A coating composition and a coating film formation method

A composition and coating technology, used in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., can solve the balance between storage stability and curability, as well as insufficient water resistance and chemical resistance, Insufficient curability, etc., to achieve the effect of excellent chemical resistance, excellent curability, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

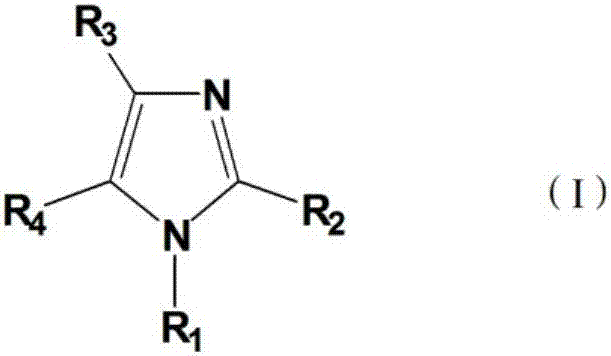

Method used

Image

Examples

Embodiment 1

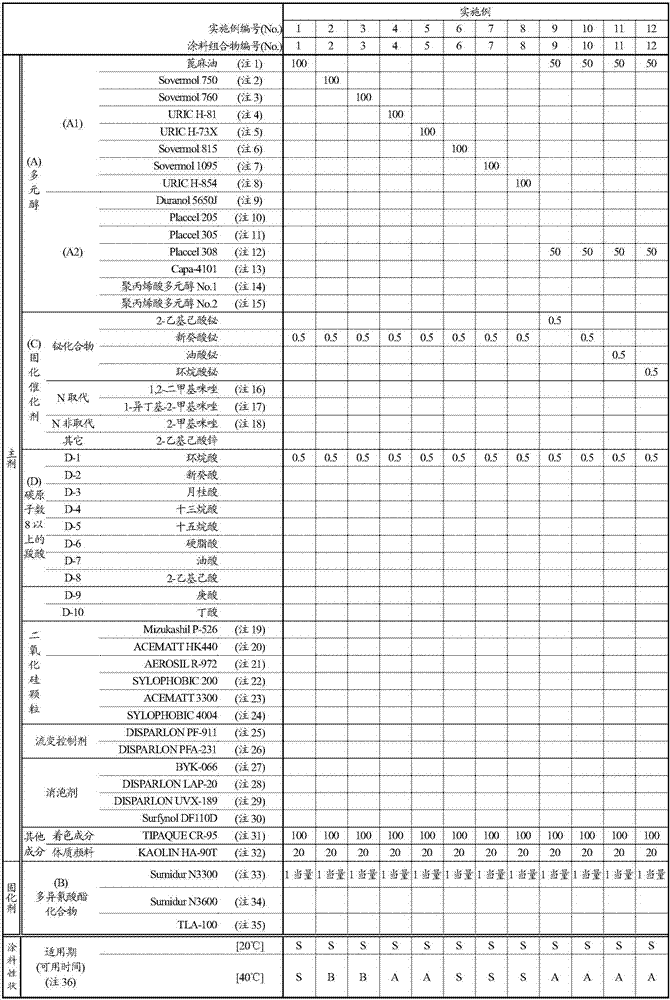

[0216] 100 parts of castor oil (Note 1), 100 parts of TIPAQUE CR-95 (Note 30), 20 parts of HA-90T (Note 31), and 37.5 parts of butyl acetate were mixed and dispersed by a sand mill to obtain a dispersion paste. In the obtained dispersion paste, 0.5 part of bismuth neodecanoate, 0.5 part of naphthenic acid, and Sumidur N3300 (Note 33) of 1 equivalent to the hydroxyl group in castor oil were mixed, and butyl acetate was added so that the solid content reached 80%. The ester was stirred, thereby obtaining coating composition No. 1. The coating workability (pot life) (Note 36) test described later was performed on the obtained coating composition No. 1. The evaluation results are shown in Table 1.

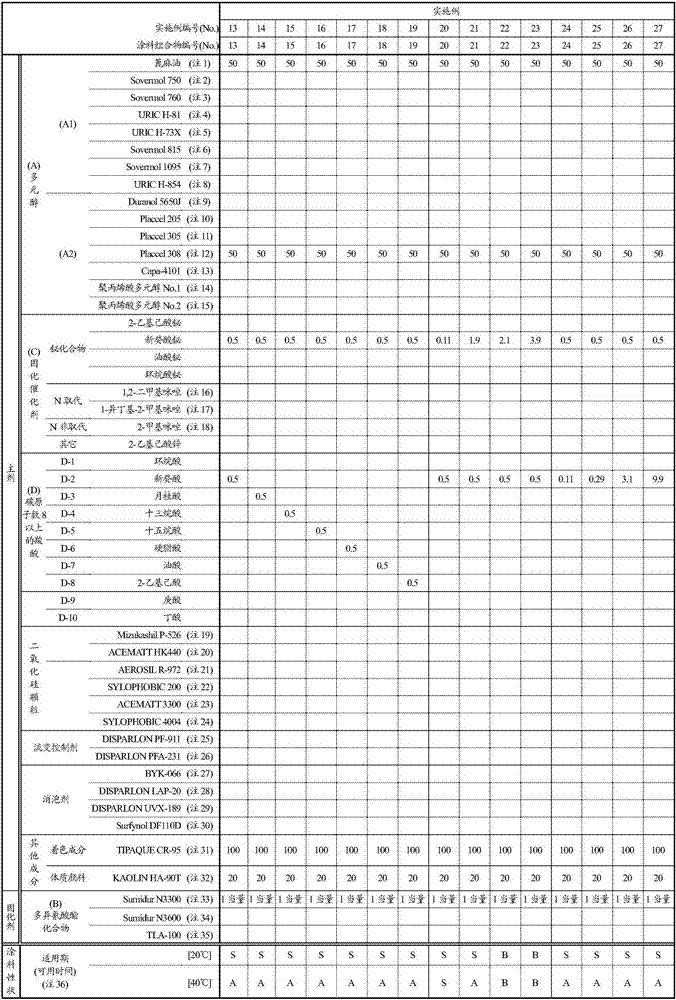

Embodiment 2~72、 comparative example 1~12

[0218] Except that the compounding of each component in Example 1 was set to the compounding shown in Tables 1 to 6, the same operations as in Example 1 were performed to obtain coating composition Nos with a solid content of 80% shown in Tables 1 to 6 .2~No.83. In addition, among the components in Tables 1 to 6, the compounding amount of a substance in which the solid content or the effective ingredient content is described in the "Note" described later indicates the compounding amount (mass part) of the solid content or the effective ingredient.

[0219] Table 1

[0220]

[0221] Table 2

[0222]

[0223] table 3

[0224]

[0225] Table 4

[0226]

[0227] table 5

[0228]

[0229] Table 6

[0230]

[0231] The "Note" in the table is as follows.

[0232] (Note 1) Castor oil: hydroxyl value 160mgKOH / g, castor oil polyol, primary hydroxyl content: secondary hydroxyl content=0:100;

[0233] (Note 2) Sovermol 750: product name, manufactured by BASF company, hydroxyl value 315mgKOH / g, polyol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com