A kind of iron-based wear-resistant composite material and preparation method thereof

A composite material and iron-based alloy technology, applied in the field of wear-resistant materials, can solve the problems of reducing the protective effect of the coating on the base material, reducing the service life of the coating, and coarse columnar crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention relates to an iron-based alloy composite coating and a preparation method, in particular to an iron-based alloy protective layer clad with a variety of powders with different particle sizes and a preparation method, in particular to a multiphase particle reinforced iron Base alloy protective coating and preparation method.

[0064] One of the technical solutions of the present invention is:

[0065] An iron-based wear-resistant composite material, comprising an iron-based alloy base material and an iron-based wear-resistant composite coating processed on the surface of the iron-based alloy base material, and the iron-based wear-resistant composite coating is mainly composed of micron La 2 O 3 Powder, micron Al 2 O 3 The powder form of powder and micron FeCrNiSiB powder is composed of micron La 2 O 3 Powder, micron Al 2 O 3In the iron-based composite powder mixed with micron FeCrNiSiB powder, in mass percentage: micron La 2 O 3 Powder 0.05%~10%, mi...

Embodiment 1

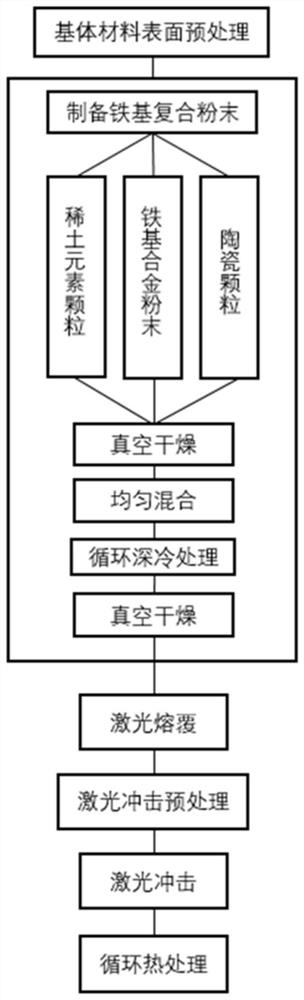

[0077] In the preparation method of the iron-based wear-resistant composite material in this embodiment, the surface of the iron-based aggregate matrix is pretreated first, and then the micron La 2 O 3 Powder, micron Al 2 O 3 The powder and the micron FeCrNiSiB powder are prepared according to a certain proportion, and are respectively subjected to vacuum drying, uniform mixing, cyclic cryogenic treatment and vacuum drying treatment, and then laser cladding to prepare an iron-based wear-resistant composite coating. Treatment, laser shock and cyclic heat treatment control the coating to ensure excellent mechanical properties of the coating.

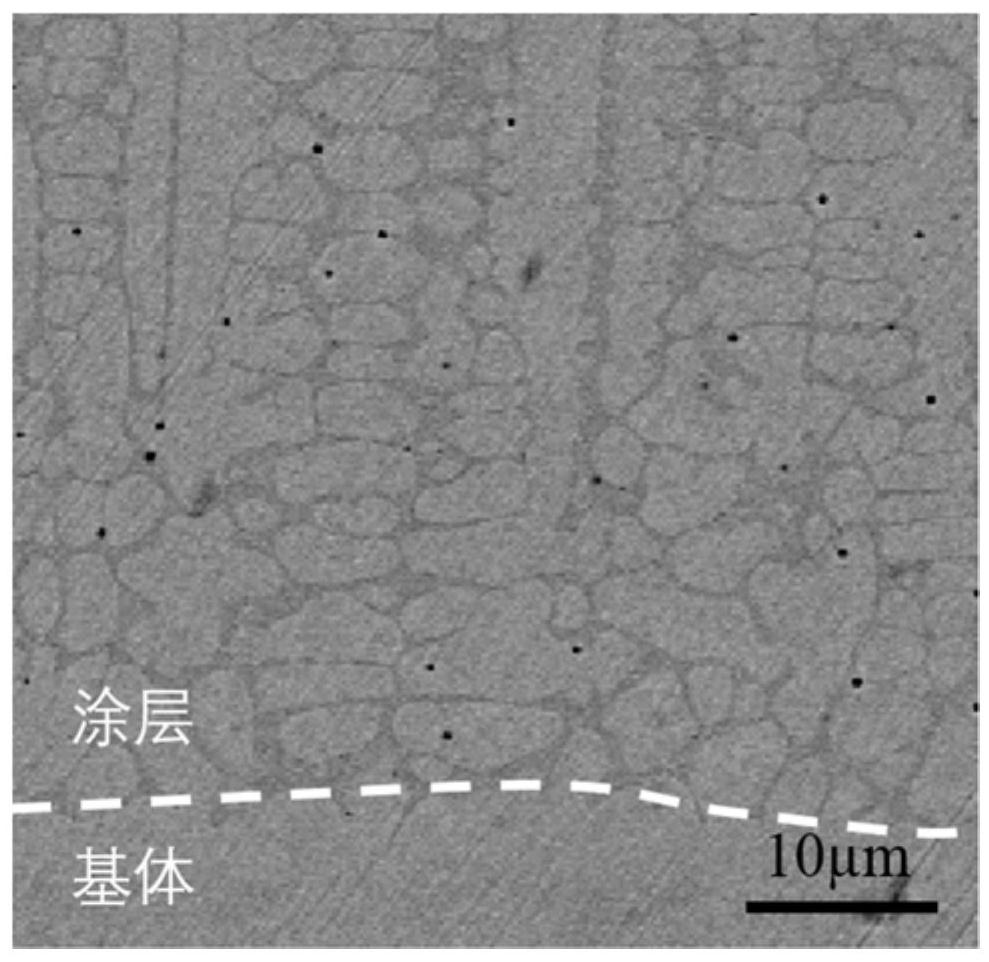

[0078] In this embodiment, the chemical composition of the micron FeCrNiSiB powder is calculated by mass percentage: Cr 5%; Ni 2%; Si1%; B 1%; Fe balance. Image 6 The particle size of the micron FeCrNiSiB powder shown is 50 μm to 200 μm. Micron La 2 O 3 The mass content of the powder is 0.1%, Figure 7 Micron La shown 2 O 3 The...

Embodiment 2

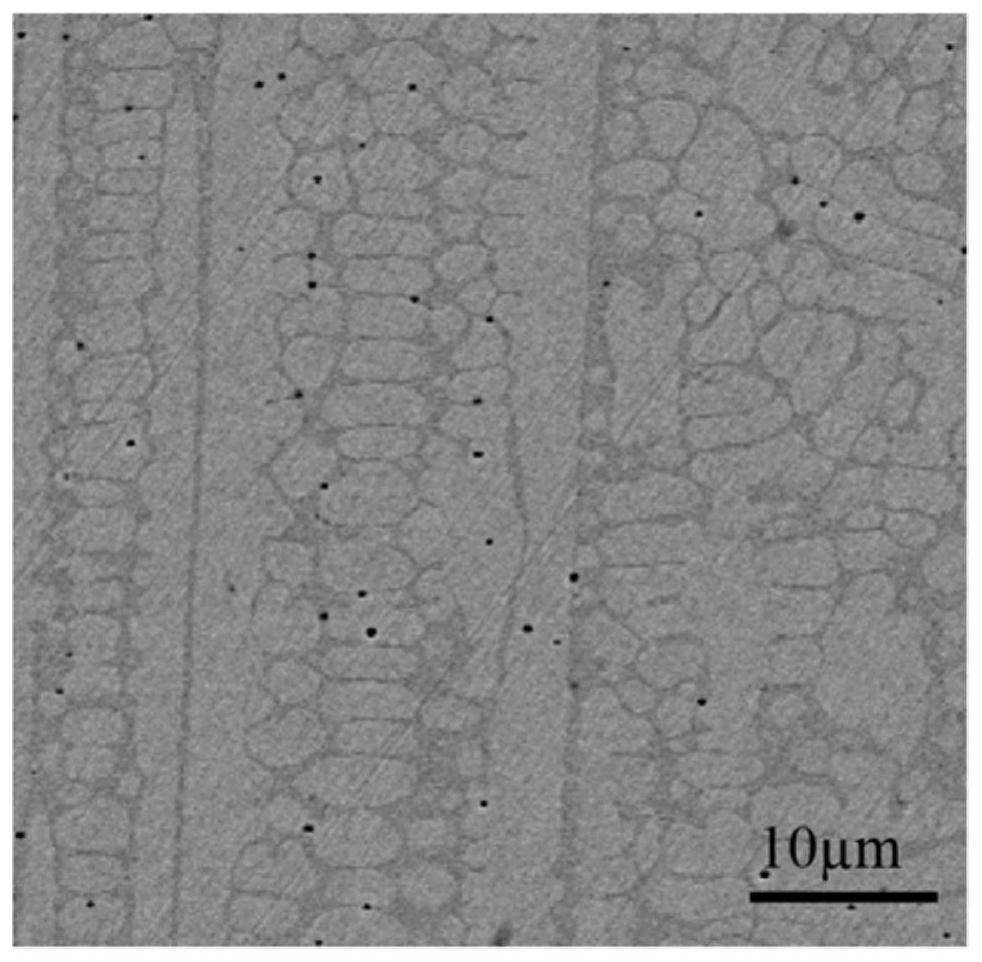

[0090] In the preparation method of the iron-based wear-resistant composite material in this embodiment, the surface of the iron-based aggregate matrix is pretreated first, and then the micron La 2 O 3 Powder, micron Al 2 O 3 The powder and the micron FeCrNiSiB powder are prepared according to a certain proportion, and are respectively subjected to vacuum drying, uniform mixing, cyclic cryogenic treatment and vacuum drying treatment, and then laser cladding to prepare an iron-based wear-resistant composite coating. Treatment, laser shock and cyclic heat treatment control the coating to ensure excellent mechanical properties of the coating.

[0091] In this embodiment, the chemical composition of the micron FeCrNiSiB powder is calculated by mass percentage: Cr 10%; Ni 4%; Si 3%; B 2%; Fe balance. Micron La 2 O 3 The mass content of the powder is 0.5%, micron La 2 O 3 The particle size distribution of the powder is 0.1 μm to 10 μm. micron Al 2 O 3 The mass content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com