Simple hollow fiber membrane coating tool

A fiber membrane and hollow technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of mutual adhesion, poor coating effect, hollow fiber membrane bending, etc., and achieve the effect of easy manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

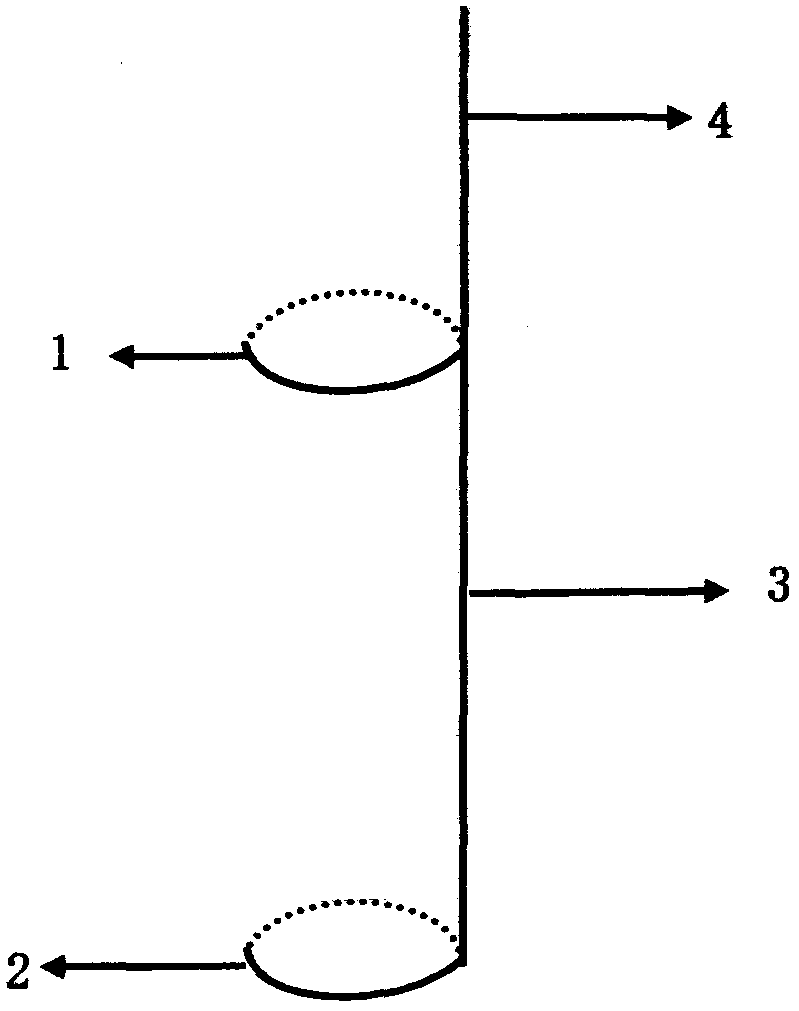

[0010] The fixed film part is composed of two circular iron wires (1) (2) parallel to each other up and down, such as figure 1 shown. Take a pliable iron wire and twist one end of the wire with hand pliers to form a first circle, the diameter of which is slightly smaller than the diameter of the coating cylinder. According to the amount of coating liquid prepared, at a certain distance from the first circle, twist the iron wire into a second circle with pliers, and the size of the second circle is equal to and parallel to the first circle. The part of the wire (3) that connects the two circles is used as the support part, and the remaining part of the wire (4) is used as the handle part.

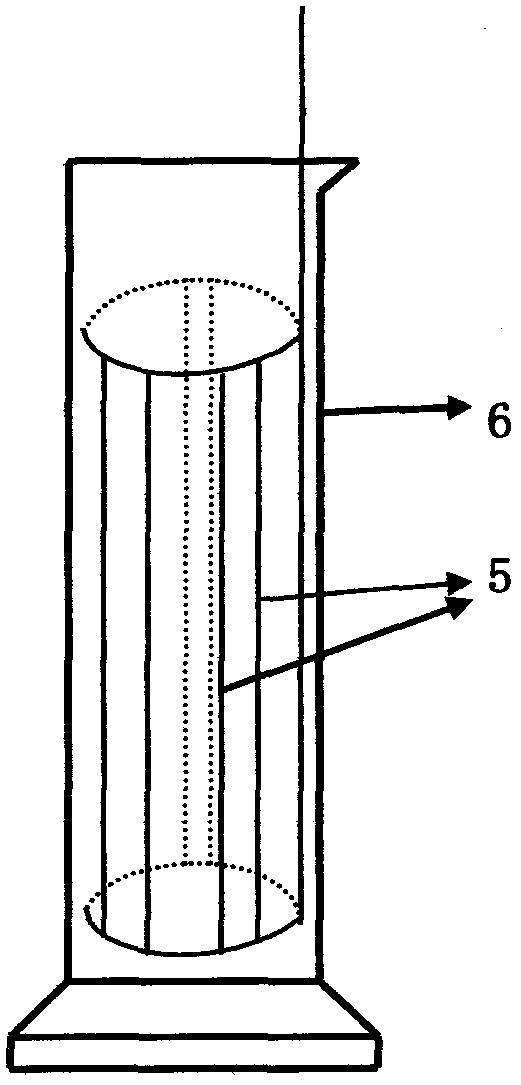

[0011] The present invention is suitable for manual application, such as figure 2 shown. The upper and lower two round iron wires are used to fix the hollow fiber membrane (5), and the tool of the present invention is directly placed in the measuring cylinder (6) containing the coating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com