Preparation method of high transparent precipitated silica for plastic anti-block agent

A technology of precipitated silica and anti-blocking agent, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, dyed organic silicon compounds, etc. It can solve the problem of poor surface properties, poor compatibility, and difficulty in dispersing plastic films. problem, to achieve the effect of improved transparency, increased compatibility, and excellent comprehensive indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

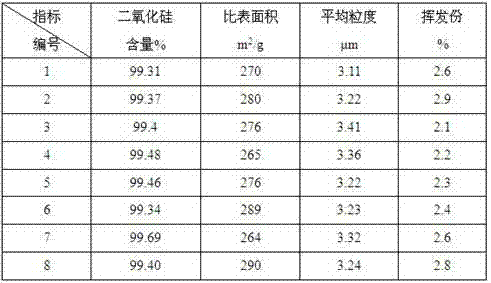

Embodiment 1

[0021] 1) Dilute the industrial sodium silicate with a modulus of 3.0 to a concentration of silicon dioxide with a mass content of 5% industrial sodium silicate solution; at an initial temperature of 45 °C, dropwise add a 95% mass content of inorganic acid solution, inorganic The acid is selected from one or more of sulfuric acid, nitric acid, and phosphoric acid; the addition amount is 20% of the total amount of sulfuric acid used, then the temperature is raised to 80-90 ° C, and the temperature is maintained for 1-1.5 hours, and the remaining sulfuric acid is added dropwise at this temperature, Keep the final adjusted pH value of 3-4;

[0022] 2) washing, the washing method is selected from one or more of water washing and alcohol washing, and washing with water until the mass content of sodium ions is below 0.1%;

[0023] 3) Beat the washed filter cake with high-speed stirring, add a surfactant, the surfactant is selected from γ-chloropropyltrimethoxysilane, and the additio...

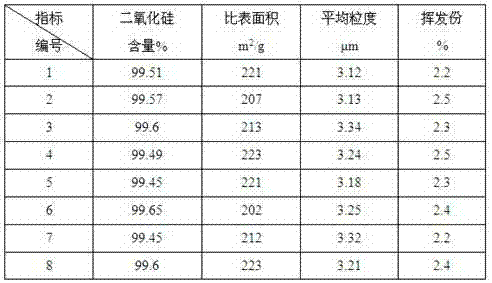

Embodiment 2

[0029] 1) Dilute the industrial sodium silicate with a modulus of 3.1 to a concentration of silicon dioxide with a mass content of 6% industrial sodium silicate solution; at an initial temperature of 50 °C, dropwise add an inorganic acid solution with a mass content of 95%, inorganic acid solution The acid is selected from one or more of sulfuric acid, nitric acid and phosphoric acid; the add-on is 22% of the total amount of sulfuric acid used, then the temperature is raised to 80-90 ° C, kept for 1-1.5 hours, and the remaining sulfuric acid is added dropwise at this temperature, Keep the final adjusted pH value of 3-4;

[0030] 2) washing, the washing method is selected from one or more of water washing and alcohol washing, and washing with water until the mass content of sodium ions is below 0.1%;

[0031] 3) Beat the washed filter cake with high-speed stirring, add a surfactant, the surfactant is selected from fatty alcohol polyoxyethylene ether, and the addition amount is ...

Embodiment 3

[0037] 1) Dilute the industrial sodium silicate with a modulus of 3.2 to a concentration of silicon dioxide with a mass content of 7% industrial sodium silicate solution; at an initial temperature of 55 °C, dropwise add an inorganic acid solution with a mass content of 95%. The acid is selected from one or more of sulfuric acid, nitric acid, and phosphoric acid; the addition amount is 24% of the total amount of sulfuric acid used, and then the temperature is raised to 80-90 ° C, maintained for 1-1.5 hours, and the remaining sulfuric acid is added dropwise at this temperature, Keep the final adjusted pH value of 3-4;

[0038] 2) washing, the washing method is selected from one or more of water washing and alcohol washing, and washing with water until the mass content of sodium ions is below 0.1%;

[0039] 3) Beat the washed filter cake with high-speed stirring, add a surfactant, and the surfactant is selected from fatty alcohol polyoxyethylene ether and polyoxyethylene sorbitan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com