Method for quickly judging battery fault

A battery failure and fast technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., to achieve vehicle maintenance, reduce market failure reporting, and enhance brand competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

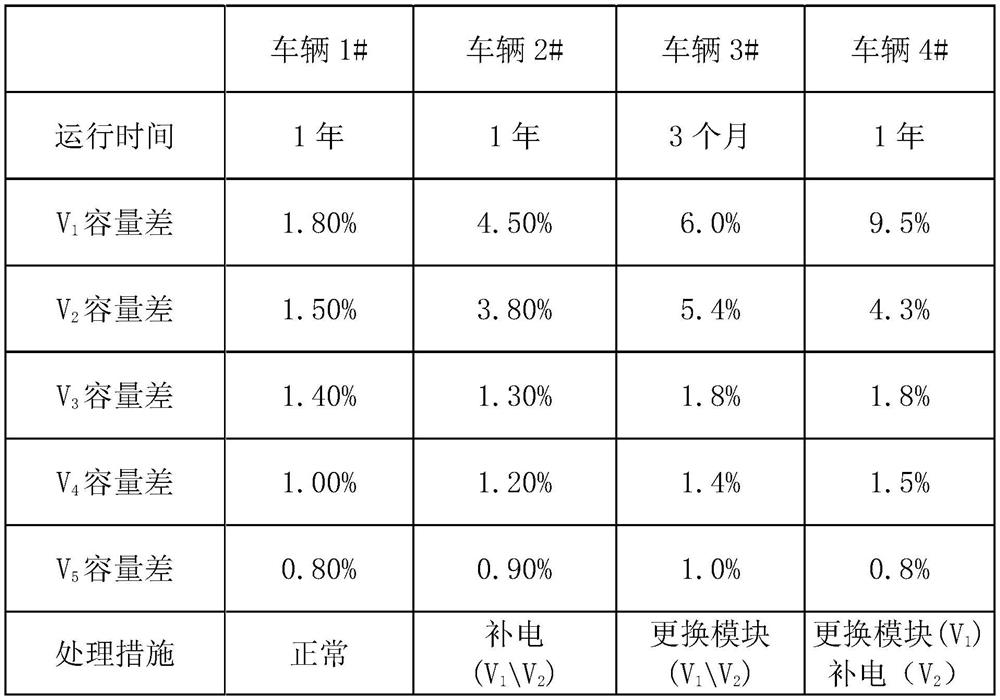

Examples

Embodiment Construction

[0029] In the following, the technical solution of the present invention will be described in detail through specific embodiments, and many specific details are set forth in the following description so as to fully understand the present invention. However, the present invention can be implemented in many other ways different from those described here, and those skilled in the art can make similar improvements without departing from the connotation of the present invention, so the present invention is not limited by the specific implementation disclosed below.

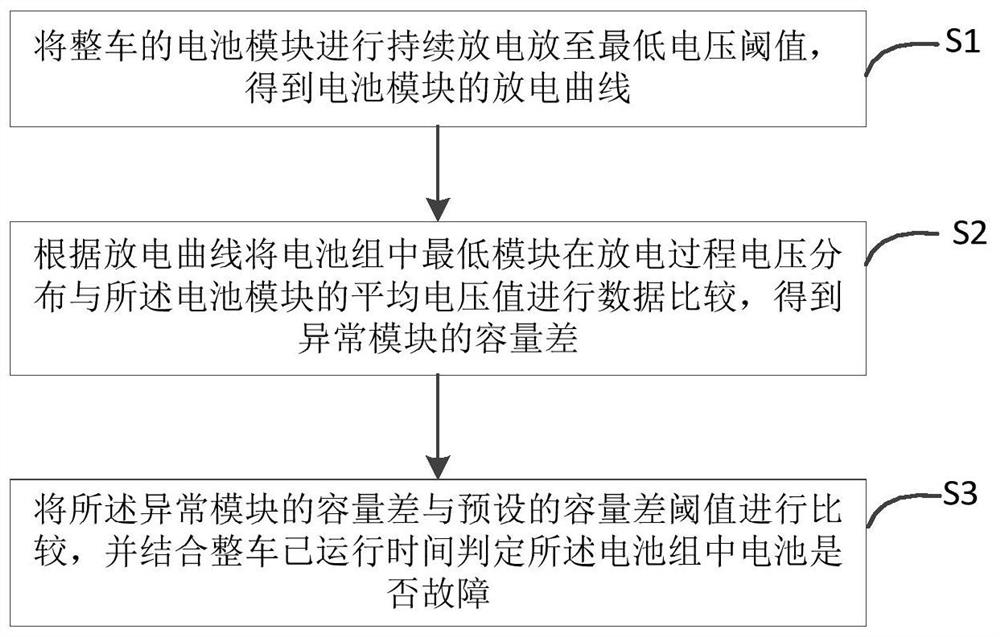

[0030] like figure 1 As shown, a method for rapidly determining a battery failure proposed by the present invention includes steps S1 to S3:

[0031] S1: Continuously discharge the battery module of the whole vehicle to the lowest voltage threshold to obtain the discharge curve of the battery module;

[0032] For the regular maintenance of vehicles operating in the market, during the maintenance period, the battery mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com