Patents

Literature

30results about How to "Improve brand competitiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

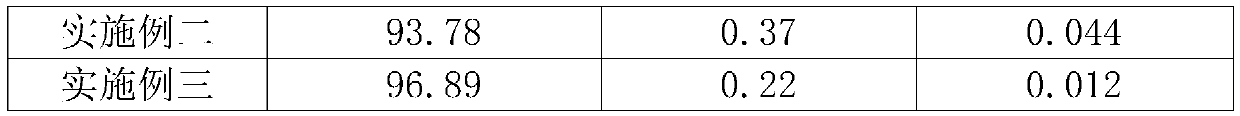

Optimal setting method for relationship curve of emulsion flow and rolling speed in cold rolling process

ActiveCN106909723ASmall fluctuationQuality assuranceForecastingDesign optimisation/simulationEmulsionStrip steel

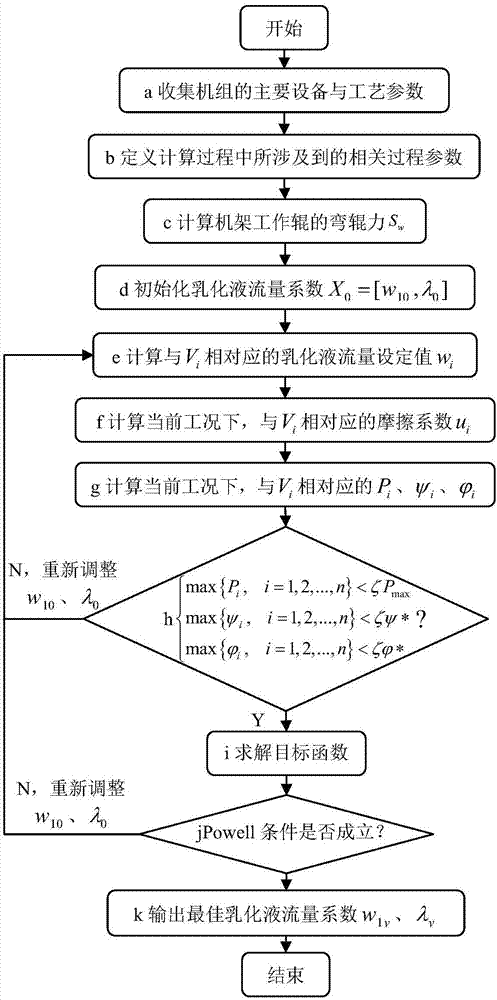

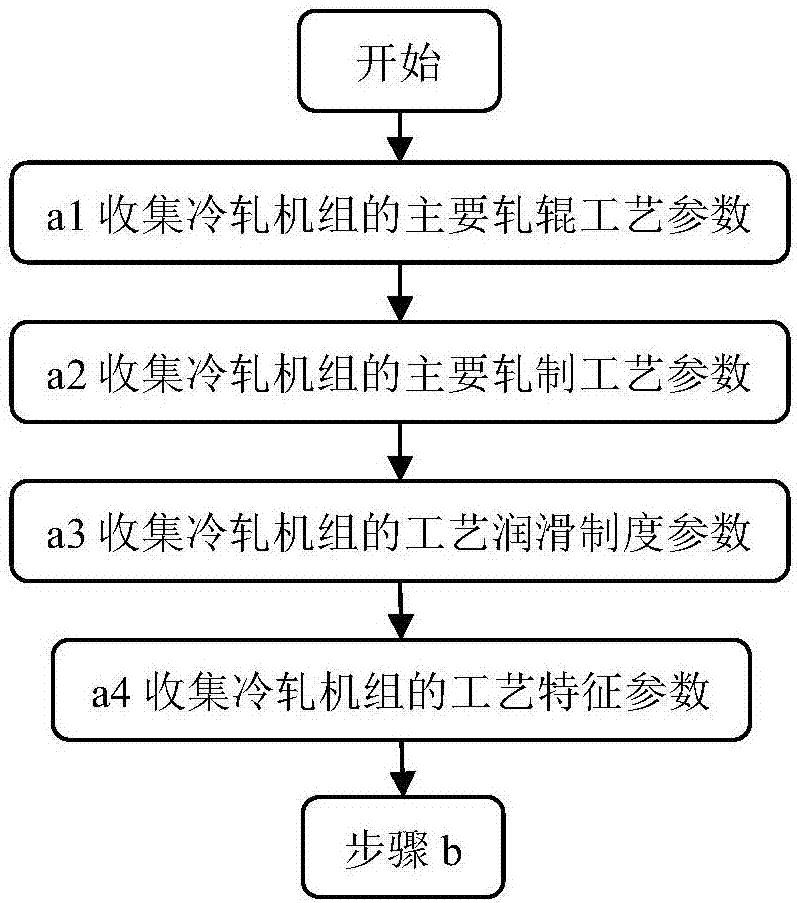

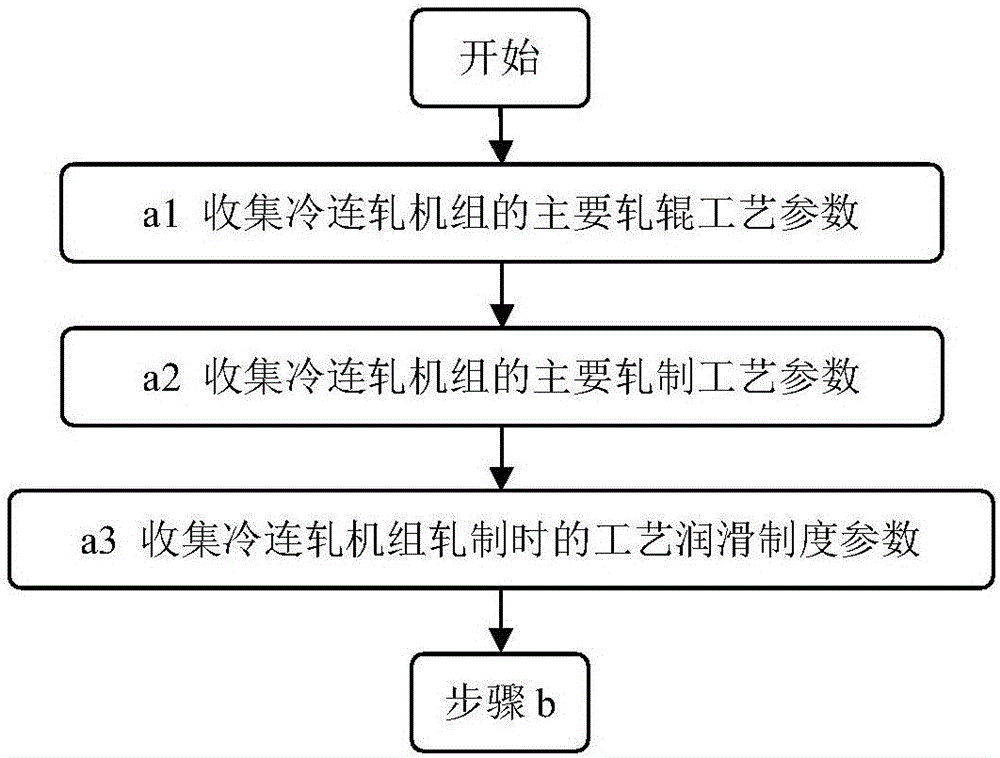

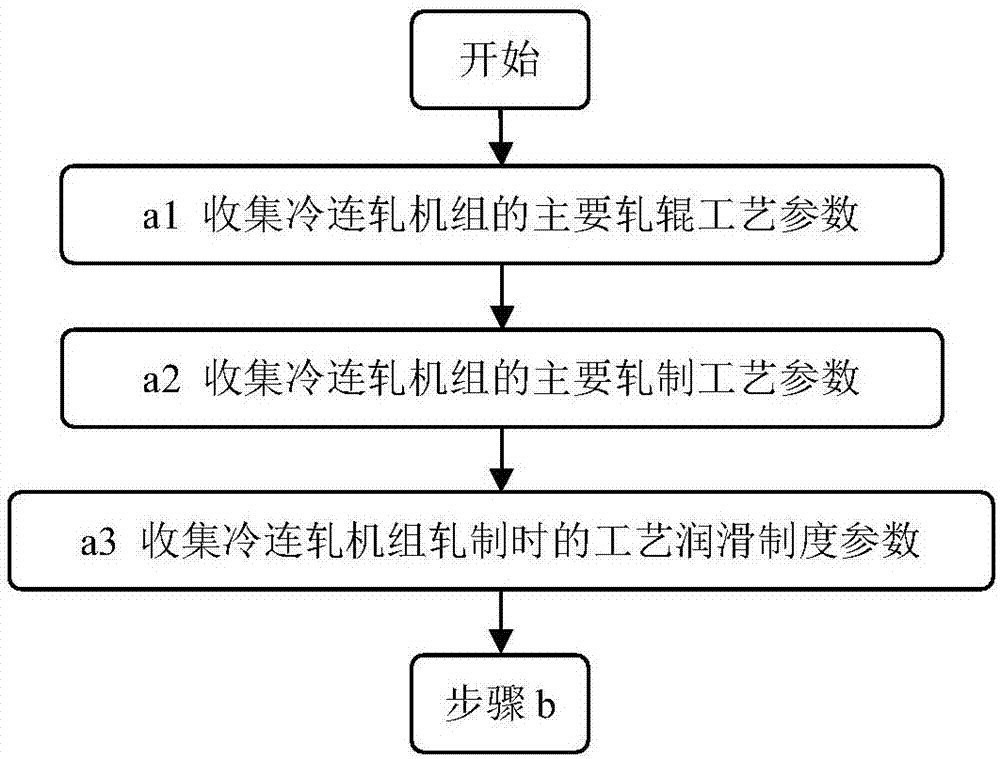

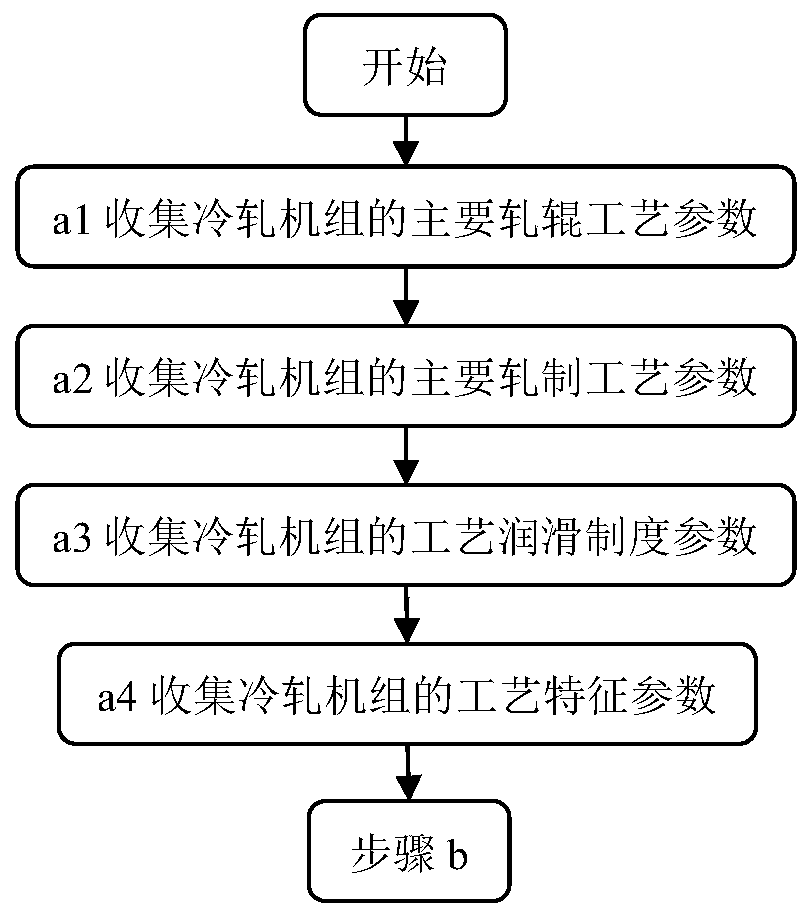

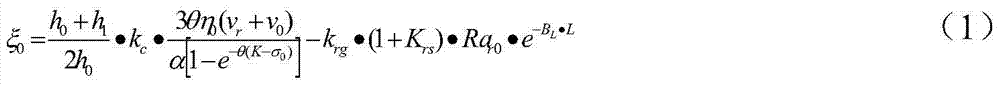

Provided is an optimal setting method for the relationship curve of the emulsion flow and the rolling speed in the cold rolling process. The method mainly comprises the following steps: 1, collecting main equipment and process parameters of a cold rolling unit; 2, defining the process parameters involved in the optimization process of the emulsion flow; 3, calculating the roll bending force of a rack working roll; 4, initializing the emulsion flow coefficient; 5, calculating the set value of the emulsion flow corresponding to Vi; 6, calculating the friction coefficient mui corresponding to Vi; 7, calculating the rolling pressure, slipping factor and thermal slipping injury index corresponding to Vi; 8, solving the objective function; 9, outputting the best emulsion flow coefficient, and determining the relationship curve of the best emulsion flow and speed. The method has the advantages that the overall fluctuation rate and the maximum fluctuation rate of the rolling pressure can be kept smaller during the speed-up and speed-down process, and it is ensured that the slipping and thermal slipping defects are prevented from occurring in the rolling process, thus the surface quality and the strip shape control precision of strip steels are improved.

Owner:YANSHAN UNIV

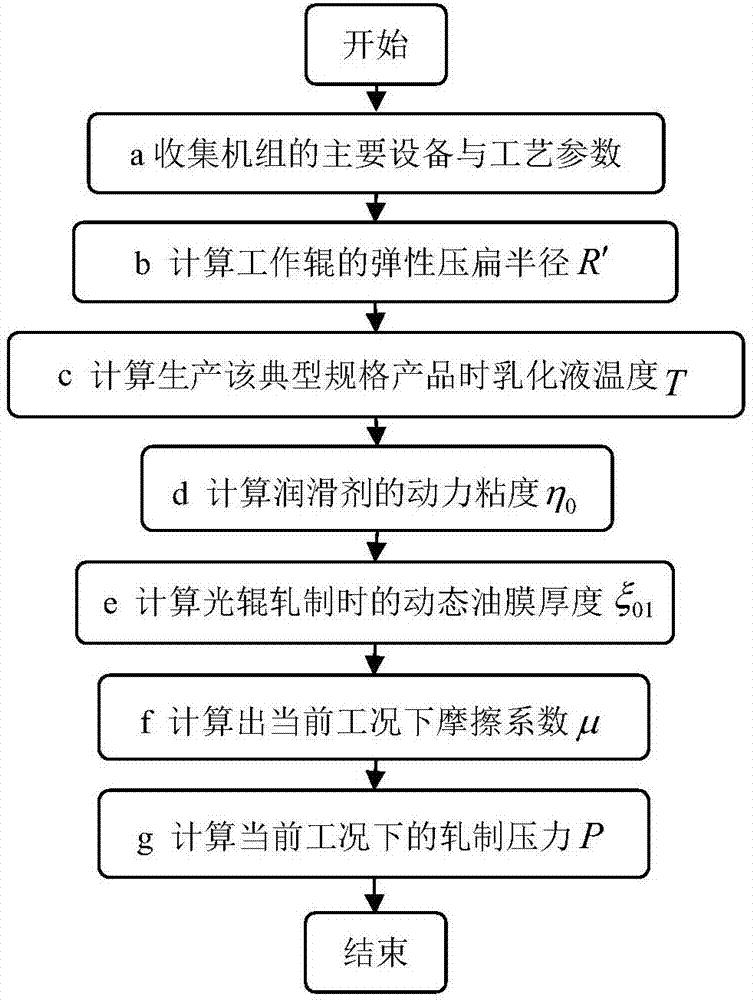

Method for predicting changes of rolling pressure with change of rolling speed in cold rolling process

ActiveCN106391725AQuality assuranceGuaranteed accuracyRoll force/gap control deviceRollsEmulsionStrip steel

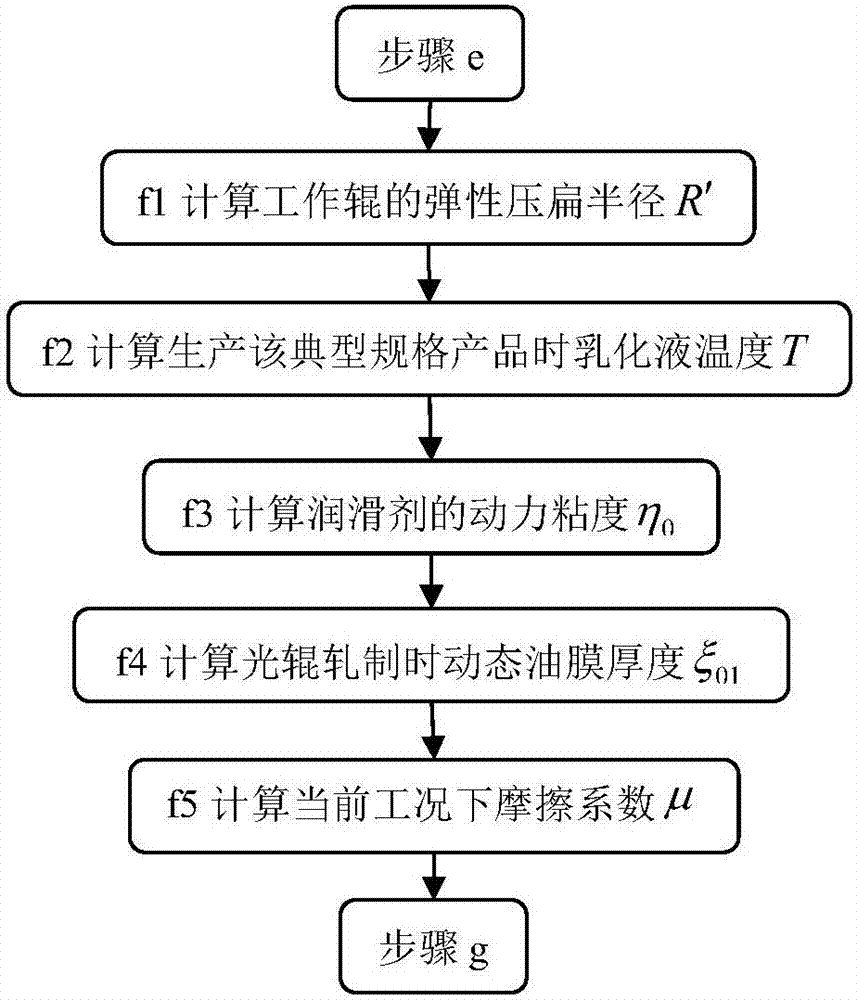

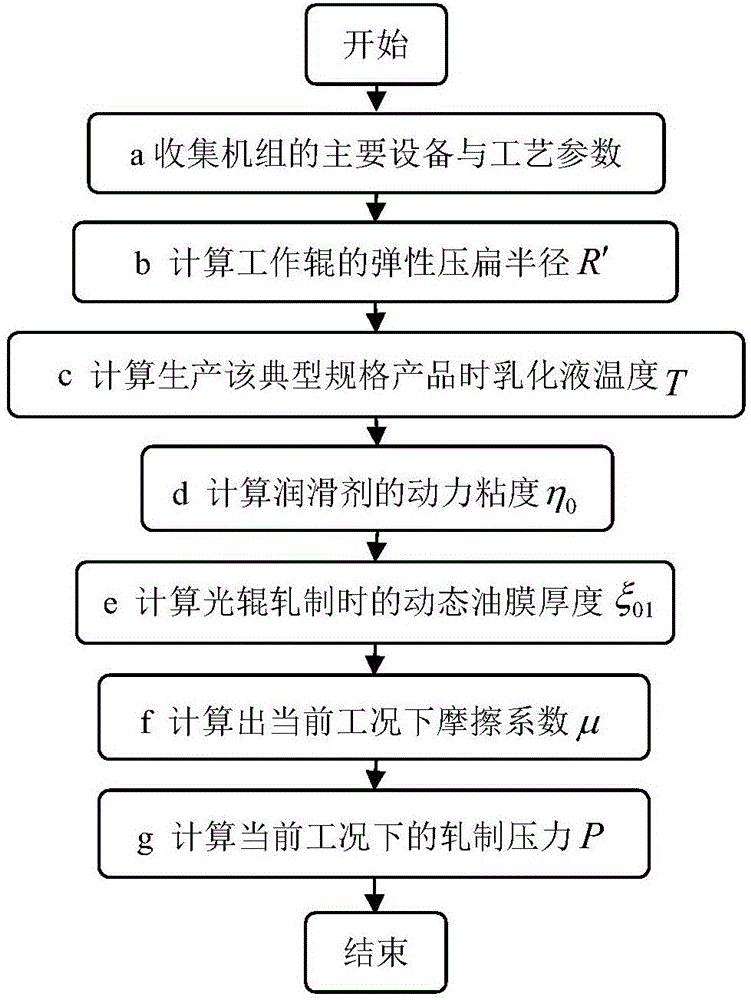

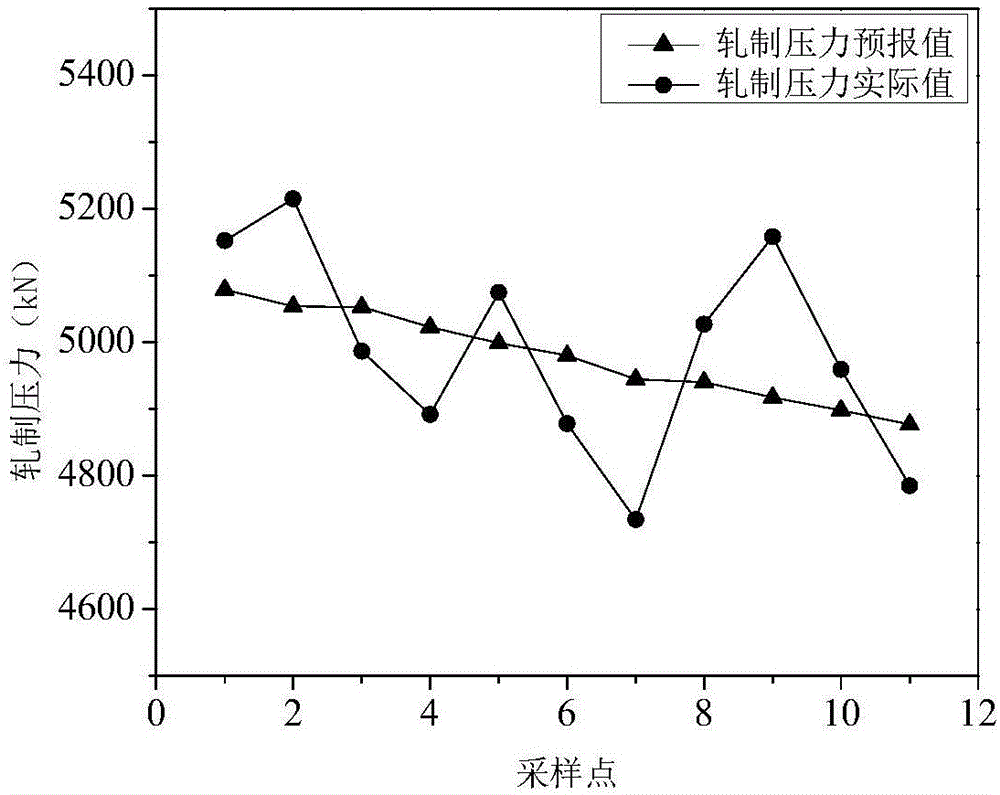

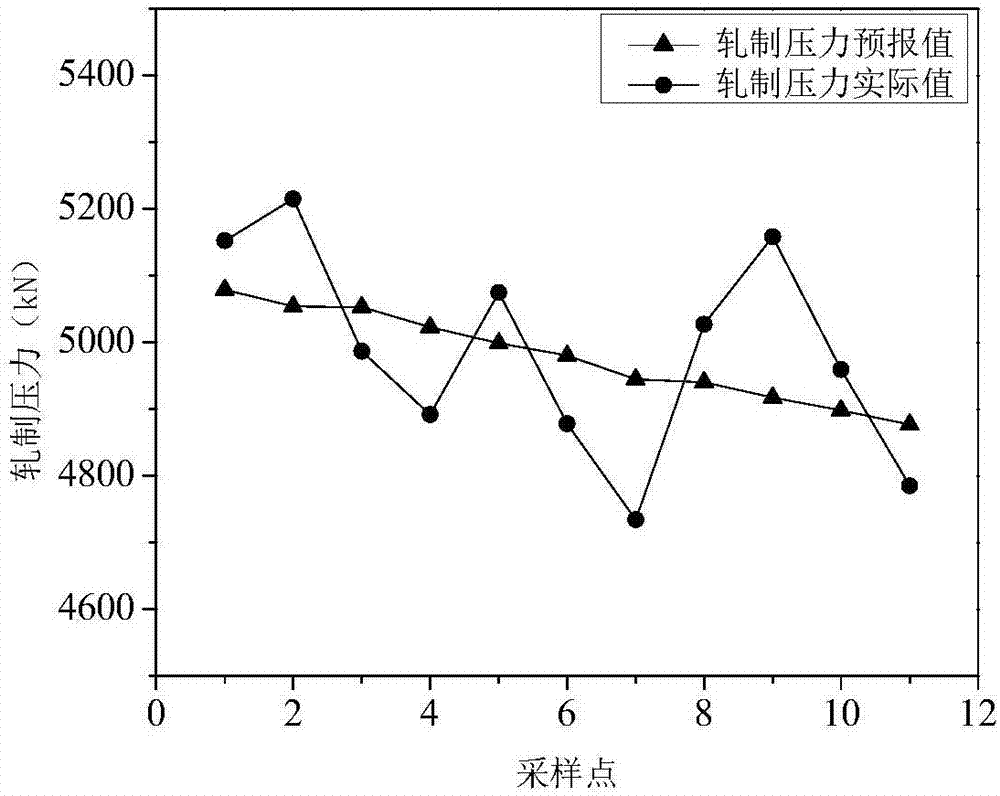

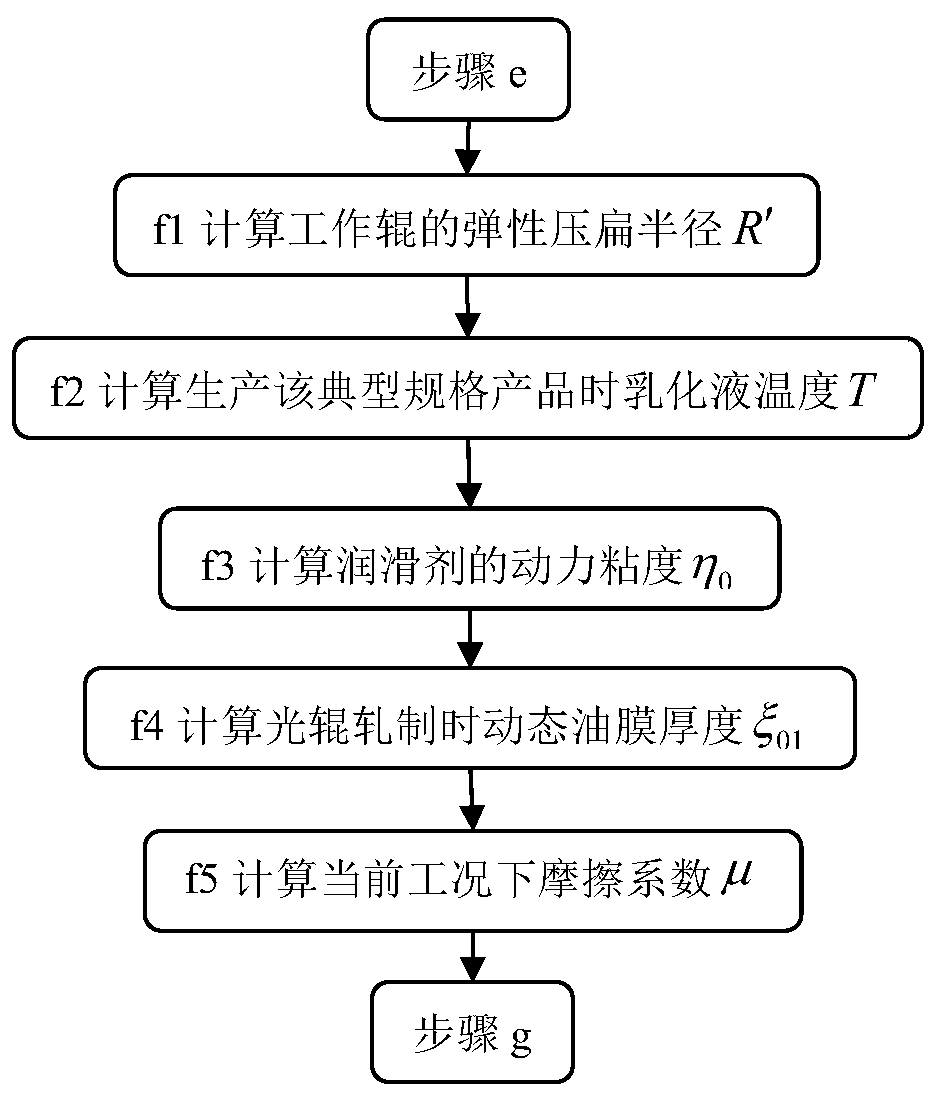

The invention discloses a method for predicting the changes of a rolling pressure with the changes of a rolling speed in a cold rolling process. The method comprises the following computer executed steps: (1) collecting main equipment and technological parameters of a cold continuous rolling unit; (2) calculating an elastic flattening radius of a working roller; (3) calculating the temperature of emulsion in the rolling process for producing products of the typical specification under the current working condition; (4) calculating power viscosity of a lubricant; (5) calculating dynamic oil film thickness in rolling of a smooth roller; (6) calculating the friction coefficient in the rolling process under the current working condition; and (7) calculating the rolling pressure under the current working condition. The method disclosed by the invention can realize on-line prediction of changes of the rolling pressure in a speed increasing and reducing process and can be used for monitoring the change condition of the rolling pressure in the speed increasing and reducing process in real time so as to provide a control strategy in time, so the rolling pressure fluctuation degree is greatly alleviated, on-site workers can be provided with an on-line rapid early warning mechanism, and the surface quality and strip shape accuracy of strip steel are guaranteed.

Owner:唐山市榕泽钢材加工有限公司

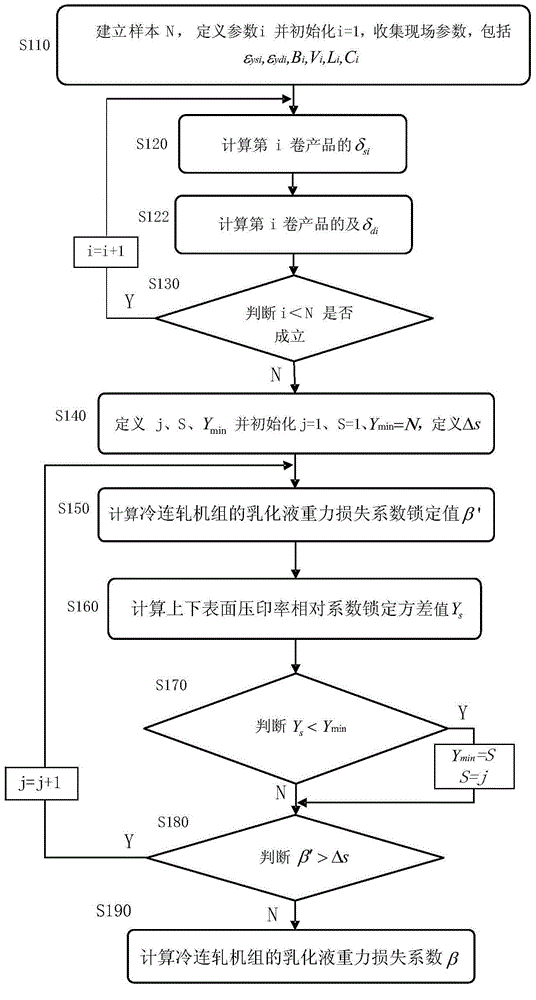

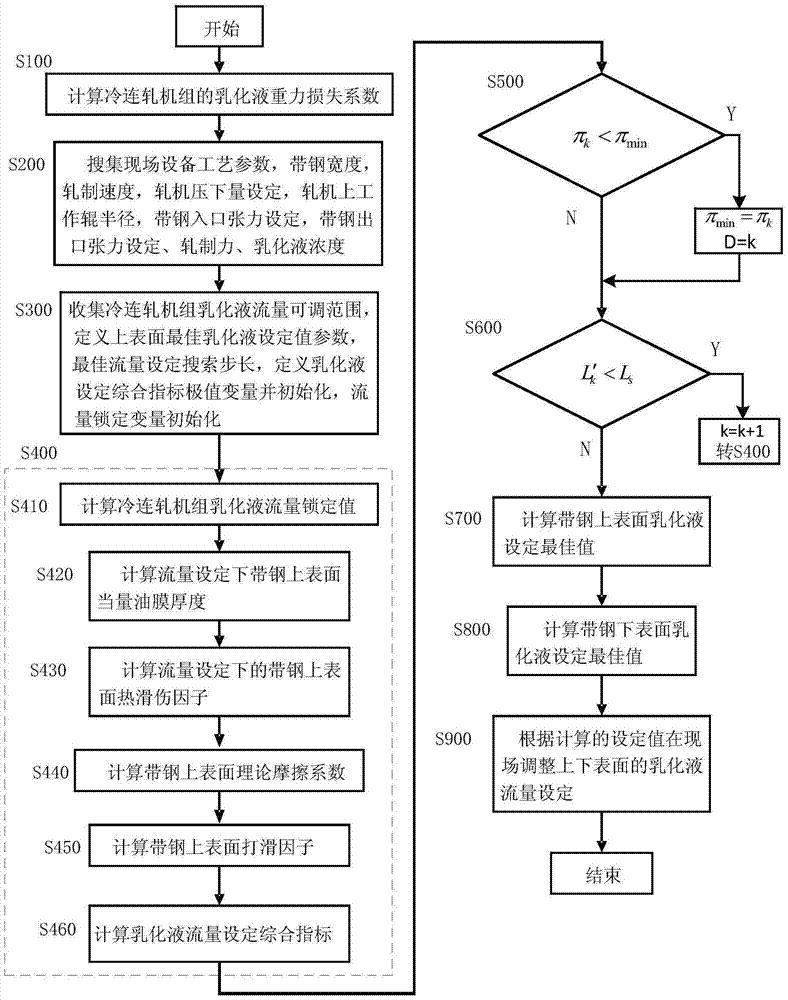

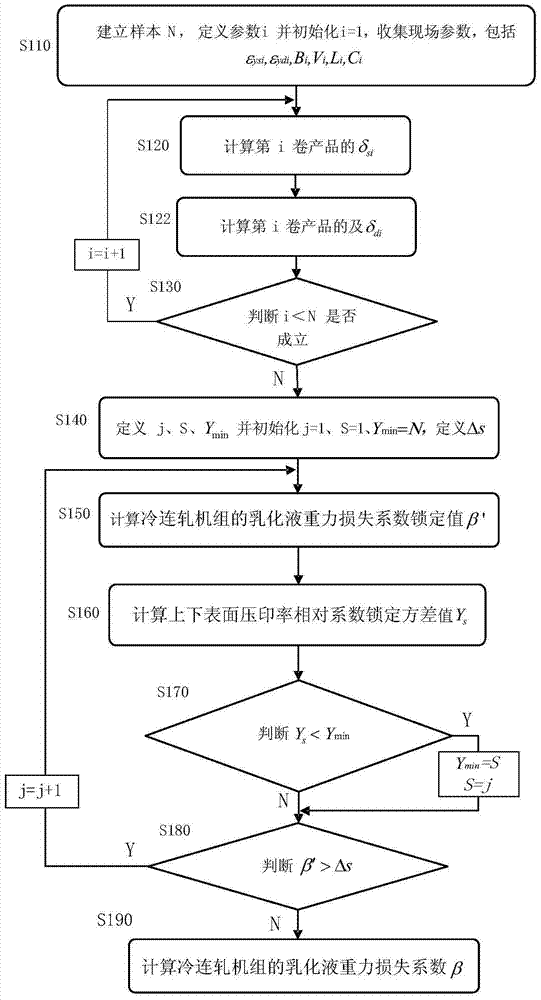

Emulsion flow differential setting method for cold continuous rolling unit

ActiveCN106363023AReduce the difference in adhesionGuaranteed surface qualityTemperature control deviceRollsEmulsionStrip steel

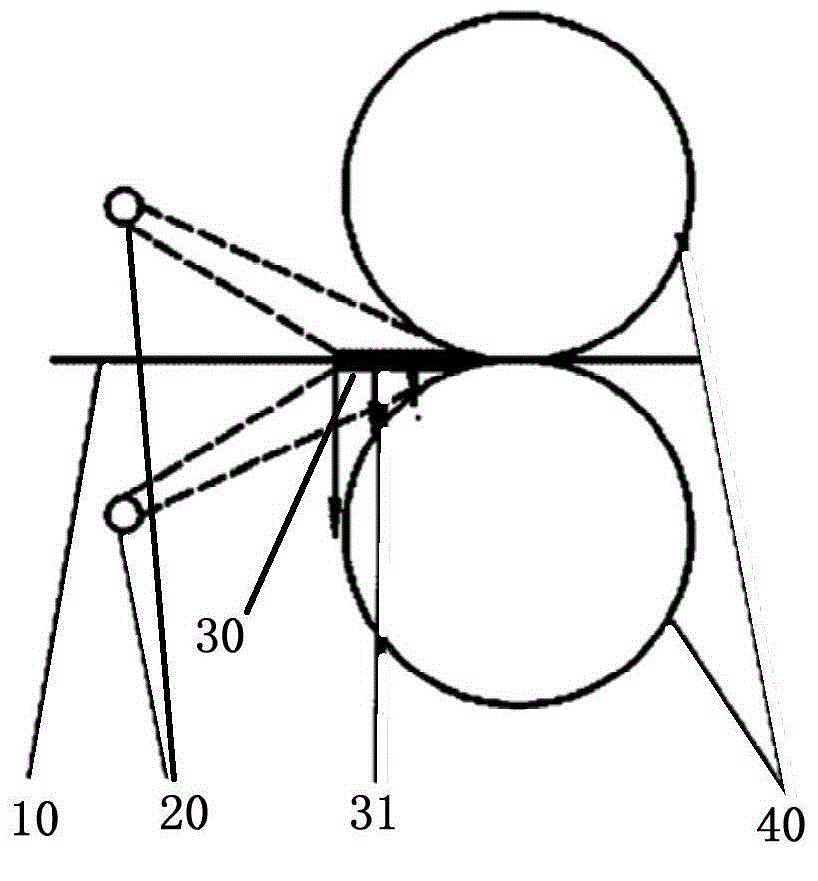

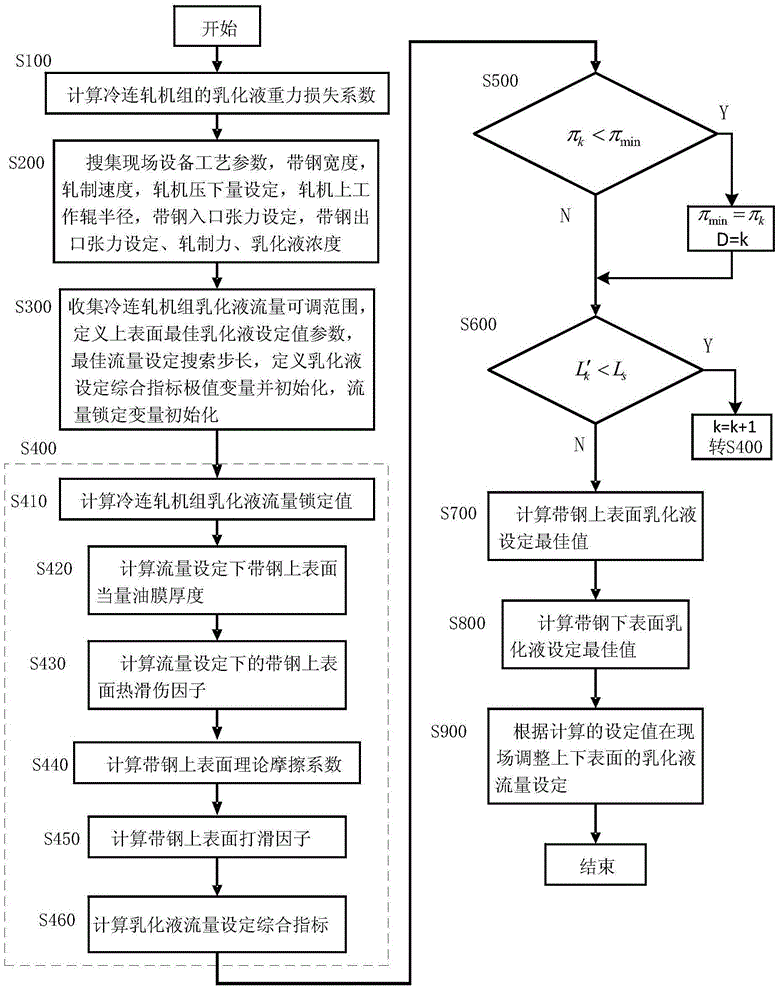

The invention provides an emulsion flow differential setting method for a cold continuous rolling unit, and relates to a control device or method specially suitable for a metal rolling machine or machined products of the metal rolling machine, in particular to a spray flow control method for the emulsion on the upper surface and the lower surface of strip steel of a cold continuous rolling unit in the cold continuous rolling unit rolling process. The emulsion flow differential setting method comprises the following steps that the gravity loss coefficient of the emulsion is calculated; the technology parameters of site equipment are collected; the flow setting comprehensive index of the emulsion is calculated; and an optimum setting value of the emulsion on the upper surface and the lower surface of the strip steel is obtained after searching. According to the emulsion flow differential setting method for the cold continuous rolling unit, flow differential setting for the spray volume of the emulsion on the upper surface and the lower surface of the strip steel is conducted, and the spray flow of the emulsion on the upper surface and the lower surface of the strip steel is adjusted, so that the spray flow differentiation of the emulsion on the upper surface and the lower surface of the strip steel is achieved; and the loss, caused by the influence of the gravity, of the emulsion on the lower surface of the strip steel is compensated, the adhesion volume difference of the emulsion on the upper surface and the lower surface of the strip steel is reduced, and therefore the roughness difference of the upper surface and the lower surface of the strip steel is reduced, the quality of the strip steel surfaces is guaranteed, brand competitiveness is improved, and benefits are brought to an enterprise.

Owner:BAOSHAN IRON & STEEL CO LTD

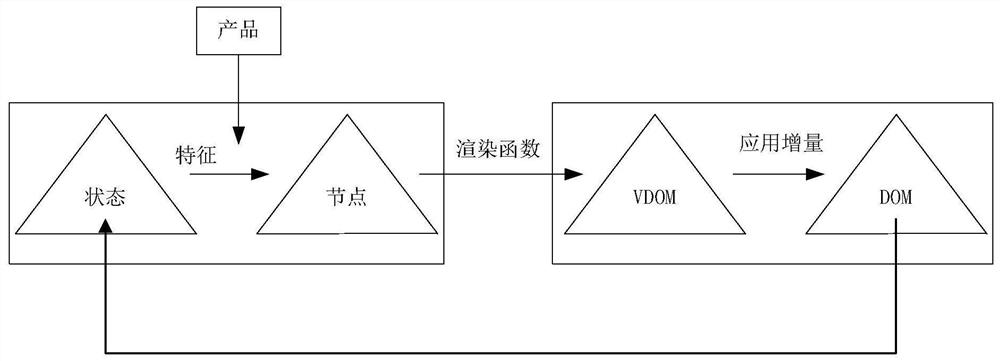

Distribution store position matching system

InactiveCN104216705AFilling the gap in e-commerce technologyImprove brand competitivenessSpecific program execution arrangementsUser needsInternet business

The invention provides a distribution store position matching system which is one of the core technologies of a distribution type E-business technology. The development of a distribution store is obstructed due to the blank of a position matching technology so that a chain business type merchant can not develop internet businesses. The difficulty of automatically determining and intelligently matching a user position by a distribution store system is mainly overcome. The special requirements that position matching work of two types of users need to be carried out by the distribution store system at the same time are met. The technical essentials of the distribution store position matching system are that the system can convert automatically-obtained position point data of the users to position group data. Position matching of the users of the both transaction sides is automatically carried out by the distribution store system so that an intelligent matching function of the positions of the users in interaction is realized. The distribution store position matching system is the distribution type E-business core technology and the main usage supports to develop a distribution type E-business platform or system, so that user position identification and matching functions are provided for the distribution store system.

Owner:宋子诚

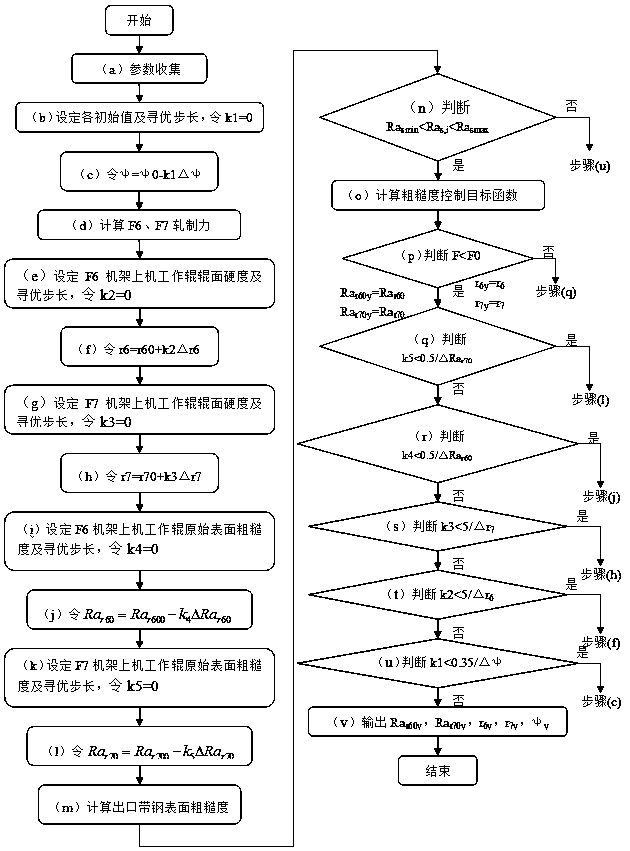

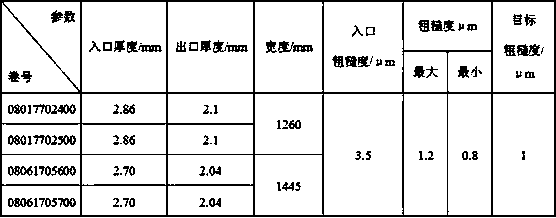

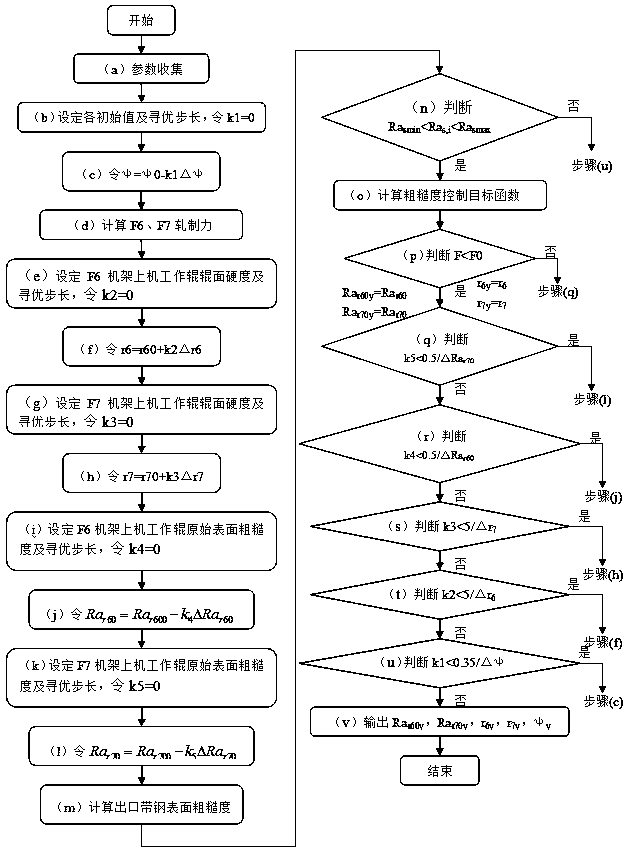

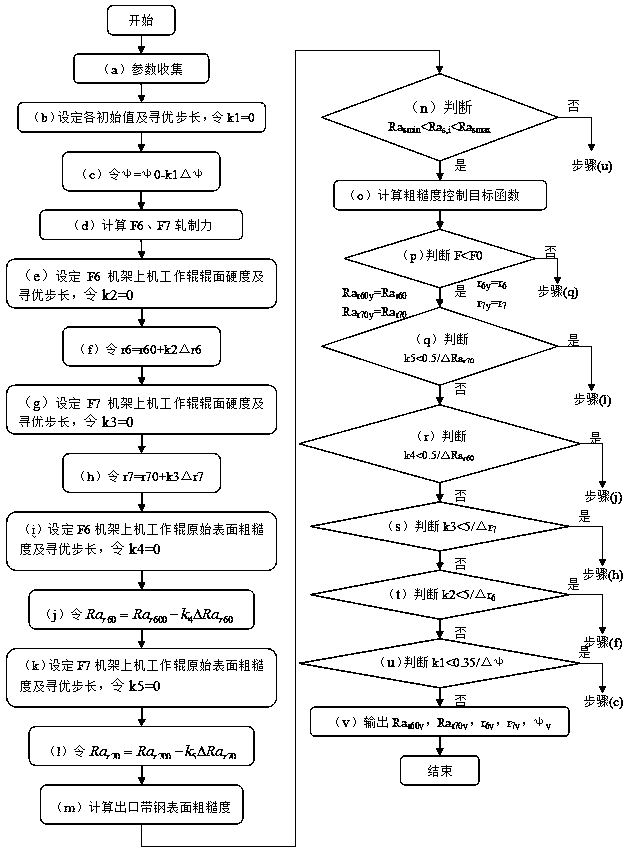

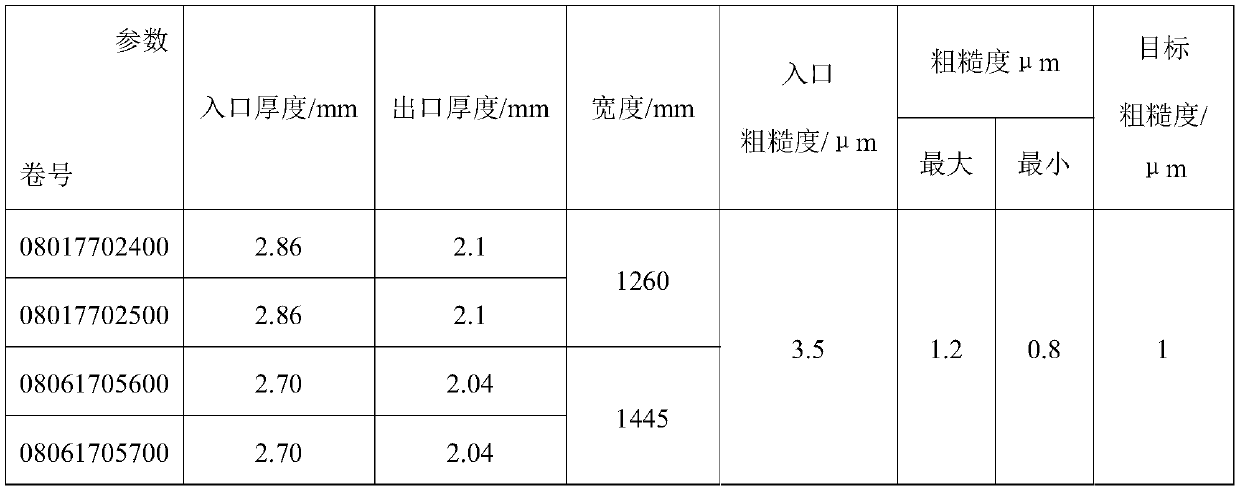

Outlet strip steel surface roughness control method suitable for hot continuous rolling unit

ActiveCN107234135AThe calculation result is accurateGuaranteed surface qualityProfile control deviceMetal rolling arrangementsReduction rateSurface roughness

The invention provides an outlet strip steel surface roughness control method suitable for a hot continuous rolling unit. Under the precondition of collecting strip steel characteristic parameters, rolling process parameters and roller use process parameters to calculate the outlet strip steel surface roughness, the method can control the strip steel surface roughness on the work site according to user requirements on the strip surface roughness through reasonable linked setting of the operating surface roughness and the operating surface hardness of working rollers of F6 and F7 frames of the hot continuous rolling unit and the reduction rate between the two frames, so that the benefits are brought to enterprises.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

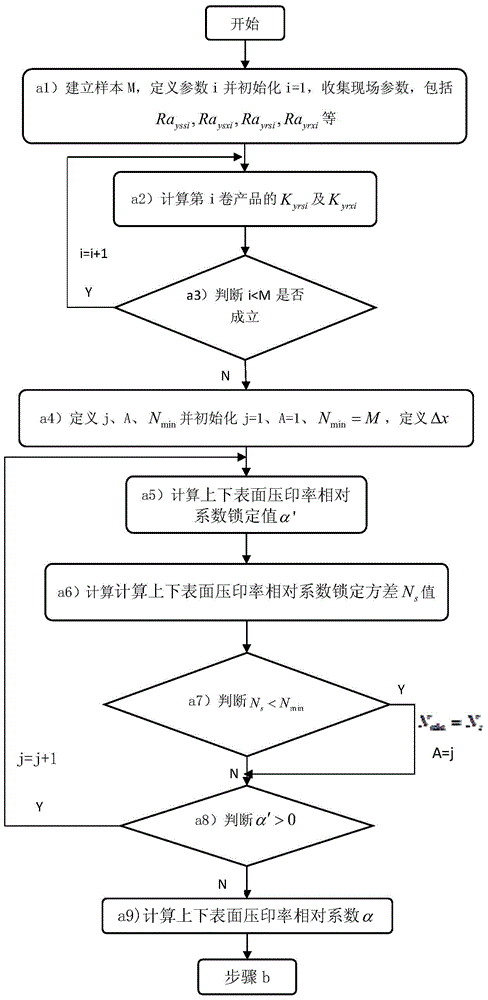

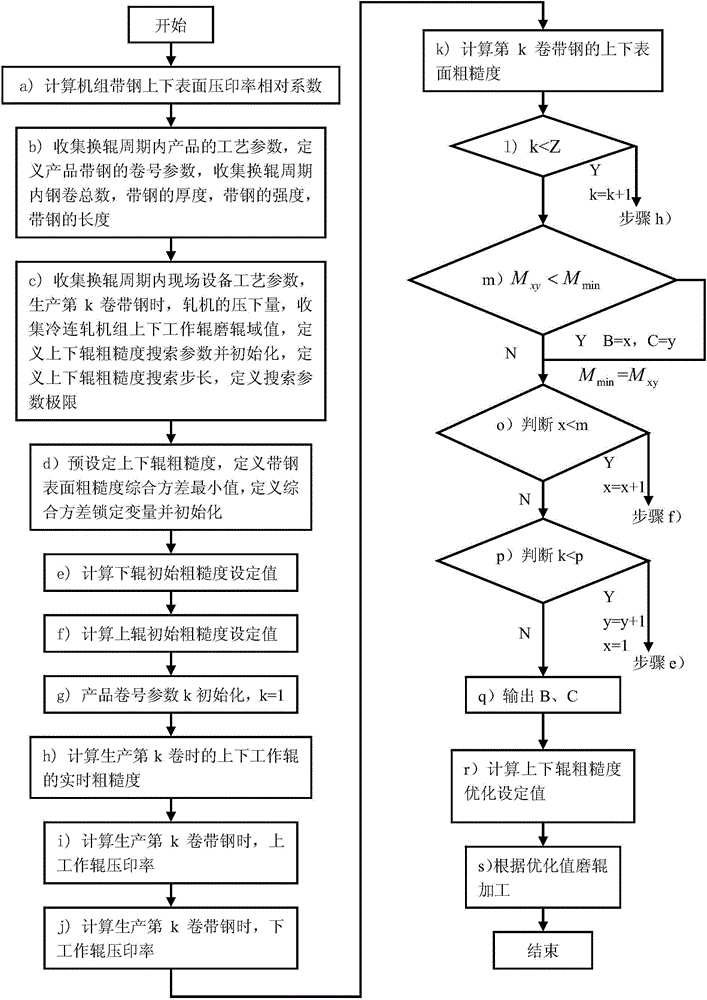

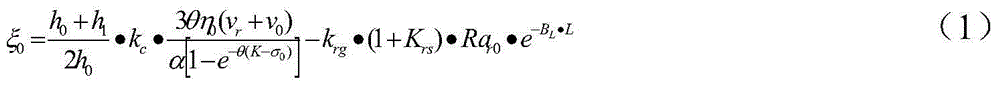

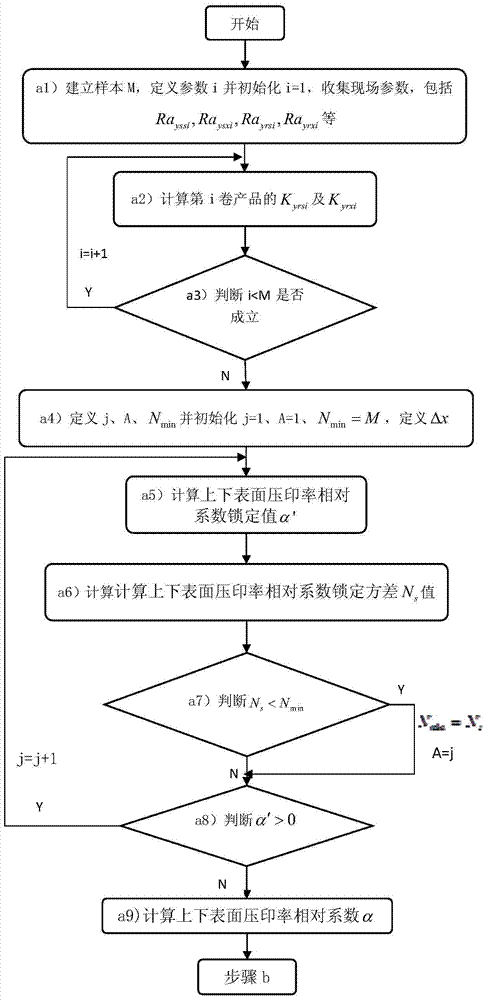

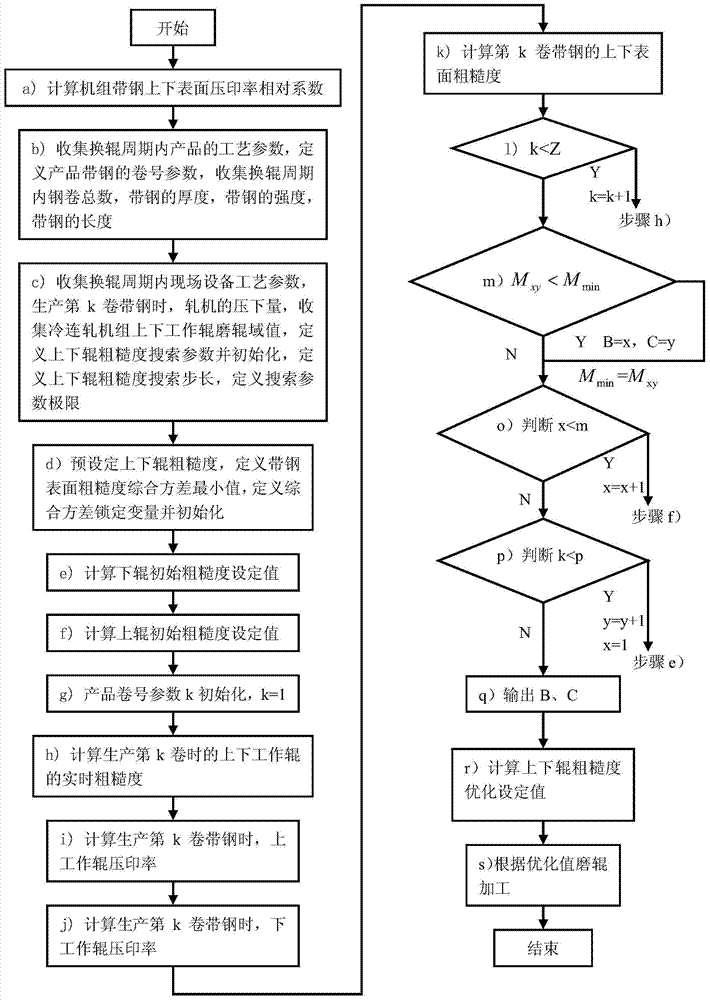

Comprehensive setting method suitable for original roughness of surfaces of upper and lower working rolls of cold continuous rolling unit

ActiveCN106311758AGuaranteed surface qualityAdhesion difference reducedProfile control deviceEmulsionStrip steel

The invention discloses a comprehensive setting method suitable for original roughness of surfaces of upper and lower working rolls of a cold continuous rolling unit, belonging to the field of cold rolling. The method is characterized in that according to the coining ratio relative coefficient of the upper and lower surfaces of strip steel of the unit, product technological parameters and on-site technological parameters in a roll changing cycle are collected; real-time roughness of the upper and lower working rolls when the kth reel is produced is obtained; optimization setting values of roughness of the upper and lower rolls are calculated; by setting reasonable original roughness of the surfaces of the upper and lower working rolls, the difference of emulsion adhesion amount of the upper and lower surfaces of the strip steel is compensated through the roughness setting of the upper and lower working rolls, and roughness difference between the upper and lower surfaces of the strip steel is then reduced, so that the surface quality of the strip steel is ensured. The comprehensive setting method can be widely applied to machining treatment of the surfaces of the upper and lower working rolls of the cold continuous rolling unit and the field of production technique control of the cold continuous rolling unit.

Owner:BAOSHAN IRON & STEEL CO LTD

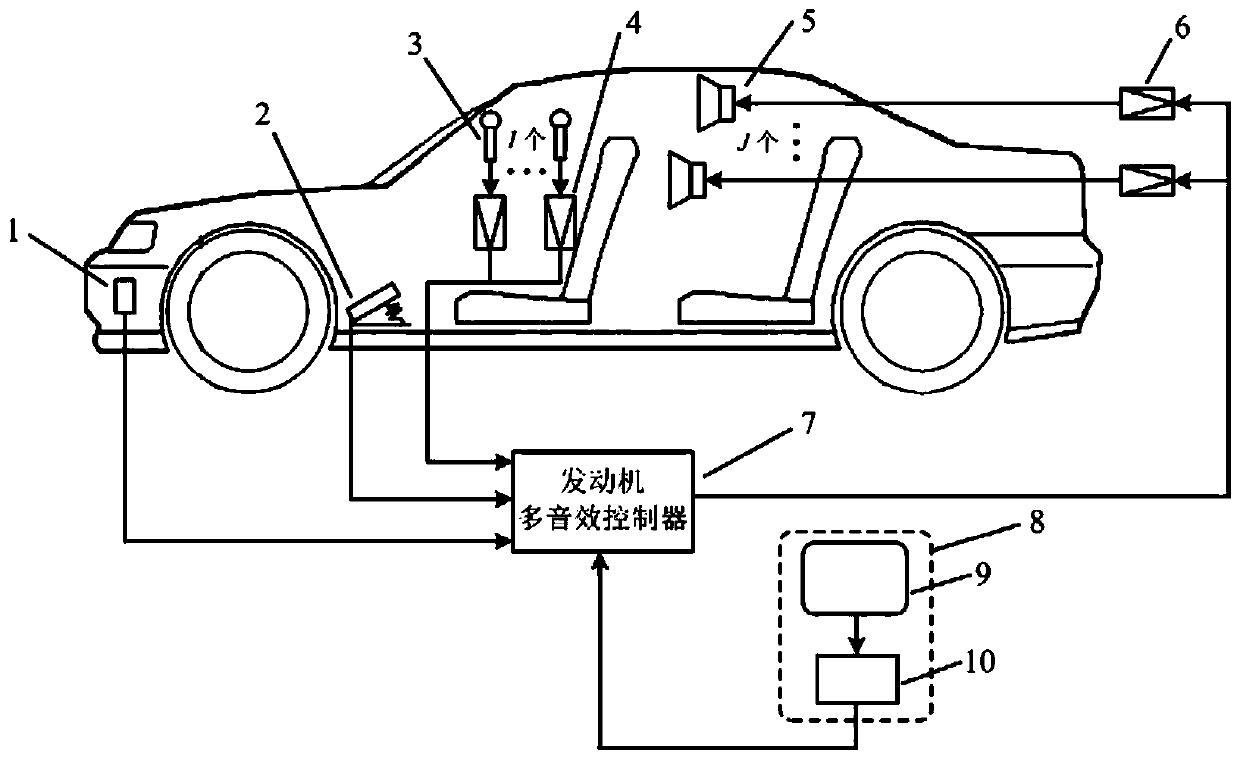

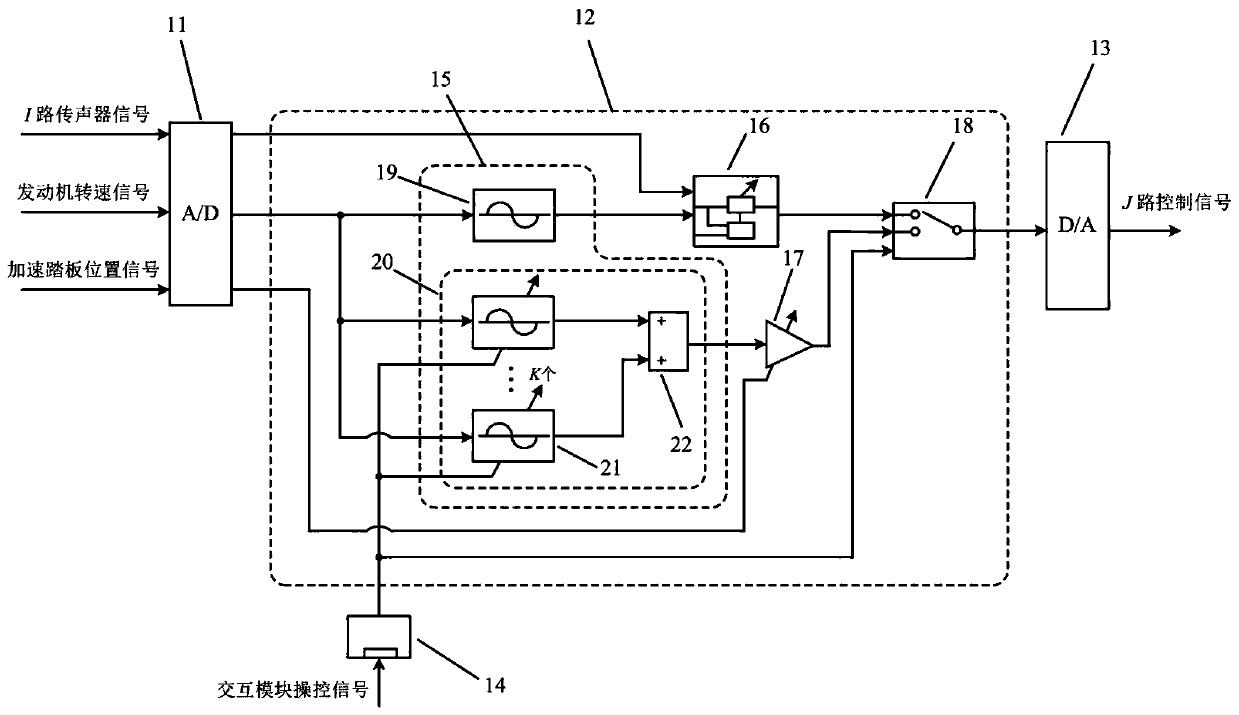

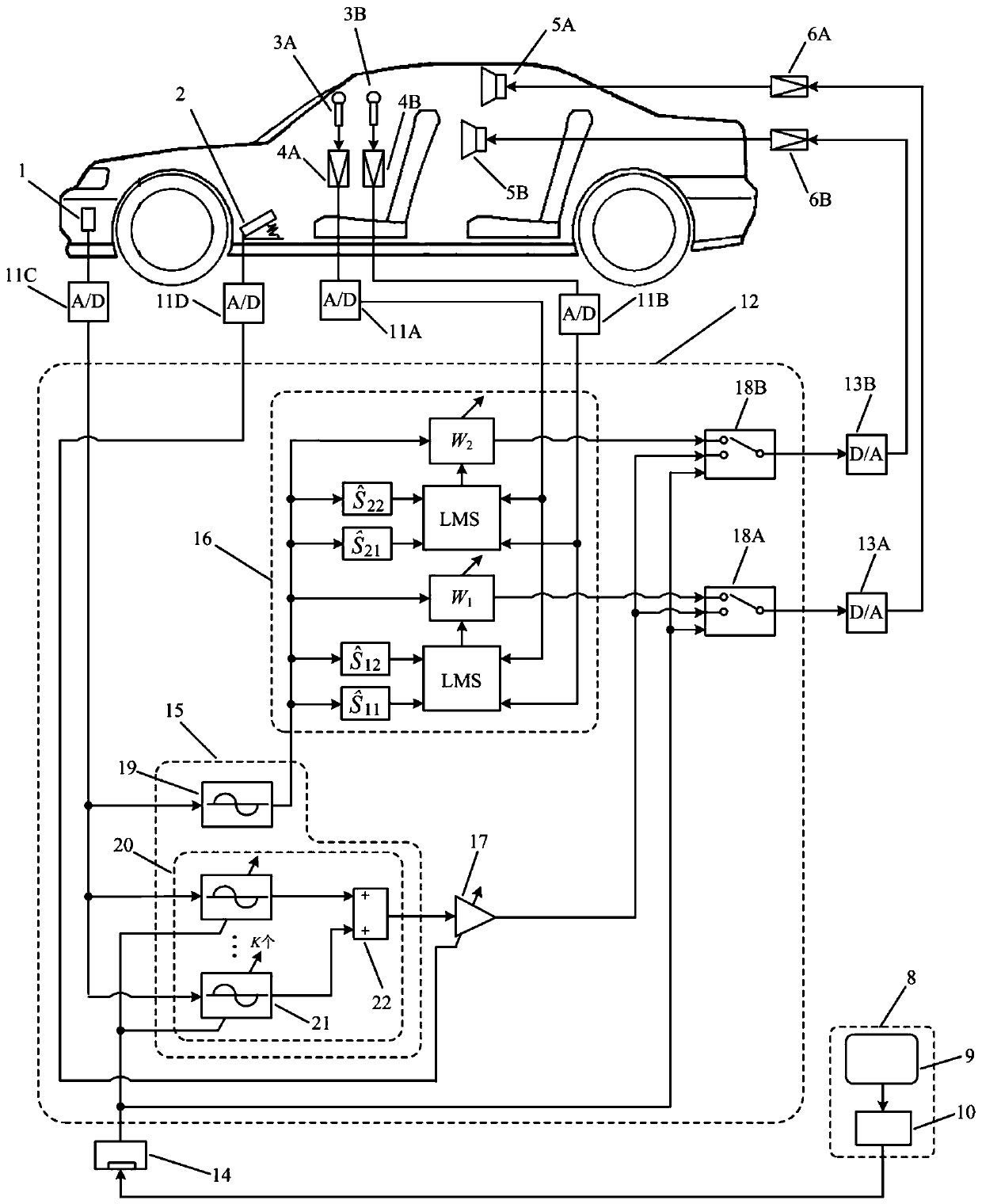

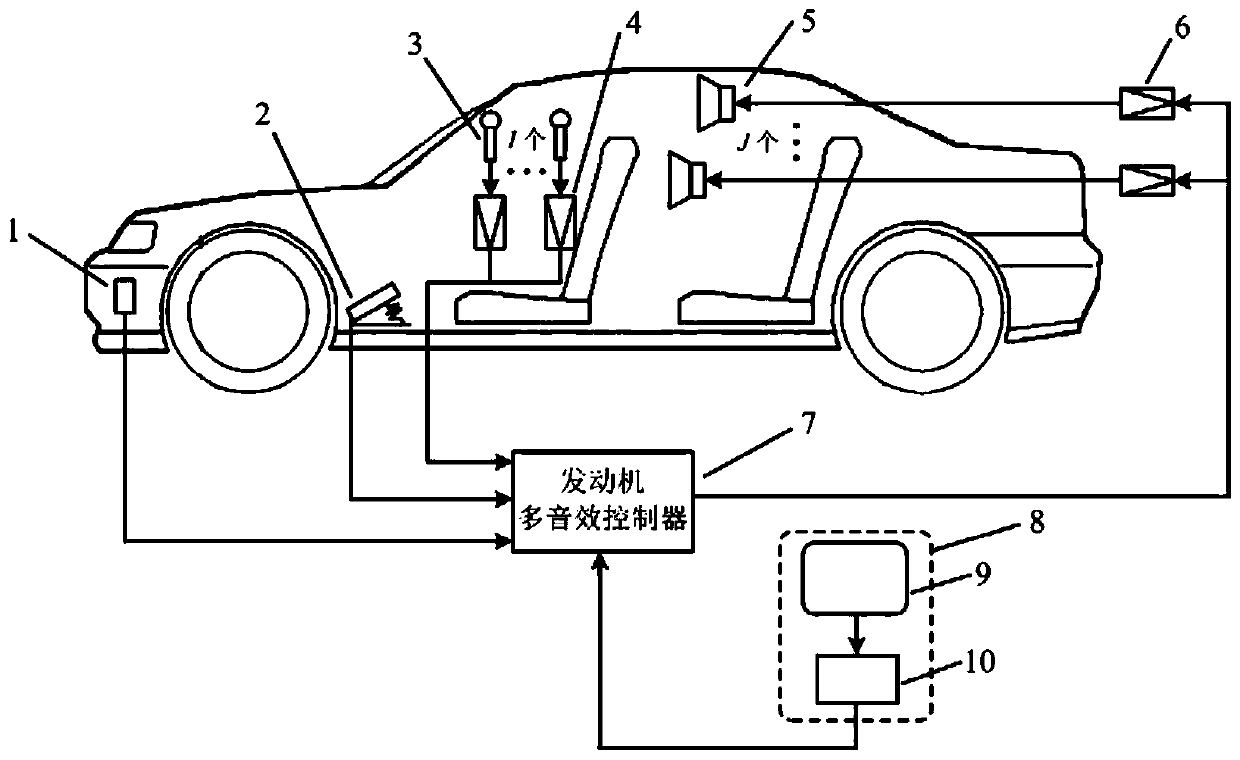

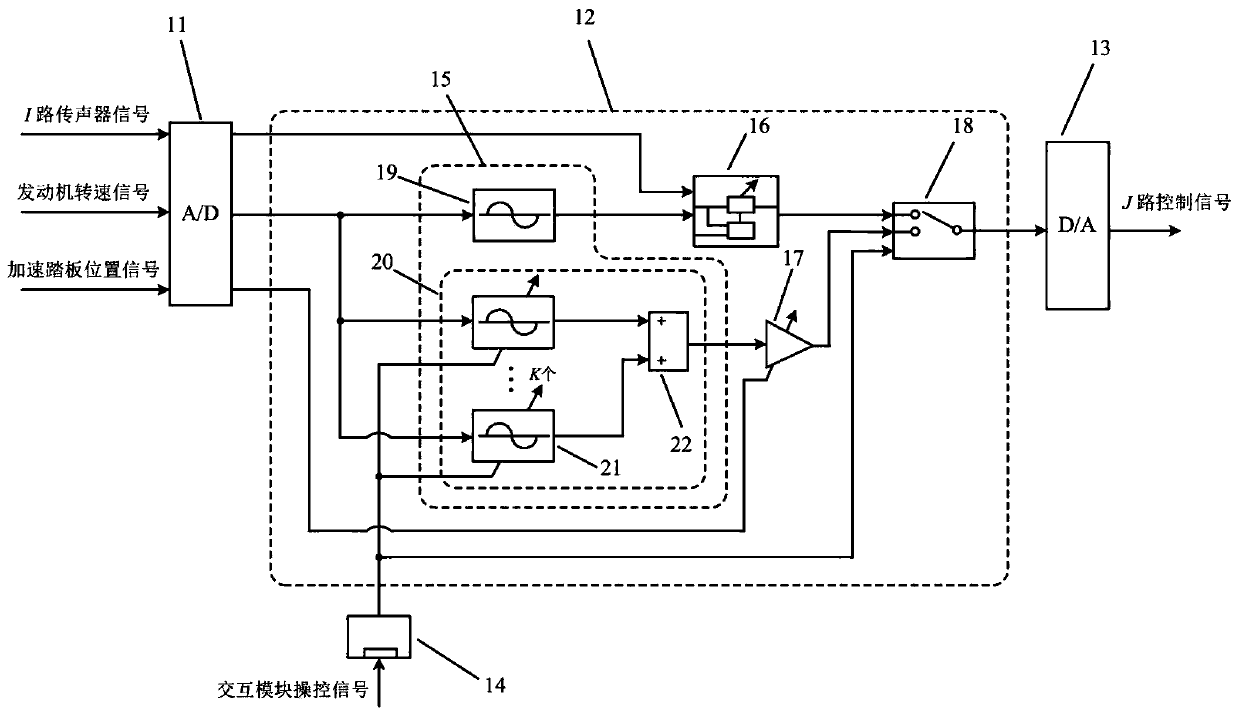

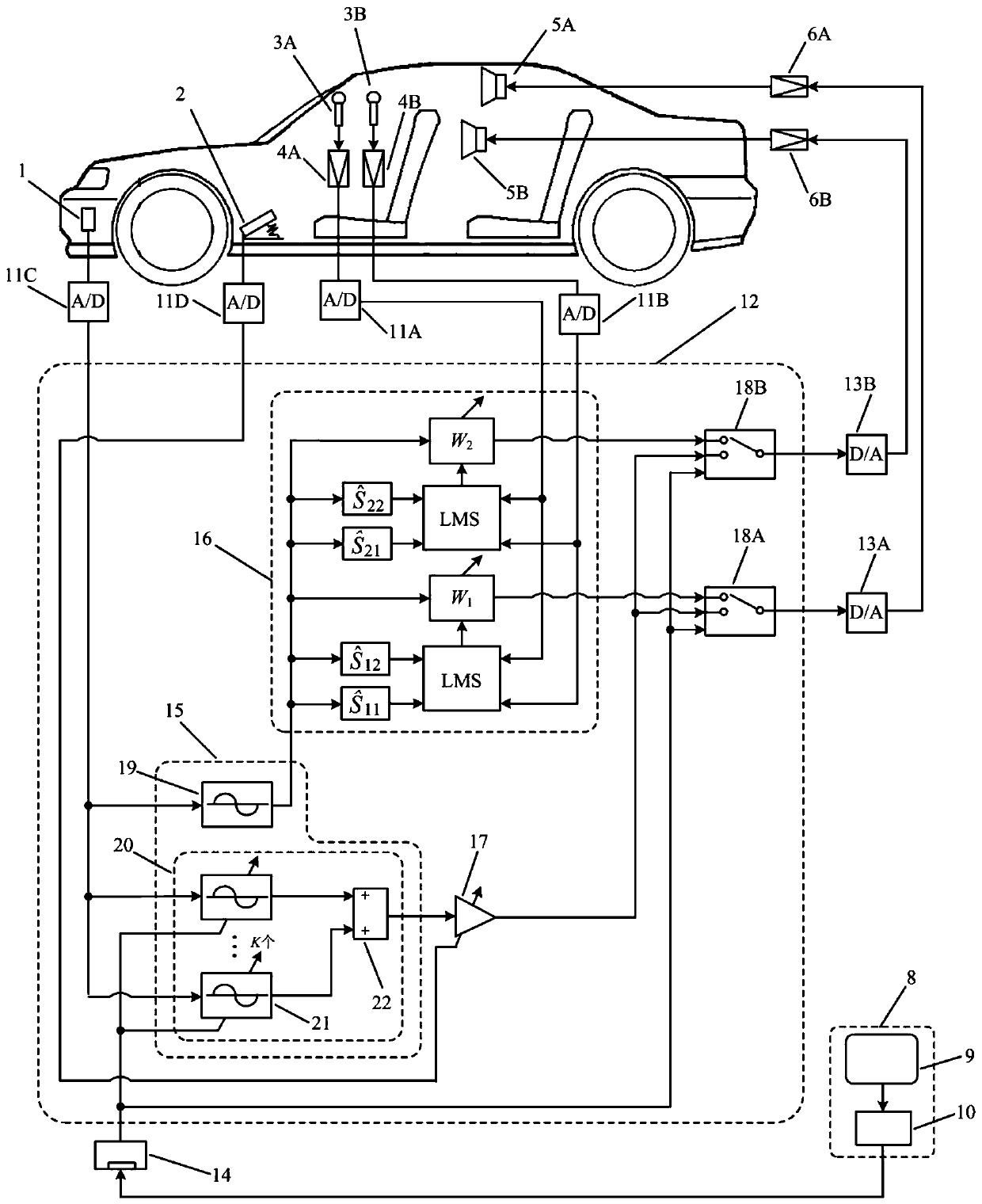

In-vehicle engine multi-sound-effect active control system

ActiveCN110126840AFlexible and more effective hearing effectLow costElectric/fluid circuitControl devicesControl signalMicrophone

The invention discloses an in-vehicle engine multi-sound-effect active control system, and relates to an active control technology of vehicle interior sound. The system comprises an engine speed sensor, an accelerator pedal position sensor, a microphone, a microphone preamplifier, a speaker, a power amplifier, an engine multi-sound-effect controller and a human-computer interaction module; the engine multi-sound-effect controller includes an A / D conversion module, a multi-sound-effect processing module, a D / A conversion module and a communication interface; a software architecture of the multi-sound-effect processing module includes an order signal generator, an ignition self-adaptive control module, a dynamic gain adjuster and a control signal selection module; the system obtains three in-vehicle sound effects of "comfortable", "powered" and "sporty" by actively weakening or actively adding engine sound of appropriate order components, the sound preferences and needs of different groups of people can be met, driving interaction and experience are enhanced, and the brand competitiveness and attractiveness of vehicle products are enhanced.

Owner:JIANGSU UNIV

Method for improving financial competitive power of enterprises

InactiveCN101887540AImprove brand competitivenessOptimize property right structureResourcesStrategy methodEnterprise management

The invention relates to a method for improving the financial competitive power of enterprises. Enterprise strategic management needs support from enterprise financial management, and the financial management in which enterprise fund management is an important content must reflect the requirements of enterprise strategies and ensure the implement of the enterprise strategies. The value of the application of a financial strategy model and a financial strategy method in enterprise management lies in that the financial strategy model and the financial strategy method can ensure the sound financial condition of the enterprise, effectively control the financial crisis of the enterprises and guarantee the smooth realization of the strategies of the enterprises. For solving the competitive power problem of enterprises, the invention provides the method for improving the financial competitive power of enterprises. The method of the invention comprises: intensifying the application of value chain analysis and improving brand competitive power; strengthening inter-enterprise strategic alliance establishment; optimizing property right structure, and improving financial efficiency; and strengthening cost control and period expense control.

Owner:王磊

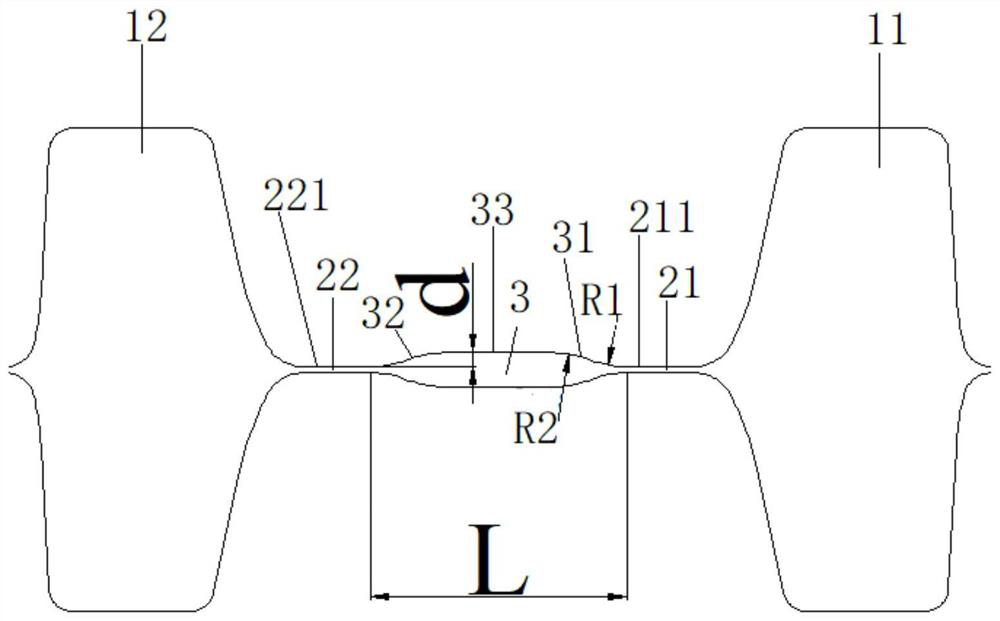

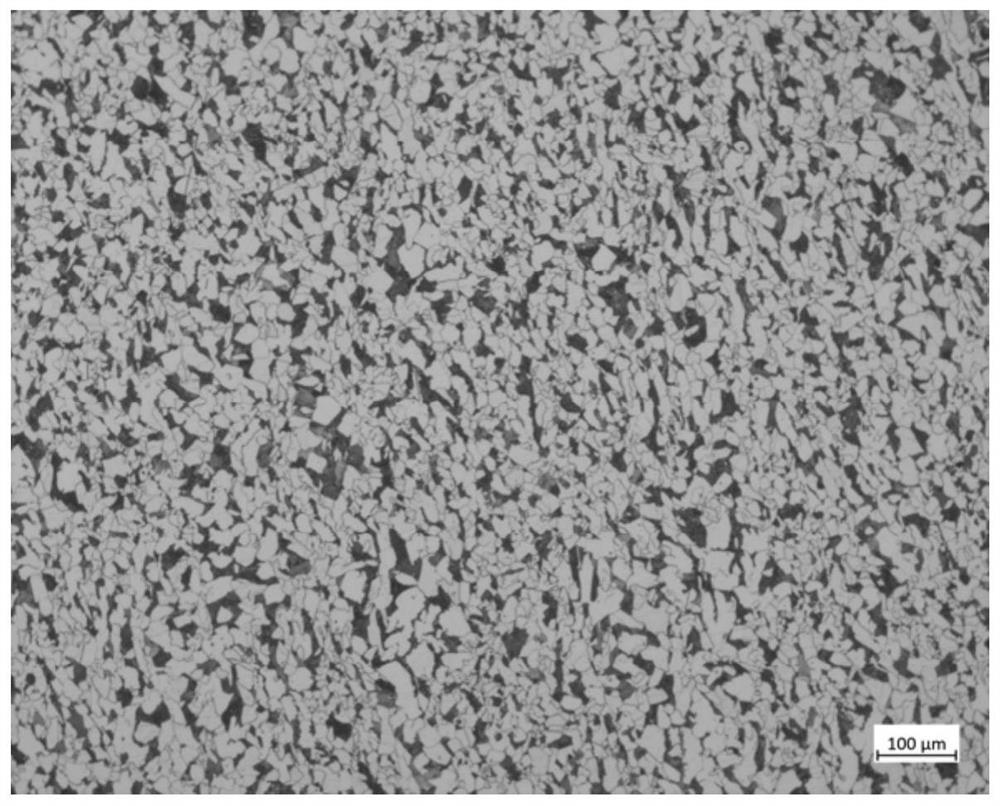

Wide-flange heavy hot-rolled H-shaped steel, and production method and application thereof

ActiveCN113604740AMeet the bearing capacity requirementsAvoid destructionTemperature control deviceExcavationsMaterials scienceIndustrial engineering

The invention provides wide-flange heavy hot-rolled H-shaped steel, and a production method and application thereof. The wide-flange heavy hot-rolled H-shaped steel comprises the following components: 0.11 to 0.15 percent of C, 0.35 to 0.45 percent of Si, 1.30 to 1.60 percent of Mn, at most 0.015 percent of P, at most 0.015 percent of S, 0.03 to 0.05 percent of V, 0.030 to 0.050 percent of Nb, at most 0.0002 percent of H, at most 0.008 percent of N, 0.010 to 0.015 percent of Alt and the balance of Fe and trace residual elements. In the rough rolling stage, through hole pattern design optimization, the thickness of a web is reserved, metal distribution of the flanges and the web is optimized, more metal is provided for broadening of the flanges, and then the wide-flange heavy hot-rolled H-shaped steel with the flange width greater than or equal to 500 mm and the flange thickness being 80 mm to 140 mm is obtained. The product meets the bearing capacity requirements of high-rise and super high-rise buildings on the hot-rolled H-shaped steel for foundation pit supporting.

Owner:MAANSHAN IRON & STEEL CO LTD

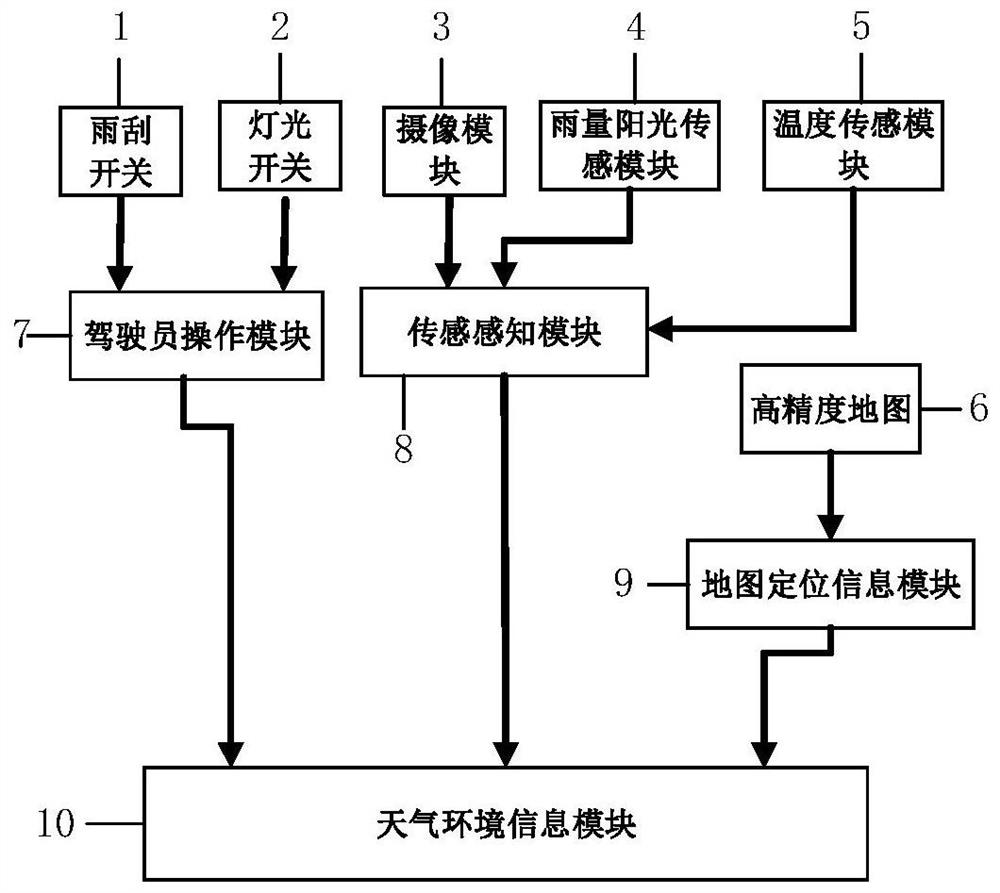

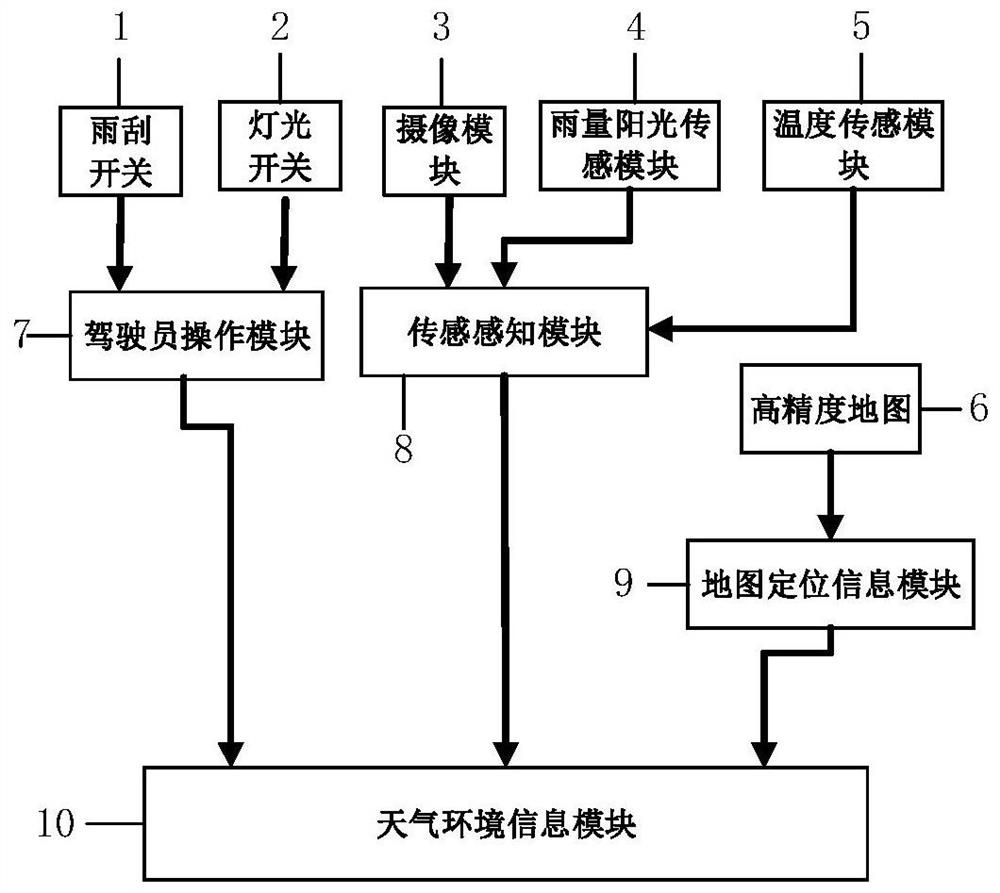

Meteorological condition prediction method and device for self-driving vehicle, vehicle and controller

ActiveCN112849161AAddressing deficiencies in imperfect monitoringImprove securityICT adaptationVisibilityIn vehicle

The invention relates to a meteorological condition prediction method and device for a self-driving vehicle, a vehicle and a controller, and aims to solve the problem that in the prior art, the real meteorological environment of the environment where the vehicle is located cannot be predicted, so that safety threats exist in vehicle driving. The method comprises the steps of determining a third initial rainfall level based on windscreen wiper information, determining a light level based on lamplight information, and determining an illumination level based on visibility information and information of an environment scene where a vehicle is located; determining a final rainfall level based on the first initial rainfall level, the second initial rainfall level and the third initial rainfall level; determining a final illumination level based on the illumination level, the light level, the pollution level information and the weather type information; determining whether the environment temperature exceeds the standard or not based on the environment temperature information; and according to the result, determining whether the meteorological condition of the current environment of the vehicle meets automatic driving or not.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

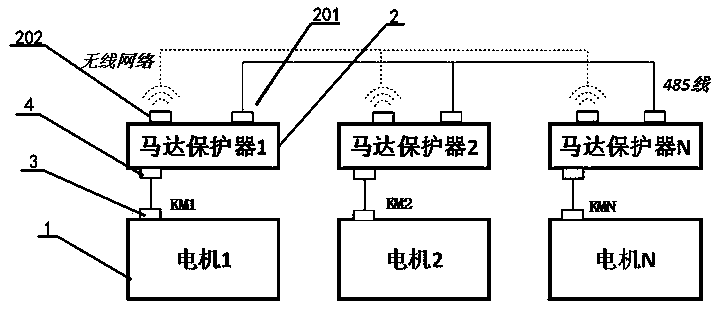

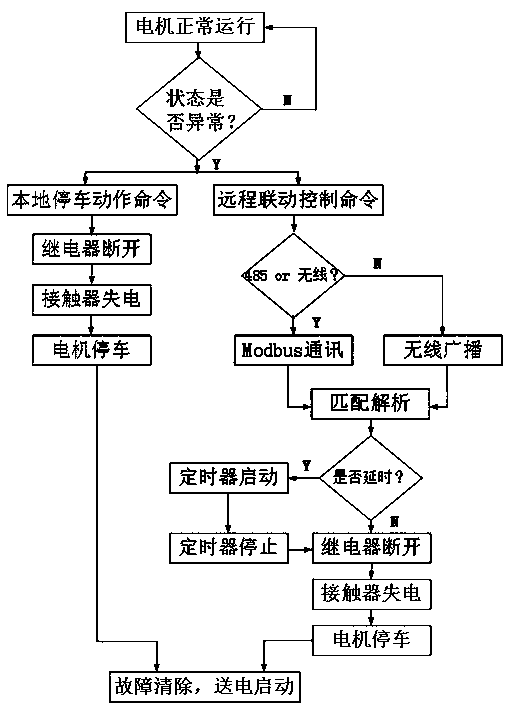

A motor linkage control method based on a motor protector

InactiveCN109194201AImprove brand competitivenessReduce manufacturing costMultiple dynamo-electric motors speed regulationElectricityElectric machine

Owner:HENAN SENIOR ELECTRIC

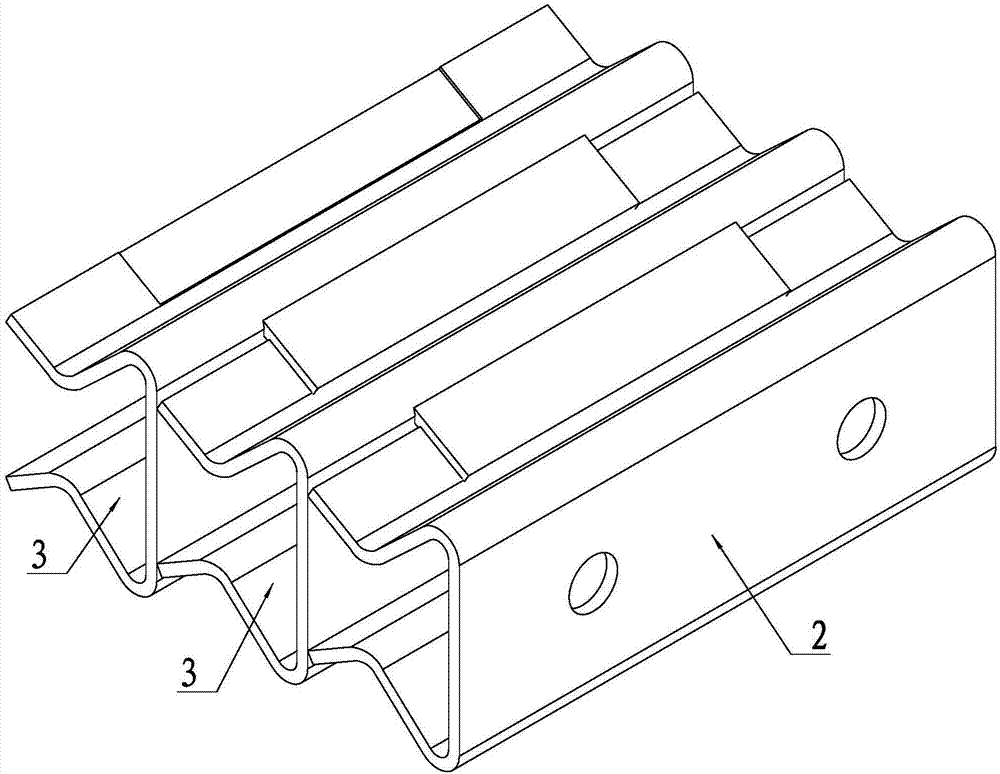

Wire clamp for fixing cable in case

InactiveCN107546667AImprove brand competitivenessImprove satisfactionElectrical apparatusEngineeringMechanical engineering

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

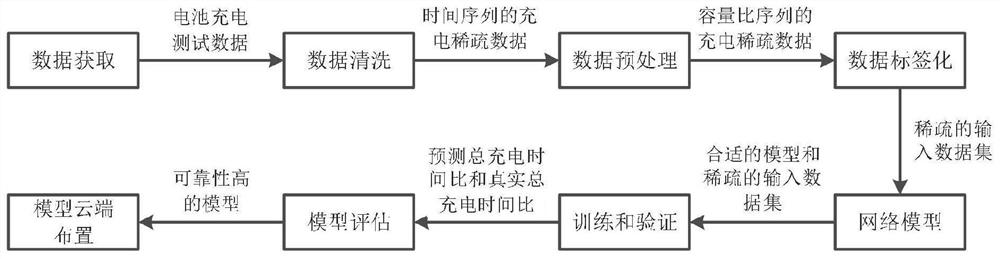

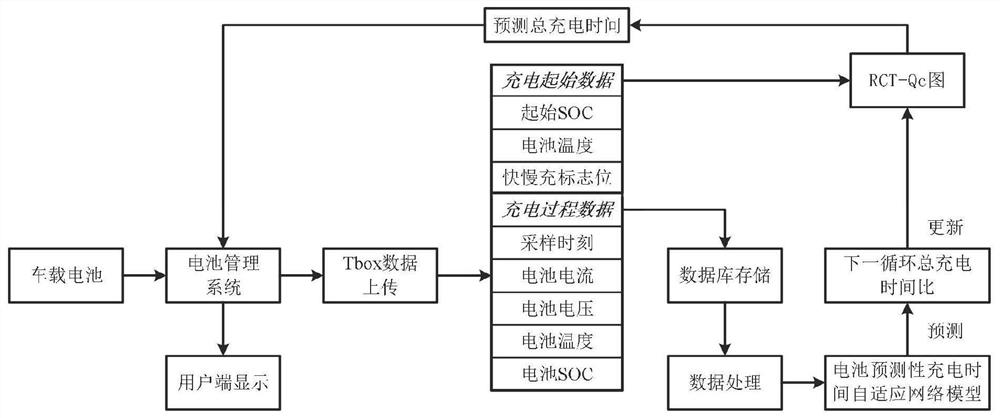

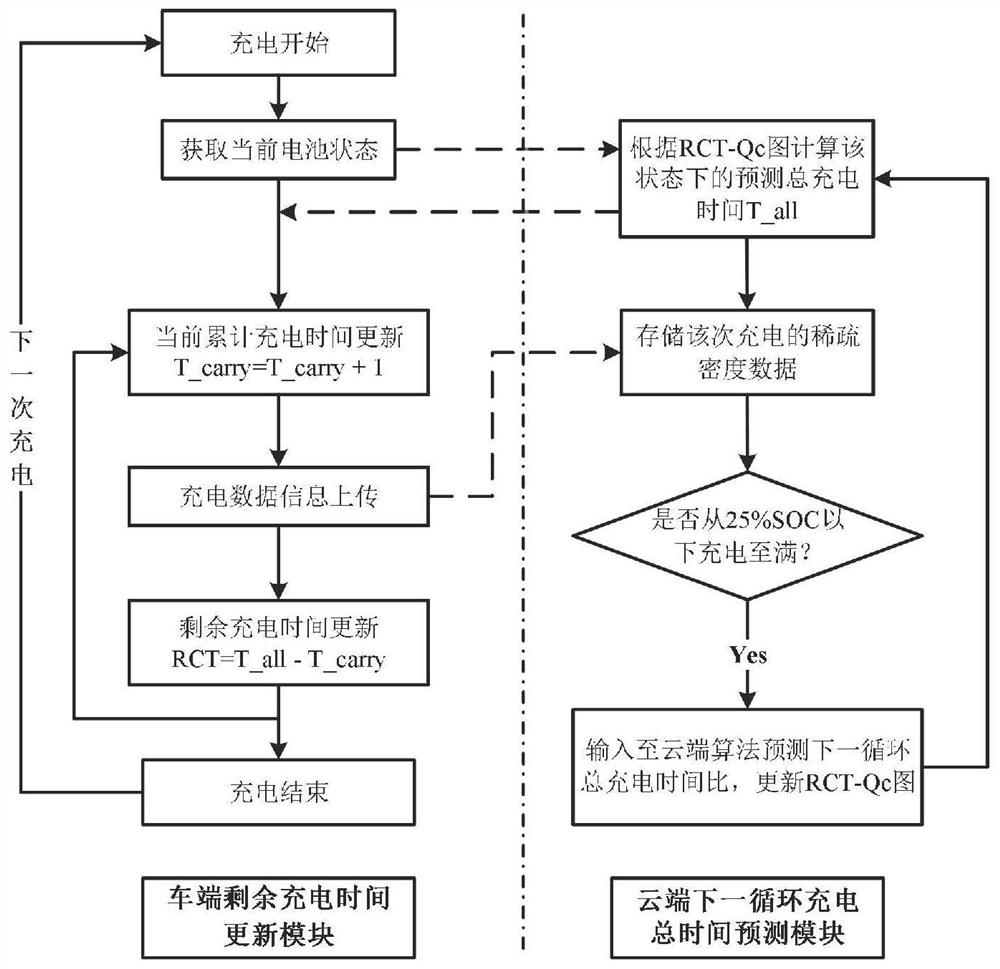

Electric vehicle residual charging time prediction method and system based on cloud sparse charging data

ActiveCN113119796AAvoid uncertainty and low life cycle coverage issuesGuaranteed forecast accuracyElectric vehicle charging technologyVehicular energy storageElectrical batteryElectric vehicle

The invention provides an electric vehicle residual charging time prediction method and system based on cloud sparse charging data. The method comprises the steps of 1, battery charging test data is obtained, a battery predictive charging time adaptive network model is established, cross validation and statistical evaluation are performed on the model, and a trained network model is arranged at the cloud; 2, the cloud receives and stores sparse data of battery charging, detects whether the data meets a preset condition or not, and predicts the total charging time of the next cycle and updates the remaining time-capacity ratio diagram by using the network model if the data meets the preset condition; and 3, the cloud inquires the remaining time-capacity ratio diagram, the predicted total charging time in the current state is recorded, the current accumulated charging time is recorded at the same time, and the remaining charging time of the battery is predicted. The technical problem that the online residual charging time of the current electric vehicle is difficult to accurately obtain in the whole life cycle is solved, and the user experience is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Preparation method of whitening and freckle-removing cream

PendingCN112043636AImprove whitening degreeEnhance brand competitiveness and purchasing powerCosmetic preparationsToilet preparationsNutritional compositionErythritol

The invention provides a preparation method of whitening and freckle-removing cream. The whitening and freckle-removing cream comprises the following raw materials of water, glycerine, butanediol, caprylic / capric triglyceride, cyclopentasiloxane, nicotinamide, butyrospermum parkii butter, isopropyl myristate, hydrogenated polyisobutene, erythritol, cetostearyl alcohol, cetostearyl glucoside, glyceryl stearate, PEG-100 stearate, polydimethylsiloxane and 3-o-ethyl ascorbic acid. According to the whitening and freckle-removing cream disclosed by the invention, through matching of preparation processes of preparing a skin caring mixture A, preparing a nutrient solution mixture B, preparing an emulsification caring solution C, preparing a thickening agent solution D, performing sterilizing andhomogenizing, performing cooling, performing filling and performing packaging, more nutritional ingredients and effective ingredients for inhibiting and reducing melanin can be added into a cream matrix of the whitening and freckle-removing cream; so that the freckle-removing cream can be used for sufficient lightening impurity freckles, can be used for a long time, can achieve the effect of removing freckles, and besides, can increase the whiteness of the face, so that the skin of the face becomes cleaner and whiter.

Owner:文艳

A method for controlling the surface roughness of strip steel at the outlet of hot continuous rolling mill

ActiveCN107234135BThe calculation result is accurateGuaranteed surface qualityMetal rolling arrangementsProfile control deviceReduction rateSurface roughness

The invention provides an outlet strip steel surface roughness control method suitable for a hot continuous rolling unit. Under the precondition of collecting strip steel characteristic parameters, rolling process parameters and roller use process parameters to calculate the outlet strip steel surface roughness, the method can control the strip steel surface roughness on the work site according to user requirements on the strip surface roughness through reasonable linked setting of the operating surface roughness and the operating surface hardness of working rollers of F6 and F7 frames of the hot continuous rolling unit and the reduction rate between the two frames, so that the benefits are brought to enterprises.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A Prediction Method Applicable to the Variation of Rolling Pressure with Rolling Speed in Cold Rolling Process

ActiveCN106391725BQuality assuranceGuaranteed accuracyRoll force/gap control deviceRollsEmulsionStrip steel

The invention discloses a method for predicting the changes of a rolling pressure with the changes of a rolling speed in a cold rolling process. The method comprises the following computer executed steps: (1) collecting main equipment and technological parameters of a cold continuous rolling unit; (2) calculating an elastic flattening radius of a working roller; (3) calculating the temperature of emulsion in the rolling process for producing products of the typical specification under the current working condition; (4) calculating power viscosity of a lubricant; (5) calculating dynamic oil film thickness in rolling of a smooth roller; (6) calculating the friction coefficient in the rolling process under the current working condition; and (7) calculating the rolling pressure under the current working condition. The method disclosed by the invention can realize on-line prediction of changes of the rolling pressure in a speed increasing and reducing process and can be used for monitoring the change condition of the rolling pressure in the speed increasing and reducing process in real time so as to provide a control strategy in time, so the rolling pressure fluctuation degree is greatly alleviated, on-site workers can be provided with an on-line rapid early warning mechanism, and the surface quality and strip shape accuracy of strip steel are guaranteed.

Owner:唐山市榕泽钢材加工有限公司

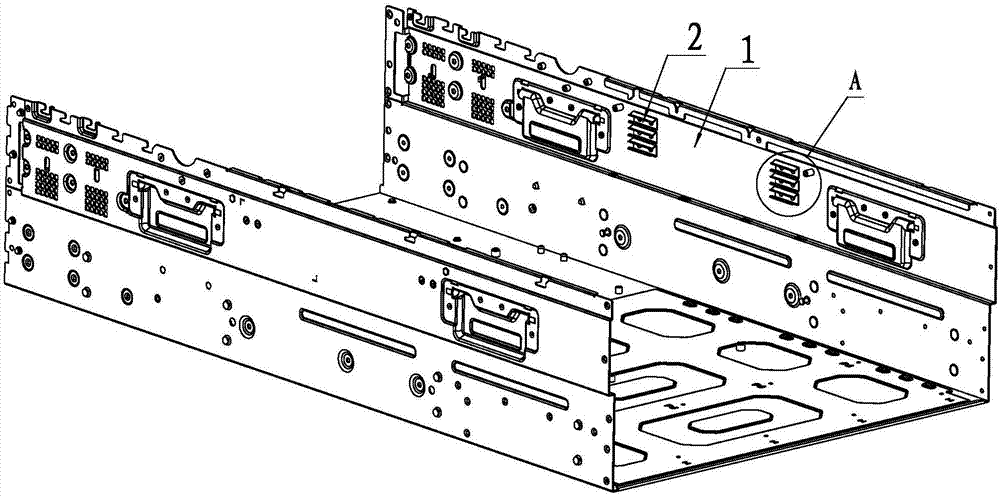

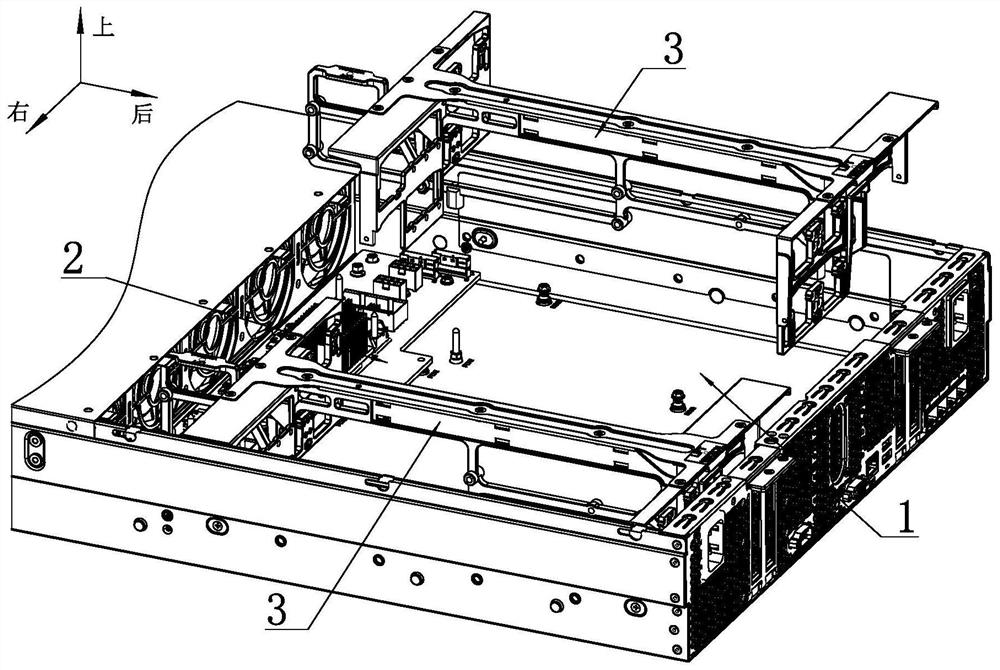

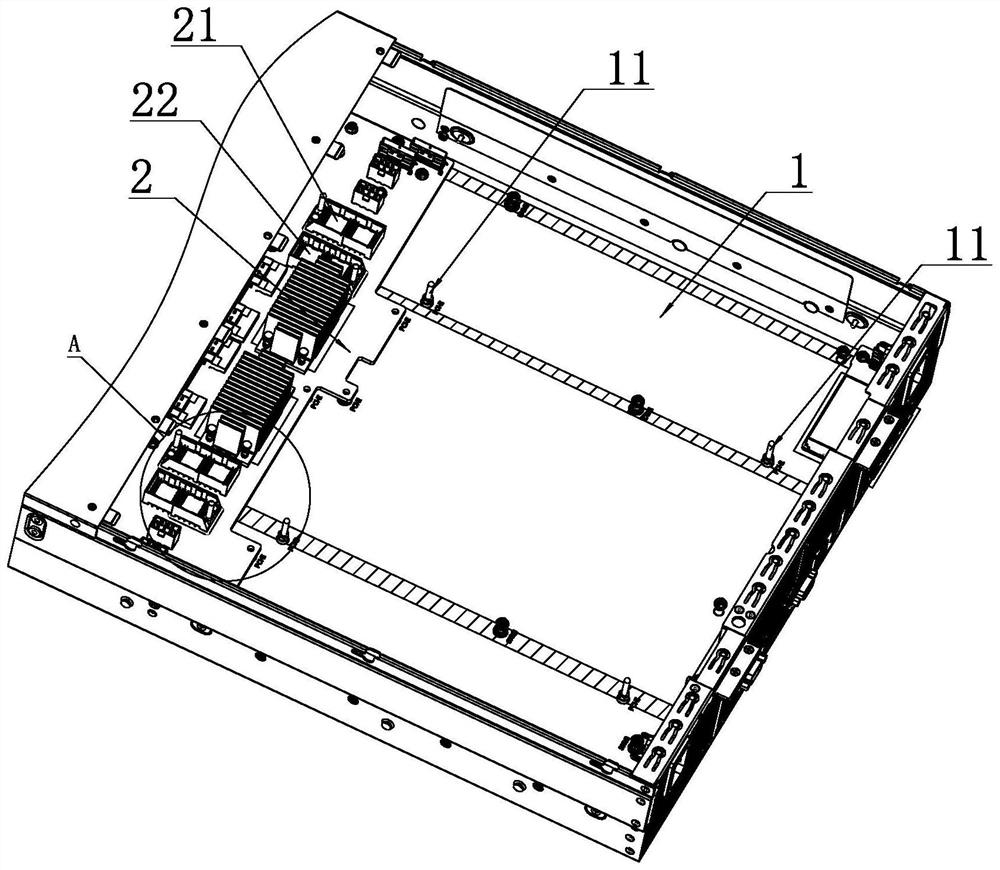

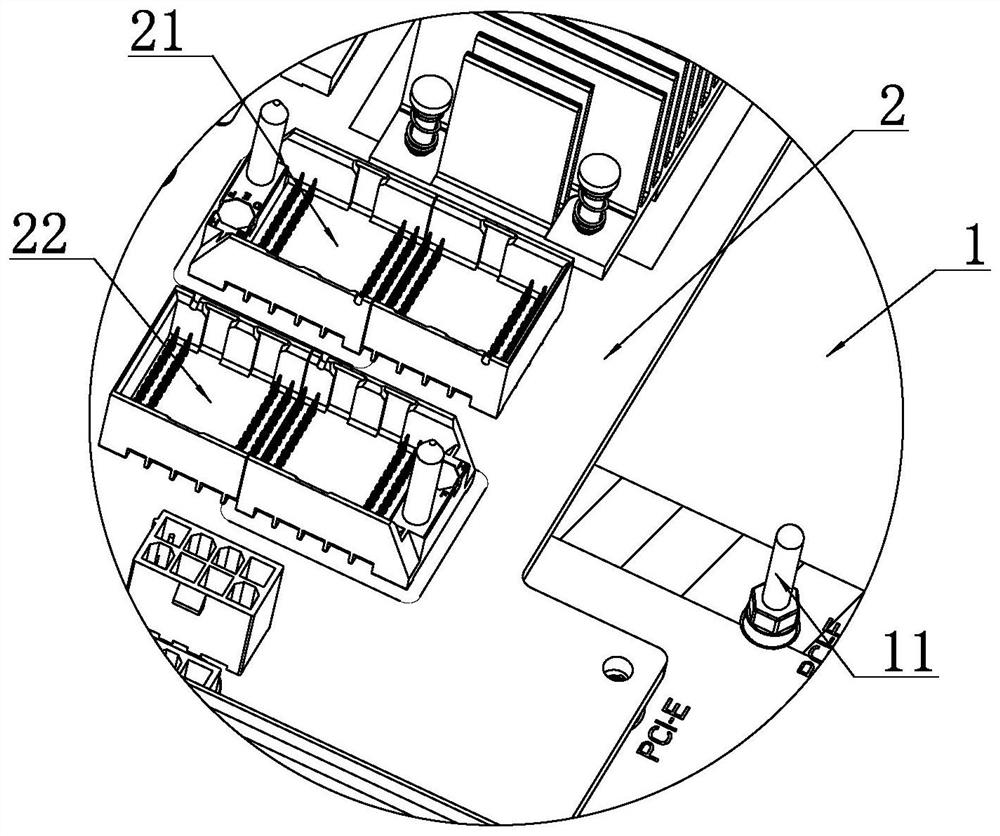

A gpu card fixing structure suitable for 2u servers

ActiveCN107943226BIncrease the number ofImprove satisfactionDigital processing power distributionCustomer delightEngineering

The invention discloses a GPU card fixing structure suitable for a 2U server. The fixing structure is provided with a main fixing plate on the chassis bottom plate. Take board. A left GPU plug and a right GPU plug are respectively provided on the inside surfaces of the left adapter board and the right adapter board, and the left GPU plug protrudes to the left from the right side of the right adapter board, and the The right GPU plug protrudes leftward from the left side of the left adapter board, and the left GPU plug and the right GPU plug are respectively plugged with GPU cards. The front ends of the outer surfaces of the left adapter board and the right adapter board are respectively provided with a left adapter board plug and a right adapter board plug, and a left adapter board plug is fixedly arranged on the GPU board on the chassis bottom plate. slot and the right adapter board slot, the GPU board is connected with the main board through a cable. This fixed structure increases the number of GPU cards in the same space, increases product function requirements, and improves brand competitiveness and customer satisfaction.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

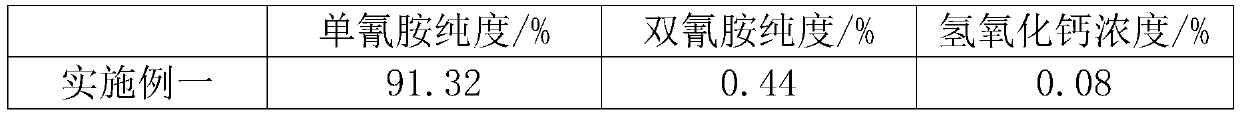

A kind of preparation method of high-quality cyanamide aqueous solution

ActiveCN108862321BRaw materials are cheap and easy to getHigh purityCyanamideHydrogenCalcium cyanamide

The invention discloses a preparation method of a high-quality cyanamide water solution. The preparation method has the advantages that the calcium oxide is used as the raw material, is low in price,and is easy to obtain; the high-temperature alloy chips are mixed into the calcium oxide and urea powder, and are used as the bath salt, so that the heating effect of the powder at high temperature isimproved, the yield rate of calcium cyanamide is increased, and the high-temperature alloy chips are easy to recycle and reutilize; the crude powder of the calcium cyanamide is rinsed by cold water,so that the content of calcium oxide impurities in the crude product of calcium cyanamide is reduced; the pH (potential of hydrogen) value of a dissolving system is controlled by a phosphoric acid solution, so that the generation of the side reaction product of dicyandiamide is favorably inhibited, the purity of the cyandiamide is favorably improved, the quality of the product is improved, and thepositive meaning is realized on improvement of whole quality of cyandiamide industry and brand competitiveness of enterprise.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Optimal setting method for relationship curve between emulsion flow rate and rolling speed in cold rolling process

ActiveCN106909723BSmall fluctuationQuality assuranceForecastingDesign optimisation/simulationEmulsionFrictional coefficient

Provided is an optimal setting method for the relationship curve of the emulsion flow and the rolling speed in the cold rolling process. The method mainly comprises the following steps: 1, collecting main equipment and process parameters of a cold rolling unit; 2, defining the process parameters involved in the optimization process of the emulsion flow; 3, calculating the roll bending force of a rack working roll; 4, initializing the emulsion flow coefficient; 5, calculating the set value of the emulsion flow corresponding to Vi; 6, calculating the friction coefficient mui corresponding to Vi; 7, calculating the rolling pressure, slipping factor and thermal slipping injury index corresponding to Vi; 8, solving the objective function; 9, outputting the best emulsion flow coefficient, and determining the relationship curve of the best emulsion flow and speed. The method has the advantages that the overall fluctuation rate and the maximum fluctuation rate of the rolling pressure can be kept smaller during the speed-up and speed-down process, and it is ensured that the slipping and thermal slipping defects are prevented from occurring in the rolling process, thus the surface quality and the strip shape control precision of strip steels are improved.

Owner:YANSHAN UNIV

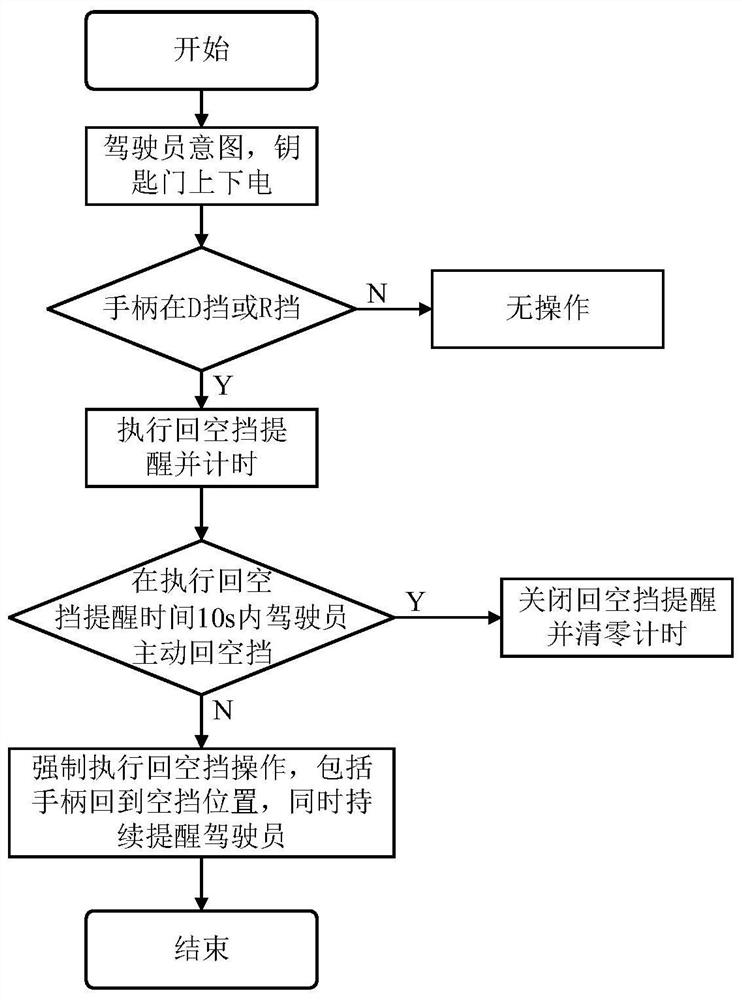

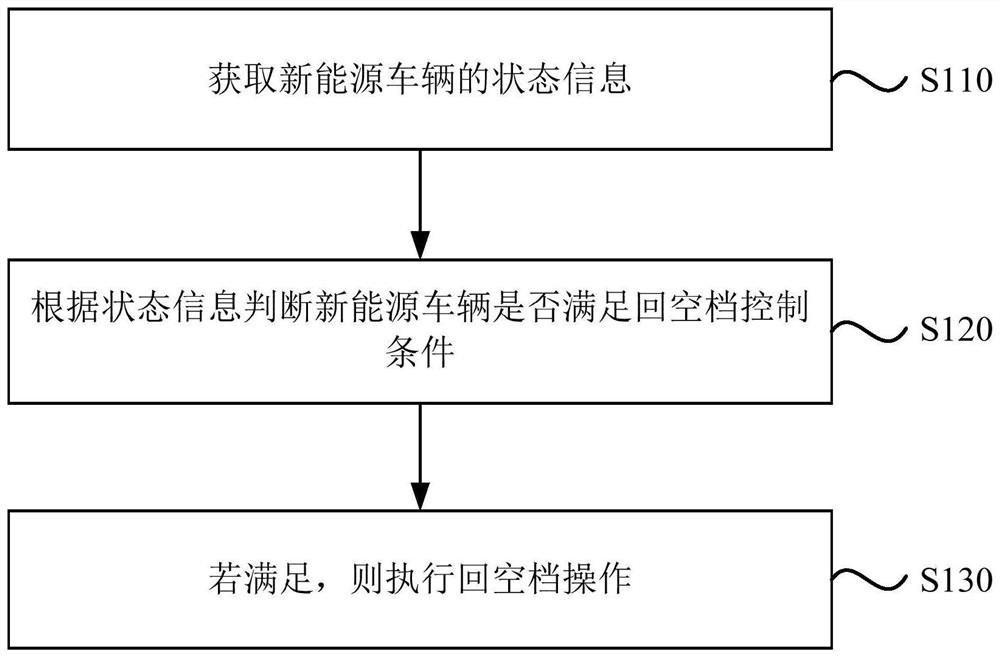

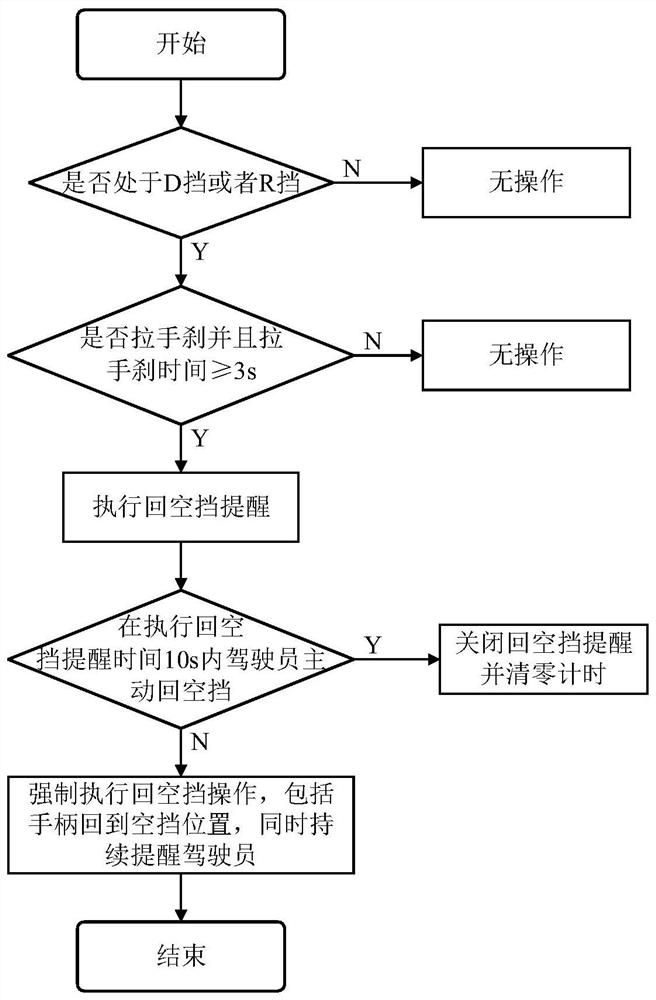

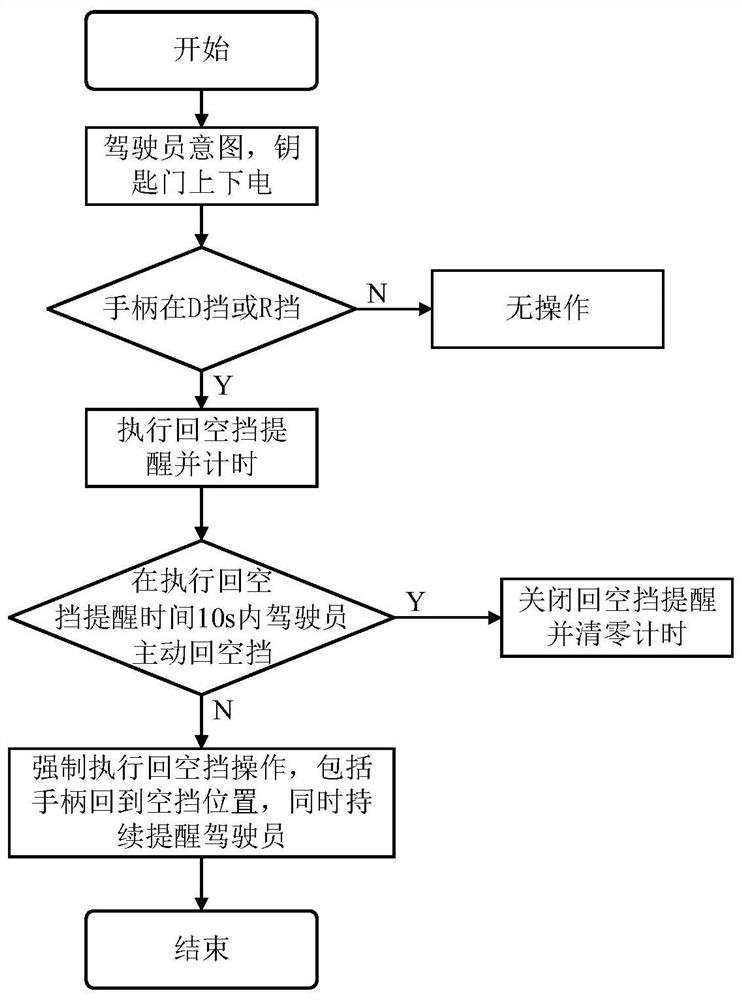

New energy vehicle neutral gear return control method, device and equipment and storage medium

ActiveCN112555403AExtended service lifeReduce noiseGearing controlControl devicesDriver/operatorNew energy

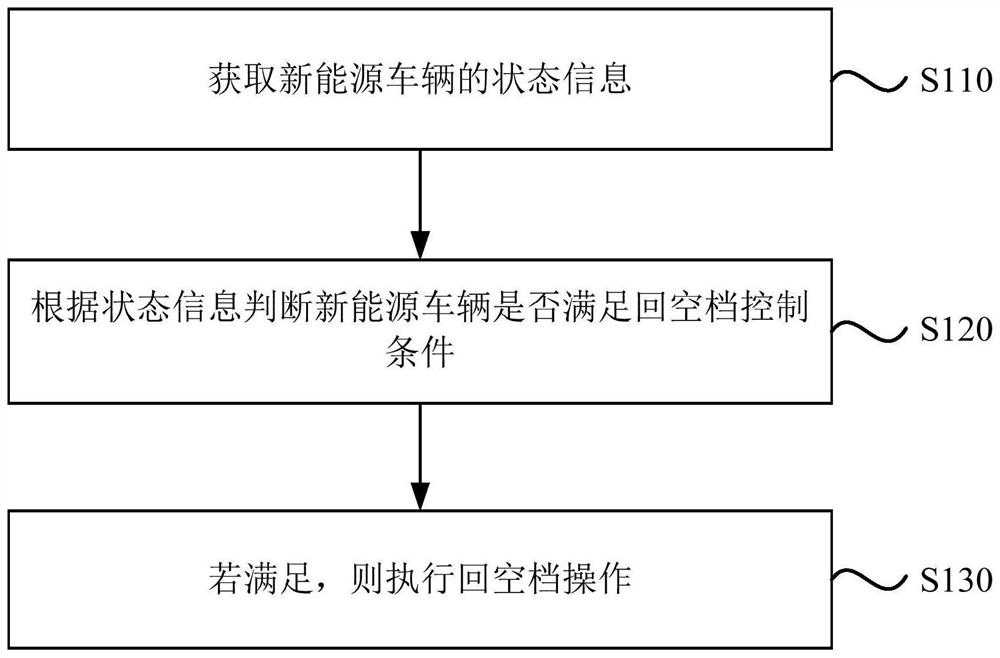

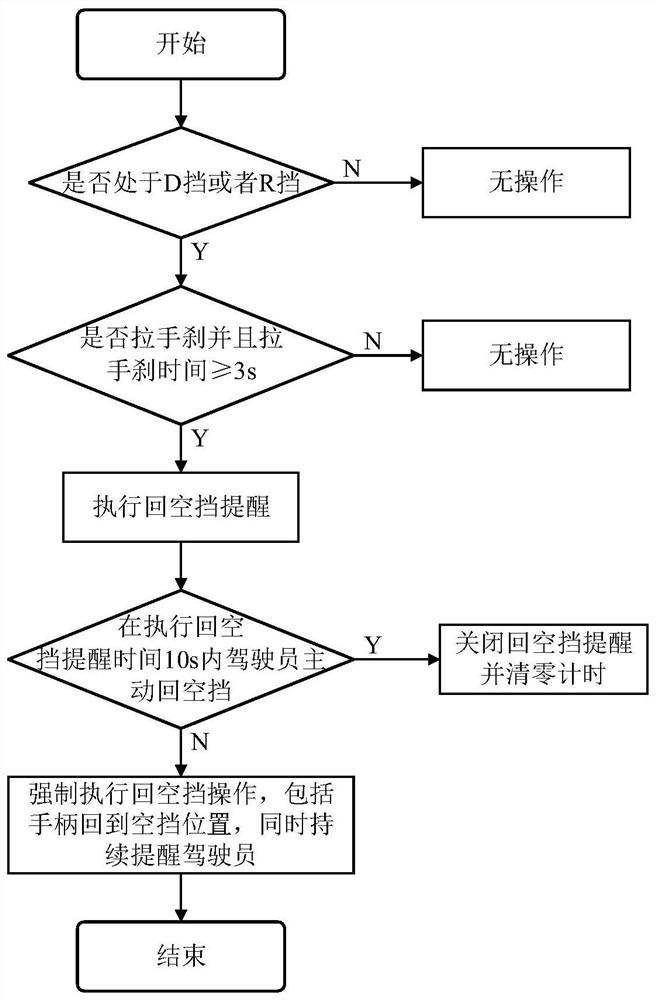

The invention discloses a new energy vehicle neutral gear return control method, device and equipment and a storage medium. The method comprises the steps of obtaining state information of a new energy vehicle; judging whether the new energy vehicle meets a neutral gear return control condition or not according to the state information; and executing neutral gear return operation if the control condition is met. According to the technical scheme, an automatic gearbox can be switched from a driving gear to a neutral gear through operations such as vehicle sound reminding, handle forced neutralgear return and automatic gearbox neutral gear return. The method has the advantages that the service life of the automatic gearbox can be prolonged, the noise of a transmission system can be lowered,engine fuel consumption can be lowered, exhaust emissions can be reduced, meanwhile, the operating requirements of drivers of different styles can be met adaptively in the starting process, and the safety and brand competitiveness of the whole vehicle are improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

Meteorological condition prediction method, device, vehicle and controller for automatic driving vehicle

ActiveCN112849161BAddressing deficiencies in imperfect monitoringImprove securityICT adaptationVisibilityEngineering

The solution relates to a method, device, vehicle and controller for predicting weather conditions of an autonomous vehicle to solve the problem in the prior art that the real weather environment of the vehicle environment cannot be predicted, which leads to safety threats to autonomous driving. The method includes: determining the third initial rainfall level based on wiper information, determining the light level based on light information, determining the light level based on visibility level information and environmental scene information of the vehicle; based on the first initial rainfall level, the second initial rain level and The third initial rainfall level is to determine the final rainfall level; based on the light level, light level, pollution level information and weather type information, the final light level is determined; based on the ambient temperature information, it is determined whether the ambient temperature exceeds the standard; Whether the meteorological conditions of the environment meet the requirements of automatic driving.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

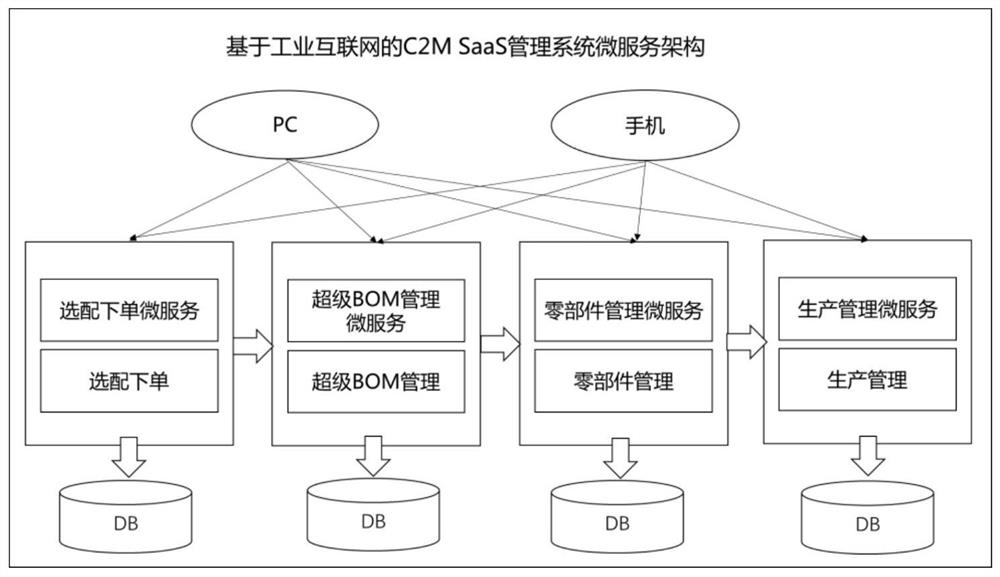

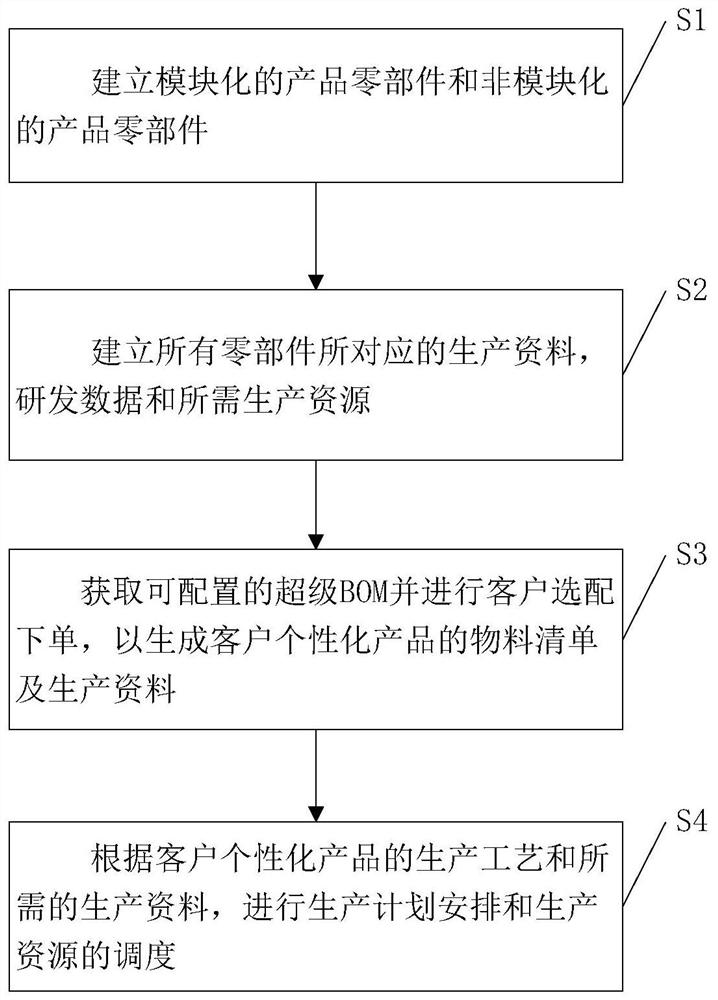

C2M SaaS management system and method based on industrial internet

PendingCN113298375AReduce inventory costsImprove brand competitivenessResourcesManufacturing computing systemsIndustrial InternetBill of materials

The invention discloses a C2M SaaS management system and method based on the industrial Internet, and the system comprises a part management micro-service assembly which is used for building modularized product parts and non-modularized product parts; a super BOM management micro-service component, used for establishing production materials corresponding to all parts; a selective order placing micro-service component, used for acquiring a configurable super BOM and carrying out customer selective order placing so as to generate a bill of materials and production materials of customer personalized products; a production management micro-service component, used for carrying out production plan arrangement and production resource scheduling according to the production process of the personalized product of the customer and required production materials. By implementing the embodiment of the invention, the effects are as follows: a C2M large-scale personalized customization mode is realized through combined management of each component; therefore, the manufacturing industry is helped to face challenges of multiple varieties, small batches, customization and order driving, manufacturing requirements are quickly responded, and both efficiency and flexibility are considered.

Owner:北京蔚蓝数字工业科技有限公司

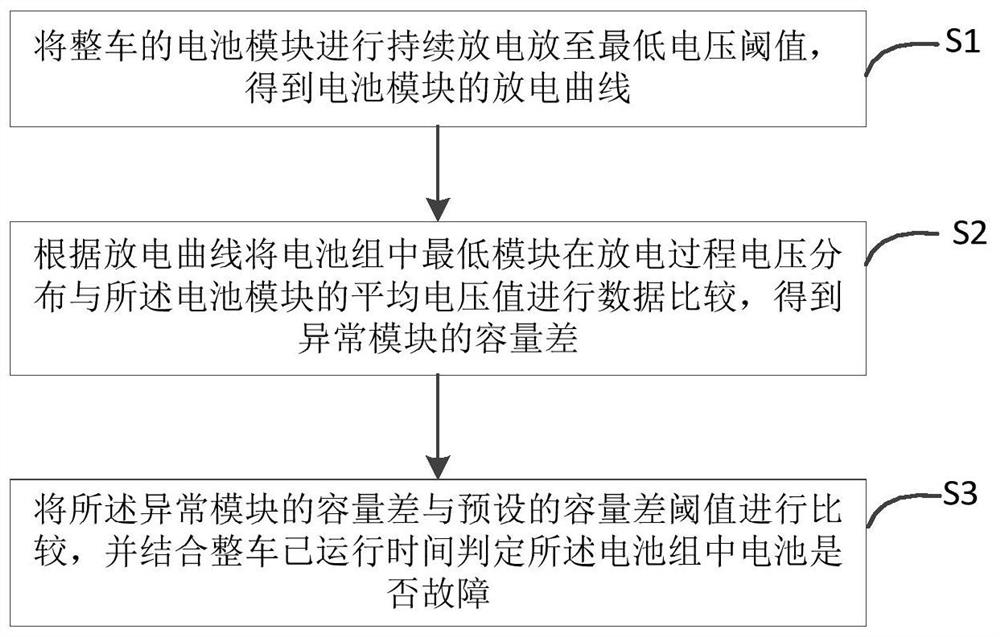

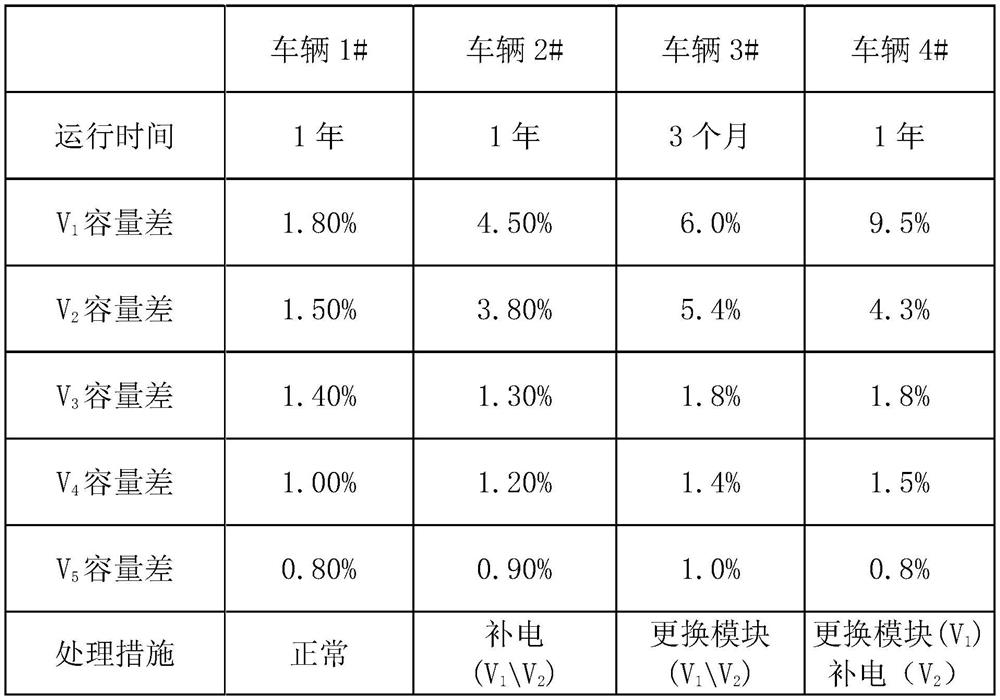

Method for quickly judging battery fault

PendingCN113533974AAchieve maintenanceAchieve Consistency MaintenanceElectrical testingEngineeringFaulty cell

The invention discloses a method for quickly judging a battery fault, which comprises the following steps of: S1, continuously discharging a battery module of a whole vehicle to a minimum voltage threshold to obtain a discharging curve of the battery module; S2, performing data comparison on the voltage distribution of the lowest module in the battery pack in the discharging process and the average voltage value of the battery module according to the discharging curve to obtain the capacity difference of an abnormal module; and S3, comparing the capacity difference of the abnormal module with a preset capacity difference threshold, and judging whether a battery in the battery pack breaks down or not according to the comparison result and the running time of the whole vehicle. Through the battery fault judgment method, a battery fault can be pre-judged in advance, market fault rate report is reduced, maintenance is performed in advance, and the brand competitiveness of the battery is enhanced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

In-car engine multi-sound active control system

ActiveCN110126840BMulti-dimensional attribute improvementFlexible and more effective hearing effectElectric/fluid circuitControl devicesAutomotive productControl signal

The invention discloses an in-vehicle engine multi-sound-effect active control system, and relates to an active control technology of vehicle interior sound. The system comprises an engine speed sensor, an accelerator pedal position sensor, a microphone, a microphone preamplifier, a speaker, a power amplifier, an engine multi-sound-effect controller and a human-computer interaction module; the engine multi-sound-effect controller includes an A / D conversion module, a multi-sound-effect processing module, a D / A conversion module and a communication interface; a software architecture of the multi-sound-effect processing module includes an order signal generator, an ignition self-adaptive control module, a dynamic gain adjuster and a control signal selection module; the system obtains three in-vehicle sound effects of "comfortable", "powered" and "sporty" by actively weakening or actively adding engine sound of appropriate order components, the sound preferences and needs of different groups of people can be met, driving interaction and experience are enhanced, and the brand competitiveness and attractiveness of vehicle products are enhanced.

Owner:JIANGSU UNIV

Comprehensive setting method for surface roughness of upper and lower work rolls suitable for tandem cold rolling mill

ActiveCN106311758BGuaranteed surface qualityAdhesion difference reducedProfile control deviceWork rollEmulsion

The invention discloses a comprehensive setting method suitable for original roughness of surfaces of upper and lower working rolls of a cold continuous rolling unit, belonging to the field of cold rolling. The method is characterized in that according to the coining ratio relative coefficient of the upper and lower surfaces of strip steel of the unit, product technological parameters and on-site technological parameters in a roll changing cycle are collected; real-time roughness of the upper and lower working rolls when the kth reel is produced is obtained; optimization setting values of roughness of the upper and lower rolls are calculated; by setting reasonable original roughness of the surfaces of the upper and lower working rolls, the difference of emulsion adhesion amount of the upper and lower surfaces of the strip steel is compensated through the roughness setting of the upper and lower working rolls, and roughness difference between the upper and lower surfaces of the strip steel is then reduced, so that the surface quality of the strip steel is ensured. The comprehensive setting method can be widely applied to machining treatment of the surfaces of the upper and lower working rolls of the cold continuous rolling unit and the field of production technique control of the cold continuous rolling unit.

Owner:BAOSHAN IRON & STEEL CO LTD

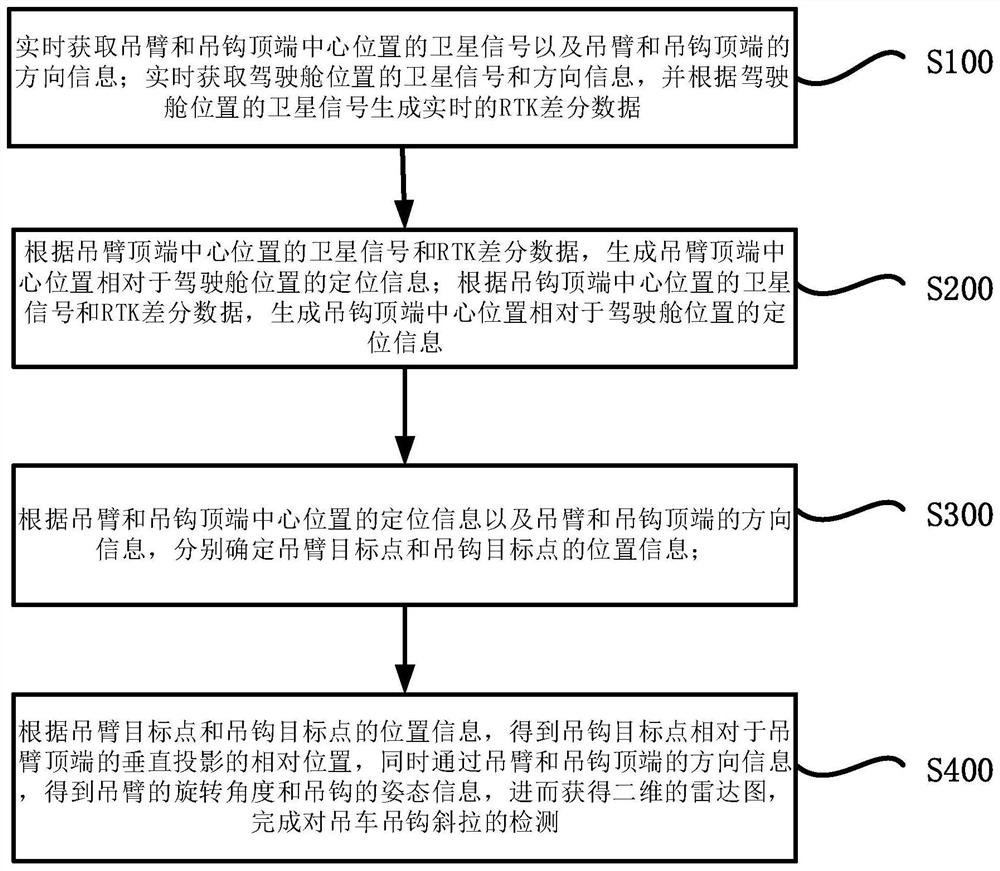

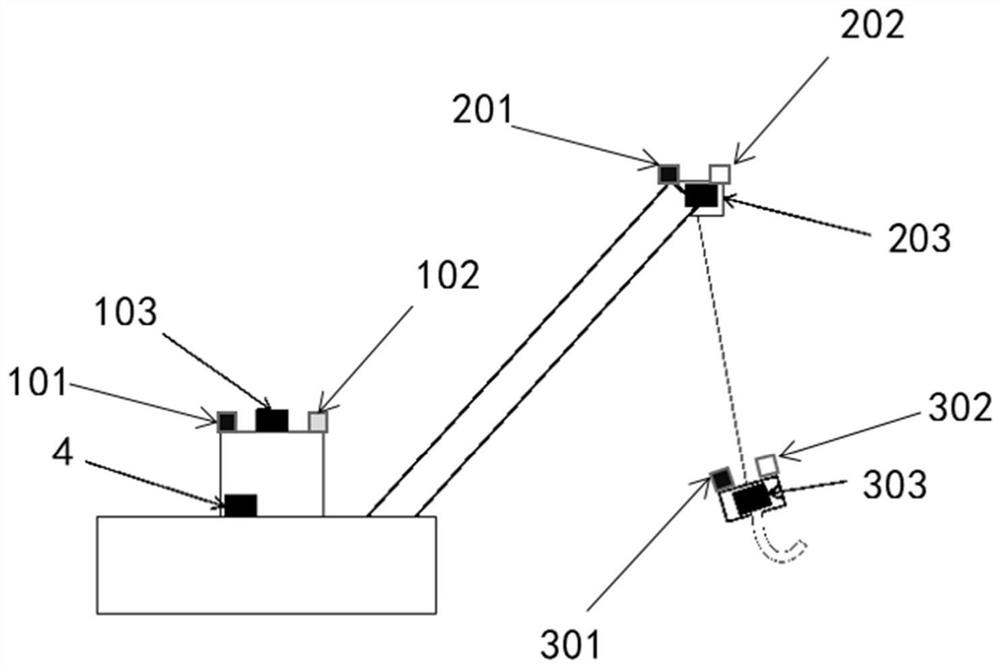

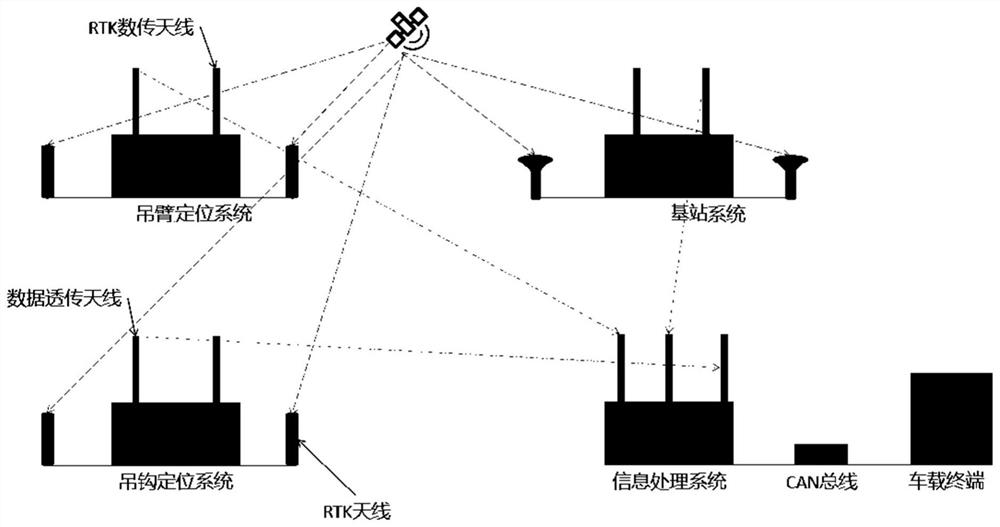

Detection method and detection system for heavy crane hook cable pull

ActiveCN113526349BReduced risk of rolloverUnderstand intuitiveSatellite radio beaconingCranesVertical projectionRollover

The invention provides a detection method and detection system for the oblique pull of a heavy-duty crane hook, which can obtain the satellite signal and direction information of the center position of the top of the boom and the top of the hook in real time; obtain the satellite signal and direction information of the cockpit position in real time, and Generate real-time RTK differential data according to the satellite signal; according to the satellite signal and RTK differential data at the center position of the top of the boom and the top of the hook, respectively generate positioning information of the center position of the top of the boom and the center of the hook top relative to the position of the cockpit; According to the positioning information of the center position of the top of the boom and the top of the hook, the target point is determined, and the relative position of the target point of the hook relative to the vertical projection of the top of the boom is obtained. At the same time, the direction information of the top of the boom and the hook is used to obtain the The rotation angle and the attitude information of the hook are obtained to obtain a two-dimensional radar map. The invention improves construction efficiency, saves additional communication costs and labor costs, and greatly reduces the probability of cable-stayed rollover.

Owner:上海亥伯智能科技有限公司

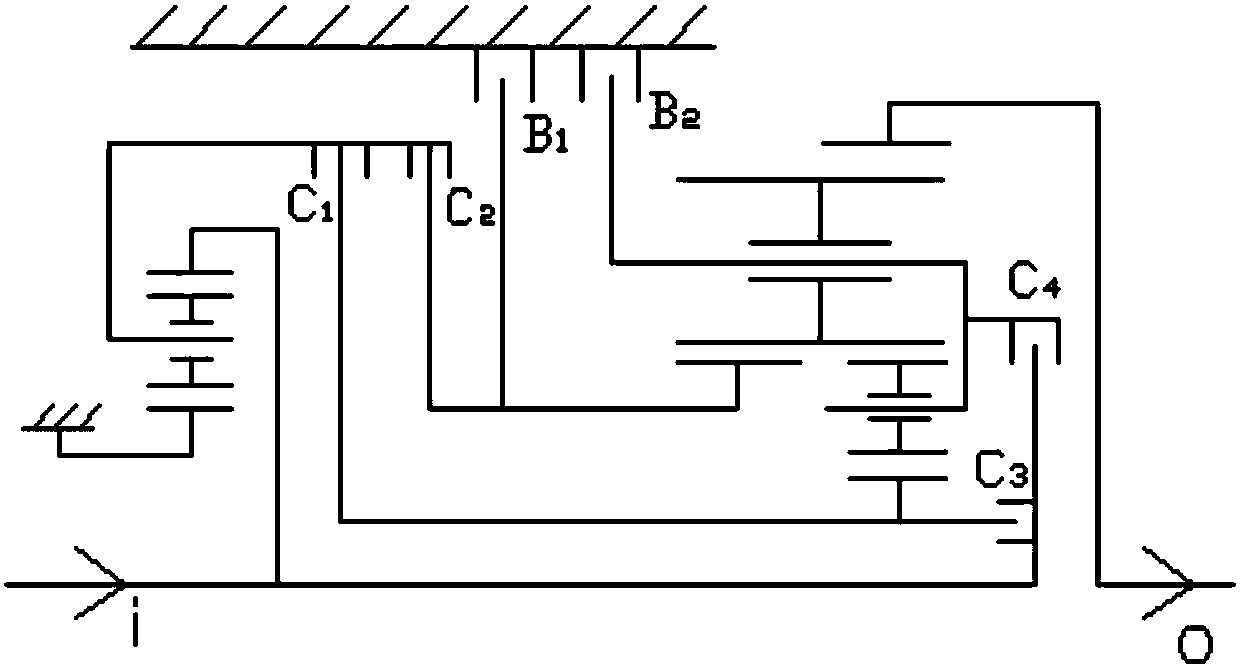

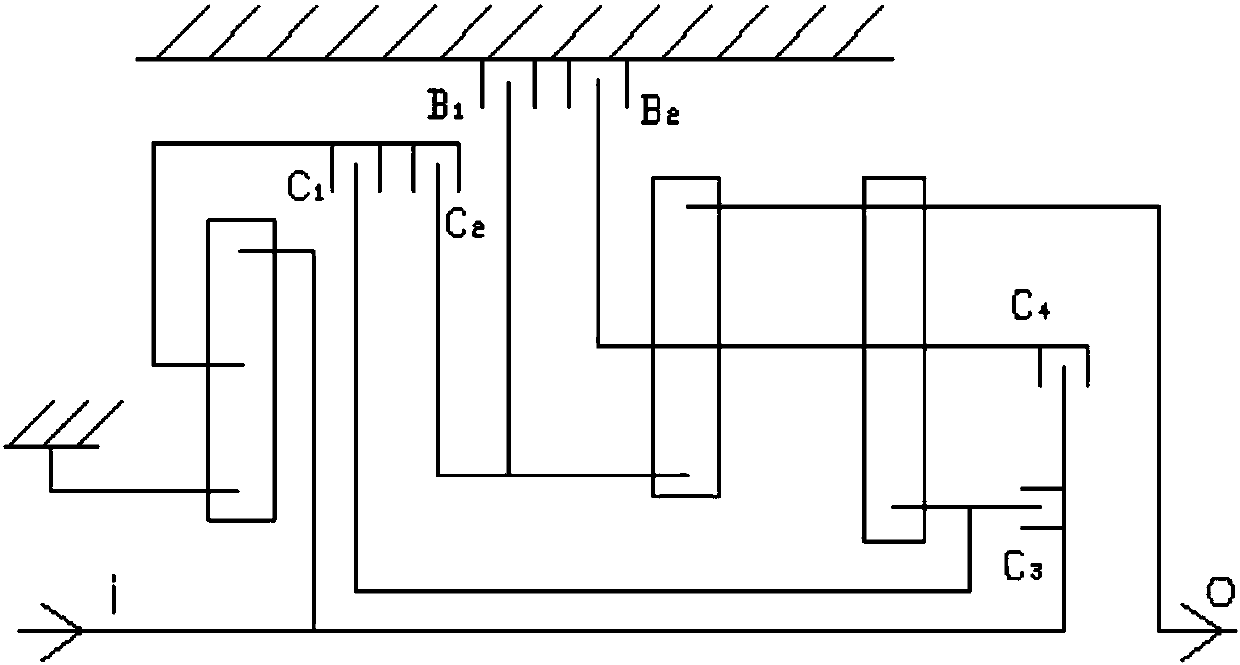

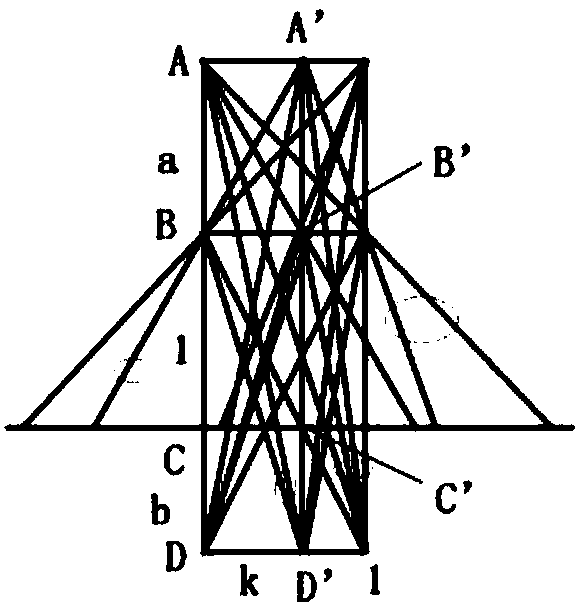

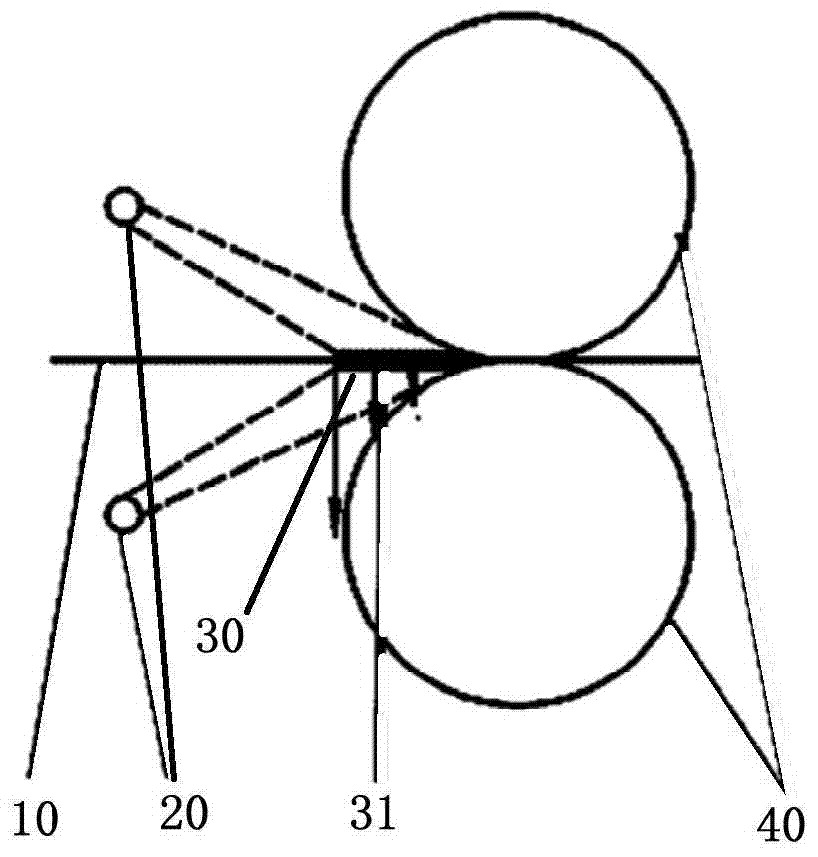

Novel 7-speed automobile automatic transmission

PendingCN108278338AImprove powerIncrease the number of gearsToothed gearingsGearing controlAutomatic transmissionElectrical and Electronics engineering

The invention discloses a novel 7-speed automobile automatic transmission. The novel 7-speed automobile automatic transmission comprises three planet rows, sequentially, the first single-planet wheelplanet row, the second single-planet wheel planet row and the third single-planet wheel planet row from left to right, wherein the planet rows are composed of sun wheels, gear rings and planet carriers; in the first single-planet wheel planet row, the gear ring is normally connected with an input shaft, and the sun wheel is normally connected with a transmission shell; the three planet rows are connected in series and parallel; the second planet row and the third planet row are connected in parallel to form a Ravigneaux structure; the first planet row and the Ravigneaux structure are connectedin series; and the second planet row and the third planet row share the same planet carrier and the same gear ring. The novel 7-speed automobile automatic transmission can be designed as a front-engine automatic transmission, the front-engine automatic transmission has the advantages of small size and light weight, the total weight of vehicles can be decreased, and fuel consumption is reduced.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

A method for setting differential flow rate of emulsion in tandem cold rolling mill

ActiveCN106363023BReduce the difference in adhesionGuaranteed surface qualityTemperature control deviceRollsEmulsionStrip steel

Owner:BAOSHAN IRON & STEEL CO LTD

A new energy vehicle back to neutral control method, device, equipment and storage medium

ActiveCN112555403BExtended service lifeReduce noiseGearing controlControl devicesAutomatic transmissionDriver/operator

The invention discloses a new energy vehicle back-to-neutral control method, device, equipment and storage medium. The method includes: obtaining status information of the new energy vehicle; judging whether the new energy vehicle satisfies the control condition for returning to neutral gear according to the status information; It can switch the automatic transmission from the driving gear to neutral through the vehicle sound reminder, the handle is forced to return to neutral, and the automatic transmission is returned to neutral. The advantages include prolonging the service life of the automatic transmission, reducing the noise of the transmission system, and reducing engine fuel consumption. , reduce exhaust emissions, and at the same time, it can adapt to different styles of driver's operation needs during the start process, improving vehicle safety and brand competitiveness.

Owner:FAW JIEFANG AUTOMOTIVE CO

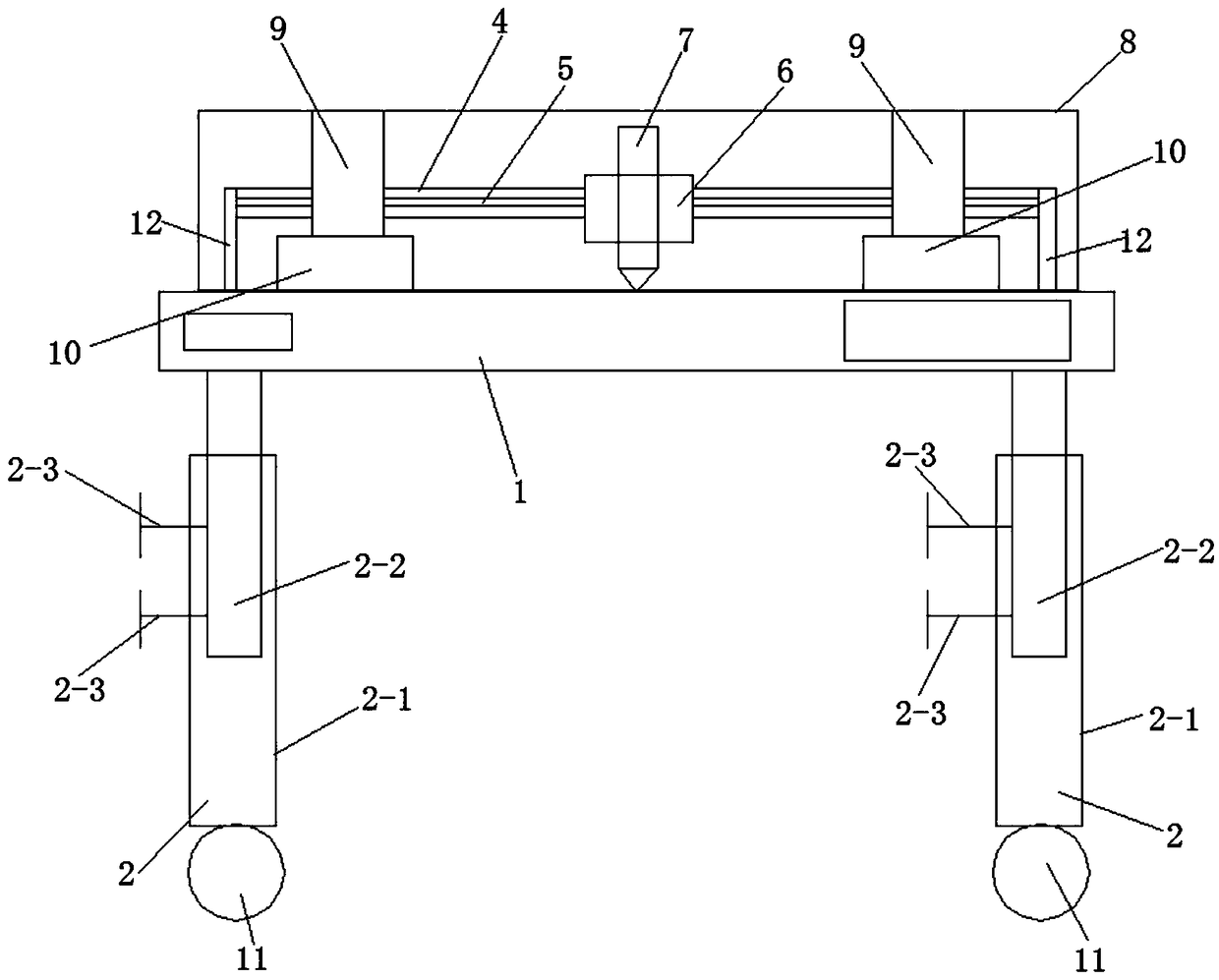

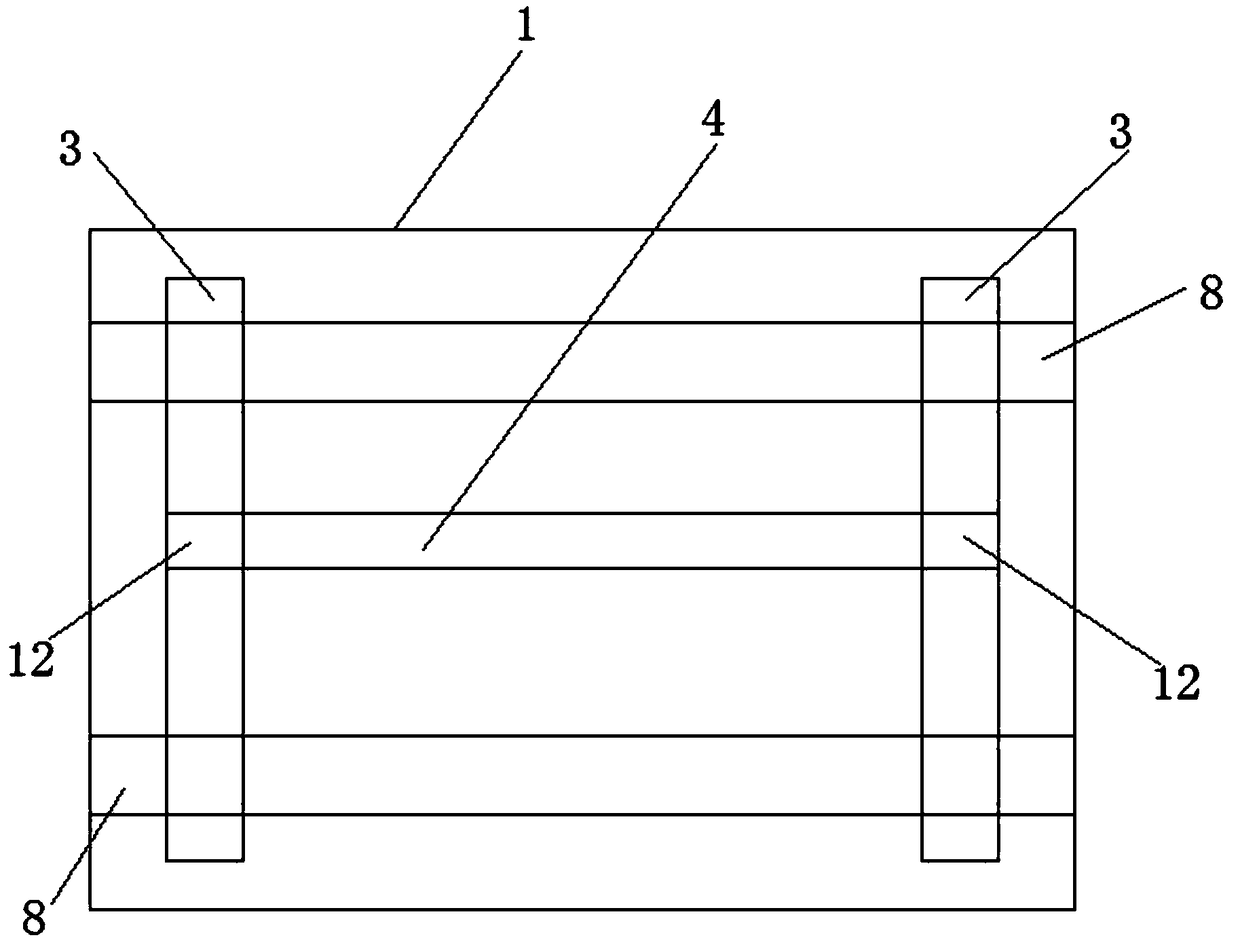

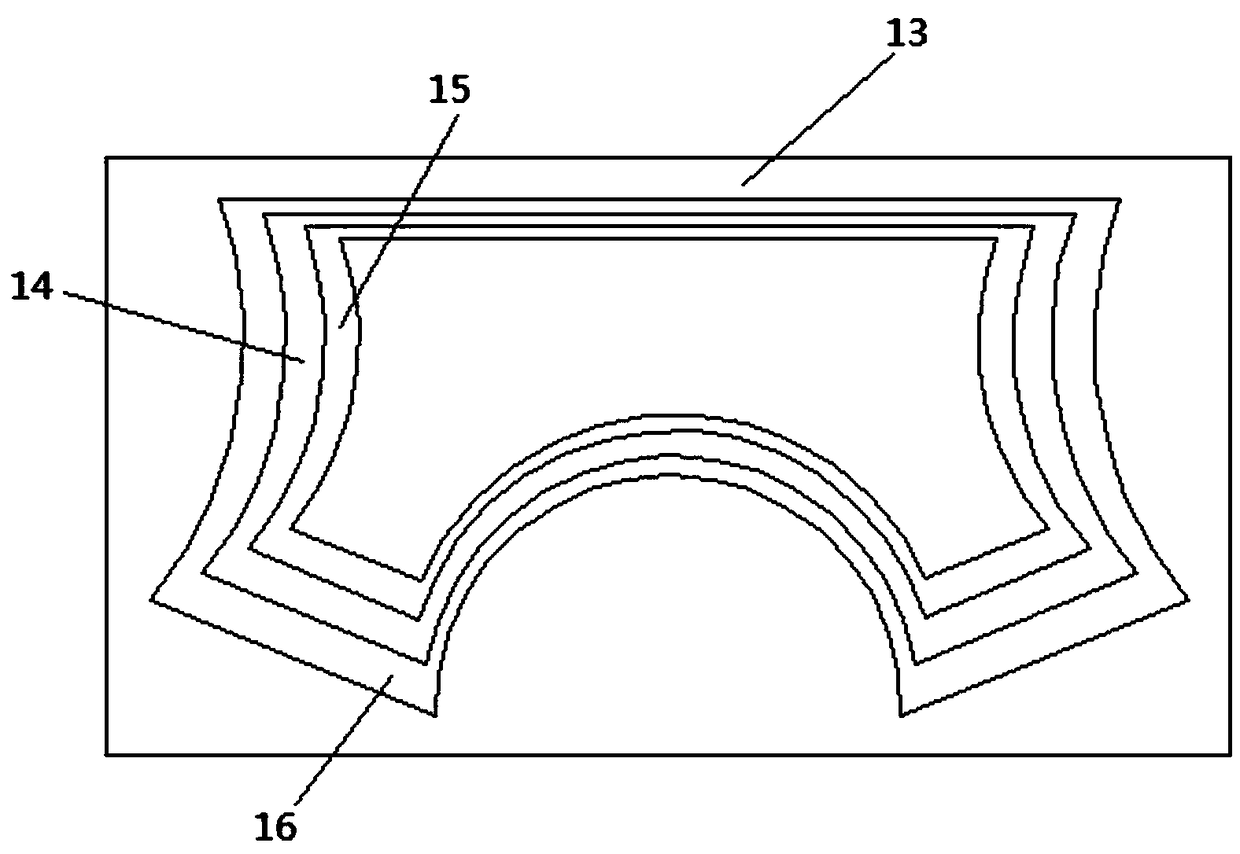

Milling machine for garment template

InactiveCN108741345AImprove satisfactionEasy to operateClothes making applicancesEngineeringManufacturing efficiency

The invention discloses a milling machine for a garment template. The milling machine for the garment template comprises a working table, wherein a height-adjustable supporting leg is arranged below the working table; guide tracks A are separately arranged on two opposite sides of the working table; a cross beam support is arranged between the two guide tracks A; a guide track B is arranged on thecross beam support; a positioner is arranged on the guide track B; and a milling head is arranged on the positioner; two pressure plate mechanisms are separately arranged at two opposite ends of theworking table; and a milling template is arranged on the working table. By the template manufactured by the milling machine, the clothing manufacture efficiency can be improved.

Owner:YINCHUAN RUINA CLOTHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com