Method for suppressing steam turbine for geothermal power generation from scaling

A technology for geothermal power generation and steam turbines, which is applied in the direction of cleaning methods using liquids, machines/engines, chemical instruments and methods, etc. The effect of good scale and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

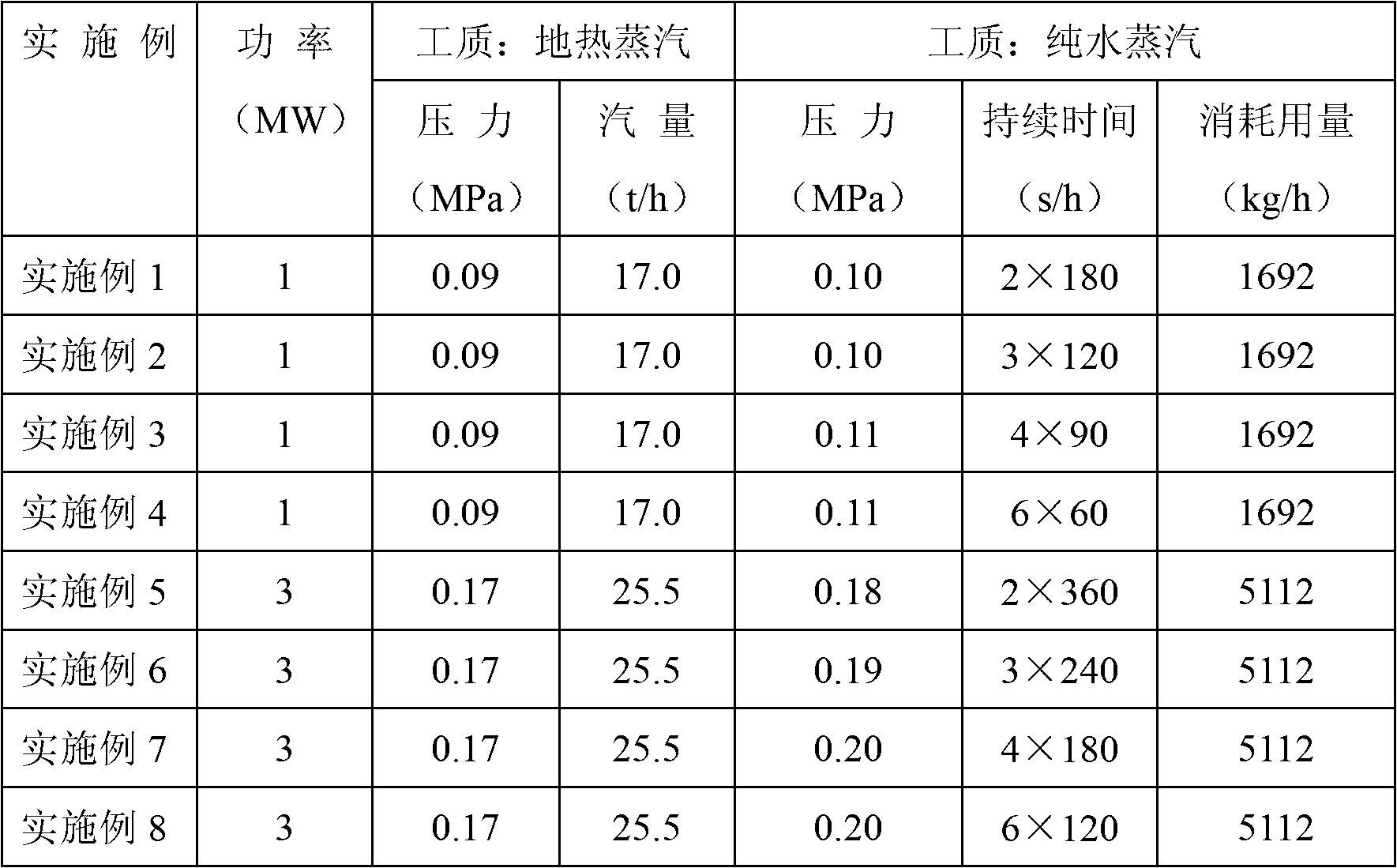

Embodiment 1

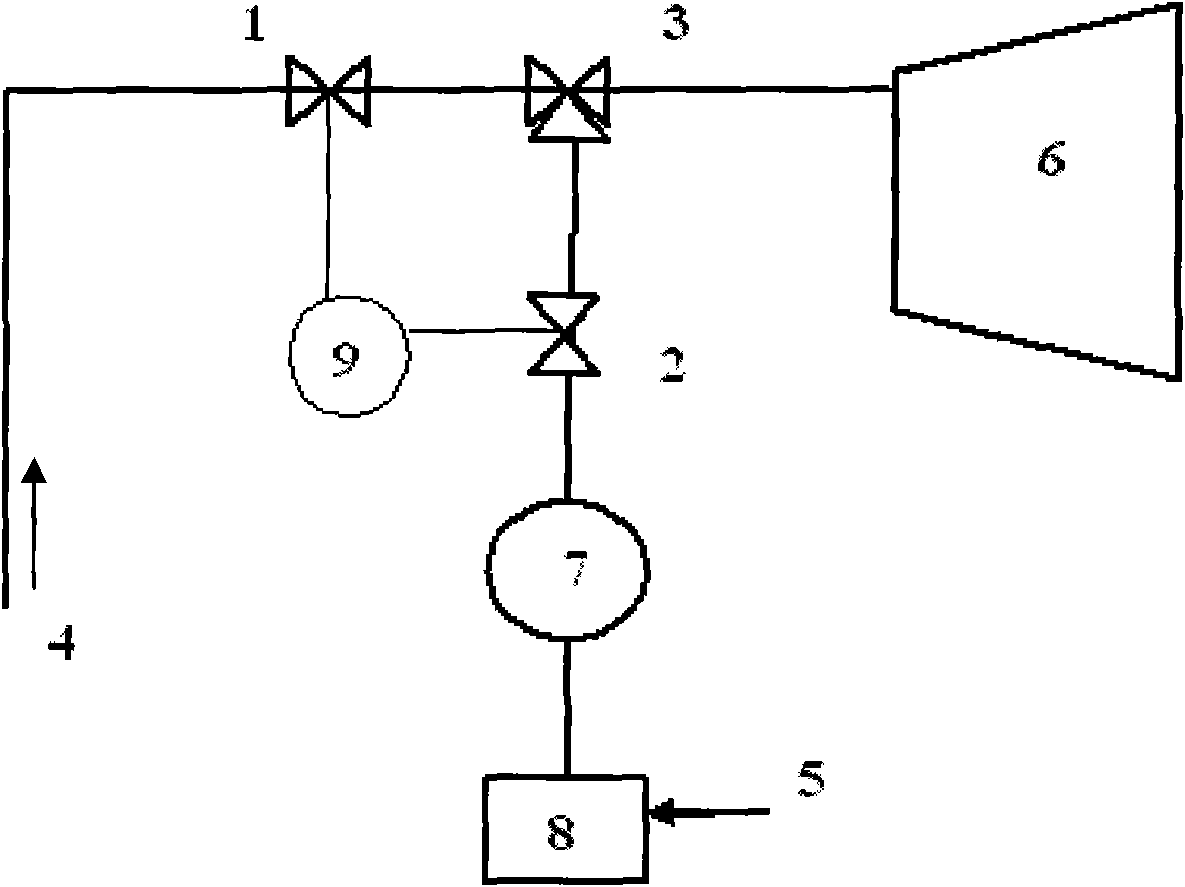

[0025] A method of inhibiting fouling of steam turbines for geothermal power generation, such as figure 1 As shown, the method includes the following steps:

[0026] (1) Connect the steam turbine 6 for geothermal power generation with one end of the three-way valve 3 through the geothermal steam pipeline, and connect the other end of the three-way valve 3 with one end of the geothermal steam pipeline control valve 1 through the geothermal steam pipeline, and the geothermal steam pipeline control valve 1 The other end is connected to the pipeline, and there is geothermal steam 4 in the pipeline, the third inlet and outlet of the three-way valve 3 is connected to one end of the pure water steam pipeline control valve 2 through the pure water steam pipeline, and the other end of the pure water steam pipeline control valve 2 is connected to There is a steam storage tank 7, the steam storage tank 7 is connected to the steam generator 8 through pipelines, the geothermal steam pipeli...

Embodiment 2

[0030] A method for inhibiting fouling of a steam turbine for geothermal power generation, the method comprising the following steps:

[0031] (1) Connect the steam turbine for geothermal power generation to one end of the three-way valve through the geothermal steam pipeline, the other end of the three-way valve is connected to one end of the geothermal steam pipeline control valve through the geothermal steam pipeline, and the other end of the geothermal steam pipeline control valve is connected to the pipeline, There is geothermal steam in the pipeline, the third entrance and exit of the three-way valve is connected with one end of the pure water steam pipeline control valve through the pure water steam pipeline, and the other end of the pure water steam pipeline control valve is connected with a steam storage tank, and the steam storage tank is connected with the pipeline through the pipeline. The steam generator is connected, the geothermal steam pipeline control valve, th...

Embodiment 3

[0035] A method for inhibiting fouling of a steam turbine for geothermal power generation, the method comprising the following steps:

[0036](1) Connect the steam turbine for geothermal power generation to one end of the three-way valve through the geothermal steam pipeline, the other end of the three-way valve is connected to one end of the geothermal steam pipeline control valve through the geothermal steam pipeline, and the other end of the geothermal steam pipeline control valve is connected to the pipeline, There is geothermal steam in the pipeline, the third entrance and exit of the three-way valve is connected with one end of the pure water steam pipeline control valve through the pure water steam pipeline, and the other end of the pure water steam pipeline control valve is connected with a steam storage tank, and the steam storage tank is connected with the pipeline through the pipeline. The steam generator is connected, the geothermal steam pipeline control valve, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com