A preparation method of conductive polymer-carbon coated silicon oxide composite material

A conductive polymer and silicon oxide technology, applied in the direction of electrochemical generators, circuits, electrical components, etc., can solve the problems of low initial charge and discharge efficiency, poor conductivity, poor cycle performance, etc., to achieve industrial production and application, Low manufacturing cost and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

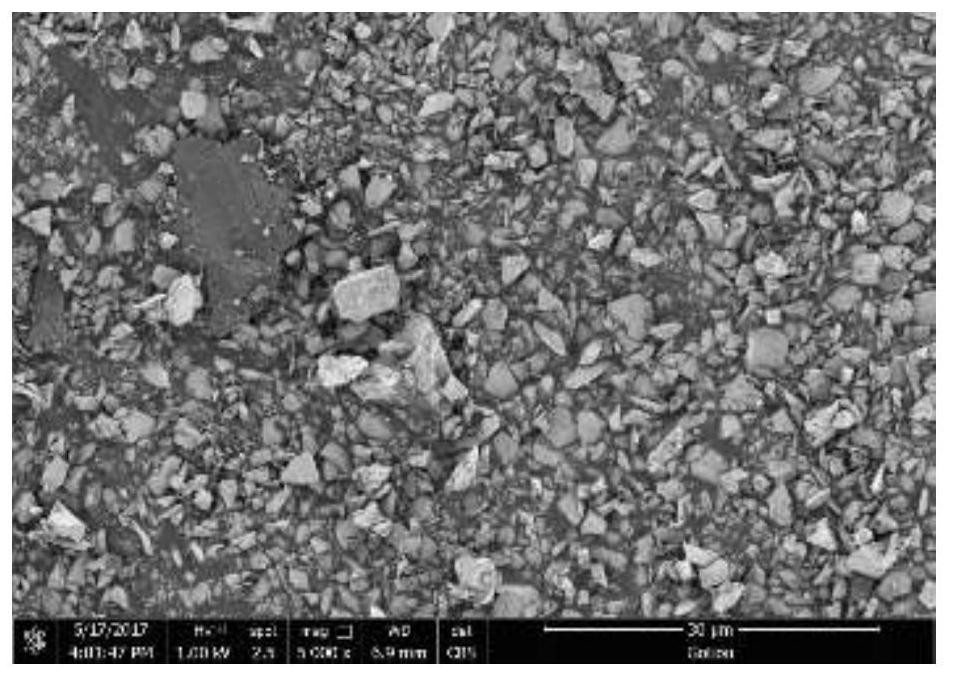

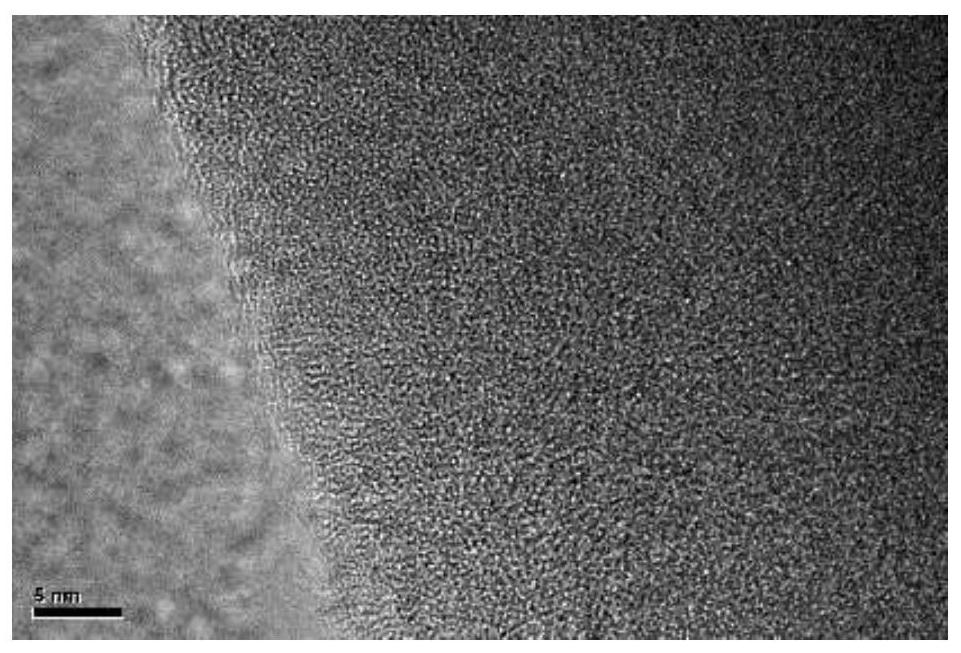

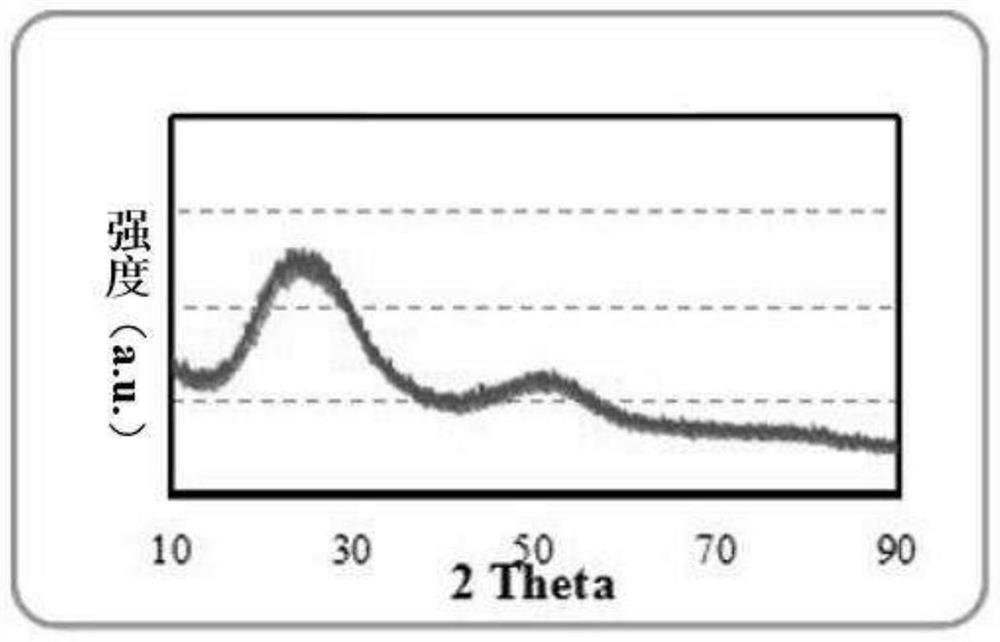

[0038](1) Add 1000g of silicon oxide with a D50 of 10μm into the high-speed mixer, then add 100g of coal tar pitch with a D50 of 25μm, and 12g of starch as a pore-forming agent, and the mixing time in the high-speed mixer is 15min , obtain silicon oxide / bitumen / pore-forming agent mixture after mixing;

[0039] (2) Put the silicon oxide / pitch / pore-forming agent mixture obtained above into a rotary furnace, and sinter at a constant temperature of 300°C for 2 hours in a nitrogen atmosphere, and then raise it to 450°C for 4 hours to obtain a carbon coating The silicon oxide material precursor is then transferred to a tube furnace to continue carbonization at a high temperature of 900°C in a nitrogen atmosphere for 4 hours to obtain a carbon-coated silicon oxide material, which is crushed by jet milling before use;

[0040] (3) Take 20 g of carbon-coated silicon oxide in ethanol, add 0.2 g of 3-aminopropyltrimethoxysilane to reflux after magnetic stirring, the reflux temperature is...

Embodiment 2

[0044] (1) Add 1,000 g of silicon oxide with a D50 of 5 μm into the high-speed mixer, and then sequentially add 150 g of petroleum pitch with a D50 of 30 μm, and 20 g of starch as a pore-forming agent. The mixing time in the high-speed mixer is 25 minutes. Obtain silicon oxide / bitumen / pore-forming agent mixture after mixing;

[0045] (2) Put the silicon oxide / pitch / pore-forming agent mixture obtained above into a rotary furnace, and sinter at a constant temperature of 300°C for 8 hours in a nitrogen atmosphere, and then raise it to 550°C for 6 hours to obtain a carbon coating The silicon oxide material precursor is then transferred to a tube furnace and carbonized at a high temperature of 950°C in a nitrogen atmosphere for 7 hours to obtain a carbon-coated silicon oxide material, which is crushed by a jet milling method before use;

[0046] (3) Take 15g of carbon-coated silicon oxide in ethanol, add 0.075g of 3-ureapropyltrimethoxysilane after magnetic stirring, and reflux at ...

Embodiment 3

[0049] (1) Add 1000 g of silicon oxide with a D50 of 8 μm into the high-speed mixer, then add 120 g of petroleum asphalt with a D50 of 30 μm, and 15 g of urea as a pore-forming agent. The mixing time in the high-speed mixer is 12 minutes. Obtain silicon oxide / bitumen / pore-forming agent mixture after mixing;

[0050] (2) Put the silicon oxide / pitch / pore-forming agent mixture obtained above into a rotary furnace, and sinter at a constant temperature of 300°C for 6 hours in a nitrogen atmosphere, and then raise it to 520°C for 3 hours to obtain a carbon coating The silicon oxide material precursor is then transferred to a tube furnace to continue carbonization at a high temperature of 1000°C in a helium atmosphere for 5 hours to obtain a carbon-coated silicon oxide material, which is crushed by jet milling before use;

[0051] (3) Take 10 g of carbon-coated silicon oxide in ethanol, add 1.5 g of ethylenediaminepropyltriethoxysilane to reflux after magnetic stirring, the reflux te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com