Iron-based wear-resistant composite material and preparation method thereof

A technology of composite materials and iron-based alloys, applied in metal material coating technology, metal processing equipment, coatings, etc. Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention relates to an iron-based alloy composite coating and its preparation method, in particular to an iron-based alloy protective layer clad with powders of various particle sizes and its preparation method, in particular to a multiphase particle-reinforced iron coating Base alloy protective coating and preparation method thereof.

[0064] One of technical solutions of the present invention is:

[0065] An iron-based wear-resistant composite material includes an iron-based alloy base material and an iron-based wear-resistant composite coating processed on the surface of the iron-based alloy base material. The iron-based wear-resistant composite coating is mainly composed of micron La 2 o 3 Powder, Micron Al 2 o 3 Powder and powder form of micron FeCrNiSiB powder, composed of micron La 2 o 3 Powder, Micron Al 2 o 3Powder and micron FeCrNiSiB powder mixed iron-based composite powder, in mass percentage: micron La 2 o 3 Powder 0.05%~10%, micron Al 2 o 3...

Embodiment 1

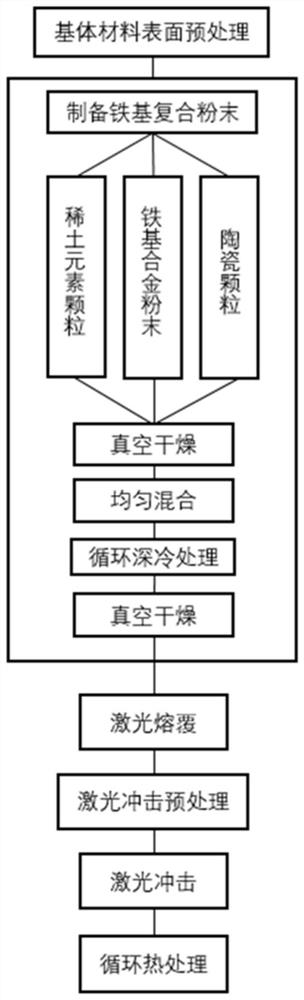

[0077] In the preparation method of the iron-based wear-resistant composite material in this embodiment, the surface of the iron-based total substrate is pretreated first, and then the surface of the micron La 2 o 3 Powder, Micron Al 2 o 3 The powder and micron FeCrNiSiB powder are prepared in a certain proportion, and are subjected to vacuum drying, uniform mixing, cycle cryogenic treatment and vacuum drying treatment in sequence, and then the iron-based wear-resistant composite coating is prepared by laser cladding, and finally the laser shock pretreatment is carried out respectively. Processing, laser shock and cyclic heat treatment regulate the coating to ensure that the coating has excellent mechanical properties.

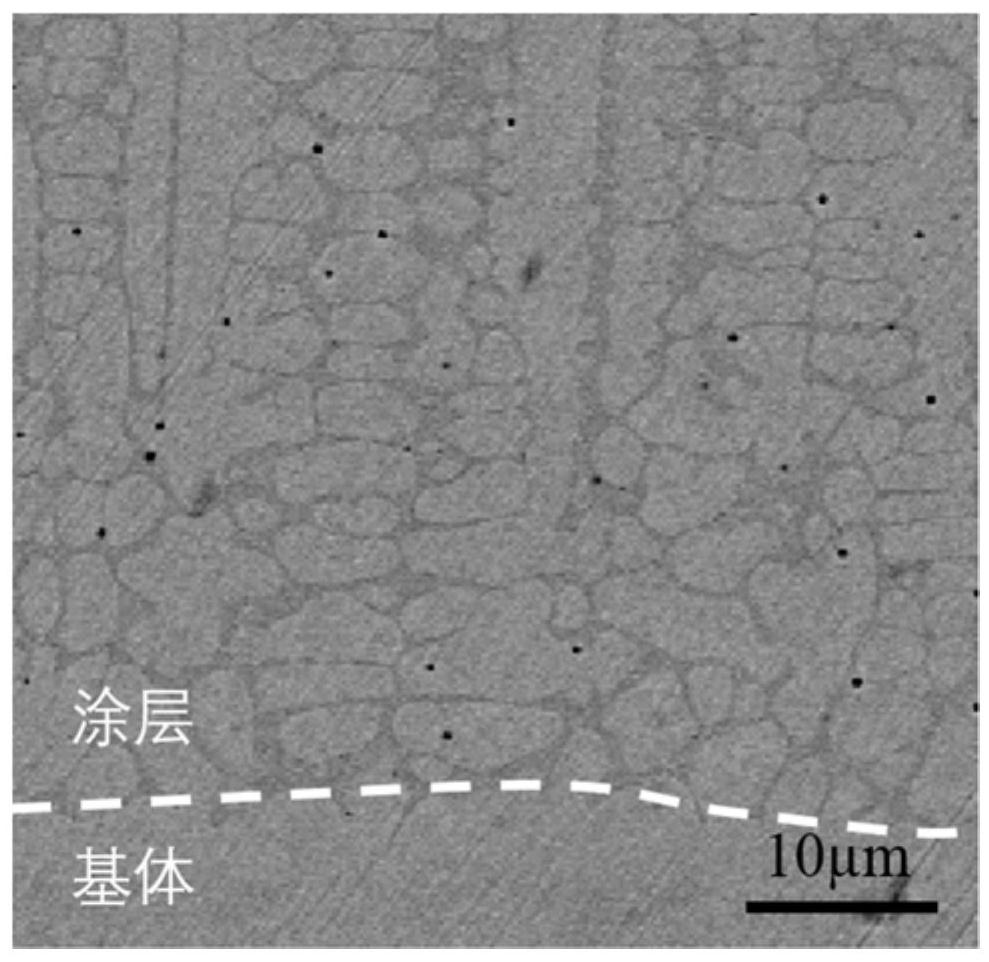

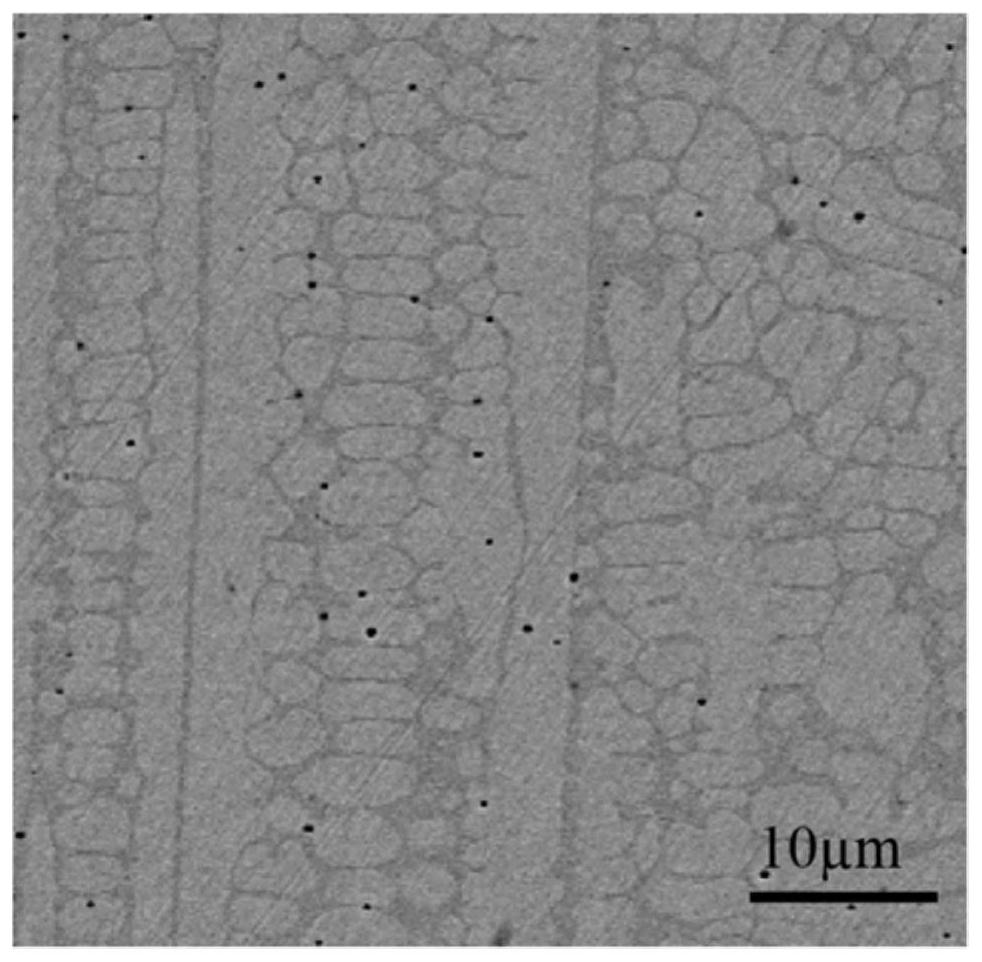

[0078] In this embodiment, the chemical composition of the micron FeCrNiSiB powder is calculated by mass percentage: Cr 5%; Ni 2%; Si 1%; B 1%; Fe balance. Figure 6 The particle size of the micron FeCrNiSiB powder shown is 50 μm to 200 μm. Micron La 2 o ...

Embodiment 2

[0090] In the preparation method of the iron-based wear-resistant composite material in this embodiment, the surface of the iron-based total substrate is pretreated first, and then the surface of the micron La 2 o 3 Powder, Micron Al 2 o 3 The powder and micron FeCrNiSiB powder are prepared in a certain proportion, and are subjected to vacuum drying, uniform mixing, cycle cryogenic treatment and vacuum drying treatment in sequence, and then the iron-based wear-resistant composite coating is prepared by laser cladding, and finally the laser shock pretreatment is carried out respectively. Processing, laser shock and cyclic heat treatment regulate the coating to ensure that the coating has excellent mechanical properties.

[0091] In this embodiment, the chemical composition of the micron FeCrNiSiB powder is by mass percentage: Cr 10%; Ni 4%; Si 3%; B 2%; Fe balance. Micron La 2 o 3 The mass content of the powder is 0.5%, micron La 2 o 3 The particle size distribution of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com