Preparation method of high-purity fine-grained zirconia ceramic bar for flame spraying

A technology of flame spraying and crystal zirconia, which is applied in the field of material surface protection, can solve the problems of low impurity content of zirconia powder raw materials, high impurity content of coating, poor coating uniformity, etc., and achieve low content of impurity elements and good coating structure Dense and good melting state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

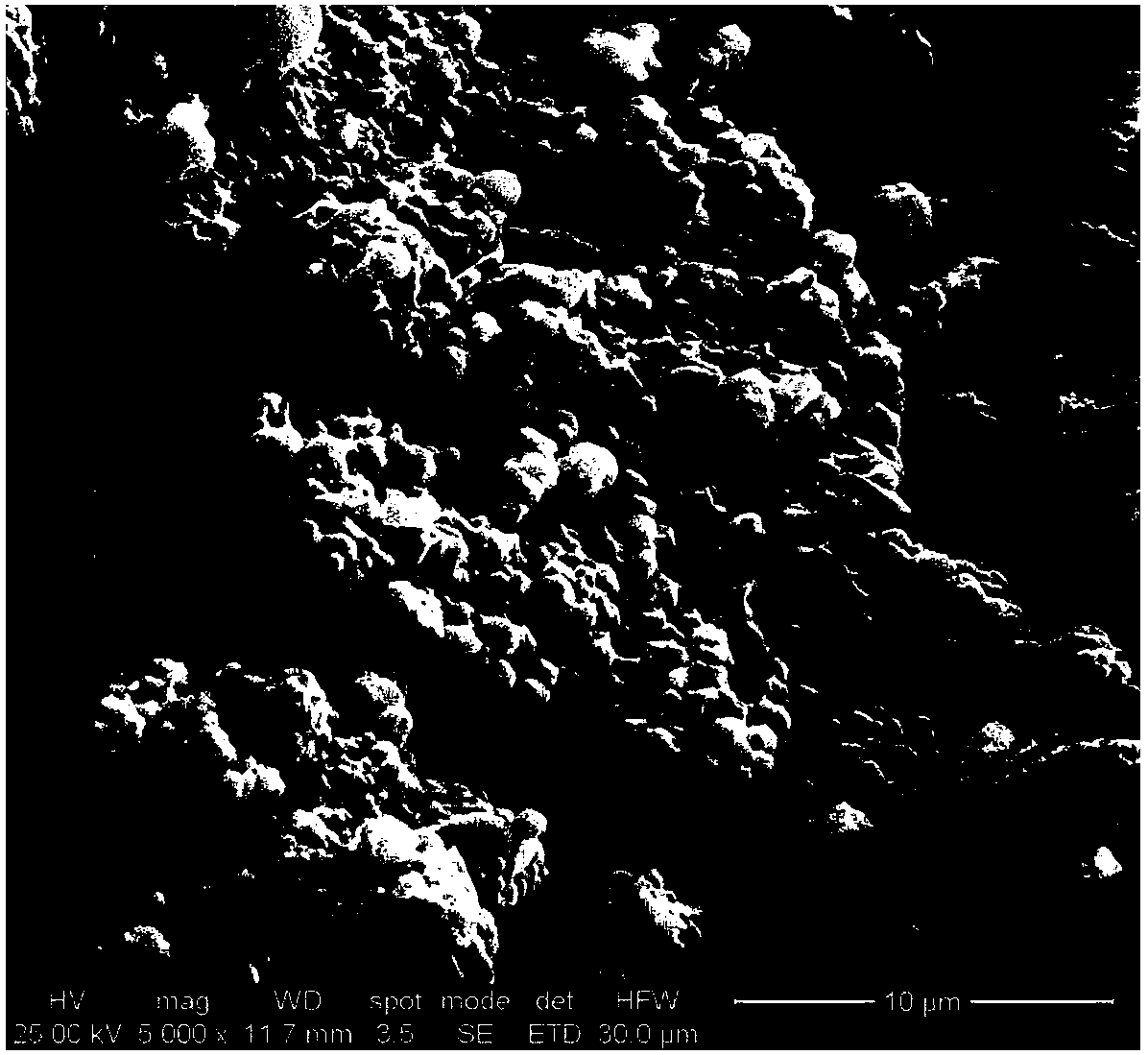

Image

Examples

Embodiment 1

[0021] The selected primary grain size is 5-30nm, and the contents of 12 impurity elements such as Fe, Mn, Mg, Pb, Ti, W, Cr, Co, V, Mo, As, Ni are 7ppm, 6ppm, 10ppm, 7ppm, 10ppm respectively , 8ppm, 8ppm, 9ppm, 7ppm, 7ppm, 2ppm, 7ppm high-purity nano-zirconia powder is made by spraying and granulating process, the main particle size distribution range is 0.4-11.5μm, and the average particle size is d 50 =2.446μm spherical zirconia powder raw material.

[0022] Take 10 parts of polyvinyl alcohol with a degree of polymerization of 1600, dissolve it in 90 parts of distilled water at 85°C, stir evenly, and keep warm in a constant temperature water bath at 85°C for 6 hours. Mix zirconia powder raw materials, binder, paraffin, and glycerin in a mass ratio of 100:35:8:3, and use a vacuum mixer to mix and knead the mud until a zirconia plastic mud ball is obtained, and put the mud ball in a sealed state Aging for 15h.

[0023] Put the zirconia plastic clay ball into the vacuum extr...

Embodiment 2

[0026] The selected primary grain size is 10-40nm, and the contents of 12 impurity elements such as Fe, Mn, Mg, Pb, Ti, W, Cr, Co, V, Mo, As, Ni are 7ppm, 6ppm, 10ppm, 7ppm, 10ppm respectively , 8ppm, 8ppm, 9ppm, 7ppm, 7ppm, 2ppm, 7ppm high-purity nano-zirconia powder is made by spraying and granulating process, the main particle size distribution range is 0.4-11.5μm, and the average particle size is d 50 =2.446μm spherical zirconia powder raw material.

[0027] Take 20 parts of polyvinyl alcohol with a degree of polymerization of 1500, dissolve it in 80 parts of distilled water at 85°C, stir evenly, and keep it in a constant temperature water bath at 80°C for 10 hours. Mix zirconia powder raw materials, binder, paraffin, and glycerin in a mass ratio of 100:65:5:4, and use a vacuum mixer to mix and knead the mud until the zirconia plastic mud ball is obtained, and put the mud ball in a sealed state Aging 20h.

[0028] Put the zirconia plastic clay ball into the vacuum extrud...

Embodiment 3

[0031] The selected primary grain size is 5-30nm, and the contents of 12 impurity elements such as Fe, Mn, Mg, Pb, Ti, W, Cr, Co, V, Mo, As, Ni are 7ppm, 6ppm, 10ppm, 7ppm, 10ppm respectively , 8ppm, 8ppm, 9ppm, 7ppm, 7ppm, 2ppm, 7ppm high-purity nano-zirconia powder is made by spraying and granulating process, the main particle size distribution range is 0.4-11.5μm, and the average particle size is d 50 =2.446μm spherical zirconia powder raw material.

[0032] Take 10 parts of polyvinyl alcohol with a degree of polymerization of 1800, dissolve it in 90 parts of distilled water at 85°C, stir evenly, and keep it in a constant temperature water bath at 90°C for 6 hours. Mix zirconia powder raw materials, binder, paraffin, and glycerin in a mass ratio of 100:50:10:6, and use a vacuum mixer to mix and knead the mud until the zirconia plastic mud ball is obtained, and put the mud ball in a sealed state Aging 20h.

[0033] Put the zirconia plastic clay ball into the vacuum extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com