Water-based plastic paint applicable to composite layer coating film, and preparation process thereof

A technology of plastic paint and composite layer, which is applied in the direction of coating, etc., can solve the problems that the coating film of the composite layer needs to be improved, and achieve good mechanical properties and physical and chemical properties, good coating appearance, and good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

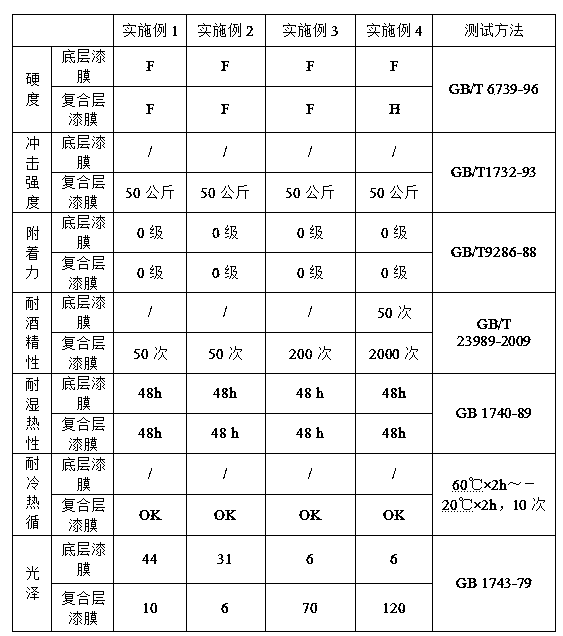

Examples

Embodiment 1

[0036] Pearlescent water-based plastic paint:

[0037] (1) Take 7 parts of cosolvents, add 2 parts of auxiliary agents under stirring and mix well, then add 18 parts of deionized water and 1 part of 25% ammonia water in turn, add 4 parts of LTW resin after stirring again to make solution A;

[0038] (2) Take 60 parts of water-based acrylic emulsion, add in solution A under stirring, and stir to make solution B;

[0039] (3) After taking 6 parts of KC110 pearl powder and neutralizing it with 1 part of 25% ammonia water, under high-speed stirring, add it to solution B, and finally add 1 part of alkali swelling thickener, stir evenly, and filter to obtain pearlescent water-based plastic paint .

[0040] White water-based plastic paint:

[0041] (1) Take 5 parts of co-solvent, add 2 parts of auxiliary agent under stirring and mix well, then add 13 parts of deionized water and 1 part of 25% ammonia water in turn, add 2 parts of LTW resin after stirring again to make solution A ;...

Embodiment 2

[0046] Glass flash drill water-based plastic paint:

[0047] (1) Take 17 parts of cosolvents, add 2 parts of auxiliary agents under stirring and mix well, then add 12 parts of deionized water and 1 part of 25% ammonia water in turn, add 4 parts of LTW resin after stirring again to make solution A;

[0048] (2) Take 60 parts of water-based acrylic emulsion, add in solution A under stirring, and stir to make solution B;

[0049] (3) Take 5 parts of 2230 glass flash diamond powder and neutralize it with 1 part of 25% ammonia water, add it to solution B under high-speed stirring, and finally add 1 part of alkali swelling thickener, stir evenly, and filter to obtain glass flash diamond Water-based plastic paint.

[0050] Silver white water-based plastic paint:

[0051] (1) Take 17 parts of co-solvent, add 2 parts of auxiliary agent under stirring and mix well, then add 19 parts of deionized water and 1 part of 25% ammonia water in turn, add 4 parts of LTW resin after stirring aga...

Embodiment 3

[0056] White water-based plastic paint:

[0057] (1) Take 5 parts of cosolvent, add 2 parts of auxiliary agent under stirring and mix well, then add 11 parts of deionized water and 1 part of 25% ammonia water in turn, add 4 parts of LTW resin after stirring again to make solution A;

[0058] (2) Take 50 parts of water-based acrylic emulsion, add solution A under stirring and stir to make solution B;

[0059] (3) After neutralizing 25 parts of R980 titanium dioxide with 1 part of 25% ammonia water, under high-speed stirring, add it into solution B, finally add 1 part of alkali swelling thickener, stir evenly, filter, and package the white water-based plastic Preparation of paint.

[0060] Use 1000 sandpaper to polish the defects of plastic PMMA, wipe with 6# solvent oil, blow dust with high-pressure airflow, spray white water-based plastic paint on the plastic, level it at room temperature, bake at 45 ℃ for 15 minutes, form a bottom coating film, Appearance and performance were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com