Emulsion flow differential setting method for cold continuous rolling unit

A cold tandem rolling unit and flow setting technology, applied in the direction of rolling mill control devices, rolls, metal rolling, etc., can solve the problems of different emulsion adhesion, affect the surface quality of the strip, and the difference in roughness, etc., to ensure that the strip The effect of improving steel surface quality, improving brand competitiveness, and reducing roughness differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

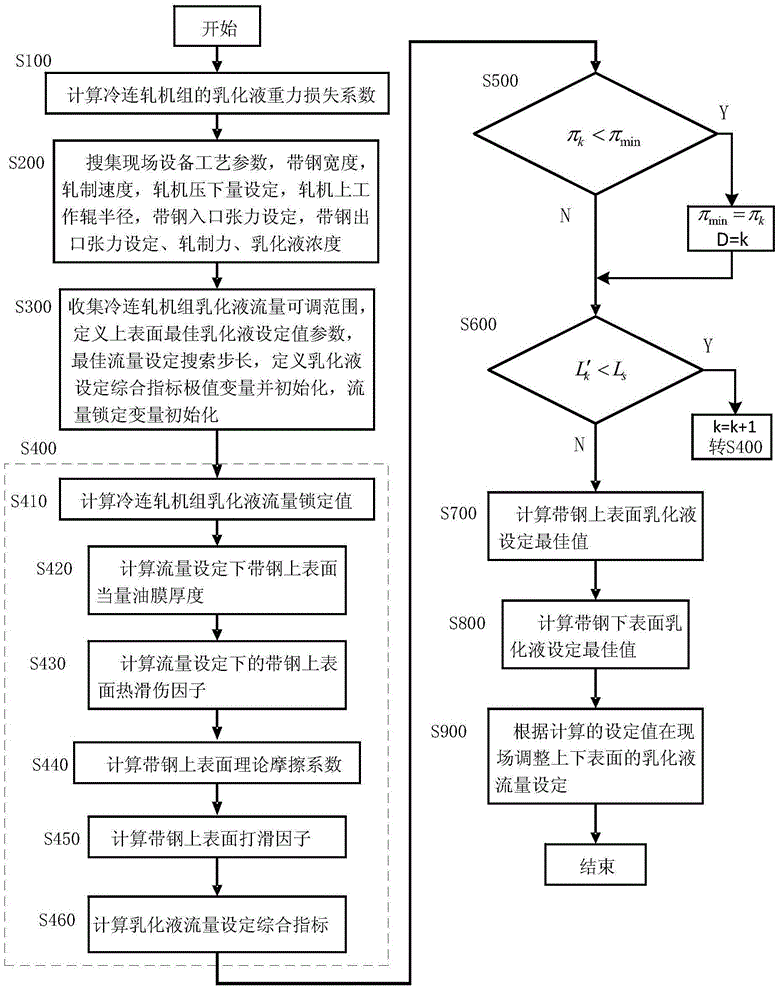

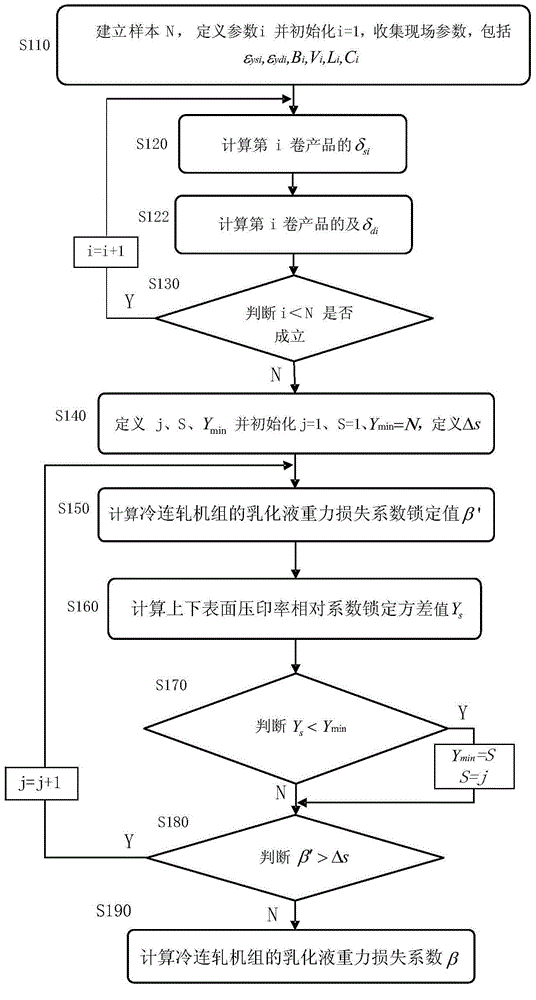

[0058] In order to further illustrate the application process of the related technology described in the present invention, so as to better understand the above-mentioned technical solution of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings and embodiments.

[0059] figure 2 It is an embodiment of the method for setting the differential flow rate of the emulsion in the tandem cold rolling mill of the present invention, which is used for the computer control system of the emulsion injection flow rate on the upper and lower surfaces of the strip steel in the tandem cold rolling mill. Taking the tandem cold rolling unit of the production line as an example, the detailed setting process of the inventive method for setting the differential flow rate of the emulsion in the tandem cold rolling unit is introduced in detail.

[0060] exist figure 2 In the shown control flow chart, the emulsion differential flow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com