Food-grade powder coating as well as preparation method and application thereof

A technology of powder coating and phenolic epoxy resin, applied in the field of coatings, can solve the problems of short curing time, heavy corrosion resistance, limitation, etc., and achieve the effects of short curing time, good adhesion and low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Examples are further listed below to describe the present invention in detail. It should also be understood that the following examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the principles set forth in the present invention all belong to the present invention scope of protection. The specific process parameters and the like in the following examples are only examples of the appropriate range, that is, those skilled in the art can make a selection within the appropriate range through the description herein, and are not limited to the specific data exemplified below.

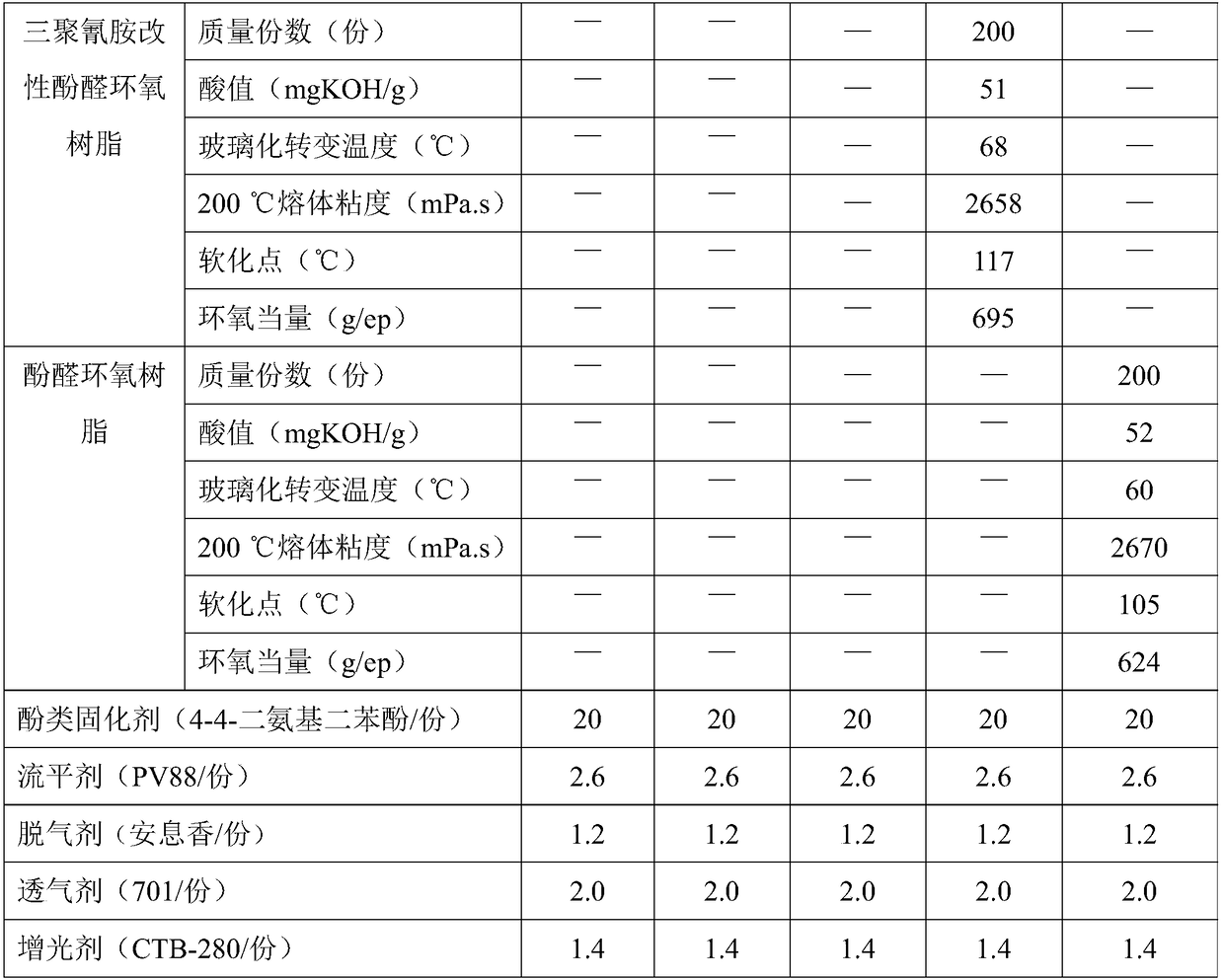

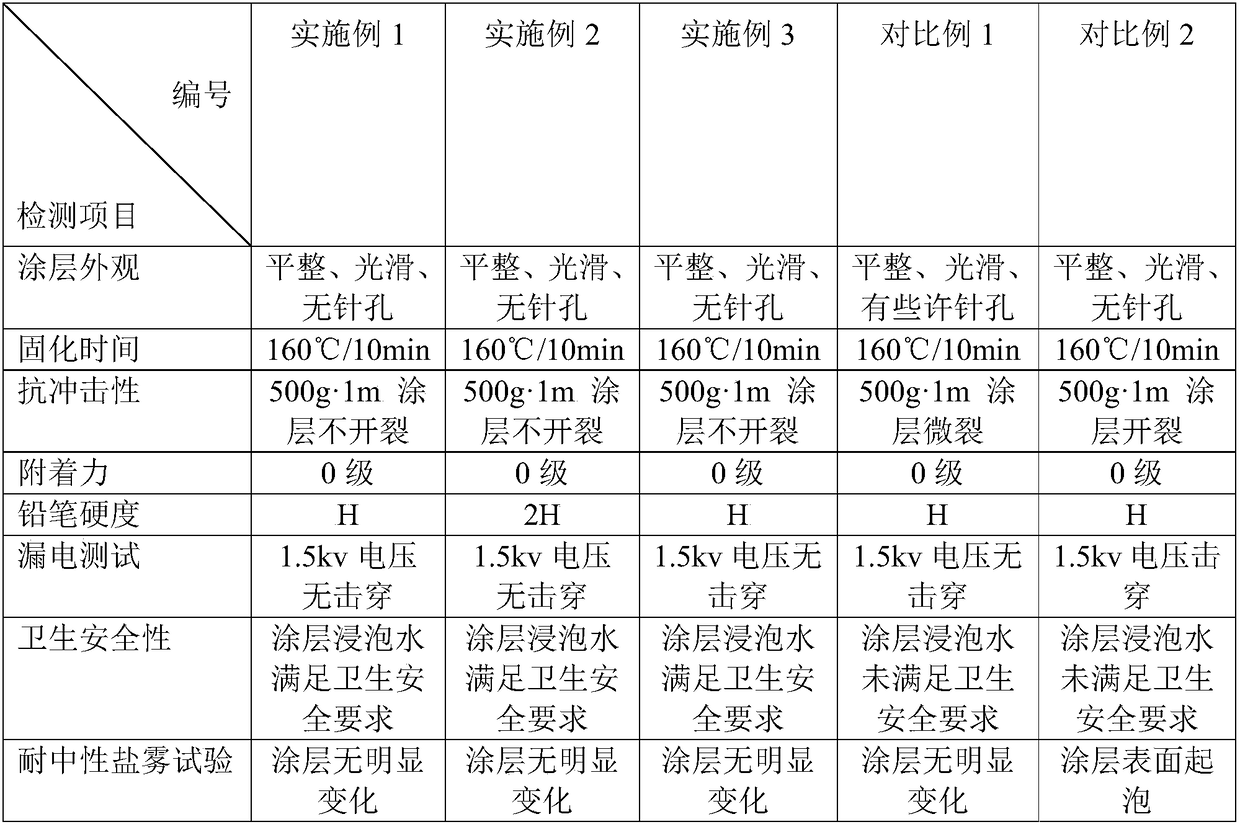

[0034] Below in conjunction with embodiment and comparative example the present invention is described in detail, and the component of the powder coating of each embodiment and comparative example sees table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com