Patents

Literature

80results about How to "Good coating appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

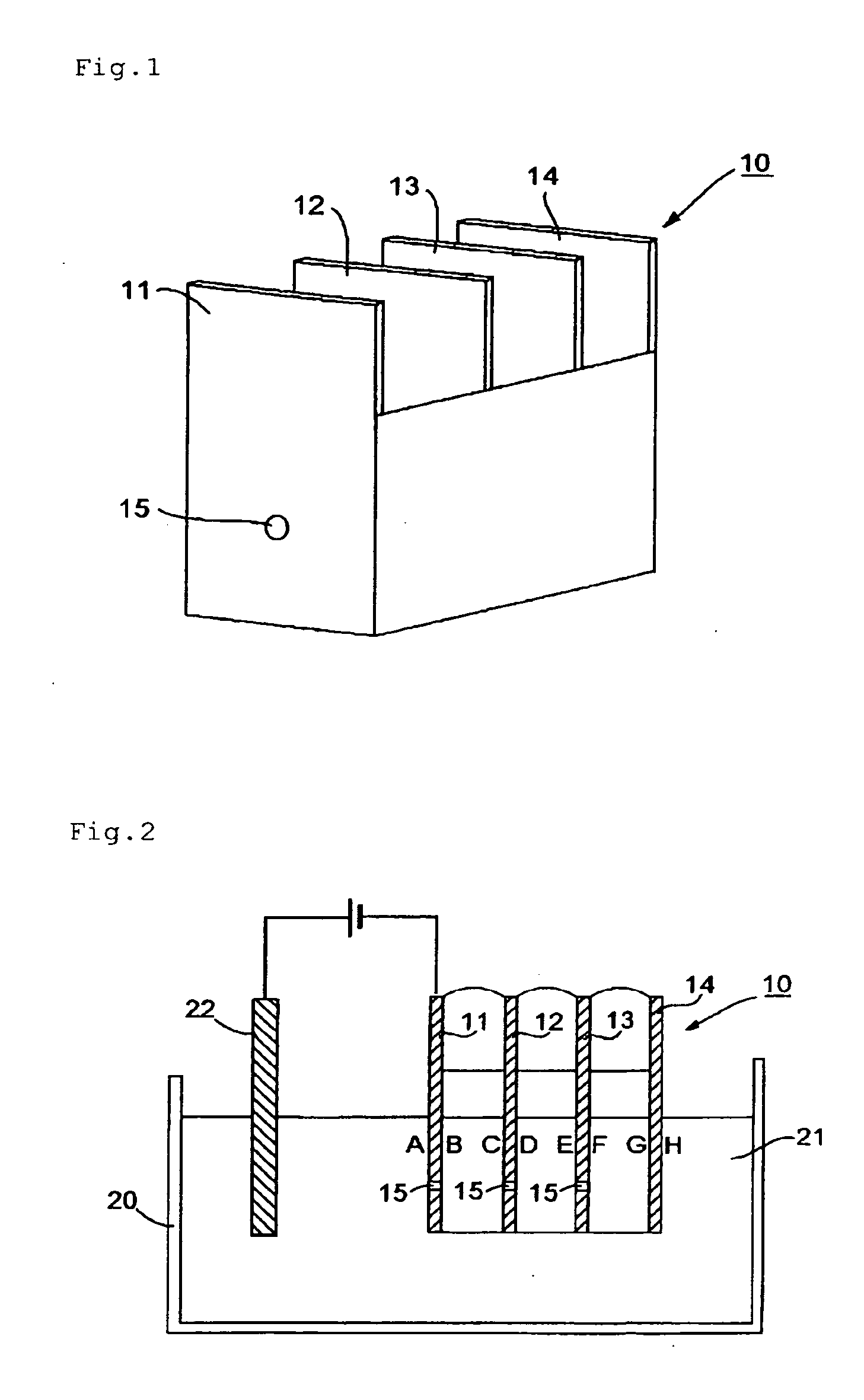

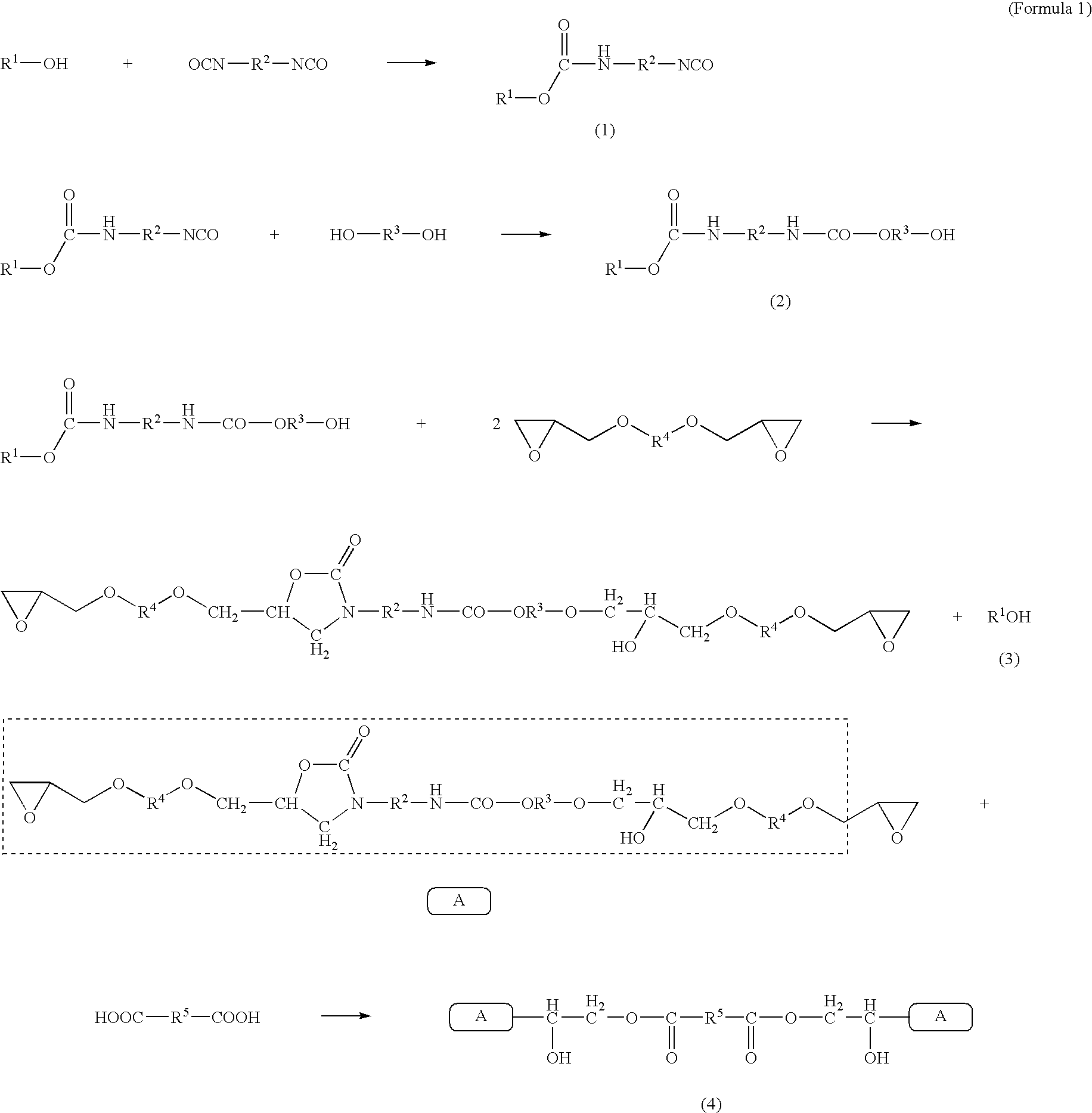

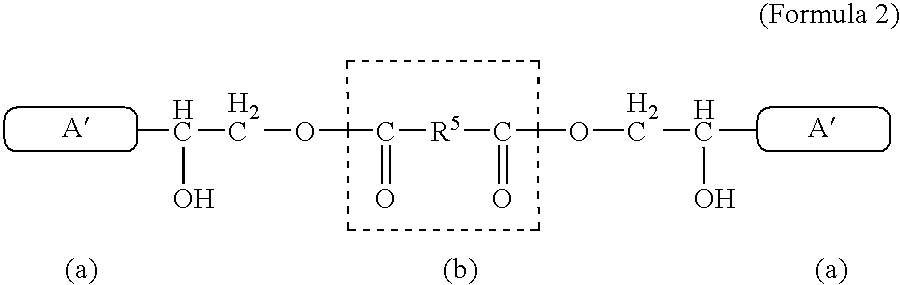

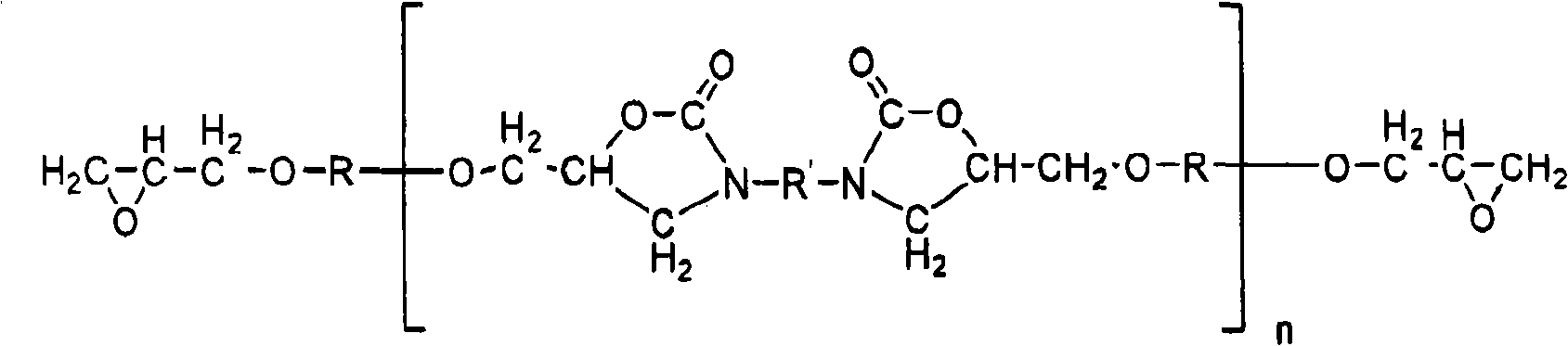

Method for making amine-modified epoxy resin and cationic electrodeposition coating composition

InactiveUS20060280949A1Good dispersionReduce environmental loadElectrolysis componentsVolume/mass flow measurementPrepolymerChemistry

The present invention provides a cationic electrodeposition coating composition having good appearance of coated film and high throwing power, and a method for making an amine-modified epoxy resin used for the cationic electrodeposition coating composition. The present invention relates to a method for making an amine-modified epoxy resin comprised in a cationic electrodeposition coating composition comprising the steps of: providing a half blocked isocyanate by reaction of an isocyanate compound with a blocking agent, preparing a blocked prepolymer by reaction of the half blocked isocyanate with a polyol, forming an epoxy resin containing oxazolidone ring by reaction of the blocked prepolymer with a diglycidyl ether type epoxy resin, chain-extending the epoxy resin containing oxazolidone ring with at least saturated or non-saturated hydrocarbon group containing dicarboxylic acid, and modifying the chain-extended epoxy resin with an amine.

Owner:NIPPON PAINT CO LTD

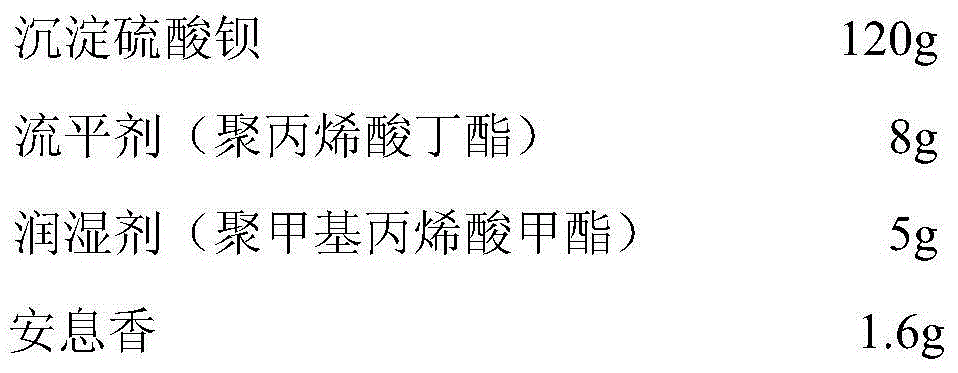

Method of forming a composite coating film comprising a pigment and resin emulsion

InactiveUS6541070B2Low water resistanceReduce dispersionPretreated surfacesEmulsion paintsWater basedMeth-

The present invention provides a method of forming a composite coating film which makes it possible to attain both appearance and workability in a high-humidity environment. The method of forming a composite coating film according to the present invention comprises applying a water-based base coat composition on a substrate, and then a clear coat thereon, wherein said water-based base coat composition comprises a pigment and a resin emulsion obtained by emulsion polymerization of an alpha, beta-ethylenically unsaturated monomer mixture, said alpha,beta-ethylenically unsaturated monomer mixture having an acid value of 3 to 50 mg KOH / g and containing at least 65% by weight of a (meth)acrylic ester whose ester moiety contains 1 or 2 carbon atoms.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS

Acrylic resin composition dispersed in water

InactiveUS20050221107A1Good lookingSufficient dispersion stabilityMeat/fish preservationSynthetic resin layered productsDispersion stabilityMeth-

It is an object to provide an acrylic resin composition dispersed in water. The composition has excellent appearance and sufficient dispersion stability, is stable even in one-package composition, exhibits physical properties of coating film excellent in water resistance, solvent resistance and weathering resistance, and sufficiently deals with recent environmental issues. It is also an object of the present invention to provide a coating film formed using such an acrylic resin composition dispersed in water. It is also an object of the present invention to provide a coating film formed using such an acrylic resin composition dispersed in water. The acrylic resin composition dispersed in water is an one-package composition obtained by combining a polymer comprising a monomer unit containing an aliphatic hydrocarbon group having 8 to 24 carbon atoms and a (meth)acrylic acid monomer unit, an oxazoline compound having two or more oxazoline rings and a specific amine compound.

Owner:NIPPON SHOKUBAI CO LTD

Method of forming composite coating film

InactiveUS20010033897A1Low water resistanceReduce dispersionPretreated surfacesEmulsion paintsWater basedMeth-

The present invention provides a method of forming a composite coating film which makes it possible to attain both appearance and workability in a high-humidity environment. The method of forming a composite coating film according to the present invention comprises applying a water-based base coat composition on a substrate, and then a clear coat thereon, wherein said water-based base coat composition comprises a pigment and a resin emulsion obtained by emulsion polymerization of an alpha,beta-ethylenically unsaturated monomer mixture, said alpha,beta-ethylenically unsaturated monomer mixture having an acid value of 3 to 50 and containing at least 65% by weight of a (meth)acrylic ester whose ester moiety contains 1 or 2 carbon atoms.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS

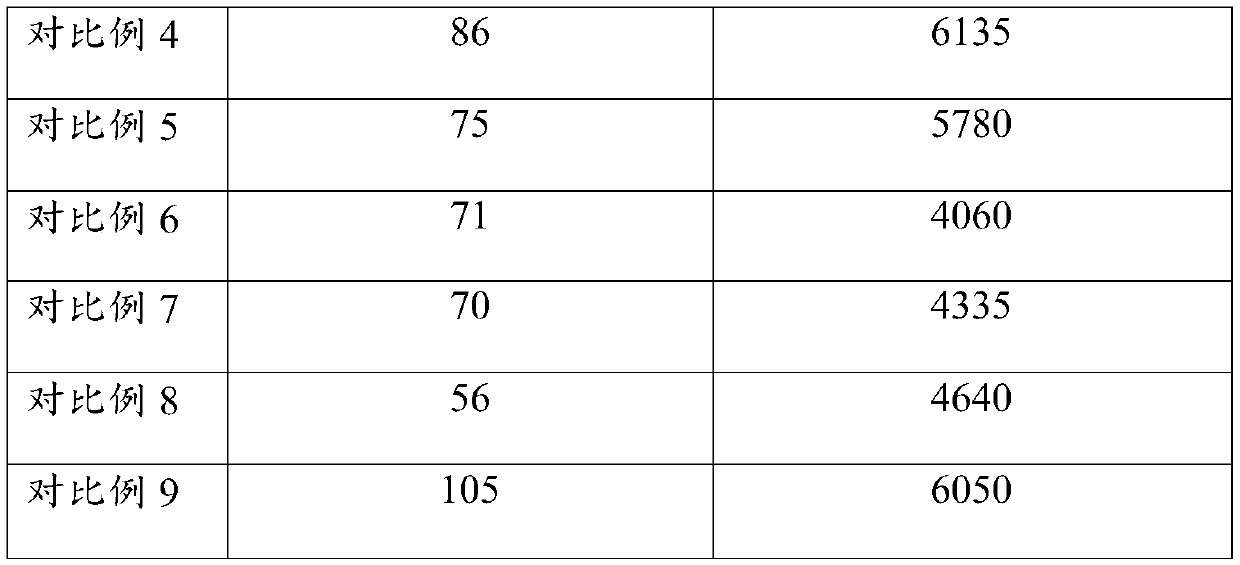

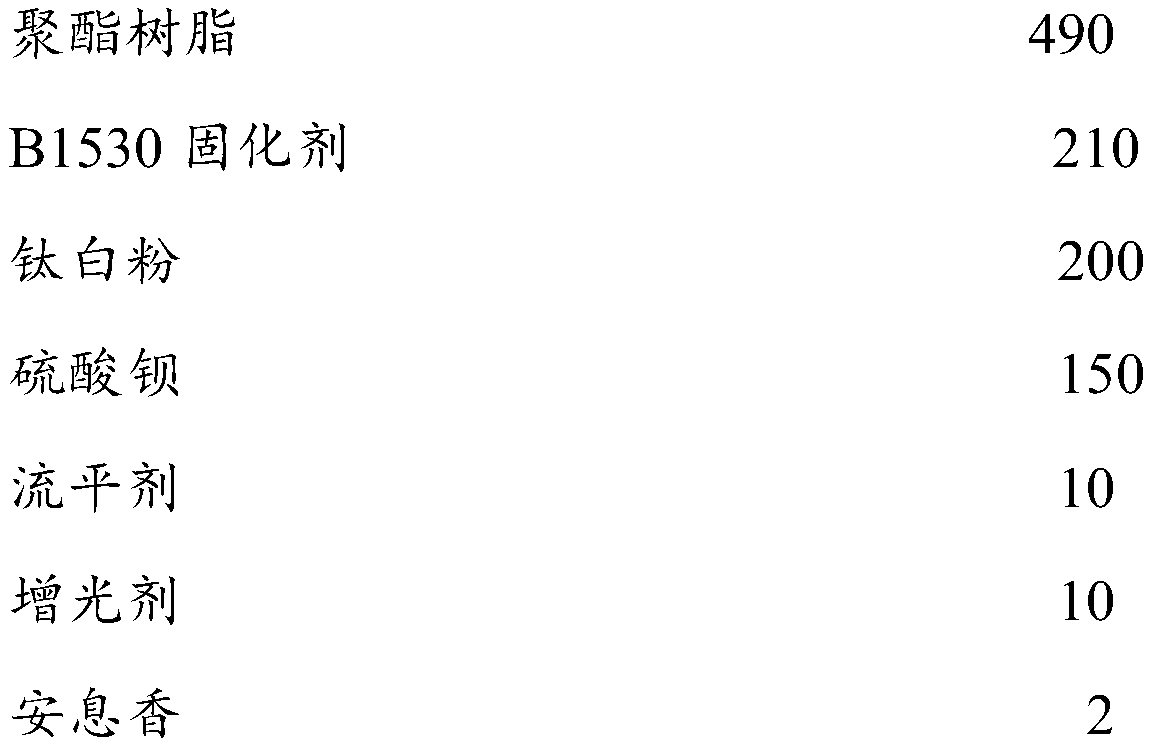

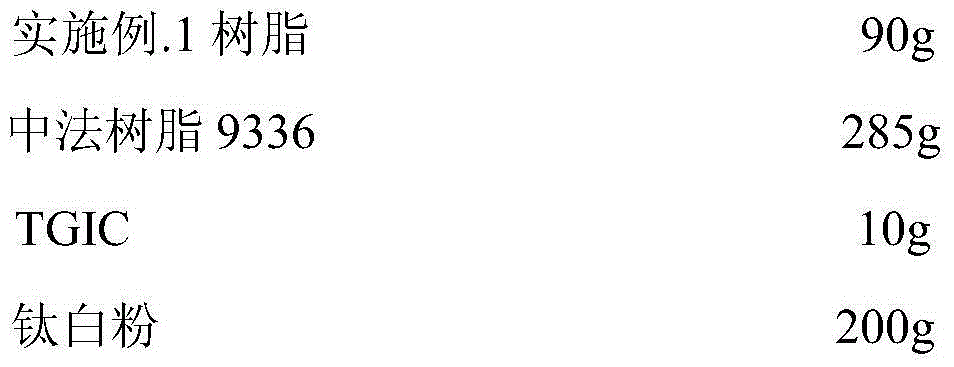

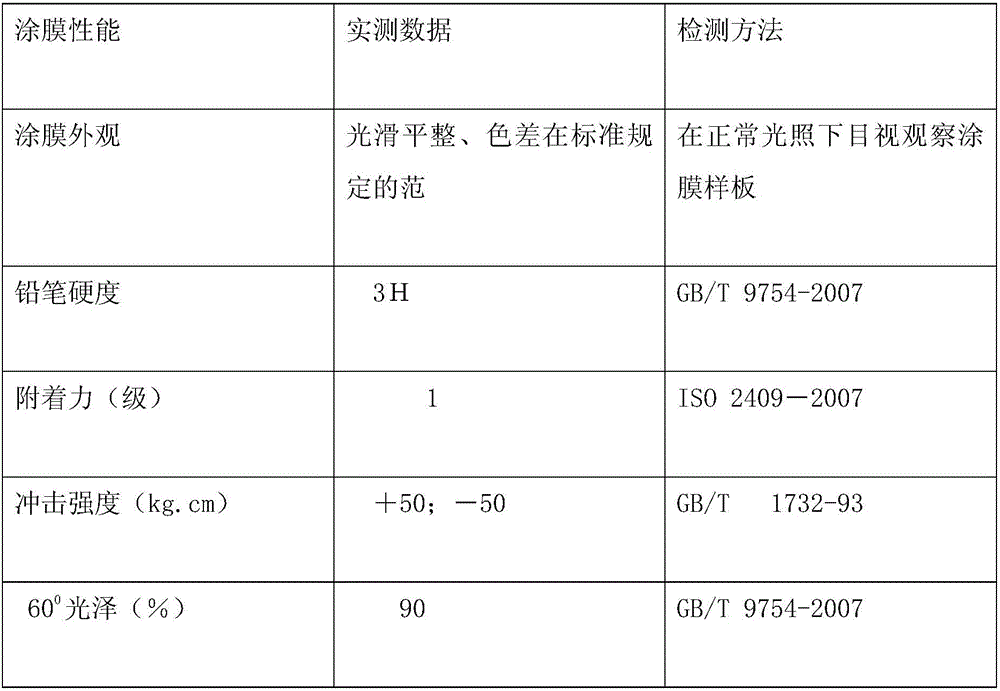

PU curable powder paint polyester resin excellent in cold resistance and production method

ActiveCN110156973ASlow curingGuaranteed leveling timePowdery paintsPolyester coatingsHydroxystearic AcidResorcinol

The invention belongs to the field of polyester resin, and relates to PU curable powder paint polyester resin excellent in cold resistance and a production method thereof. The polyester resin is formed through copolymerization of terephthalic acid, 3,3-tetramethyleneglutaric acid, resorcinol-O,O'-diacetic acid, DL-12-hydroxystearic acid, N-butyldiethanolamine, 1,4-cyclohexanedimethanol, catechin and the like. According to the PU curable powder paint polyester resin excellent in cold resistance and the production method thereof, by means of the 3,3-tetramethyleneglutaric acid, the resorcinol-O,O'-diacetic acid, the DL-12-hydroxystearic acid and the N-butyldiethanolamine which are excellent in cold resistance, a chain segment of the polyester resin is soft, and the low-temperature resistanceperformance is outstanding, so that the low-temperature brittleness of final film is reduced; and the obtained polyester resin and a polyurethane curing agent can be cured, the cold resistance of thefilm is excellent, the impact is almost unaffected after freezing is conducted at 0 DEG C and -5 DEG C for 6 h respectively, and the performance of the final film completely meets the requirements ofpowder paint.

Owner:黄山嘉恒科技有限公司

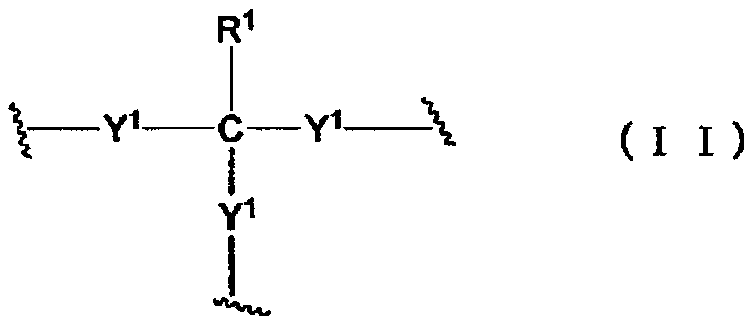

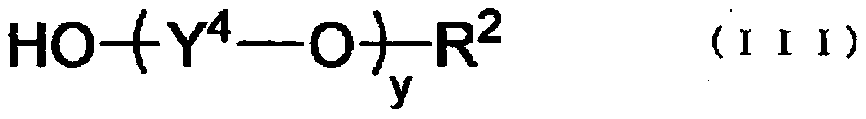

Isocyanate composition, aqueous dispersion of isocyanate composition, production method therefor, coating composition, and coating film

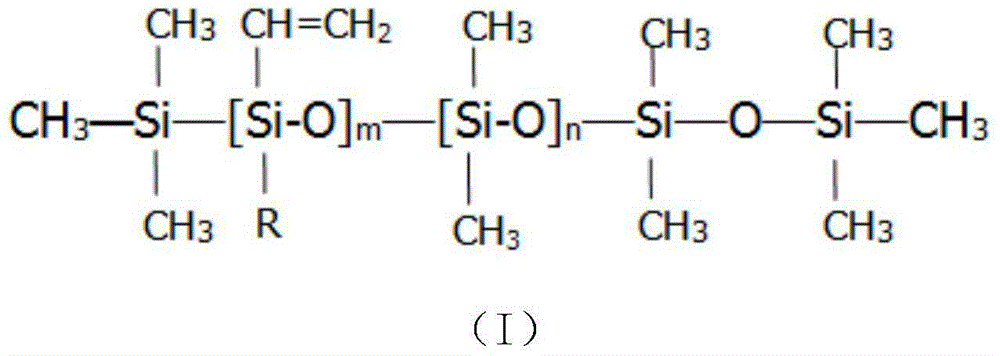

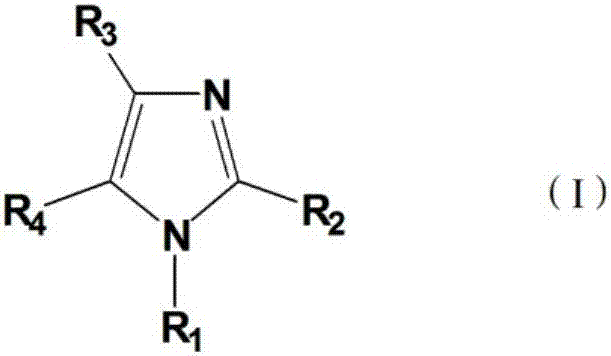

ActiveCN109843953ALow viscosityLow water dispersibilityPolyurea/polyurethane coatingsWater dispersiblePolymer science

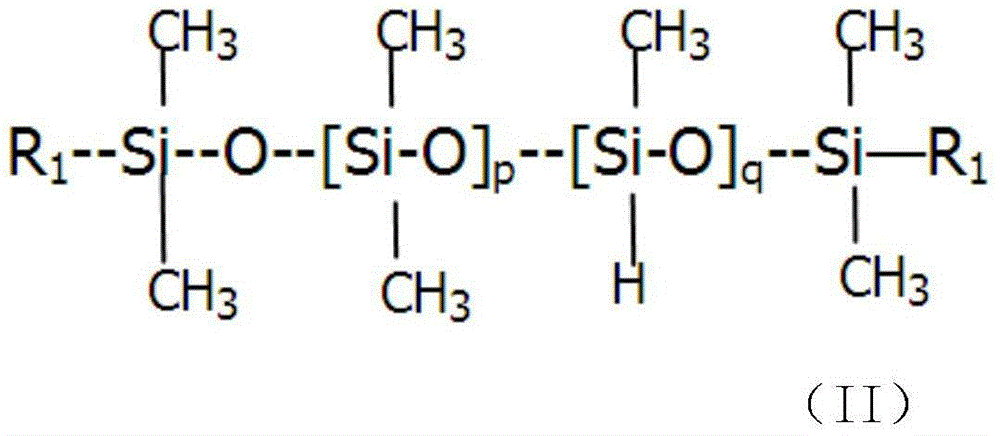

The isocyanate composition has a balance of low viscosity, water dispersion properties, drying properties and water resistance, and contains an isocyanate compound represented by general formula (I).In general formula (I), A is a residue containing a structure from the reaction of an active hydrogen-containing hydrophilic compound and an isocyanate group, and the sum (m + n) of the average numberof m and the average number of n is 3. m is an integer of 1 or more. R is a group represented by general formula (II).

Owner:ASAHI KASEI KK

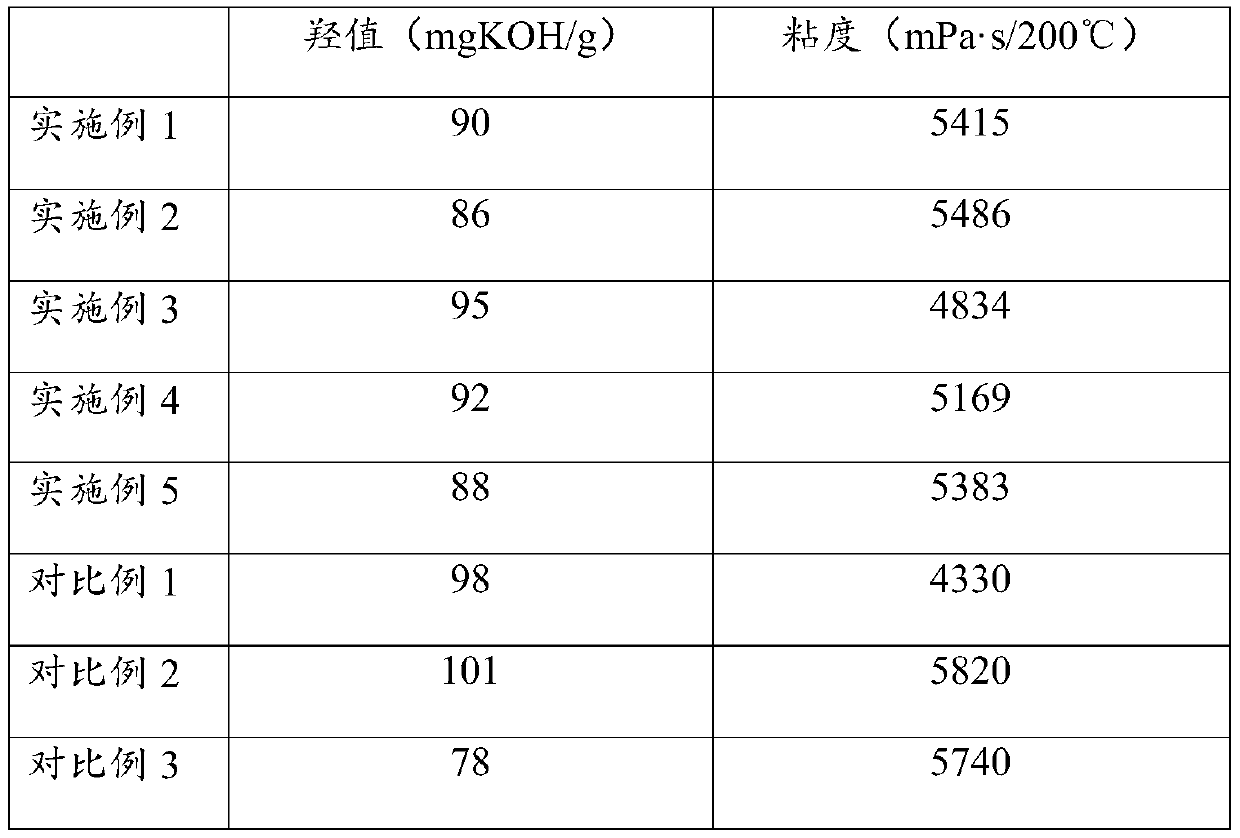

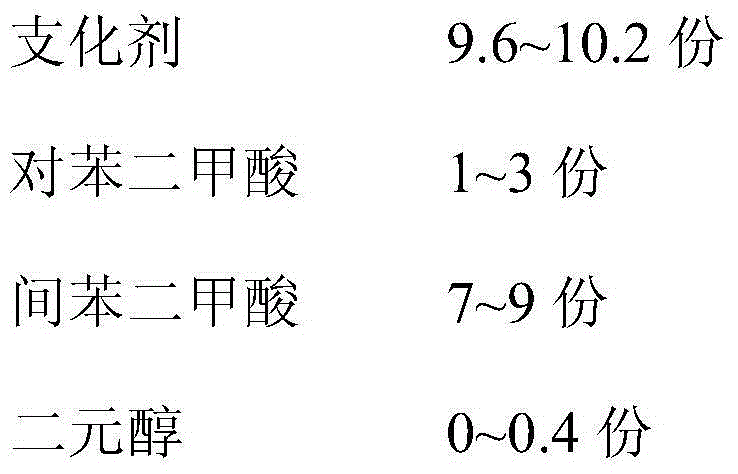

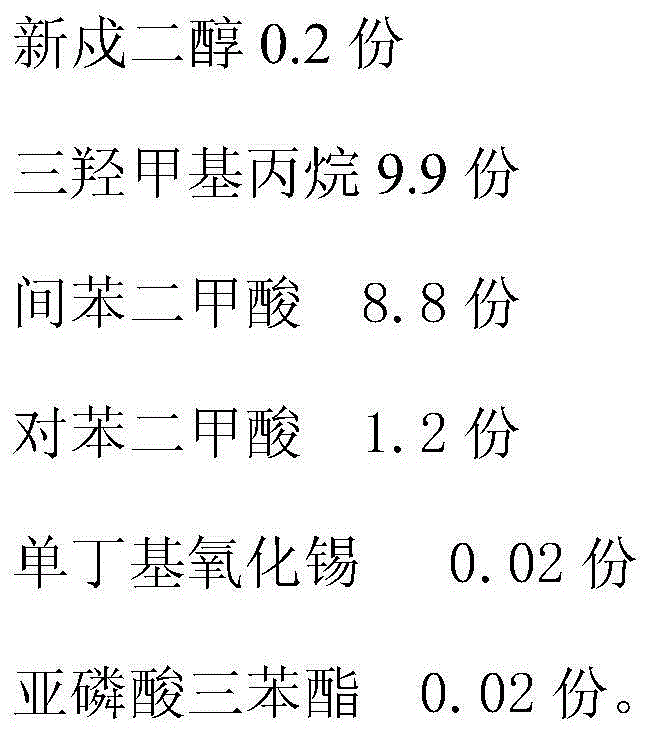

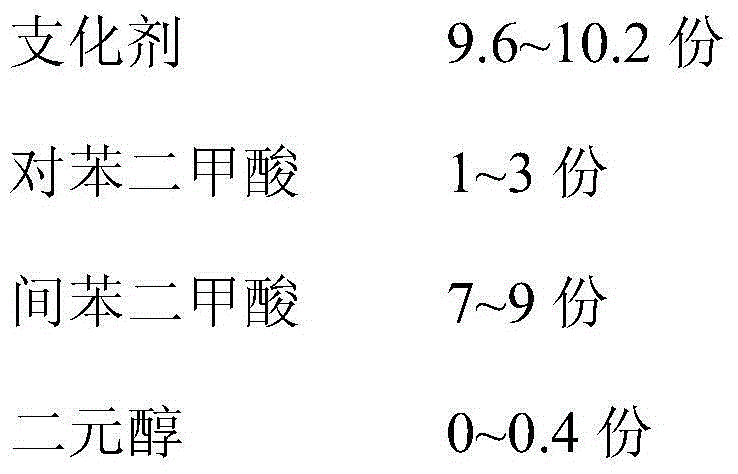

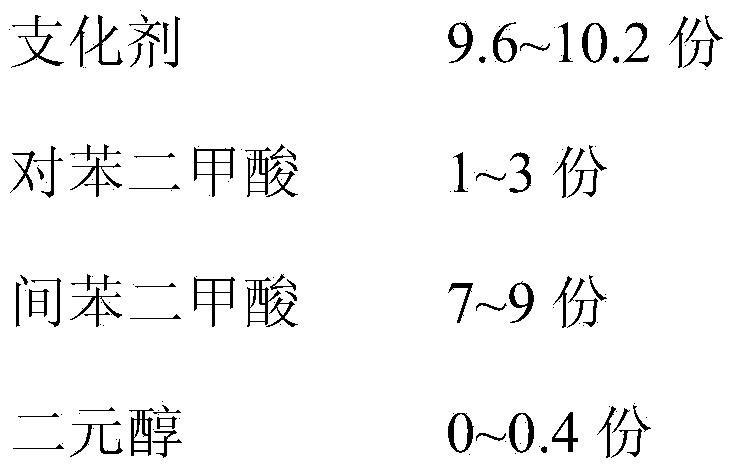

Preparation method of hydroxyl-terminated polyester resin for co-extruding extinction powder coating

InactiveCN104356371AGood storage stabilityReduce glossPowdery paintsPolyester coatingsLeveling effectExtinction

The invention discloses a preparation method of hydroxyl-terminated polyester resin for co-extruding an extinction powder coating. The preparation method comprises the following steps: adding dihydric alcohol and a branching agent into a synthetic reaction container, heating until materials are molten, adding p-terephthalic acid, m-phthalic acid and an esterified catalyst, then adding an antioxidant for reacting, to obtain the hydroxyl-terminated polyester resin for co-extruding the extinction powder coating. Compared with the prior art, the synthesized polyester resin has the following advantages that the glass transition temperature Tg of the polyester resin is more than 51 DEG C, and the storage stability can be provided; the viscosity is 2800-3000Pa.s (200 DEG C), and low viscosity can provide a good leveling effect; and the polyester resin has high hydroxyl value and can be subjected to coextrusion and extinction together with polyester resin having low hydroxyl value, and has low glossiness of 7-10%.

Owner:ANHUI SHENJIAN NEW MATERIALS

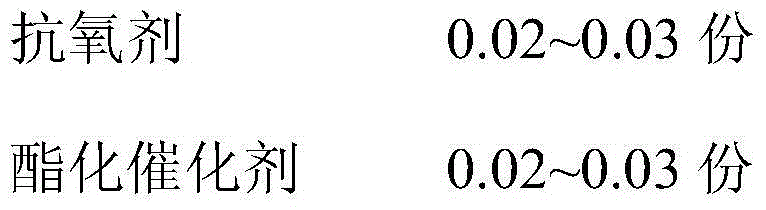

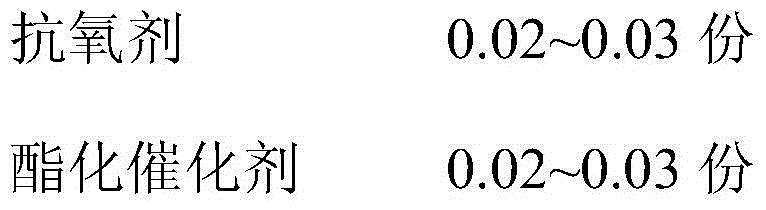

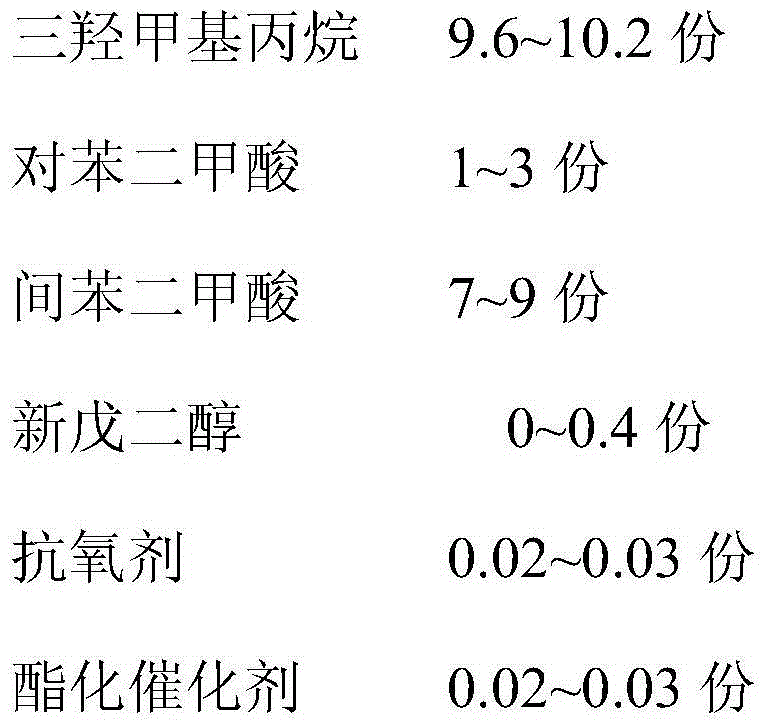

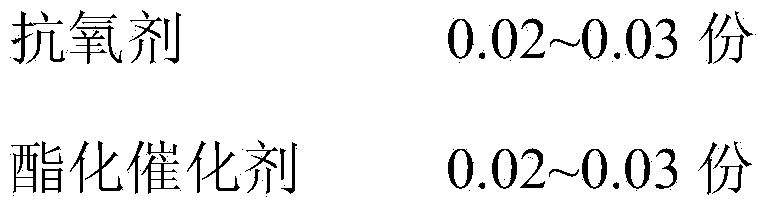

Terminal hydroxyl polyester resin for co-extrusion extinction powder coating and preparation method of terminal hydroxyl polyester resin

InactiveCN104448266AGood storage stabilityReduce glossPowdery paintsPolyester coatingsLeveling effectExtinction

The invention discloses terminal hydroxyl polyester resin for co-extrusion extinction powder coating and a preparation method of the terminal hydroxyl polyester resin. The terminal hydroxyl polyester resin comprises trimethylolpropane, terephthalic acid, isophthalic acid, neopentyl glycol, an antioxygen and an esterification catalyst. Compared with the prior art, the synthesized polyester resin has the advantages that the glass transition temperature Tg of the polyester resin is higher than 51 DEG C; the polyester resin can provide a good storage stability; the viscosity is 2800-3000mPa.s (200 DEG C), and a good leveling effect can be provided due to the low viscosity; the polyester resin has a high hydroxyl value, carries out co-extrusion extinction with a low hydroxyl value, and has low luster being 7-10 percent.

Owner:ANHUI SHENJIAN NEW MATERIALS

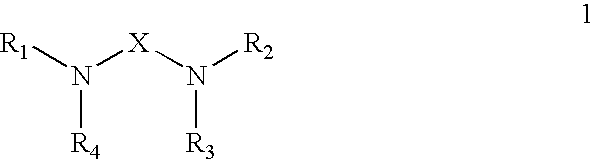

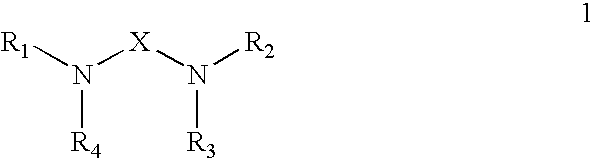

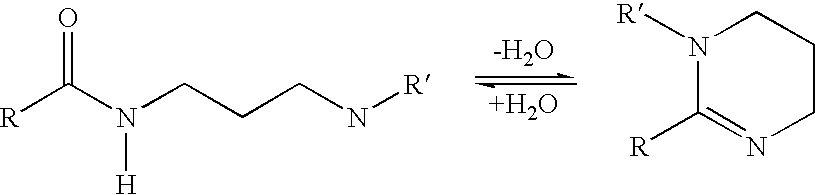

Polyamide Curing Agent Compositions

The present invention provides polyamide curing agent compositions comprising the reaction products of (1) multifunctional amines of structure 1where R1 is CH2CH2CH2NH2; R2, R3 and R4 independently are H or CH2CH2CH2NH2, and X is CH2CH2 or CH2CH2CH2 with (2) dimer fatty acids, optionally in combination with monofunctional fatty acids, the reaction product preferably comprising at least 15 wt % tetrahydropyrimidine-containing components. The curing agent compositions are useful for crosslinking epoxy resins to produce coatings, adhesives, floorings, composites and other articles.

Owner:EVONIK OPERATIONS GMBH

Method for manufacturing high strength galvanized steel sheet and high strength galvanized steel sheet

ActiveUS20150044503A1Good coating appearanceImprove corrosion resistanceHot-dipping/immersion processesFurnace typesChemical compositionHigh intensity

A method for manufacturing a high strength galvanized steel sheet and a high strength galvanized steel sheet are provided. A base steel sheet having a chemical composition comprising C: 0.03% to 0.35%, Si: 0.01% to 0.50%, Mn: 3.6% to 8.0%, Al: 0.001% to 1.000%, P≦0.10%, S≦0.010%, and the balance comprising Fe and incidental impurities, on a percent by mass basis, is subjected to annealing and galvanization treatment, wherein the maximum steel sheet temperature in an annealing furnace is 600° C. or higher and 700° C. or lower, the steel sheet transit time in a temperature region of the maximum steel sheet temperature of 600° C. or higher and 700° C. or lower is specified to be 30 seconds or more and 10 minutes or less, and the dew point in an atmosphere is specified to be −45° C. or lower.

Owner:JFE STEEL CORP

Hydroxyl-terminated polyester resin for co-extrusion extinction powder paint

PendingCN104327257AGood storage stabilityReduce glossPowdery paintsPolyester coatingsLeveling effectAlcohol

The invention discloses hydroxyl-terminated polyester resin for co-extrusion extinction powder paint. The hydroxyl-terminated polyester resin comprises a branching agent, terephthalic acid, isophthalic acid, dihydric alcohol, an antioxidant and an esterification catalyst. Compared with the prior art, the polyester resin synthesized in the invention has the advantage that the glass transition temperature Tg of the polyester resin is higher than 51 DEG C and good storage stability can be provided; the viscosity is 2800-3000mPa.s (200 DEG C) so as to provide good leveling effects, a hydroxyl value is relatively high so as to have very low gloss of 7-10% as low-hydroxyl-value co-extrusion extinction.

Owner:ANHUI SHENJIAN NEW MATERIALS

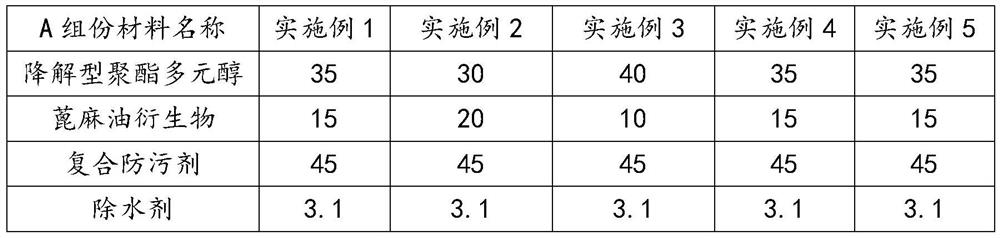

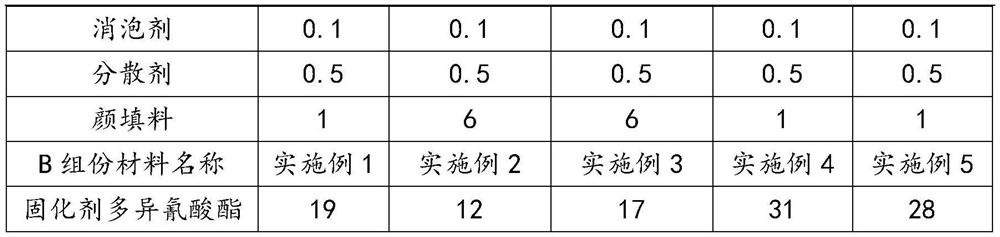

Solvent-free marine antifouling coating and preparation method thereof

InactiveCN112955513AFacilitated releaseNot easy to attachAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to the technical field of coatings, in particular to a solvent-free marine antifouling coating and a preparation method thereof. The coating comprises a component A and a component B. The component A comprises degradable polyester polyol, a castor oil derivative, a composite antifouling agent, a dewatering agent, a defoaming agent, a dispersing agent and pigment filler; and the component B is a curing agent polyisocyanate. According to the solvent-free marine antifouling coating provided by the invention, due to the introduction of isocyanate and the formation of a net structure in the degradable polyester polyurethane resin, a coating film has excellent adhesive force and impact resistance; meanwhile, due to breakage of ester bonds, the paint film can be slowly degraded, the antifouling agent in the coating is released, and the antifouling effect is good. The degradable polyester polyol is combined with the castor oil derivative, so that the crosslinking density and the crosslinking speed of the coating can be adjusted, the mechanical property of the coating is optimized, the reasonable working life of a coating system is obtained, the viscosity of the coating system can be adjusted and controlled, no organic solvent needs to be added, and the environment-friendly characteristic is achieved.

Owner:XIAMEN SUNRUI SHIP COATING

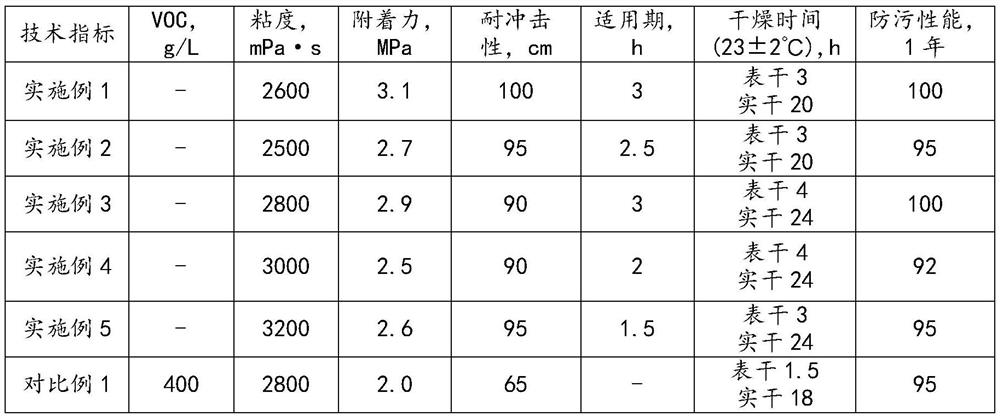

Method for forming multilayered coating film

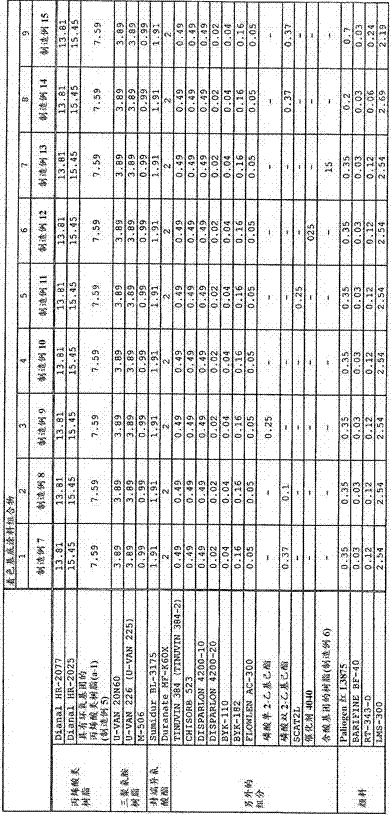

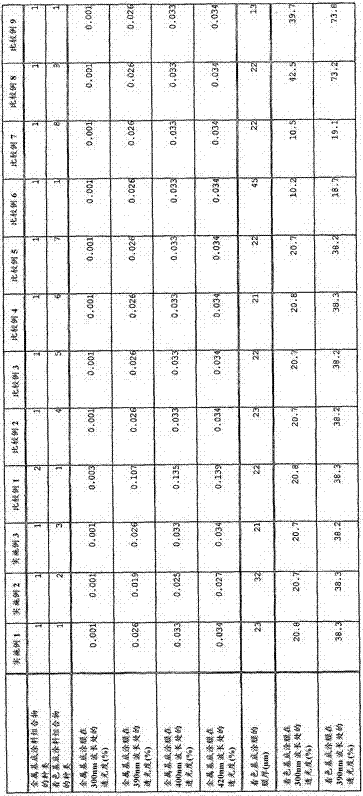

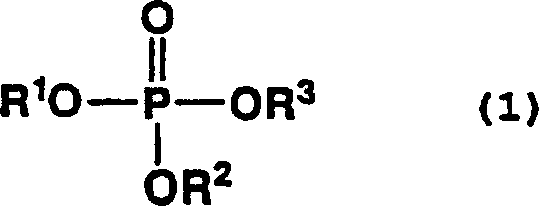

ActiveCN107969118AHigh saturationIncrease brightnessSynthetic resin layered productsPolyurea/polyurethane coatingsO-Phosphoric AcidAcrylic resin

The present invention addresses the problem of providing a method which, even when intermediate coating is omitted, can form a multilayered coating film (candy color coating film) that has an excellent coating film appearance and that is not inferior in coating film performance to multilayered coating films obtained by conventional coating methods. The present invention provides a method for forming a multilayered coating film which comprises a metallic base coating film formed from a metallic base coating composition containing a color pigment (i) and a glitter pigment (ii), a color base coating film formed from a color base coating composition, and a clear coating film, wherein the color base coating composition comprises an acrylic resin (a), a melamine resin (b), a blocked isocyanate compound (c), a phosphoric acid compound (d), and a color pigment (e), the metallic base coating film has a light transmission of 0.0001-0.1% in the wavelength range of 300-420 nm, the color base coating film has a light transmission of 20-70% in the wavelength range of 300-420 nm, and the color base coating film, after baking and curing, has a dry-state thickness of 21-40 [mu]m.

Owner:นิปปอน เพนท์ ออโตโมทีฟ โคทติ้งส์ โค แอลทีดี

Acrylic resin composition dispersed in water

InactiveUS7282531B2Good lookingFully dispersedMeat/fish preservationSynthetic resin layered productsDispersion stabilityMeth-

It is an object to provide an acrylic resin composition dispersed in water. The composition has excellent appearance and sufficient dispersion stability, is stable even in one-package composition, exhibits physical properties of coating film excellent in water resistance, solvent resistance and weathering resistance, and sufficiently deals with recent environmental issues. It is also an object of the present invention to provide a coating film formed using such an acrylic resin composition dispersed in water. It is also an object of the present invention to provide a coating film formed using such an acrylic resin composition dispersed in water. The acrylic resin composition dispersed in water is an one-package composition obtained by combining a polymer comprising a monomer unit containing an aliphatic hydrocarbon group having 8 to 24 carbon atoms and a (meth)acrylic acid monomer unit, an oxazoline compound having two or more oxazoline rings and a specific amine compound.

Owner:NIPPON SHOKUBAI CO LTD

Epoxy resin curing agent of aliphatic diamine/styrene addition product

The epoxy resin curing agent of the present invention comprises a polyamino compound obtainable by addition reaction of aliphatic diamine represented by the formula (1) and styrene and a curing accelerator comprising an organic compound having at least one carboxyl group and at least one hydroxyl group within the molecule, which can achieve a low viscosity without containing environmental harmful substances such as phenol and solvents. In addition, the epoxy resin composition using said epoxy resin curing agent shows an excellent curability at low temperature and it provides a cured coating film having excellent appearanceH2N—H2C-A-CH2—NH2 (1)wherein A is a phenylene group or a cyclohexylene group.

Owner:MITSUBISHI GAS CHEM CO INC

High residual adhesive rate solvent-type paper isolation agent and preparation method thereof

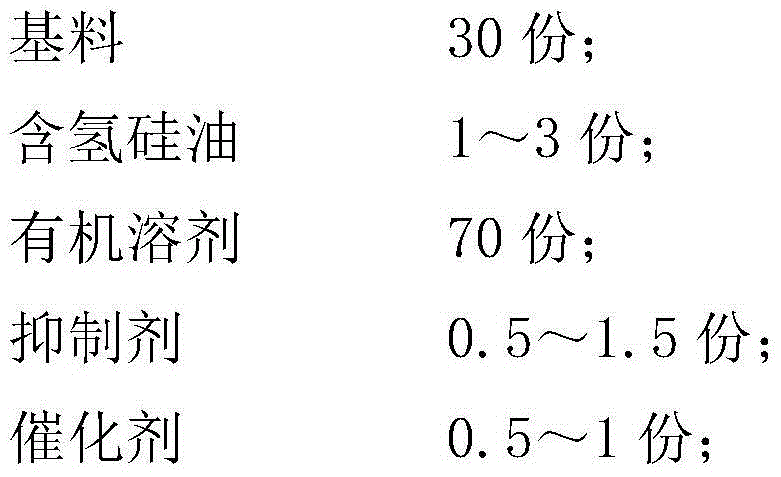

ActiveCN104130705AHigh residual adhesionSolvent-based paper release agents with high residual tack can be used at lower residual tackCoatingsCoatings without pigmentsHydrogenOrganic solvent

The invention belongs to the field of organosilicon chemistry, and discloses a high residual adhesive rate solvent-type paper isolation agent and a preparation method thereof; the high residual adhesive rate solvent-type paper isolation agent is composed of the following components by weight: 30 parts of a base material, 1-3 parts of hydrogen-containing silicone oil, 70 parts of an organic solvent, 0.5-1.5 parts of an inhibitor and 0.5-1 part of a catalyst. The preparation method comprises the following steps: (1) mixing the base material and the organic solvent, then adding the catalyst, mixing and stirring evenly; (2) then adding the inhibitor, mixing and stirring evenly; and (3) adding the hydrogen-containing silicone oil mixing and stirring evenly to obtain the high residual adhesive rate solvent-type paper isolation agent. The high residual adhesive rate solvent-type paper isolation agent can fast cure at a lower temperature, is excellent in effect, good in appearance of coating, good in substrate adhesion, low in silicon transfer, and low in stripping force, and the residual adhesive rate is up to 85-90%.

Owner:惠州市永卓科技有限公司

Jar coating composition

InactiveCN101037565AGood effectGood coating appearanceLiquid surface applicatorsPolyester coatingsSolubilityOrganic solvent

The invention provides a coating composition for a kettle, the composition contains: (A) crystalline polyester resin particles using an ethylene terephthalate unit as a main component, (B) crystalline polyester resin particles using an butylene terephthalate unit as a main component, and (c) an organic solvent having a solubility of less than 5% by weight when being lower than 40 DEG C and more than 99% by weight when being higher than 180 DEG C, for the particles (A) and the particles (B), wherein proportions of the particles (A) and the particles (B) are based on a total of the two, the proportion of the particles (A) is 95-30% by weight and the proportion of the particles (B) is 5-70% by weight, the content of the organic solvent (C) is 50-500 parts relative to 100 parts of the total of the particles (A) and the particles (B) by weight.

Owner:KANSAI PAINT CO LTD

Epoxy-group-containing solid resin, and preparation method and application thereof

ActiveCN104558376AGood coating appearanceImprove mechanical propertiesPowdery paintsEpoxyMethacrylate

The invention discloses an epoxy-group-containing solid resin which is prepared by carrying out solution polymerization on the following three monomers in percentage by weight: 6-92% of monomer A, 0-86% of monomer B and 2-40% of monomer C. The monomer A is acrylate and / or methacrylate; the monomer B is a vinyl monomer; and the monomer C is epoxy unsaturated polyfunctional group ester and / or epoxy unsaturated polyfunctional group ether. The epoxy-group-containing solid resin product and production process are environment-friendly, are free from the restrictions of the use region, and are low in cost. The solid resin can be matched with the existing material formula by an existing device technique to manufacture a thermosetting powder paint, and the prepared powder paint has high performance.

Owner:姚林生

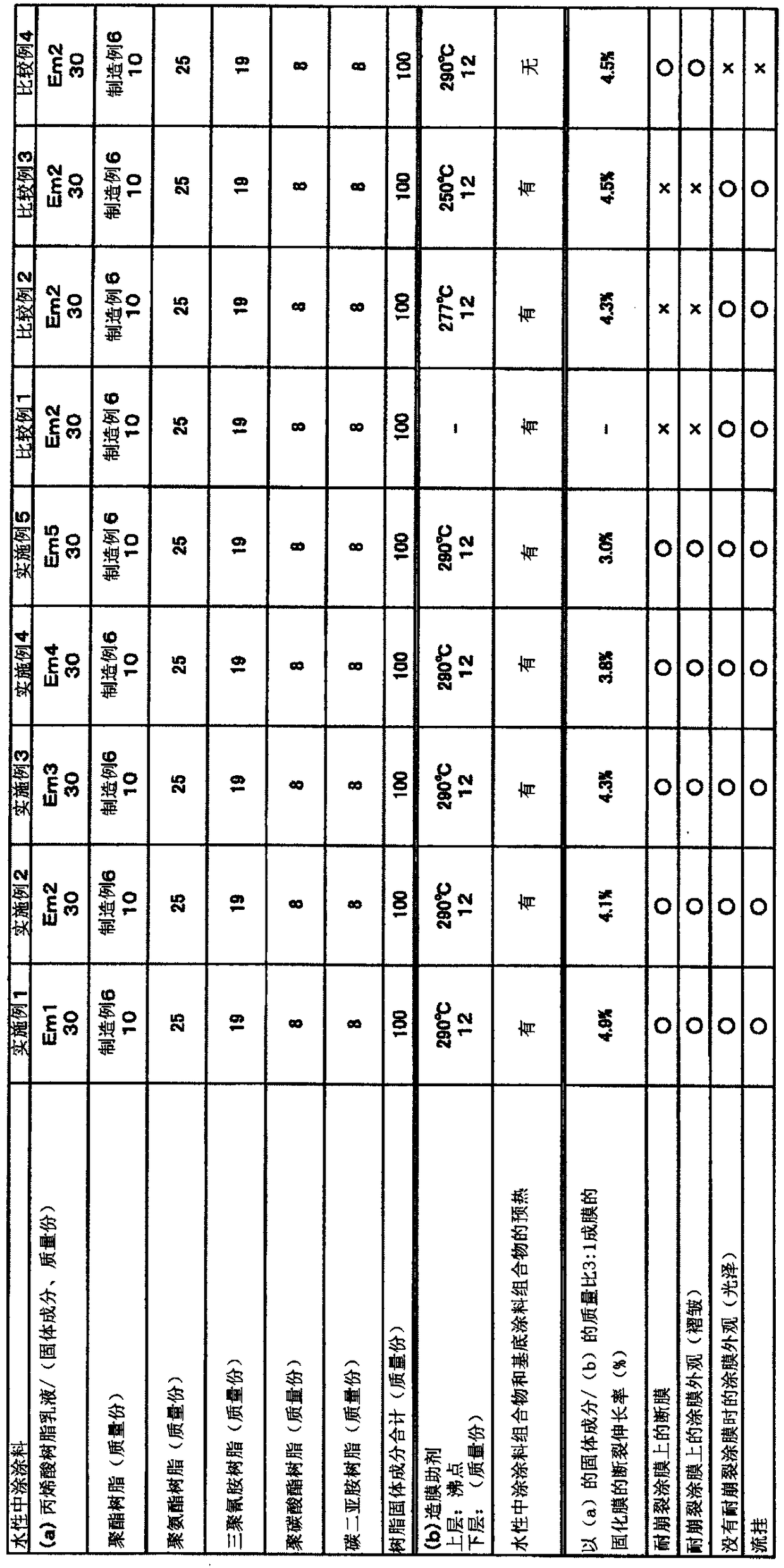

Method for forming multilayer coating film

InactiveCN108686913AGood flexibilityPrevent saggingPretreated surfacesElectrophoretic coatingsSolid componentEmulsion

The objective of the invention is to keep the softness of a coating film in a film making process and obtain a smooth coating film even if on a base material with thermal expansion / contractibility. The invention provides a method for forming a multilayer coating film, which is a method for form a multilayer coating film on an automobile vehicle body. The method comprises following steps of coatingwaterborne intermediate coating compositions, preheating coated intermediate coating compositions under 60-90 DEG C for 3-10 minutes so as to form un-solidified intermediate coating films, forming preheated un-solidified substrate coating films and un-solidified transparent coating films and baking and solidifying the un-solidified coating films so as to form a multilayer coating film. The intermediate coating compositions comprise coating film forming resin. The coating film forming resin comprises (a) acrylic resin emulsion with regulated physical property, and film making auxiliaries including fatty acid diester compounds with the boiling point from 280 DEG to 350 DEG C in the waterborne intermediate coating compositions. Mixing and film making are performed on the (a) and the (b) so that the elongation at break of a solidification film is 1% or over is obtained, wherein mass ratio of the solid components of the (a) to the (b) is 3 : 1.

Owner:นิปปอน เพนท์ ออโตโมทีฟ โคทติ้งส์ โค แอลทีดี +1

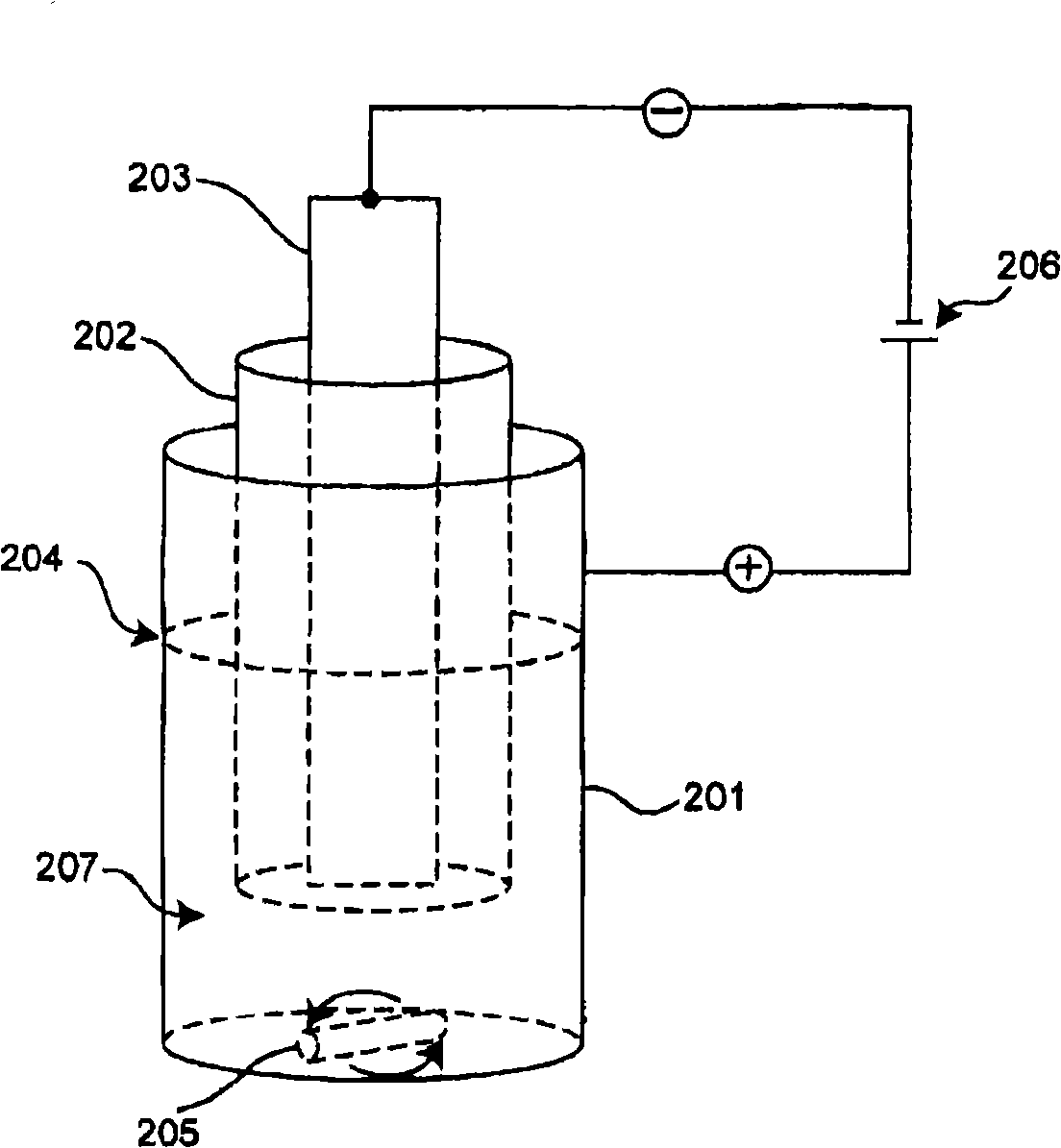

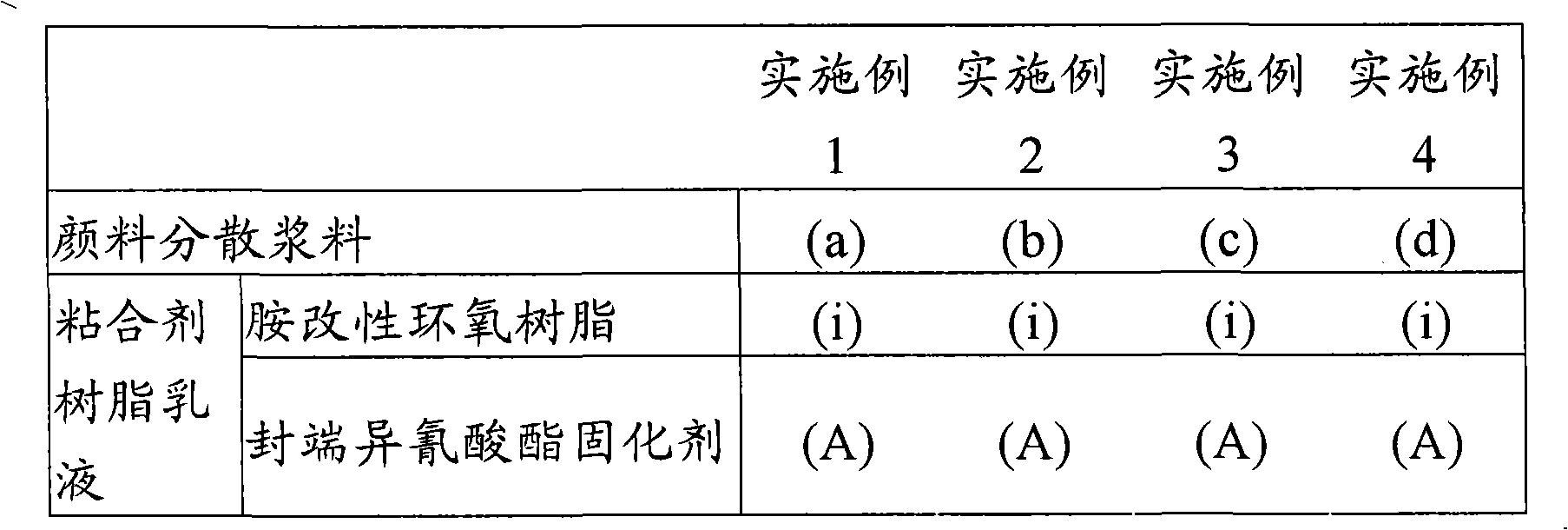

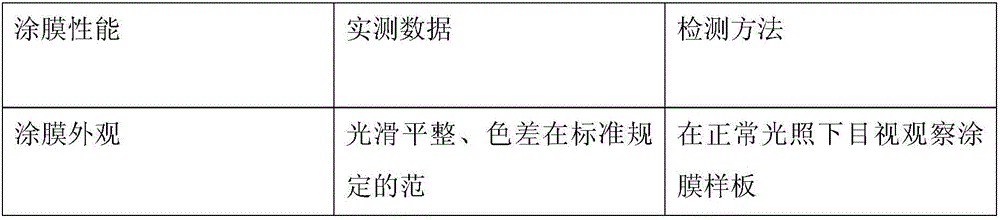

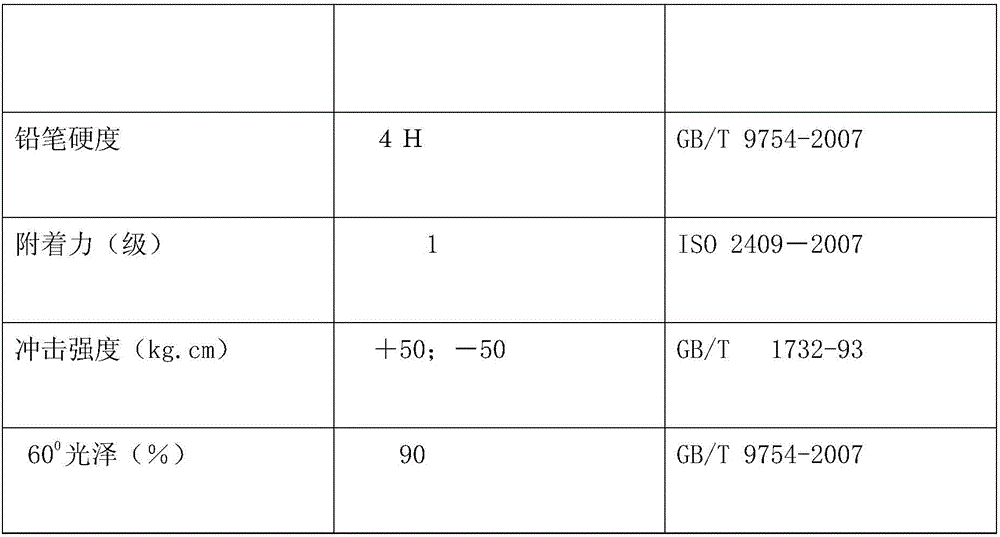

Method for preparing cationic electrodeposition coating composition

ActiveCN107969130AEfficient preparationEasy to manufactureElectrophoretic coatingsPolyurea/polyurethane coatingsOrganic acidPolymer science

The objective of the present invention is to provide a method for preparing a cationic electrodeposition coating composition that contains a bismuth compound and exhibits excellent coating material stability, curability, coating film appearance and the like. The present invention provides a method for preparing a cationic electrodeposition coating composition, which comprises a step for mixing a resin emulsion (i) and a pigment-dispersed paste, and wherein: the resin emulsion (i) contains an aminated resin (A) and a blocked isocyanate curing agent (B); the pigment-dispersed paste contains a bismuth mixture (C) that is obtained by mixing a bismuth compound (c1) and an organic acid (c2) in advance, a pigment-dispersed resin (D), an amine-modified epoxy resin emulsion (ii) that contains an amine-modified epoxy resin (E), and a pigment (F); the pigment-dispersed resin (D) has a hydroxyl number of 20-120 mgKOH / g; and the amine-modified epoxy resin (E) has a hydroxyl number of 150-650 mgKOH / g.

Owner:นิปปอน เพนท์ ออโตโมทีฟ โคทติ้งส์ โค แอลทีดี

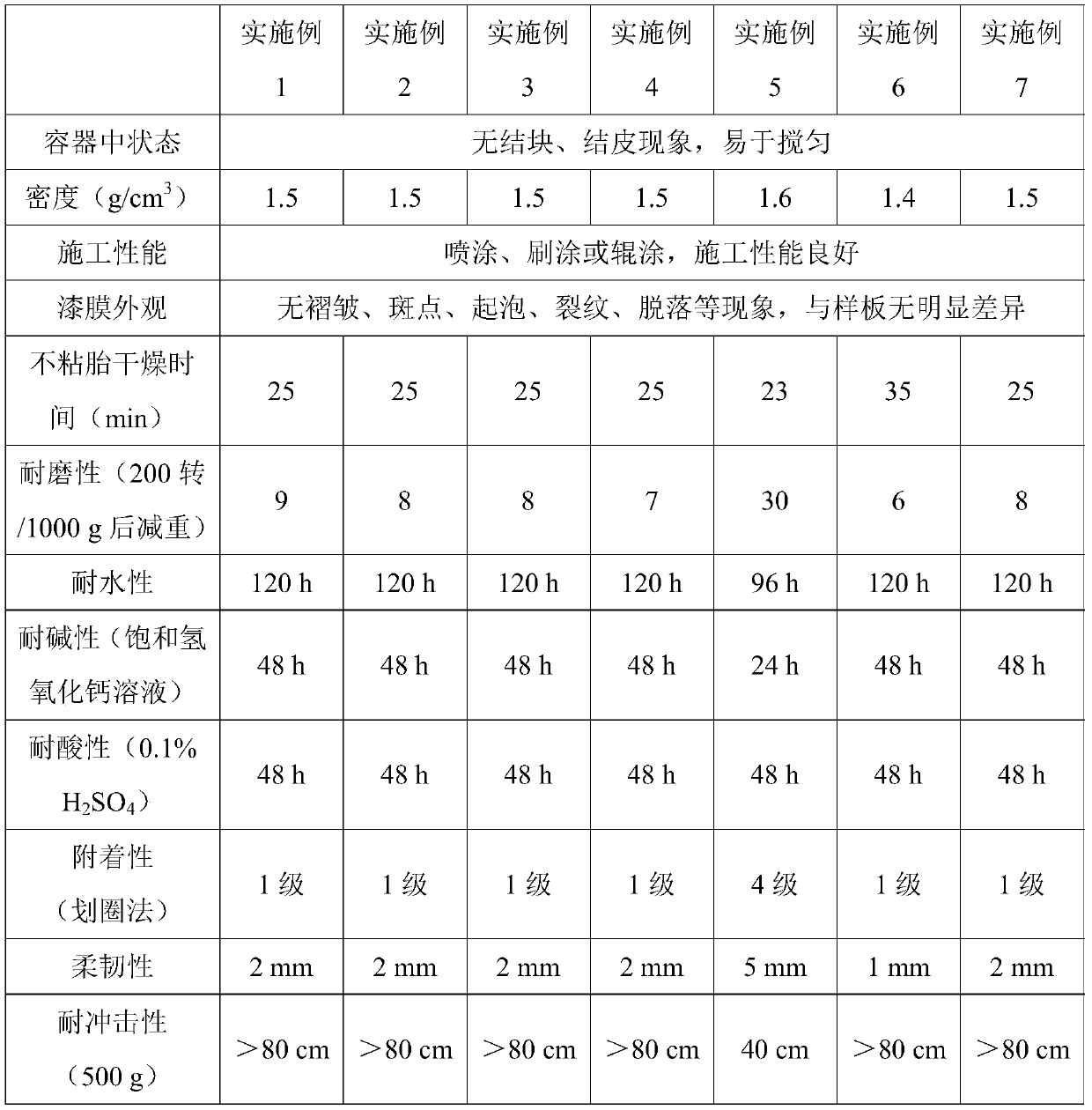

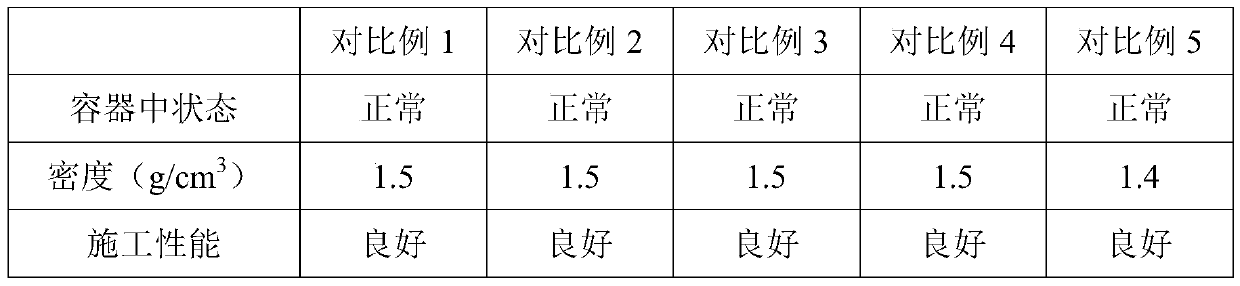

Water-based floor marking coating and preparation method thereof

InactiveCN110577794AImprove adhesionImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedPliability

The invention provides a water-based floor marking coating and a preparation method thereof. The water-based floor marking coating comprises a component A and a component B; the component A comprises,by weight, 35-55 parts of a waterborne polyurethane resin, 15-20 parts of a pigment, 15-25 parts of a filler and 0.1-0.3 part of an adhesion promoter; and the component B comprises an isocyanate curing agent. The design of the components and the mutual cooperation of the components at a specific ratio make the activation period and the curing speed of the coating balanced, so the coating is suitable for marking coating of floor surfaces such as workshops, underground garages, playgrounds, warehouses and the like, and a film formed after curing the coating has characteristics of high cross-linking density, good appearance, excellent base material adhesion, excellent flexibility, excellent wear resistance and excellent impact resistance, and can provide a long-lasting identification markingfunction for the floor surfaces.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

Heat-resisting powder coating for auto vent pipe and preparing method thereof

InactiveCN105949964AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsPowdery paintsEpoxyBoron nitride

The invention provides heat-resisting powder coating for an auto vent pipe. The heat-resisting powder coating is prepared from, by weight, 10-20 parts of organosilicon-modified epoxy resin, 80-90 parts of o-cresol formaldehyde epoxy resin, 10-20 parts of hydroxyl polyester resin, 10-15 parts of polyisocyanate, 10-12 parts of polyester polyol, 1-2 parts of silane coupling agent, 1-2 parts of antioxidant 1010, 4-6 parts of ethylene propylene diene monomer, 3-5 parts of silicon carbide, 1-2 parts of boron nitride, 15-20 parts of mica powder, 2-3 parts of 2,6-tert-butyl-4-methylphenol, 0.5-1.0 part of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 15-18 parts of superfine barium sulfate, 8-10 parts of carbon black, 0.5-0.7 part of benzoin and 1-2 parts of performance additive. The coating is high in heat resistance, low in curing temperature, short in curing time, high in adhesive force and resistant to acid and alkali, and can be applied to coating of the auto vent pipe, and a coating film is high in levelling property and good in appearance.

Owner:合肥燕美新材料科技有限公司

Method of forming composite coating film

InactiveUS20030148129A1Low water resistanceReduce dispersionOrnamental textile articlesSynthetic resin layered productsMethacrylatePolymer science

The present invention provides a method of forming a composite coating film which makes it possible to attain both appearance and workability in a high-humidity environment. The method of forming a composite coating film according to the present invention comprises applying a water-based base coat composition on a substrate, and then a clear coat thereon, wherein said water-based base coat composition comprises a pigment and a resin emulsion obtained by emulsion polymerization of an alpha, beta-ethylenically unsaturated monomer mixture, said alpha, beta-ethylenically unsaturated monomer mixture having an acid value of 3 to 50 and containing at least 65% by weight of a (meth)acrylic ester whose ester moiety contains 1 or 2 carbon atoms.

Owner:NIPPON PAINT CO LTD

Sealing method

InactiveCN1649978AShape has no effectSmooth appearanceLiquid surface applicatorsOther chemical processesEngineeringHot melt

A sealing method comprising affixing an adhesive tape (e.g., a pressure-sensitive adhesive tape) to an adherend to be sealed, placing a sealing article that contains a hot-melt / fluidizable thermosetting sealing material on the adhesive tape, and heating the sealing article to a temperature sufficient to allow the article hot-melt / fluidize and thermoset. The adhesive tape has a substrate that suppresses penetration of air trapped in the affixing step between the adherend and adhesive tape into the sealing article.

Owner:3M INNOVATIVE PROPERTIES CO

Powder coating with good weather resistance and method for preparing powder coating

InactiveCN106047059AImprove performanceGood storage stabilityRubber derivative coatingsPowdery paintsDiethylene glycol monobutyl etherFiber

The invention provides powder coating with good weather resistance. The powder coating is made of, by weight, 50-60 parts of epoxy resin, 20-30 parts of acrylic resin, 3-4 parts of diethyl glutaric anhydride, 1-2 parts of imidazole, 4-6 parts of chlorinated rubber, 0.1-0.4 part of hindered amine light stabilizers, 0.2-0.4 part of benzotriazole light stabilizers, 0.3-0.5 part of tetrabutyl amine-di-[methyl orthophthalic disulfide] complex copper, 12-16 parts of sepiolite powder, 3-5 parts of short fibers, 10-15 parts of carbon black, 2-3 parts of mica powder, 1-2 parts of diethylene glycol monobutyl ether, 10-15 parts of precipitated barium sulfate, 2-4 parts of castor oil, 2-4 parts of aluminum powder, 0.5-1.0 part of benzoin, 0.2-0.5 part of 2, 6-tert-butyl-4-methylphenol, 0.1-0.3 part of bis-n-dodecanol ester and 3-5 parts of modifying auxiliaries. The powder coating has the advantages that the powder coating is high in application property and adhesion and short in curing time, the weather resistance of the powder coating can reach 20 years, and films are good in leveling property and appearance.

Owner:合肥燕美新材料科技有限公司

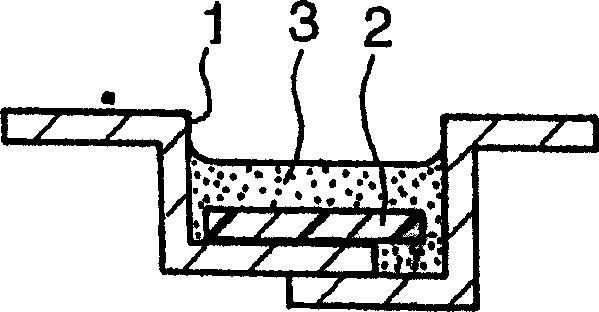

Method for forming electrodeposition coating

InactiveCN101302642AReduce generationGood coating appearanceElectrophoretic coatingsPolyurea/polyurethane coatingsSolid contentZinc

The present invention is intended to provide a process for forming an electrodeposition coating film, wherein generation of gas pinhole is reduced and coating film appearance is excellent without using a specific resin as a binder resin. The present invention relates a process for forming an electrodeposition coating film having reduction of generation of gas pinhole, comprising a step of electrocoating by immersing an article to be coated in a cationic electrodeposition coating composition, wherein, the cationic electrodeposition coating composition comprises 10 to 30 parts by weight of a pigment comprising zinc oxide based on 100 parts by weight of a solid content of the coating composition, and the content of zinc oxide contained in the pigment is 0.25 to 5 parts by weight based on 100 parts by weight of the pigment.

Owner:NIPPON PAINT CO LTD

Heat-resistant and flame-resistant powder coating for gas-cooker body surface layer and preparing method thereof

InactiveCN105860783AGood chemical stabilityGood adhesionFireproof paintsAnti-corrosive paintsMethacrylatePolyvinylpyrrolidone

The invention provides a heat-resistant and flame-resistant powder coating for a gas-cooker body surface layer. The heat-resistant and flame-resistant powder coating is prepared from, by weight, 8-10 parts of organic silicon resin, 10-20 parts of thermosetting fluorocarbon resin, 20-30 parts of hydroxyl polyester resin, 2-4 parts of isocyanate curing agent, 1-2 parts of 3-glycidoxypropyltrimethoxysilane, 5-8 parts of ferric oxide, 4-6 parts of ethylene-propylene-diene monomer, 5-10 parts of silica micropowder, 2-4 parts of zinc oxide, 4-6 parts of zirconium oxide, 15-20 parts of kaolin fine powder, 1-2 parts of bi-( 3,5-tertiary butyl-4-hydroxy phenyl ) sulfide, 5-8 parts of magnesium hydroxide, 8-10 parts of aluminum hydroxide, 0.5-1.0 part of 2-ethylhexyl methacrylate, 1-2 parts of polyvinylpyrrolidone, 0.2-0.4 part of acrylic ester flatting agent, 6-8 parts of carbon black and 3-4 parts of modified assistant. The heat-resistant and flame-resistant powder coating is good in heat resistance and flame resistance, low in curing temperature, short in curing time, good in coating flatting performance, high in adhesive force, good in coating appearance and resistant to acid and alkali, and can be applied to the gas-cooker body surface layer.

Owner:合肥燕美新材料科技有限公司

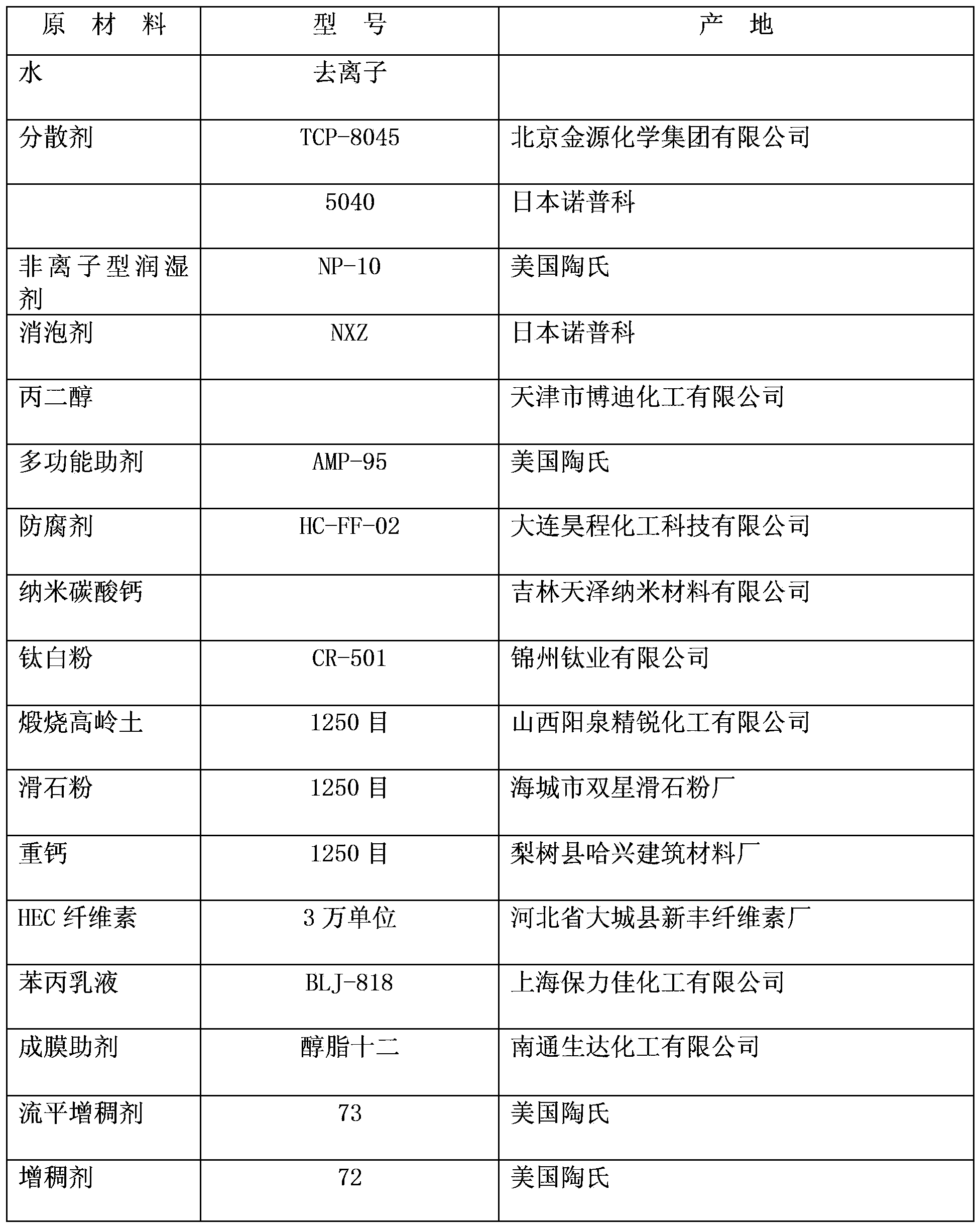

Preparation method of special-purpose nanometer modifier of water-based coating

InactiveCN103525129AGood storage stabilityNo settlementEmulsion paintsPigment treatment with macromolecular organic compoundsWater basedWater baths

The invention discloses a preparation method of a special-purpose nanometer modifier of water-based coating, which belongs to the fields of chemical engineering and fine chemical engineering, and relates to a preparation method of a nanometer modifier added into water-based coating. The preparation method comprises the following steps of preparing nanometer calcium carbonate powder into a sizing agent with mass fraction of 10%-35%; placing the sizing agent into a constant-temperature water-bath slot for heating; slowly adding the prepared modifying agent of a certain proportion into the sizing agent within 5 minutes under a certain stirring speed after a predetermined temperature is reached. After beings stirred for certain time, the modified serous fluid is filled into a container for sealing and storing after being cooled to the room temperature. The preparation method disclosed by the invention has the beneficial effect that the modifier disclosed by the invention is added into a water-based coating formula system, so that a difficult problem that the nanometer calcium carbonate powder is not easy to disperse and easy to unite in the coating formula is successfully solved and dust pollution is reduced; after replacing titanium dioxide according to a proportion, contrast ratio and covering power of the material are improved, washing resistance is obviously strengthened, and fineness of emulsion paint is high; moreover, storage performance is excellent and sedimentation is not easy.

Owner:天成高新纳米复合材料有限公司

Powder coating for washing machine shell and preparation method of powder coating

InactiveCN105860776ACorrosion resistantImprove water resistanceAntifouling/underwater paintsPaints with biocidesEpoxyEthylamine

The invention provides a powder coating for a washing machine shell. The powder coating is prepared from, by weight, 80-90 parts of o-cresol-formaldehyde epoxy resin, 30-32 parts of hydantoin epoxy resin, 2-3 parts of ethanediamine, 0.5-1.0 part of boron trifluoride ethylamine complex, 3-5 parts of rosin modified phenolic resin, 2-4 parts of glycerin, 2-4 parts of nano-silicon dioxide, 2-4 parts of dimethyl silicone oil, 6-8 parts of vermiculite power, 1-3 parts of leveling agent, 1-2 parts of triethanolamine, 2-3 parts of oleic acid, 0.5-1 part of white oil, 20-25 parts of titanium dioxide, 3-5 parts of light calcium carbonate, 0.2-1 part of molybdenum disulfide, 0.1-0.5 part of benzoin and 0.3-0.5 part of modified negative ion powder. The powder coating is good in corrosion resistance, water resistance and insulating property, low in curing temperature and short in curing time, the coating film is good in leveling property, high in adhesion, good in appearance, resistant to acid and alkali and capable of purifying air, and the coating can be used for household electrical appliances of washing machines and the like.

Owner:合肥燕美新材料科技有限公司

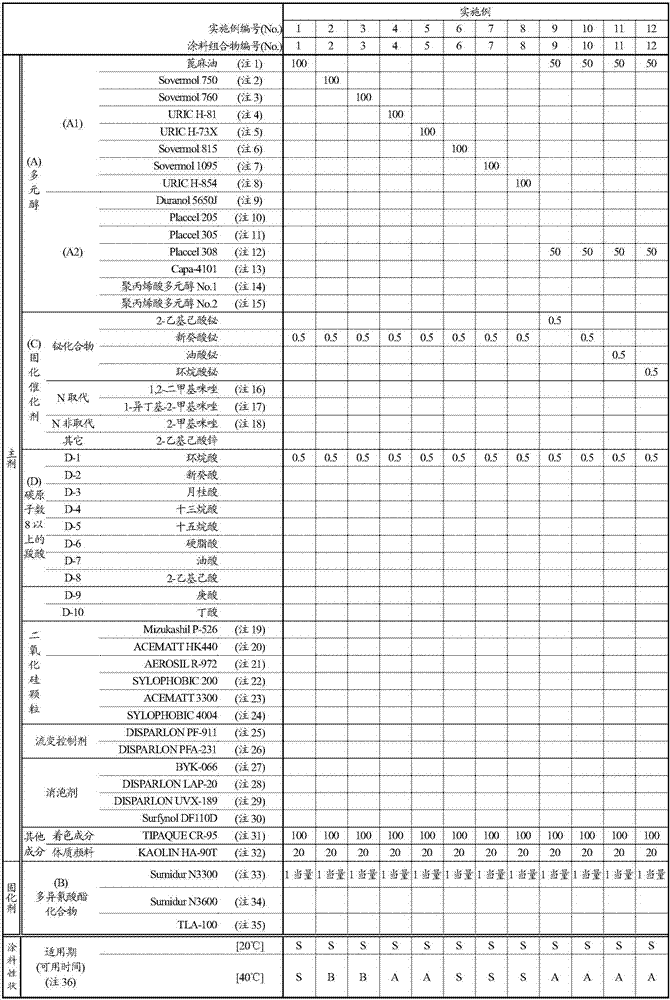

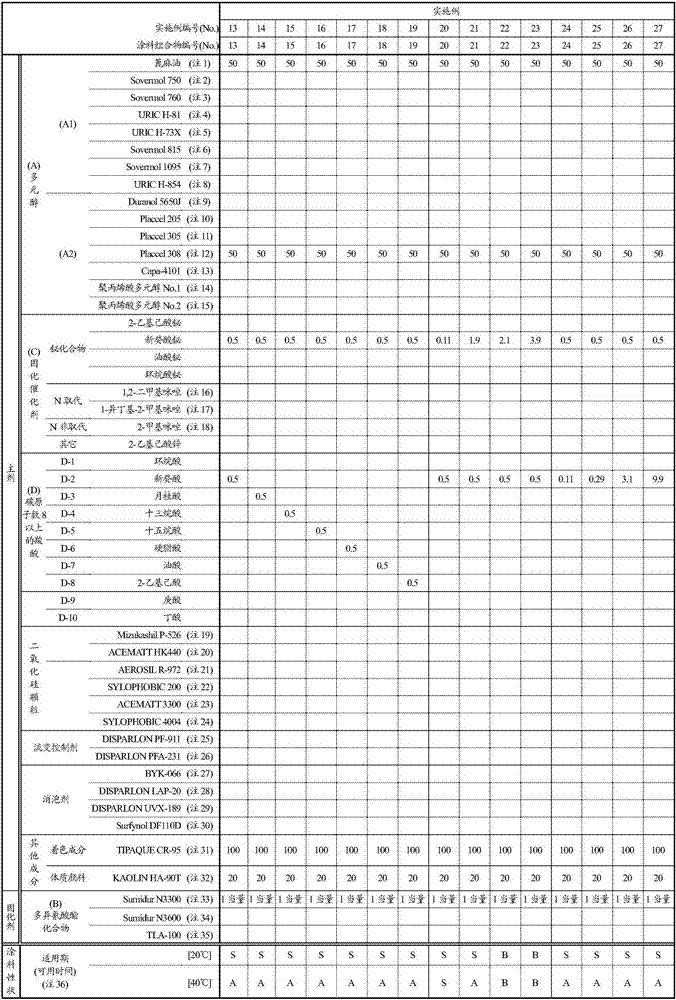

A coating composition and a coating film formation method

ActiveCN107298932AFor long-term storageImprove impact resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsCarboxylic acidFatty acid

The present invention provides a coating composition and a coating film formation method of the coating composition, which have extremely excellent storage stability and less dependency on the coating environment such as humidity after storage, and have excellent curability. The resulting coating film is excellent in impact resistance, bending resistance, water resistance and chemical resistance. The coating composition comprisses a polyol (A), a polyisocyanate compound (B), a curing catalyst (C), and a carboxylic acid (D) having 8 or more carbon atoms. The polyol (A) contains a polyol (A1) having a structural unit derived from a fatty acid having 8 or more carbon atoms. This component (C) contains a bismuth compound (C1)d. And the content of the component (D) is in the range of 0.1 part by mass to 10 parts by mass based on 100 parts by mass of the solid content of the polyol (A).

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com