Epoxy-group-containing solid resin, and preparation method and application thereof

A solid resin and epoxy-based technology, applied in coatings, powder coatings, etc., can solve problems such as hazards, sodium chloride production, and environmental pollution, and achieve environmental friendliness, low curing temperature, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

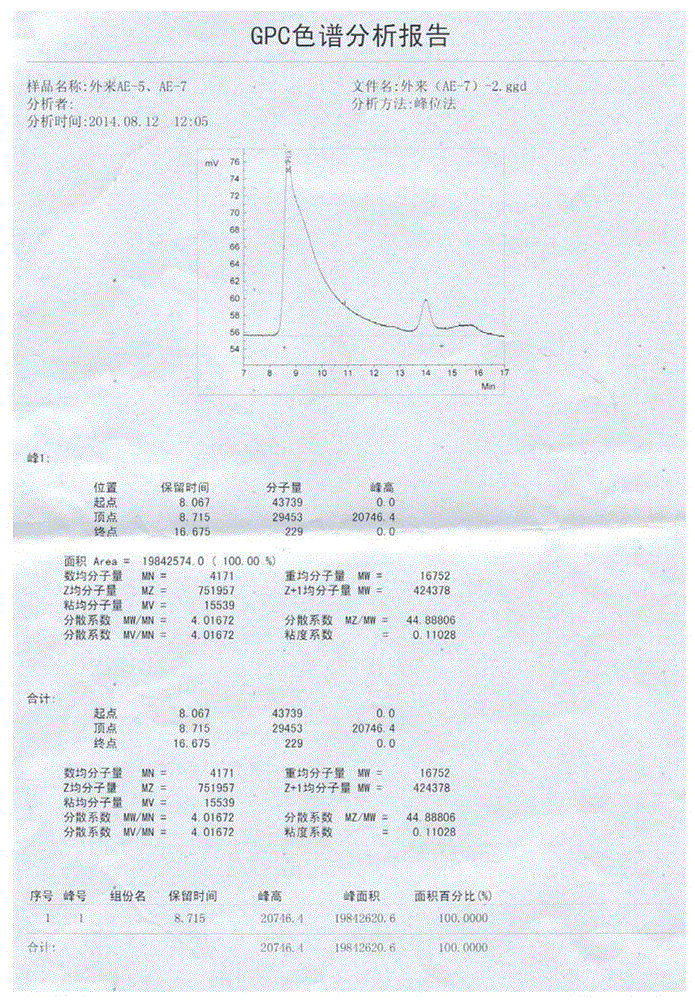

Image

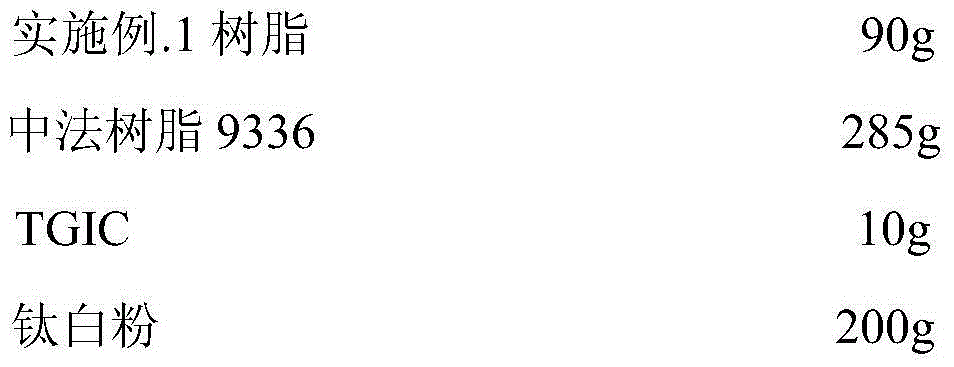

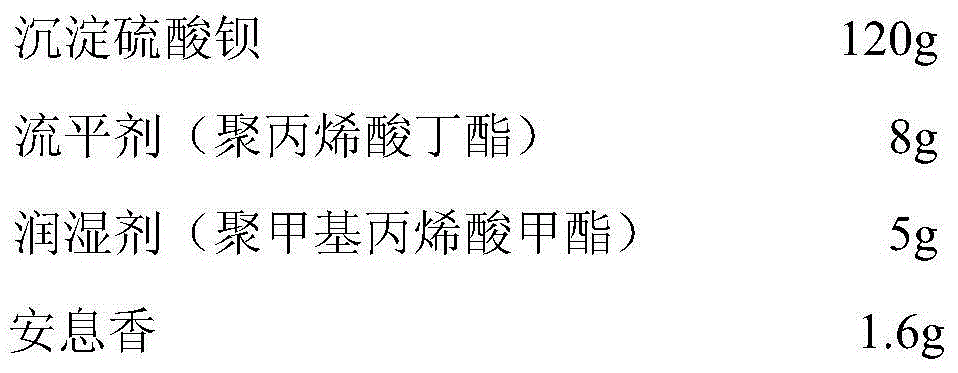

Examples

Embodiment 1

[0030] Toluene (260 g) and epoxidized soybean oil (10.7 g) were added to a 1000 mL glass multi-necked reaction flask equipped with a stirrer, thermometer, distillation column and two dropping funnels. Methyl methacrylate (218.4 g), n-butyl acrylate (68.9 g), glycidyl methacrylate (72.8 g), styrene (20.0 g) and chain regulator dodecyl were then added to a funnel. Mixture I of mercaptans (2.0 g). A mixture II of toluene (160.0 g) and the initiator dibenzoyl peroxide (14.0 g) was added to another funnel. Heat up the temperature and stir, open the distillation column to cool the water, add the mixed solution I and the mixed solution II dropwise at 100-105°C at the same time, and drop them completely within 1 hour. Then keep warm at 110-125°C for 3 hours. After the double bond is not reduced by infrared or chemical method, the temperature is raised to 170°C, and the vacuum is gradually evacuated. 30 minutes. In addition to the negative pressure, the material is discharged into a...

Embodiment 2

[0033] Toluene (300 g) and epoxidized soybean oil (150 g) were added to a 1000 mL glass multi-necked reaction flask with stirring, thermometer, distillation column and two dropping funnels. A mixture I of styrene (150 g), methyl methacrylate (156 g) and chain regulator tert-hexadecyl mercaptan (5.0 g) was then added to a funnel. Mixture II of toluene (160.0 g) and initiator azobisisobutyronitrile (14.0 g) was added to another funnel. Heat up the temperature and stir, open the distillation column to cool the water, add the mixed solution I and the mixed solution II dropwise at 80-95°C at the same time, and drop them completely within 1 hour. Then keep it warm at 115-125°C for 3 hours. After the double bond is not reduced by infrared or chemical method, heat up to 170°C, gradually vacuumize, change negative pressure to remove solvent, until 170°C / -0.09Mp above, keep 30 minutes. In addition to the negative pressure, the material is discharged into a stainless steel plate while ...

Embodiment 3

[0036] In a 1000 mL glass multi-necked reaction flask with stirring, thermometer, distillation column and two dropping funnels, add xylene (280 g) and epoxy linseed oil (70 g). Next, a mixture I of methyl methacrylate (280 g), n-butyl acrylate (70 g) and chain regulator n-dodecyl mercaptan (3.0 g) was added to a funnel. A mixture II of xylene (160.0 g) and initiator dibenzoyl peroxide (21 g) was added to another funnel. Heat up and stir, turn on the distillation column to cool water, add the mixed solution I and the mixed solution II dropwise at 105-120°C at the same time, the two are dropped simultaneously within 1 hour, and the temperature at the top of the distillation column does not exceed 30°C. Then keep warm at 125-130°C for 3 hours. After the double bond is not reduced by infrared or chemical method, the temperature is raised to 170°C, and the vacuum is gradually pumped, and the negative pressure is used to remove the solvent until it is above 170°C / -0.09Mp. 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com