Preparation method of special-purpose nanometer modifier of water-based coating

A technology for water-based coatings and modifiers, which can be used in coatings, fibrous fillers, dyed polymer organic compounds, etc., to solve problems such as market confusion, and achieve good performance stability, good storage stability, and good dispersion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

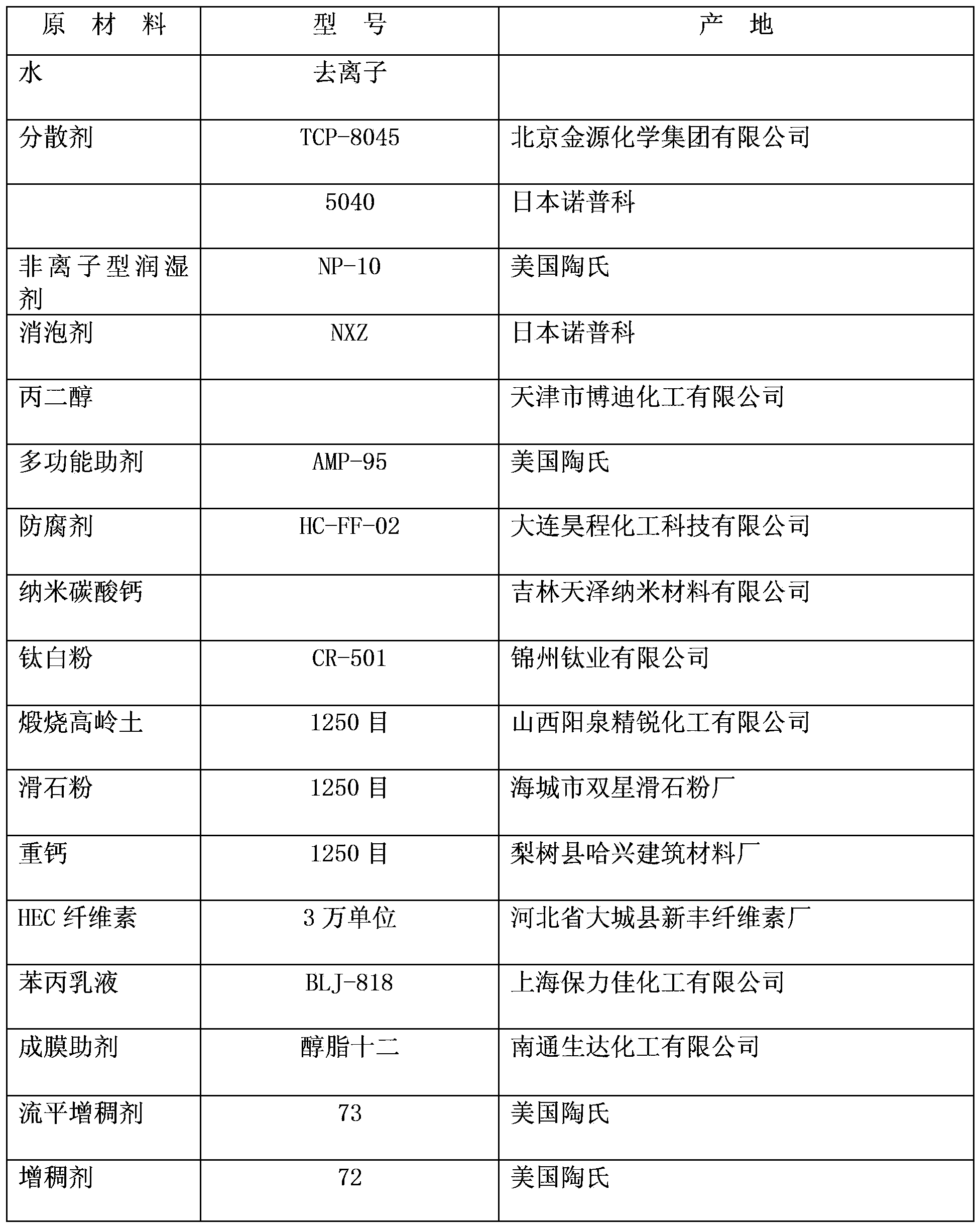

[0037] Embodiment 1: A certain amount of nano-calcium carbonate powder meeting the above requirements is made into a slurry with a mass fraction of 15%, put into a constant temperature water bath for heating, and after reaching a predetermined temperature of 60°C, the Under the stirring speed, slowly add the prepared 1.2% modifier into the slurry within 5 minutes. After stirring for 0.5 hours, cool the modified slurry to room temperature, put it in a container, and seal it for storage.

Embodiment 2

[0038] Embodiment 2: A certain amount of nano-calcium carbonate powder meeting the above requirements is made into a slurry with a mass fraction of 20%, put into a constant temperature water bath for heating, and after reaching a predetermined temperature of 65°C, the slurry is heated at 300 rpm. Under the stirring speed, slowly add the prepared modifier with a ratio of 1.5% into the slurry within 5 minutes. After stirring for 1 hour, cool the modified slurry to room temperature, put it in a container, and seal it for storage.

Embodiment 3

[0039] Embodiment 3: A certain amount of nano-calcium carbonate powder meeting the above requirements is made into a slurry with a mass fraction of 25%, put into a constant temperature water bath for heating, and after reaching a predetermined temperature of 70°C, at a speed of 300 revolutions per minute Under the stirring speed, slowly add the prepared modifier with a ratio of 1.8% into the slurry within 5 minutes. After stirring for 1.5 hours, cool the modified slurry to room temperature, put it in a container, and seal it for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com