A kind of preparation method of high-quality cyanamide aqueous solution

A technology of cyanamide and aqueous solution, which is applied in the direction of cyanamide, etc., can solve the problems of reducing product quality, achieve the effect of improving product quality, cheap raw materials, improving overall quality and corporate brand competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

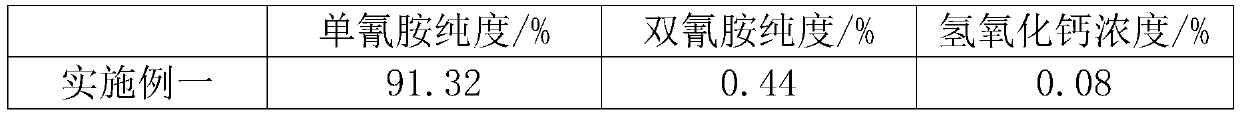

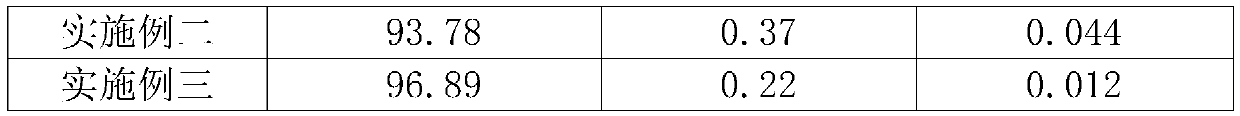

Embodiment 1

[0017] A kind of preparation method of high-quality cyanamide aqueous solution, comprises the following steps:

[0018] (1) Preparation of calcium cyanamide: mix calcium oxide and urea and grind to obtain a mixed powder with a particle size of 0.3 mm, then fully stir the mixed powder and superalloy chips, mix evenly, and place Calcined at 260°C for 3 hours under the protection of nitrogen, then raised the temperature to 650°C and continued to calcined for 1 hour. After the reaction was completed, it was cooled to room temperature under nitrogen atmosphere, and the obtained crude calcium cyanamide was ground with a pair of roller mills to obtain The fine particles with a particle size of 0.3mm are magnetically separated by a magnetic separator to remove superalloy debris, collect the fine particles and rinse the fine particles with clean water at 0°C for 3 times. Each rinsing time is 3 minutes. After rinsing, filter and collect the remaining sediment, and dry at 40°C to obtain ...

Embodiment 2

[0026] A kind of preparation method of high-quality cyanamide aqueous solution, comprises the following steps:

[0027] (1) Preparation of calcium cyanamide: mix calcium oxide with urea and grind to obtain a mixed powder with a particle size of 0.4 mm, then fully stir the mixed powder and superalloy chips, mix evenly, and place Calcined at 320°C for 4 hours under the protection of nitrogen, then raised the temperature to 750°C and continued to calcine for 2 hours. After the reaction was completed, it was cooled to room temperature under nitrogen atmosphere, and the obtained crude calcium cyanamide was ground with a pair of roller mills to obtain The fine particles with a particle size of 0.4mm are magnetically separated by a magnetic separator to remove superalloy debris, collect the fine particles and rinse the fine particles with 1°C water for 4 times. Each rinsing time is 4 minutes. After rinsing, filter and collect the remaining precipitate, and dry it at 50°C to obtain ca...

Embodiment 3

[0035] A kind of preparation method of high-quality cyanamide aqueous solution, comprises the following steps:

[0036] (1) Preparation of calcium cyanamide: mix calcium oxide with urea and grind to obtain a mixed powder with a particle size of 0.5 mm, then fully stir the mixed powder and superalloy chips, mix evenly, and place Calcined at 400°C for 5h under the protection of nitrogen, then raised the temperature to 850°C for 3h, cooled to room temperature under nitrogen atmosphere after the reaction, and ground the obtained crude calcium cyanamide with a roller mill to obtain The fine particles with a particle size of 0.5mm are magnetically separated by a magnetic separator to remove superalloy debris, collect the fine particles and rinse the fine particles with clean water at 3°C for 5 times. Each rinsing time is 5 minutes. After rinsing, filter and collect the remaining sediment, and dry at 60°C to obtain calcium cyanamide for later use;

[0037] (2) Preparation of cyana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com