A motor linkage control method based on a motor protector

A technology of linkage control and protector, which is applied in the direction of multiple motor speed adjustments, can solve the problems of enterprises that are not suitable for small-scale production and high production costs, achieve good functional highlights, meet factory needs, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

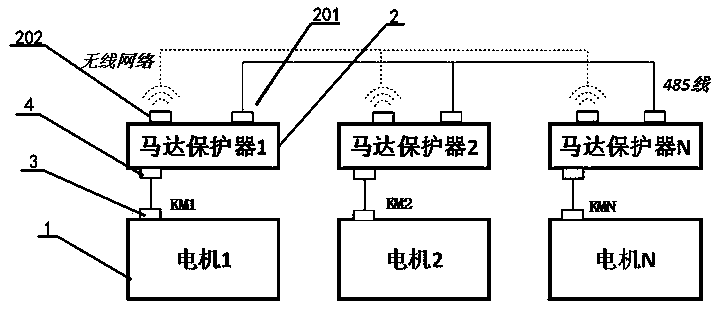

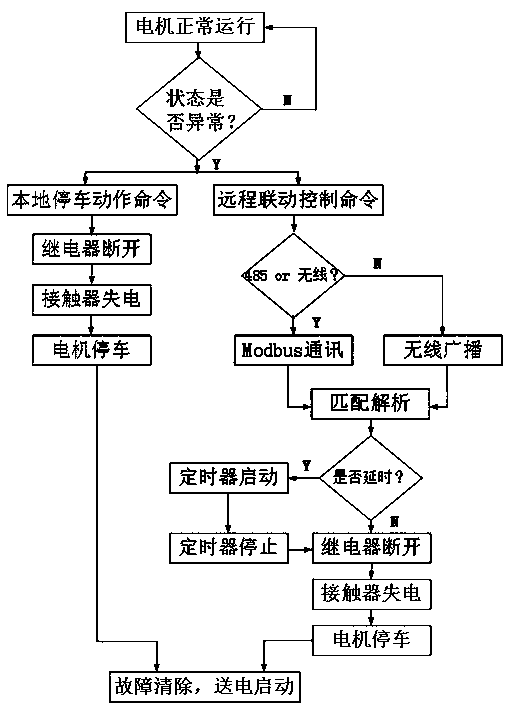

[0014] As shown in the figure: a motor linkage control method based on a motor protector. A motor protector 2 is installed on each motor 1 that is linked to each other. The motor protector 2 controls the on-off of the contactor 3 electrically connected to the motor 1. To control the rotation and stop of the motor 1, and each motor protector 2 is provided with a 485 port 201, a wireless module 202 and a timer, the 485 port 201 is electrically connected to each other through a 485 line, and the wireless network of the wireless module 202 covers the entire interconnected motor protector.

[0015] For motor protectors 2 that are relatively close to each other, the linkage control is relatively simple. By connecting the respective 485 ports 201 in series, the hardware part can be completed. For motor protectors 2 that are far away from each other, the motor protector 2 can External or built-in WiFi module or ZigBee module, and realize a wide range of wireless network coverage throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com