A kind of preparation method of polypropylene melt-blown battery diaphragm

A polypropylene melt-blown and battery separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problem that the barrier properties of positive and negative active materials are general, cannot be used in the field of battery separators, and the strength of melt-blown nonwovens is poor. and other problems, to achieve the effect of low price, excellent chemical purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

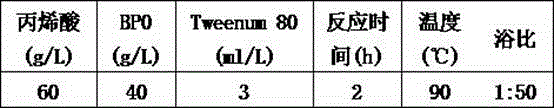

[0021] (1) Polypropylene melt-blown non-woven fabric battery separator processing: select the raw material of polypropylene slices with a melt index of 20g / 10min, add hydrophilic masterbatch with a mass ratio of 3%, and perform injection molding in a screw injection molding machine to obtain plasticization Uniform polypropylene melt, the screw injection molding machine adopts a single-screw injection molding machine composed of three-segment screws. In order to obtain high plasticizing capacity and output, an ultra-long screw with a length of 18d is used, and the diameter of the screw is 45mm; Fluctuation and uneven plasticization, choose a high-horsepower motor to drive to increase the driving force of the screw; the injection nozzle and the screw barrel passage are carefully designed to avoid the formation of dead angles, so that the material will not stay and be damaged by heat. High-precision thermistor temperature control is used to ensure accurate temperature control of t...

Embodiment 2

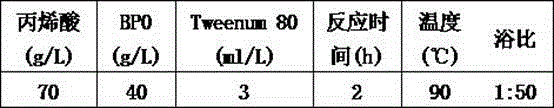

[0029] (1) Polypropylene melt-blown non-woven fabric battery separator processing: select the raw material of polypropylene slices with a melt index of 24g / 10min, add hydrophilic masterbatch with a mass ratio of 5%, and perform injection molding in a screw injection molding machine to obtain plasticization Uniform polypropylene melt, the screw injection molding machine adopts a single-screw injection molding machine composed of three-stage screws. In order to obtain high plasticizing capacity and output, an ultra-long screw with a length of 20d is used, and the diameter of the screw is 65mm; Fluctuation and uneven plasticization, choose a high-horsepower motor to drive to increase the driving force of the screw; the injection nozzle and the screw barrel passage are carefully designed to avoid the formation of dead angles, so that the material will not stay and be damaged by heat. High-precision thermistor temperature control is used to ensure accurate temperature control of the...

Embodiment 3

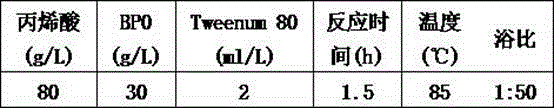

[0037] (1) Polypropylene melt-blown non-woven fabric battery separator processing: select the raw material of polypropylene slices with a melt index of 28g / 10min, add hydrophilic masterbatch with a mass ratio of 4%, and perform injection molding in a screw injection molding machine to obtain plasticization For uniform polypropylene melt, the screw injection molding machine adopts a single-screw injection molding machine composed of three-stage screws. In order to obtain high plasticizing capacity and output, an ultra-long screw with a length of 19d and a screw diameter of 60mm is used; in order to avoid the speed of the screw. Fluctuation and uneven plasticization, choose a high-horsepower motor to drive to increase the driving force of the screw; the injection nozzle and the screw barrel passage are carefully designed to avoid the formation of dead angles, so that the material will not stay and be damaged by heat. High-precision thermistor temperature control is used to ensure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com