Patents

Literature

39results about How to "Improve coating appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

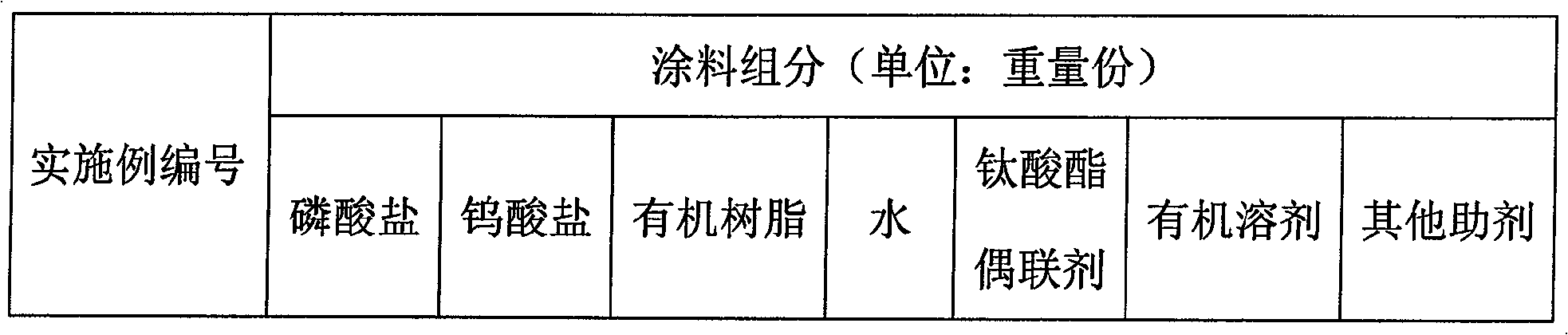

Non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance

ActiveCN101560342AImprove corrosion resistanceImprove coating appearanceAnti-corrosive paintsPolyurea/polyurethane coatingsTungstateOrganic phosphates

The invention discloses a non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance. The semi-organic phosphate insulating paint comprises the following main components: water-soluble phosphate, tungstate, organic resin, water, a titanate coupling agent, an organic solvent and the like; and contents of the components of the insulating paint (parts by weight) based on 100 parts of the water-soluble phosphate by weight are as follows: 1-15 parts of the tungstate, 20-200 parts of the organic resin, 500-2000 parts of the water, 0.1-3 parts of the titanate coupling agent, 10-50 parts of the organic solvent and 0.1-3 parts of other paint addictives. The semi-organic phosphate insulating paint contains no harmful ingredients restricted by an EU directive RoHS, which can meet the requirements for environmental protection; and compared with the common phosphate coating, the coating of the semi-organic phosphate insulating paint has better corrosion resistance, good insulating property, good adhesiveness, good blanking property, good welding property, good heat resistance and the like, which can meet the requirements of electric motor and transformermanufacturers for application to the electric steel coating.

Owner:MAANSHAN IRON & STEEL CO LTD

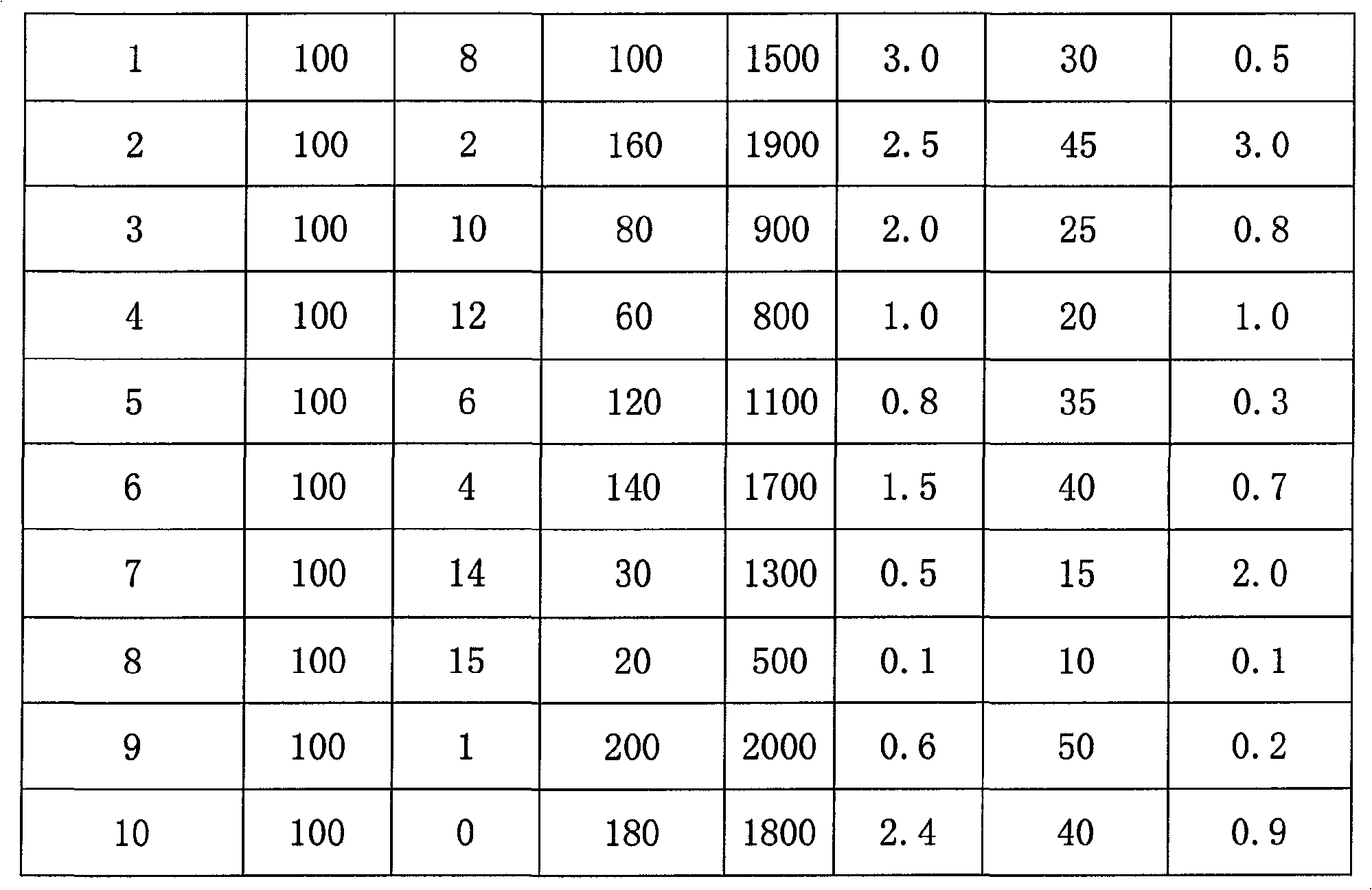

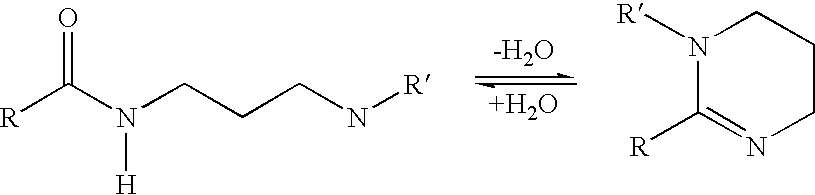

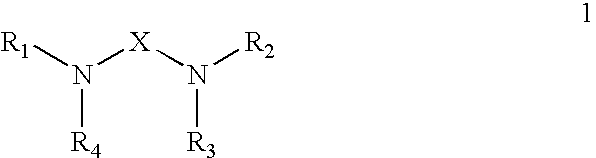

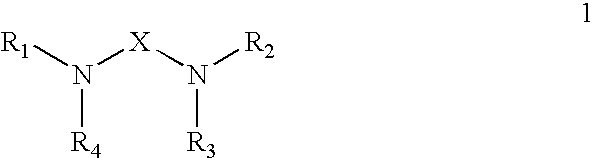

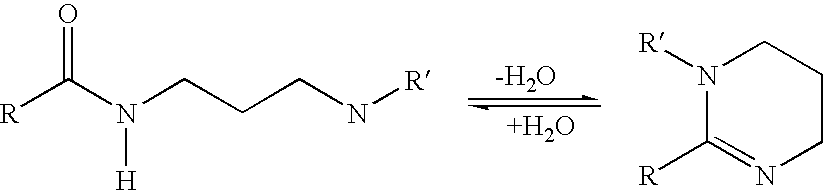

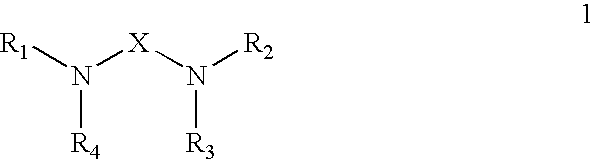

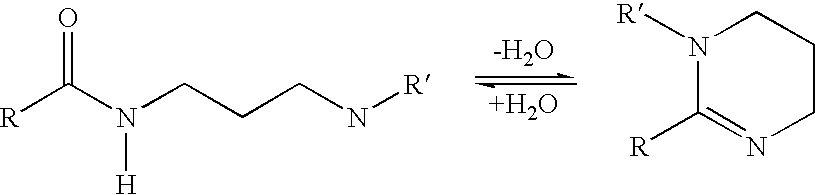

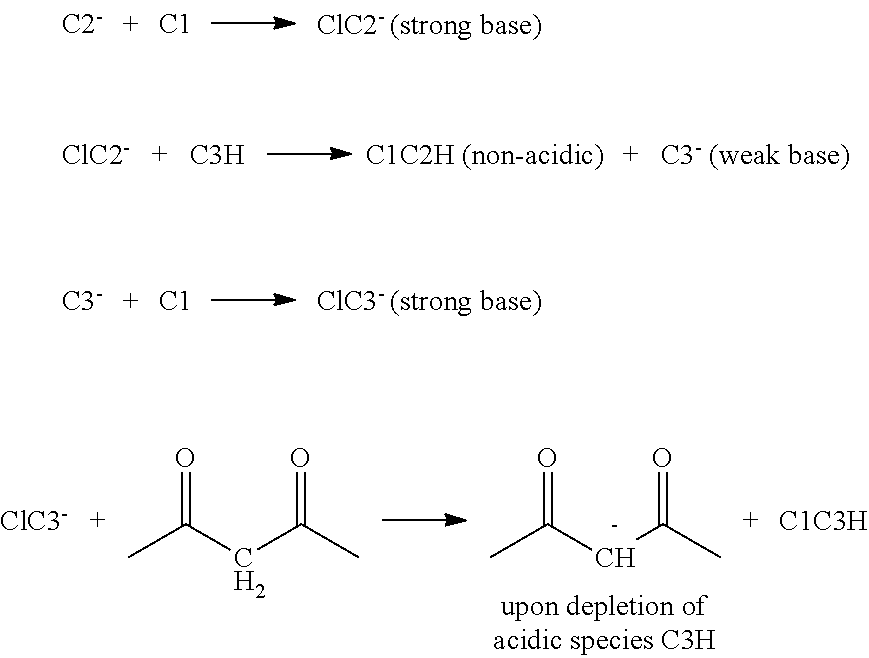

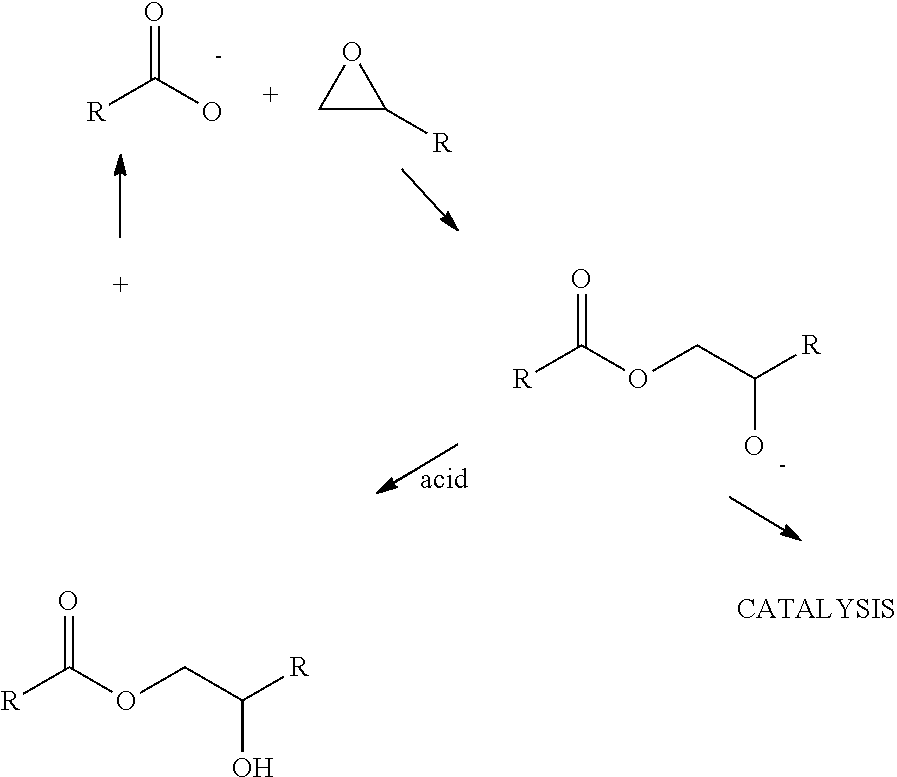

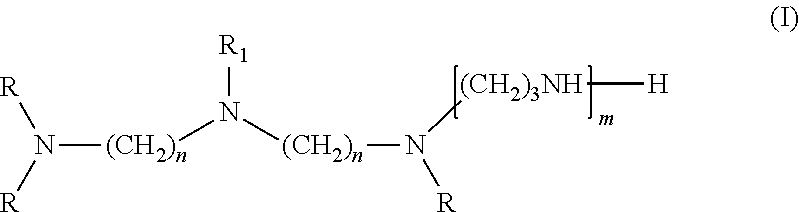

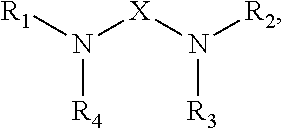

Polyamide curative from substituted amine and dimer fatty acid or ester

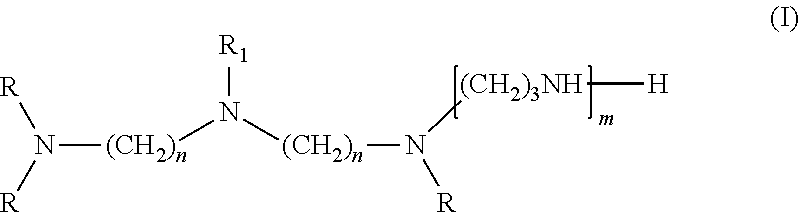

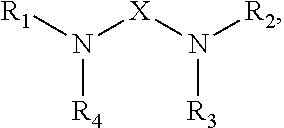

The present invention provides polyamide curing agent compositions comprising the reaction products of (1) multifunctional amines of structure 1where R1 is CH2CH2CH2NH2; R2, R3 and R4 independently are H or CH2CH2CH2NH2, and X is CH2CH2 or CH2CH2CH2 with (2) dimer fatty acids, optionally in combination with monofunctional fatty acids, the reaction product preferably comprising at least 15 wt % tetrahydropyrimidine-containing components. The curing agent compositions are useful for crosslinking epoxy resins to produce coatings, adhesives, floorings, composites and other articles.

Owner:EVONIK OPERATIONS GMBH

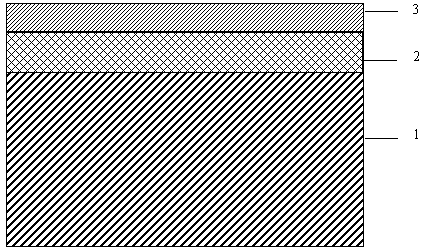

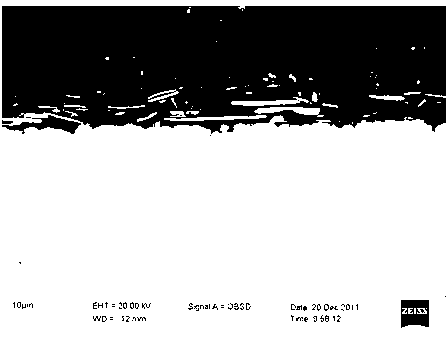

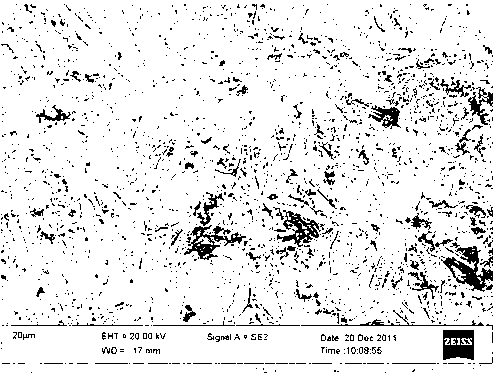

Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

ActiveCN102936455AControl thicknessImprove protectionPretreated surfacesAnti-corrosive paintsAcrylic resinRare earth

The invention belongs to the technical field of surface treatment and particularly relates to a neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and a preparation method thereof. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating is composed of a bottom coating and a top coating, the thickness of the bottom coating is in a range from 10mum to 25mum, the chemical components of the bottom coating comprise 55% to 65% of one or two types of metals of zinc and aluminum, 0% to 5% of one or a plurality of types of metals of nickel, chromium, molybdenum, neodymium, praseodymium, cobalt and titanium and 34% to 40% of neutral resins, the thickness of the top coating is in a range from 5mum to 15mum, and the chemical components of the top coating comprise 55% to 65% of one or a plurality of types of metals of zinc, aluminum, titanium, molybdenum, nickel, cobalt and chromium and 35% to 45% of phenolic resins or acrylic resins. The preparation method includes that firstly the surface of a permanent magnet is preprocessed, a centrifugal immersion tossing is utilized to prepare the bottom coating, and a rolling spraying process is utilized to prepare the top coating. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and the preparation method thereof have the advantages that by means of double layers of coatings, the corrosion resistance is high, the surface binding force is high, the usage temperature is higher than 200 DEG C, the magnetic property of the neodymium iron boron rare earth permanent magnet is improved, the service life is prolonged, and the service environment is widened.

Owner:SHENYANG GENERAL MAGNETIC

HOT-DIP Al-Zn COATED STEEL SHEET AND METHOD FOR MANUFACTURING THE SAME (AS AMENDED)

ActiveUS20130236739A1Excellent coat appearance and corrosion resistanceReduce weightHot-dipping/immersion processesPretreated surfacesSheet steelSurface oxide

There is provided a hot-dip Al—Zn coated steel sheet that has a steel sheet containing Si and Mn as a base steel sheet and has excellent coating appearance and corrosion resistance. The Al—Zn coating layer has an Al content in the range of 20% to 95% by mass. The Al—Zn coating layer has a Ca content in the range of 0.01% to 10% by mass. Alternatively, the Ca and Mg content is in the range of 0.01% to 10% by mass. A steel sheet surface layer within 100 μm from a surface of the base steel sheet directly under the Al—Zn coating layer contains less than 0.060 g / m2 per surface of an oxide of at least one selected from Fe, Si, Mn, Al, P, B, Nb, Ti, Cr, Mo, Cu, and Ni in total.

Owner:JFE STEEL CORP

Dispersion and aqueous coating composition comprising the dispersion

The present invention relates to a dispersion comprising an acryl-modified cellulose ester derivative (D) dispersed in an aqueous medium, wherein a hydrophobic acrylic resin (B) and a hydrophilic acrylic resin (C) are grafted onto a cellulose ester derivative (A) in the acryl-modified cellulose ester derivative (D). The dispersion has excellent long-term storage stability, and aqueous coating compositions comprising the dispersion can form coating films with excellent coating workability, solvent resistance, chemical resistance, water resistance, and excellent curability.

Owner:KANSAI PAINT CO LTD

Polyamide curative from substituted amine mixture and dimer fatty acid or ester

The present invention provides polyamide curing agent compositions comprising the reaction products of (1) multifunctional amines of structure 1where R1 is CH2CH2CH2NH2; R2, R3 and R4 independently are H or CH2CH2CH2NH2, and X is CH2CH2 or CH2CH2CH2 with (2) dimer fatty acids, optionally in combination with monofunctional fatty acids, the reaction product preferably comprising at least 15 wt % tetrahydropyrimidine-containing components. The curing agent compositions are useful for crosslinking epoxy resins to produce coatings, adhesives, floorings, composites and other articles.

Owner:EVONIK OPERATIONS GMBH

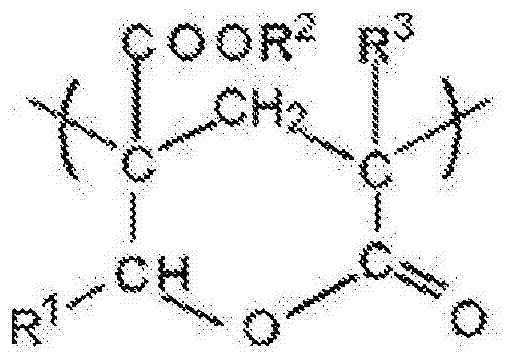

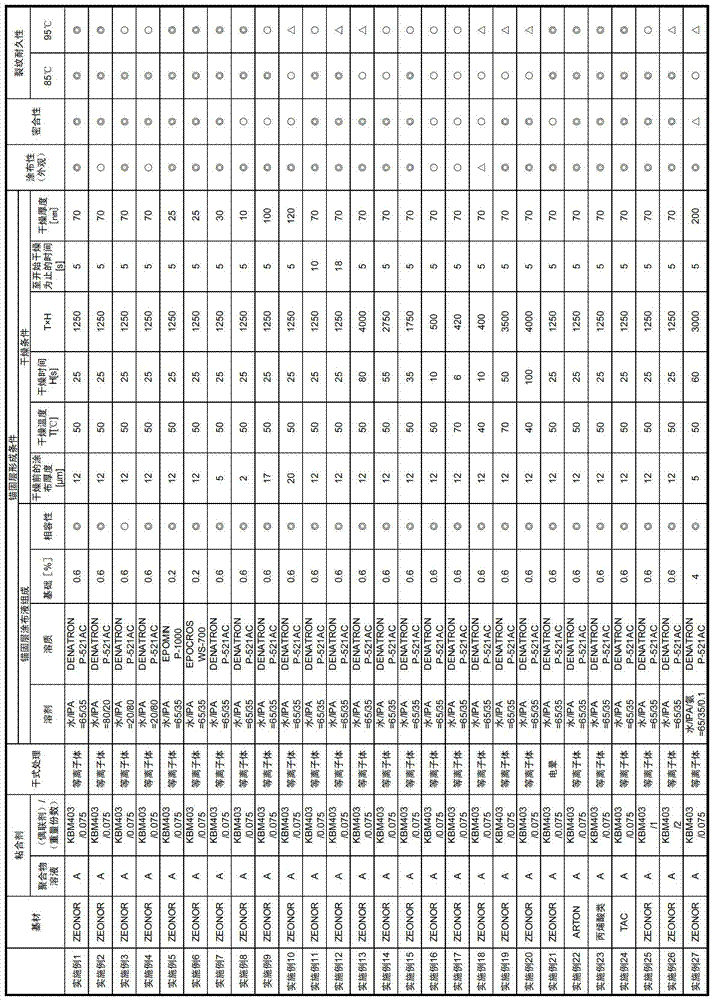

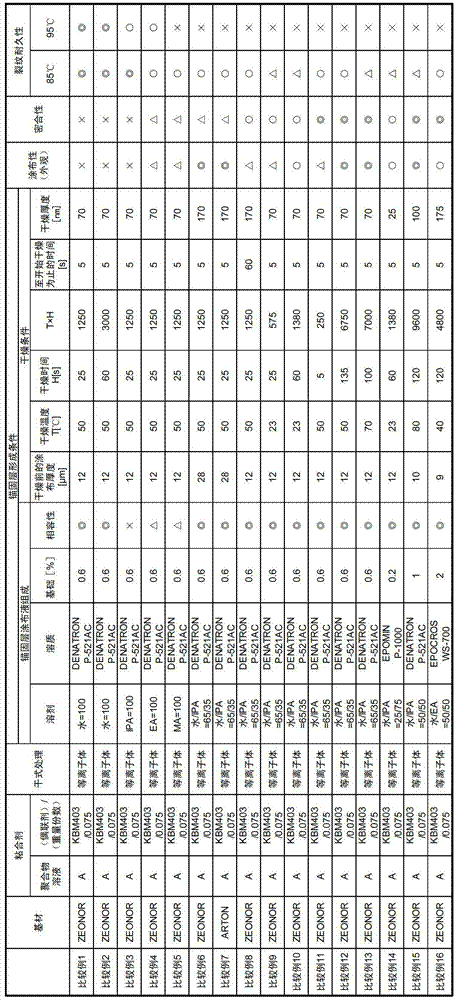

Process for production of adhesive optical film

InactiveUS20130171371A1Improve adhesionImprove coating appearanceFilm/foil adhesive primer layersPretreated surfacesAlcoholSolvent

A method for production of an adhesive optical film comprises the step of forming an anchor layer by applying an anchor layer-forming coating liquid to the optical film to form a coating with a thickness of 20 μm or less before drying, wherein the anchor layer-forming coating liquid contains a mixed solvent composed mainly of water and an alcohol, and a binder resin, and by drying the coating under drying conditions satisfying both of the following requirements:(1) the drying temperature T is between 40° C. and 70° C.; and(2) the value (T×H) obtained by multiplying the drying temperature T (° C.) by the drying time H (seconds) satisfies the relation400≦(T×H)≦4,000to remove the mixed solvent.

Owner:NITTO DENKO CORP

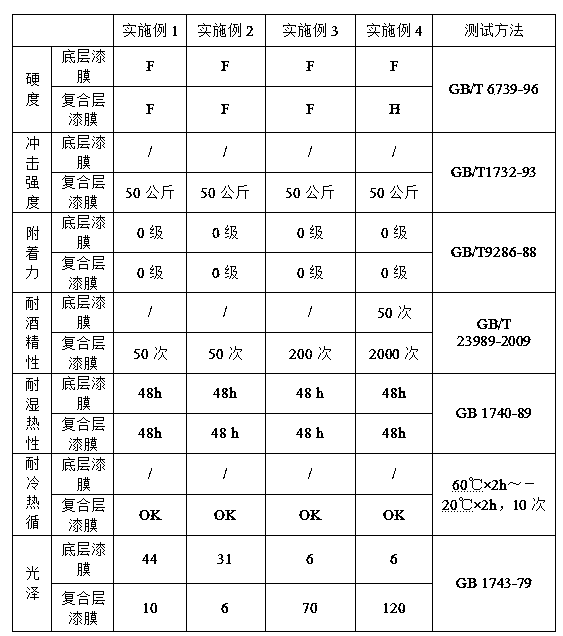

Water-based plastic paint applicable to composite layer coating film, and preparation process thereof

InactiveCN103525216AImprove coating appearanceImprove the decorative effectCoatingsSolvent basedCoating

The invention discloses water-based plastic paint applicable to a composite layer coating film. The water-based plastic paint consists of the following components in parts by weight: 45 to 60 parts of water-based acrylic acid emulsion, 10 to 25 parts of deionized water, 1 to 2 parts of aid, 2 to 4 parts of LTW resin, 1 to 2 parts of 25% ammonia water, 5 to 17 parts of cosolvent, 1 to 5 parts of alkali swelling thickening agent and 5 to 30 parts of pigment. The invention discloses a preparation process of the water-based plastic paint. The water-based plastic paint can perform implementation of a composite layer paint film and also can perform implementation in combination with solvent type plastic paint, and the formed coating has ideal physical properties.

Owner:GUANGZHOU KINTE IND +1

Polyamide Curing Agent Compositions

The present invention provides polyamide curing agent compositions comprising the reaction products of (1) multifunctional amines of structure 1where R1 is CH2CH2CH2NH2; R2, R3 and R4 independently are H or CH2CH2CH2NH2, and X is CH2CH2 or CH2CH2CH2 with (2) dimer fatty acids, optionally in combination with monofunctional fatty acids, the reaction product preferably comprising at least 15 wt % tetrahydropyrimidine-containing components. The curing agent compositions are useful for crosslinking epoxy resins to produce coatings, adhesives, floorings, composites and other articles.

Owner:EVONIK OPERATIONS GMBH

Process for production of adhesive optical film

ActiveCN103080263AImprove coating appearanceAvoid crackingNon-macromolecular adhesive additivesFilm/foil adhesive primer layersAlcoholPolymer science

A process for producing an adhesive optical film, comprising a step of applying an anchor layer coating solution that comprises a mixed solvent containing water and an alcohol as the main components and a binder resin onto an optical film in such a manner that the thickness of the resulting coating before drying becomes 20 [mu]m or less and then drying the resulting product under the drying conditions which fulfill both the requirements (1)-(2) mentioned below to remove the mixed solvent, thereby forming an anchor layer: (1) the drying temperature (T) is 40 to 70 DEG C; and (2) a value (TH) produced by multiplying the drying temperature (T) ( DEG C) with a drying time (H) (sec) is 400 to 4000 inclusive.

Owner:NITTO DENKO CORP

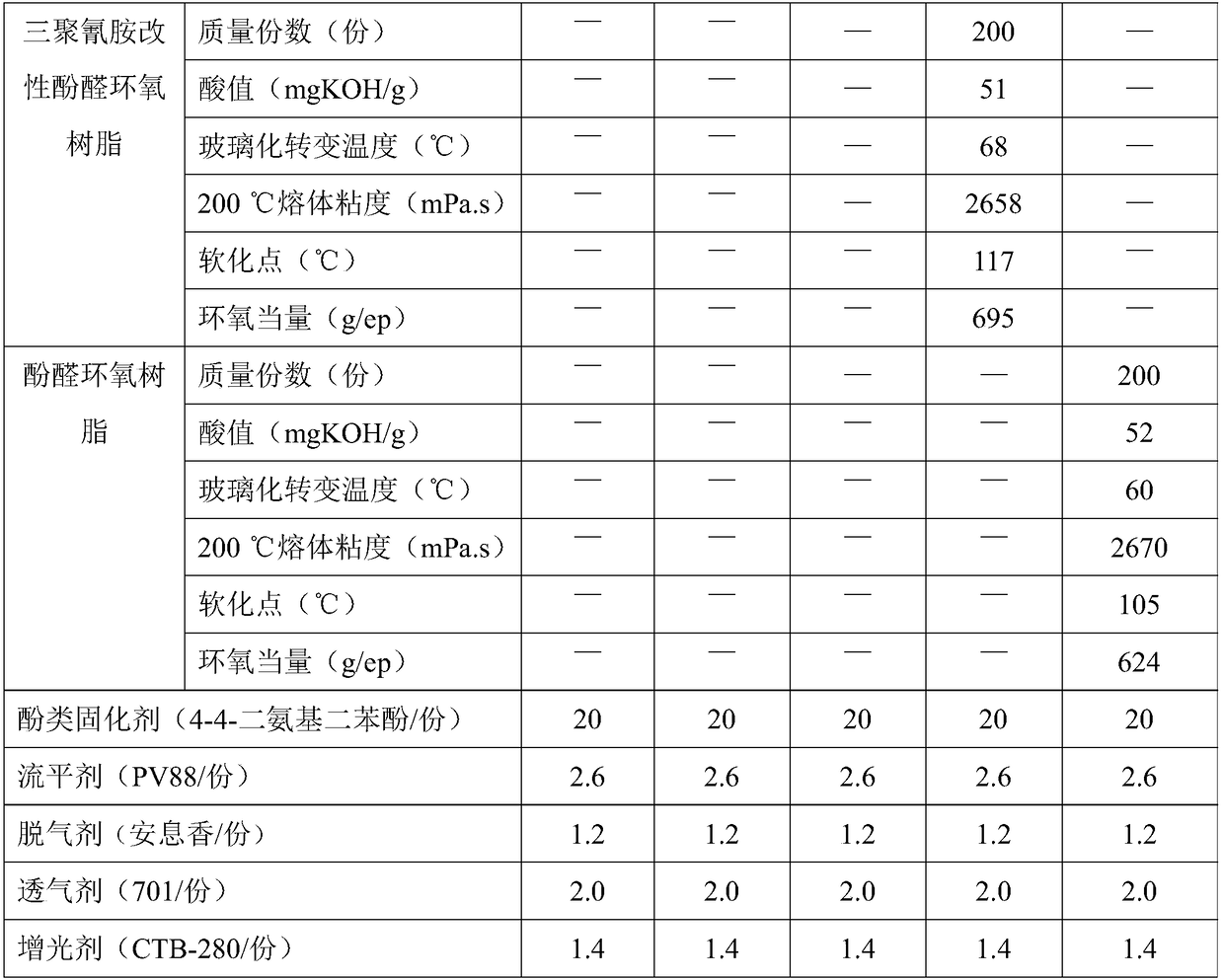

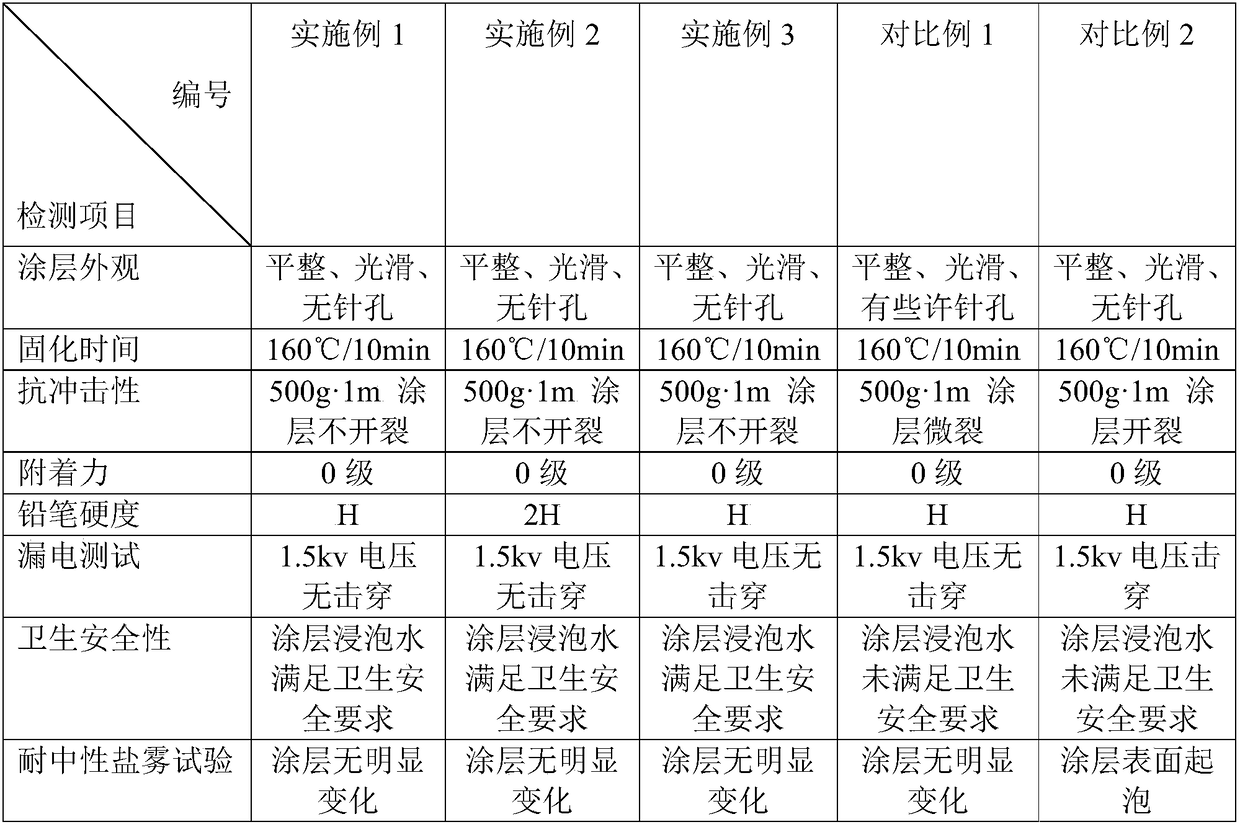

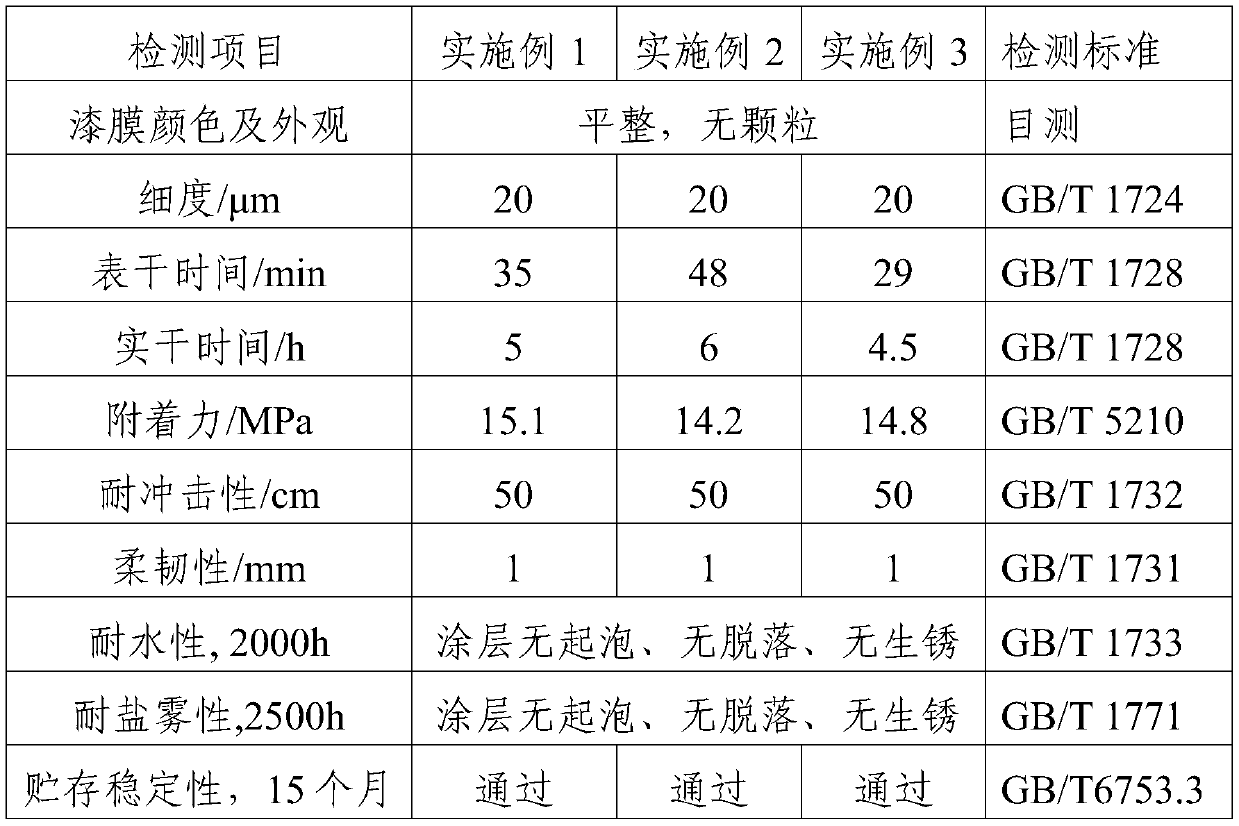

Food-grade powder coating as well as preparation method and application thereof

ActiveCN109337523AStrong impact resistanceLow curing temperatureAnti-corrosive paintsPowdery paintsWater pipeCorrosion

The invention discloses a food-grade powder coating as well as a preparation method and application thereof. The powder coating comprises modified phenolic epoxy resin, a phenolic curing agent and anaid. The powder coating has the properties of high corrosion resistance, strong impact resistance, low curing temperature, short curing time, good adhesion force, excellent coating appearance and thelike, can meet the food-grade health and safety requirements and is particularly suitable for the protection of water-related workpieces or containers such as water pipes, valves and water faucets andthe like for drinking water or groundwater.

Owner:GUANGZHOU KINTE IND

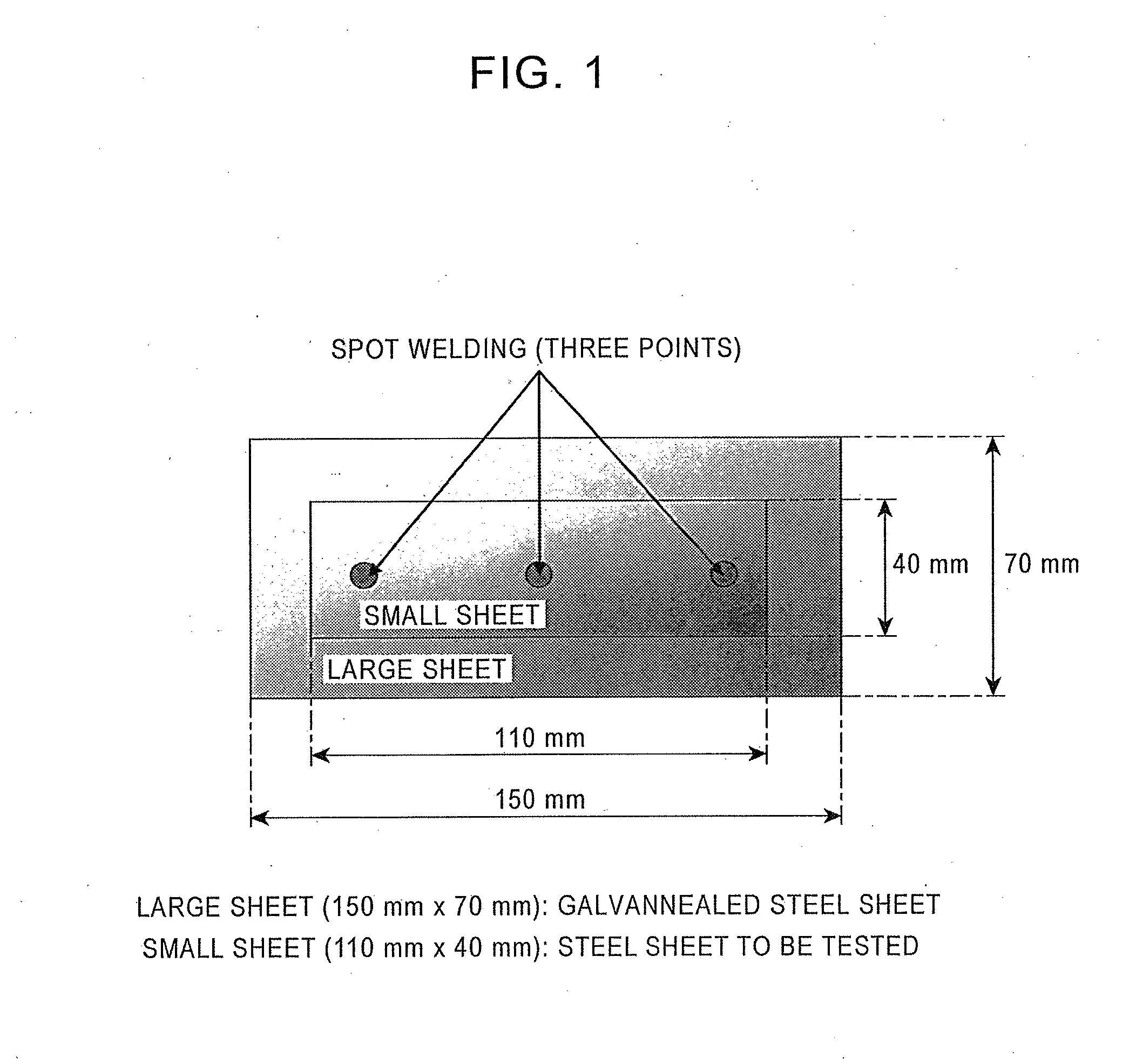

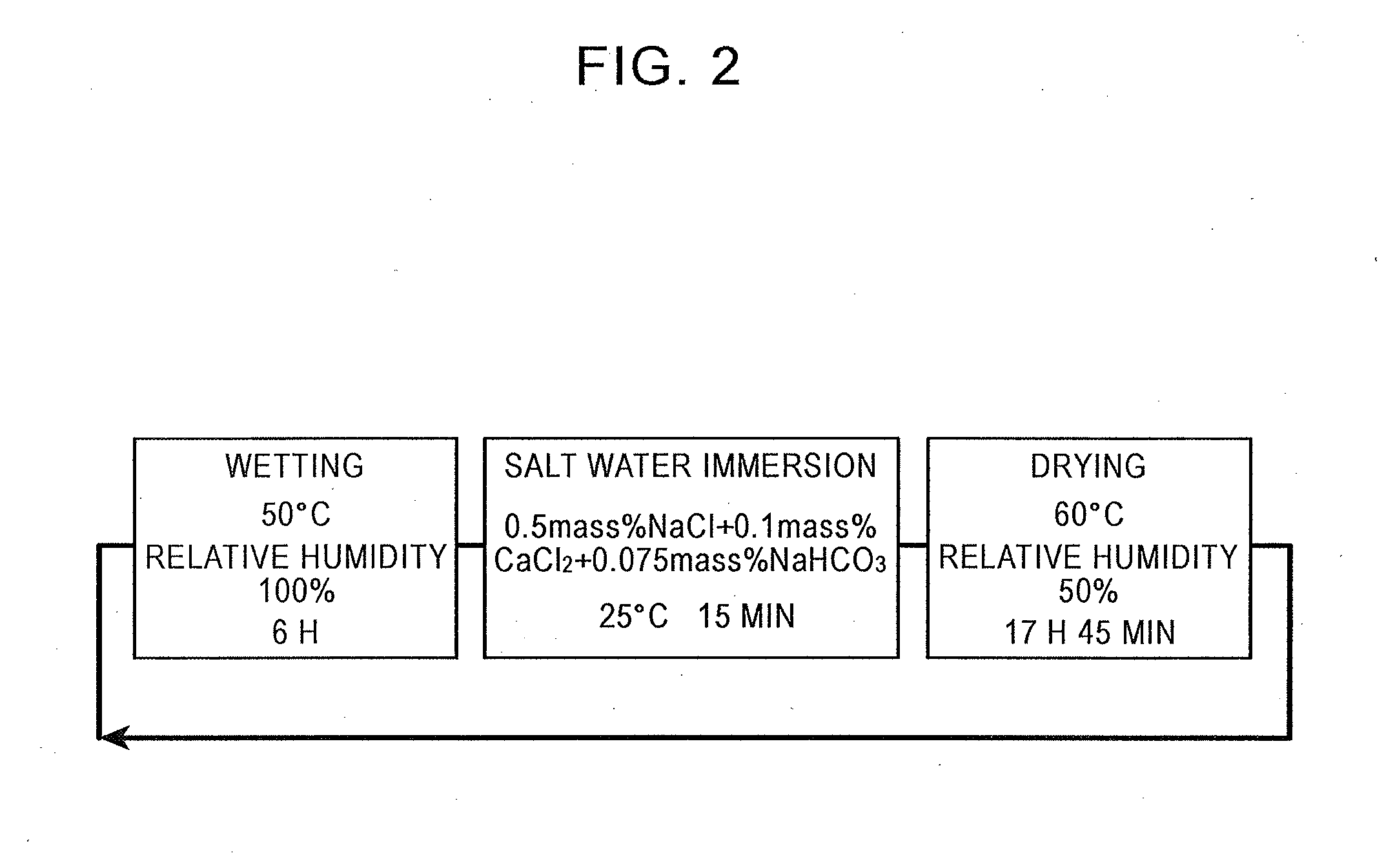

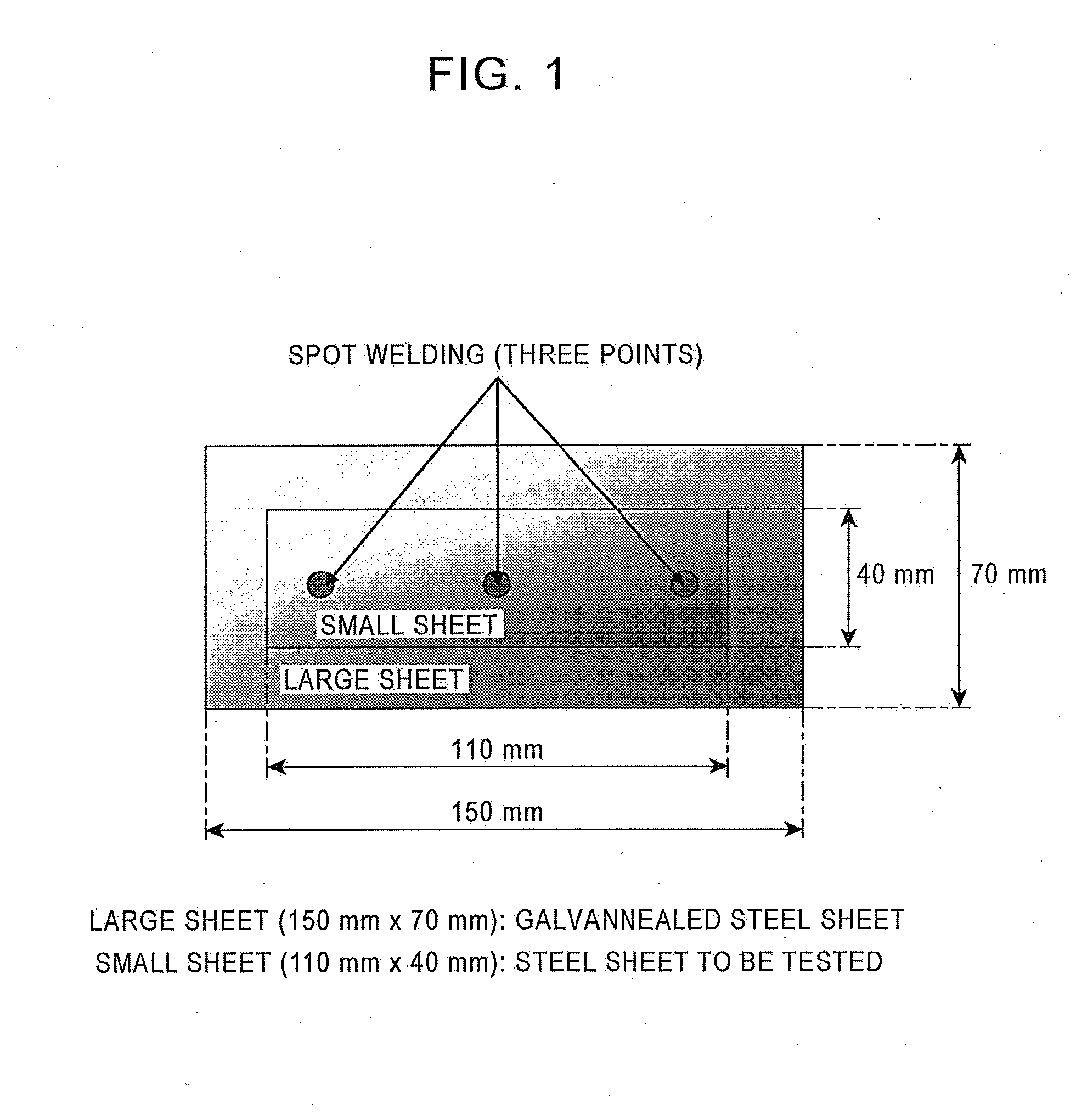

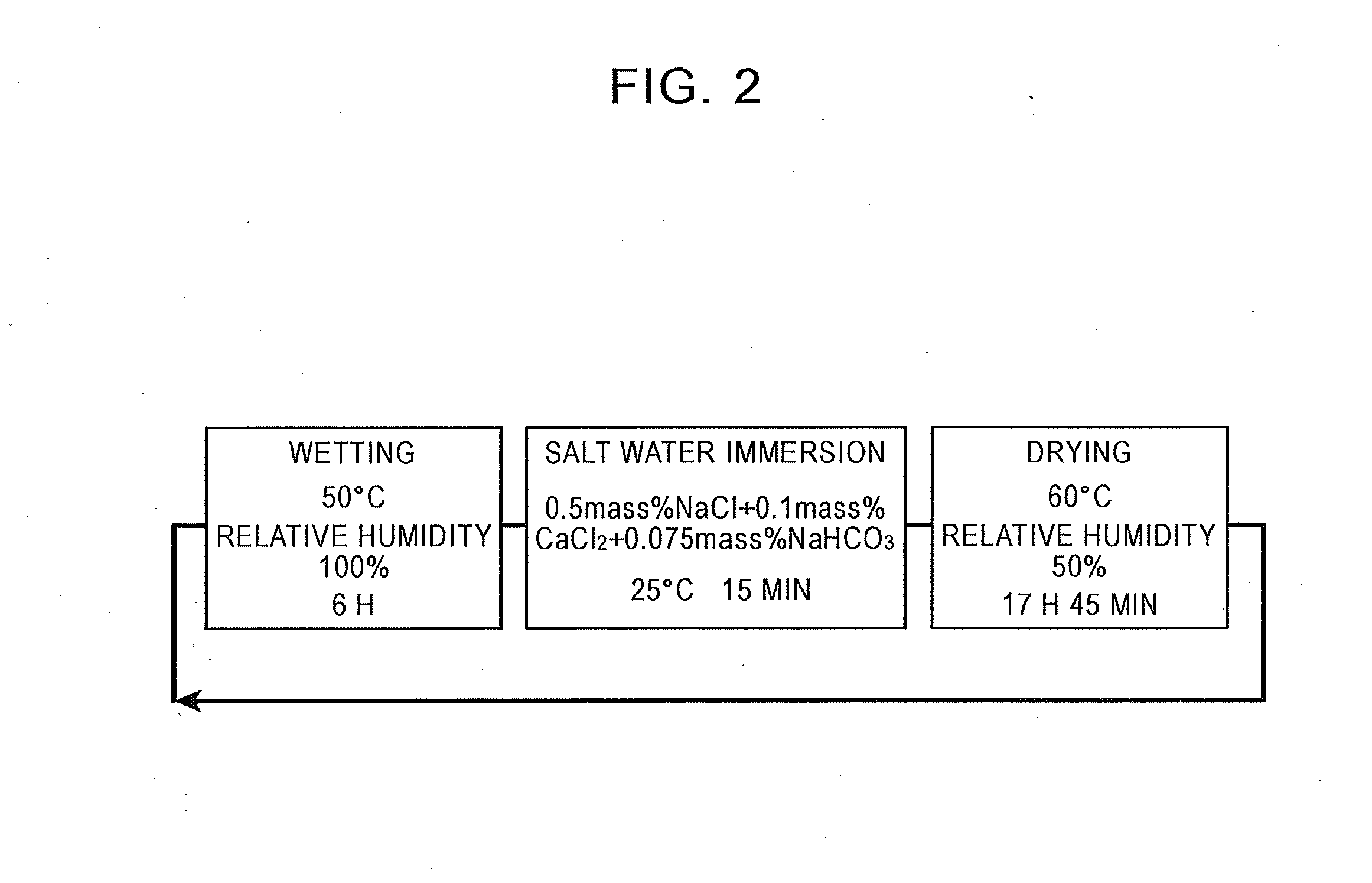

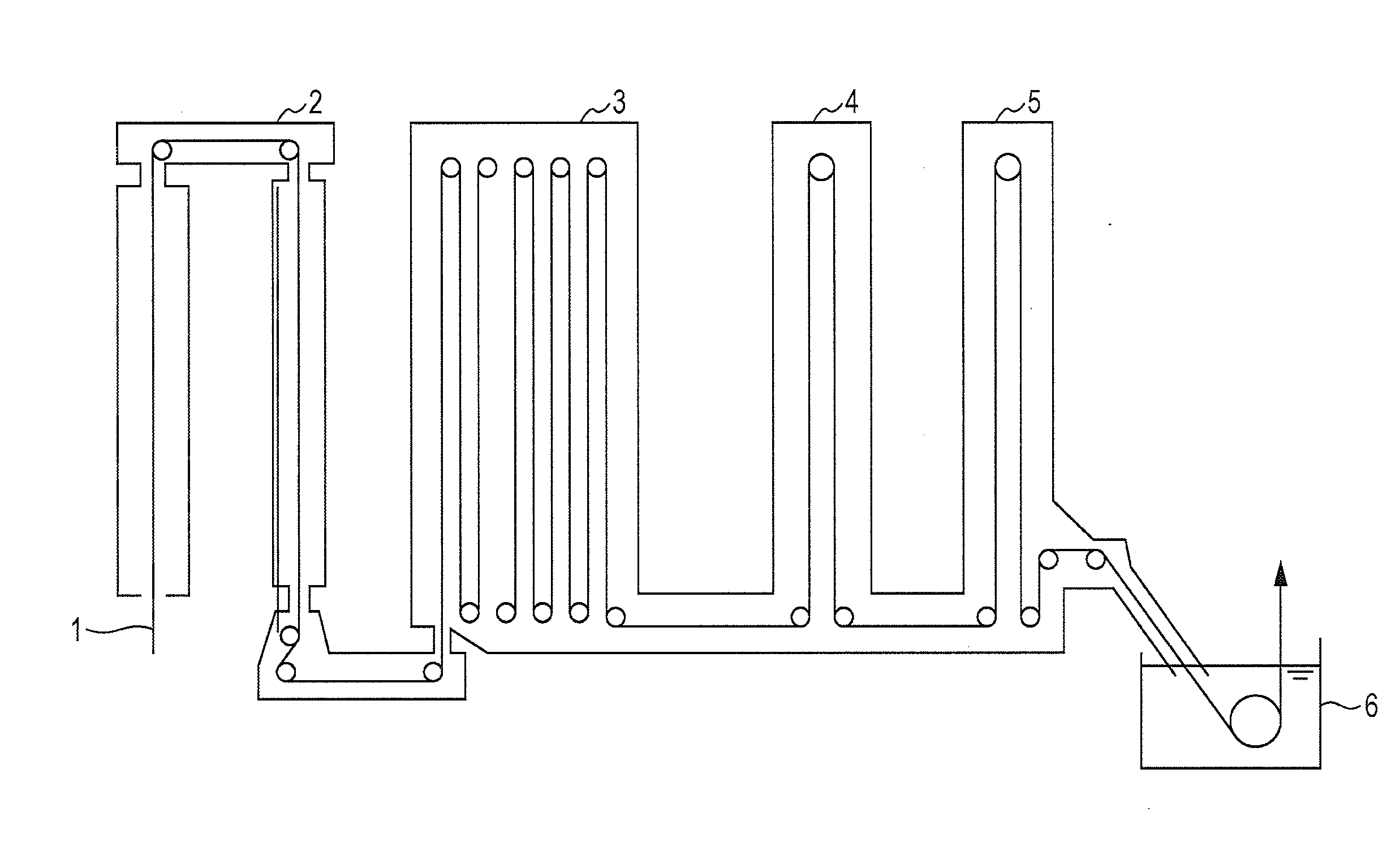

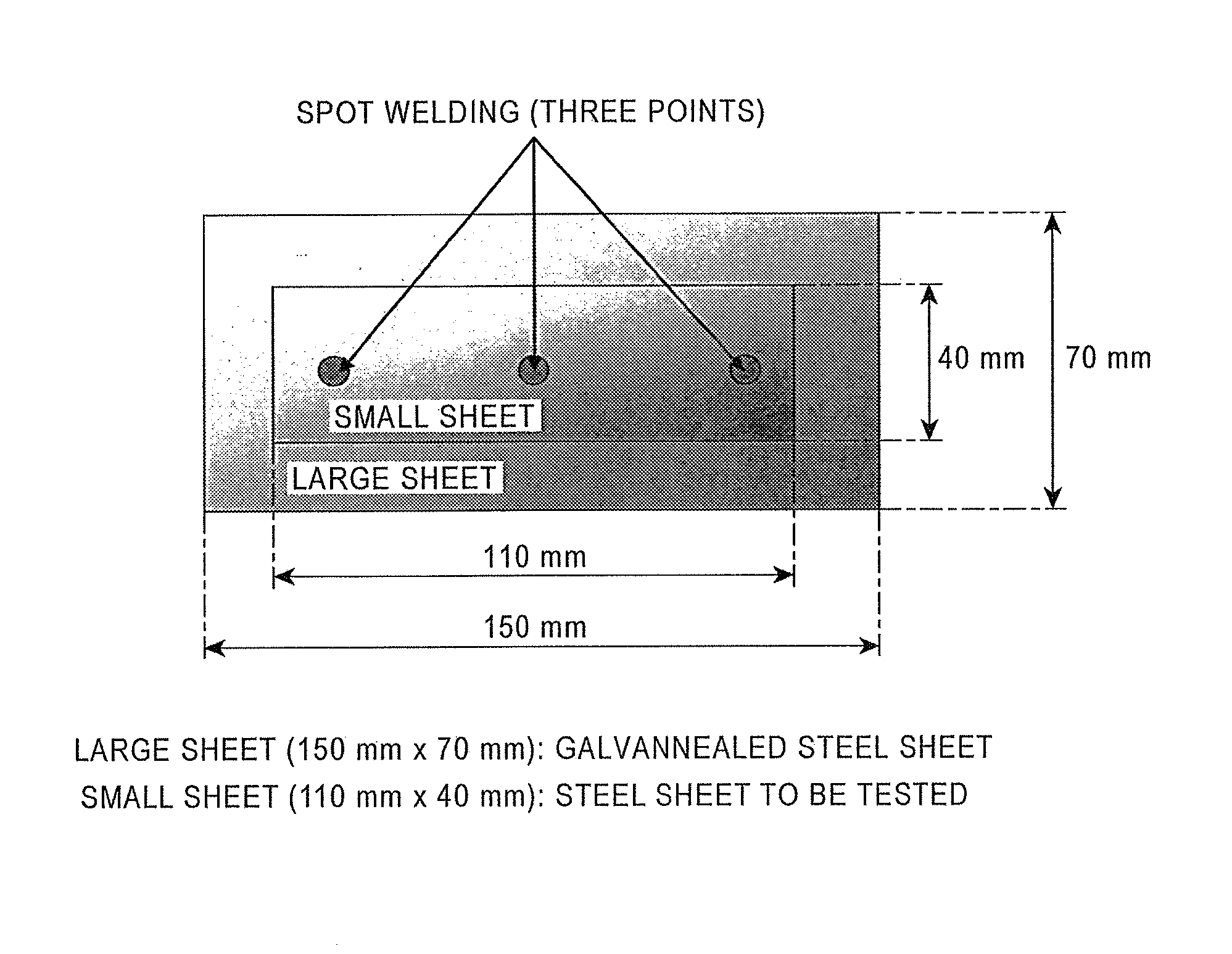

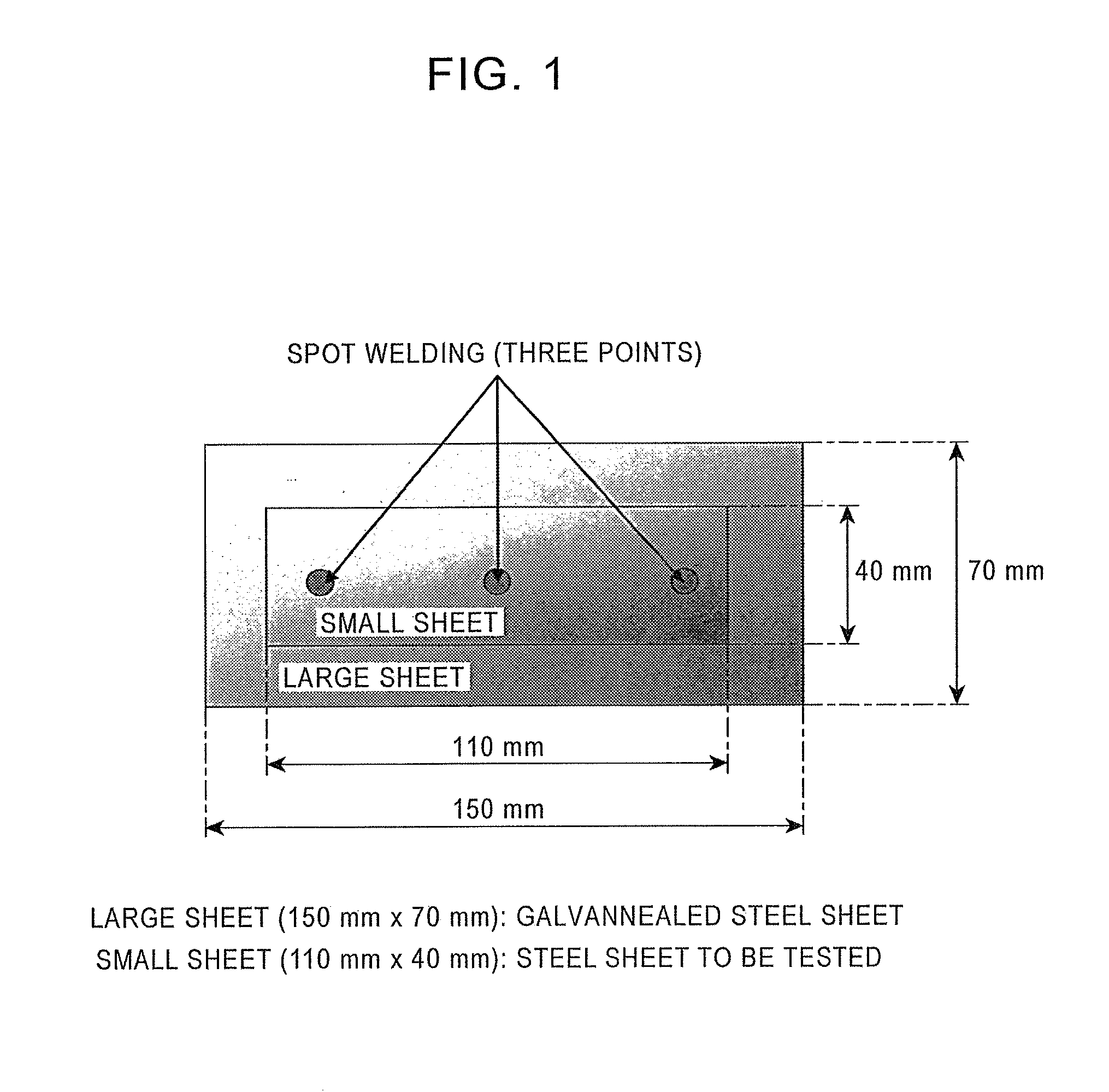

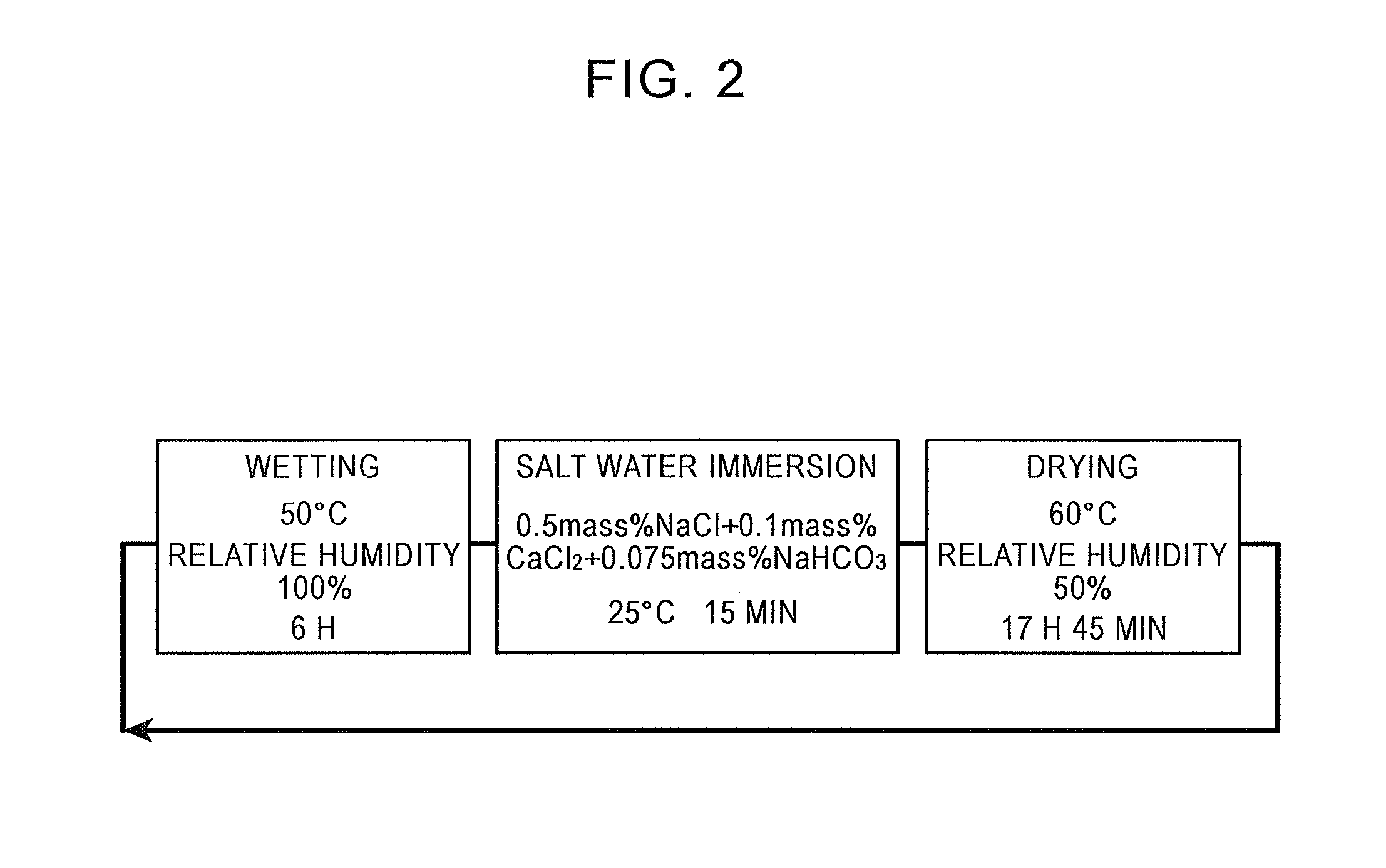

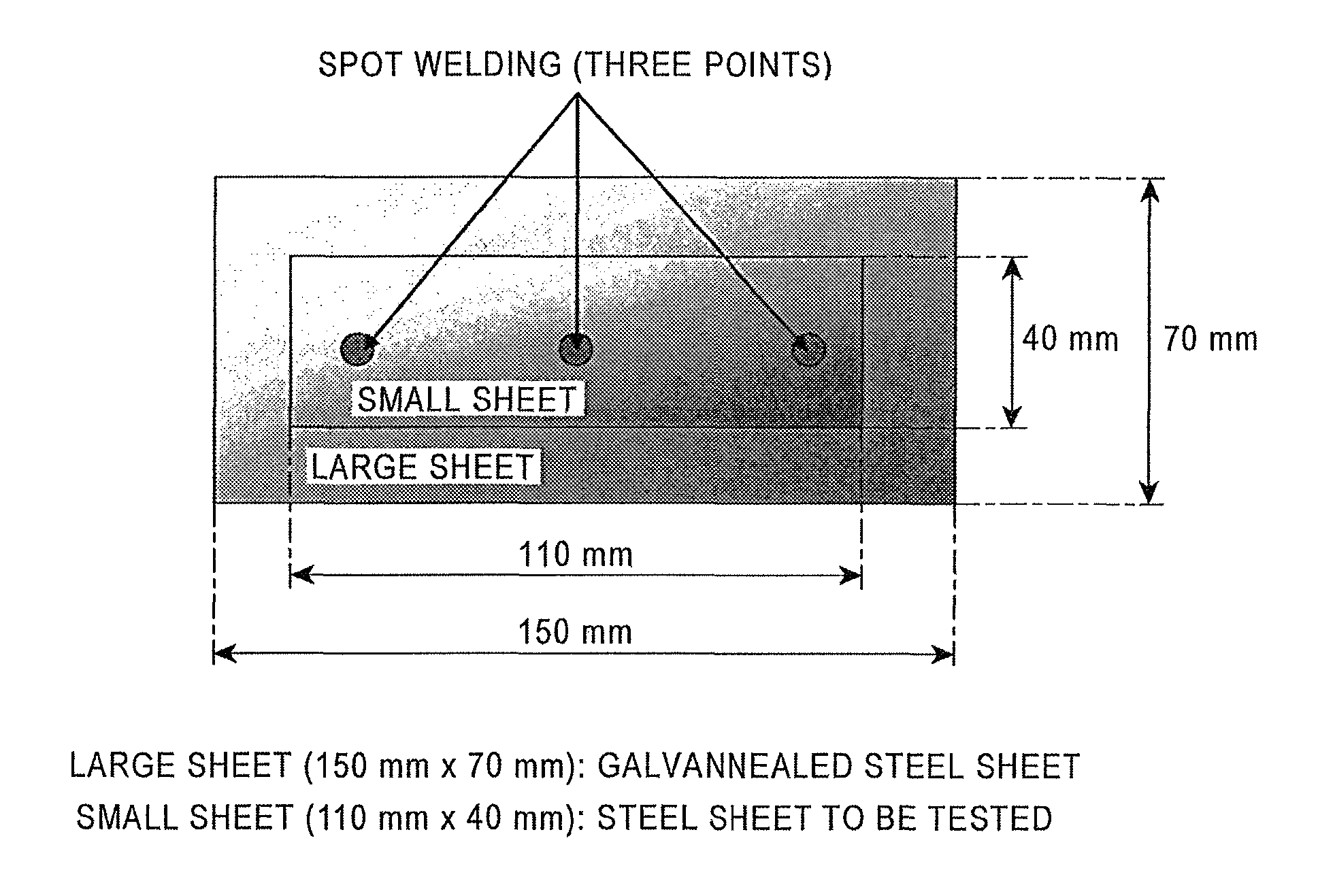

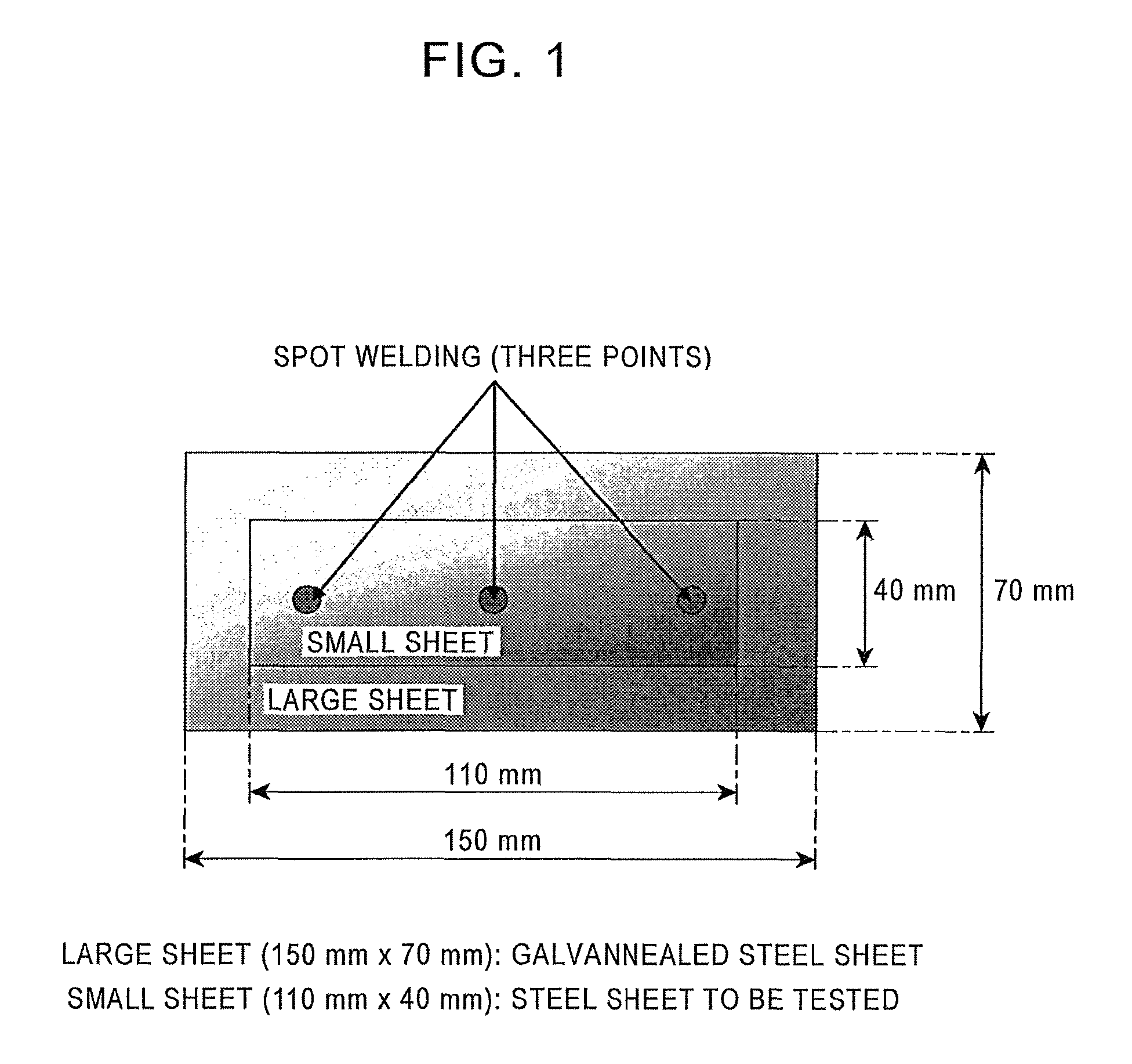

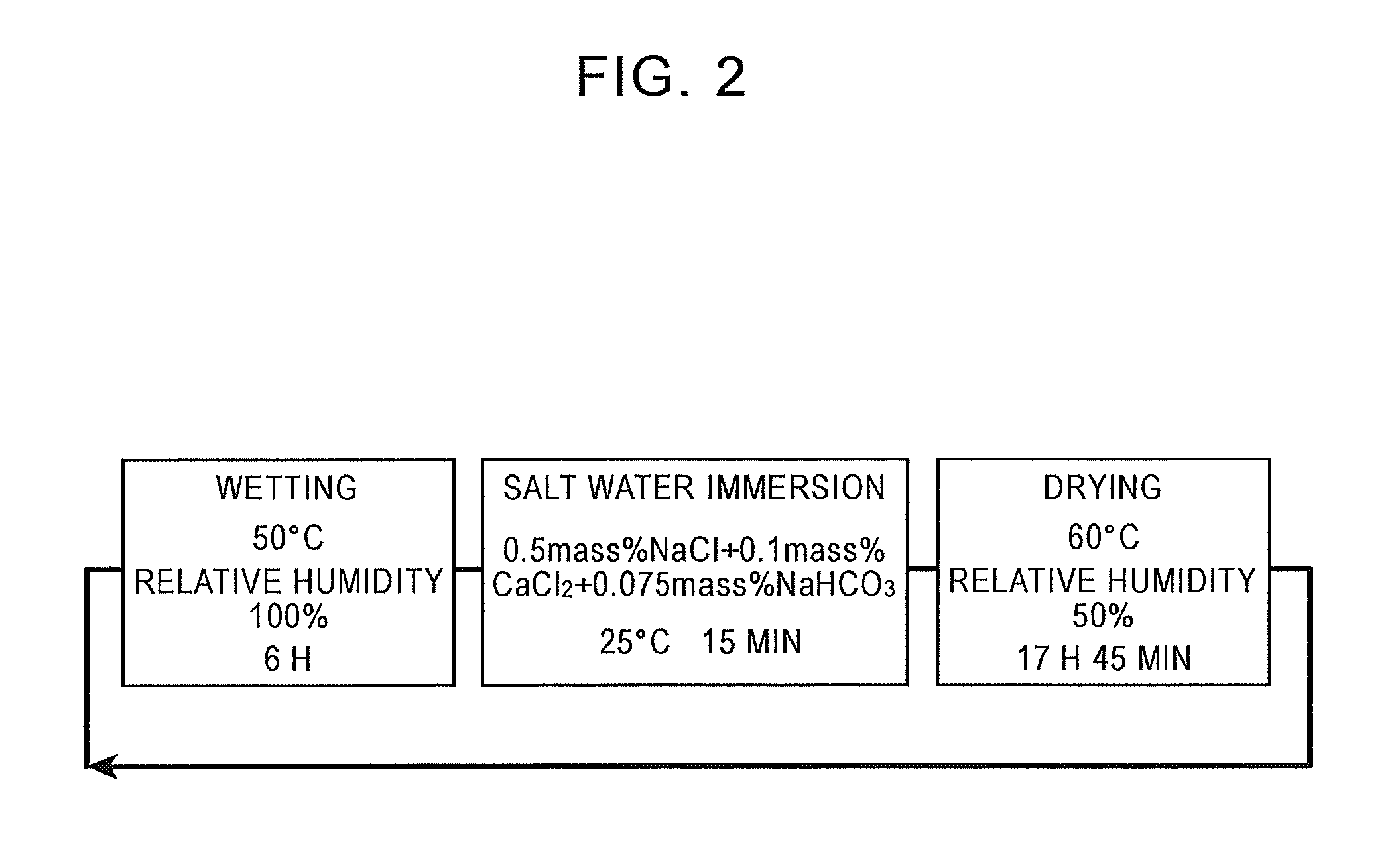

Method for manufacturing high strength galvanized steel sheet and high strength galvanized steel sheet

ActiveUS20150044503A1Good coating appearanceImprove corrosion resistanceHot-dipping/immersion processesFurnace typesChemical compositionHigh intensity

A method for manufacturing a high strength galvanized steel sheet and a high strength galvanized steel sheet are provided. A base steel sheet having a chemical composition comprising C: 0.03% to 0.35%, Si: 0.01% to 0.50%, Mn: 3.6% to 8.0%, Al: 0.001% to 1.000%, P≦0.10%, S≦0.010%, and the balance comprising Fe and incidental impurities, on a percent by mass basis, is subjected to annealing and galvanization treatment, wherein the maximum steel sheet temperature in an annealing furnace is 600° C. or higher and 700° C. or lower, the steel sheet transit time in a temperature region of the maximum steel sheet temperature of 600° C. or higher and 700° C. or lower is specified to be 30 seconds or more and 10 minutes or less, and the dew point in an atmosphere is specified to be −45° C. or lower.

Owner:JFE STEEL CORP

HOT-DIP Al-Zn COATED STEEL SHEET

ActiveUS20130295411A1Nice appearanceImprove corrosion resistanceHot-dipping/immersion processesSolid state diffusion coatingSurface layerSheet steel

There is provided a hot-dip Al—Zn coated steel sheet that has a steel sheet containing Si and Mn as a base steel sheet and has excellent coating appearance and corrosion resistance. The Al—Zn coating layer has an Al content in the range of 20% to 95% by mass. The Al—Zn coating layer has a Ca content in the range of 0.01% to 10% by mass. Alternatively, the Ca and Mg content is in the range of 0.01% to 10% by mass. A steel sheet surface layer within 100 μm from a surface of the base steel sheet directly under the Al—Zn coating layer contains 0.06 to 1.0 g / m2 per surface of an oxide of at least one selected from Fe, Si, Mn, Al, P, B, Nb, Ti, Cr, Mo, Cu, and Ni in total.

Owner:JFE STEEL CORP

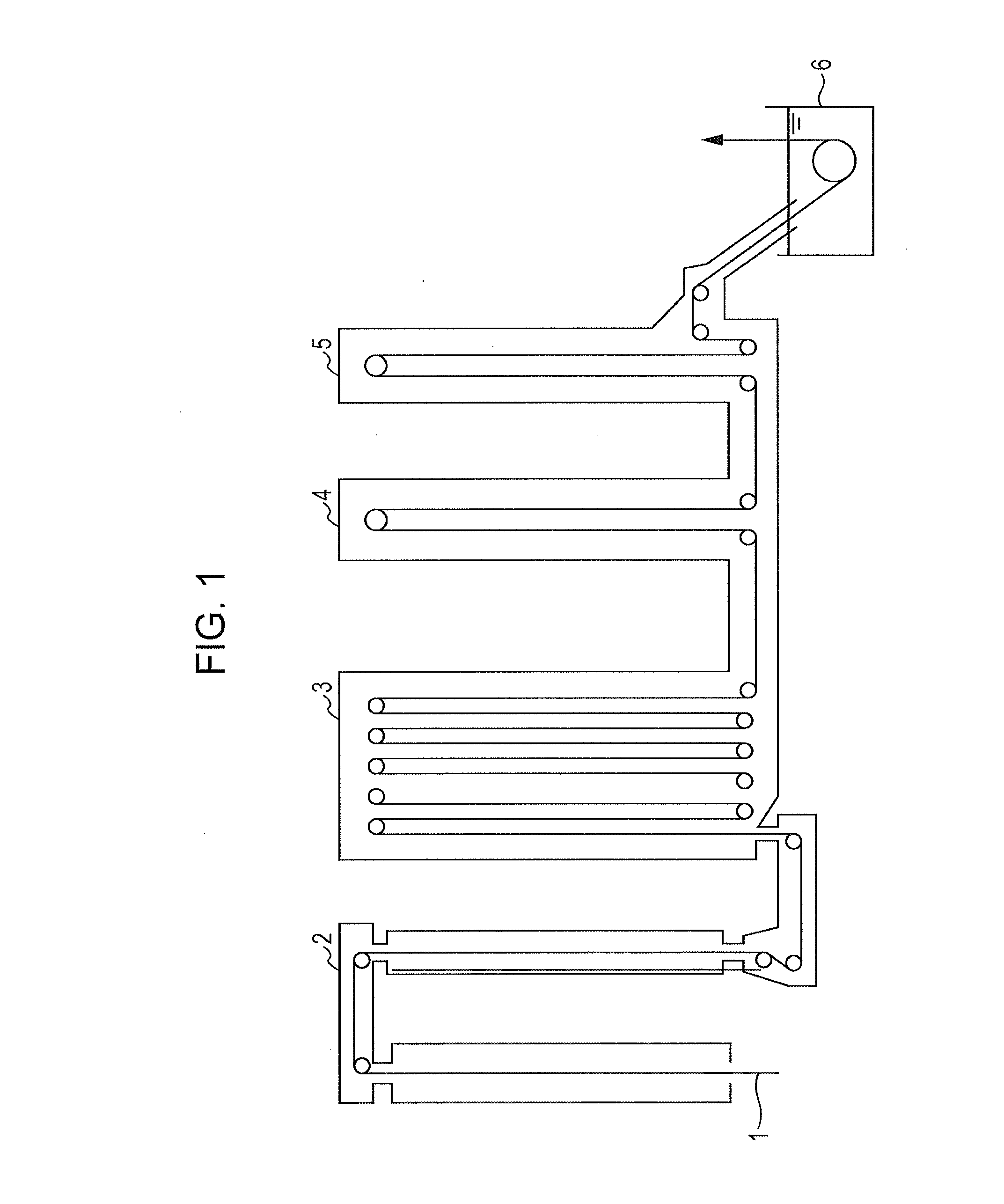

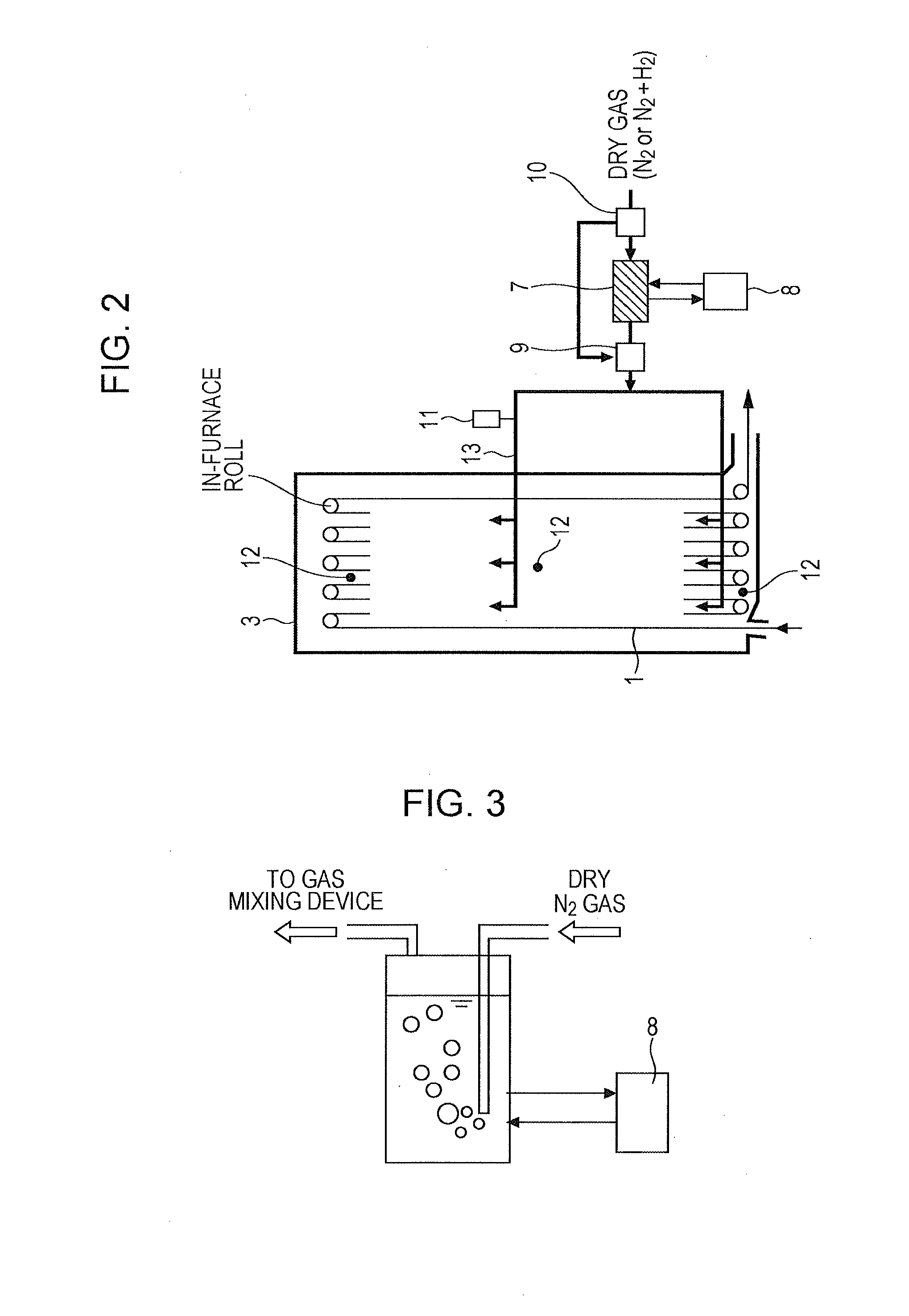

Method for controlling dew point of reduction furnace, and reduction furnace

InactiveUS20160363372A1Beautiful surface appearanceDecrease in productivityHot-dipping/immersion processesMaintainance of heating chambersHot-dip galvanizationDry gas

Provided are a method for controlling a dew point in a reducing furnace and a reducing furnace in which, even in the case of galvanizing Si-added steel, coating adhesion can be secured, alloying treatment can be performed without increasing the alloying temperature excessively, and it is possible to obtain a hot-dip galvanized steel sheet having an excellent coating appearance. When a steel sheet is subjected to annealing and hot-dip galvanizing treatment using continuous hot-dip galvanizing equipment including at least a radiant tube-type reducing furnace, a mixed gas of a dry gas and a humidified gas by a humidifying device having a water vapor permeable membrane is used as a gas to be supplied into the reducing furnace. The mixed gas is supplied into the reducing furnace, thereby controlling the dew point in the reducing furnace.

Owner:JFE STEEL CORP

Aqueous epoxy zinc-enriched antirust priming paint for railway steel bridges and preparation method thereof

InactiveCN110922857AGood electrical conductivityStrong electron mobilityAntifouling/underwater paintsPaints with biocidesCardanolWeather resistance

The invention provides an aqueous epoxy zinc-enriched antirust priming paint for railway steel bridges and a preparation method thereof, and relates to the technical field of paints. The priming paintcomprises a component (a) and a component (b) according to a mass ratio of 1:4. The component (a) is prepared from following raw materials: aqueous epoxy resin emulsion, graphene coated glass fibers,nano antimony doped tin dioxide, nano titanium dioxide, an epoxy silane coupling agent, n-butyl alcohol, propylene glycol mono-methyl ether, an antifoaming agent (A), and deionized water; and the component (b) is prepared from following raw materials: a cardanol modified polyamide curing agent, zinc powder, a filling material, a thixotropic agent, an antifoaming agent (B), a dispersant, a flush-rust resistant agent, and a mixed solvent. By adding graphene coated glass fibers and nano antimony doped tin dioxide into the paint, the prepared epoxy zinc-enriched antirust priming paint has an excellent corrosion resistant performance, a strong adhesion force, and good weatherability even if the zinc powder content is low.

Owner:安徽壹信通讯科技有限公司

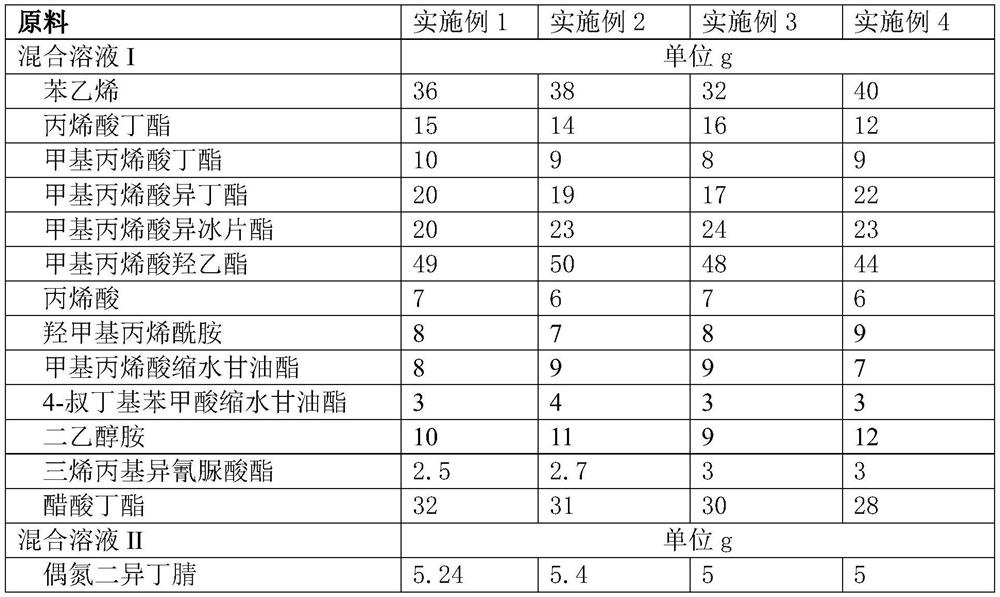

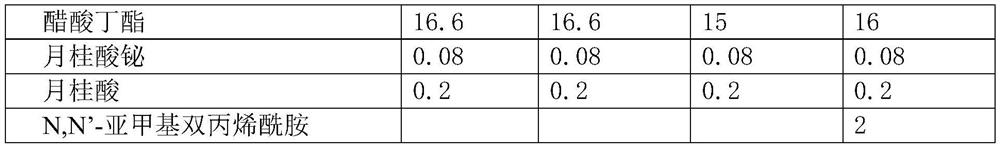

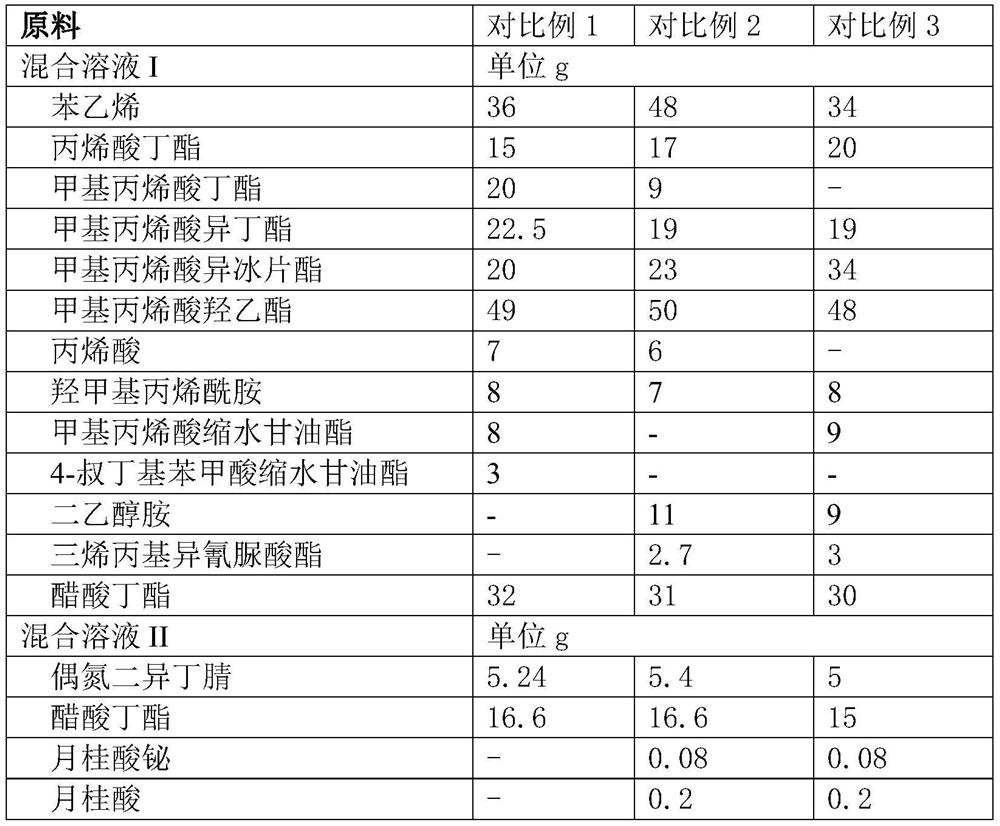

Acrylic resin with high solid content, weather resistance and appearance

The invention discloses acrylic resin with high solid content, weather resistance and appearance, which is characterized in that the acrylic resin comprises monomers, an initiator, a crosslinking accelerator, a catalyst and an organic solvent as raw materials through polymerization reaction in a micro-channel reactor, wherein the monomer comprises styrene, acrylic acid, hydroxymethyl acrylamide, glycidyl methacrylate, 4-tert-butyl benzoic acid glycidyl ester, diethanol amine and at least three of the following acrylate: butyl acrylate, butyl methacrylate, isobutyl methacrylate, isobornyl methacrylate and hydroxyethyl methacrylate. The method has the advantages of high transfer rate, short contact time, few byproducts, higher conversion rate, good operability, high safety, rapid and directamplification and the like, and the obtained acrylic resin has the characteristics of high solid content, high weather resistance and high appearance, and is particularly suitable for production of high-quality coatings.

Owner:苏州聚洸高分子科技有限公司

Coating material or ink compositions

InactiveCN1339054AStrong penetrating powerImprove coating appearanceInksPaints for electrolytic applicationsUV curingVegetable oil

The present invention provides a modifying agent for resins for paints or resins for inks, containing fatty acids obtained by the enzymatic decomposition of vegetable oils or fats, the resins for paints or resins for inks modified with the modifying agent, and a paint or ink composition containing the resin for the paint or resin for the ink. The paint or ink composition of the present invention has electrodeposition potential or UV curing property and is excellent in the appearance of the paint film, finishing sharpness and adhesion.

Owner:THE NISSHIN OILLIO GRP LTD

Powder coating composition

PendingUS20210062009A1Good coating performanceIncrease crosslink densityPolyurea/polyurethane coatingsPowdery paintsPolymer scienceMetal alloy

The invention relates to powder coating compositions suitable for low temperature powder coating crosslinking typically at curing temperature is between 75 and 140° C. which can be used for powder coating temperature-sensitive substrates like MDF, wood, plastic or temperature sensitive metal alloys.

Owner:ALLNEX NETHERLANDS BV

Hot-dip Al—Zn coated steel sheet

ActiveUS9234267B2Nice appearanceIncrease resistanceHot-dipping/immersion processesThin material handlingSurface layerAl content

There is provided a hot-dip Al—Zn coated steel sheet that has a steel sheet containing Si and Mn as a base steel sheet and has excellent coating appearance and corrosion resistance. The Al—Zn coating layer has an Al content in the range of 20% to 95% by mass. The Al—Zn coating layer has a Ca content in the range of 0.01% to 10% by mass. Alternatively, the Ca and Mg content is in the range of 0.01% to 10% by mass. A steel sheet surface layer within 100 μm from a surface of the base steel sheet directly under the Al—Zn coating layer contains less than 0.060 g / m2 per surface of an oxide of at least one selected from Fe, Si, Mn, Al, P, B, Nb, Ti, Cr, Mo, Cu, and Ni in total.

Owner:JFE STEEL CORP

Hot-dip Al—Zn coated steel sheet

ActiveUS9034480B2Nice appearanceIncrease resistanceHot-dipping/immersion processesSolid state diffusion coatingSurface layerAl content

There is provided a hot-dip Al—Zn coated steel sheet that has a steel sheet containing Si and Mn as a base steel sheet and has excellent coating appearance and corrosion resistance. The Al—Zn coating layer has an Al content in the range of 20% to 95% by mass. The Al—Zn coating layer has a Ca content in the range of 0.01% to 10% by mass. Alternatively, the Ca and Mg content is in the range of 0.01% to 10% by mass. A steel sheet surface layer within 100 μm from a surface of the base steel sheet directly under the Al—Zn coating layer contains 0.06 to 1.0 g / m2 per surface of an oxide of at least one selected from Fe, Si, Mn, Al, P, B, Nb, Ti, Cr, Mo, Cu, and Ni in total.

Owner:JFE STEEL CORP

High-strength galvanized steel sheet and method for manufacturing the same

ActiveUS9309586B2Improve coating appearanceImprove the immunityHot-dipping/immersion processesFurnace typesFurnace temperatureSheet steel

Provided is a method for manufacturing a high-strength galvanized steel sheet, made from a steel sheet containing Si and / or Mn, having excellent exfoliation resistance during heavy machining. When a steel sheet containing 0.01% to 0.18% C, 0.02% to 2.0% Si, 1.0% to 3.0% Mn, 0.001% to 1.0% Al, 0.005% to 0.060% P, and 0.01% or less S on a mass basis, the remainder being Fe and unavoidable impurities, is annealed and galvanized in a continuous galvanizing line, a temperature region with a furnace temperature of A° C. to B° C. (600≦A≦780 and 800≦B≦900) is performed at an atmosphere dew-point temperature of −5° C. or higher in a heating process.

Owner:JFE STEEL CORP

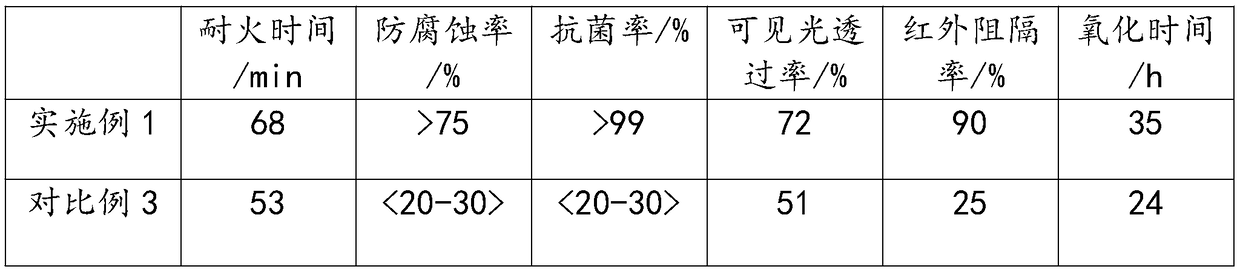

Expandable type building fireproof coating and preparation method thereof

InactiveCN109504251AGood coating appearanceCoating Appearance and WeatherabilityFireproof paintsAntifouling/underwater paintsSolventAmmonium polyphosphate

The invention discloses an expandable type building fireproof coating and a preparation method thereof. The preparation method comprises the following steps: weighting unsaturated polyester resin andthen adding into a stirring reaction kettle; adding styrene, methyl ethyl ketone peroxide, cobalt naphthenate and liquid paraffin into the reaction kettle in turn while stirring, and then reacting while stirring for 20-40min; weighting expandable graphite, ammonium polyphosphate, pentaerythritol and melamine and then adding into a grinding mill for grinding; weighting filler and then adding into the grinding mill for grinding; pouring the filler and the mixture of ammonium polyphosphate, pentaerythritol and melamine into the stirring reaction kettle, and quickly stirring and mixing for 30-60min; adding auxiliaries and solvent, and then stirring and mixing again. According to the invention, different modified resins are stirred and mixed at different ratios, so that the fireproof time of the coating is prolonged, and meanwhile, the fireproof coating has anti-ultraviolet, antibacterial, sterilizing and anticorrosion effects, and the service life of the coating is prolonged.

Owner:深圳市欧科力科技有限公司

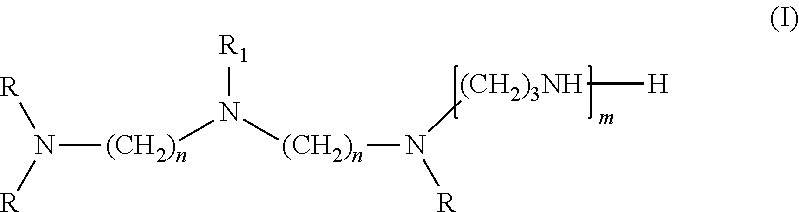

Amidoamine and polyamide curing agents, compositions, and methods

ActiveUS20170218115A1Similar and fast cure speedImprove coating appearanceOrganic compound preparationCarboxylic acid amides preparationPolyamideFatty acid

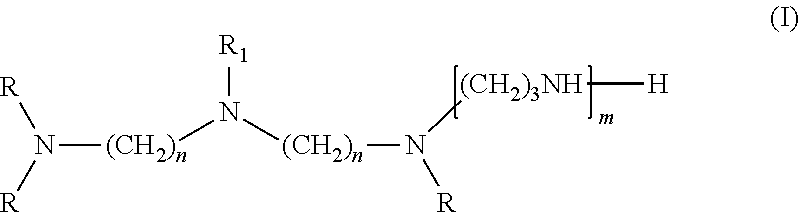

A composition including an amidoamine curing agent composition or a polyamide curing agent composition are disclosed. The composition includes the reaction products of (1) an amine component including at least one multifunctional amine of structure (I):wherein each R is independently H or CH2CH2CH2NH2; R1 is H, CH3CH2CH2N—, C1-C21 alkyl, or C1-C21 alkenyl; n is 2; and m is 1 or 2, with (2) a fatty acid or ester component selected from the group consisting of a dimer fatty acid or ester component, a monofunctional fatty acid or ester component, and combinations thereof. The amidoamine curing agent composition remains as liquid at ambient temperature.

Owner:EVONIK OPERATIONS GMBH

Method for forming multi-layered coating film and an mutli-layered coating film obtained thereof

InactiveUS20090186228A1High glossNice appearanceLiquid surface applicatorsSynthetic resin layered productsEmulsionPolyester resin

An object of the present invention relates to provide a method for forming a multi-layered coating film including a step of baking and curing an uncured intermediate coating film, an uncured base coating film and an uncured clear coating film at the same time which can give a multi-layered coating film excellent in gloss and in appearance, and to provide a multi-layered coating film obtained thereof.The present invention provides to a method for forming a multi-layered coating film in three-coat and one-bake coating method, using a solvent-borne intermediate coating composition containing an urethane-modified polyester resin (a) having a water tolerance value of 4 to 10 ml, a melamine resin (b) having a hexane tolerance value of 8 to 40 ml, a blocked isocyanate compound (c) and a nonaqueous dispersion resin (d), and a water-borne base coating composition containing an emulsion resin and a pigment.

Owner:NIPPON PAINT CO LTD +1

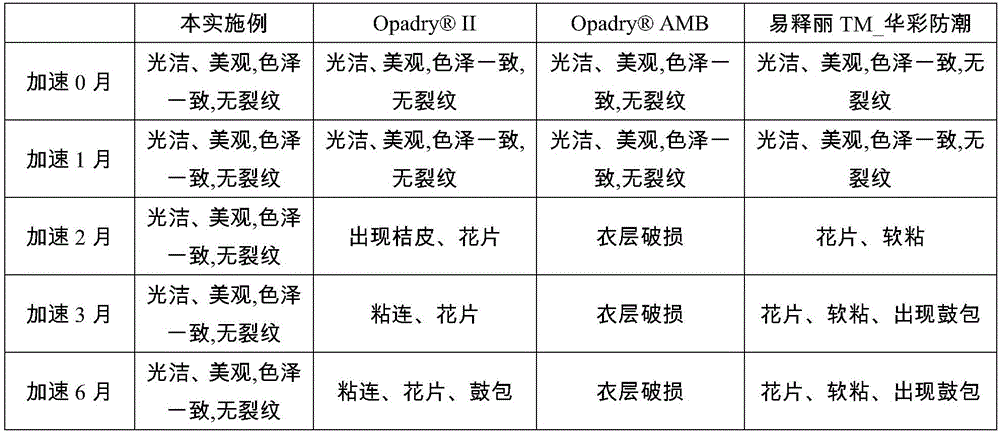

Coating auxiliary material, preparation method and coating method for traditional Chinese medicine extract preparation

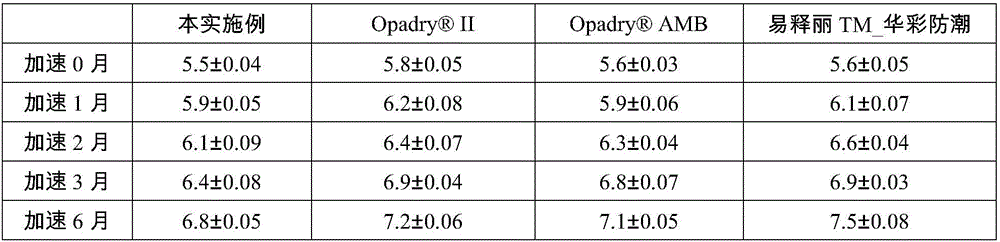

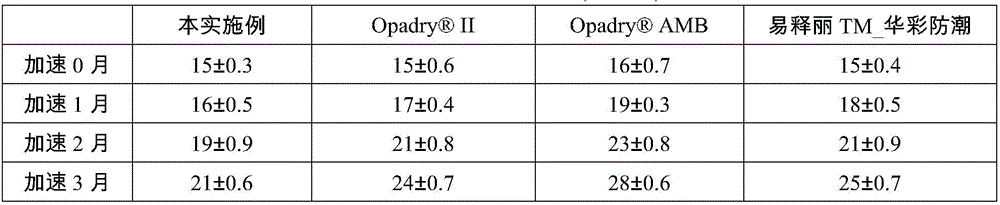

ActiveCN104000796BIncrease coverageCover blemishesPharmaceutical delivery mechanismPharmaceutical non-active ingredientsPlasticizerFilm-forming agent

A coating auxiliary material for extract preparations of traditional Chinese medicines, the main components of which include by weight: 15-20% of film-forming agent, 20-25% of plasticizer, 20-30% of colorant and 30-35% of auxiliary additives . The invention also discloses a preparation method of a coating auxiliary material used for extract preparations of traditional Chinese medicines and a coating method. The coating powder of the invention has good coating power, can cover the defects of the tablet core, and improve the appearance of the coating; The coating film has excellent barrier properties, and its moisture-proof and taste-masking effects on pharmaceutical preparations are better than ordinary coating materials; the coating preparation disintegrates quickly and has no effect on the release of pharmaceutical ingredients.

Owner:SHANDONG WOHUA PHARMACEUTICALS CO LTD

Process for production of adhesive optical film

InactiveUS8962072B2Improve adhesionImprove coating appearanceFilm/foil adhesive primer layersPretreated surfacesAlcoholDrying time

A method for production of an adhesive optical film comprises the step of forming an anchor layer by applying an anchor layer-forming coating liquid to the optical film to form a coating with a thickness of 20 μm or less before drying, wherein the anchor layer-forming coating liquid contains a mixed solvent composed mainly of water and an alcohol, and a binder resin, and by drying the coating under drying conditions satisfying both of the following requirements:(1) the drying temperature T is between 40° C. and 70° C.; and(2) the value (T×H) obtained by multiplying the drying temperature T (° C.) by the drying time H (seconds) satisfies the relation400≦(T×H)≦4,000to remove the mixed solvent.

Owner:NITTO DENKO CORP

Composition for coating and molded product using the same

ActiveUS8519052B2Improve balanceImprove coating appearanceConjugated diene hydrocarbon coatingsPolyester resinLarge size

The present invention provides a resin composition for coating which is capable of exhibiting an excellent balance between coatability, impact resistance, moldability and chemical resistance, and capable of attaining a good coating appearance, for example, even when a large-size molded product is coated. The resin composition for coating according to the present invention comprises 84.9 to 98.9 parts by mass of the below-mentioned rubber-reinforced vinyl-based resin [A], 1 to 8 parts by mass of a polyester resin [B] and 0.1 to 7.1 parts by mass of a copolymer [C] of ethylene, a (meth)acrylic acid ester and carbon monoxide (with the proviso that a total amount of the components [A], [B] and [C] ([A] +[B] +[C]) is 100 parts by mass): [Rubber-reinforced vinyl-based resin [A]]A rubber-reinforced vinyl-based resin comprising a rubber-reinforced copolymer resin [A1] obtained by polymerizing a vinyl-based monomer [b1] in the presence of a rubber polymer [a], or comprising the rubber-reinforced copolymer resin [A1] obtained by polymerizing the vinyl-based monomer [b1] in the presence of the rubber polymer [a], and a (co)polymer [A2] of a vinyl-based monomer [b2].

Owner:TECHNO UMG CO LTD

Method for manufacturing high strength galvanized steel sheet

ActiveUS10449751B2Improve coating appearanceHigh strengthHot-dipping/immersion processesFurnace typesChemical compositionHigh intensity

A method for manufacturing a high strength galvanized steel sheet which has a zinc coating layer with an amount of deposition of coating of 20 to 120 g / m2 per one surface on the surface of a base steel sheet having a chemical composition comprising C: 0.03% to 0.35%, Si: 0.01% to 0.50%, Mn: 3.6% to 8.0%, Al: 0.001% to 1.000%, P≤0.10%, S≤0.010%, and the balance comprising Fe and incidental impurities, on a percent by mass basis, is provided. In annealing and galvanization treatment of the base steel sheet in a continuous galvanizing line, the maximum steel sheet temperature in an annealing furnace is 600° C. or higher and 750° C. or lower, the steel sheet transit time in a temperature region of the steel sheet temperature of 600° C. or higher and 750° C. or lower is specified to be 30 seconds or more and 10 minutes or less, and the dew point in an atmosphere is specified to be −10° C. or higher.

Owner:JFE STEEL CORP

Amidoamine and polyamide curing agents, compositions, and methods

ActiveUS10676564B2Similar and fast cure speedImprove coating appearanceOrganic compound preparationCarboxylic acid amides preparationDimerPolymer science

Owner:EVONIK OPERATIONS GMBH

High-strength steel sheet and production method therefor and high-strength galvanized steel sheet and production method therefor (as amended)

ActiveUS10174411B2Chemical convertibility is improvedImprove coating appearanceHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

Provided is a high-strength steel sheet that has good chemical convertibility and good corrosion resistance after electro deposition painting despite high Si and Mn contents. Also provided are a method for producing the high-strength steel sheet, a high-strength galvanized steel sheet formed by using the high-strength steel sheet, and a method for producing the high-strength galvanized steel sheet. A steel sheet containing, in terms of % by mass, C: 0.03 to 0.35%, Si: 0.01 to 0.50%, Mn: 3.6 to 8.0%, Al: 0.001 to 1.00%, P≤0.10%, S≤0.010%, and the balance being Fe and unavoidable impurities is annealed under condition under which a dew point of an atmosphere in a temperature zone of 550° C. or higher and A° C. or lower (A is a particular value that satisfies 600≤A≤750) inside an annealing furnace is controlled to −40° C. or lower.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com