Aqueous epoxy zinc-enriched antirust priming paint for railway steel bridges and preparation method thereof

A water-based epoxy zinc-rich, anti-rust primer technology, applied in the field of coatings, can solve the problems of high zinc powder content, achieve the effects of enhanced anti-aging effect, improved weather resistance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

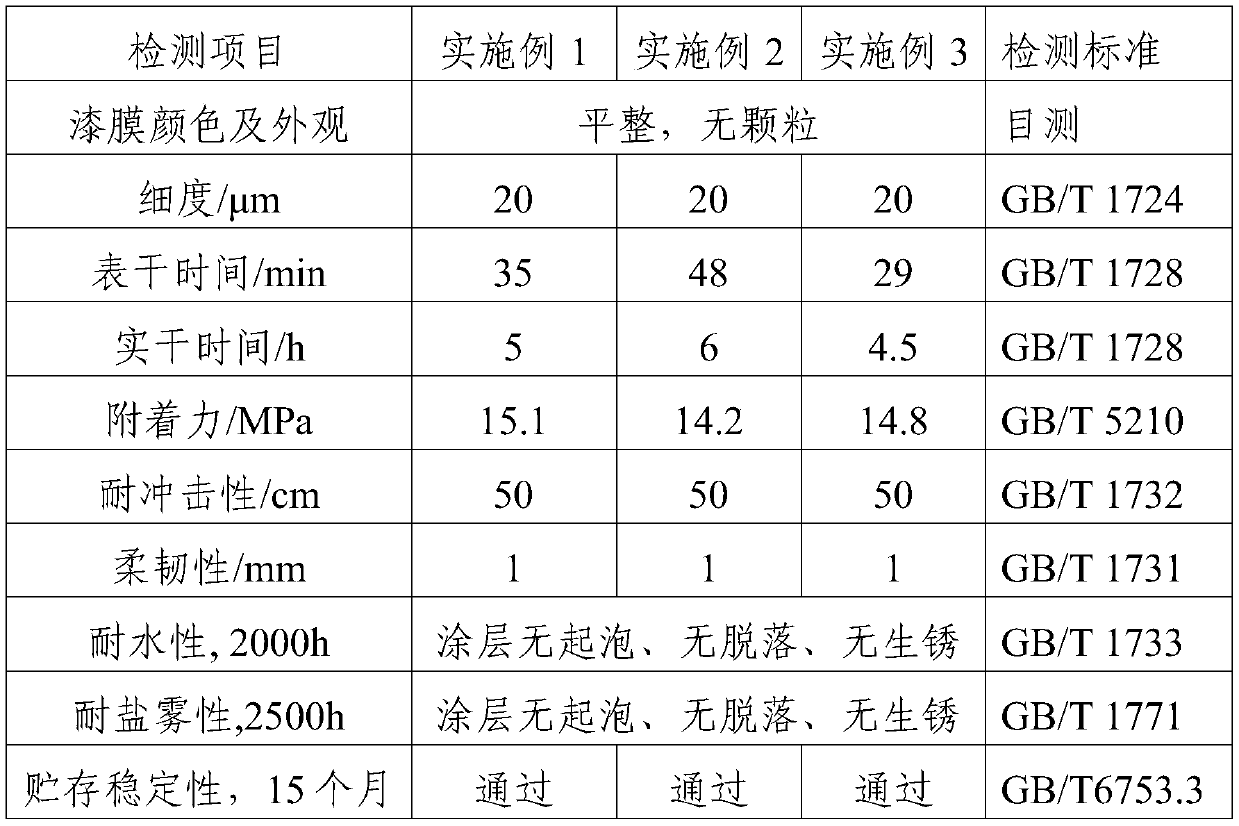

Examples

Embodiment 1

[0030] A water-based epoxy zinc-rich antirust primer for railway steel bridges, comprising component A and component B, wherein the component A and component B are composed in a mass ratio of 1:4;

[0031] Component A is made of the following raw materials in weight percentage: 62% of water-based epoxy resin emulsion, 1% of graphene-coated glass fiber, 0.5% of nano-antimony-doped tin dioxide, 0.8% of nano-titanium dioxide, γ-(2,3 -Glycidoxy)propyltrimethoxysilane 0.4%, n-butanol 4.5%, propylene glycol monomethyl ether 3%, simethicone 0.8%, deionized water 28%;

[0032] Component B is made of the following raw materials in weight percentage: cardanol modified polyamide curing agent 11%, zinc powder (5-20μm particle size) 38%, filler 27%, thixotropic agent 3.2%, BYK-025 0.3 %, BYK-181 0.3%, anti-flash rust agent 0.2%, mixed solvent 20%.

[0033] The epoxy equivalent of the aqueous epoxy resin emulsion is 700g / mol, the solid content is 54%, and the solvent is water.

[0034] Th...

Embodiment 2

[0039] A water-based epoxy zinc-rich antirust primer for railway steel bridges, comprising component A and component B, wherein the component A and component B are composed in a mass ratio of 1:4;

[0040] Component A is made of the following raw materials in weight percentage: 56% of water-based epoxy resin emulsion, 0.5% of graphene-coated glass fiber, 0.8% of nano-antimony-doped tin dioxide, 0.3% of nano-titanium dioxide, γ-(2,3 -Glycidoxy)propyltrimethoxysilane 0.4%, n-butanol 5.5%, propylene glycol monomethyl ether 4%, simethicone 0.5%, deionized water 32%;

[0041] Component B is made of the following raw materials in weight percentage: cardanol modified polyamide curing agent 11%, zinc powder (5-20μm particle size) 37%, filler 33%, thixotropic agent 3.4%, BYK-025 0.2 %, BYK-181 0.3%, anti-flash rust agent 0.1%, mixed solvent 15%.

[0042] The epoxy equivalent of the aqueous epoxy resin emulsion is 600g / mol, the solid content is 56%, and the solvent is water.

[0043] ...

Embodiment 3

[0049] A water-based epoxy zinc-rich antirust primer for railway steel bridges, comprising component A and component B, wherein the component A and component B are composed in a mass ratio of 1:4;

[0050] Component A is made of the following raw materials in weight percentage: 65% of water-based epoxy resin emulsion, 1% of graphene-coated glass fiber, 0.3% of nano-antimony-doped tin dioxide, 1.2% of nano-titanium dioxide, β-(3,4 -Epoxycyclohexyl)ethyltrimethoxysilane 0.2%, n-butanol 3.5%, propylene glycol monomethyl ether 2%, simethicone 0.8%, deionized water 26%;

[0051] Component B is made of the following raw materials in weight percentage: cardanol modified polyamide curing agent 9%, zinc powder (5-20μm particle size) 37%, filler 29%, thixotropic agent 2%, BYK-028 0.5 %, BYK-187 0.1%, anti-flash rust agent 0.4%, mixed solvent 22%.

[0052] The epoxy equivalent of the aqueous epoxy resin emulsion is 750g / mol, the solid content is 53%, and the solvent is water.

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com