Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

A rare earth permanent magnet and anti-corrosion coating technology, used in anti-corrosion coatings, devices for coating liquid on surfaces, coatings, etc. Coating corrosion resistance and other issues, to achieve the effect of high density, strong corrosion resistance, and improved impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

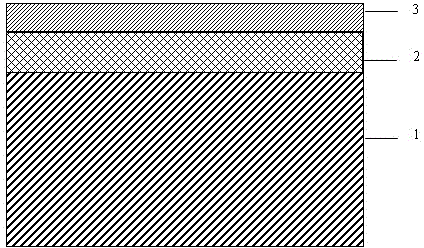

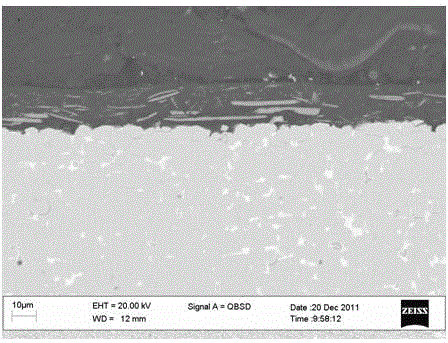

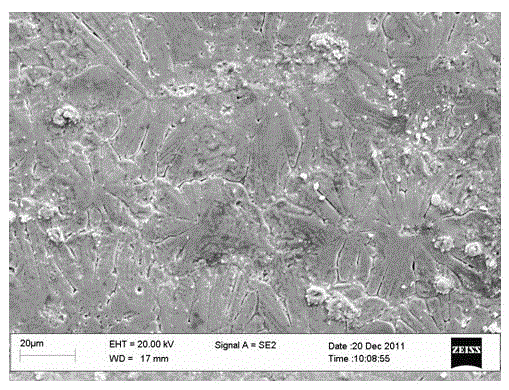

[0039] The anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet in this embodiment is composed of a bottom coating and a top coating, wherein the thickness of the bottom coating is 10 μm, and its chemical composition is: zinc 63%, chromium 2% , 35% polyimide resin; the thickness of the top coating is 15 μm, and its chemical composition is: aluminum 55%, phenolic resin 45%.

[0040] The preparation method of the anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet is carried out according to the following steps:

[0041] (1) Pretreatment: Ultrasonic degreasing is performed on the surface of 1kg NdFeB rare earth permanent magnet with a size of 15*15*50mm at 60°C in a degreasing solution with a concentration of 4% degreasing agent for 2 minutes, and then in dilute nitric acid Washing in acid for 10s, then phosphating the surface of the magnet in a phosphating solution, and drying at normal pressure at 80°C;

[0042] (2) Prepare...

Embodiment 2

[0054] The anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet in this embodiment is composed of a bottom coating and a top coating, wherein the thickness of the bottom coating is 15 μm, and its chemical composition is: aluminum 57%, molybdenum 3% , 40% polyurethane resin; the thickness of the top coating is 10 μm, and its chemical composition is: titanium 58%, acrylic resin 42%.

[0055] The preparation method of the anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet is carried out according to the following steps:

[0056] (1) Pretreatment: Ultrasonic degreasing was performed on the surface of 5kg NdFeB rare earth permanent magnets with a size of 16*8*2mm in a degreasing solution at 70°C with a concentration of 5% degreasing agent for 2 minutes, and then in dilute nitric acid Washing for 15s, then phosphating the surface of the magnet in the phosphating solution, and drying at -133KPa, 30°C under vacuum conditions;

[0...

Embodiment 3

[0069] The anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet of this embodiment is composed of a bottom coating and a top coating, wherein the thickness of the bottom coating is 20 μm, and its chemical composition is: aluminum 60%, nickel 4% , 36% polyurethane resin; the thickness of the top coating is 10 μm, and its chemical composition is: aluminum and titanium 65%, acrylic resin 35%.

[0070] Wherein, the weight ratio of aluminum and titanium is 2:1.

[0071] The preparation method of the anti-corrosion coating on the surface of the NdFeB rare earth permanent magnet is carried out according to the following steps:

[0072] (1) Pretreatment: Ultrasonic degreasing is performed on the surface of 1kg NdFeB rare earth permanent magnet with a size of 15*15*50mm at 60°C in a degreasing solution with a mass concentration of 5% degreasing agent for 2 minutes, and then in dilute nitric acid Washing treatment for 15s, then phosphating the surface of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com