-occurrence matrix. The method mainly comprises the following steps: reading a human skin image acquired by a high-definition camera instrument; calculating the average gray level of the skin image; correcting hair pixels; calculating a gray level co-occurrence matrix; calculating the feature parameters of the skin image according to the gray level co-occurrence matrix, including angular second moment, contrast, entropy and correlation; calculating the comprehensive index of skin condition; and finally, comprehensively evaluating the skin image according to the calculation result. The gray level co-occurrence matrix based on the skin image and the feature parameters of the skin image can truly and objectively reflect the condition and physical properties of skin. The comprehensive index can be used to quantitatively analyze and evaluate the skin texture. The evaluation result is basically the same with the trend of effect based on biochemical detection. A quantitative, fast, scientific and convenient evaluation method is realized. The method can be used to quantitatively analyze and evaluate the state of skin.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

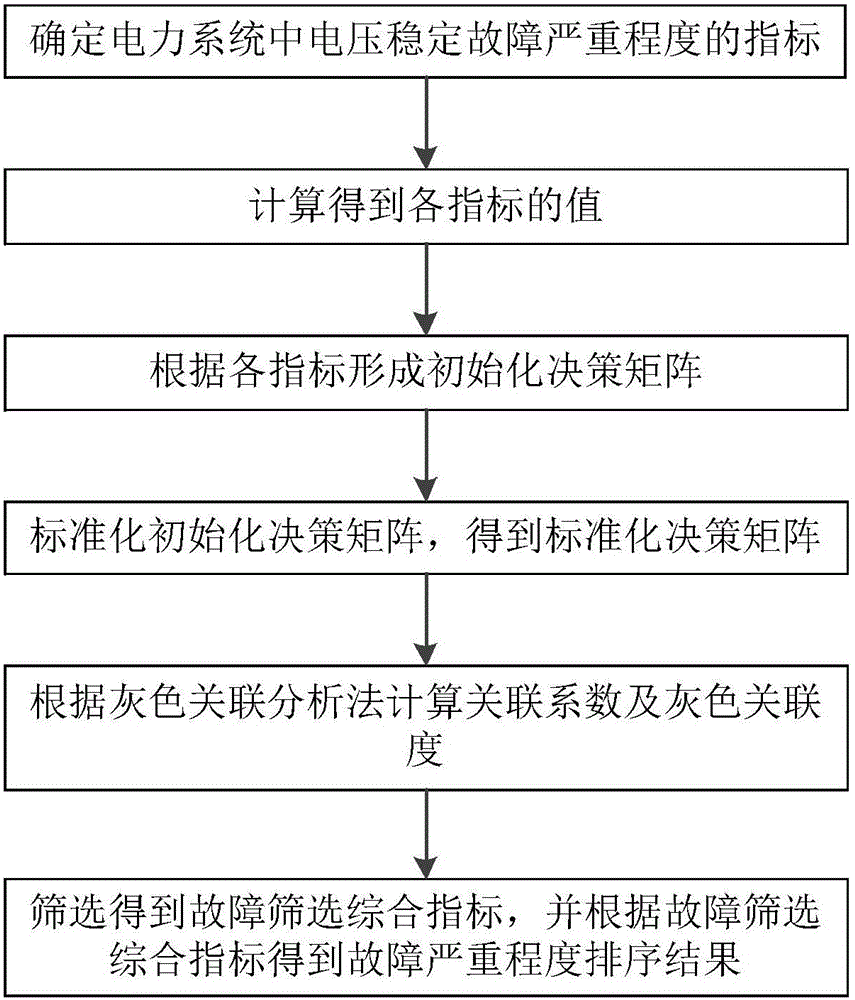

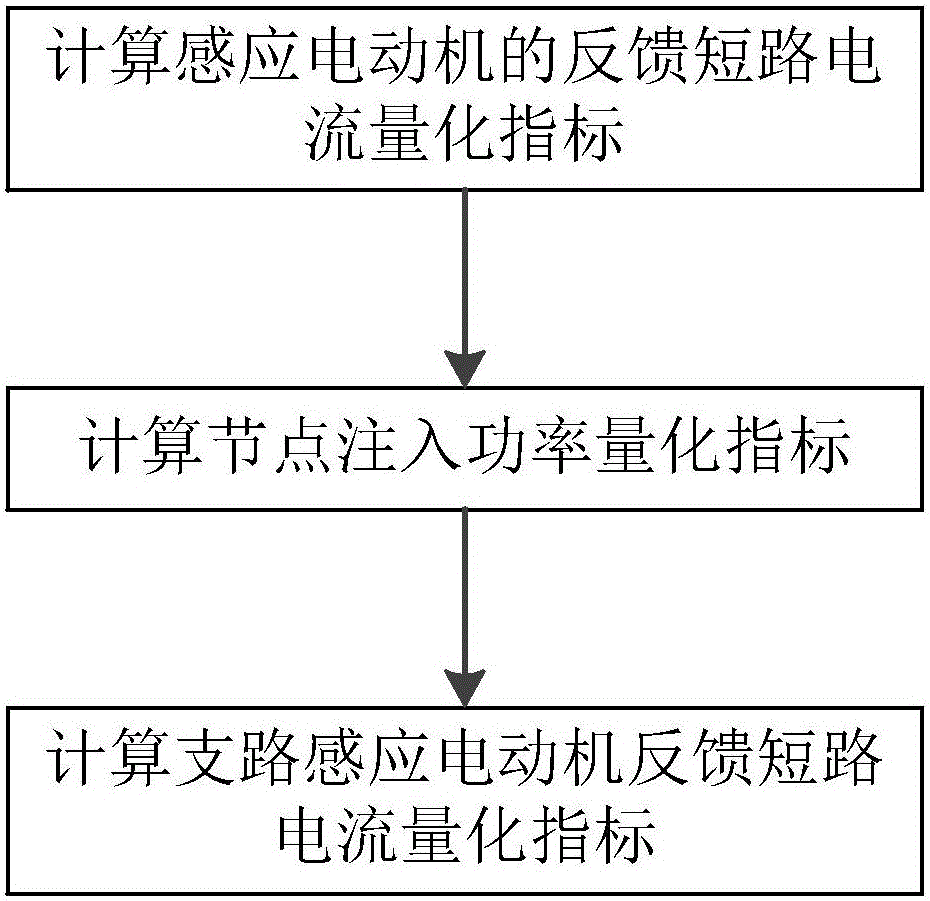

Voltage stabilization fault screening and ranking method based on grey correlation analysis method

ActiveCN106056265AEfficient screeningResourcesReactive power compensationGrey correlation analysisCorrelation coefficient

The invention provides a voltage stabilization fault screening and ranking method based on a grey correlation analysis method, which comprises the steps of determining indexes for the severity of voltage stabilization faults in an electric power system; calculating to acquire values of the indexes; forming an initialization decision-making matrix according to the indexes; standardizing the initialization decision-making matrix to acquire a standardization decision-making matrix; calculating a correlation coefficient and a grey correlation degree according to the grey correlation analysis method; and screening to acquire a fault screening comprehensive index, and acquiring a fault severity ranking result according to the fault screening comprehensive index. The method provided by the invention reflects fault severity conditions more comprehensively and more effectively, thereby being convenient for the operating and scheduling personnel to take correspondingly prevention and correction measures timely, reducing influences imposed on power grid voltage stabilization by accident disturbance, and having important significance for guiding reliable running of an actual power grid.

Owner:STATE GRID CORP OF CHINA +4

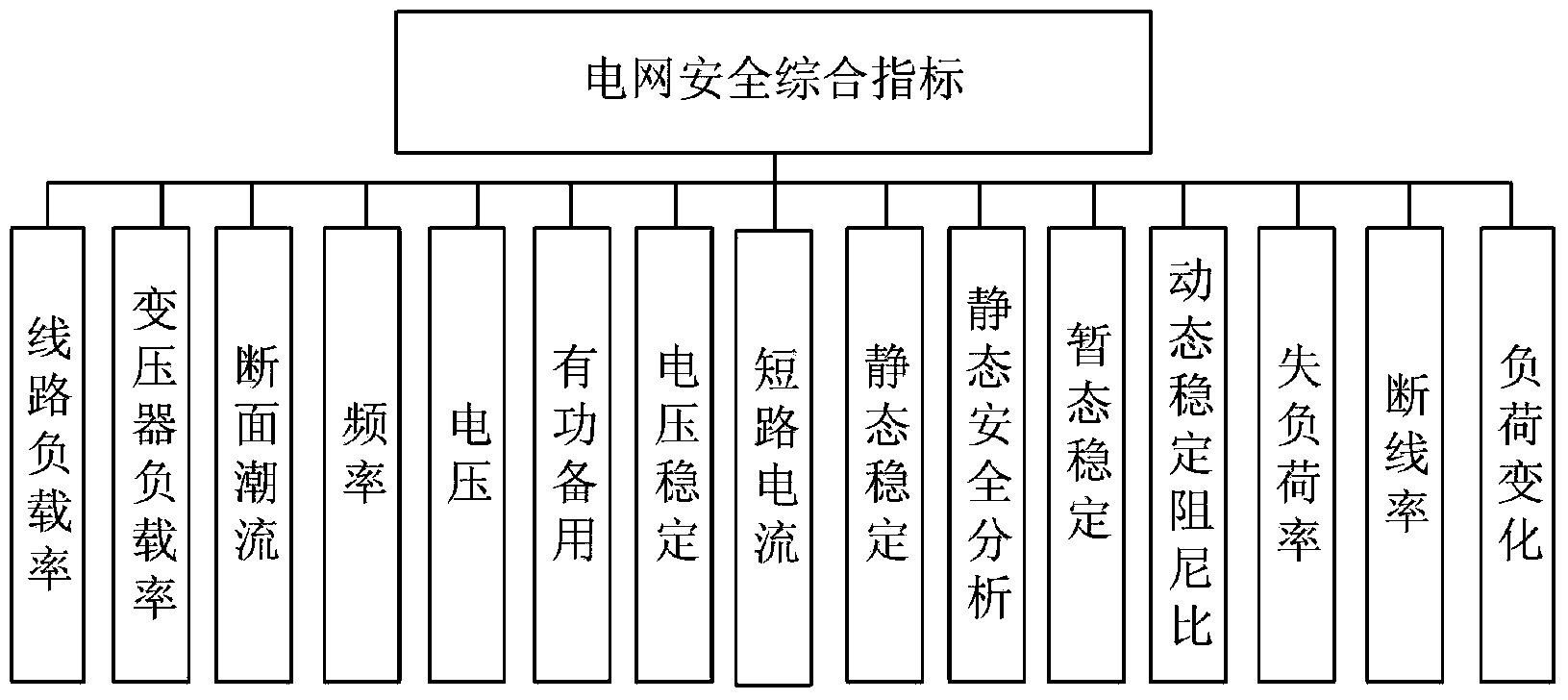

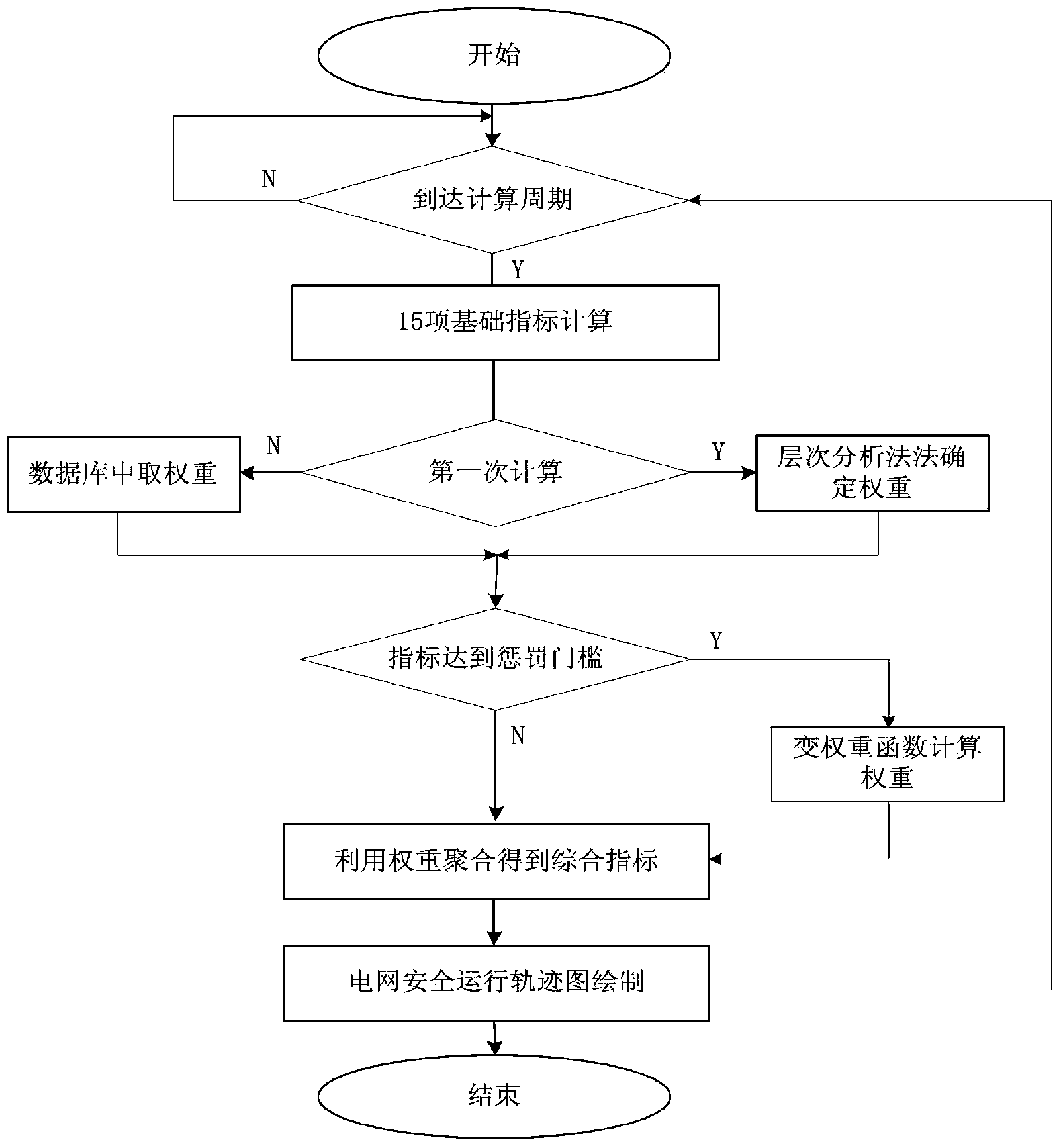

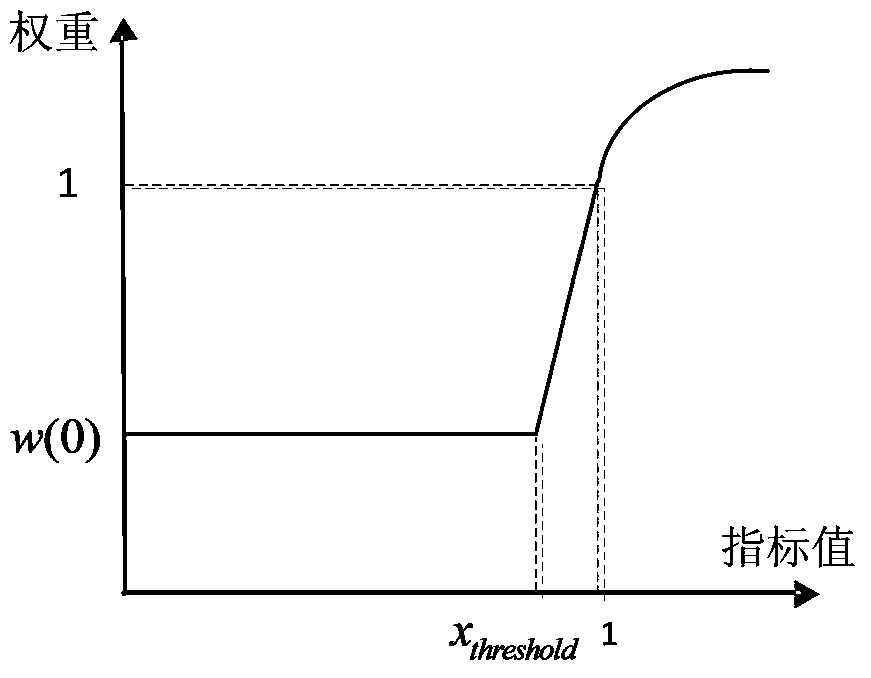

Determination method for power grid safety aggregative indicators

ActiveCN104252686AImprove rationalityImprove applicabilityData processing applicationsSafety indicatorsPower grid

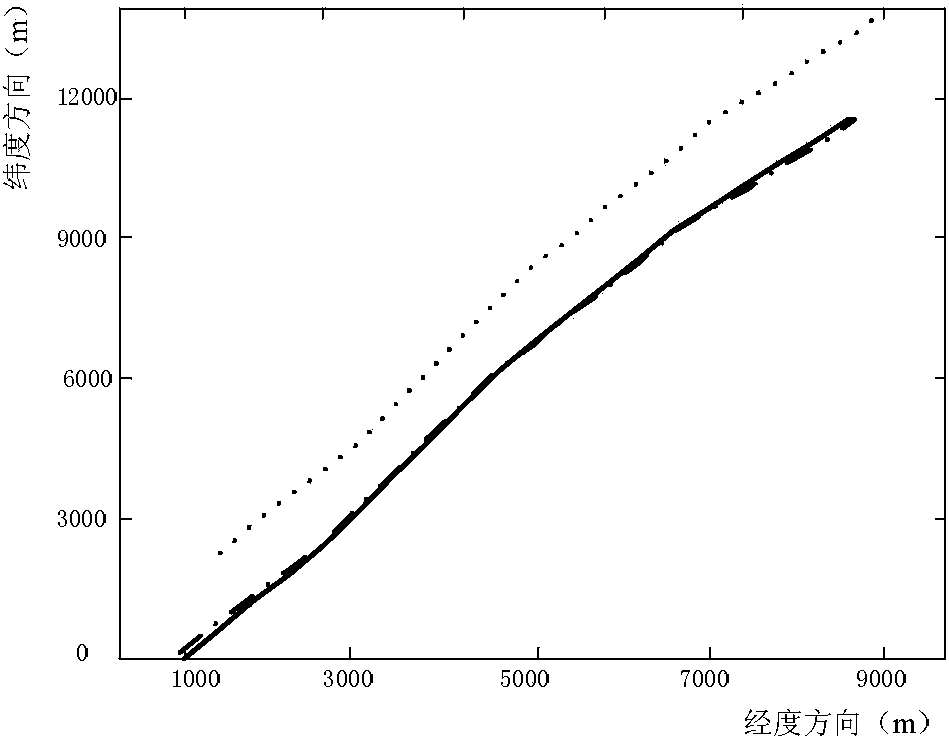

The invention relates to a determination method for power grid safety aggregative indicators. The method comprises the following steps: selecting 15 power grid safety basic indicators according to an actual power grid research result; determining a calculation formula by combining indicator constitutive property, indicator adaptability and dimension consistency; calculating initial weight of the 15 safety basic indicators under the aggregative indicators by adopting an analytic hierarchy process; revising the obtained weight of the step (2) by using a variable weight penalty function; calculating the power grid safety aggregative indicators by using the final weight; carrying out safety grade division and exhibition on a power grid operation state; drawing a power grid safety indicator movement track map. According to the determination method, the power grid safety basic indicators are screened in view of engineering functionization and the calculation formula is designed; the variable weight penalty function is introduced on the basis of obtaining all the weights by the analytic hierarchy process to be used for revising heavy-load or out-of-limit indicator weights, and current and future situations of a power grid are determined; a direct power grid situation monitoring means is provided for schedulers by the power grid safety indicator movement track map.

Owner:STATE GRID CORP OF CHINA +3

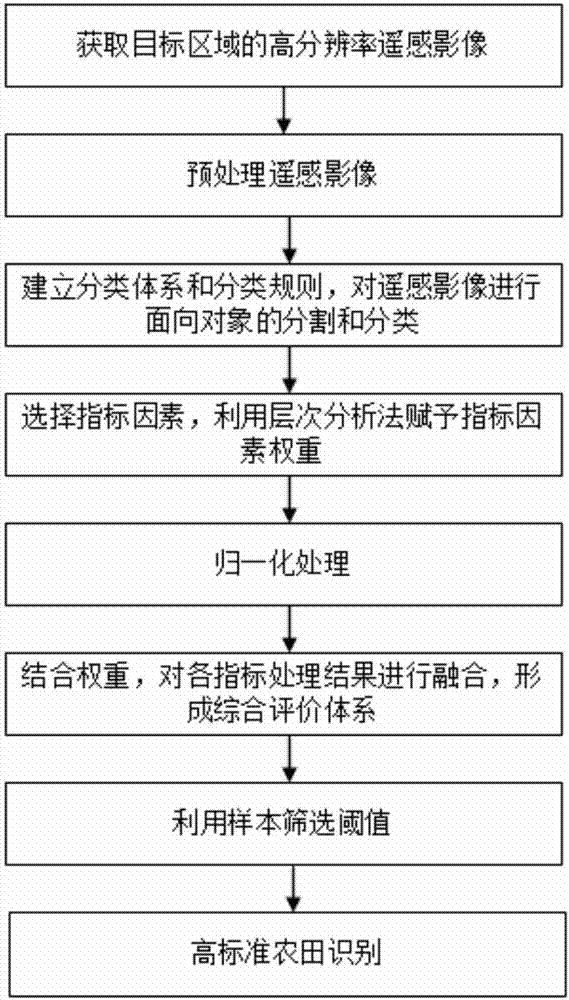

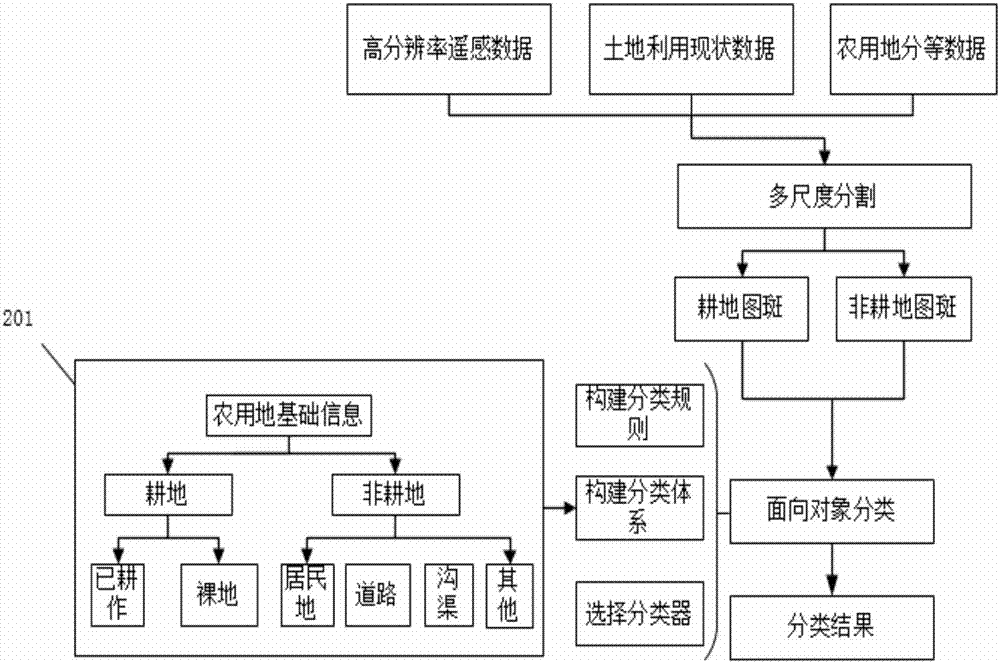

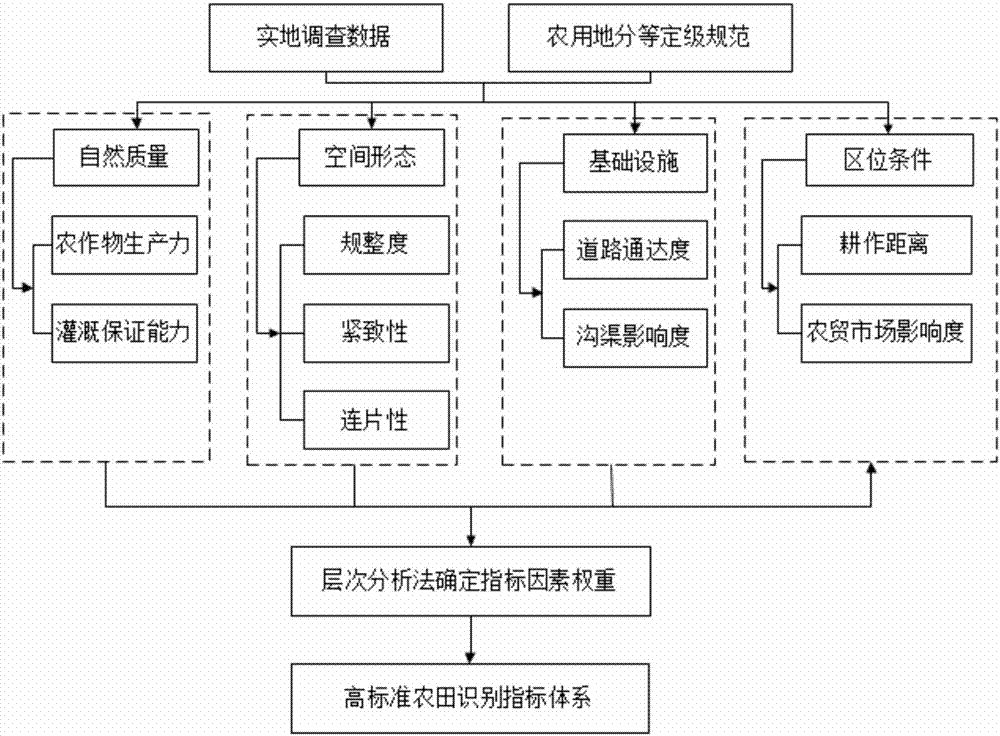

High-standard farmland recognition method based on high-resolution remote sensing image

InactiveCN107103305AQuick identificationThe recognition result is accurateCharacter and pattern recognitionComputer scienceRemote sensing

The invention provides a high-standard farmland recognition method based on a high-resolution remote sensing image. The method comprises the steps: obtaining two high-resolution remote sensing images of a target region; carrying out the preprocessing of the remote sensing images; carrying out the object-oriented classification of the two high-resolution remote sensing images after preprocessing; carrying out the superposing of the two classification results, and forming plough map spot vector data; carrying out the normalization processing of a determination index value through employing an extreme difference normalization method; carrying out the processing of the plough map spot vector data through a selected index, carrying out the fusion processing of the normalization processing result through combining with the index weight, and forming a final comprehensive index processing result; selecting samples at a high-standard farmland construction base through a grid method, calculating a plurality of high-standard farmland sample point indexes, screening out a proper threshold value, judging whether the farmland belongs to a standard farmland or not, and completing the recognition of the high-standard farmland. The method achieves the recognition of the high-standard farmland based on the high-resolution remote sensing images, is accurate in recognition result, and is quick and reliable. The method achieves the effective monitoring of the high-standard farmland, and serves for a land planning department.

Owner:XIAN UNIV OF SCI & TECH

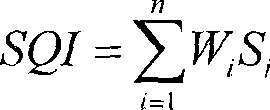

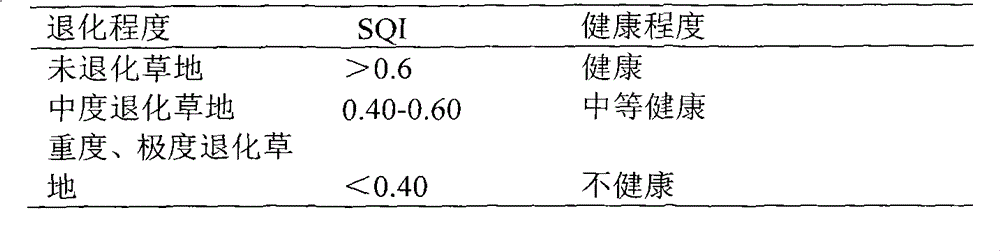

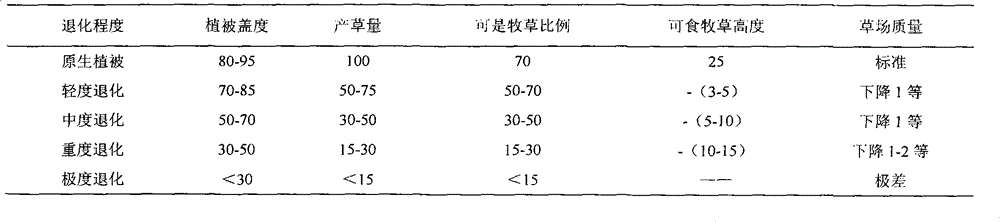

Alpine grassland soil health evaluation method based on physical, biological and chemical composite indicators

InactiveCN103065043AEasy accessEasy to acceptSpecial data processing applicationsPlant communityGrassland

An alpine grassland soil health evaluation method based on physical, biological and chemical composite indicators evaluates the alpine grassland degeneration degree by aid of a grassland degeneration index on the basis of visualized vegetation indicators. The grassland degeneration index (GDI) is composed of the integer bit and an effective figure at the bit after the decimal point, and the structure is that GDI=(100-C)*28%+(100-P)*39%+(70-E)*26%+(25-H)*7%, wherein C indicates the cover degree, P indicates grass yield proportion, E indicates edible forage grass proportion, and H indicates edible forage grass height. The GDI index can be calculated simply by measuring the cover degree, the biomass, the edible forage grass amount and the edible forage grass height of a plant community in practical application. The alpine grassland degeneration degree is judged according o the DGI index: when the DGI index is smaller than 13.9, the grassland is not degraded; when the DGI index ranges from 13.9 to 33.5, the grassland is slightly degraded; when the DGI index ranges from 33.5 to 52.4, the grassland is moderately degraded; when the DGI index ranges from 52.4 to 68.4, the grassland is seriously degraded; and when the DGI index is larger than 68.4, the grassland is extremely degraded. The alpine grassland soil health evaluation method can completely display the grassland degeneration condition information and can qualitatively and quantitatively evaluate the alpine grassland degeneration degree.

Owner:BEIJING NORMAL UNIVERSITY

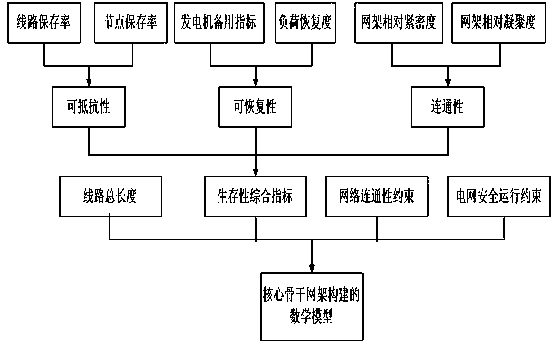

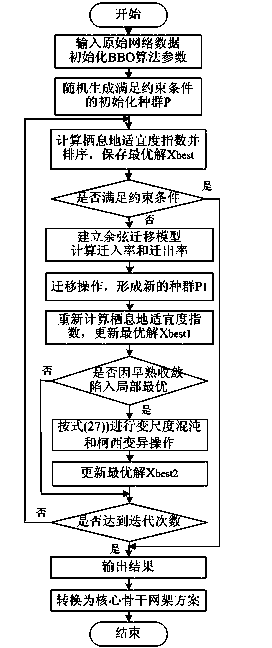

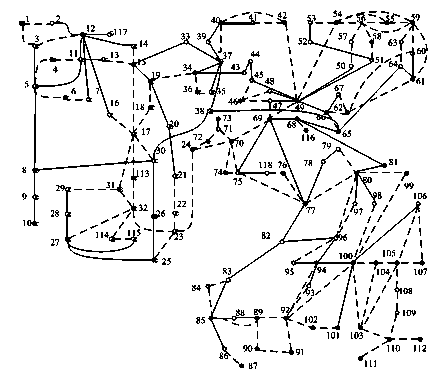

Method for constructing core backbone grid structure based on BBO algorithm and power grid survivability

ActiveCN103366062AImprove economyTaking into account resistanceData processing applicationsSpecial data processing applicationsSurvivabilityMathematical model

The invention discloses a method for constructing a core backbone grid structure based on BBO algorithm and power grid survivability. The method comprises the following steps: establishing a survivability index system taking the resistance, recoverability and connectivity of a power grid into consideration, and determining an integrated survivability index of the power grid system according to the survivability index system; step 2, using the minimum total length of a circuit and the maximum integrated survivability index as an objective function to construct a mathematical model of the core backbone grid structure; step 3, using a biogeography optimization algorithm to search the mathematical model of the core backbone grid structure and construct the core backbone grid structure of the power grid system. The method can quickly and accurately obtain a reasonable solution to the core backbone grid structure.

Owner:WUHAN UNIV

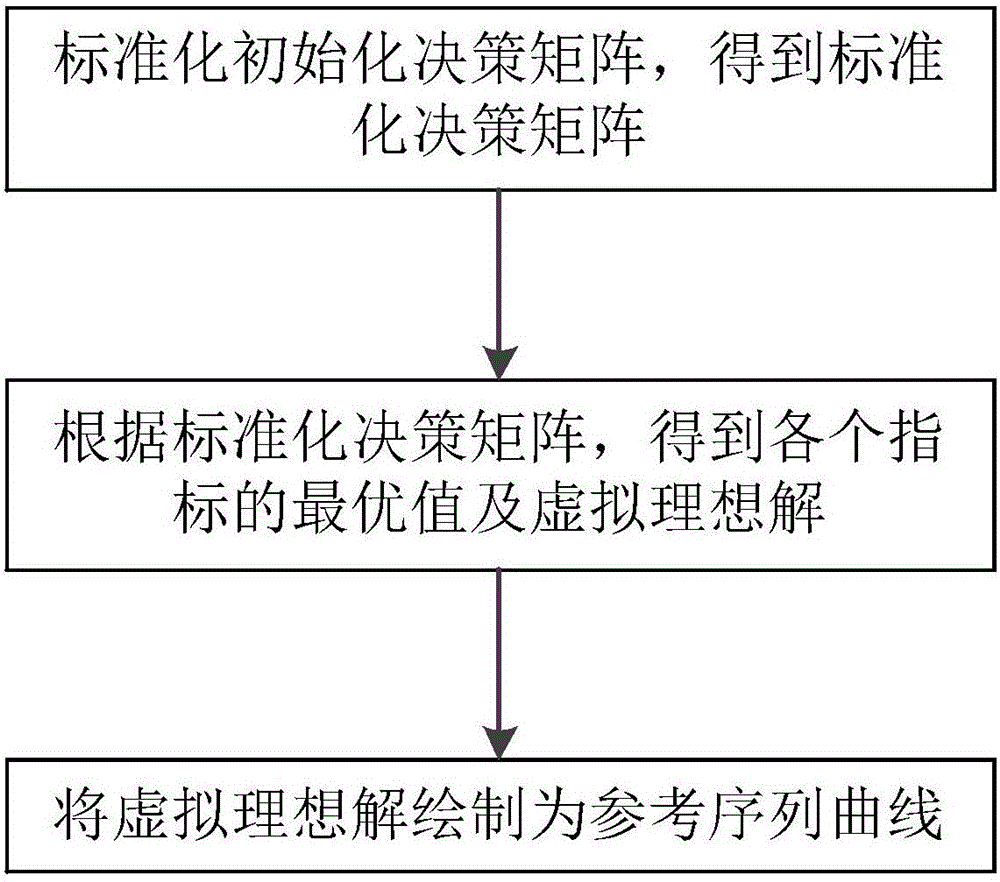

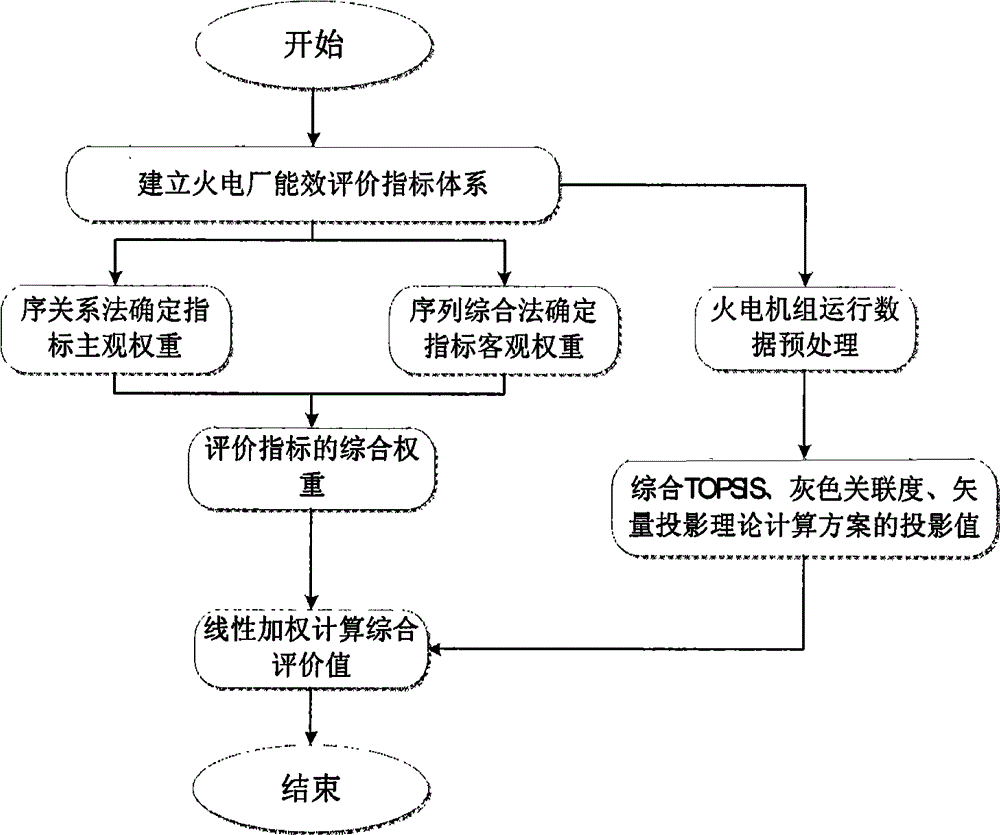

Energy efficiency comprehensive evaluation method for thermal power plant

InactiveCN104616215AAvoiding the Weakness of One-Way EvaluationDetermine scienceData processing applicationsVector theoryTOPSIS

The invention relates to an energy efficiency comprehensive evaluation method for a thermal power plant. The method comprises the following steps: building an energy efficiency comprehensive evaluation index system of the thermal power plant; determining comprehensive weight of the energy efficiency comprehensive evaluation indexes of the thermal power plant by using an order relation method and a sequence comprehensive method; analyzing by using a grey relational degree and building positive and negative ideal grey correlation decision matrixes; calculating weighting grey correlation decision matrixes through the combination of comprehensive index weight of the energy efficiency indexes; finally, calculating projection coefficient values of a unit to be evaluated according to a protection vector principle. By using a combination weighting method, the defect of single weighting is overcome; by combining TOPSIS, the grey relation theory and a projection vector theory, the weakness of grey correlation one-way evaluation is effectively avoided; meanwhile, a vector space of an index factor set is fully utilized, so that the method is particularly suitable for solving the energy efficiency evaluation problems of large-scale thermal power plants with more index factors and provides a new way for energy efficiency evaluation of the power plants.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

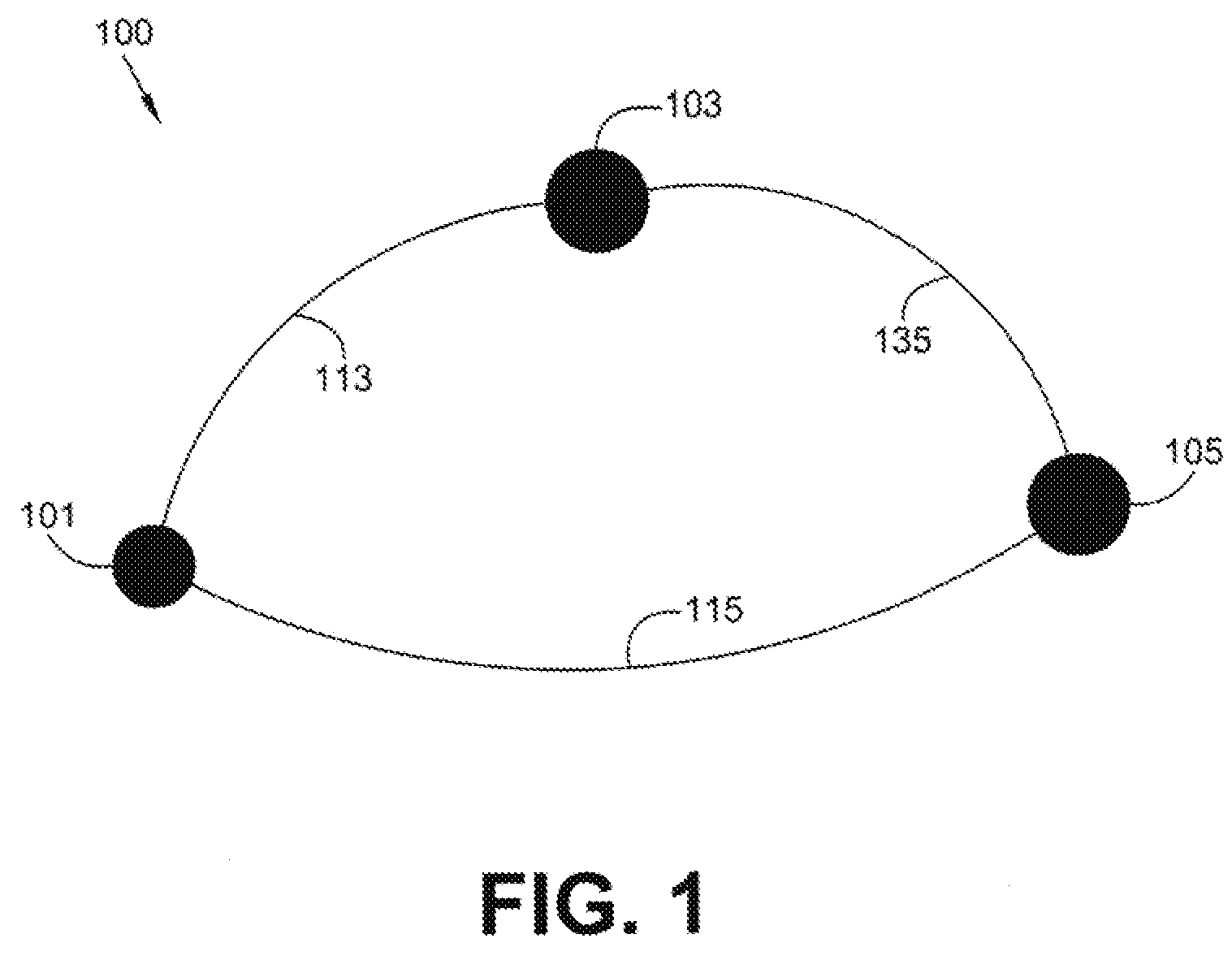

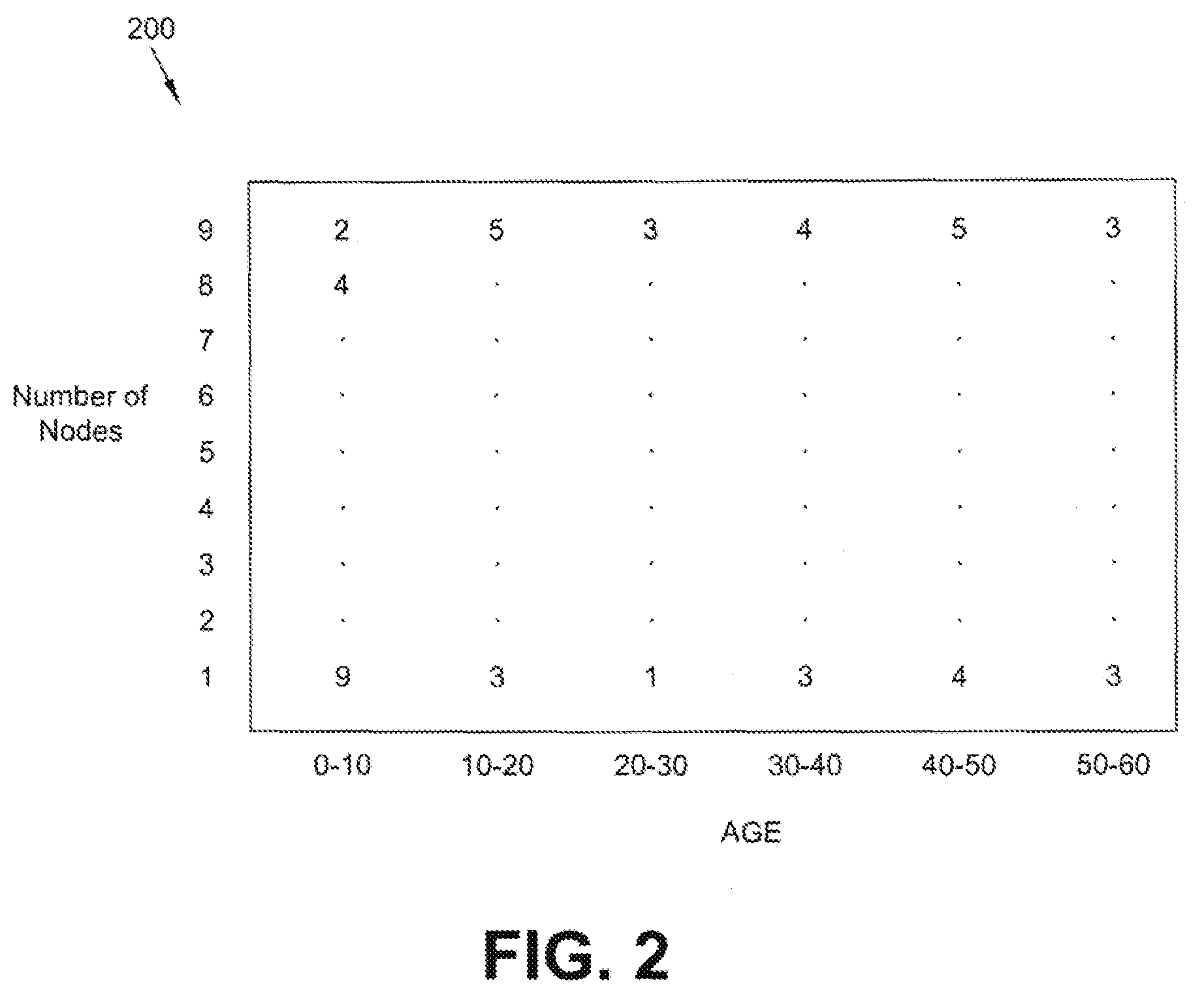

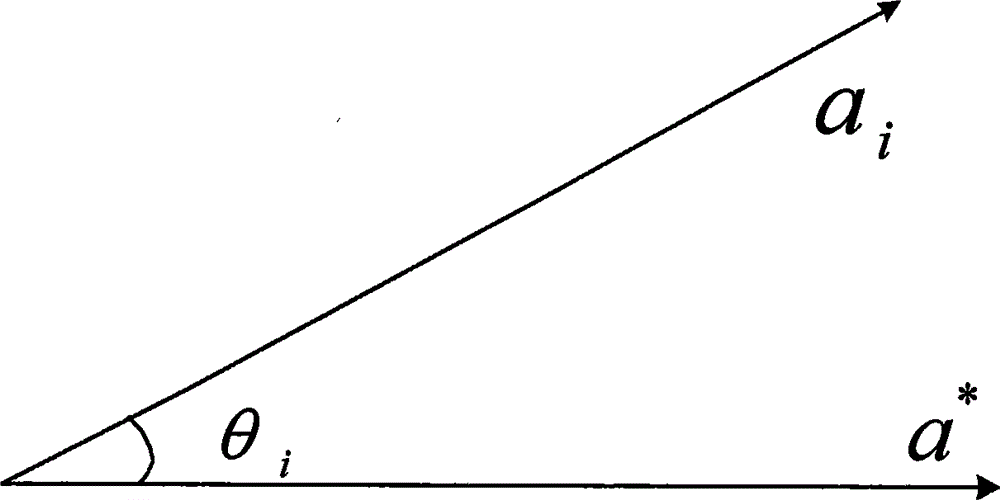

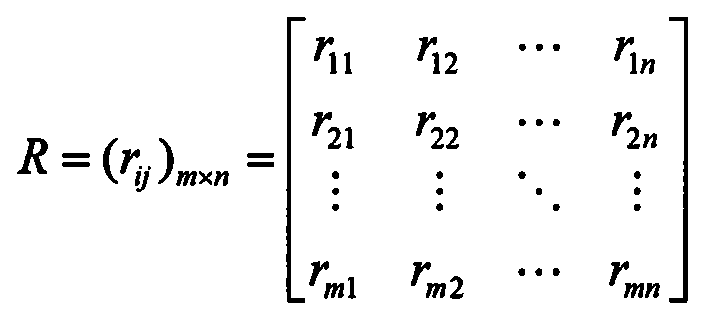

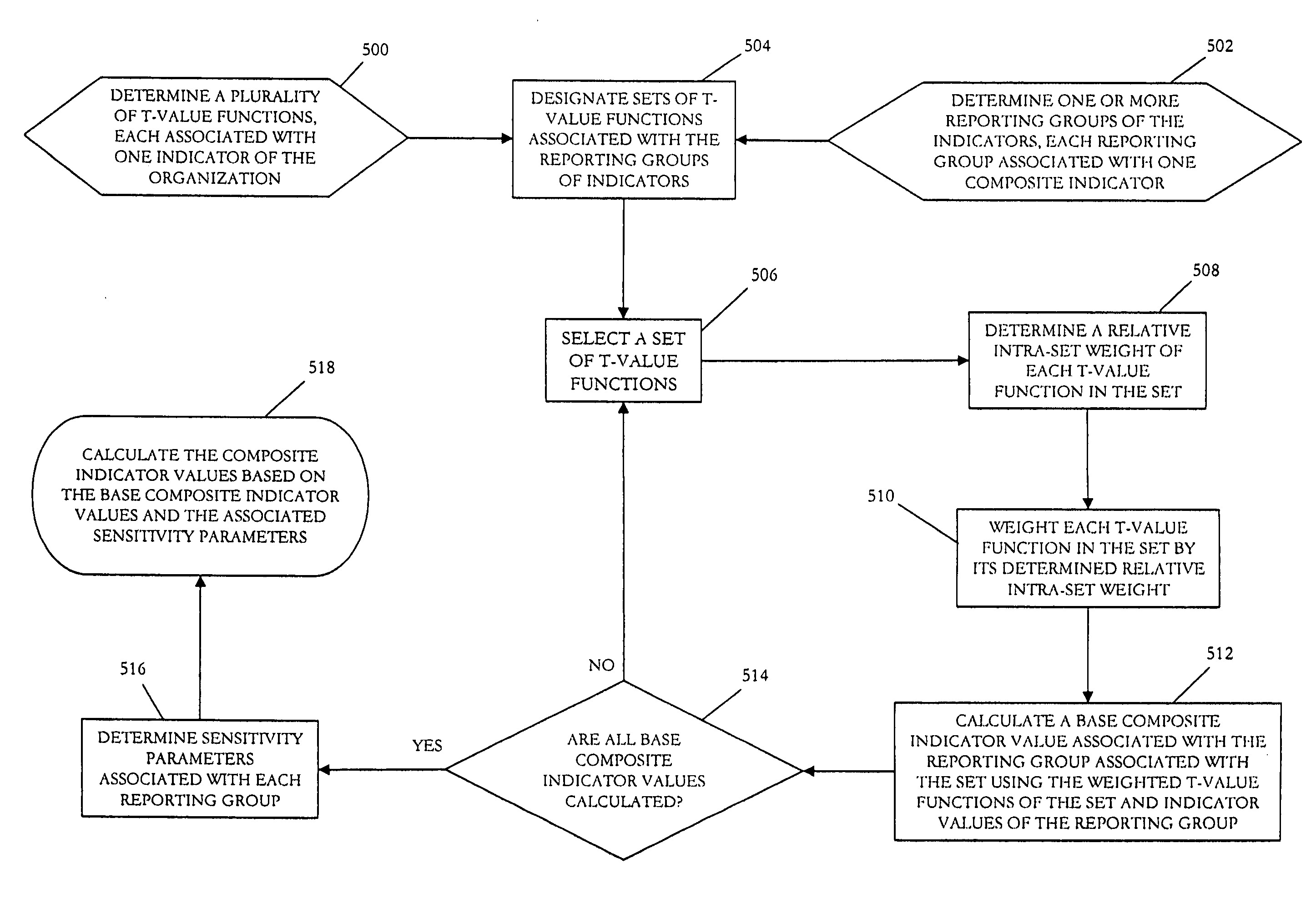

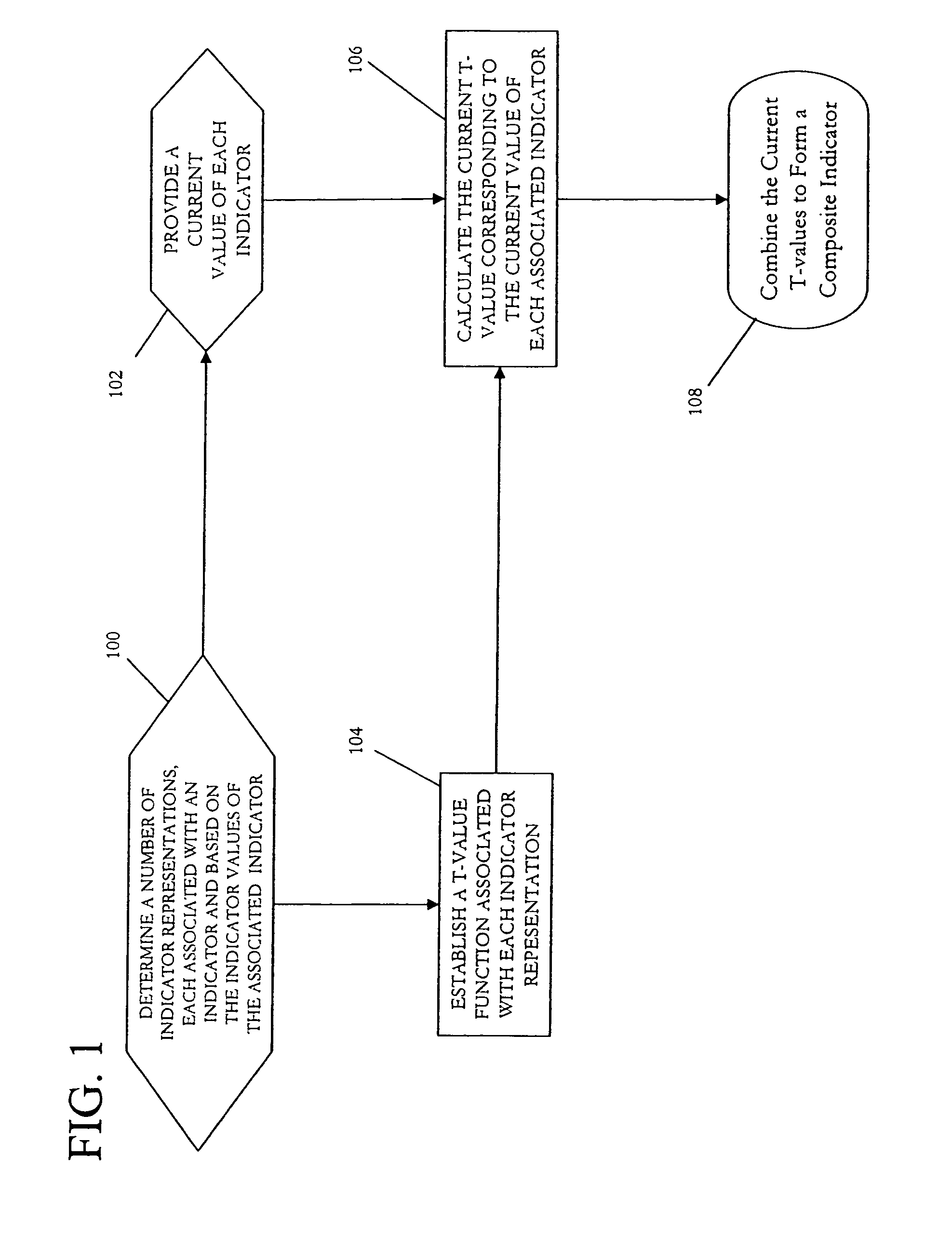

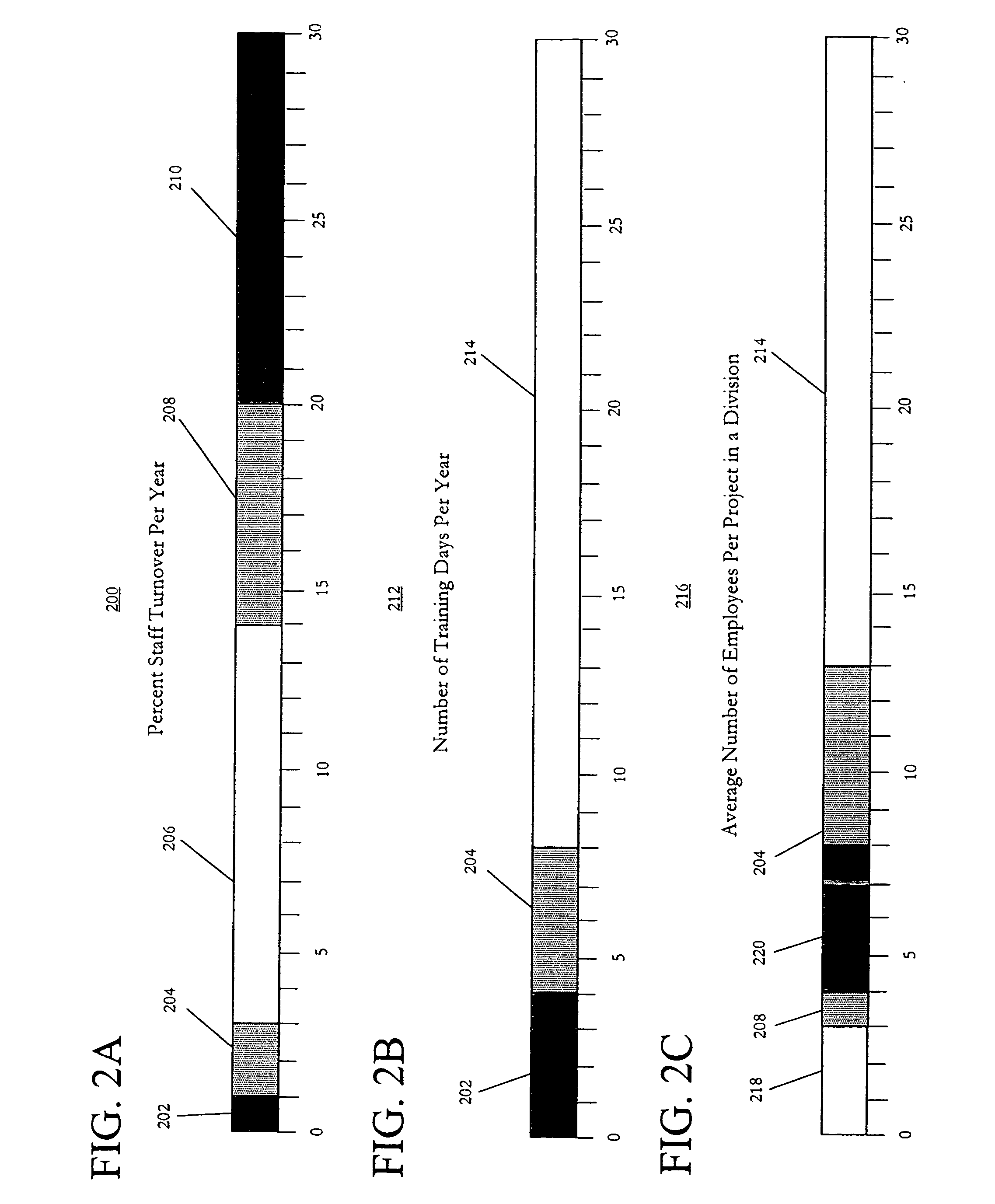

System and method for determining composite indicators

A method for determining a composite indicator value associated with a number of indicators. Indicator representations, each associated with an indicator and based on its indicator values, are determined. A current indicator value is provided for each indicator. A T-value function associated with each indicator representation is established. Each T-value function is a continuous function of the associated indicator having: a first T-value for indicator values in a first range of the associated indicator representation; a third T-value equal to or greater than a minimum value for indicator values in a third range of the associated indicator representation; and a second T-value for indicator values in a second range of the associated indicator representation that varies monotonically between the first and third range values. Current T-values corresponding to the current indicator values are calculated using the associated T-value functions. These current T-values are combined to calculate the composite indicator value.

Owner:RISK MANAGEMENT ASSOC THE

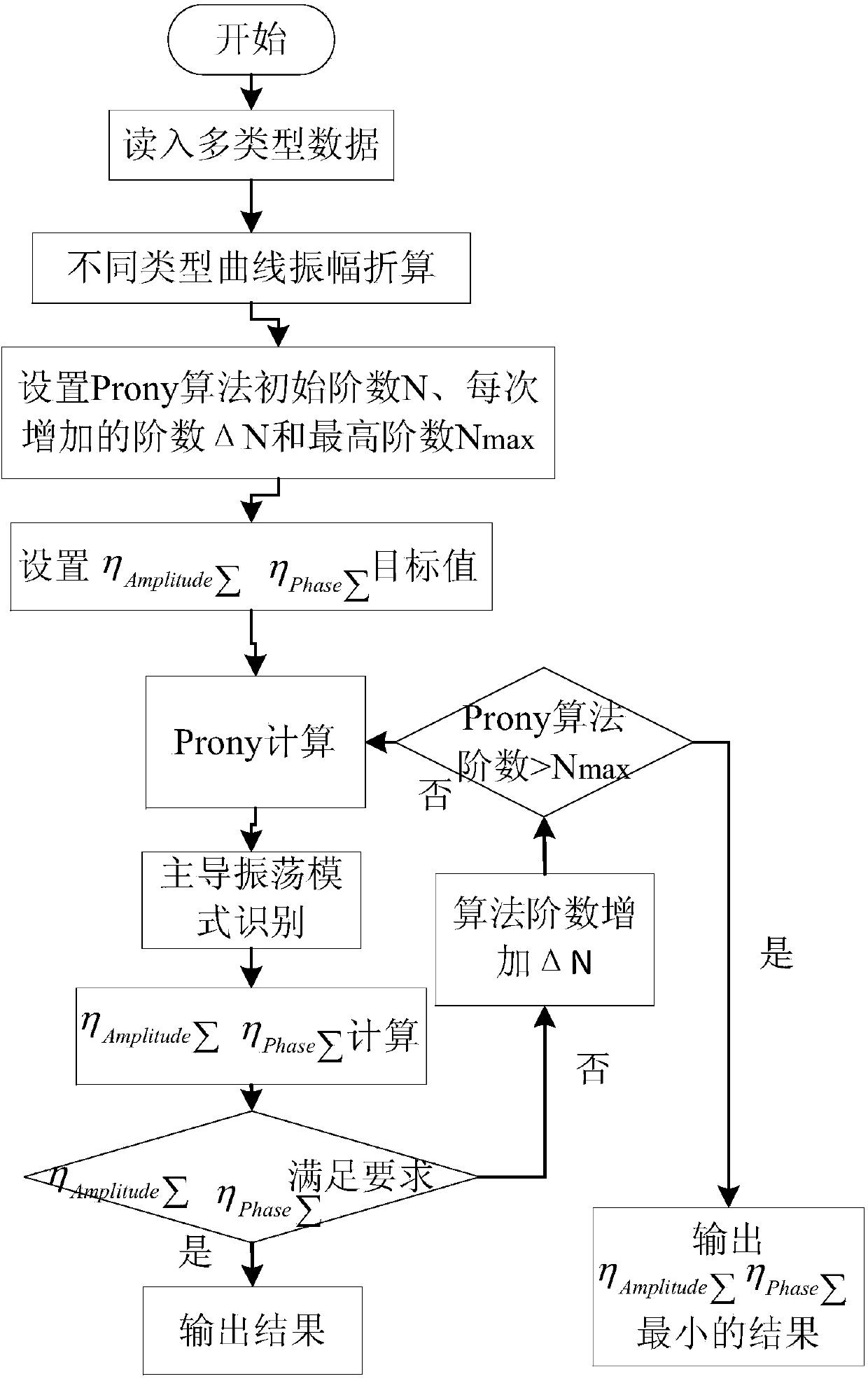

Multi-type signal-based power system low-frequency oscillation analysis method

ActiveCN104217112AReflect credibilityHas engineering application valueSpecial data processing applicationsMulti machineIndex system

The invention discloses a multi-type signal-based power system low-frequency oscillation analysis method, and belongs to the field of analyzing the stability of the power system. The method mainly comprises the steps of analyzing internal physical contact among multi-type curves of sets; formulating amplitude deviation and phase deviation evaluation indexes based on the contact, and evaluating the accuracy degree of extracting oscillation mode by the Prony algorithm; in order to avoid the signal in some type from being covered caused by over large amplitude difference of the curves in different types, performing translation processing on the amplitude of the signals in different types; giving a dominant oscillation mode identifying method, establishing a comprehensive evaluation index of a multicomputer signal, and reflecting the reliability of the Prony algorithm. The index system provided by the invention has engineering application value; according to the system, the reliability of extracting the oscillation mode information can be reflected; the appropriate Prony algorithm order can be selected according to the comprehensive index.

Owner:江苏方之得自动化科技有限公司

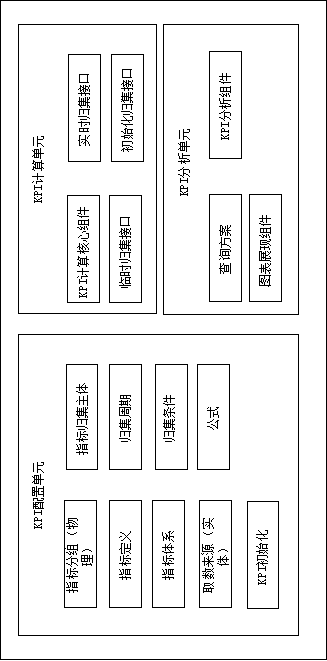

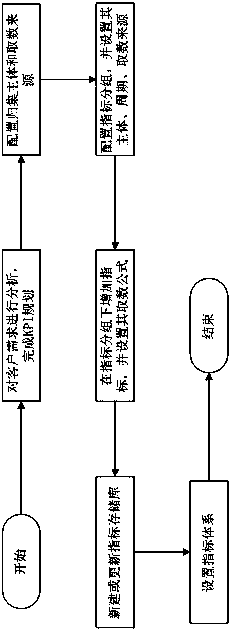

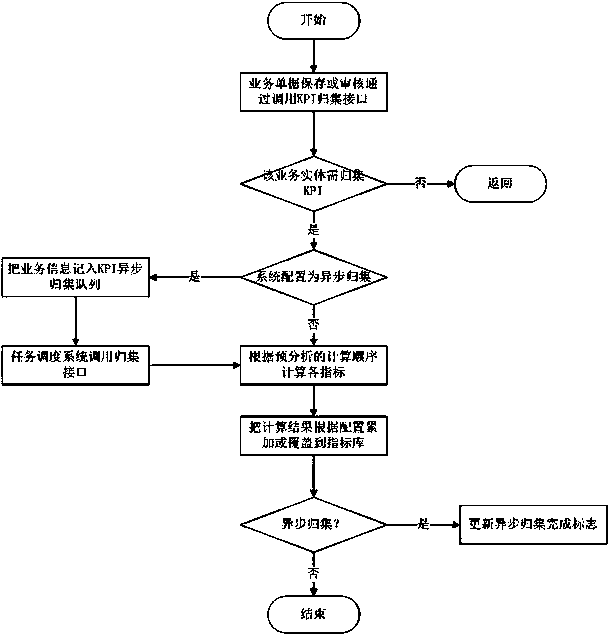

Analysis system for KPI

InactiveCN103995899AImplement imputationRealize analysisDatabase updatingResourcesQuery analysisData source

The invention discloses an analysis system for the KPI and belongs to the field of computer application. The analysis system for the KPI relates to KPI configuration, KPI calculation and KPI query analysis, wherein the KPI configuration is used for maintaining indicator groups, an indicator system and an indicator data source, collecting cycles, modes, conditions and formulae and initializing indicator data, the KPI calculation is used for calling a KPI calculation assembly according to configuration during service processing, conducting real-time or asynchronous processing on service document data so as to calculate a basic indicator and an affected composite indicator and enabling an indicator library to be updated with a result, and the KPI query analysis is used for analyzing and displaying the indicator data according to different dimensions and different cycles through charts based on user setting. Compared with the prior art, the analysis system for the KPI has the advantages that KPI data can be collected rapidly and effectively, dynamic analysis is conducted based on the KPI data, and the popularization and application value is high.

Owner:INSPUR COMMON SOFTWARE

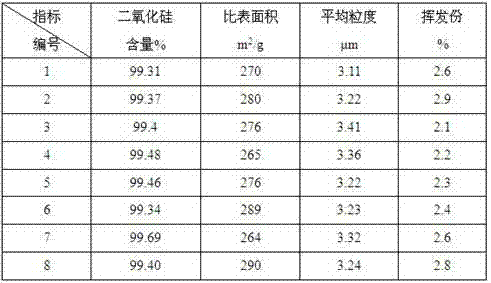

Preparation method of high transparent precipitated silica for plastic anti-block agent

InactiveCN102827495AAdjust Hole PropertiesExcellent chemical purityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsGraft reactionSodium silicate

The invention discloses a preparation method of high transparent precipitated silica for plastic anti-block agent. The preparation method takes industrial sodium silicate as raw material to produce the precipitated silica which is excellent in composite indicators such as chemical purity, pore property, average particle size, volatile matter and the like so as to be used as the plastic anti-block agent. In the whole technical process, strict technical raw materials are not needed to be used, and the reaction time is 2-5h. A great deal of hydroxyl exists on the surface of the silica, and the grafting reaction is carried out between the silica and surface active material in the pulping process, so that the compatibility between the silica and polyvinyl is improved, and the transparency of the silica in the polyvinyl is remarkably improved.

Owner:FUJIAN SANMING TONGSHENG CHEM

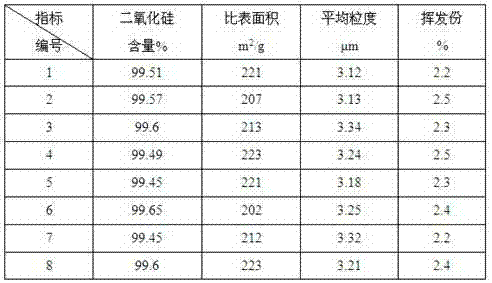

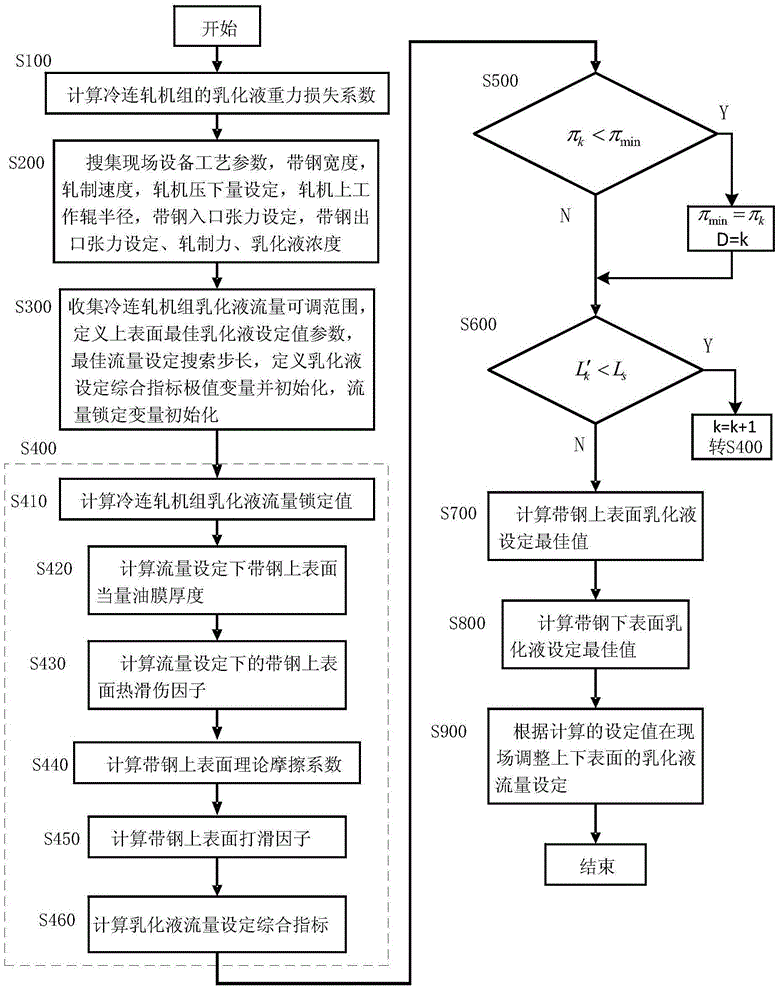

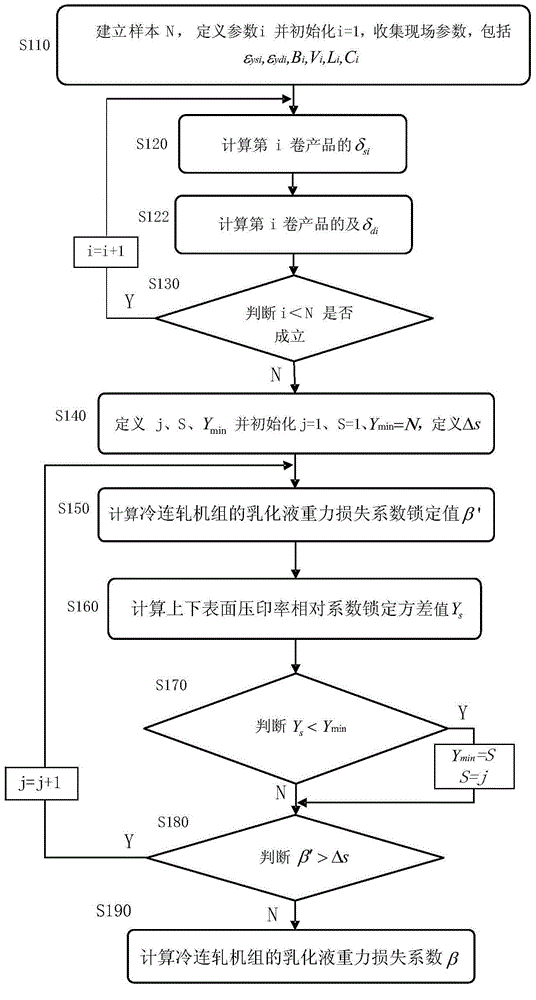

Emulsion flow differential setting method for cold continuous rolling unit

ActiveCN106363023AReduce the difference in adhesionGuaranteed surface qualityTemperature control deviceRollsEmulsionStrip steel

The invention provides an emulsion flow differential setting method for a cold continuous rolling unit, and relates to a control device or method specially suitable for a metal rolling machine or machined products of the metal rolling machine, in particular to a spray flow control method for the emulsion on the upper surface and the lower surface of strip steel of a cold continuous rolling unit in the cold continuous rolling unit rolling process. The emulsion flow differential setting method comprises the following steps that the gravity loss coefficient of the emulsion is calculated; the technology parameters of site equipment are collected; the flow setting comprehensive index of the emulsion is calculated; and an optimum setting value of the emulsion on the upper surface and the lower surface of the strip steel is obtained after searching. According to the emulsion flow differential setting method for the cold continuous rolling unit, flow differential setting for the spray volume of the emulsion on the upper surface and the lower surface of the strip steel is conducted, and the spray flow of the emulsion on the upper surface and the lower surface of the strip steel is adjusted, so that the spray flow differentiation of the emulsion on the upper surface and the lower surface of the strip steel is achieved; and the loss, caused by the influence of the gravity, of the emulsion on the lower surface of the strip steel is compensated, the adhesion volume difference of the emulsion on the upper surface and the lower surface of the strip steel is reduced, and therefore the roughness difference of the upper surface and the lower surface of the strip steel is reduced, the quality of the strip steel surfaces is guaranteed, brand competitiveness is improved, and benefits are brought to an enterprise.

Owner:BAOSHAN IRON & STEEL CO LTD

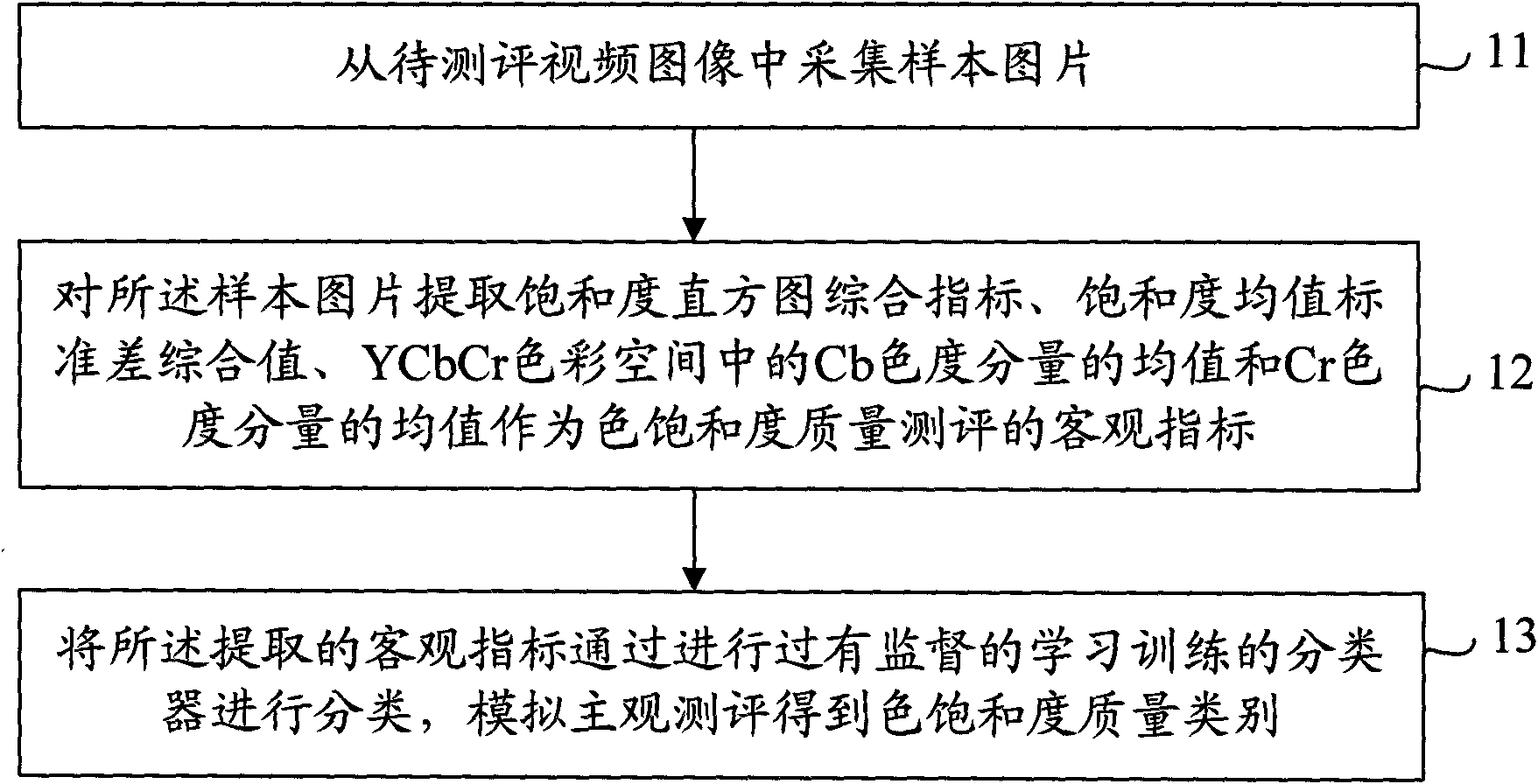

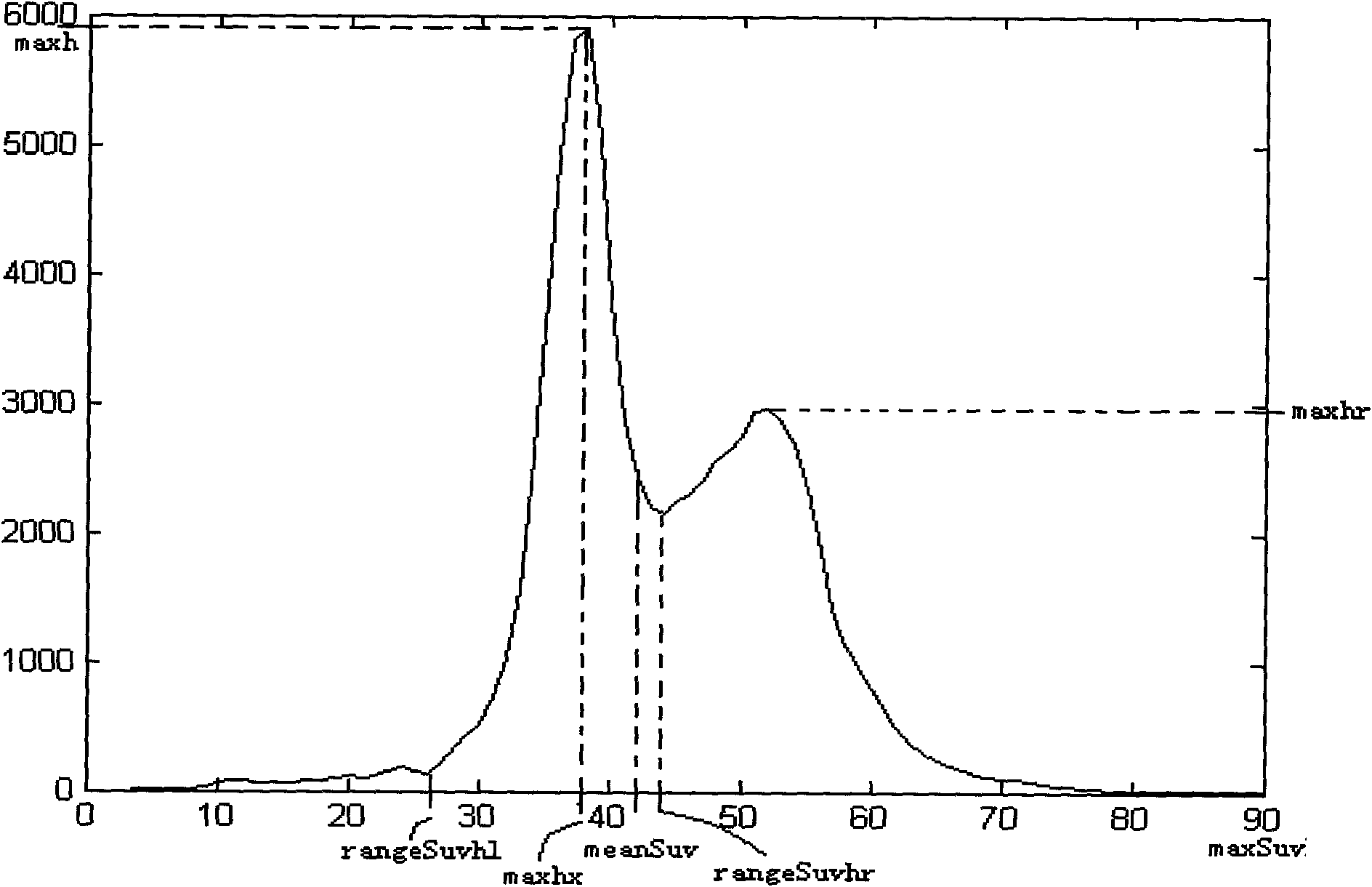

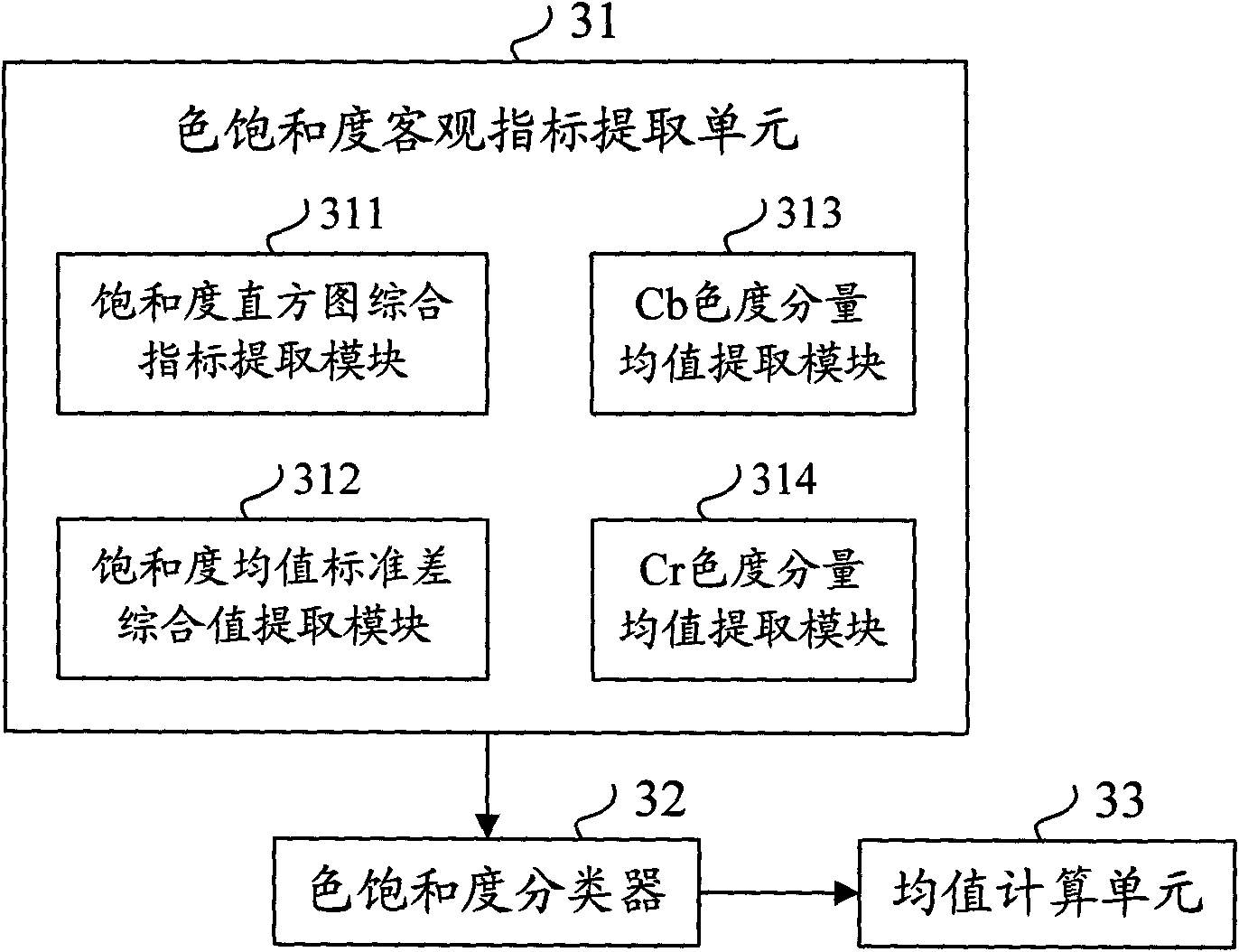

Method and subsystem for evaluating colour saturation quality

InactiveCN101605273AOvercome deficienciesImprove accuracyCharacter and pattern recognitionTelevision systemsSample imageYcbcr color space

The embodiment of the invention discloses a method and a subsystem for evaluating colour saturation quality, which can reflect the difference between two comparison images and improve the classifying accuracy rate of a colour saturation classifier. The method comprises the following steps: acquiring a sample picture from a to-be-evaluated video image; extracting a saturation column diagram composite indicator, a saturation mean value standard deviation comprehensive value, the mean value of Cb chromaticity components in an YCbCr color space and the mean value of Cr chromaticity components from the sample picture as objective indexes for evaluating colour saturation quality; and classifying the extracted objective indexes through a classifier undergoing supervised learning training and simulating subjective evaluation to obtain a colour saturation quality category. The technical scheme provided by the embodiment of the invention can be used to carry out objective evaluation of colour saturation quality of TV pictures.

Owner:HISENSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com