Ni3(Si,Ti)-TiC composite coating material and preparation method thereof

A coating material, nickel-silicon technology, applied in coating, metal material coating process, manufacturing tools, etc., can solve the problem of low toughness at room temperature and achieve uniform coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Ti powder and C powder are proportioned according to the stoichiometric ratio of TiC, and the addition is controlled at 8wt% by weight; the remainder is that Ni powder, Si powder and Ti powder are proportioned by atomic percentage as Ni78Si13Ti9; in addition, Add 5ppm of B powder.

[0021] (2) The purity of Ni powder, Si powder, Ti powder, C powder and B powder is greater than 99%, and the particle size of the powder is 100-300 mesh.

[0022] (3) Put the mixed powder into a mortar, grind and mix evenly, and then dry it as a coating material. Laser multi-layer and multi-pass cladding is carried out in the way of pre-set powder.

[0023] (4) The laser process parameters are: output power 1000-1100W, scanning speed 4-6mm / s, spot diameter 4mm, each overlap 1.8mm.

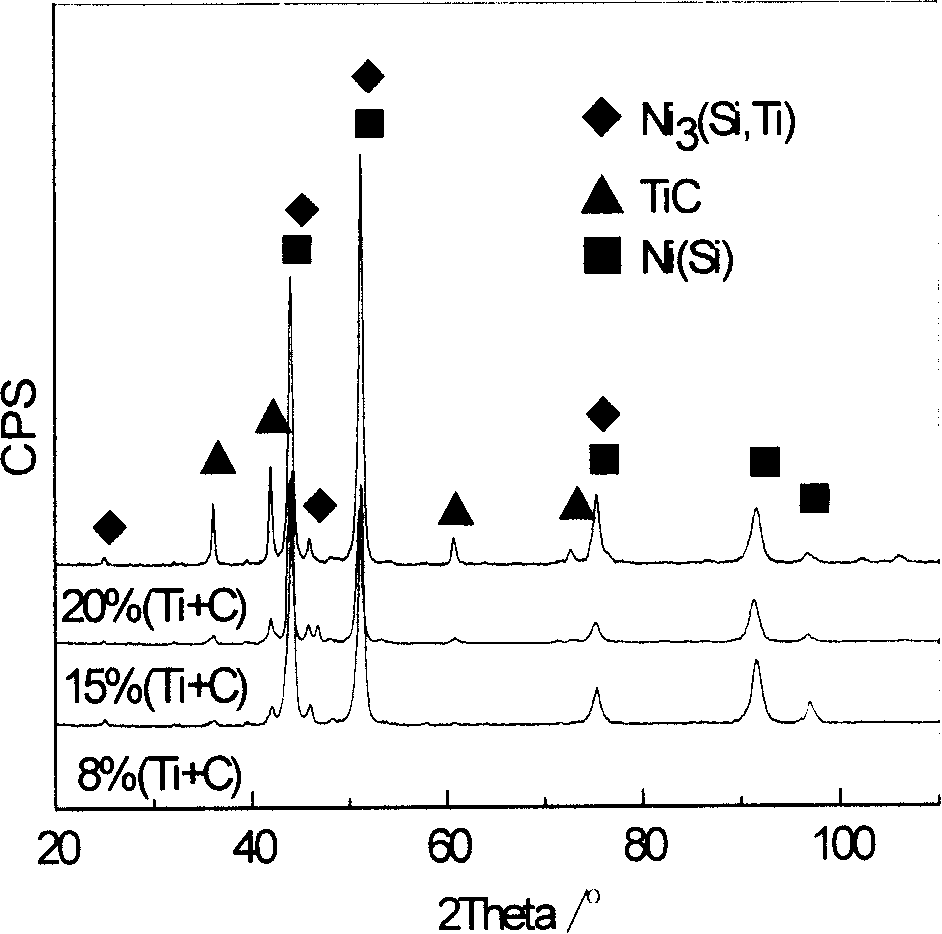

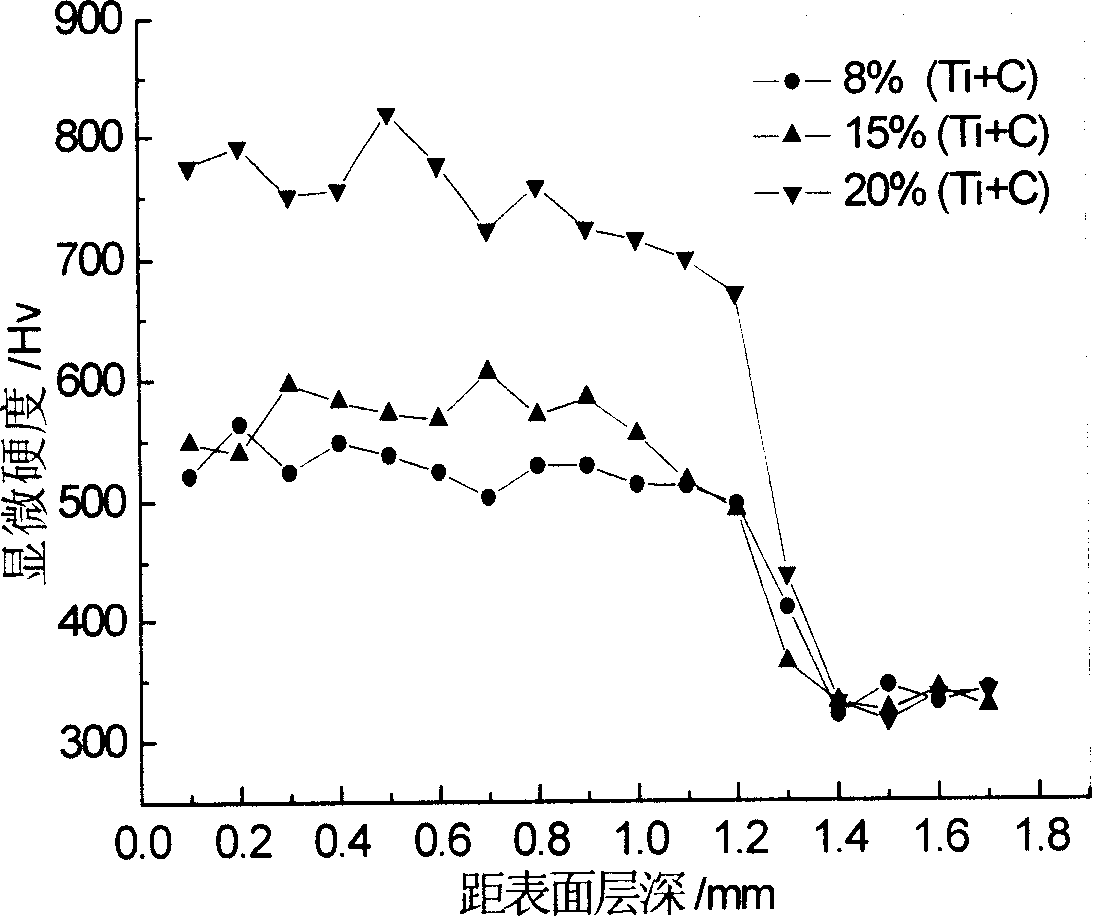

[0024] The thickness of the prepared cladding layer is about 1.5mm, the Vickers hardness reaches 530Hv, and the main structure of the coating is Ni 3 (Si, Ti) intermetallic compound, Ni(Si) solid solution ...

Embodiment 2

[0026] (1) Ti powder and C powder are proportioned by the stoichiometric ratio of TiC, and the addition is controlled at 15wt% by weight; the remainder is that Ni powder, Si powder and Ti powder are proportioned by atomic percentage as Ni78Si13Ti9; in addition, Add 5ppm of B powder.

[0027] (2) The purity of Ni powder, Si powder, Ti powder, C powder and B powder is greater than 99%, and the particle size of the powder is 100-300 mesh.

[0028] (3) Put the mixed powder into a mortar, grind and mix evenly, and then dry it as a coating material. Laser multi-layer and multi-pass cladding is carried out in the way of pre-set powder.

[0029] (4) The laser process parameters are: output power 1100-1300W, scanning speed 4-6mm / s, spot diameter 4mm, each overlap 1.8mm.

[0030] The thickness of the prepared cladding layer is about 1.5mm, the Vickers hardness reaches 580Hv, and the main structure of the coating is Ni 3 (Si, Ti), Ni(Si), and TiC.

Embodiment 3

[0032] (1) Ti powder and C powder are proportioned according to the stoichiometric ratio of TiC, and the addition is controlled at 20wt% by weight; the remainder is that Ni powder, Si powder and Ti powder are proportioned by atomic percentage as Ni78Si13Ti9; in addition, Add 5ppm of B powder.

[0033] (2) The purity of Ni powder, Si powder, Ti powder, C powder and B powder is greater than 99%, and the particle size of the powder is 100-300 mesh.

[0034] (3) Put the mixed powder into a mortar, grind and mix evenly, and then dry it as a coating material. Laser multi-layer and multi-pass cladding is carried out in the way of pre-set powder.

[0035] (4) The laser process parameters are: output power 1300-1500W, scanning speed 4-6mm / s, spot diameter 4mm, each overlap 1.8mm.

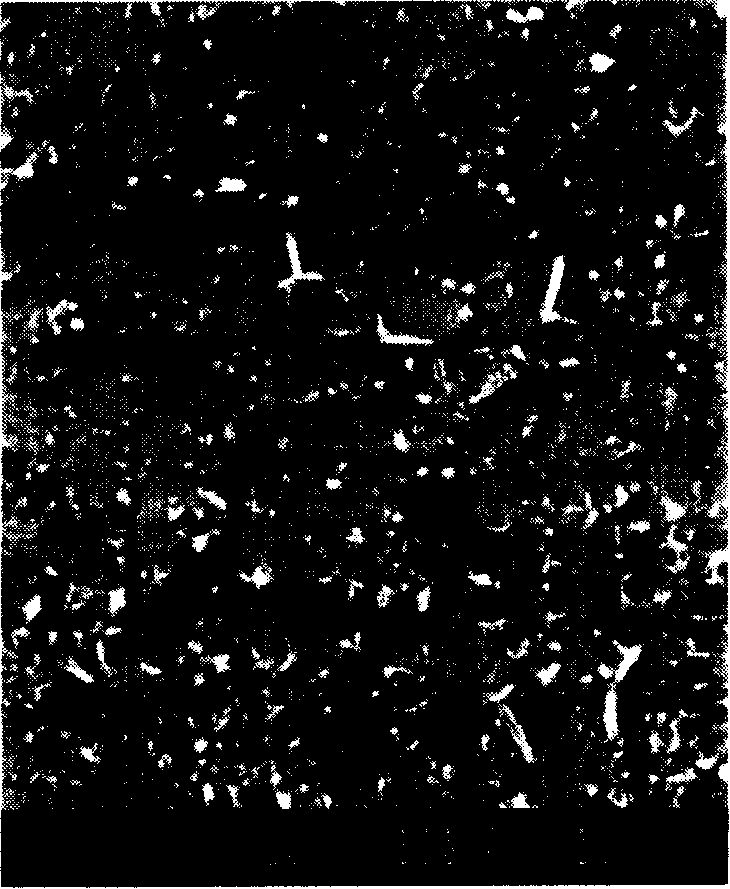

[0036] The prepared cladding layer has a thickness of about 1.5mm and a Vickers hardness of 780Hv, such as figure 1 As shown, the main structure of the coating is Ni 3 (Si, Ti) and petal-shaped TiC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com