Acrylic resin with high solid content, weather resistance and appearance

A technology of acrylic resin and high solid content, applied in the direction of coating, etc., can solve the problems of inability to prepare polyacrylic acid emulsion with high solid content or high viscosity, and the inability to use microchannel reactors, so as to improve outdoor durability and excellent coating The effect of layer appearance and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

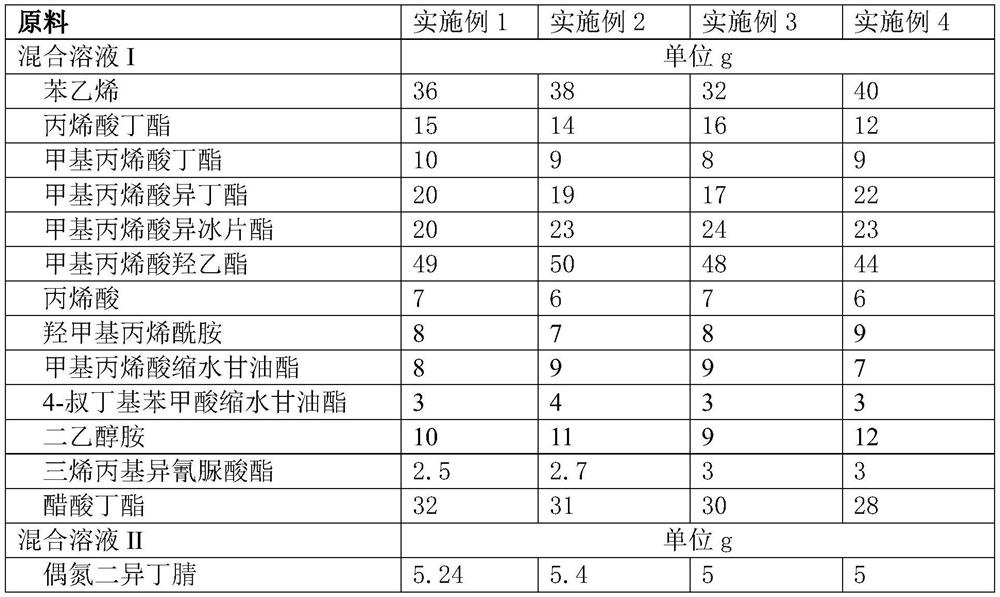

[0039] Examples 1-3 and comparative examples 1-3 of the raw materials and their dosage and reaction conditions are shown in Tables 1 and 2.

[0040] Table 1

[0041]

[0042]

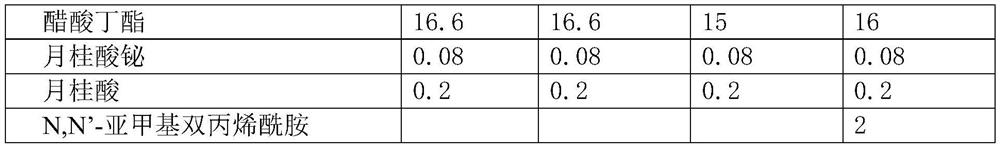

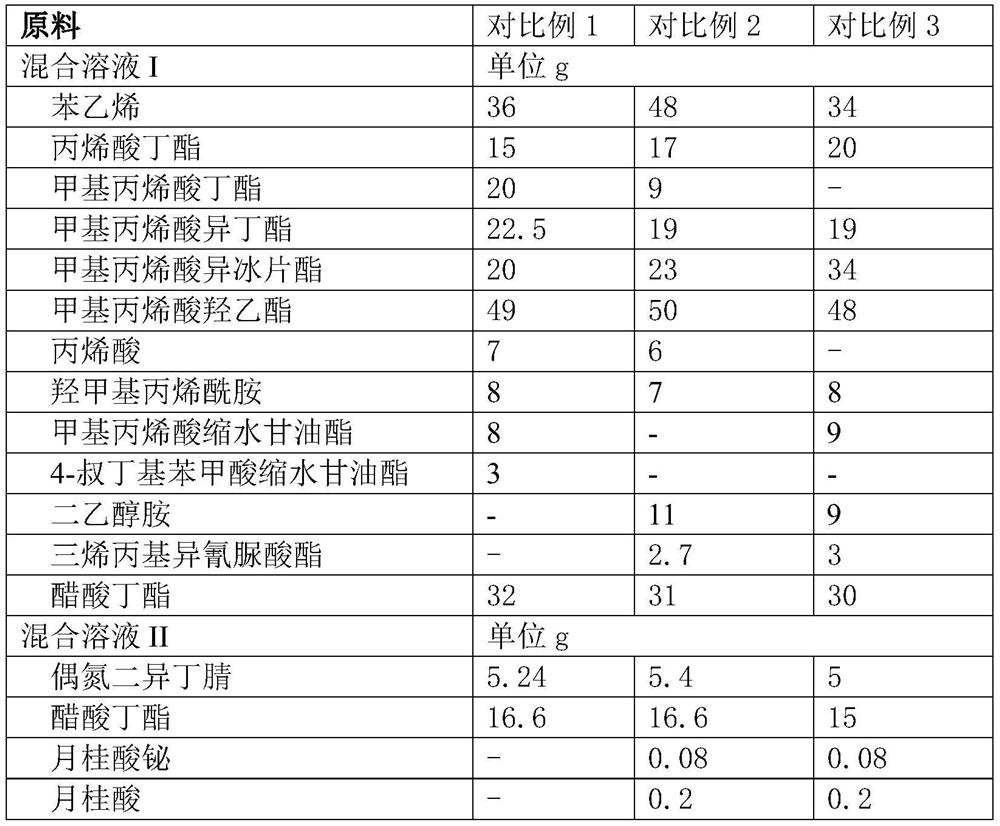

[0043] Table 2

[0044]

[0045] In Examples 1-4, the polymerization reaction was carried out at 170° C.-180° C. for 50-100 s under the condition of nitrogen filling and pressurization. The solid content of the obtained acrylic resin is 76%-80%, the viscosity is 3.0-4.0Pa.s, and the appearance is clear and transparent.

Embodiment 5

[0048] The acrylic resin obtained in Example 1 was applied to a high-solid coating system, and the results were tested, and the existing acrylic resin was used as Comparative Example 4. The paint composition is shown in Table 3, and the related properties are shown in Table 4.

[0049] table 3

[0050]

[0051]

[0052] Table 4

[0053]

[0054] The results show that the acrylic resin prepared by the present application is more environmentally friendly in the high-solid paint system, the paint has a longer service life, shorter drying time, better gloss and better weather resistance.

Embodiment 6

[0056] The acrylic resin obtained in Example 4 was applied to the quick-drying paint system, and the results were tested, and the existing acrylic resin was used as Comparative Example 5. The paint composition is shown in Table 5, and the relevant properties are shown in Table 6.

[0057] table 5

[0058]

[0059] Table 6

[0060]

[0061] Note: Test method for solvent resistance of paint film: Soak three pieces of cotton cloth in xylene (solvent resistance) or gasoline (gasoline resistance), put the cotton cloth on the sample board for 10-15 seconds and start timing for 30 minutes, when the time is up Immediately remove the cotton cloth on the board, press it on the board with a dry cloth, and scrape the paint film with your fingers back and forth. Result rating: "1" - completely intact, "2" - 1 / 4 scratches present, "3" - 1 / 2 scratches present, "4" - 3 / 4 scratches present, "5" - all scratches mark.

[0062] The results show that the acrylic resin prepared by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com