Patents

Literature

43 results about "Environmental impact reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Avoiding meat and dairy products is the single biggest way to reduce your environmental impact on the planet, according to the scientists behind the most comprehensive analysis to date of the damage farming does to the planet.

Hybrid natural-fiber composites with cellular skeletal structures

InactiveUS20050013982A1Easily and economically fabricatedStrutsConstruction materialEngineeringNatural fiber

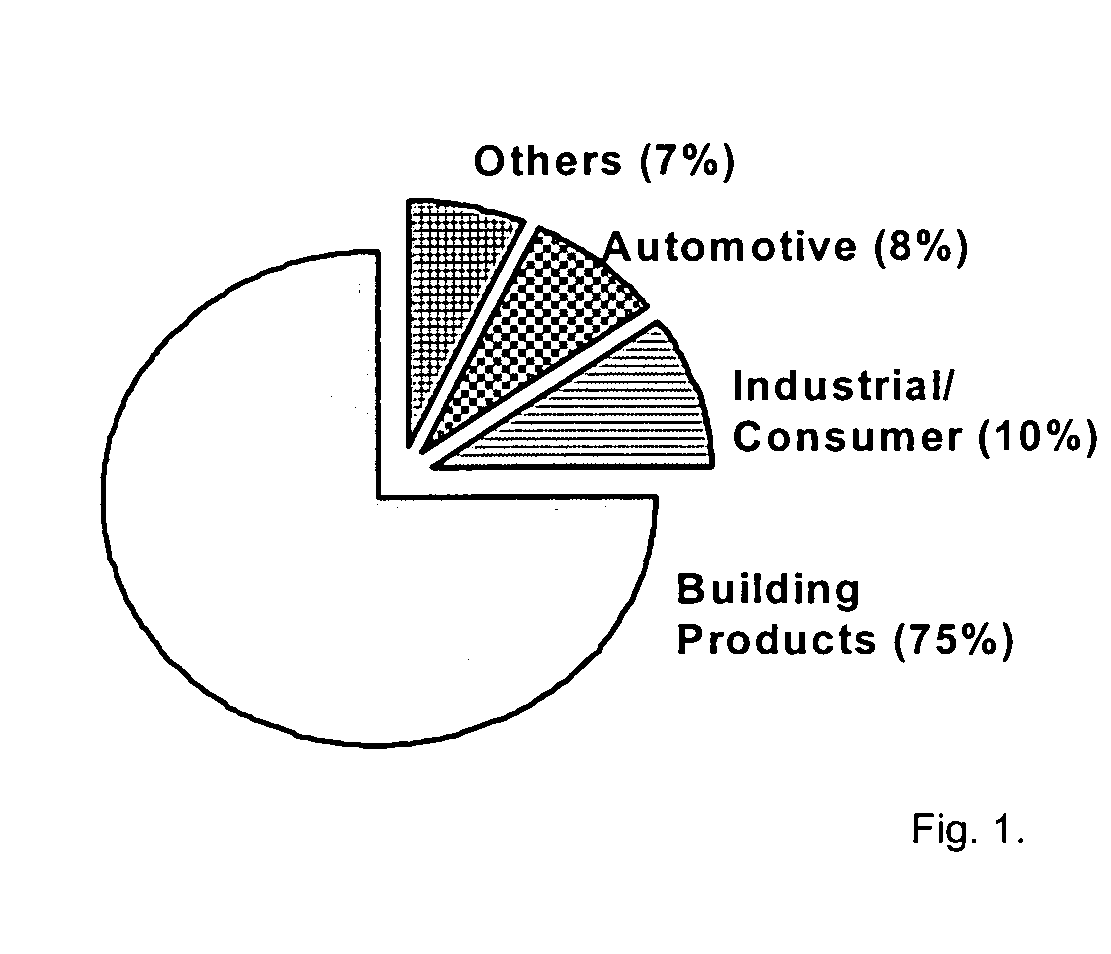

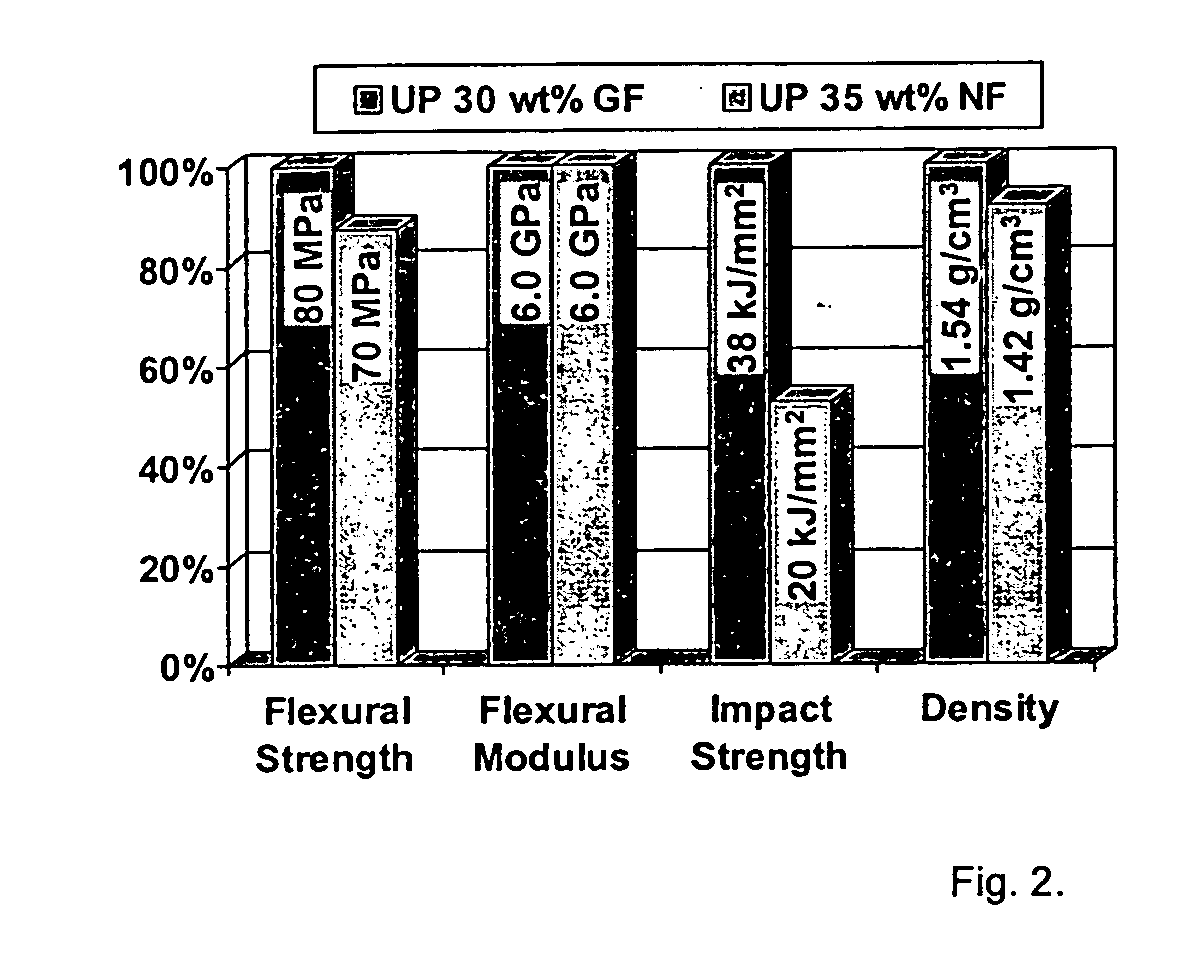

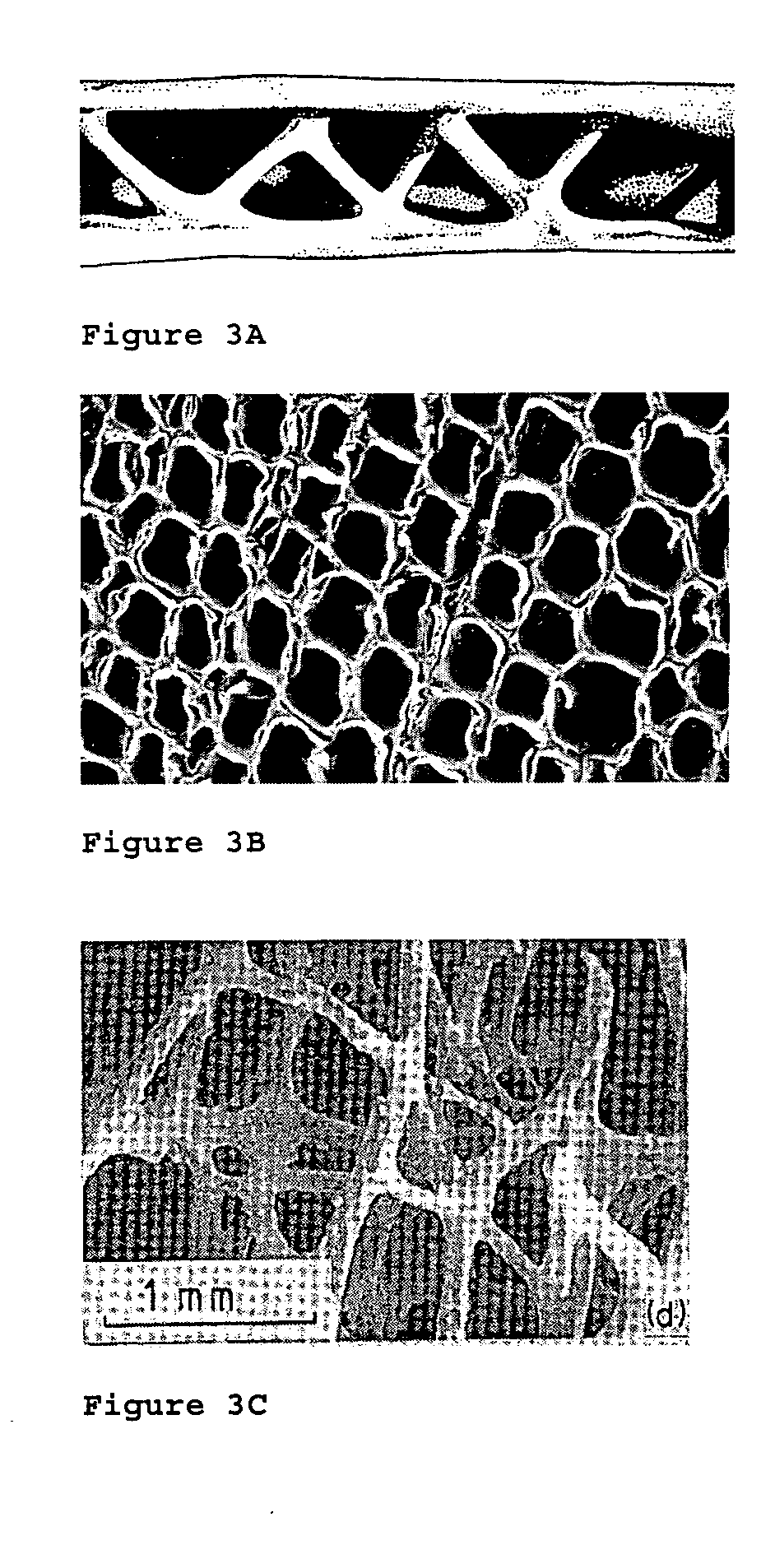

The present invention relates to composite structural members comprising polymers, natural and synthetic fibers, and nano-scale platelets arranged in two- or three-dimensional cellular skeletal structure; more particularly referring to a low-cost natural-fiber based structural member with material hybridization and material layout for improved behavior that leads to efficient structural beam and plate / panel components that can be used in a plurality of modular structures, resulting in lower cost and reduced environmental impact.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

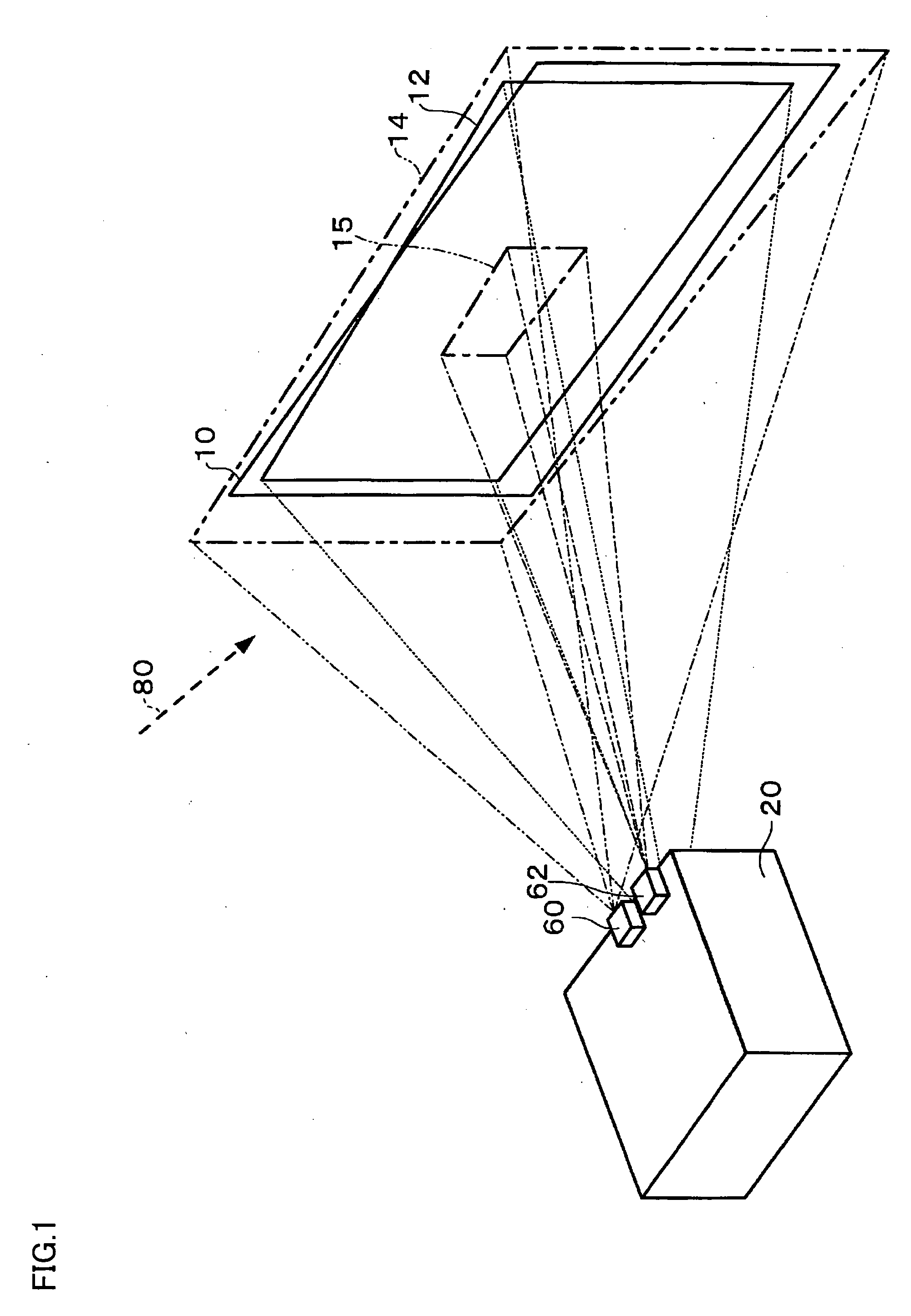

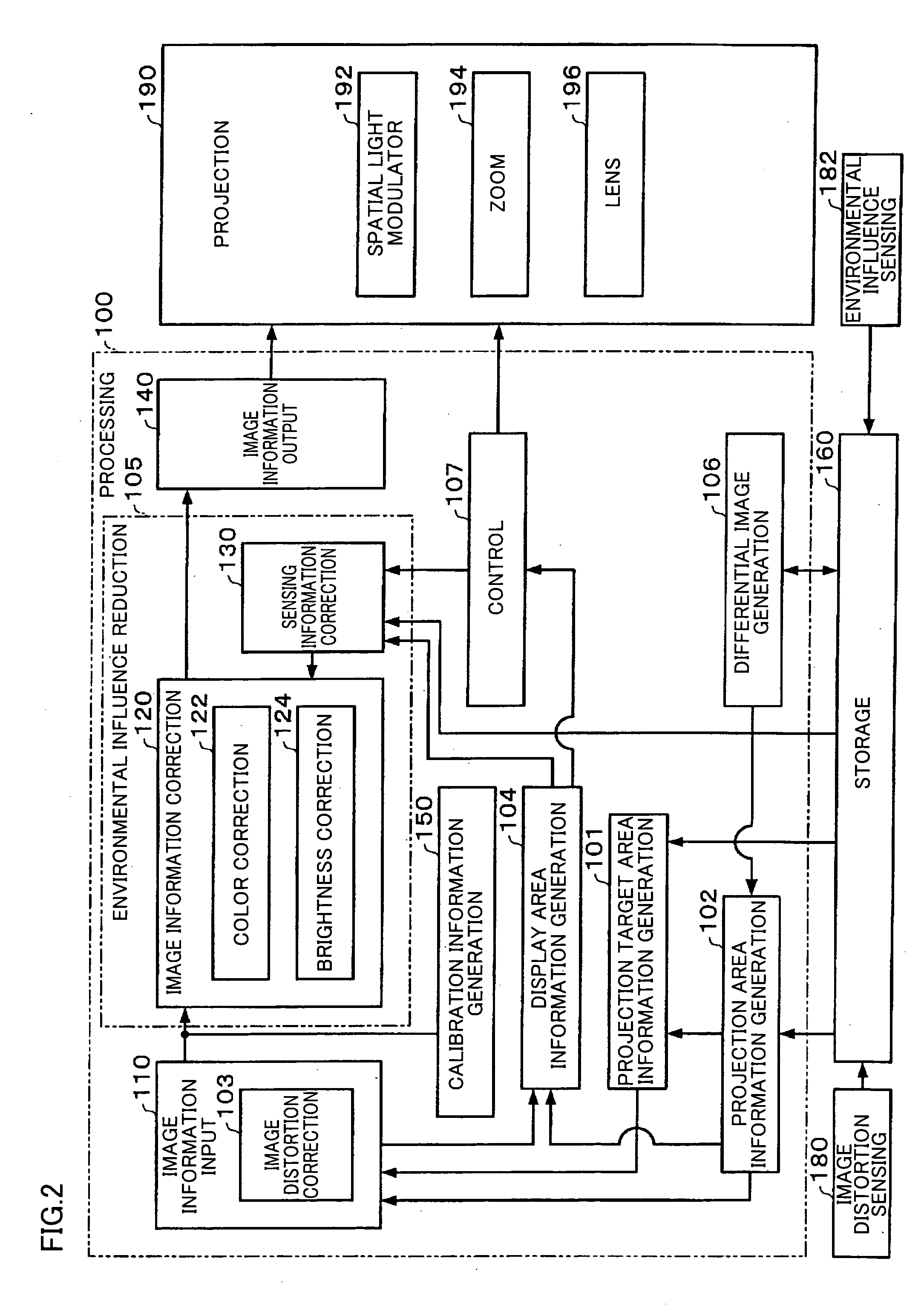

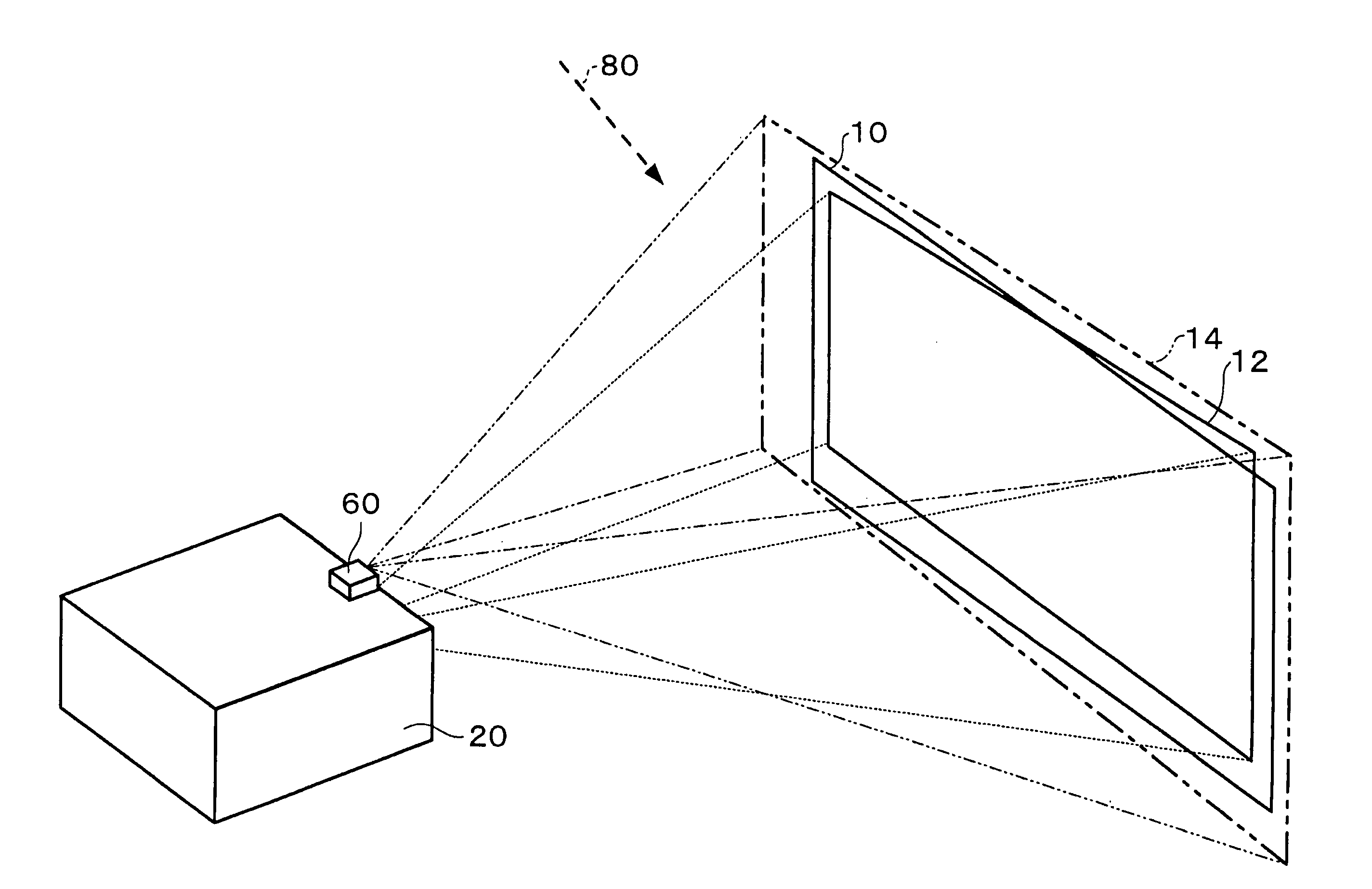

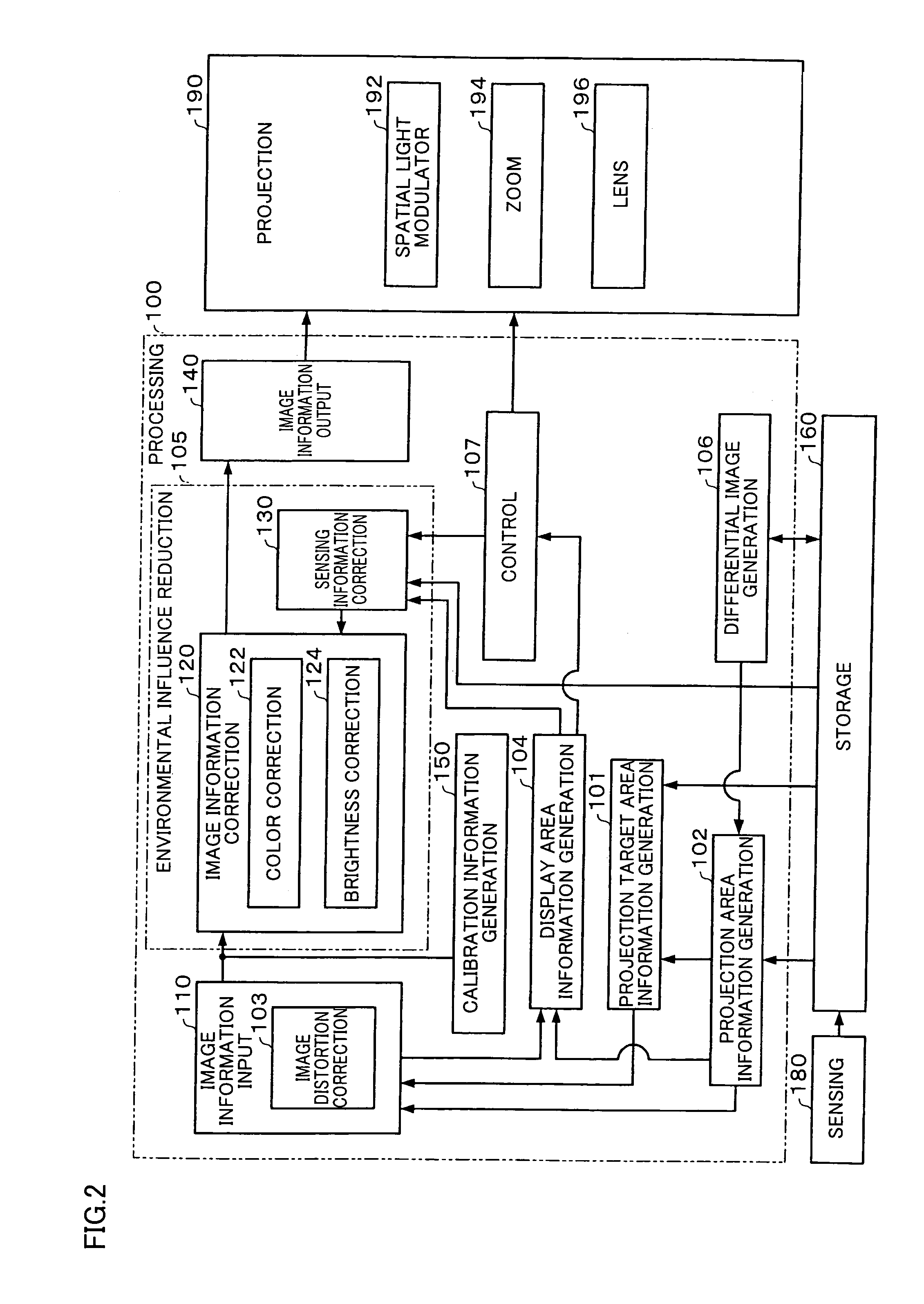

Image processing system, projector, and image processing method

InactiveUS20060181686A1Reduce processEasy to handleProjectorsColor television detailsImaging processingEnvironment effect

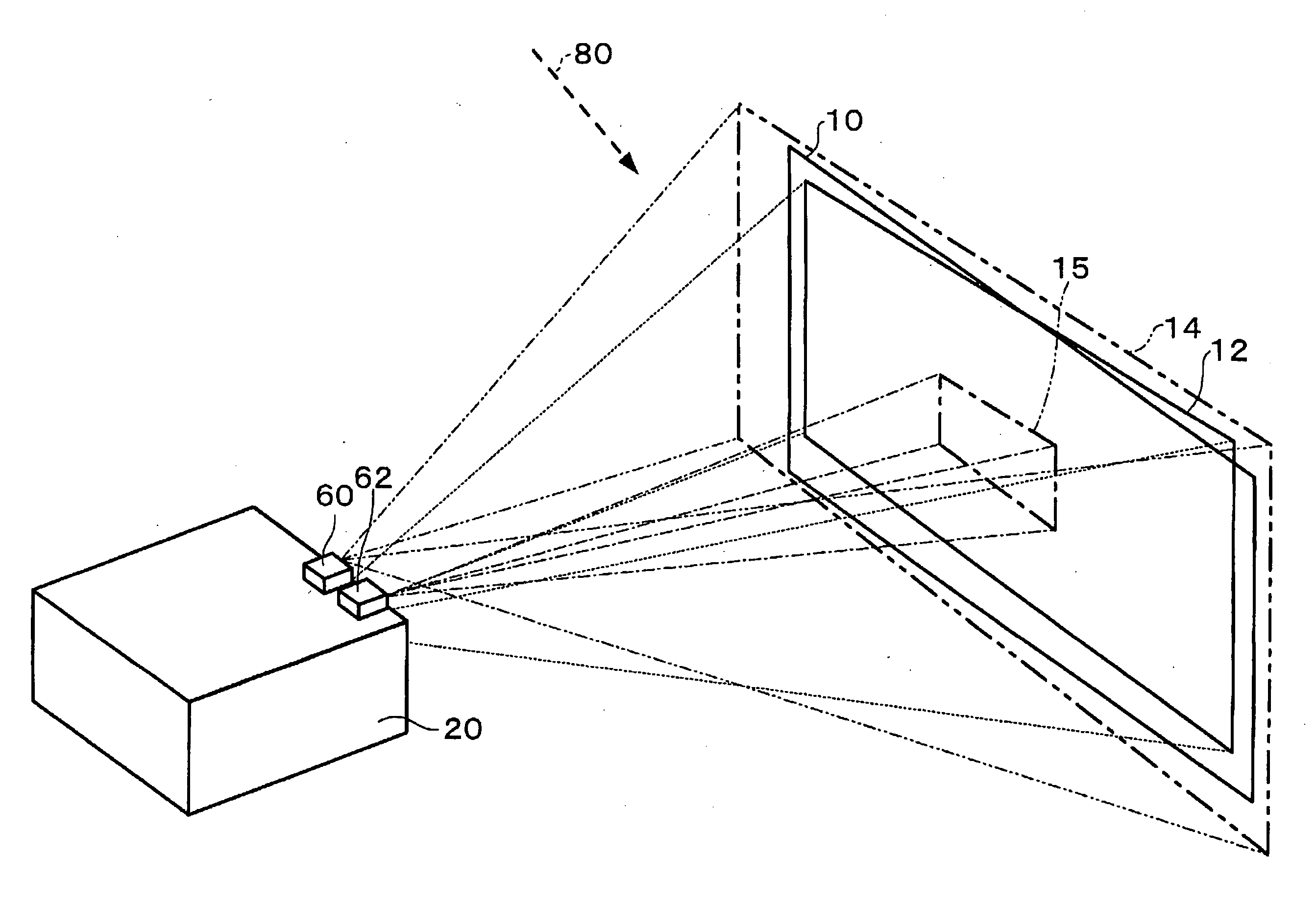

A projector includes an image distortion sensing section which generates image distortion sensing information, an environmental influence sensing section which generates environmental influence sensing information, a projection area information generation section which generates projection area information, an image distortion correction section which corrects distortion of a projection image and generates correction information indicating the degree of correction, a display area information generation section which generates display area information indicating the display area of the projection image after distortion correction based on the projection area information and the correction information, an environmental influence reduction section which performs processing of reducing environmental influence, a projection section which projects the projection image, and a differential image generation section which generates a differential image.

Owner:SEIKO EPSON CORP

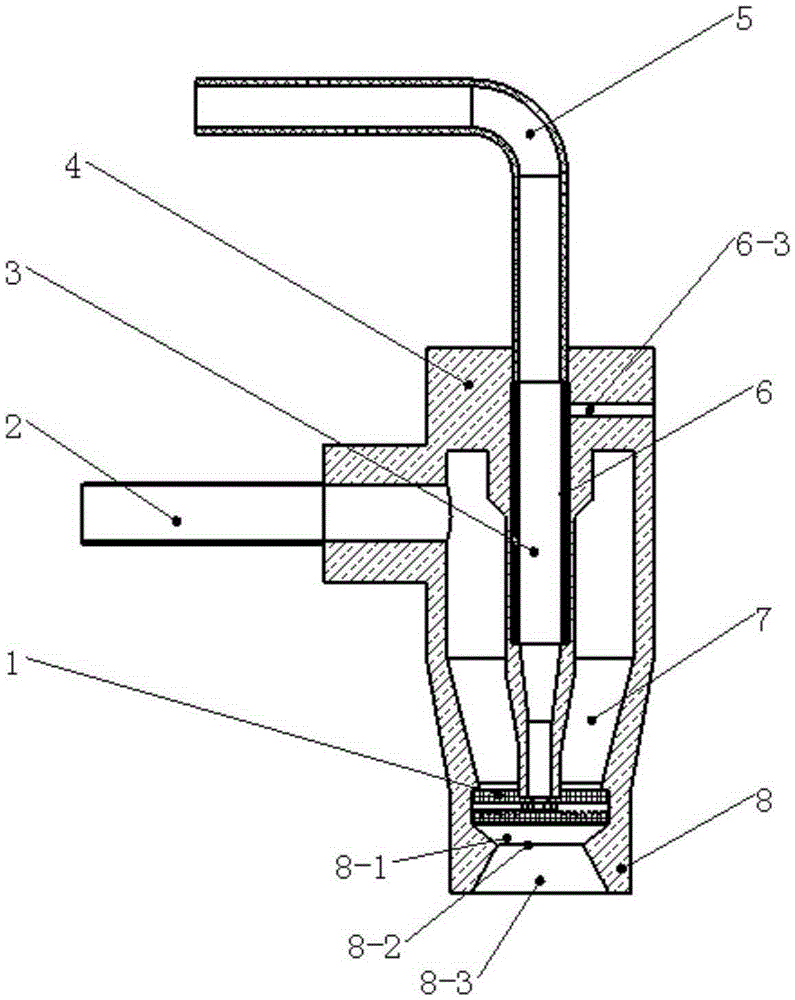

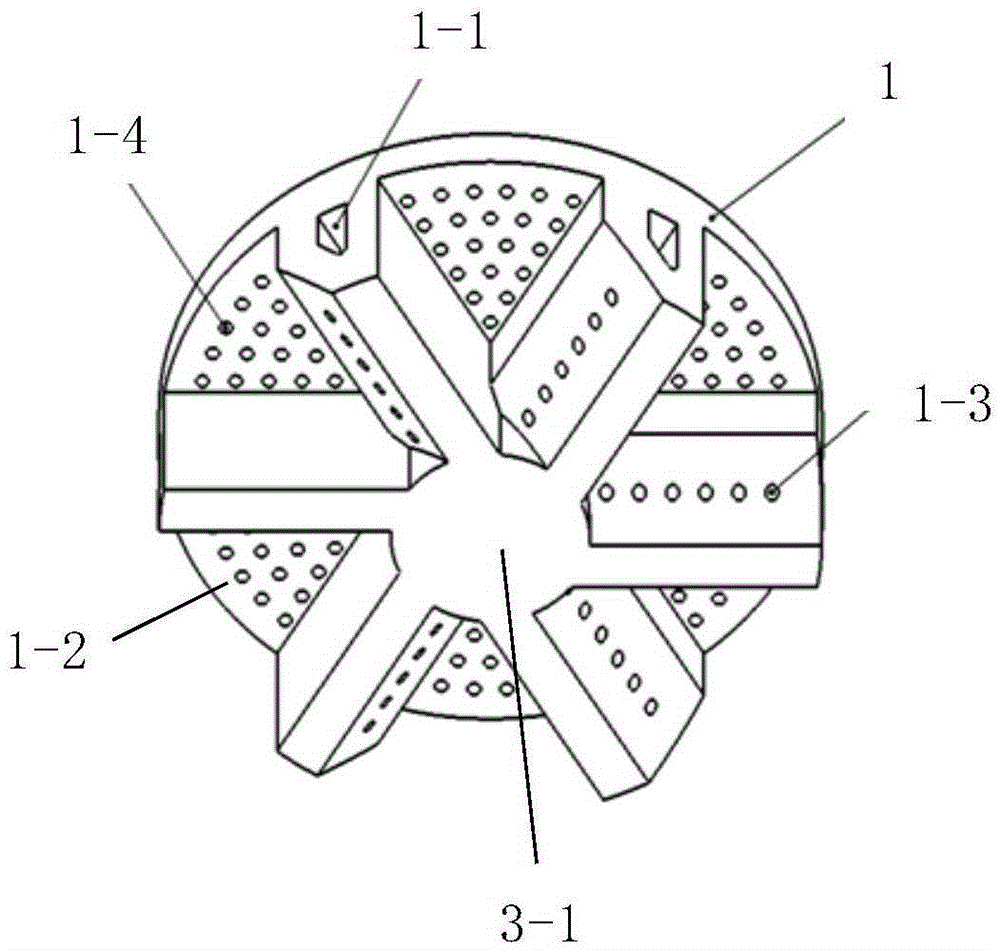

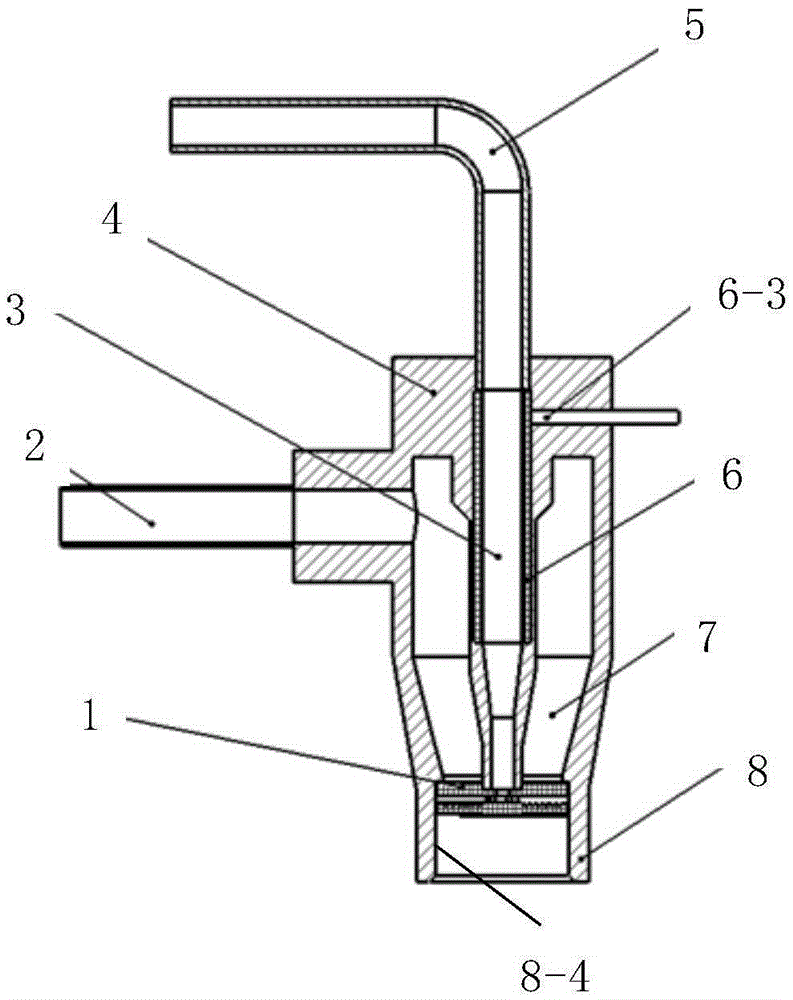

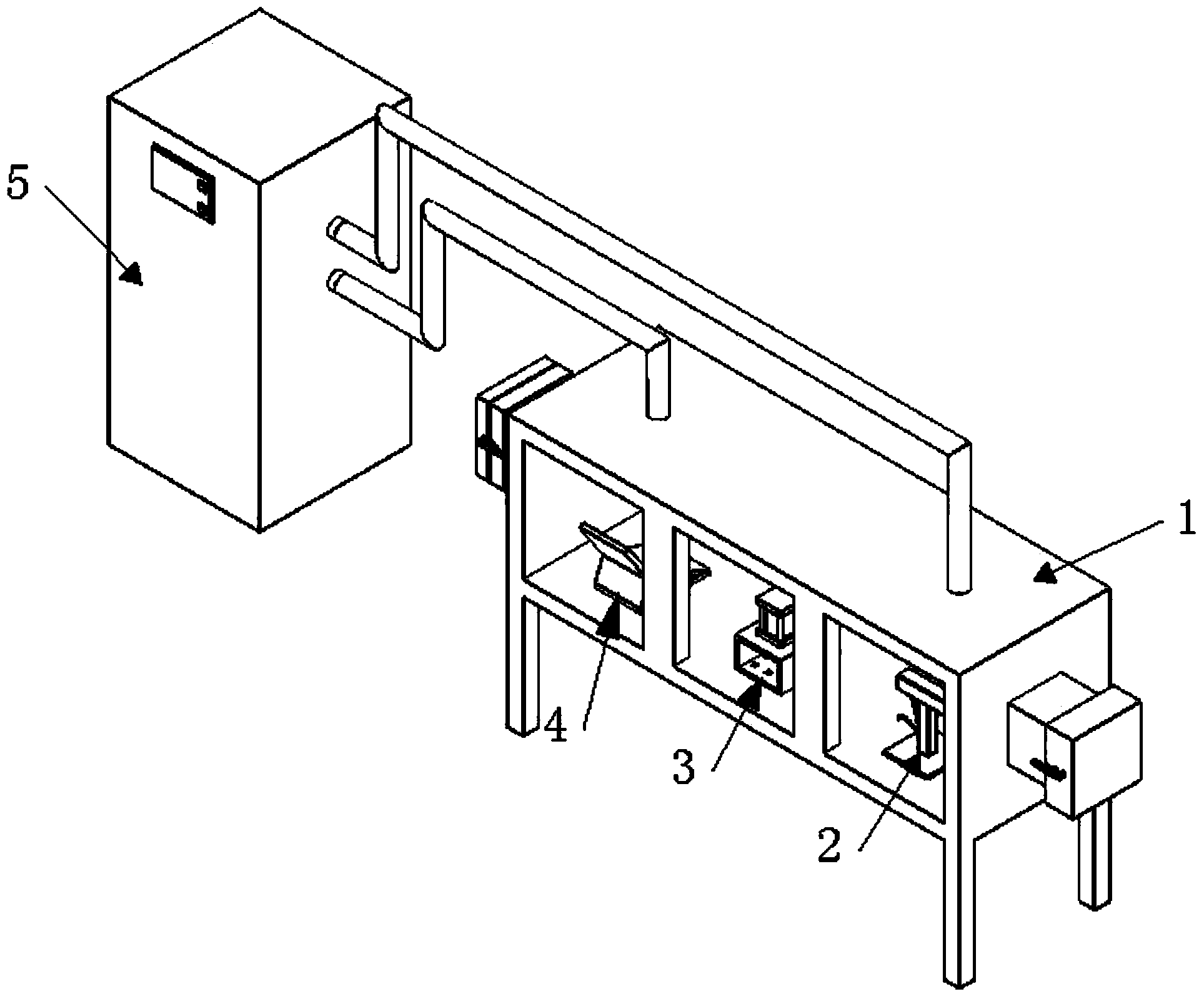

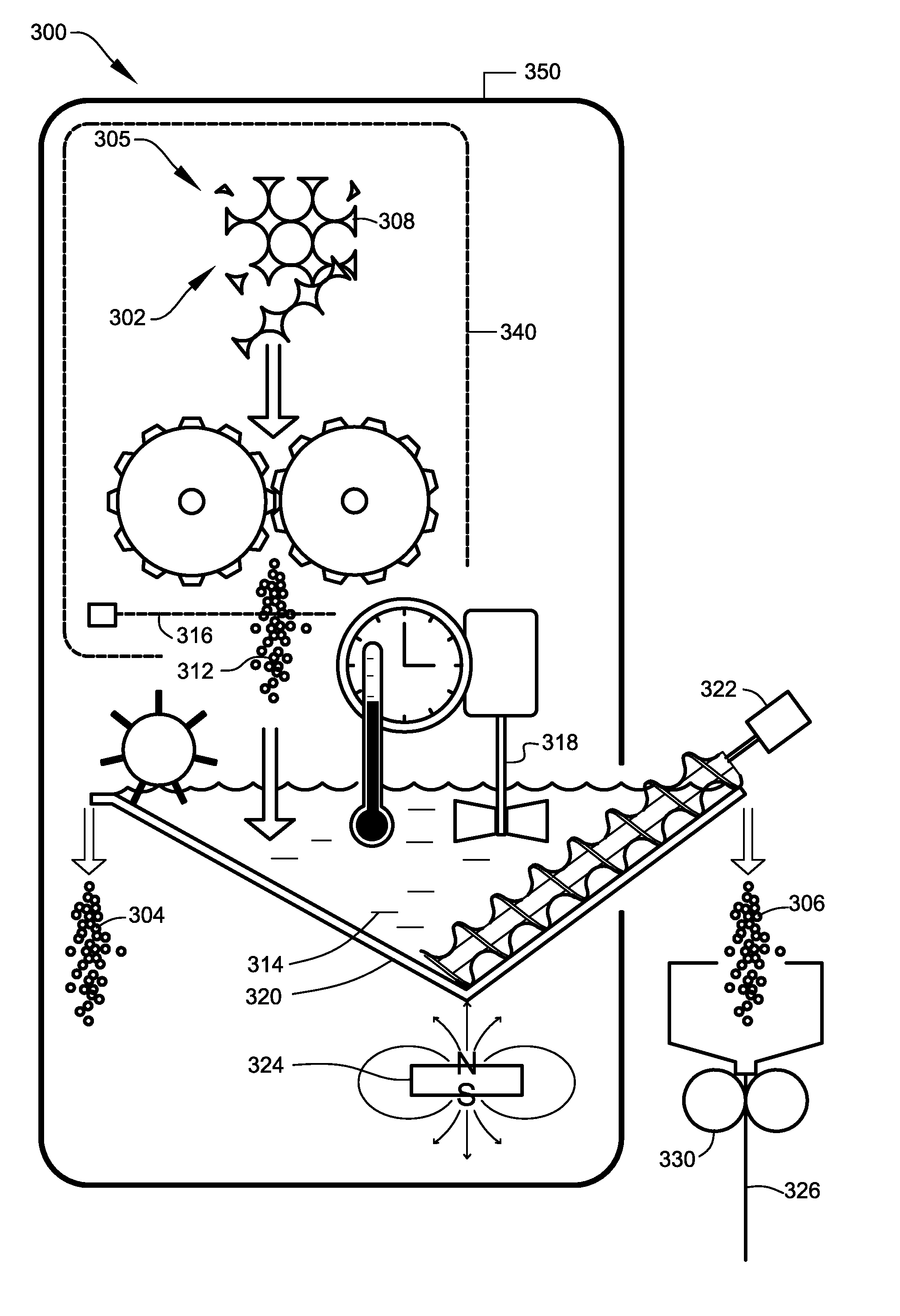

Ultrasonic or mega-sonic oscillatory two-phase-flow atomization washing device and ultrasonic or mega-sonic oscillatory two-phase-flow atomization washing method

InactiveCN105414084AHigh speedSmall particlesSemiconductor/solid-state device manufacturingLiquid spraying apparatusSpray nozzleAcoustic wave

The invention discloses an ultrasonic or mega-sonic oscillatory two-phase-flow atomization washing device and an ultrasonic or mega-sonic oscillatory two-phase-flow atomization washing method. An ultrasonic wave generation unit or a mega-sonic wave generation unit is arranged inside a nozzle main body and along the surface of the inner wall of a liquid pipeline; by generation of ultrasonic or mega-sonic oscillation, the ultrasonic or mega-sonic energy is transmitted into washing liquid which the energy passes through, so that atomized particles formed by intersection of the washing liquid ejected from a liquid guide outlet and air ejected from an air guide outlet below a gas-liquid guide component are enabled to have ultrasonic or mega-sonic energy and are downwards ejected towards a wafer surface under the acceleration or vertical guidance effect of an atomized particle guide outlet so as to realize ultrasonic or mega-sonic atomization washing; damages caused to a graphic structure of the wafer surface are effectively controlled; the removal efficiency of particle pollutants on the wafer surface is improved; the process time is shortened; the amount of washing liquor and high-purity gas is reduced; the production cost is lowered; environmental influences are reduced.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

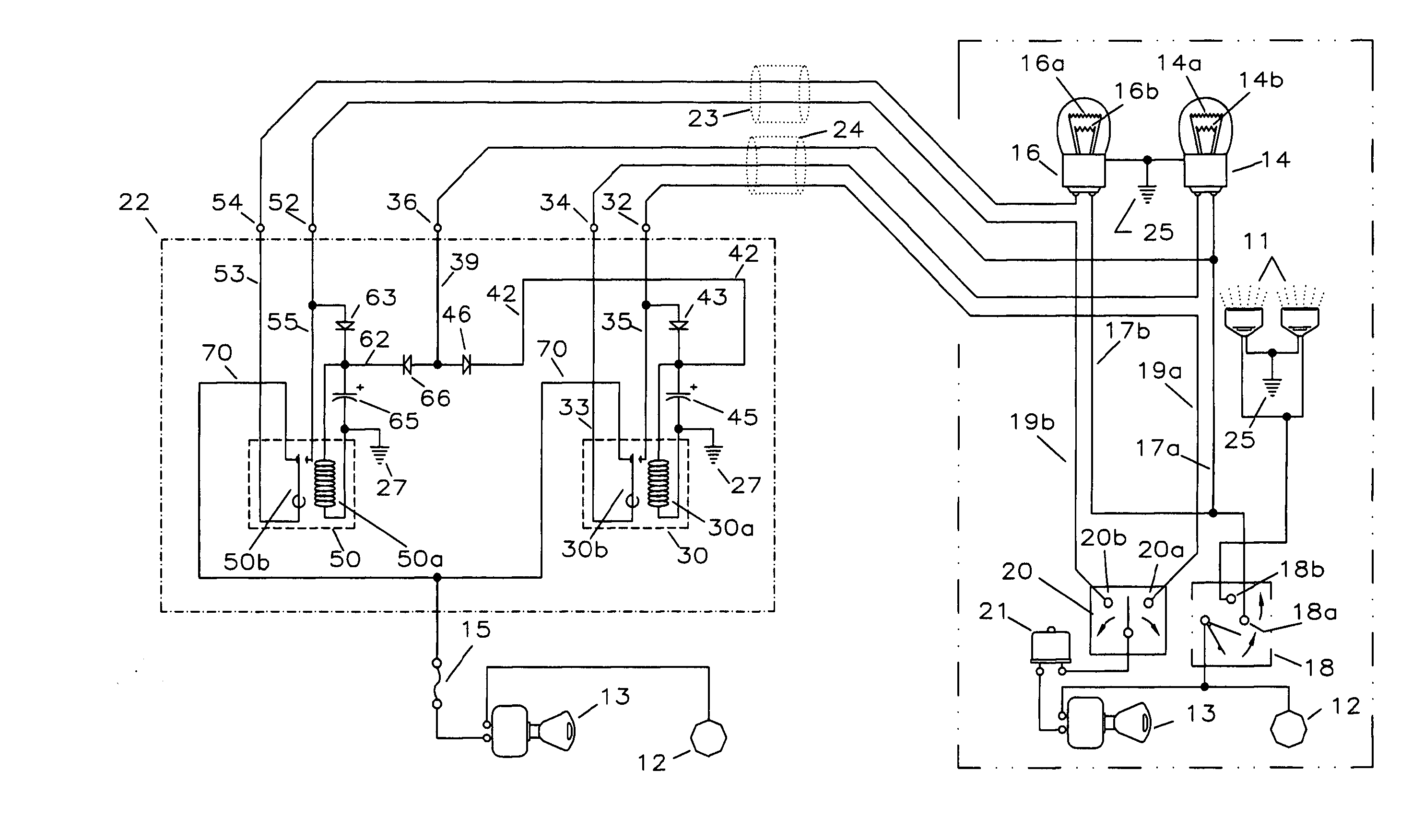

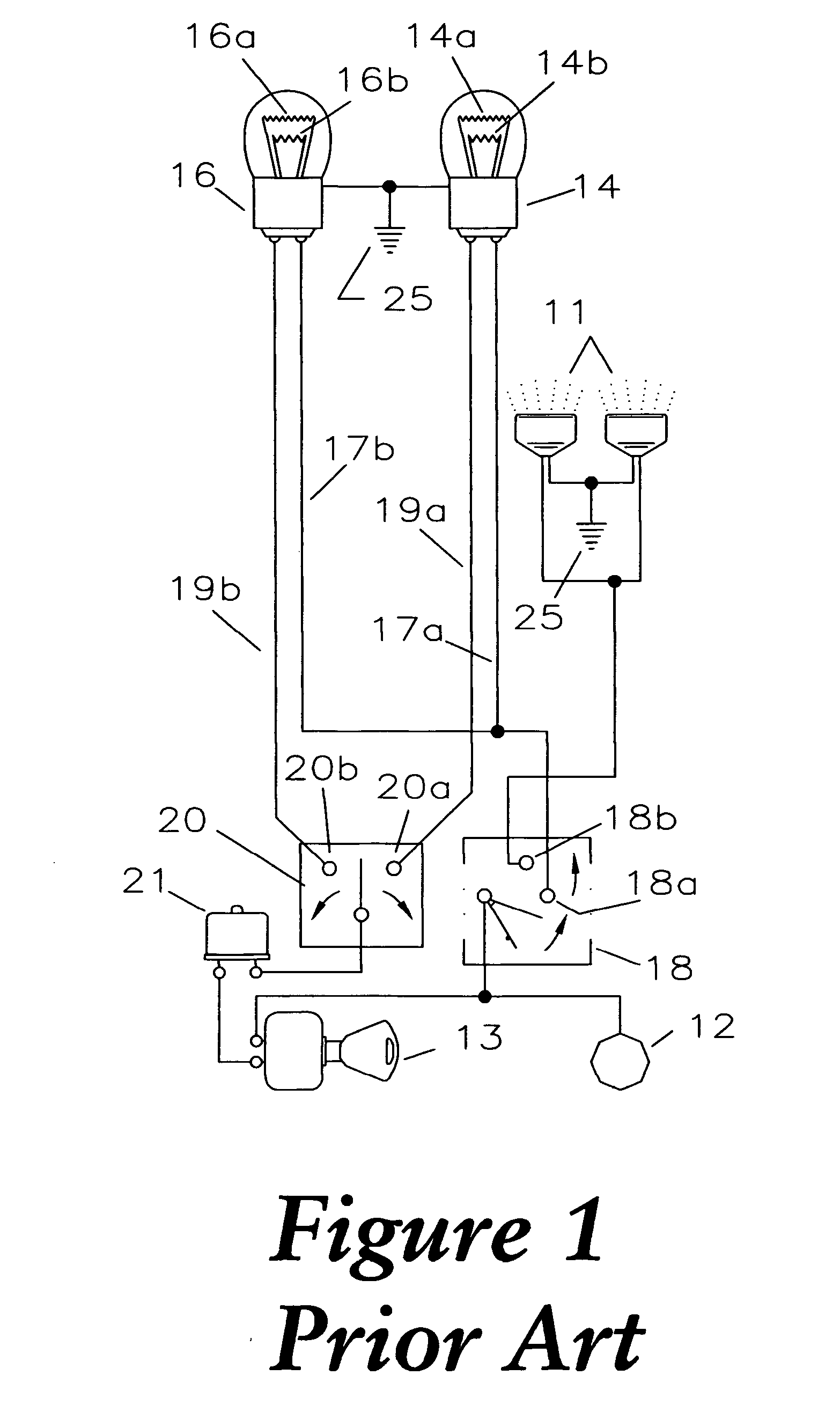

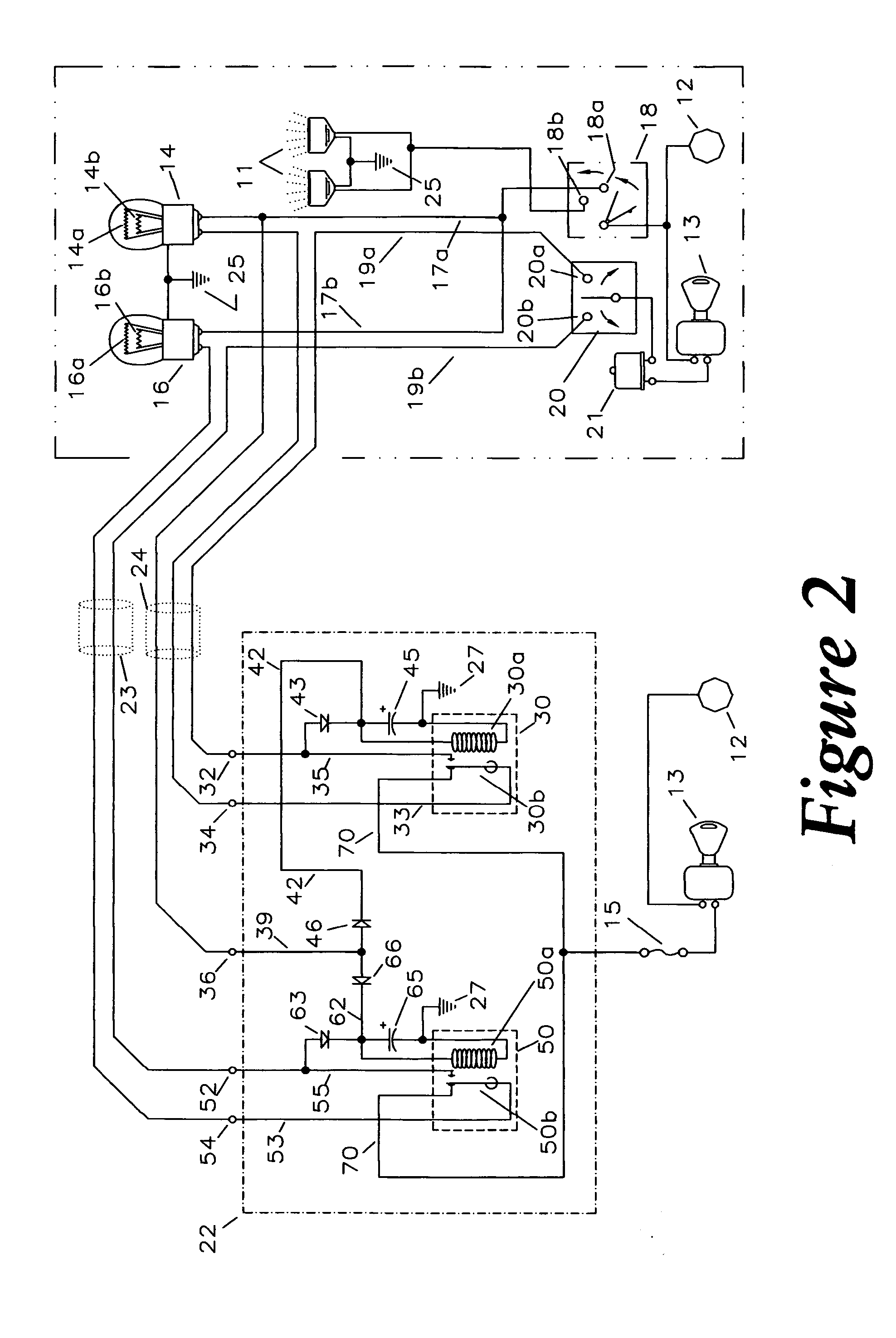

Directional lamp daytime running light module and vehicular turn signal control system

A vehicular lighting control system for controlling the illumination of a vehicle's external directional / turn signaling and / or hazard lighting, by controlling continuous illumination of pairs of the brightest filaments of single or dual filament bulb designed vehicles. The system controls to operate the brightest filaments when the operator wishes to draw attention to the vehicle for safety, or for visibility purposes, without the same system negatively affecting normal operation of existing turn signal / hazard warning systems. The system automatically and manually controls the light output as desired by the vehicle operator, incorporates the vehicle's internal turn signal bulb-failure indication subsystem to continuously monitor the target bulbs for any failure event, and employs a dynamic safety reconnect feature, an attribute which reconnects factory wiring with factory bulbs instantaneously with any signaling or hazards activation. The device employs a zero-system current drain, actual dual bulb activation / current consumption notwithstanding, for minimum environmental impact / maximum fuel conservation.

Owner:KESTERSON RAYMOND

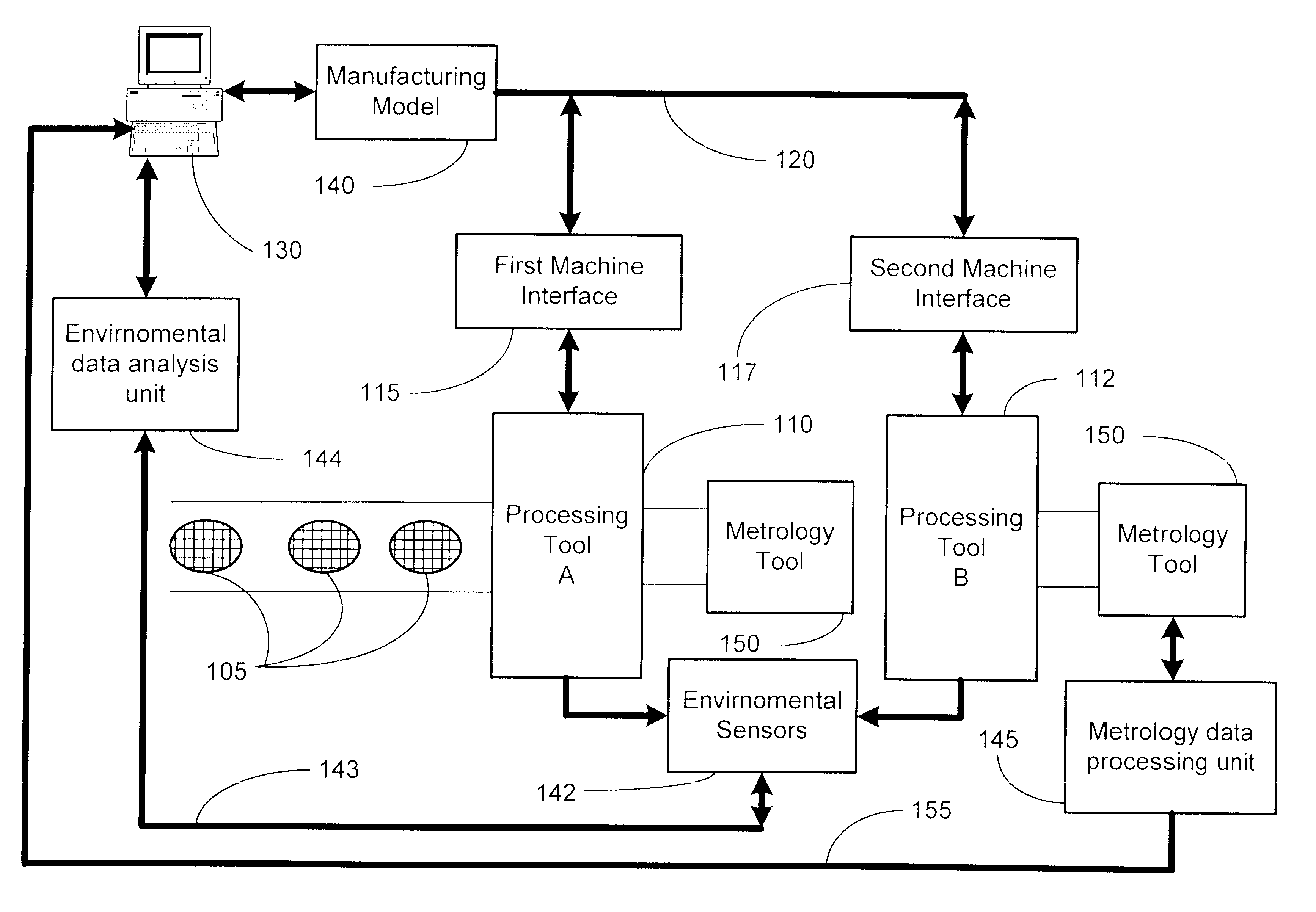

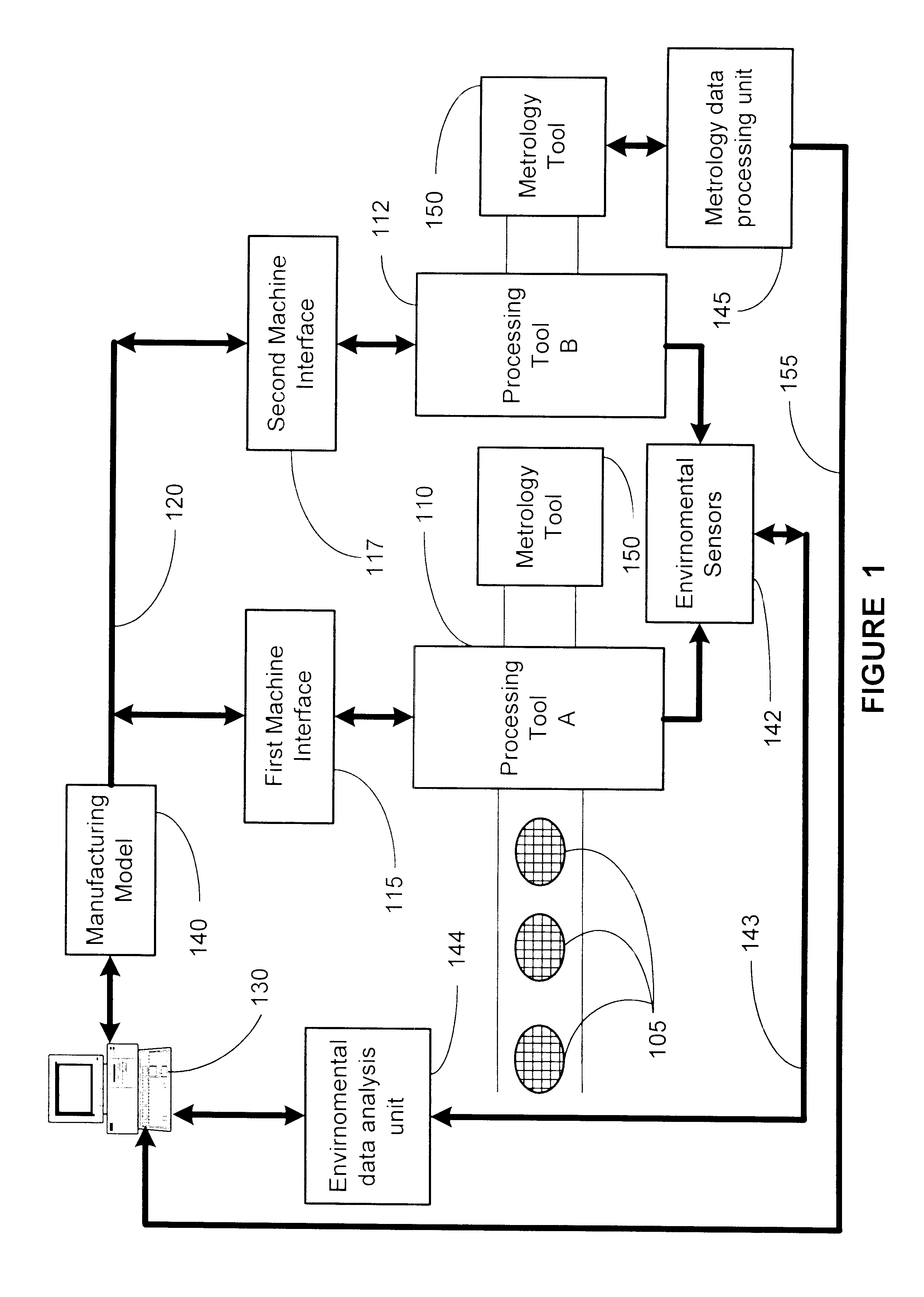

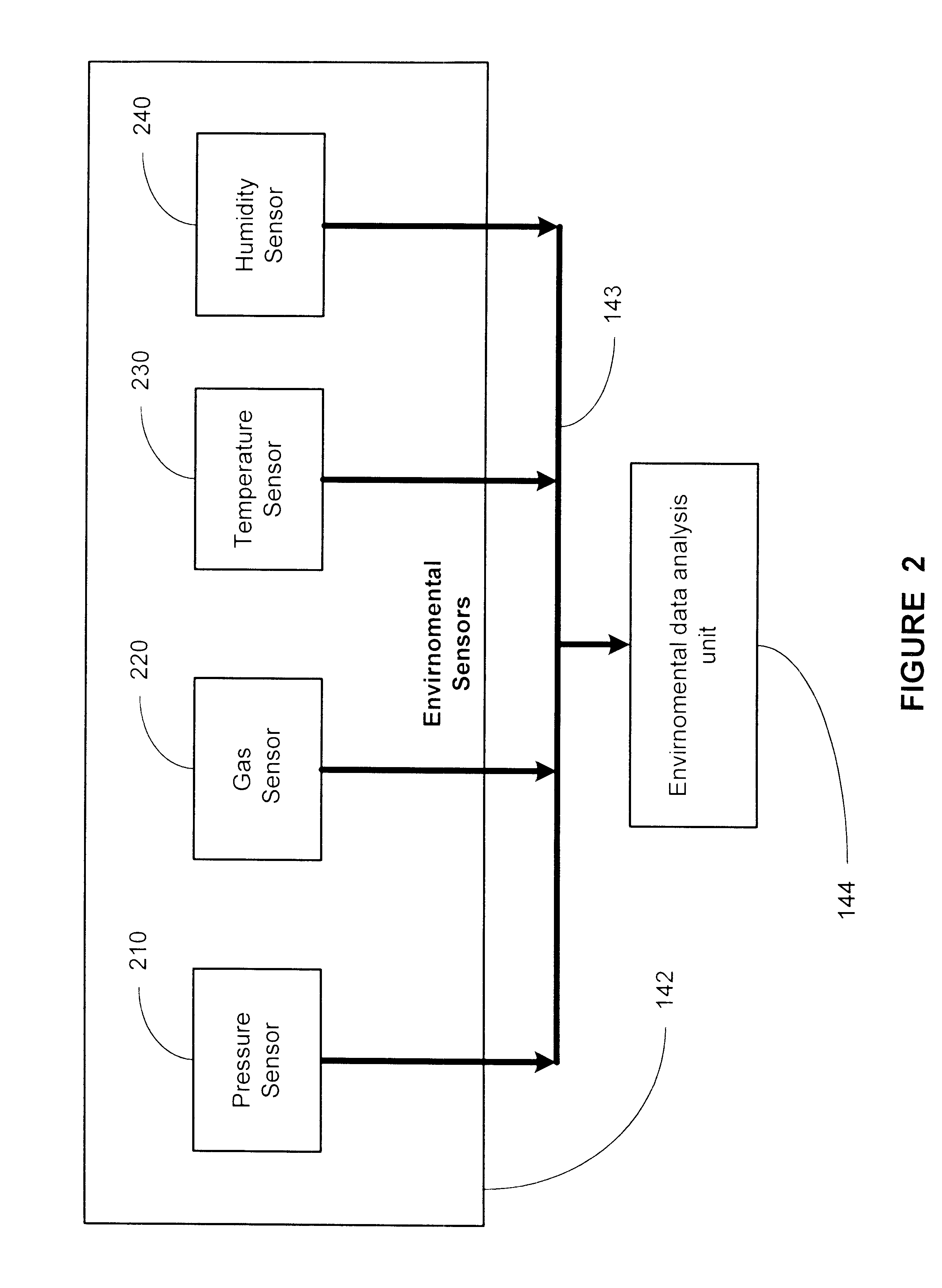

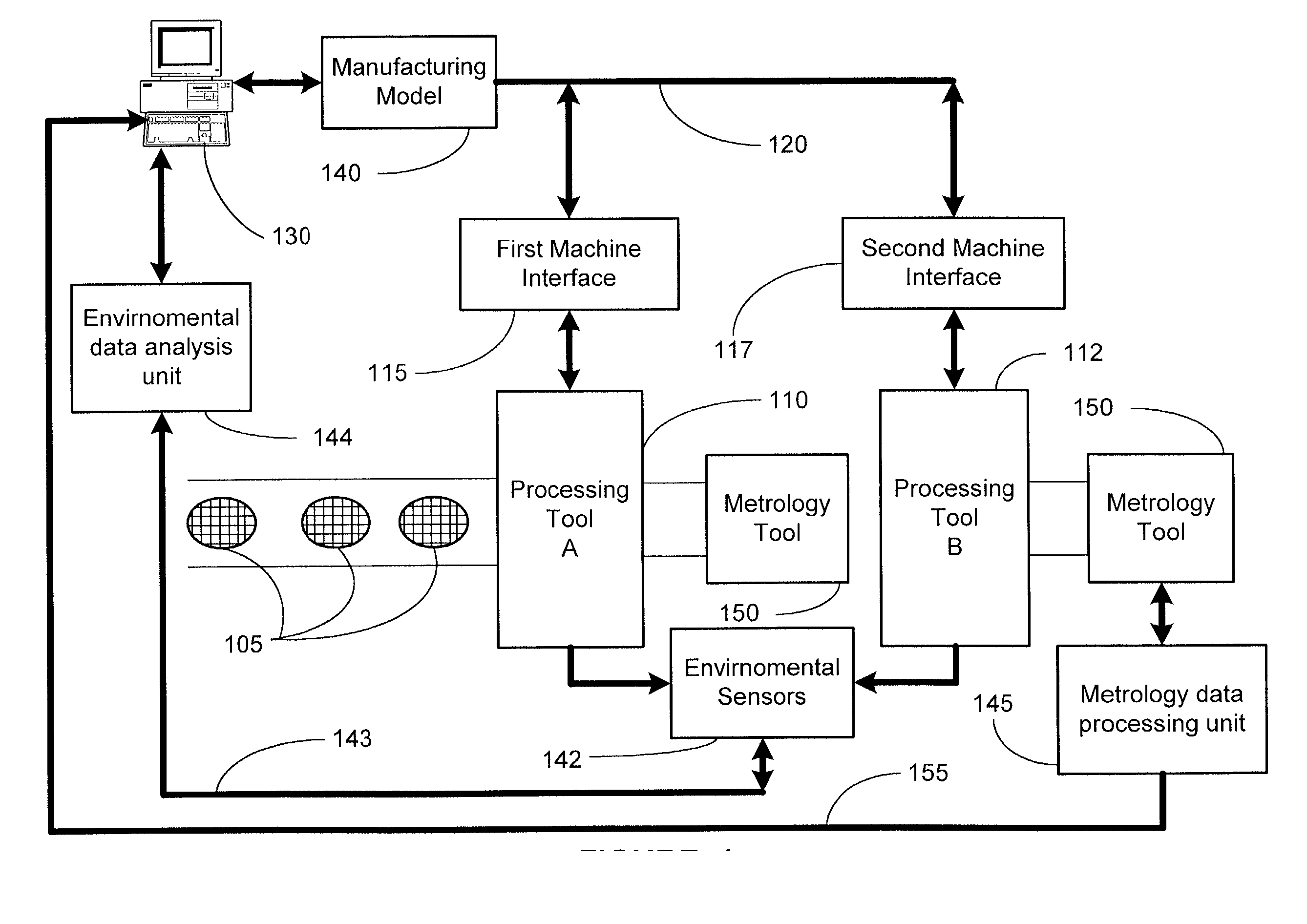

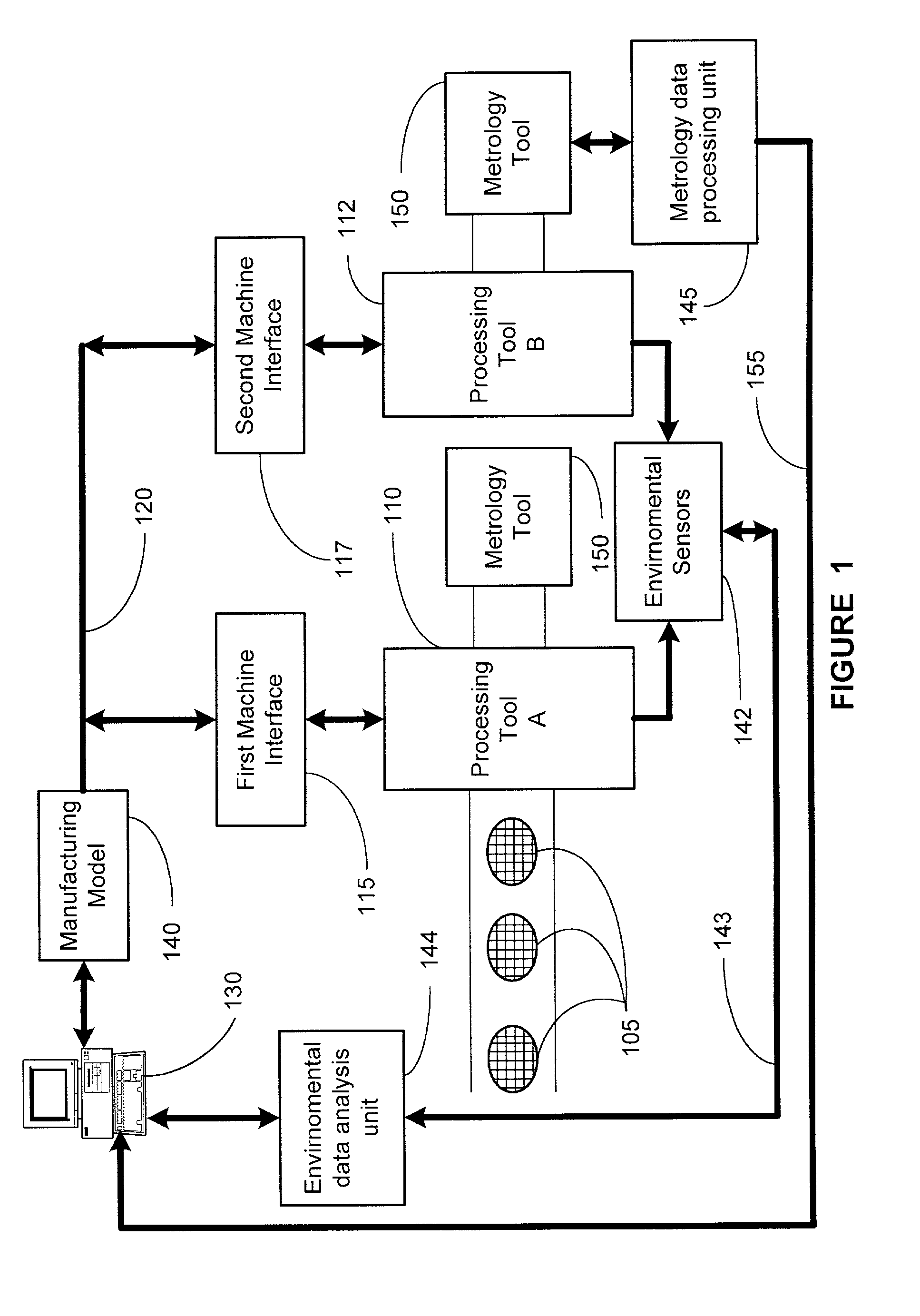

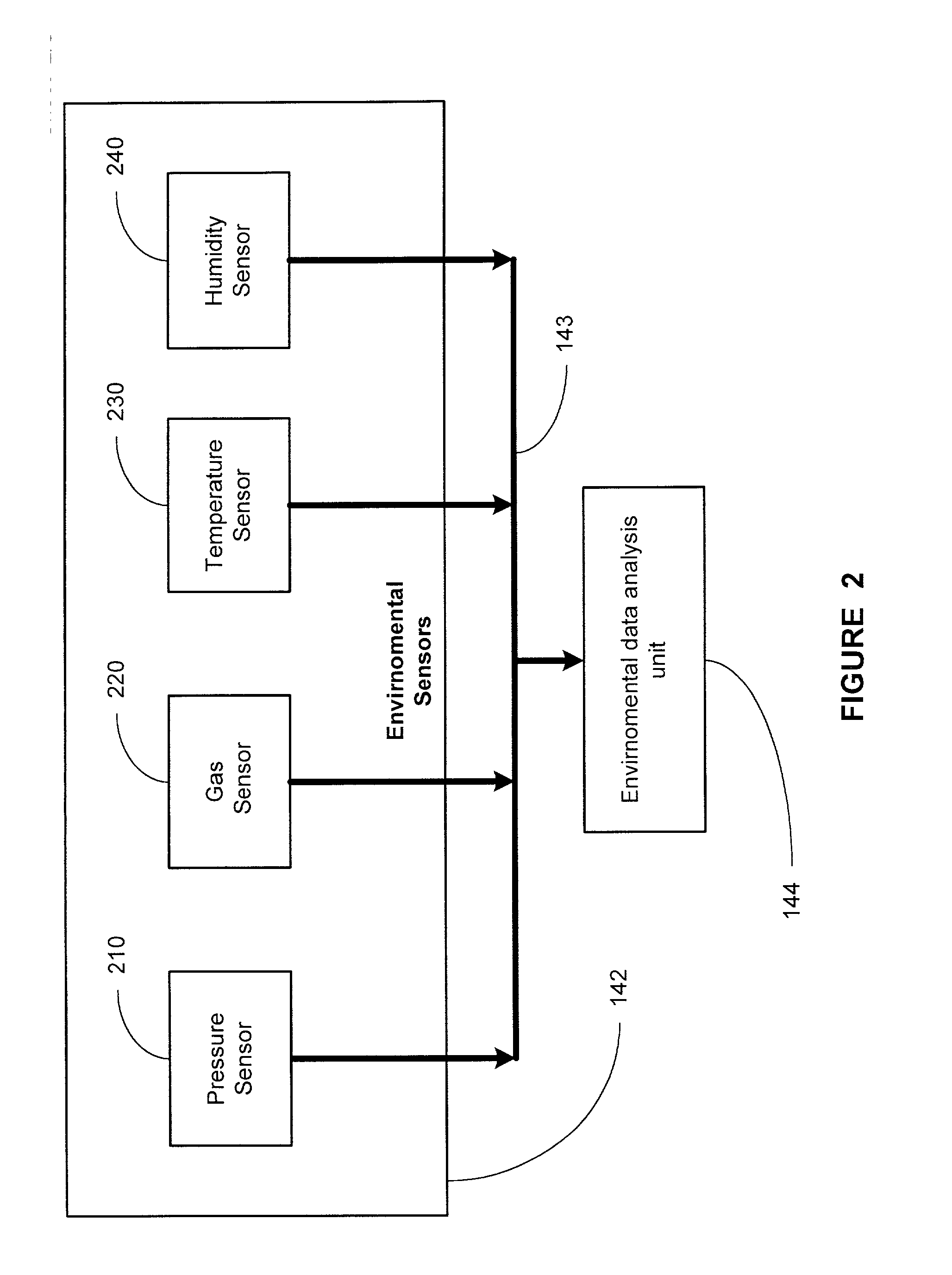

Method and apparatus for control for semiconductor processing for reducing effects of environmental effects

InactiveUS6560506B2Semiconductor/solid-state device manufacturingDigital computer detailsEnvironmental effectEnvironmental data

Owner:GLOBALFOUNDRIES INC

Method and apparatus for control of semiconductor processing for reducing effects of environmental effects

InactiveUS20020069349A1Semiconductor/solid-state device manufacturingDigital computer detailsEnvironmental effectEngineering

The present invention provides for a method and an apparatus for reducing the effects of manufacturing environmental factors. At least one process run of semiconductor devices is processed. A manufacturing environmental data analysis is performed upon the process run of semiconductor devices. A control parameter modification sequence is implemented in response to the manufacturing environmental data analysis.

Owner:GLOBALFOUNDRIES INC

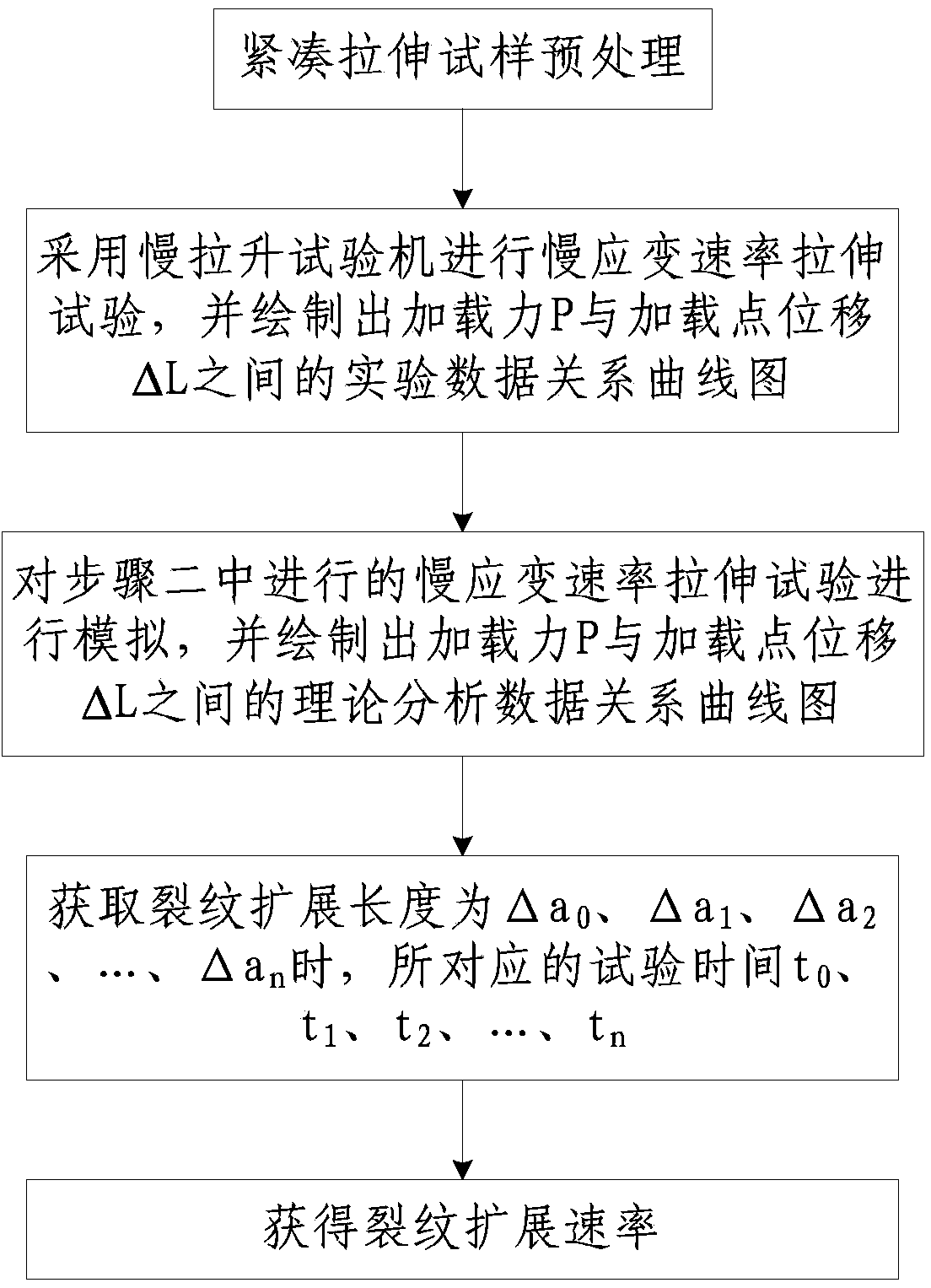

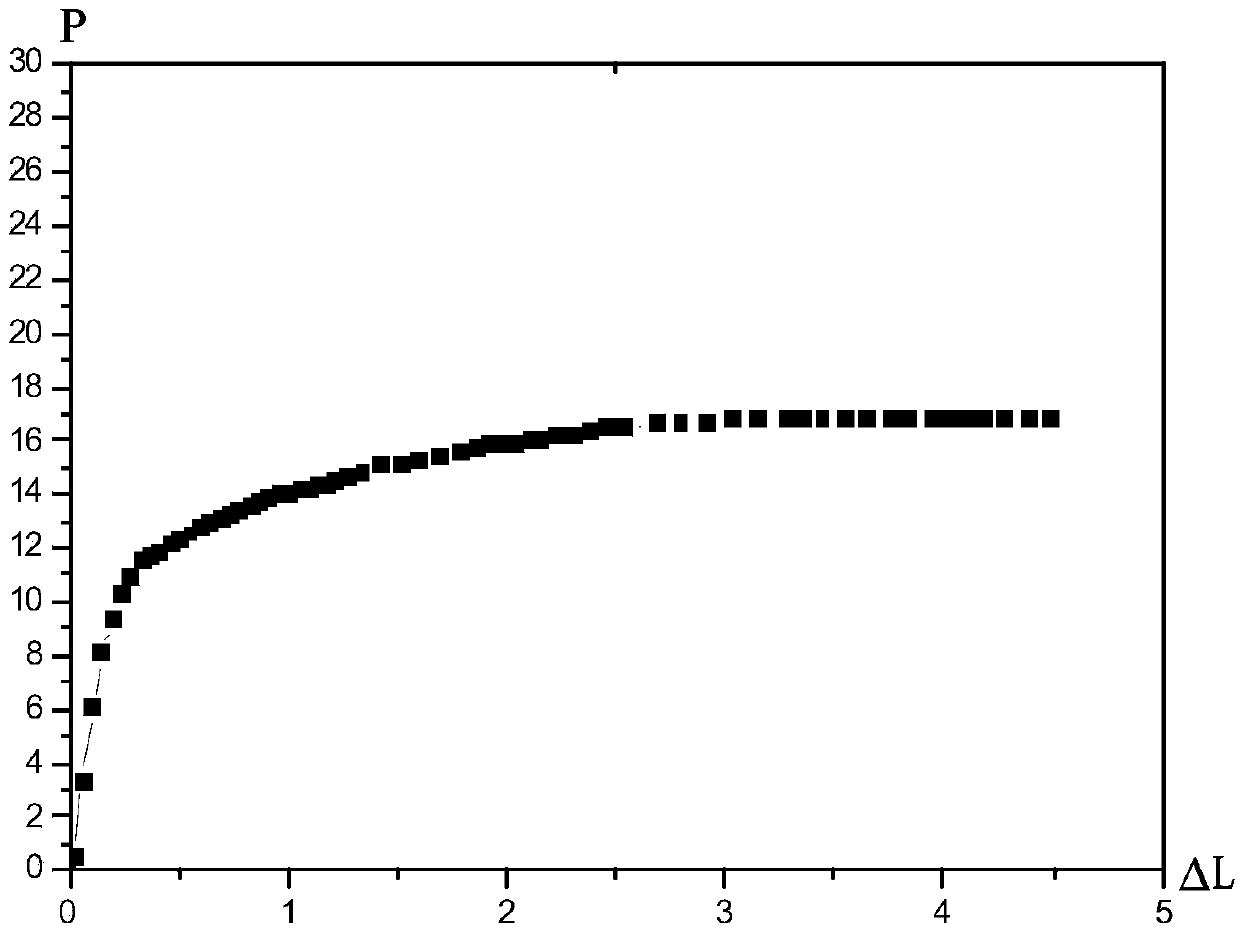

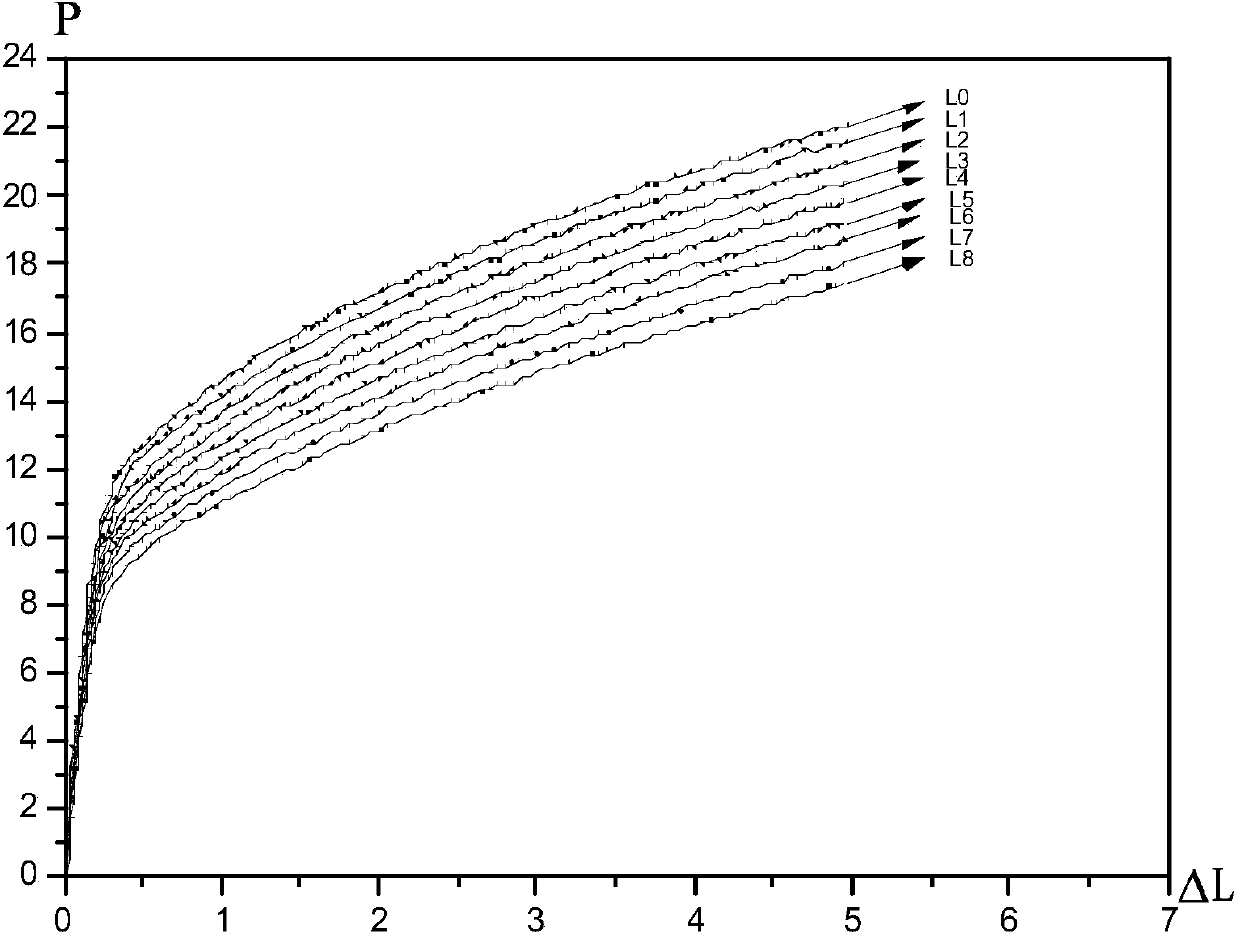

Method for measuring stress corrosion crack propagation rate by employing slow strain rate tensile

InactiveCN103698188ASimple methodEasy to implementPreparing sample for investigationMaterial strength using tensile/compressive forcesAnalysis dataTested time

The invention discloses a method for measuring stress corrosion crack propagation rate by employing slow strain rate tensile. The method comprises the following steps: 1. preprocessing a compact tension specimen; 2. carrying out a slow strain rate tensile test by adopting a slow lifting testing machine, and drawing an experimental data relationship graph between loading force P and loading point displacement deltaL; 3. simulating the slow strain rate tensile test carried out in the step 2, and drawing a theoretical analysis data relation graph between the loading force P and the loading point displacement deltaL; 4. obtaining corresponding test time t0, t1, t2,..., tn when the crack propagation lengths are deltaa0, deltaa1, deltaa2,..., deltaan; 5. obtaining the crack propagation rate. By adopting the method, the change of the loading force P and loading point displacement deltaL caused by crack propagation can be separated out, and the change of the deltaai can be predicted in real time, so that the crack propagation rate is obtained. Thus, test data distortion caused by environmental influence can be effectively alleviated, and the data accuracy is improved.

Owner:XIAN UNIV OF SCI & TECH

Test method and test device for liquid absorption rate of macromolecular microporous diaphragm

ActiveCN104062199AReduce the impactImprove consistencyWeighing by absorbing componentPhysical chemistryAbsorption rate

The invention discloses a test method for a liquid absorption rate of a macromolecular miroporous diaphragm. The test method comprises the following steps: step 1: producing a roll core according to a wound or laminated lithium ion battery, placing the roll core into an aluminum-plastic membrane, and capping and laterally sealing the aluminum-plastic membrane to obtain a diaphragm sample; step 2: carrying out vacuum baking on the diaphragm sample; step 3: weighing the baked diaphragm sample, recording the weight as G1; step 4: immersing the diaphragm sample into a solution; step 5: weighing the vacuumized and hot-sealed aluminum-plastic membrane, and recording the weight as G2, wherein the calculation formula of the liquid absorption rate of the diaphragm is as follows: eta=(G2-G1) / S*100%. The invention also discloses a test device. The test method and test device have the advantages that the manmade error can be reduced, the environment influence is alleviated, the consistency and reproducibility of the test result are high, and convenience for comparing the liquid absorption performance of the coated diaphragm and the liquid absorption performance of a basic membrane can be achieved.

Owner:SHENZHEN SENIOR TECH MATERIAL

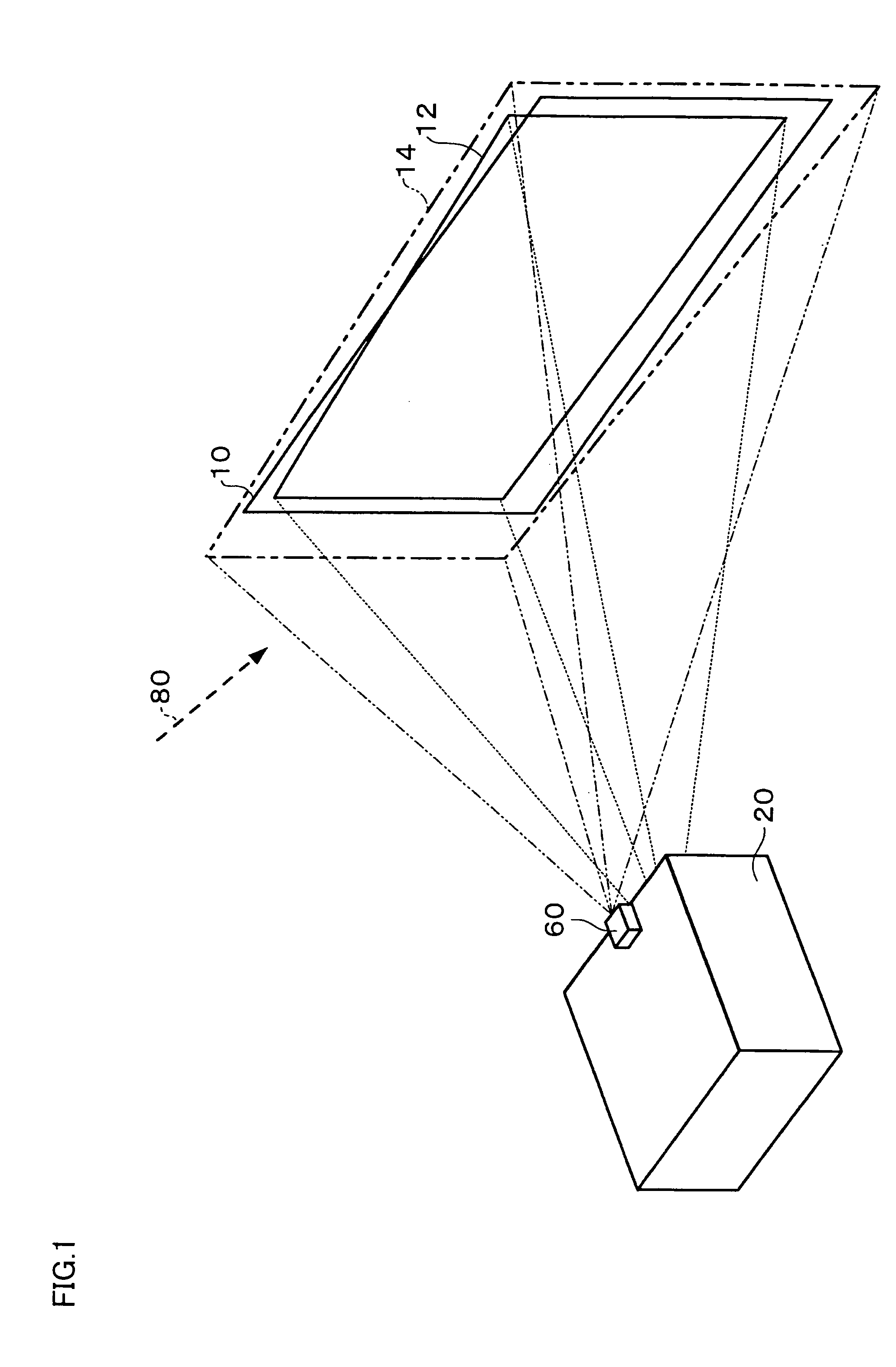

Image processing system, projector, and image processing method

InactiveUS7949202B2Reduce environmental impactProjectorsCharacter and pattern recognitionEnvironment effectImaging processing

A projector including: a sensing section which senses an area including at least a part of a projection image projected onto a projection target area to generate sensing information; a projection target area information generation section which generates projection target area information based on the sensing information; a projection area information generation section which generates projection area information based on the sensing information; an image distortion correction section which corrects distortion of the projection image and generates correction information indicating a degree of the correction; a display area information generation section which generates display area information based on the projection area information and the correction information; and an environmental influence reduction section which performs processing of reducing environmental influence based on the sensing information and the display area information.

Owner:SEIKO EPSON CORP

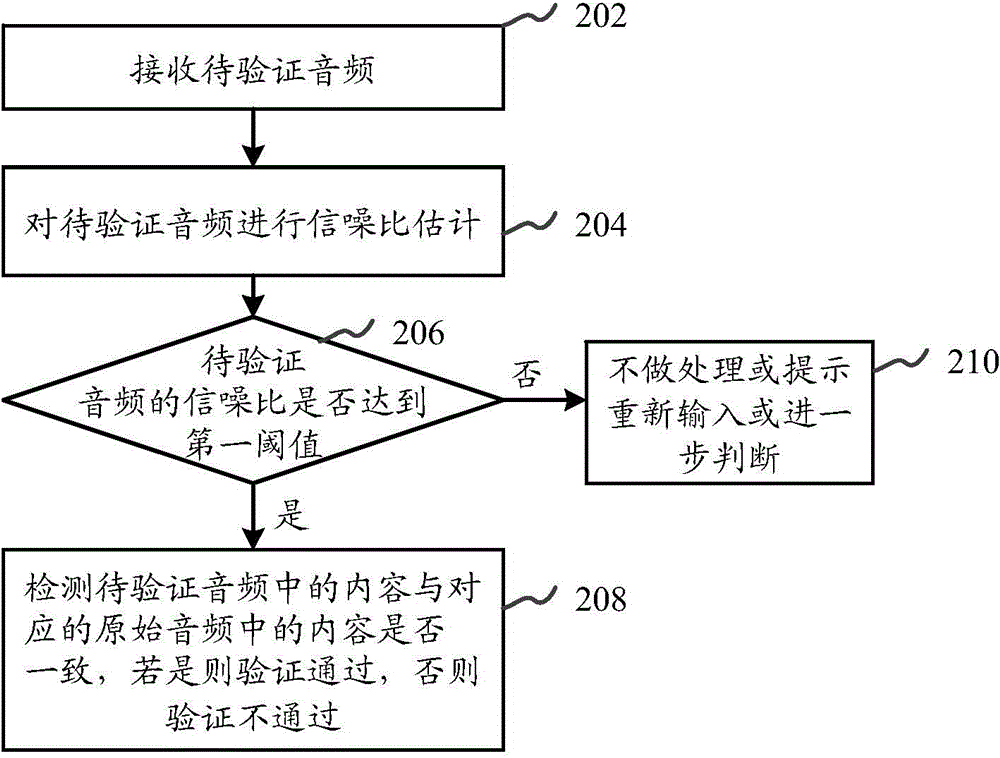

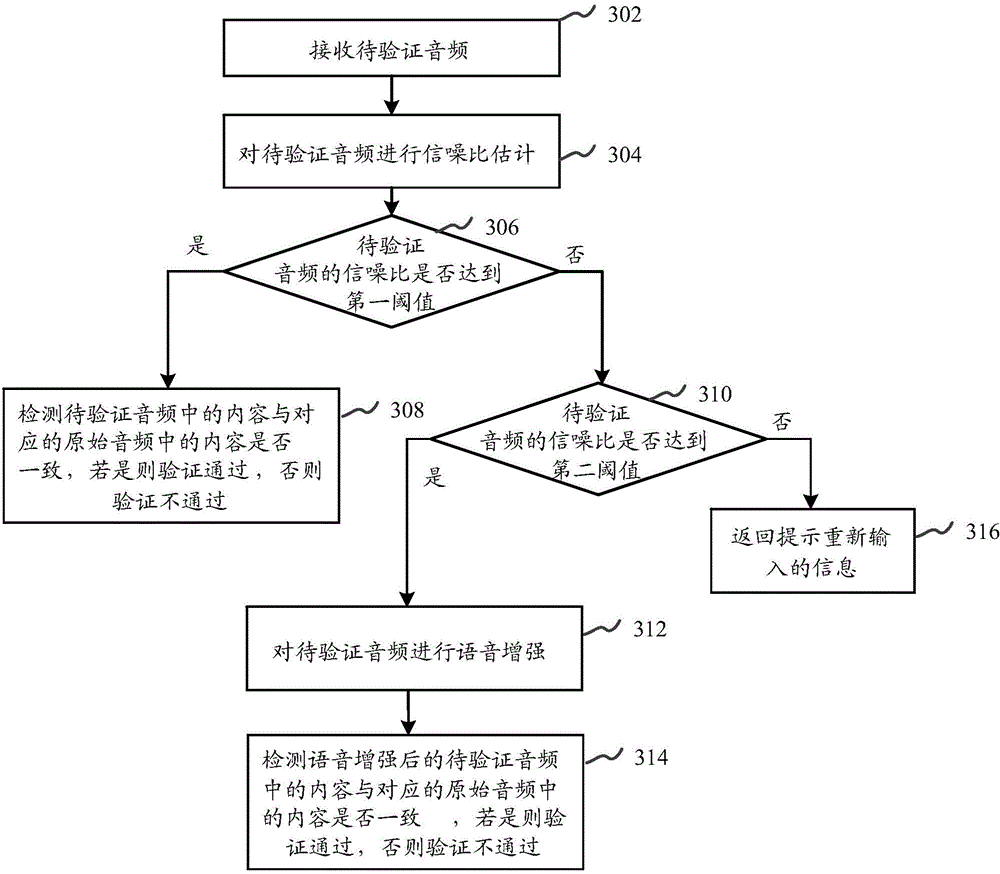

Authentication method, system and apparatus

ActiveCN105224844AReduce the impact of verificationReduce misjudgmentSpeech analysisDigital data authenticationSignal-to-noise ratio (imaging)Validation methods

The present invention provides an authentication method. The method comprises: receiving to-be-authenticated audio; performing signal-to-noise ratio estimation on the to-be-authenticated audio; and determining whether the signal-to-noise ratio of the to-be-authenticated audio reaches a first threshold, if yes, detecting whether content of the to-be-authenticated audio is consistent with content of corresponding original audio, and if yes, determining that the authentication is passed, or otherwise, determining that the authentication is not passed. With the adoption of the authentication method, an environmental impact can be reduced and speech recognition accuracy can be improved, so that the accuracy of authentication is improved and misjudgments are reduced. Furthermore, another authentication method and an authentication system and apparatus are provided.

Owner:TENCENT TECH (SHENZHEN) CO LTD

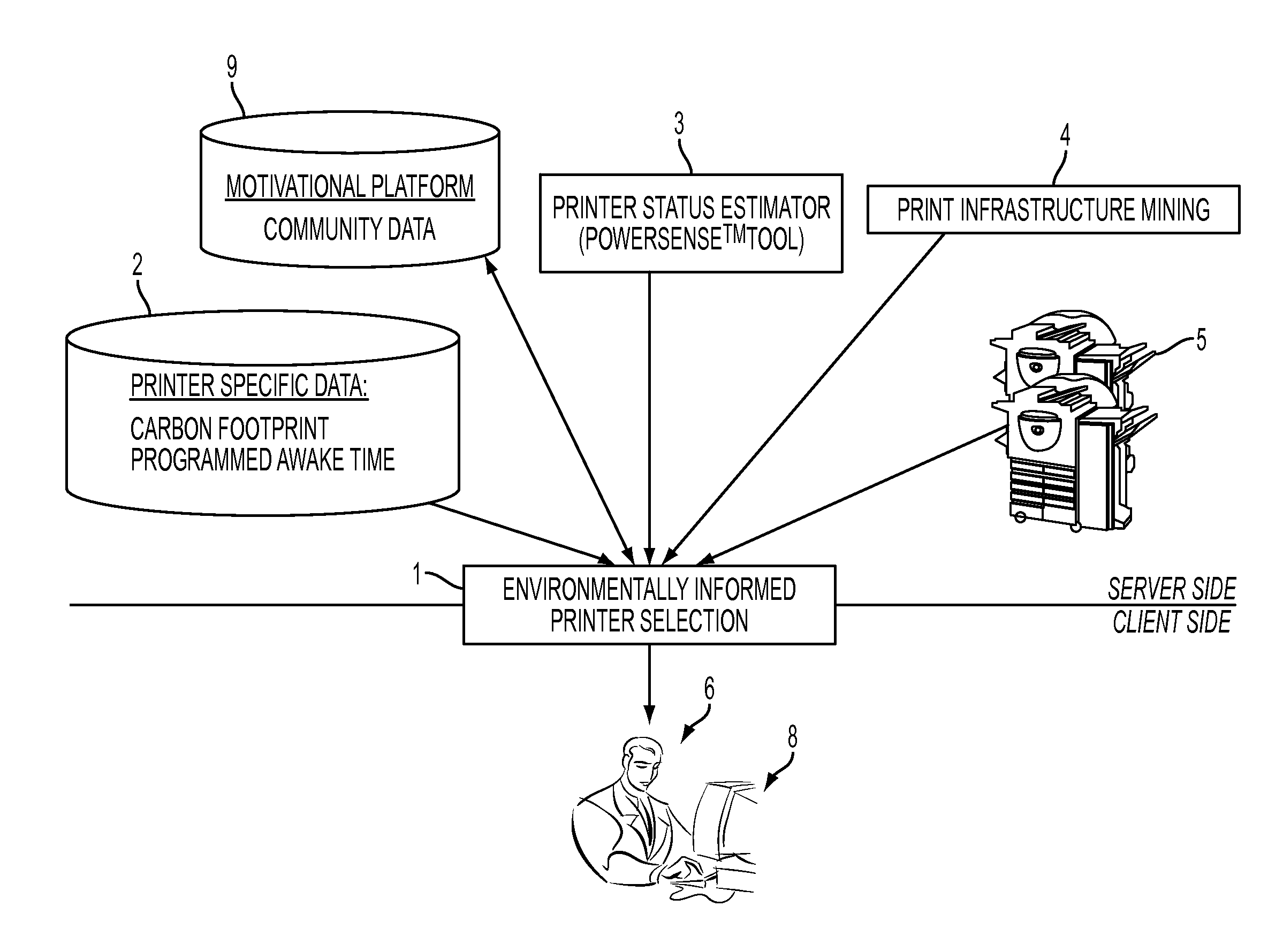

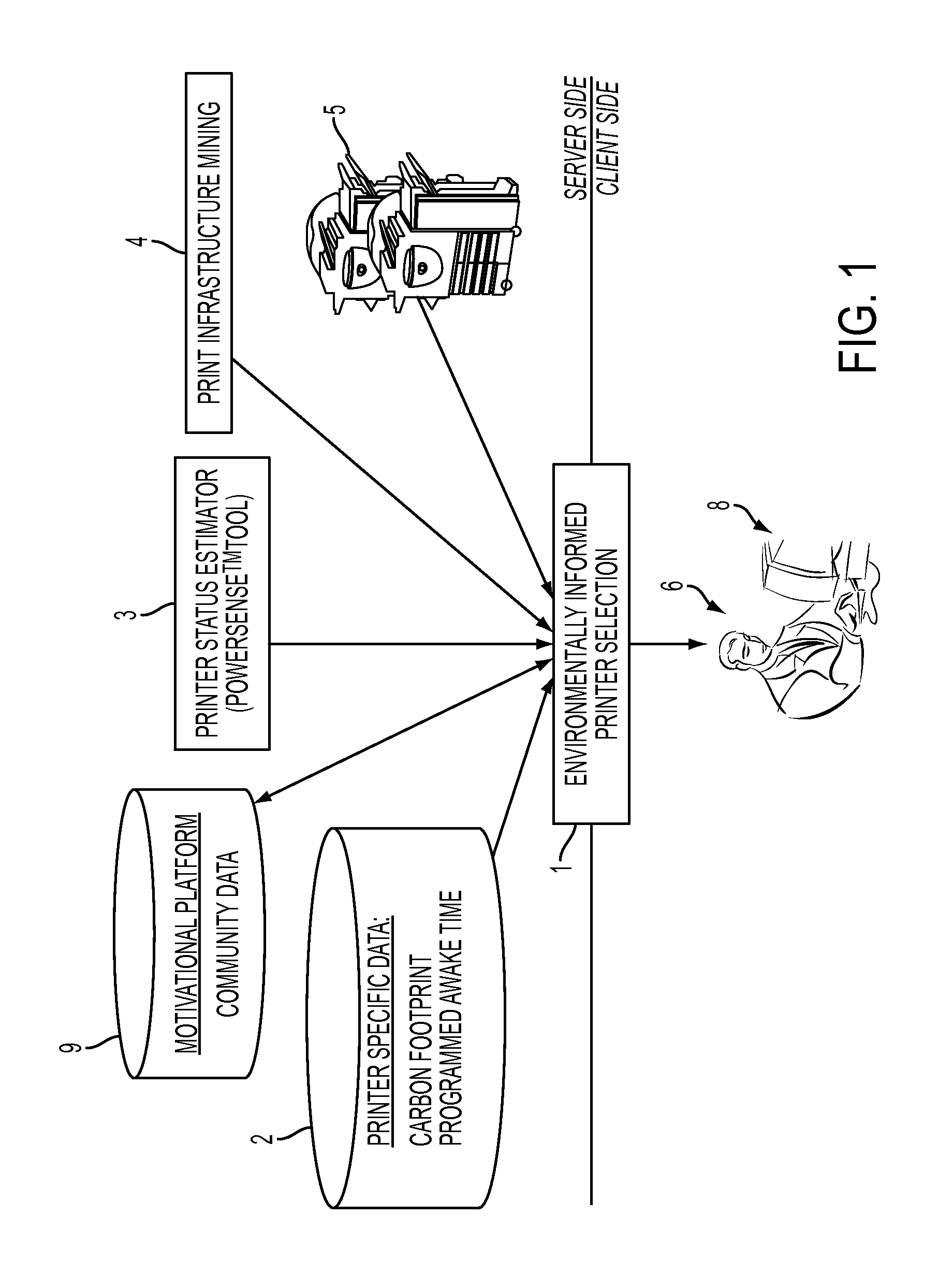

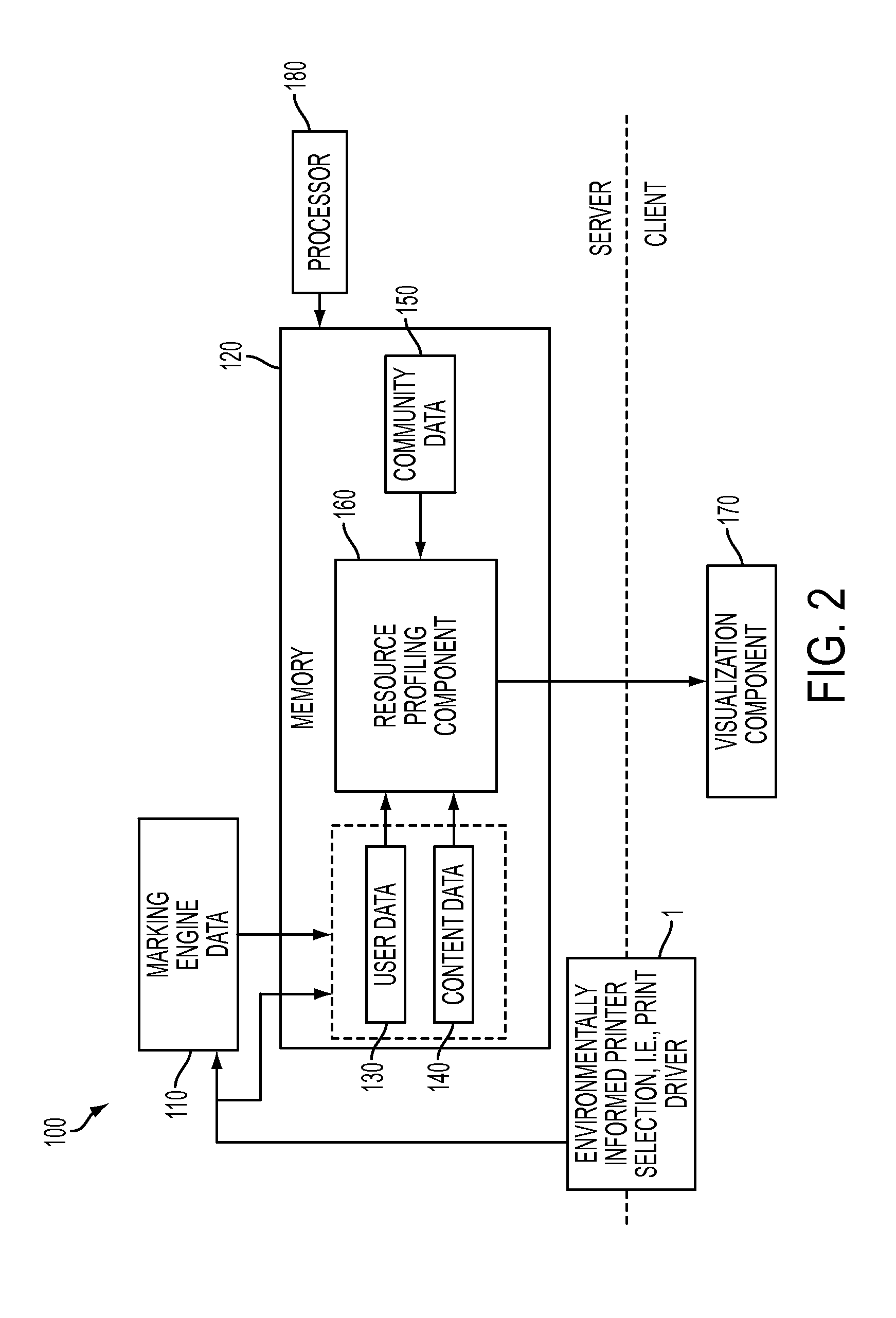

Method and system for mutual augmentation of a motivational printing awareness platform and recommendation-enabled printing drivers

ActiveUS9216591B1Reduce environmental impactTypewritersOther printing apparatusEngineeringGood practice

This disclosure provides a method and system to promote the reduction of an environmental impact by one or more users of a printing system. According to an exemplary embodiment, a printing system includes a motivational platform and an operatively associated printer driver, the motivational platform recording the historical print activity of a plurality of users associated with a group and communicating the historical print activity to the print driver which is configured to provide an active user recommended selectable printer settings for a print job, prior to being submitted, which are based on best practices within the group.

Owner:XEROX CORP

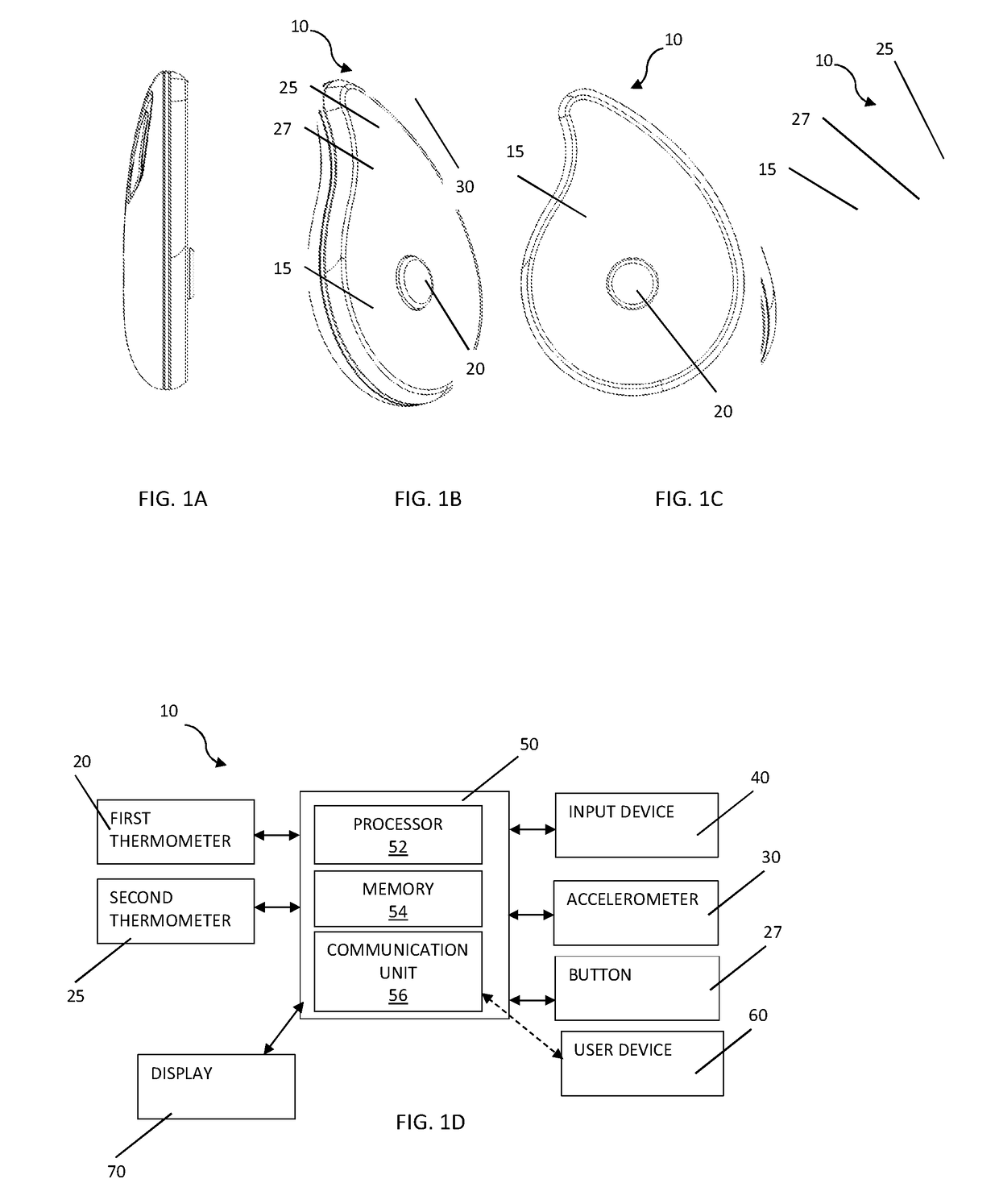

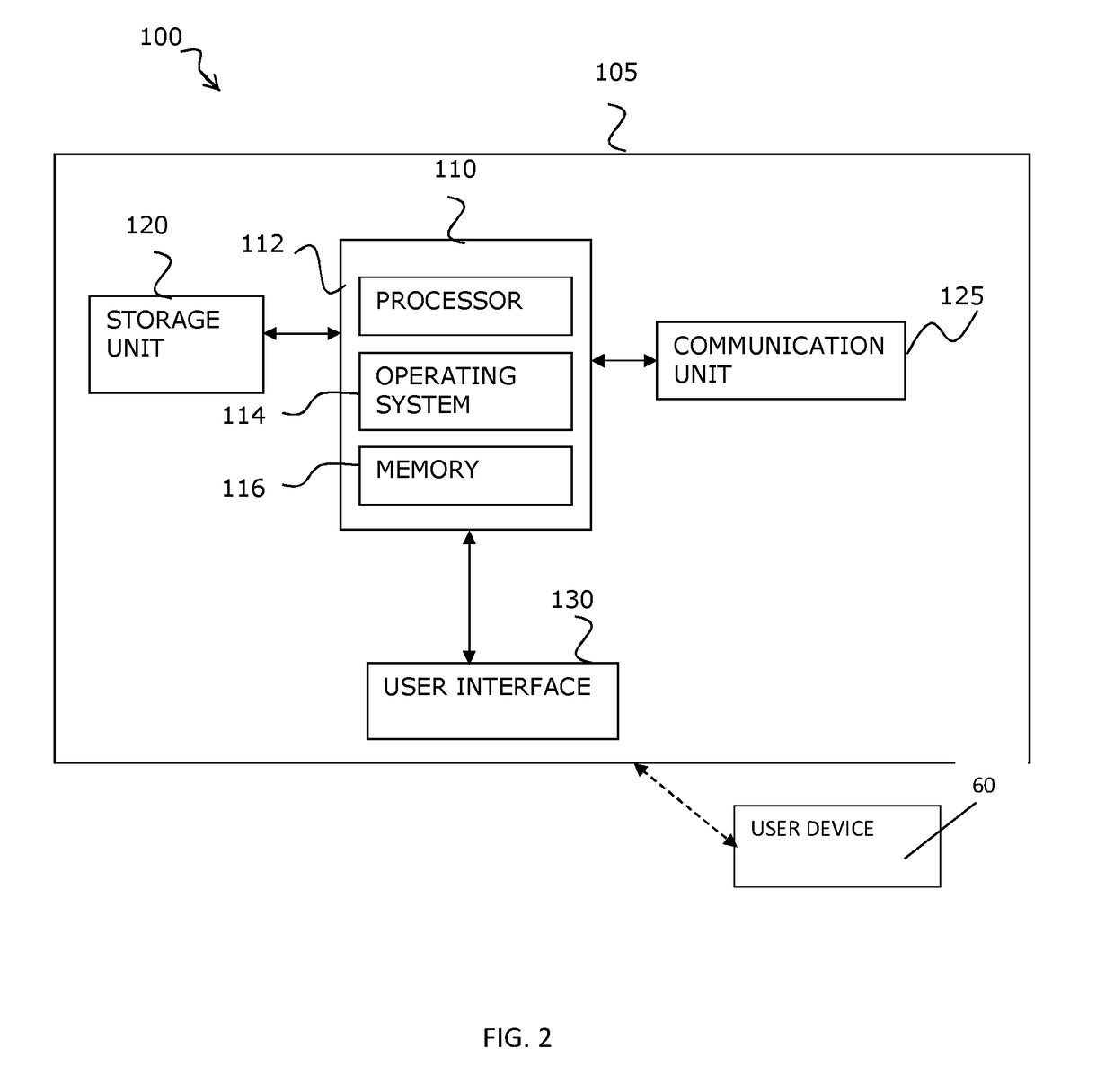

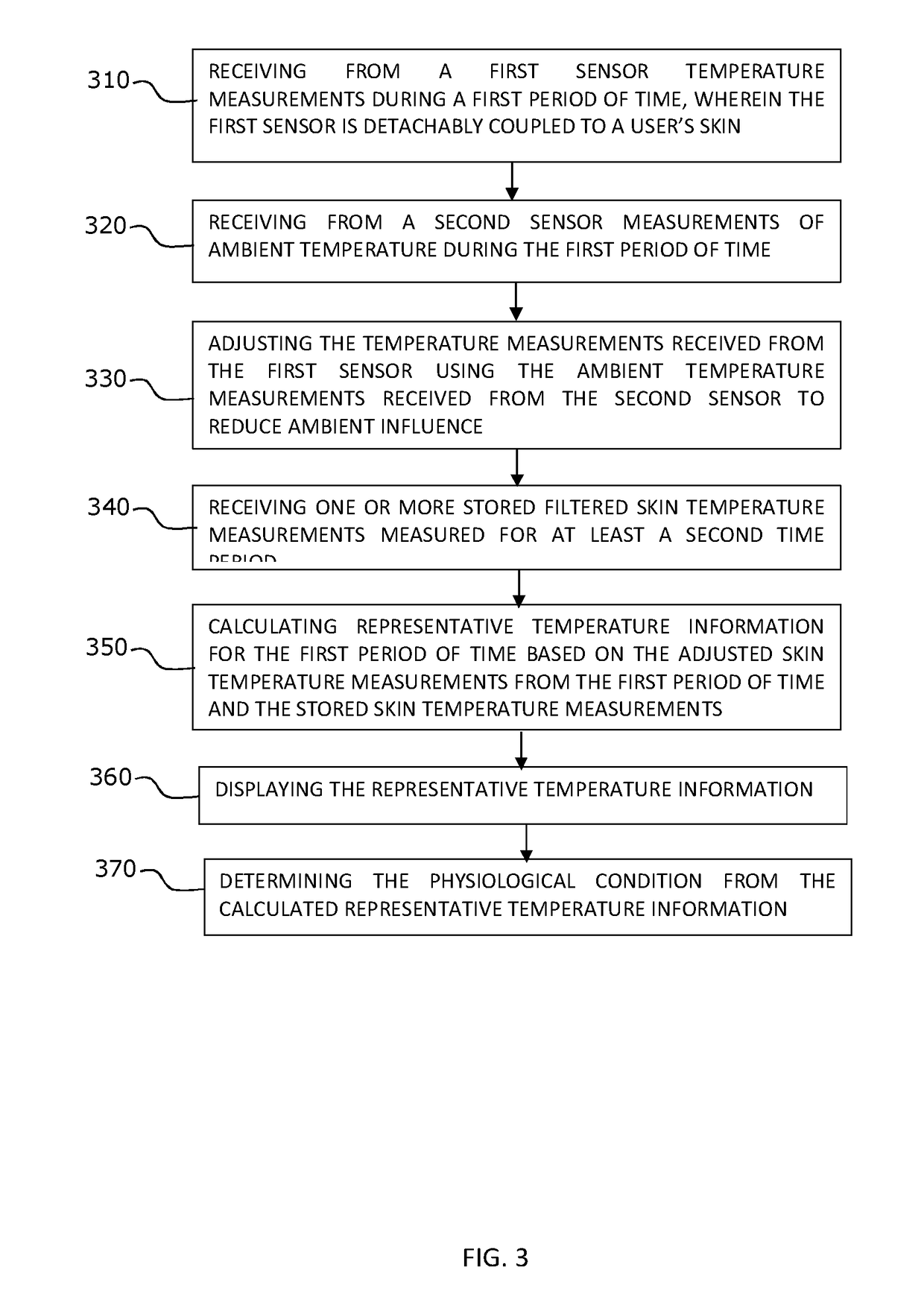

System and method for determining physiological conditions based on variations in body temperature

The invention is related to a system and method for determining a physiological condition. The system includes a processor configured to receive, from a first sensor, skin temperature measurements during a first period of time, wherein the first sensor is detachably and thermally coupleable to a user's skin, receive from a second sensor, measurements of ambient temperature during the first period of time, adjust the skin temperature measurements received from the first sensor using the ambient temperature measurements received from the second sensor to reduce ambient influence, receive one or more stored temperature measurements measured for at least a second time period, calculate representative temperature information for the first period of time based on the adjust skin temperature measurements from the first period of time and stored temperature measurements and display the representative temperature information.

Owner:TEMPDROP

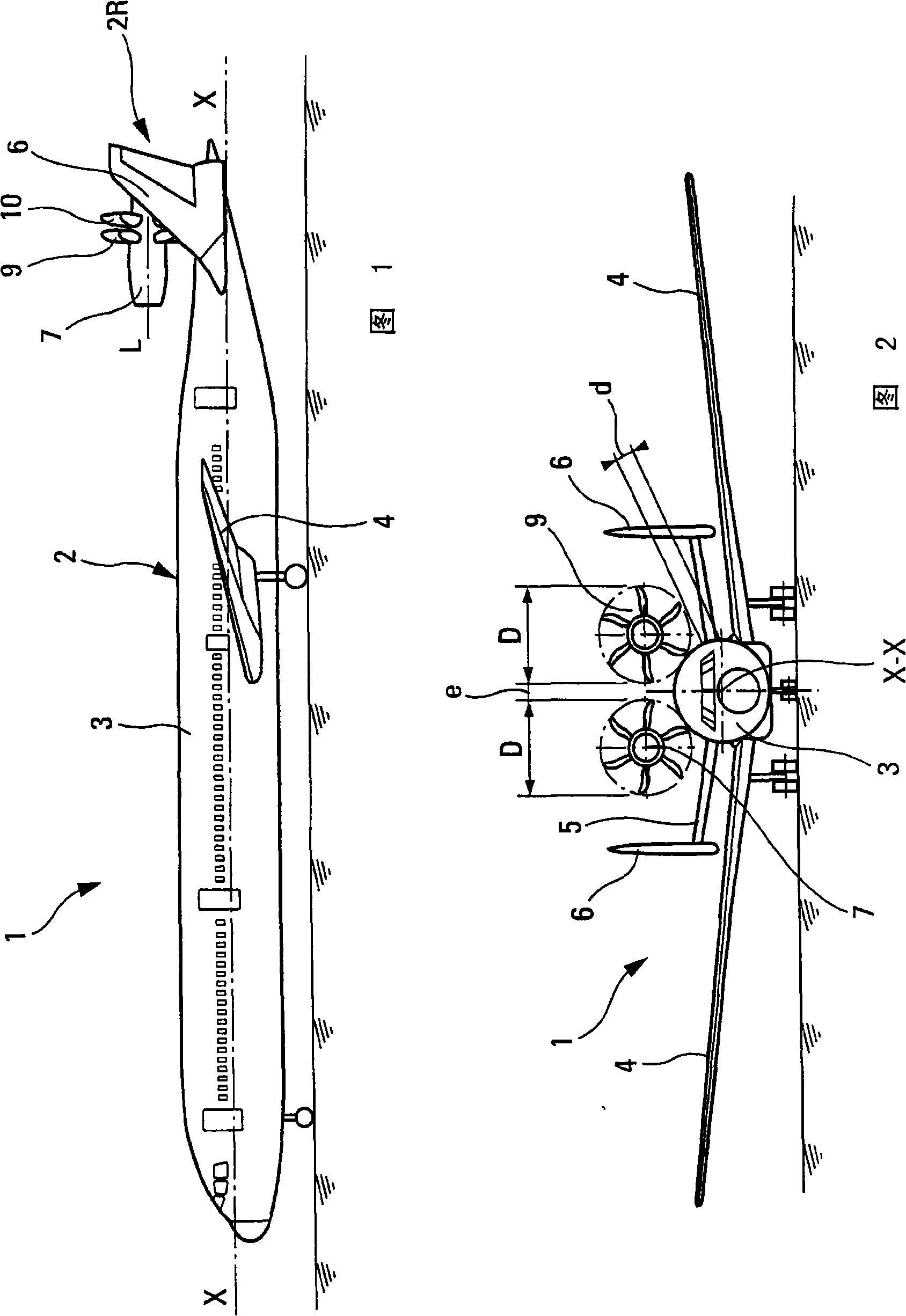

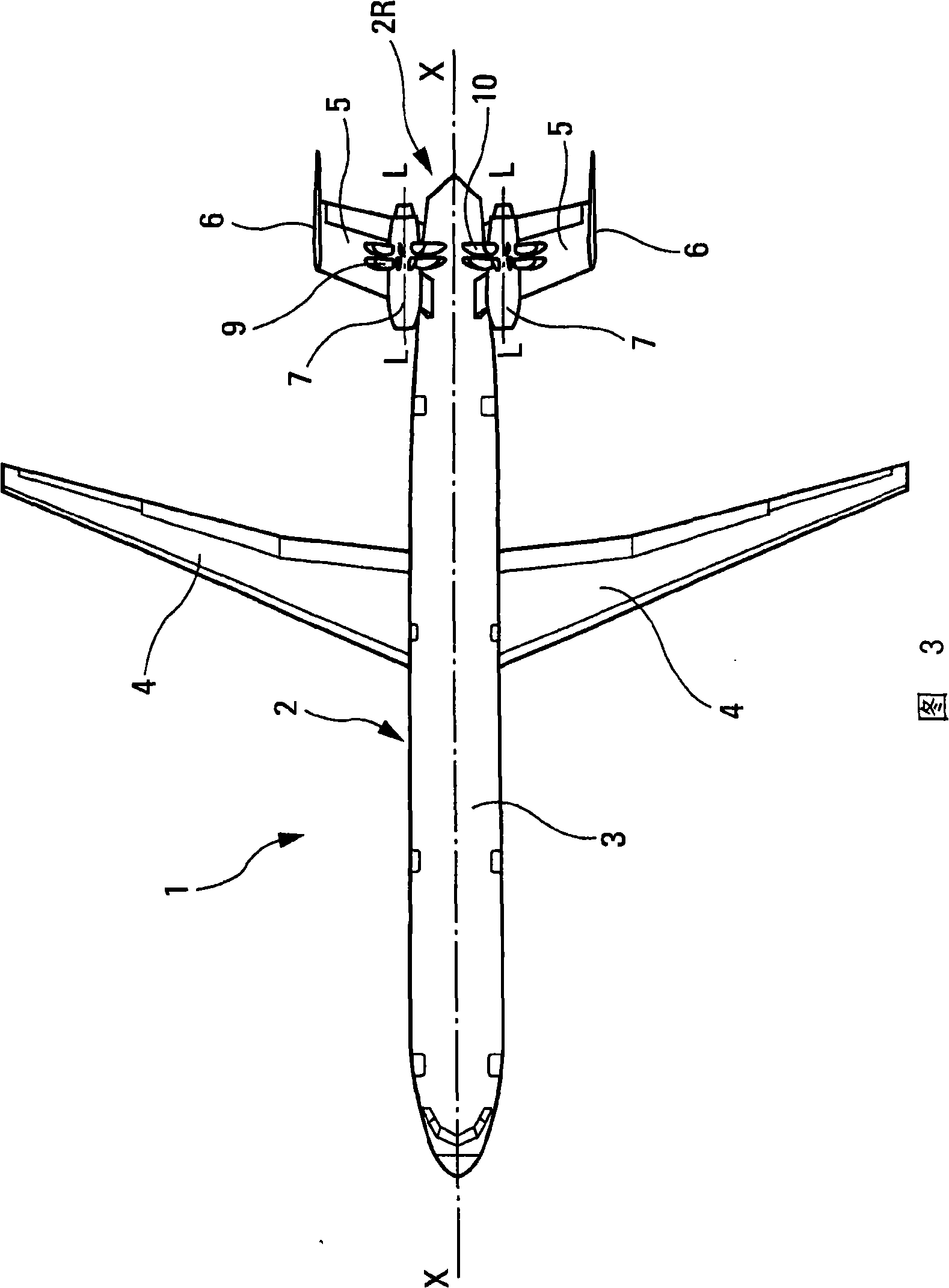

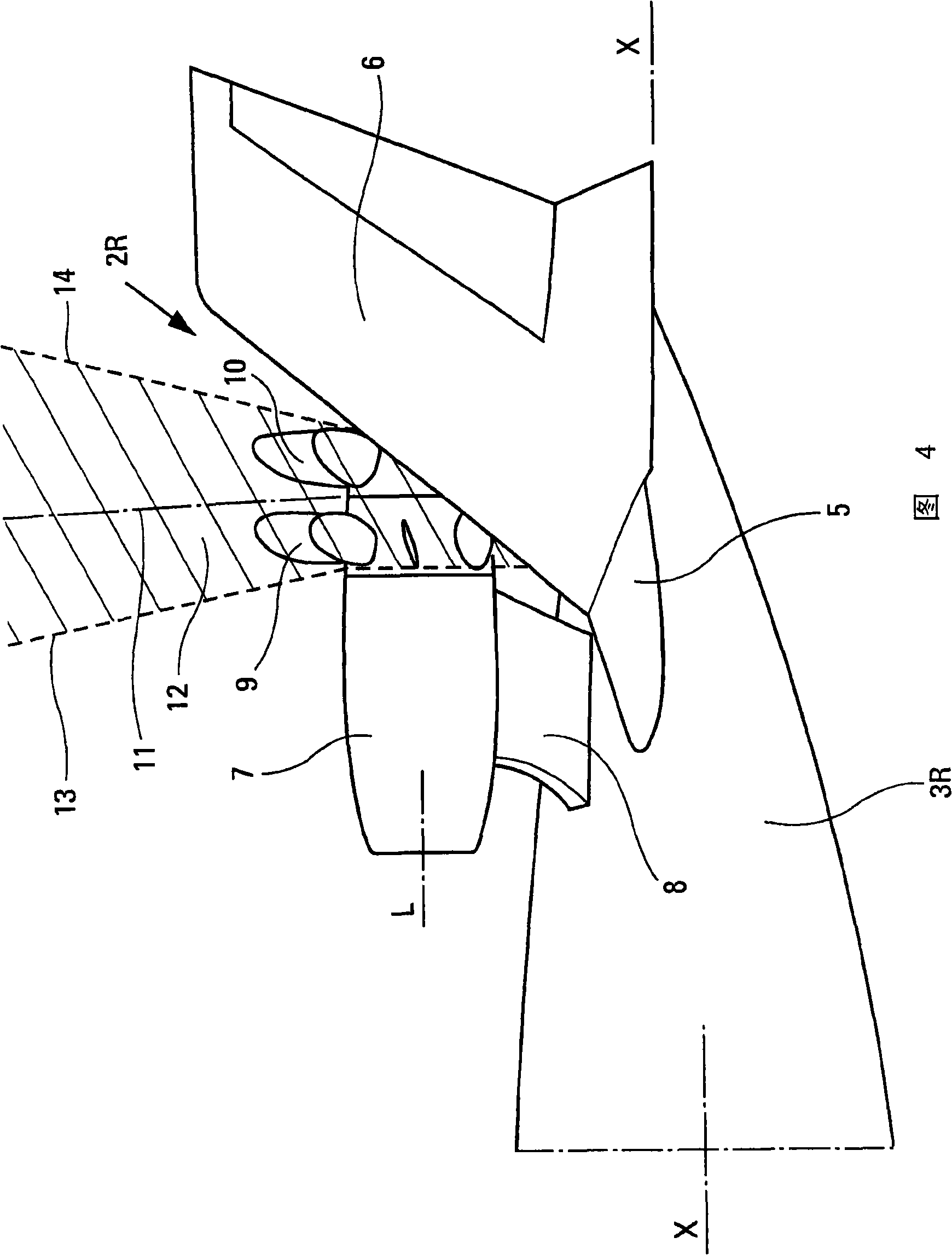

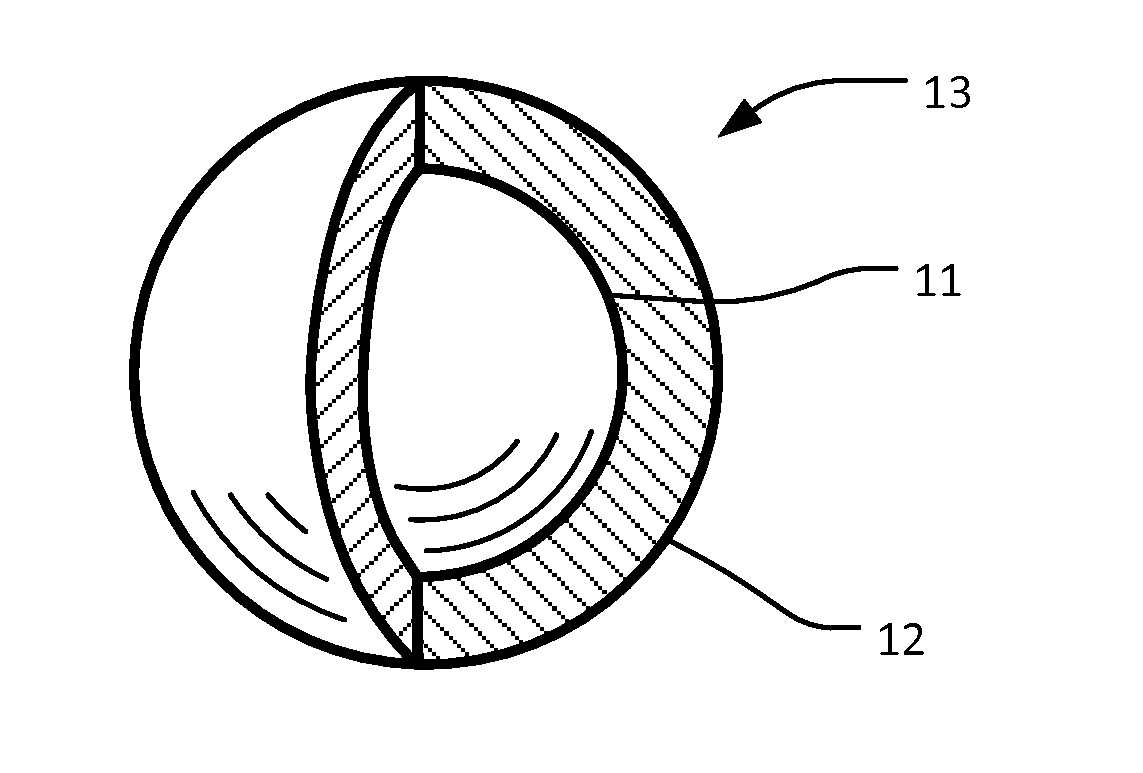

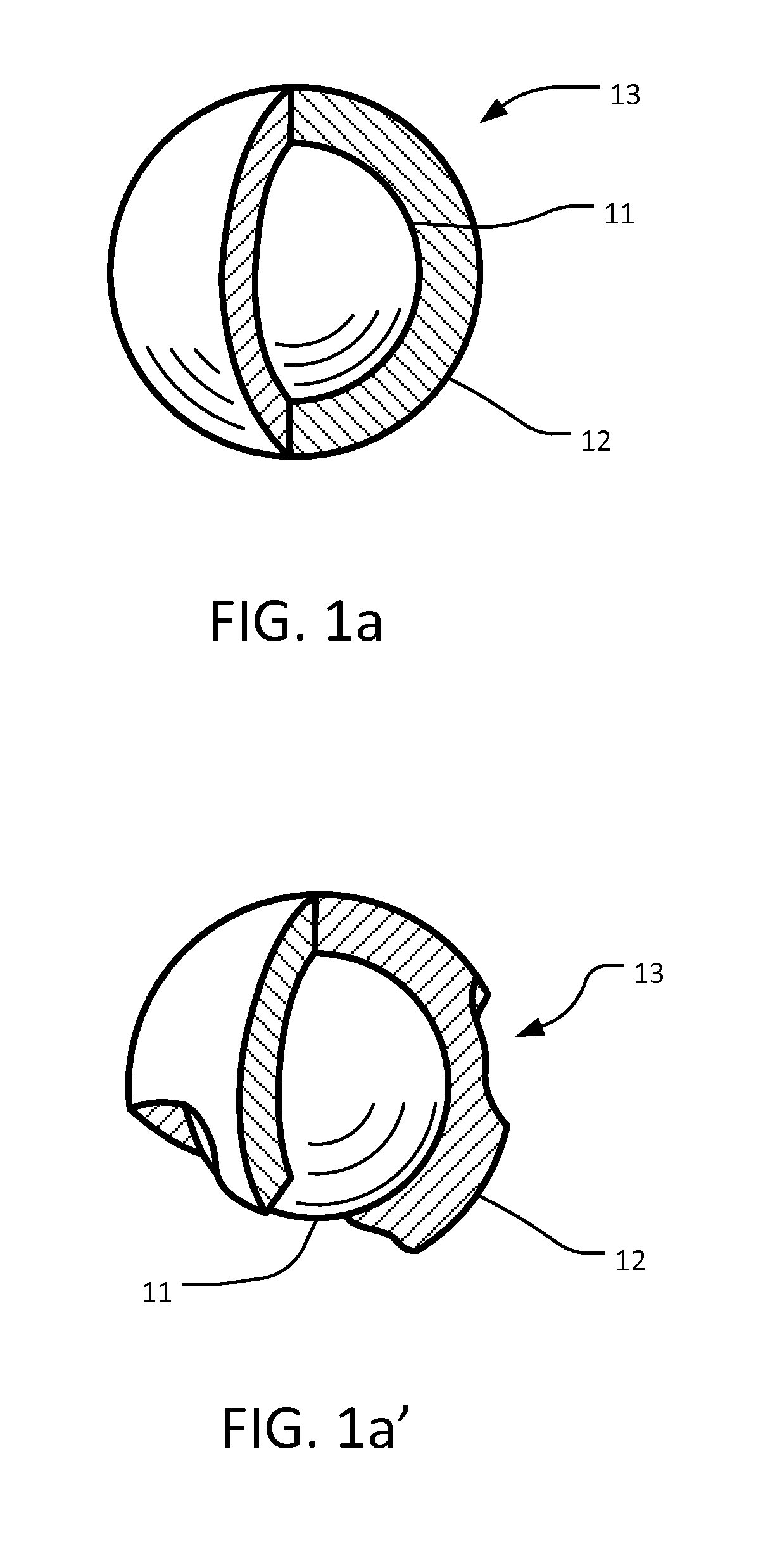

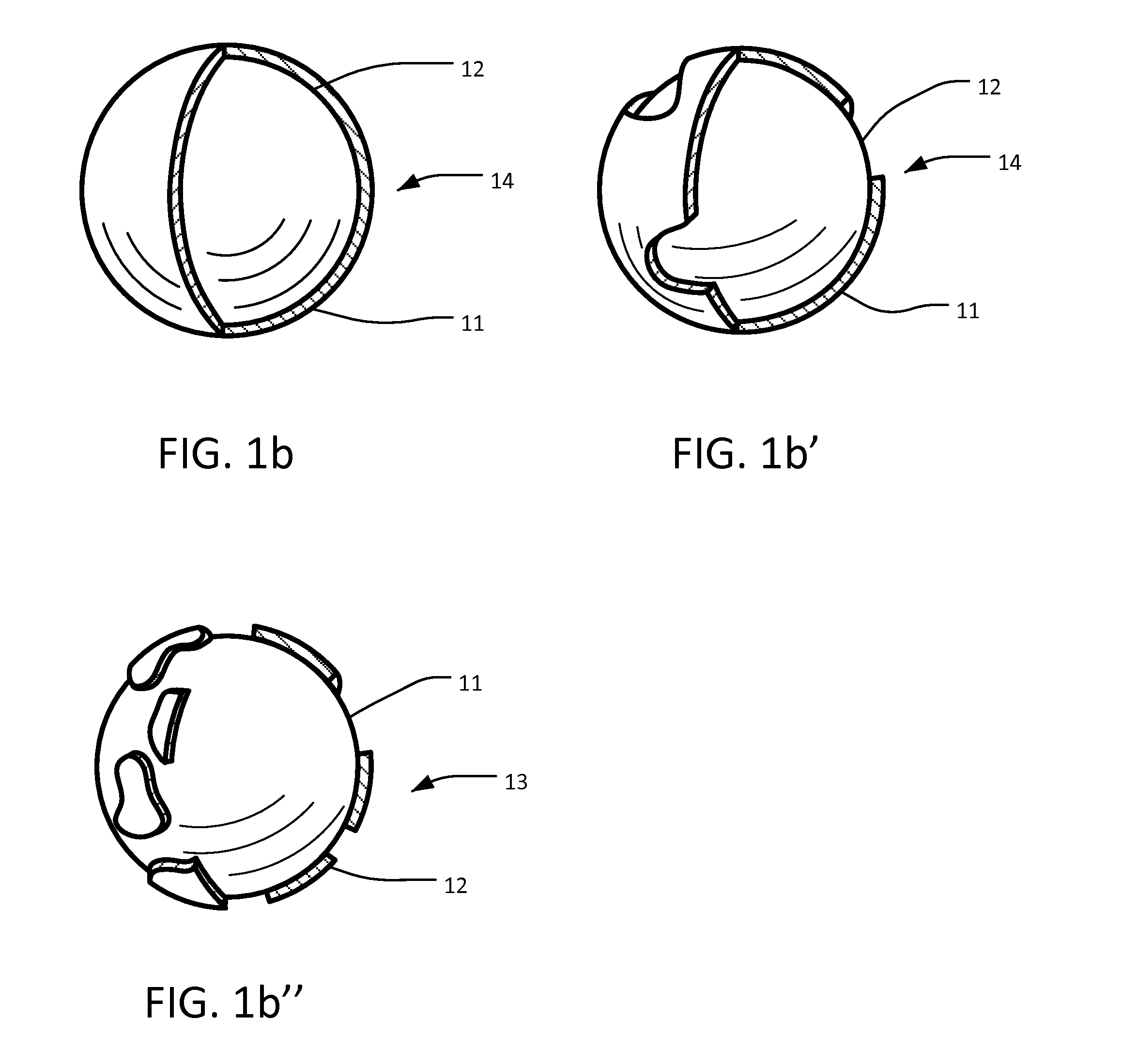

Aircraft having a reduced environmental impact

InactiveCN101300171ALow sound intensityReduce noiseGas turbine type power plantsEfficient propulsion technologiesFlight vehiclePropeller

Disclosed is an aircraft having a reduced environmental impact. According to the invention, this aircraft comprises at least one engine (7) having at least one propeller (9, 10) supported, at the rear, on the back of the aircraft with the propeller(s) that is / are arranged in line with the rear portion (2R) of the airframe forming a noise-deflecting barrier.

Owner:AIRBUS OPERATIONS (SAS)

Liquid developer containing electro-conductive particles and an electro-conductive pattern forming method using said material and an electro-conductive pattern forming apparatus using said material

A novel liquid toner development system is disclosed. The liquid development system includes conductive core-shell particles comprising silver-copper or copper-silver. A novel apparatus and method relying on the novel liquid toner development system results in electro-conductive patterning capable of high conductivity with low background fogging, reduced processing time and reduced environmental impact.

Owner:AFIT CORP

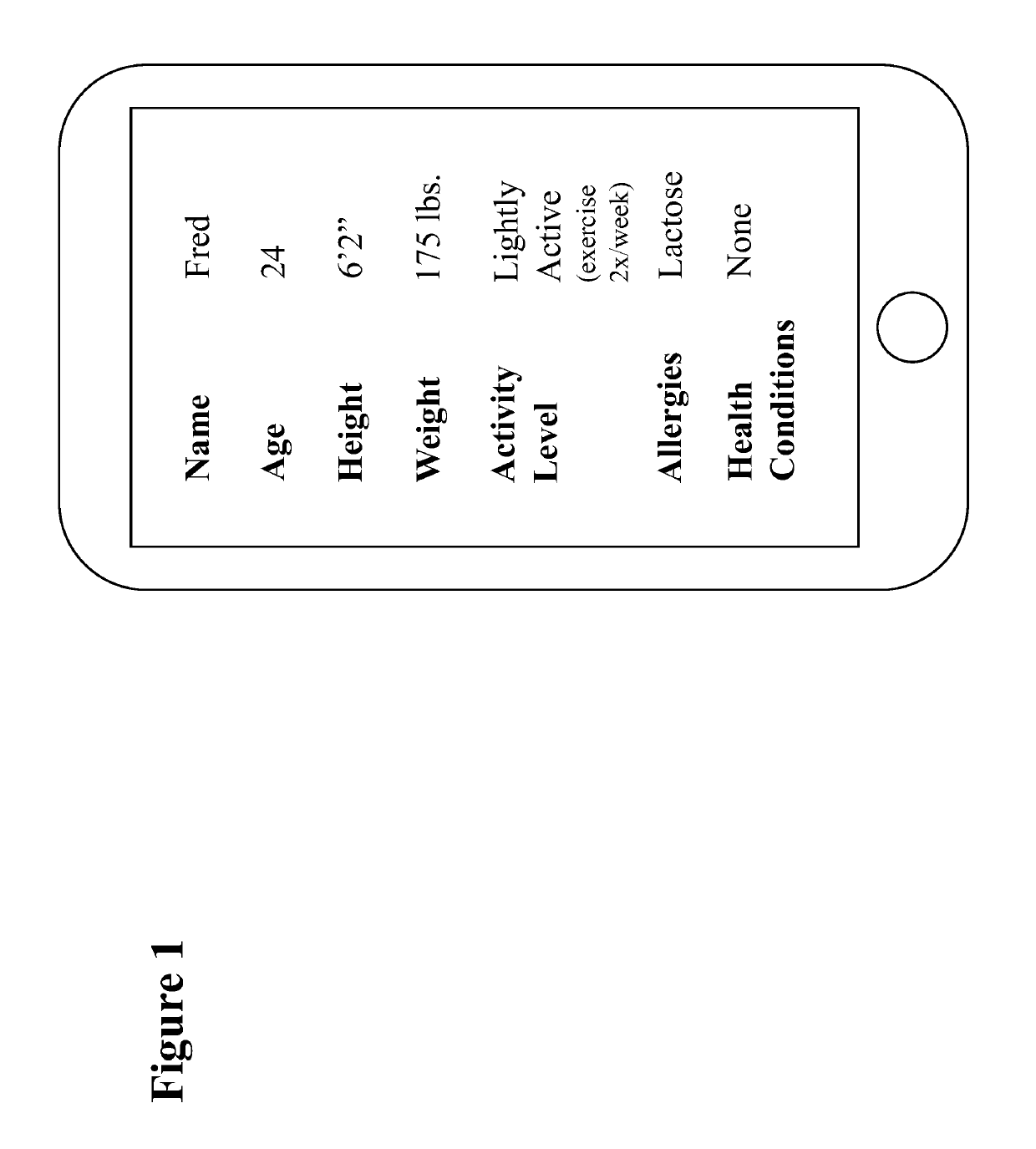

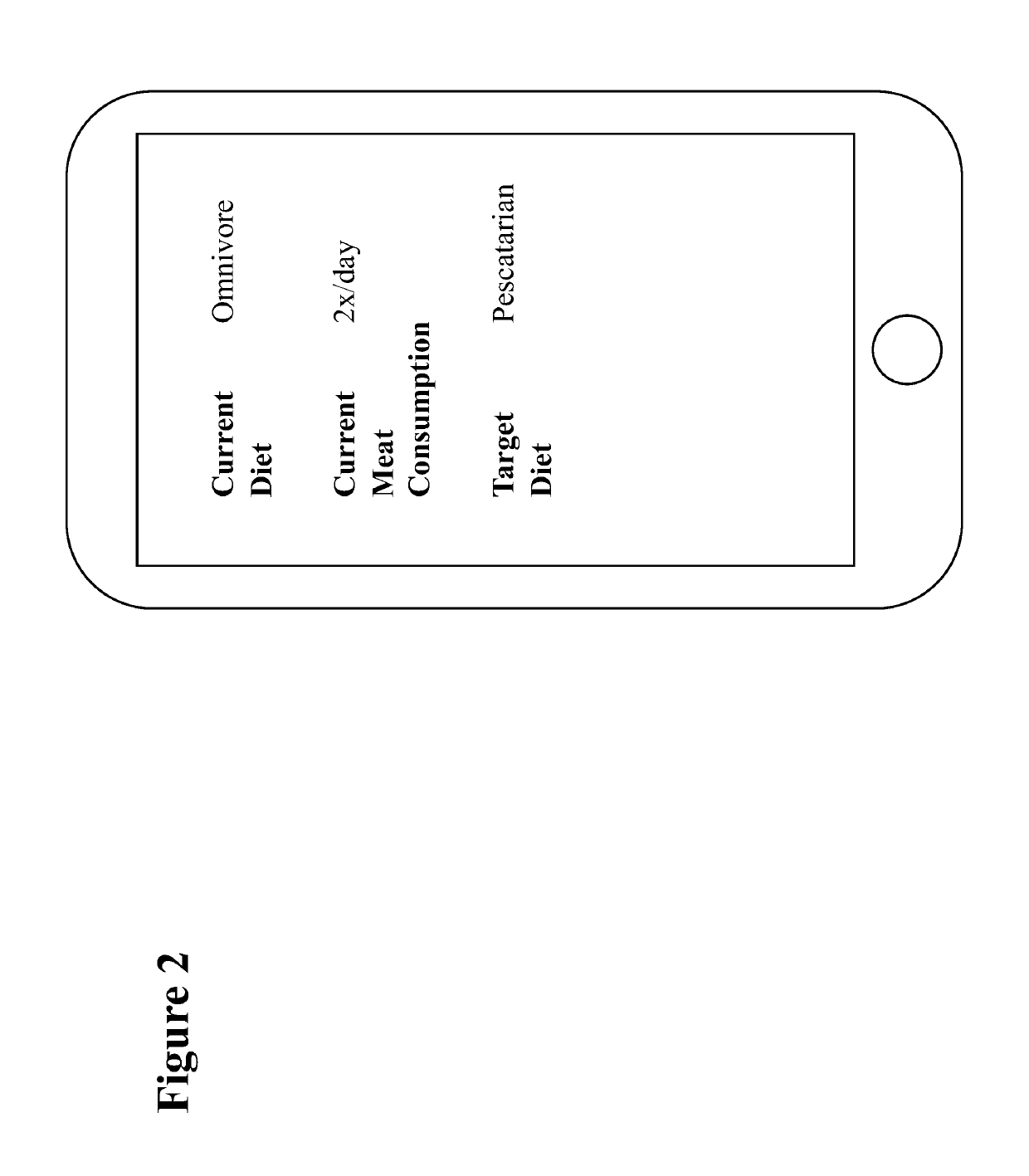

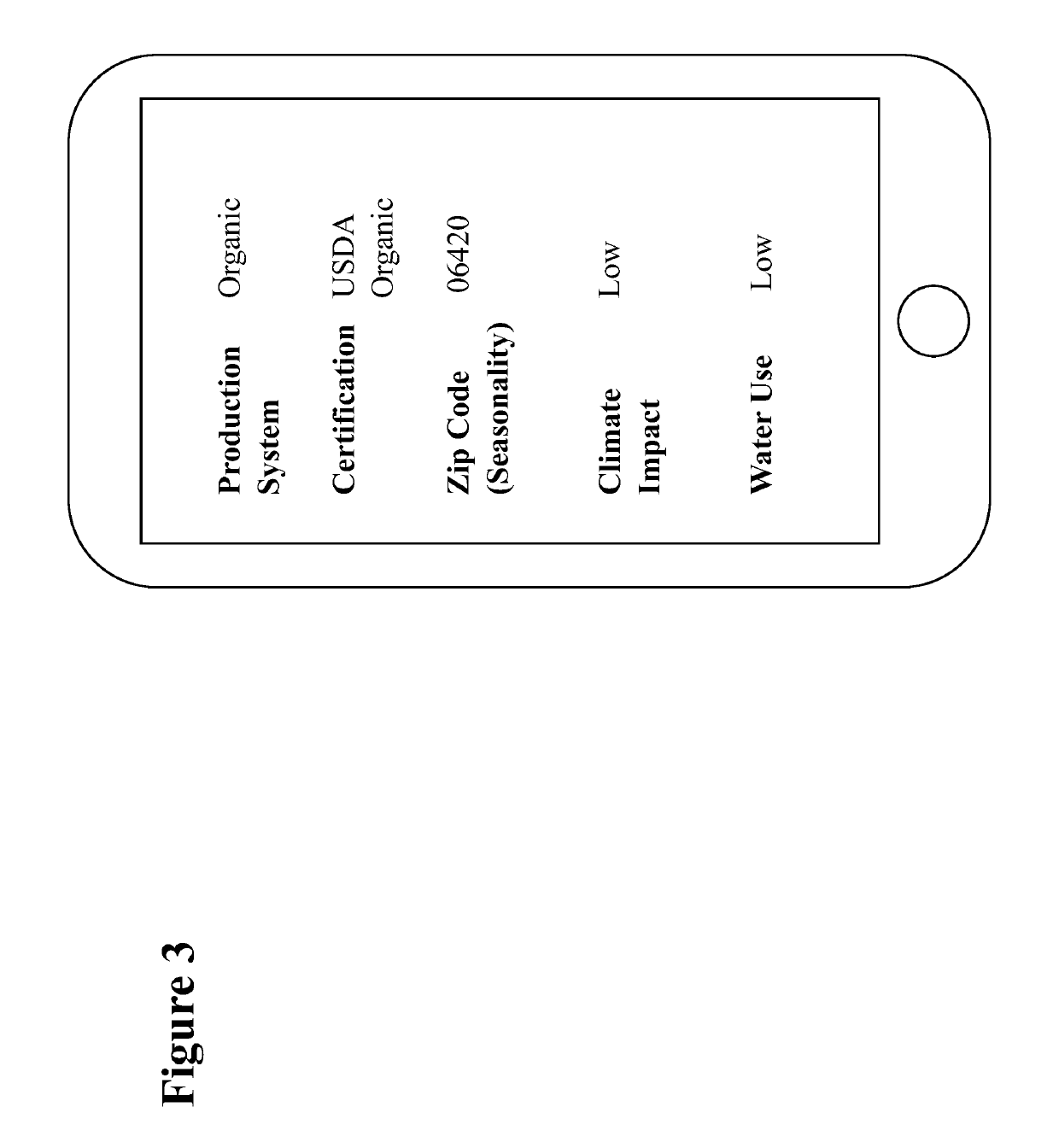

System for control over food and diet and related method to reduce environmental impact

InactiveUS20190228678A1Reduce environmental impactNutrition controlBuying/selling/leasing transactionsGuidelineAdditive ingredient

A system to control a user's food and diet to reduce their environmental impact including a device selected from the group consisting of a desktop computer, laptop, personal digital assistant (PDA), portable computer, tablet PC and wearable computer, storing a software program having instructions causing the device to receive a barcode, image, audio or text data of a food to be consumed by the user; for identifying the food and its ingredients; for analyzing the cost, nutritional content and environmental footprint of said food by a query to a database that stores information about the food; to determine the equivalency of the environmental footprint of the food; to compile each food item consumed by the user to create the user's current diet; to compare the user's current diet to an environmentally sustainable guideline diet; to generate a food recommendation to the user to reduce their environmental impact; and to connect a user to local sustainable food producers.

Owner:OSTFELD ROSEMARY ELIZABETH

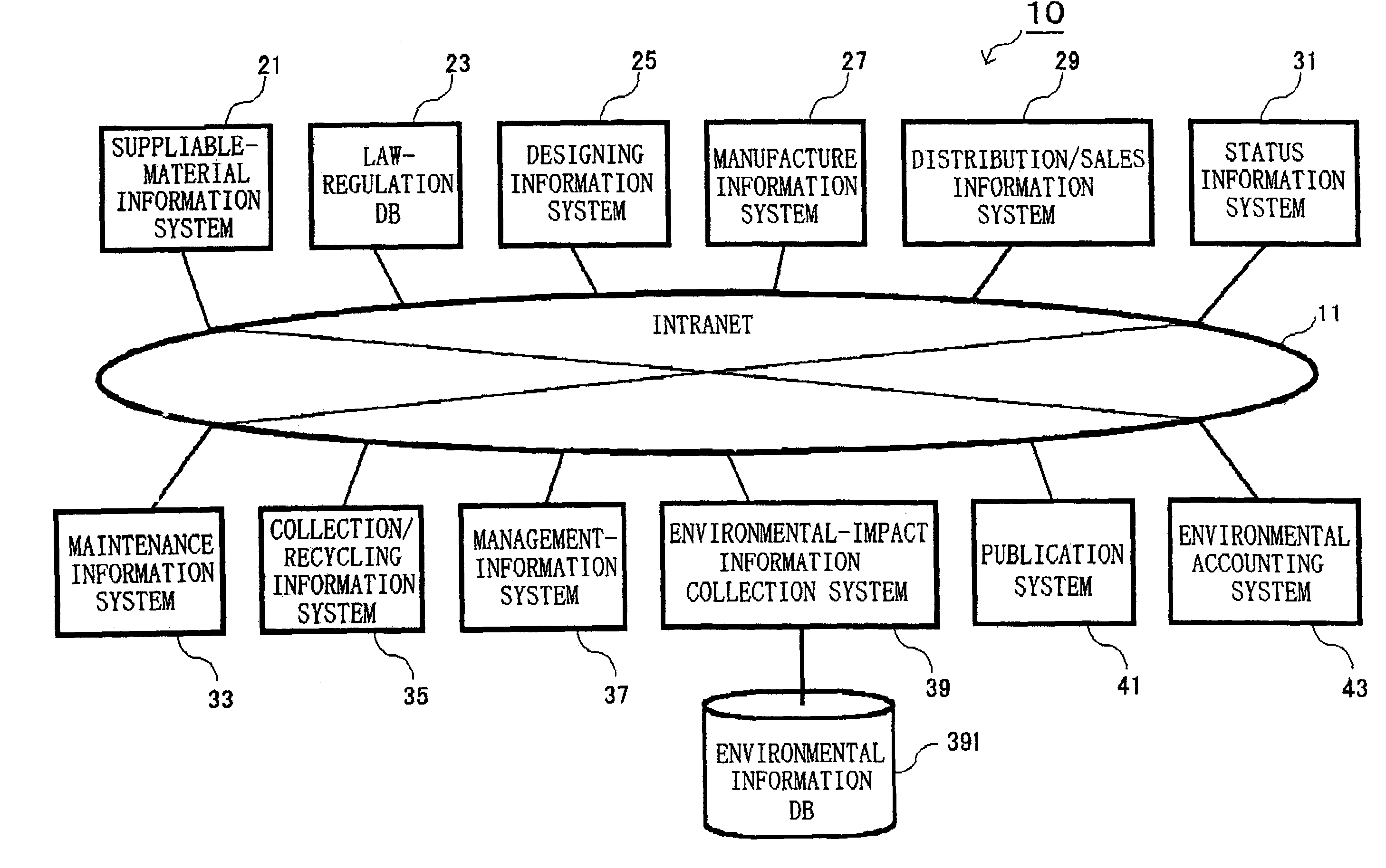

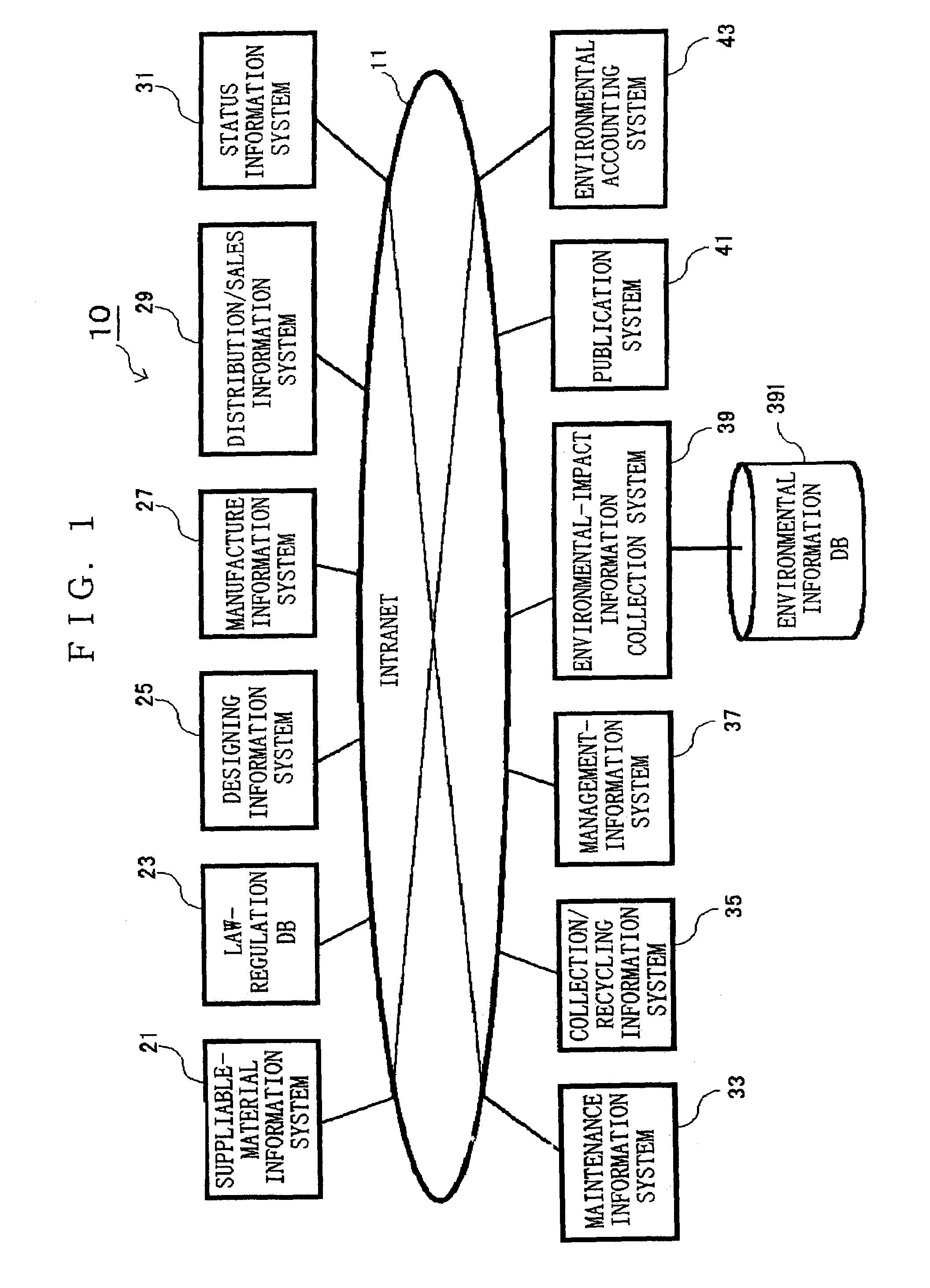

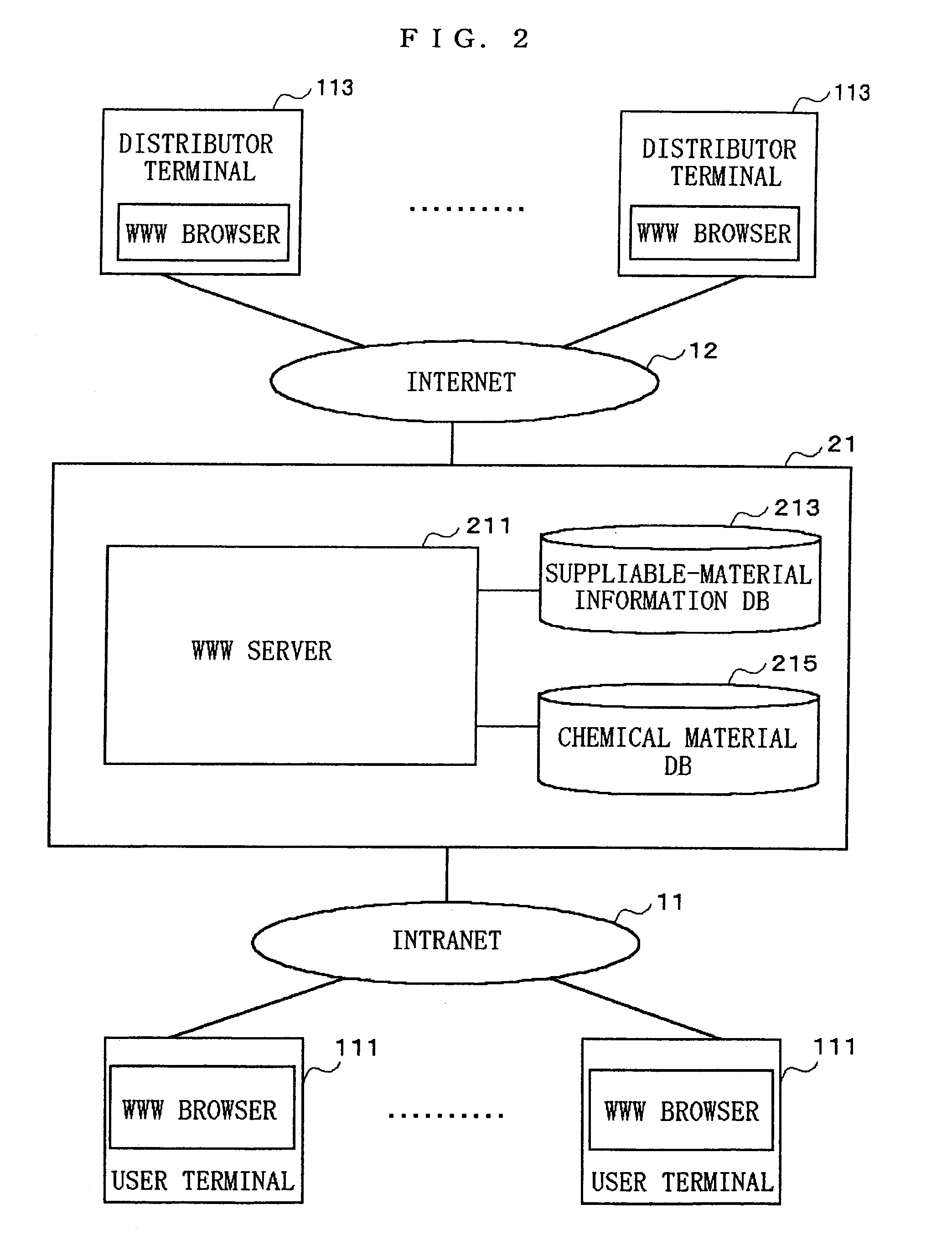

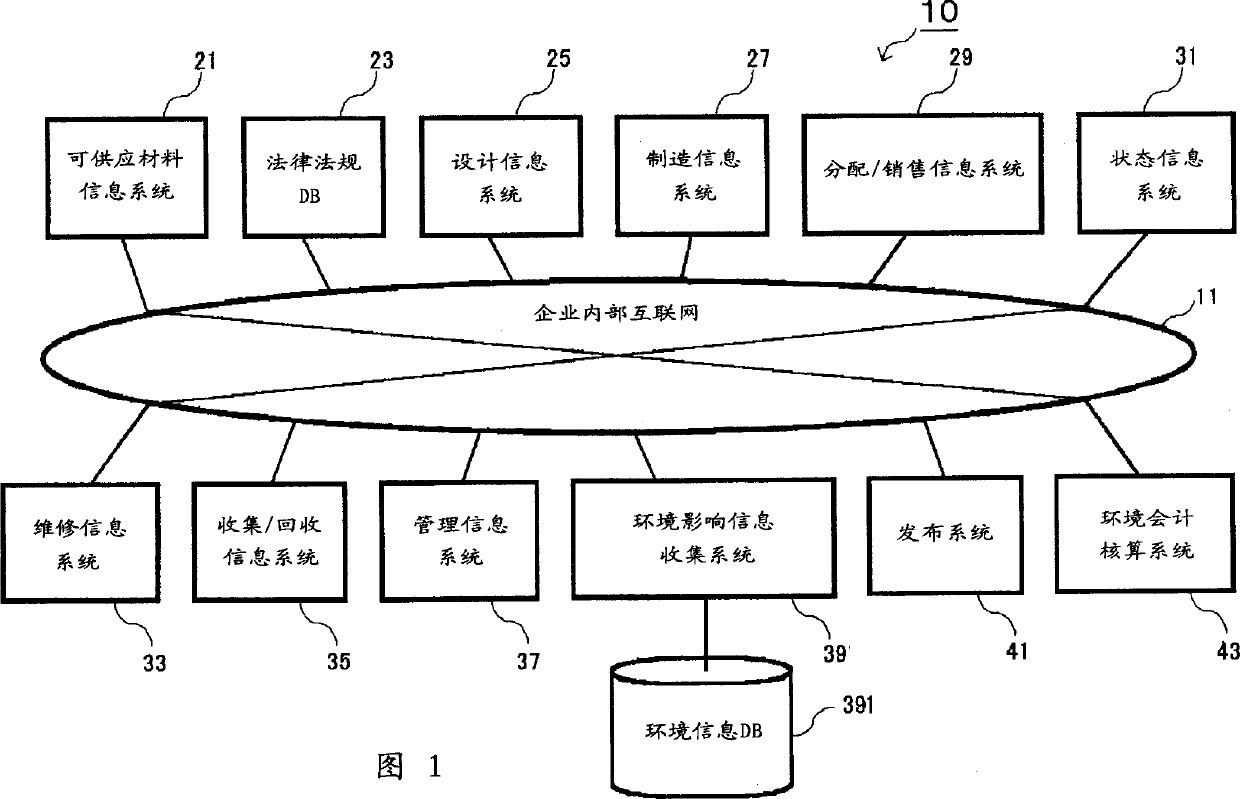

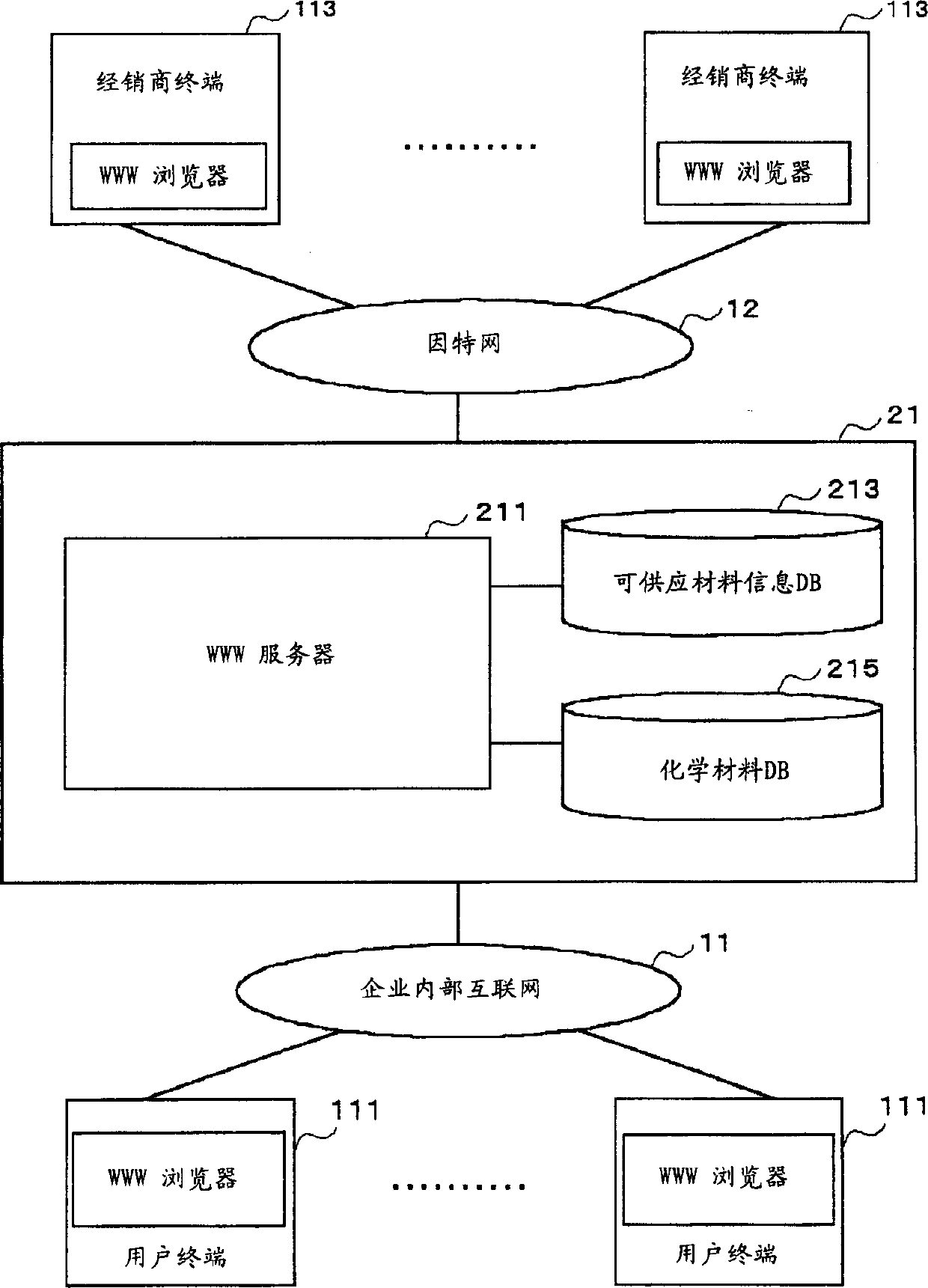

System and method for providing environmental management information, recording medium recording the information, and computer data signal

InactiveUS7177768B2Effectively minimizedHigh activityTechnology managementFinancial managementEnvironment effectCollection system

An environmental management information collection system modifies and analyzes environmental impact information, which is collected and stored in advance, and calculates a reduction amount of environmental impacts at each of a plurality of processes included in activities of an organization. A management-information system obtains the environmental impact at each process, and calculates an amount of investment for reducing the environmental impacts. An accounting system performs environmental accounting, based on the reduction amount of the environmental impacts which is obtained by the environmental impact information collection system and the amount of investment which is calculated by the management-information system.

Owner:RICOH KK

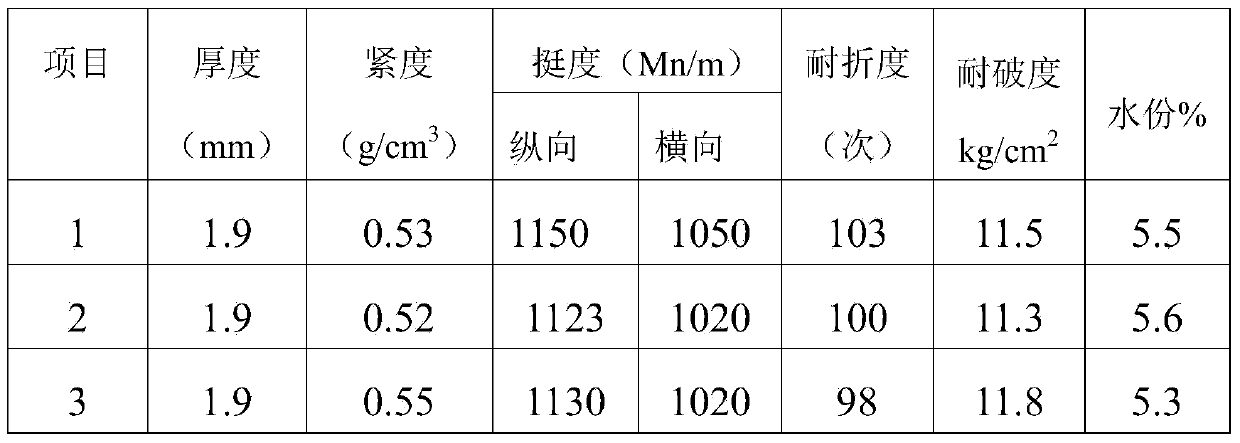

Technology for producing middle base plate by using waste cotton, waste paper and waste slurry slag

InactiveCN104195869ALow costLow withdrawal feesReinforcing agents additionPaper/cardboardCardboardFiber

The invention belongs to the technical field of papermaking, and in particular relates to a technology for producing a middle base plate by using waste cotton, waste paper and waste slurry slag. The technology comprises the following steps of pulping the waste cotton, extracting waste fibers from the waste slurry slag, removing impurities from the waste paper, performing crushing and defibering on the waste paper, performing mixing and color matching on waste, feeding slurry onto a net for forming, and performing wet-pressure dewatering through a wet paper board. According to the method, the middle base plate is produced by all types of wastes according to reasonable ratio. By virtue of the wastes in reasonable ratio, full reuse and waste fiber extraction are realized; a qualified middle base plate product is produced, so that the environment influence is reduced, and the economic benefit is achieved.

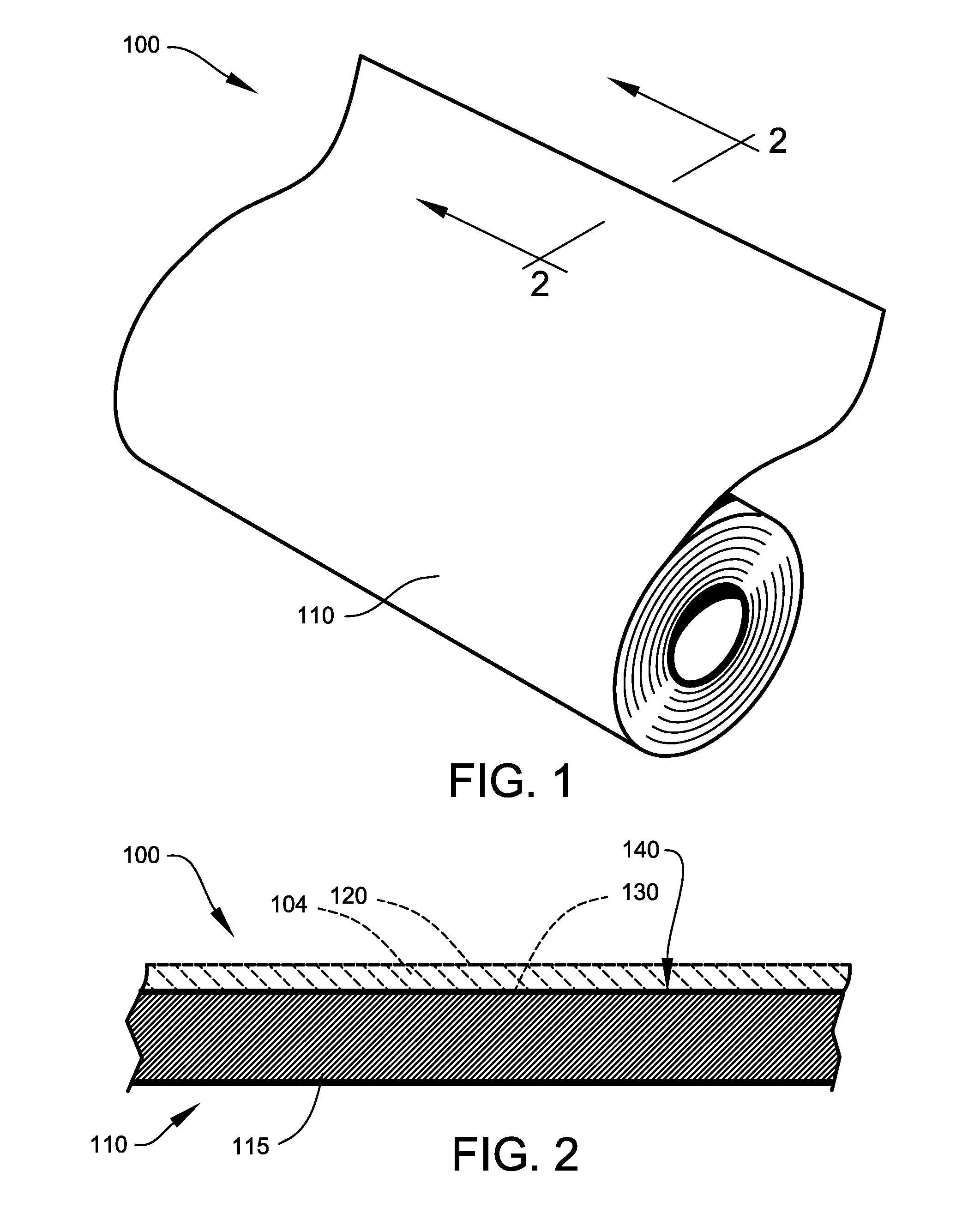

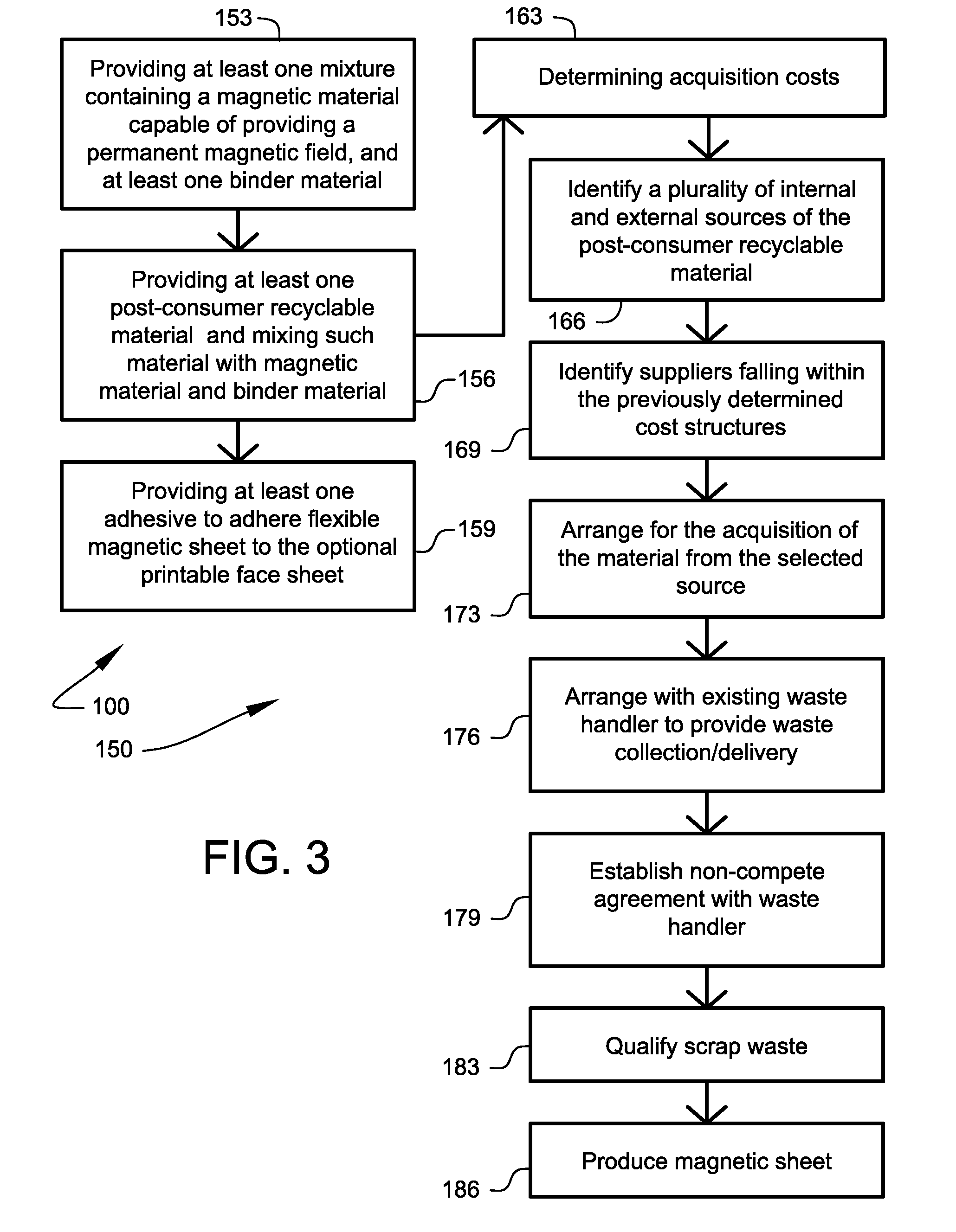

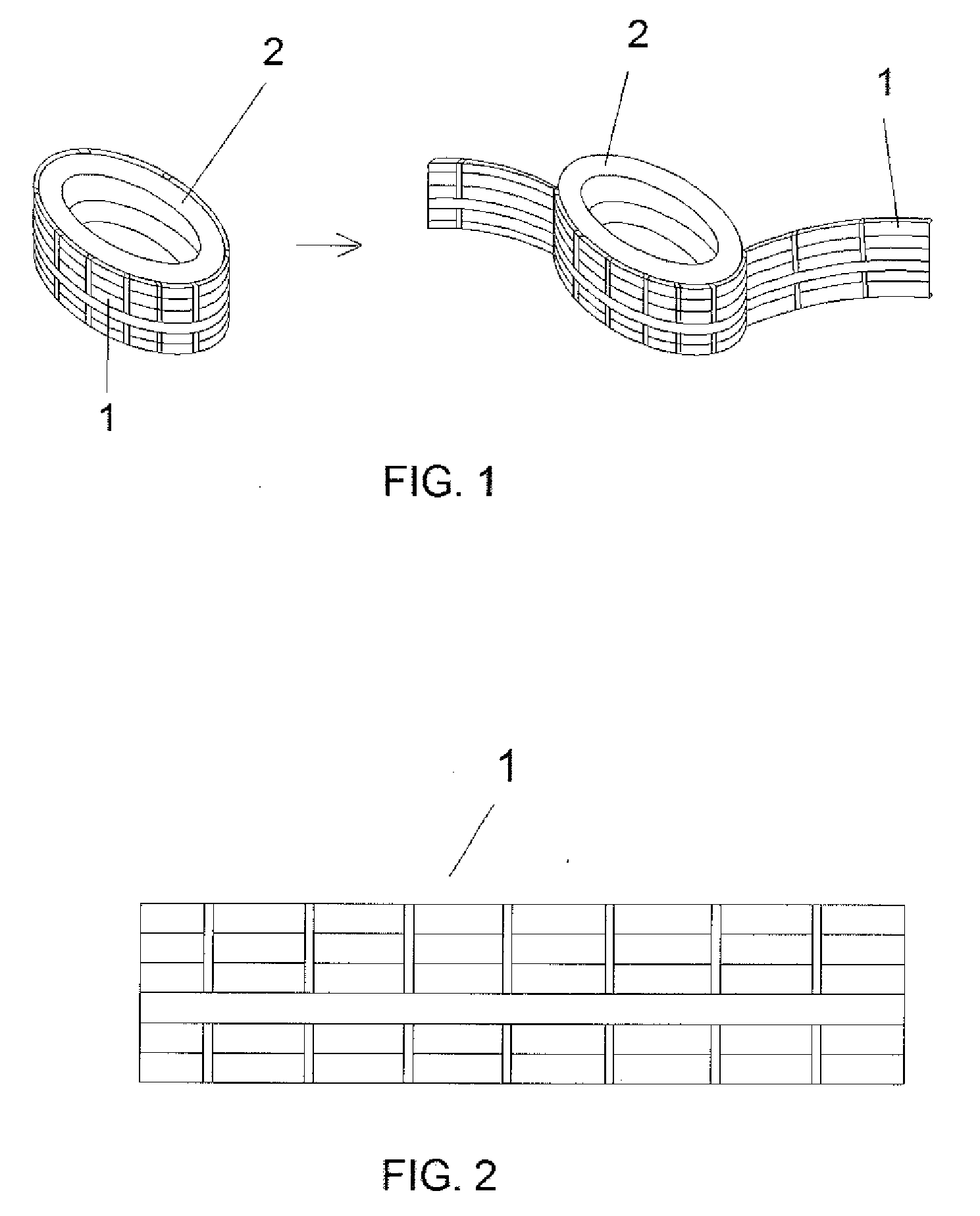

Reduced-environmental-impact magnetic sheet systems

InactiveUS20100247973A1Reduced-environmental-impact magnetic productsReduced-environmental-impact magnetic-sheet productsMagnetic paintsMagnetic materials for record carriersEngineeringRecycled products

A reduced-environmental-impact magnetic-sheet systems, processes and methods comprising flexible magnetic sheet material made with reduced-environmental-impact magnetic products from both pre-consumer and post-consumer recycled products.

Owner:MAGNUM MAGNETICS

Liquid developer containing electro-conductive particles and an electro-conductive pattern forming method using said material and an electro-conductive pattern forming apparatus using said material

A novel liquid toner development system is disclosed. The liquid development system includes conductive core-shell particles comprising silver-copper or copper-silver. A novel apparatus and method relying on the novel liquid toner development system results in electro-conductive patterning capable of high conductivity with low background fogging, reduced processing time and reduced environmental impact.

Owner:AFIT CORP

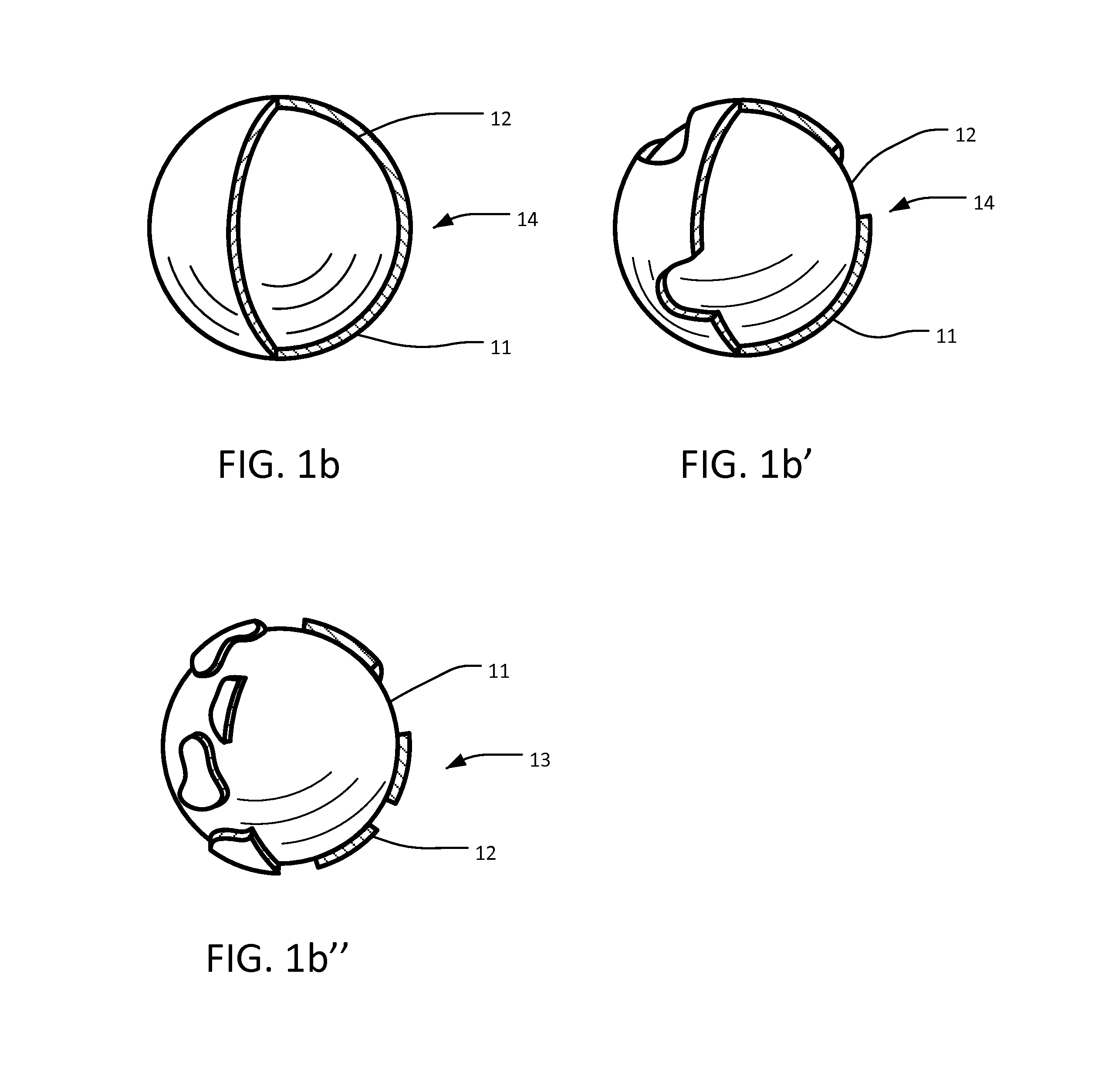

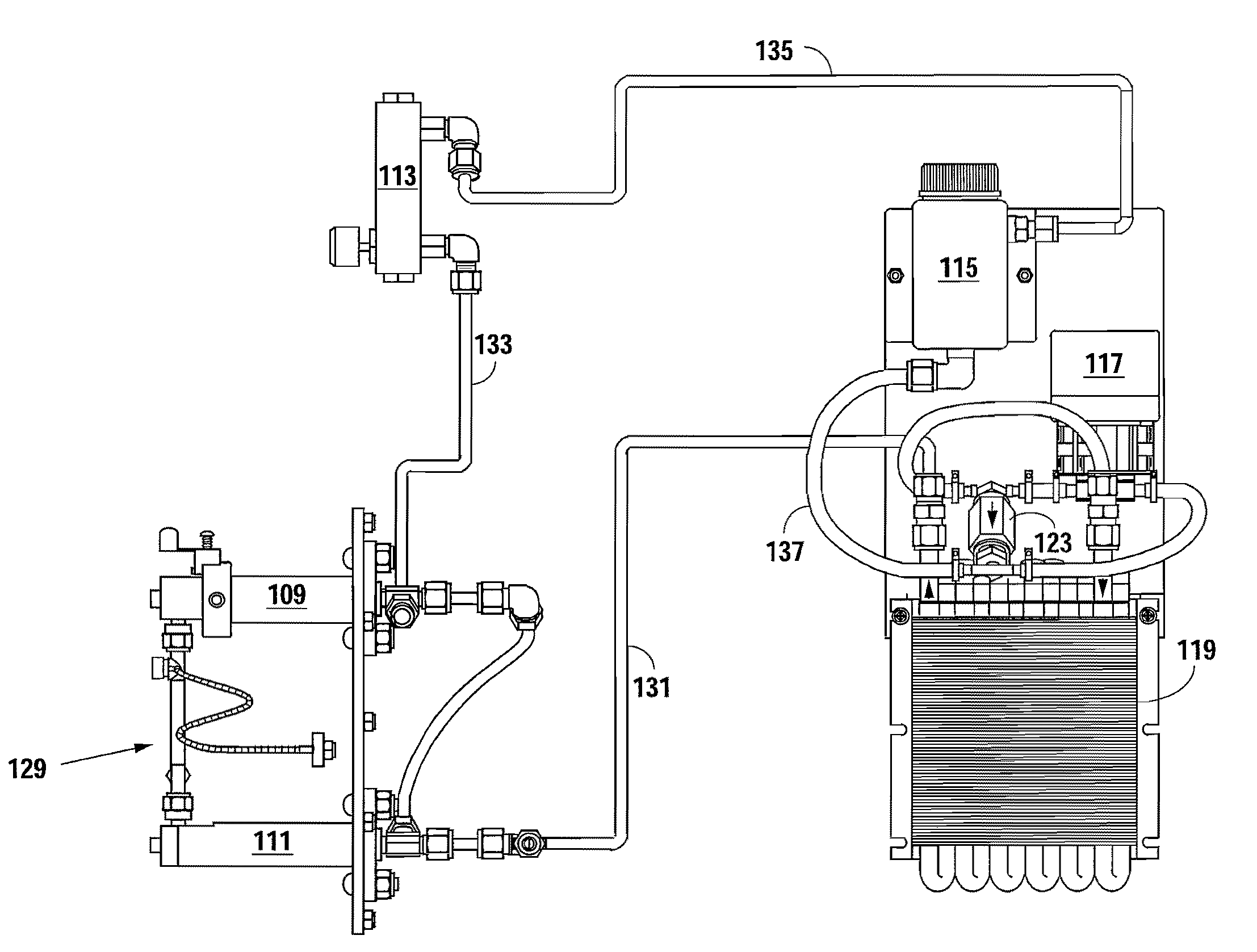

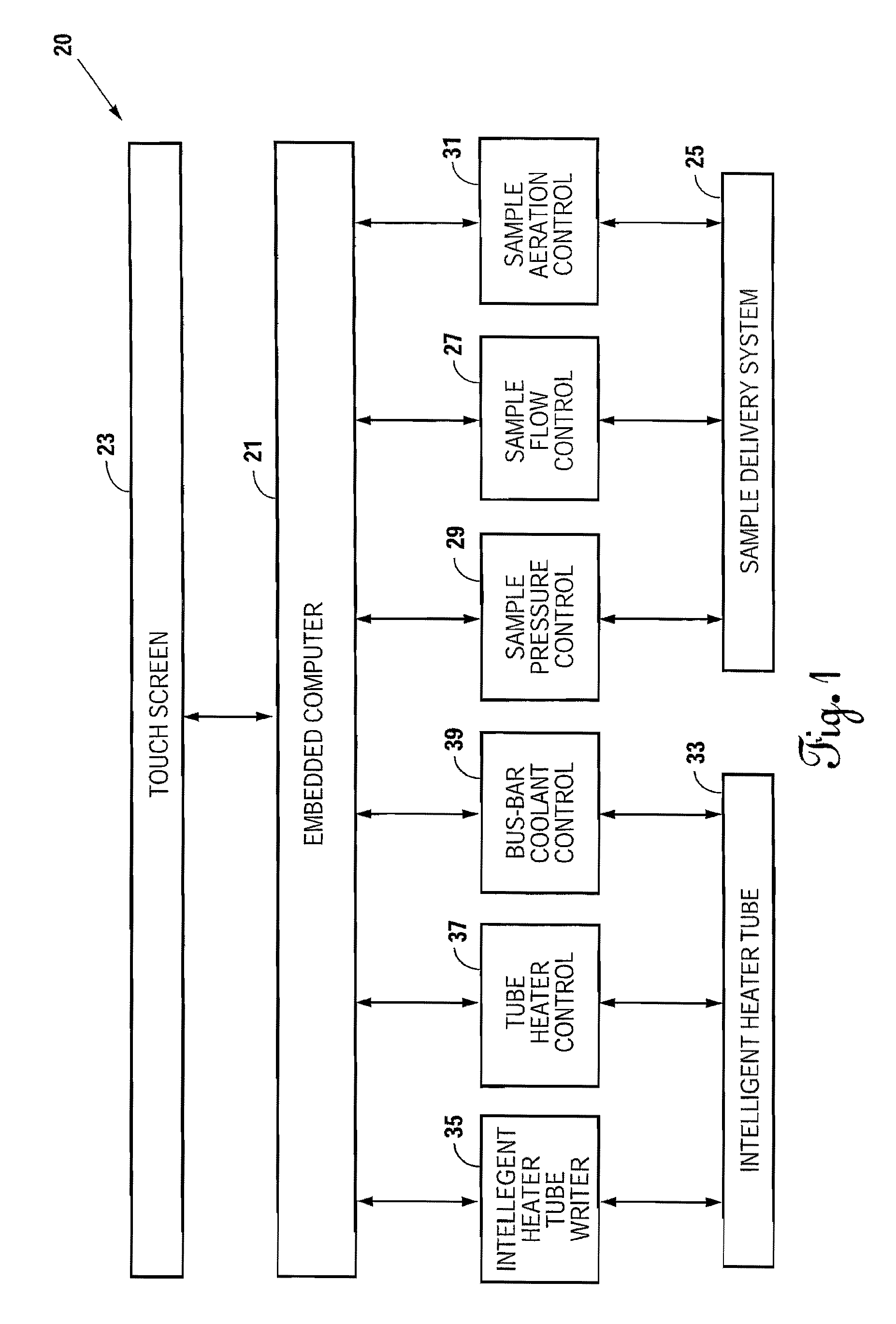

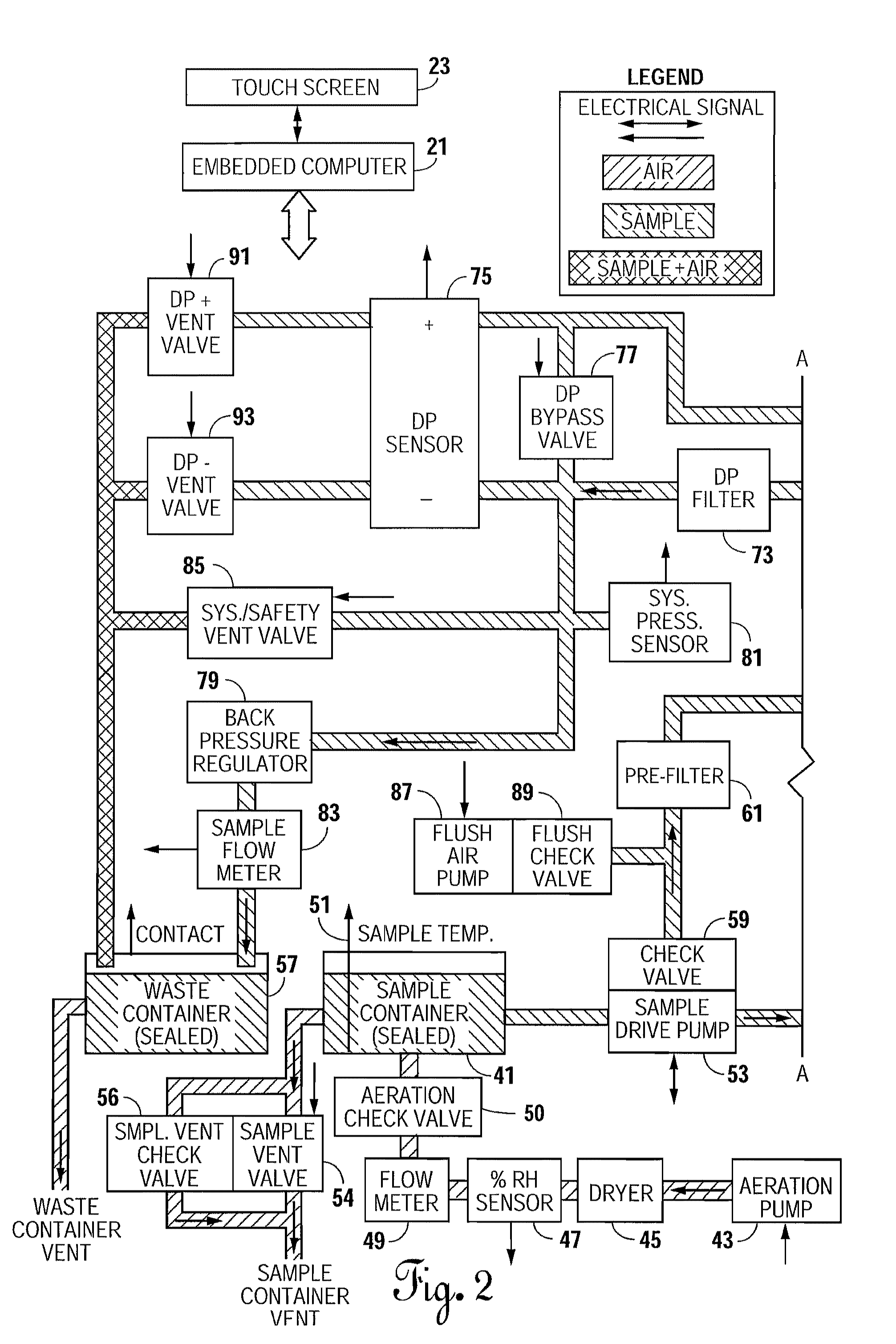

Containers used in determining the thermal stability of fuels

A thermal oxidation tester is shown for determining thermal stability of a fluid, particularly hydrocarbons, when subjected to elevated temperatures. The tendency of the heated fluid to oxidize and (1) form deposits on a surface of a heater tube and (2) form solids therein which are both measured at a given flow rate, temperature and time. The measured results are used to determine whether a fluid sample passes or fails the test. Specifically constructed containers used in a thermal oxidation tester are shown. These containers (1) reduce physical contact to hydrocarbon test fuels, (2) reduce exposure to hydrocarbon fuel vapors, (3) reduce environmental impact by reducing chemical spills, and (4) improve overall work flow of test.

Owner:PETROLEUM ANALYZER COMPANY

System and method providing environment administrative information, recording medium and data signal

An environmental management information collection system 39 modifies and analyzes environmental impact information, which is collected and stored in advance, and calculates a reduction amount of environmental impacts at each of a plurality of processes included in activities of an organization. A management-information system 37 obtains the environmental impact at each process, and calculates an amount of investment for reducing the environmental impacts. An accounting system 43 performs environmental accounting, based on the reduction amount of the environmental impacts which is obtained by the environmental impact information collection system and the amount of investment which is calculated by the management-information system 37.

Owner:RICOH KK

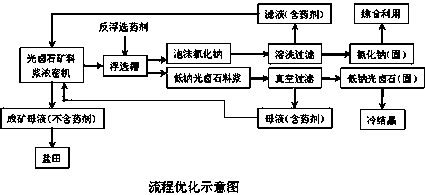

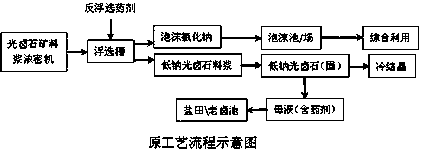

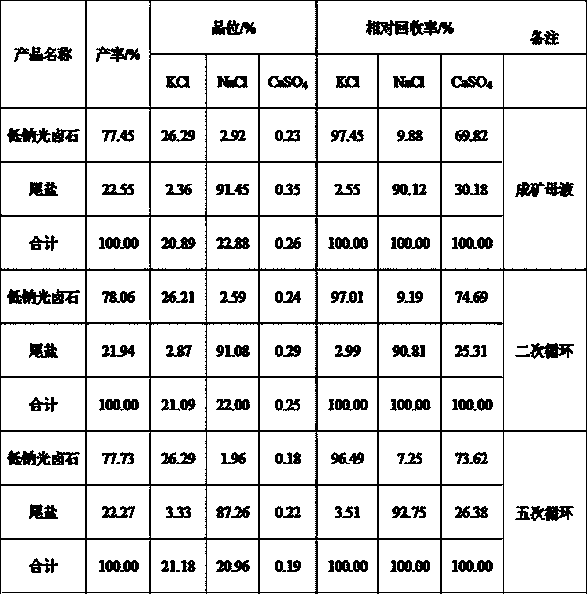

Method for reducing emission by reverse flotation reagent for carnallite mine

ActiveCN108355842AAchieve recyclingQuality improvementFlotationProcess optimizationMineral flotation

The invention relates to the field of mineral flotation. A method for reducing emission by a reverse flotation reagent for a carnallite mine is characterized by comprising the following main steps that (1) a foam sodium chloride solution washing and filtering technology is added after reverse flotation operation, filtered filtrate containing medicament returns to a carnallite slurry thickener workshop section; (2) after the reverse flotation operation, the low sodium carnallite slurry is filtered in vacuum and the filtrate containing the medicament returns to the carnallite slurry thickener workshop section as well; and (3) the filtrate containing the medicament continuously returns to the carnallite slurry thickener workshop section for recycling, and finally, ore-forming mother liquor which does not contain the medicament returns to a salt pan. Combined the process characteristics of an original technology, the method adopts a process optimization method and adds a recycling technology of mother liquor containing medicament to replace the ore-forming mother liquor, the aims of reducing the emission by the reverse flotation reagent and reducing the environmental impact are achieved, and meanwhile, fine control of a flotation operation separating index can be realized.

Owner:青海省化工设计研究院有限公司

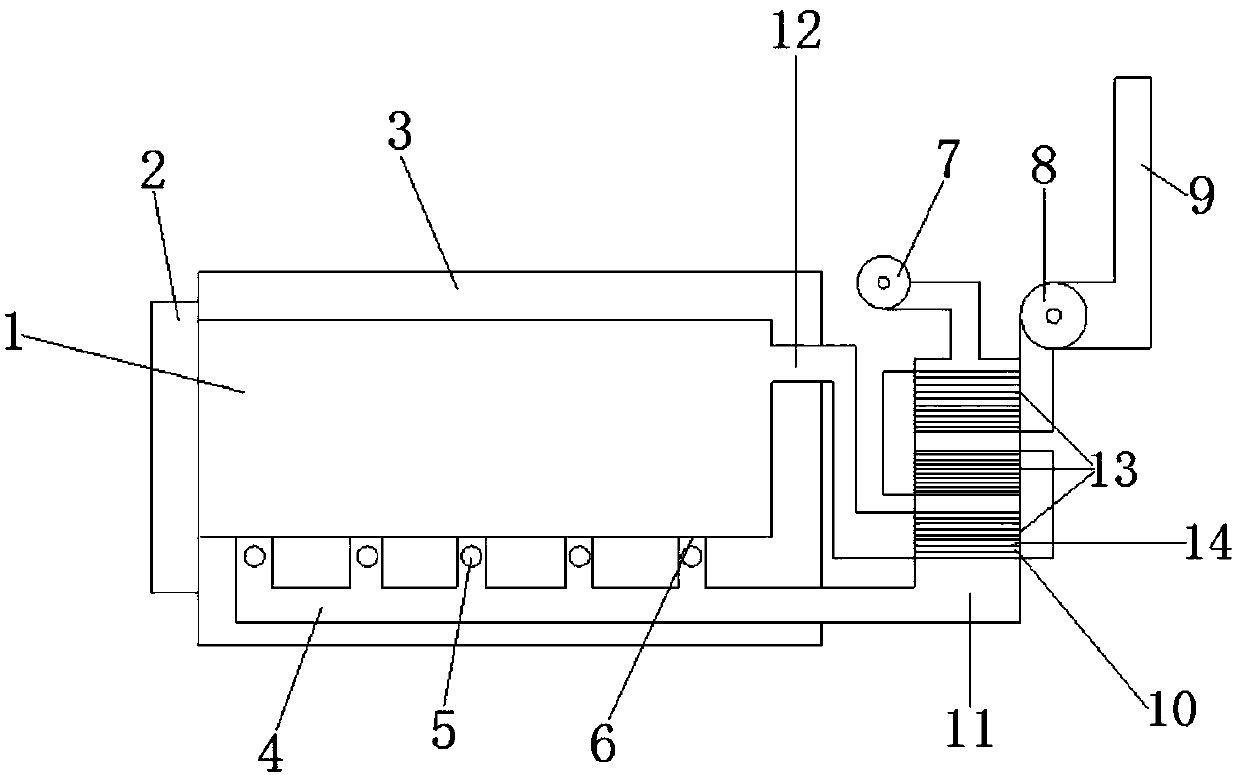

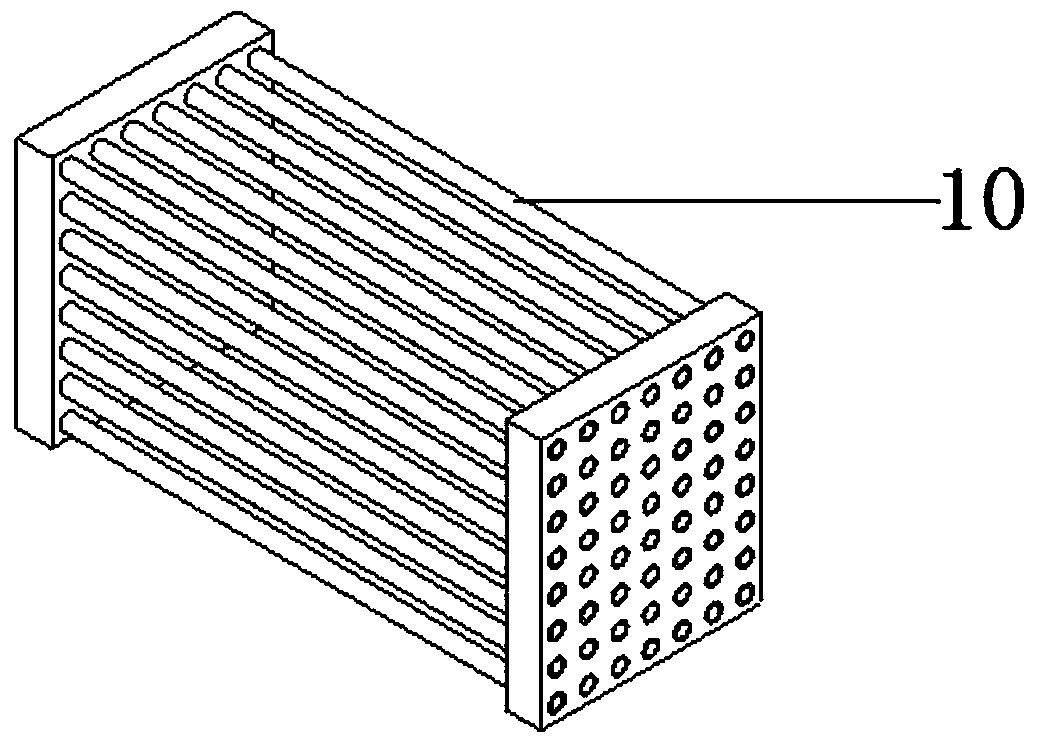

Heat exchange chamber-type energy saving shuttle kiln

InactiveCN107764072ASolve the problem of a large amount of waste heat dischargeReduce the impactFurnace typesWaste heat treatmentTemperature differenceEngineering

The invention discloses a heat exchange chamber-type energy saving shuttle kiln, comprising a kiln body 1; a furnace wall 3 is arranged on the periphery of the kiln body 1, a kiln door 2 is arranged on one side surface of the kiln body, an air exchange opening 12 is arranged opposite to the kiln door 2, the air exchange opening 12 is connected to a heat exchange chamber 11, the heat exchange chamber-type energy saving shuttle kiln is characterized in that heat exchange ceramic tubes 10 are arranged in the heat exchange chamber 11, the top of the heat exchange chamber 11 is provided with a blower 7, the side surface of the heat exchange chamber 11 is provided with a draught fan 8 connected to a chimney 9, the bottom of the kiln body 1 is provided with a burning opening 6, the burning opening 6 is connected to a gas supply pipeline by a fuel gas pipeline 5, and the bottom of the kiln body 1 is provided with a combustion air pipeline 4. The heat exchange chamber-type energy saving shuttlekiln solves the problem of massive discharge of waste heat of the chimney, when the kiln is burnt to 1600 DEG C, the temperature of the chimney is reduced to the temperature smaller than 140 DEG C from the original temperature larger than 1000 DEG C, preheating discharge is obviously reduced, environmental influence and energy waste are reduced, fuel gas is saved by about 30%, and the energy saving and emission reduction are realized truly. A temperature difference in the kiln is reduced to improve the product sintering quality, and the rate of finished products is as high as 99%.

Owner:宜兴市海科耐火材料制品有限公司

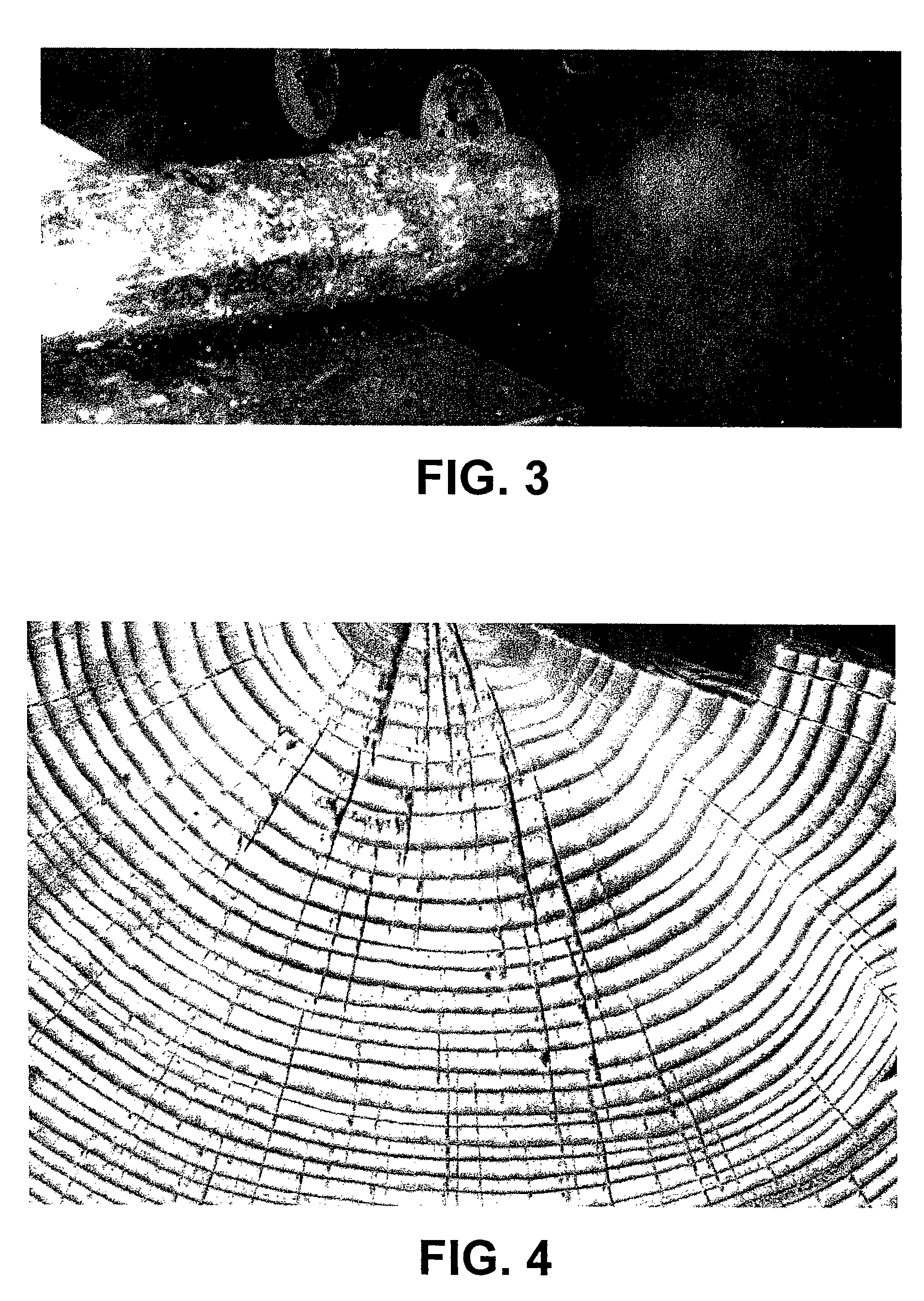

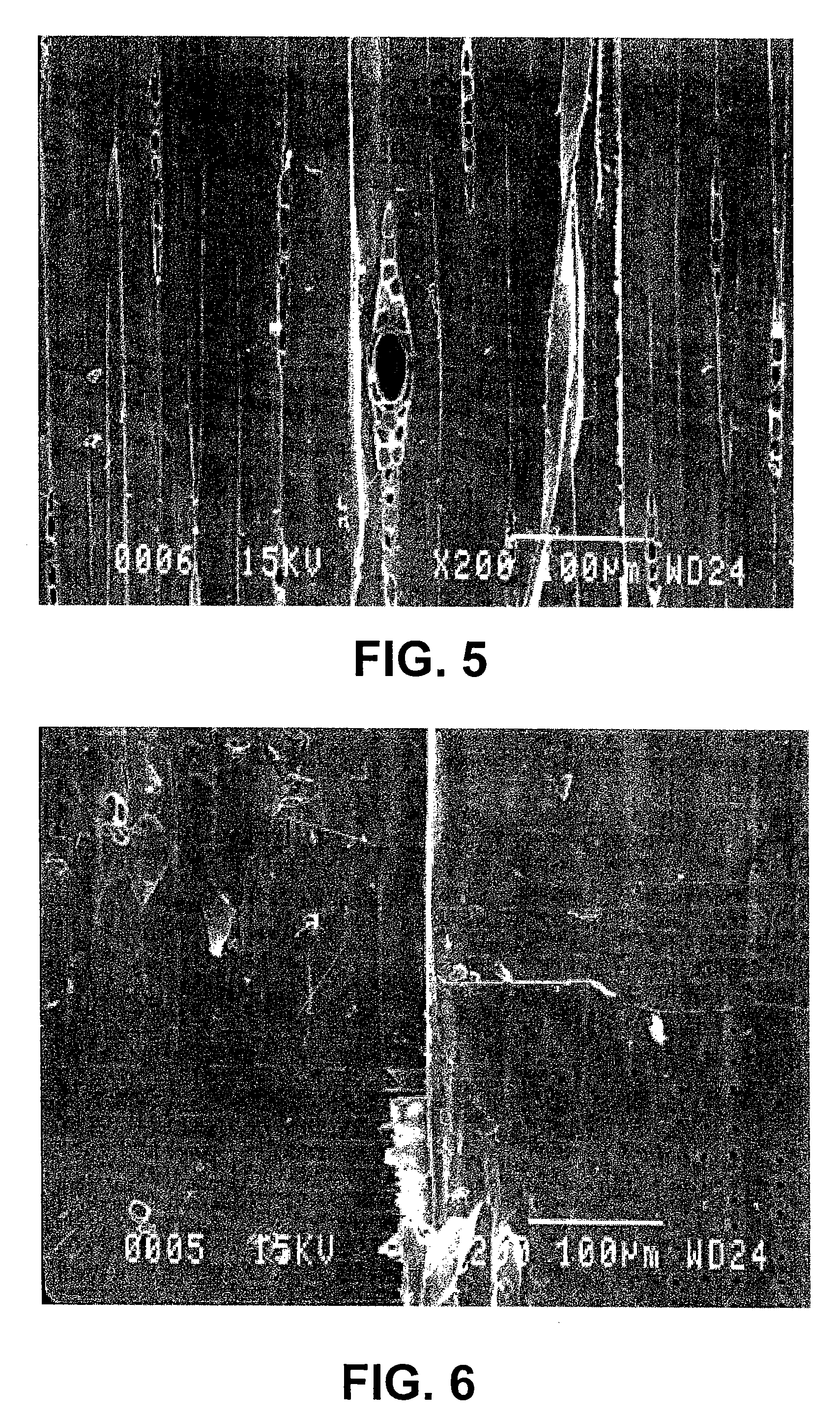

Microwave pretreatment of logs for use in making paper and other wood products

InactiveUS20060243403A1Reduce the amount requiredHigh opacityDryer sectionMachine wet endPulp and paper industryPre treatment

A method of producing pulp for use in making paper products using microwave radiation to pretreat the source of pulp prior to further processing. Practicing the method of the invention results in substantial energy savings while decreasing environmental impact and improving paper qualities.

Owner:BIOPULPING INT +1

Method for extracting ceramide from chestnut shells

ActiveCN107827768AEasy to operateEasy extractionCarboxylic acid amide separation/purificationLactariusCastanopsis sclerophylla

The invention discloses a method for extracting ceramide from chestnut shells. The method comprises the following steps: cleaning chestnut shells, crushing the cleaned chestnut shells, adding water with a weight of 3-5 times of the weight of the chestnut shells, adding lactic acid bacteria for fermentation, carrying out centrifugal separation on the obtained fermentation liquor, taking the clear liquor for later use, filtering and sterilizing the obtained clear liquor through a millipore filter membrane, and carrying out continuous chromatographic selection separation on the obtained filtrateto obtain the ceramide. According to the invention, the lactic acid bacteria are used for fermentation of the chestnut shells, and a large amount of ceramide substances can be secreted into the fermentation liquor, so that no derivatization process is needed, the operation is simple, the extraction is convenient, the fermentation period is short, the effect is quick, and the limitation by regionalclimate is avoided. The waste chestnut shells are turned into wealth, and resources are fully utilized. According to the process used for producing the ceramide, the solvent can be repeatedly used, the environmental influence is reduced, and the economic cost is reduced.

Owner:JINZHAI LIMIN BIOTECH CO LTD

Vacuum sealing method of lithium ion battery

InactiveCN108199085AGuaranteed capacityGuaranteed service lifeFinal product manufactureElectrolyte accumulators manufactureLithium-ion batteryEnvironmental impact reduction

The invention belongs to the technical field of battery manufacturing, and discloses a vacuum sealing method of a battery. According to the method, a battery to be sealed is placed in a vacuum environment of (-40)-(-60) KPa for at least 5 minutes and then is sealed, thus, gas in the battery can be enabled to be completely discharged on the premise that an electrolyte is not pumped out of the battery, highly-uniform pressure in the battery can be maintained, the retention quantity of the electrolyte in the battery is increased, the capacity of the battery is ensured, the service lifetime of thebattery is ensured, and meanwhile, the shape of the battery also can be enabled not to be changed. Moreover, the method is reasonable in process parameter setting, the environmental influence can beeffectively reduced in the vacuum environment, the method is simple and convenient to operate, the sealed environment can be rapidly optimized, the method is suitable for mass production, and a basisis provided for sealing a single battery as well as the product quality requirement is ensured.

Owner:HEBEI YINLONG NEW ENERGY +1

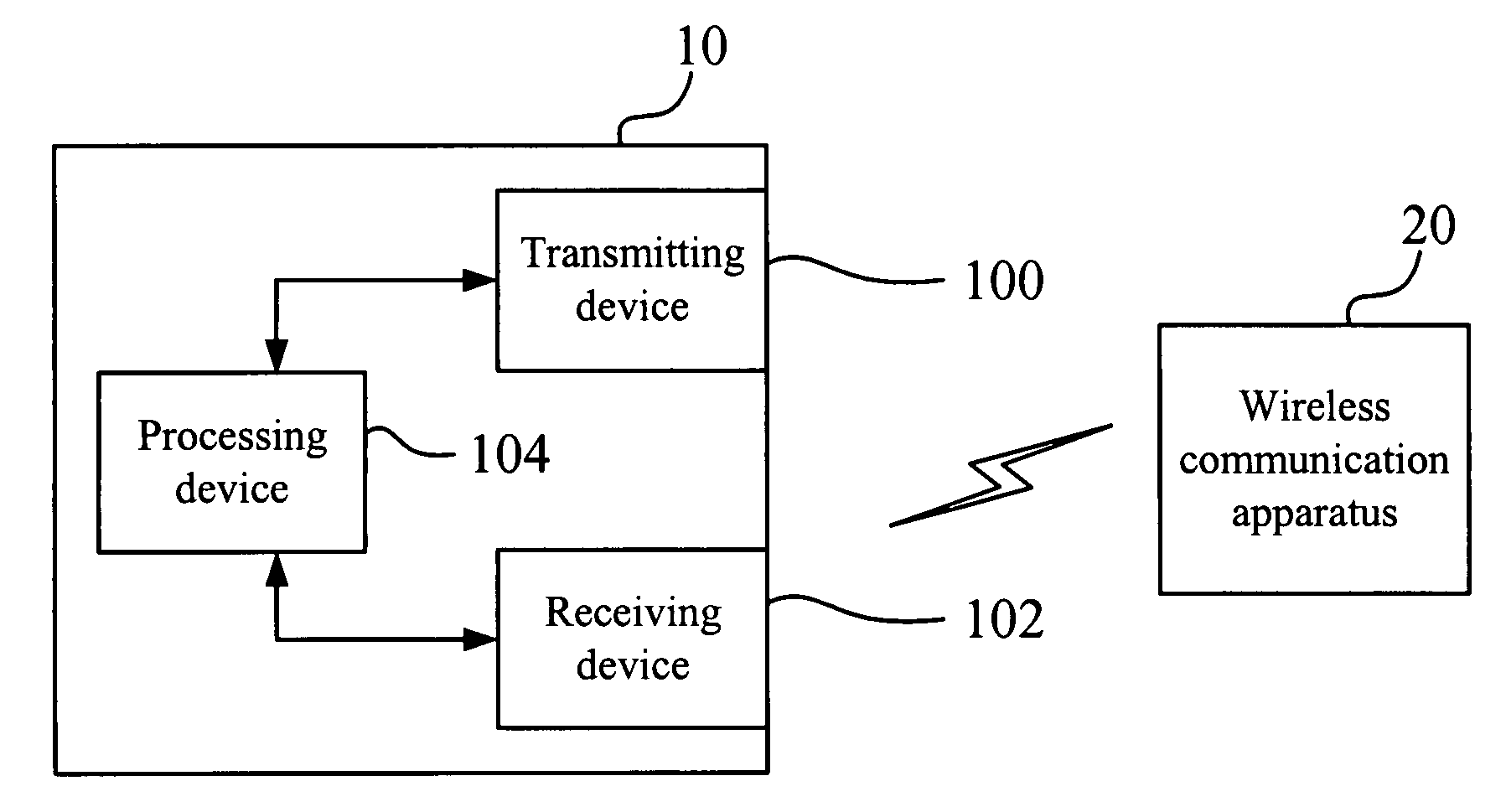

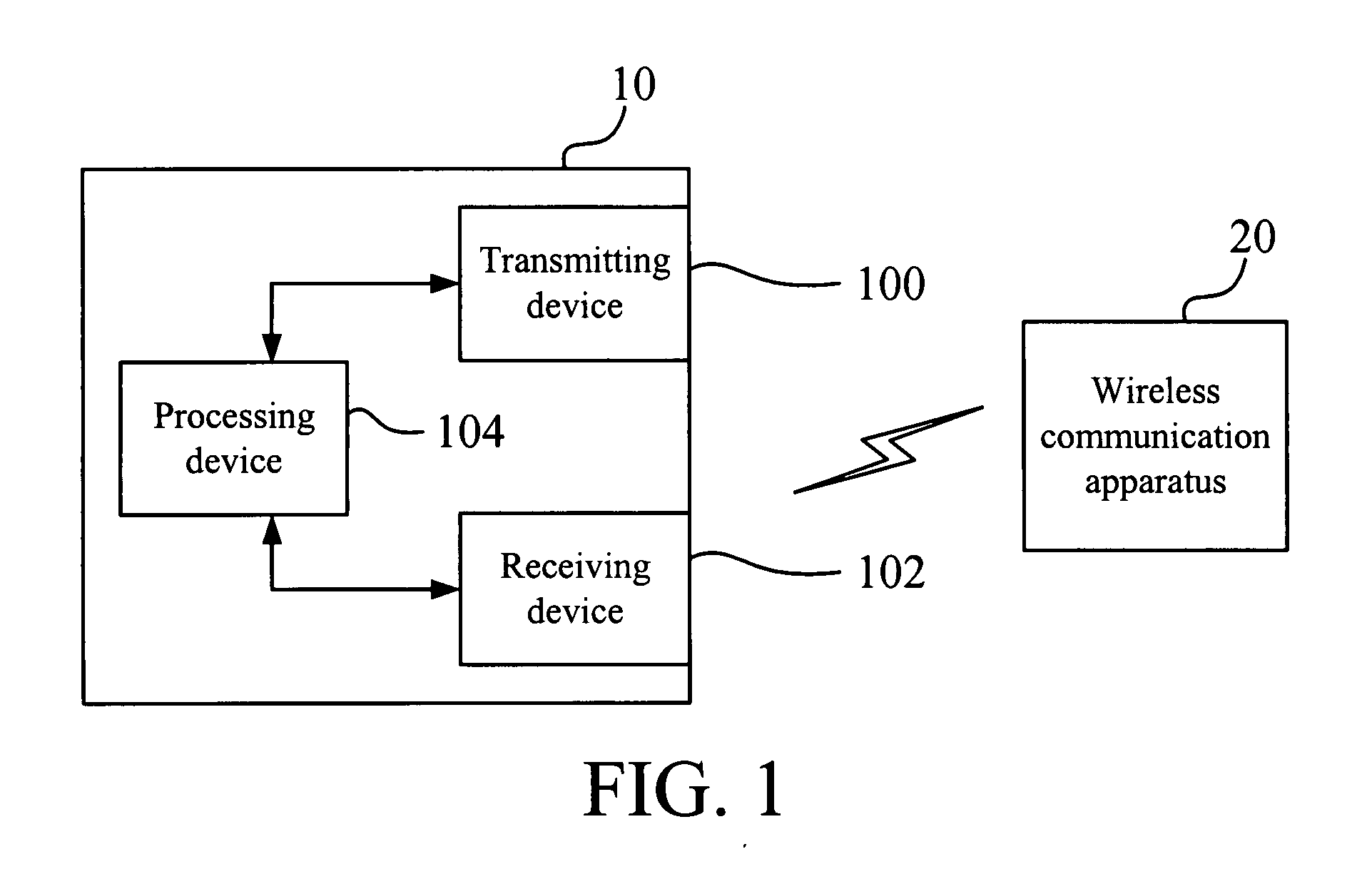

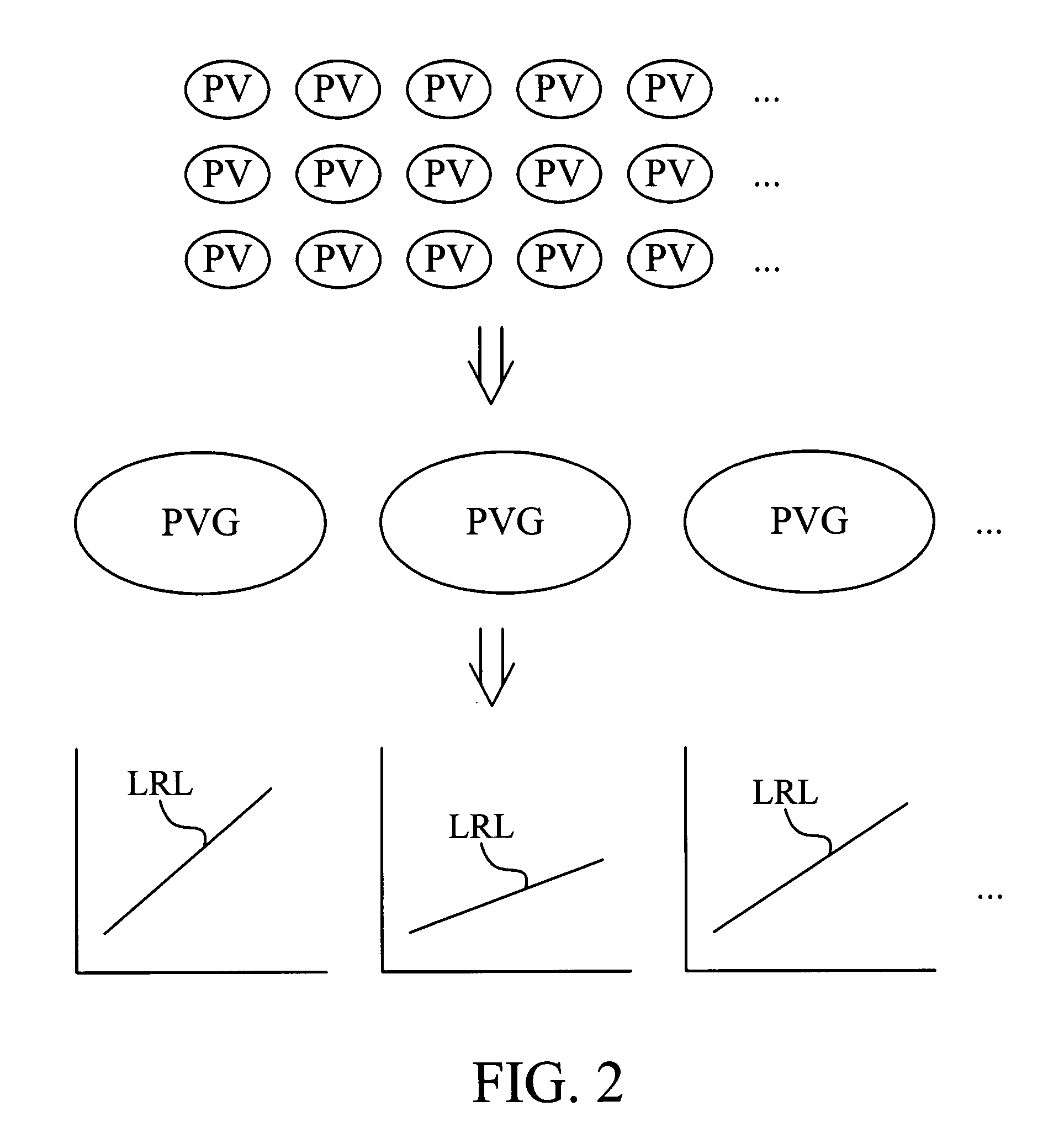

Positioning system of positioning wireless communication apparatus

InactiveUS20080280629A1Accurate valueAccurate communicationPosition fixationRadio/inductive link selection arrangementsComputer sciencePositioning system

The invention provides a positioning system of positioning a wireless communication apparatus. The positioning system transmits and receives positioning signals which have different frequency bands and generates corresponding positioning values according to the positioning signals. The positioning system then judges and selects positioning values which have less error from the generated positioning values, and calculates an average value of the selected positioning values. Therefore, positioning of the wireless communication apparatus will be more precise. Furthermore, if the positioning system is implemented in a radio-wave-based wireless communication environment, the N positioning signals can be polarized in a linear polarization way, a left-handed circular polarization way or a right-handed circular polarization way, so as to reduce the environmental impact to enhance precision of the positioning.

Owner:QUANTA COMPUTER INC

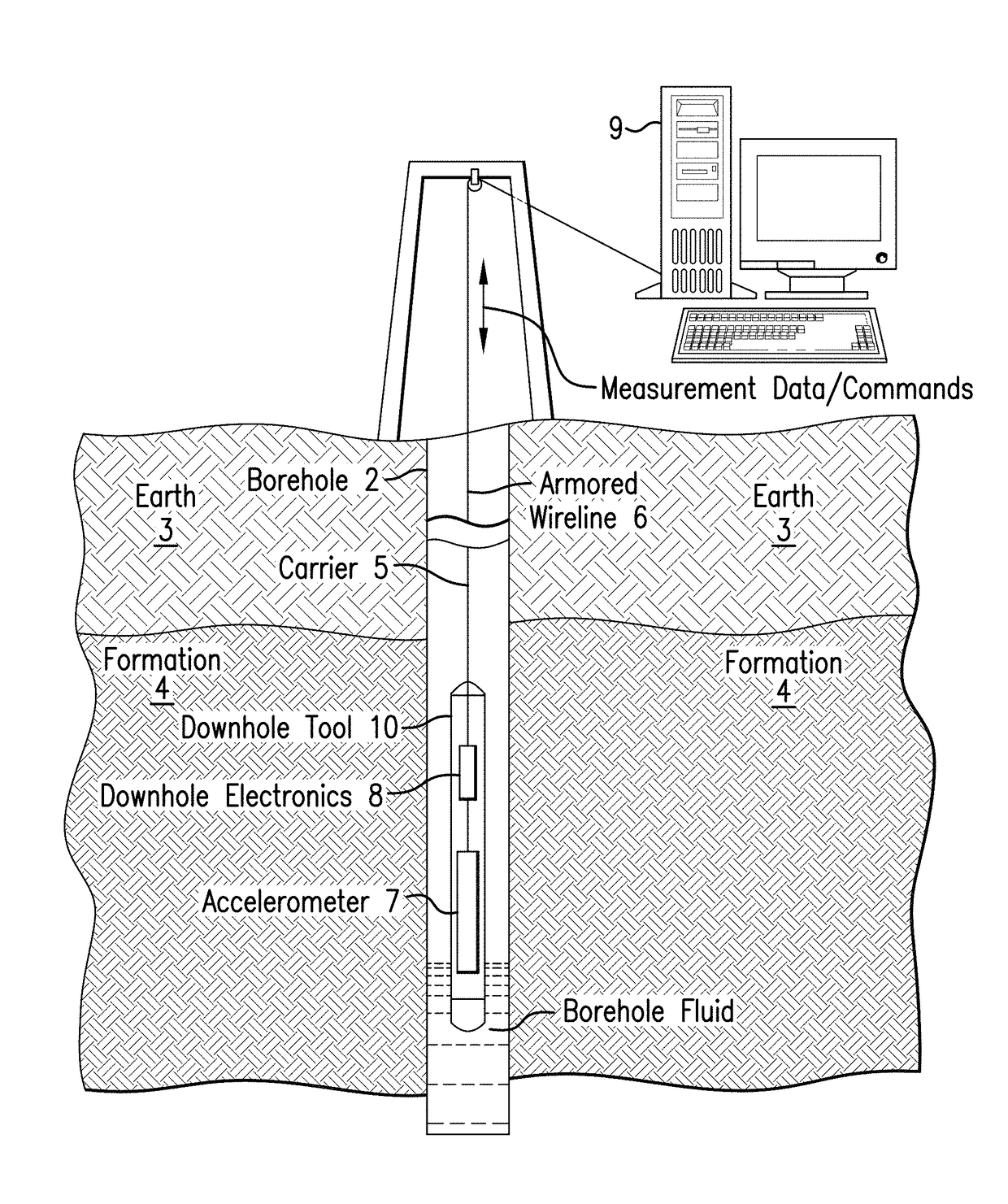

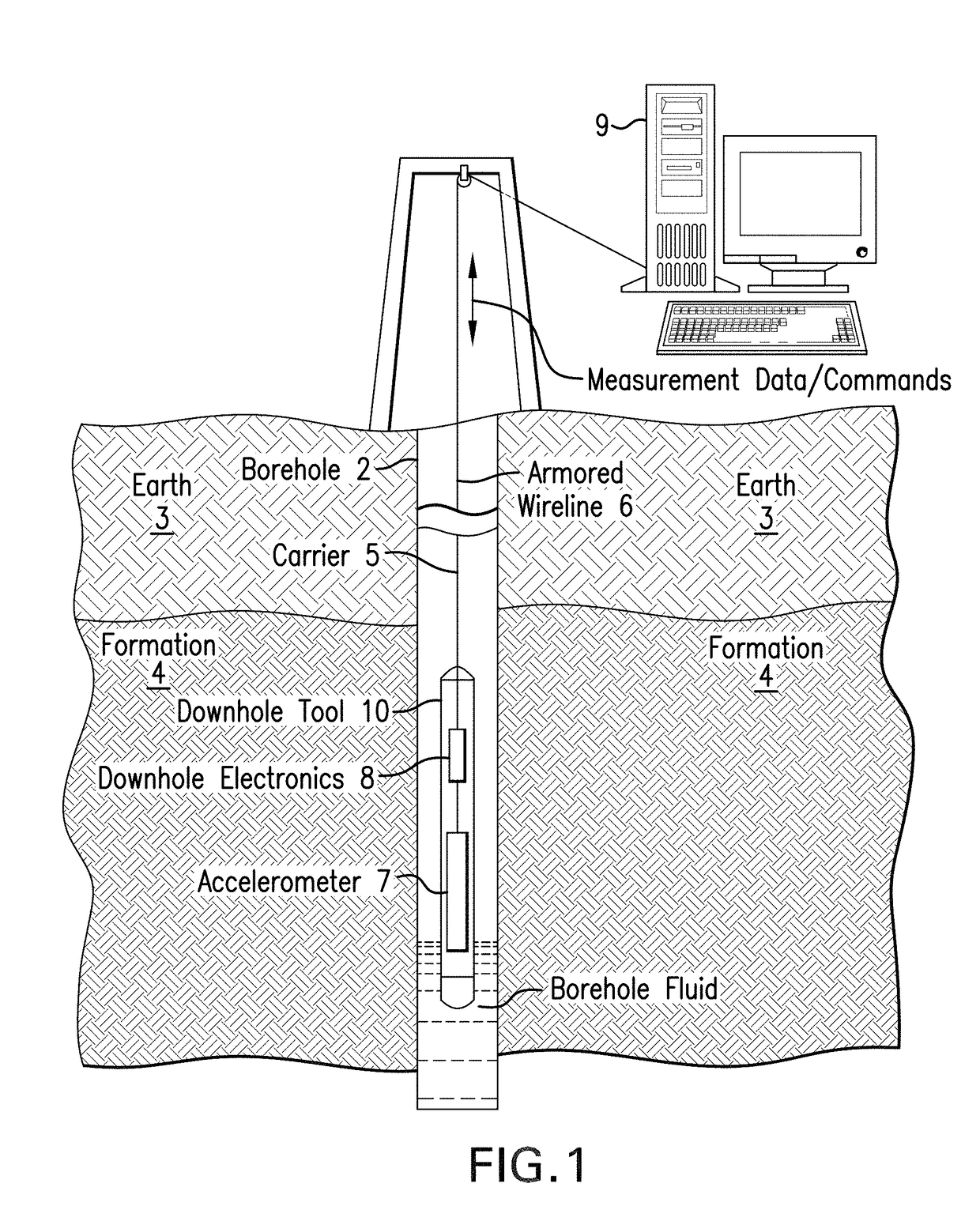

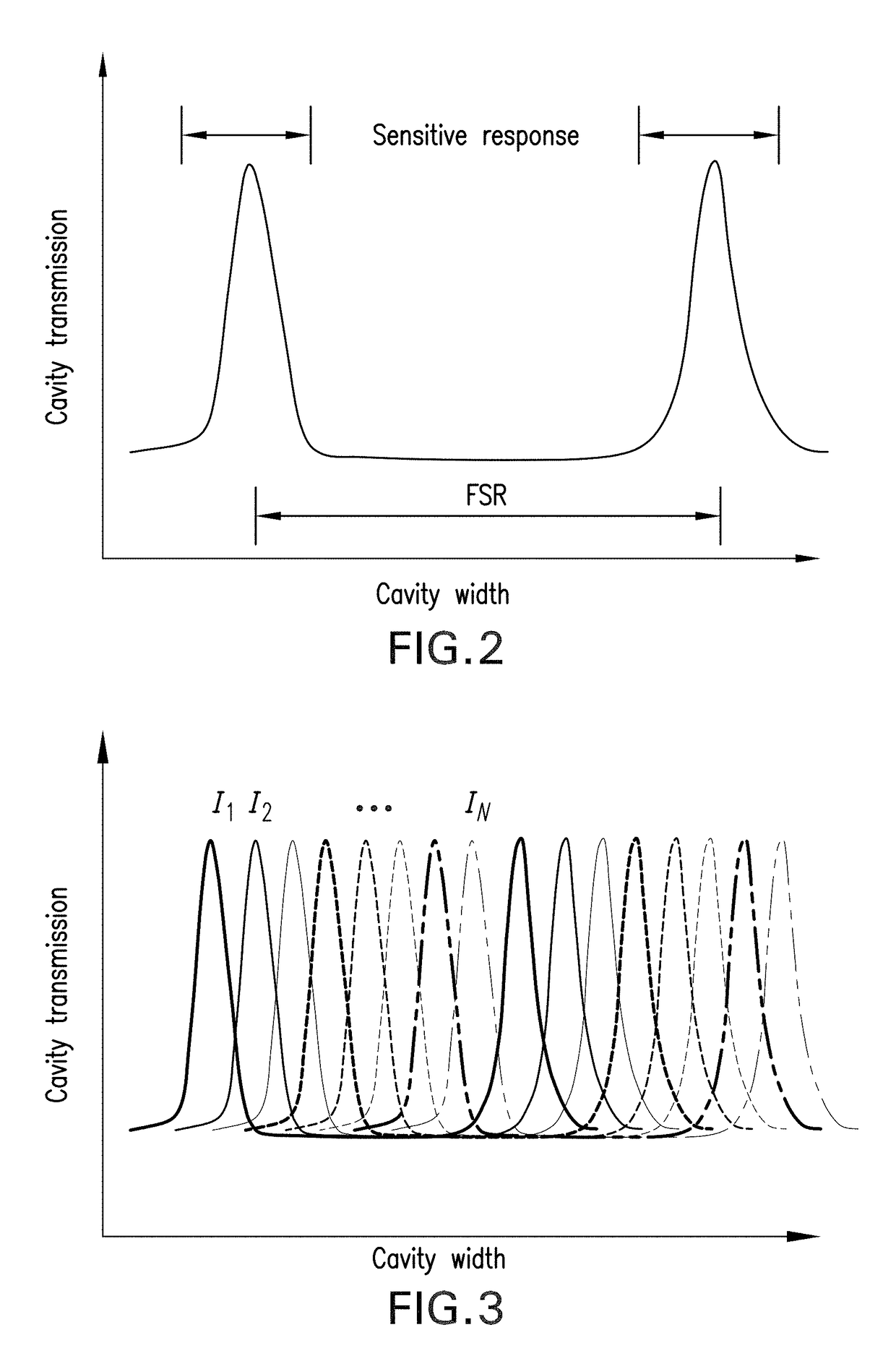

Measuring acceleration using interferometry with reduced environmental effects

InactiveUS20170212144A1Acceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementPhotovoltaic detectorsEnvironmental effect

An apparatus for measuring acceleration includes: a reference cavity having a first fixed reflecting surface and a second fixed reflecting surface; a sense cavity having a fixed reflecting surface and a non-fixed reflecting surface, the non-fixed reflecting surface being configured to be displaced when subject to an acceleration force; a light source to illuminate the reference and sense cavities; a controller to vary a wavelength of light emitted by the light source and / or an index of refraction of an optical medium of the cavities; a photodetector to detect light emitted by the reference and sense cavities; an interferometer sensor to measure using the detected light, for each variation of the wavelength of light and / or the index of refraction a reference displacement of the reference cavity and a sense displacement of the sense cavity; and a processor to calculate the acceleration using each of the reference displacements and the sense displacements.

Owner:BAKER HUGHES INC

Heat energy recovery and deodorization device for sewage explosion tank

InactiveCN106882865ALarge processing energySpeed up evaporationHeat pumpsSpecific water treatment objectivesSustainable economyEvaporation

The invention discloses a heat energy recovery and deodorization device for a sewage explosion tank. The device comprises a heat absorption disc, a deodorization cover and a heat pump, wherein the heat absorption disc is arranged in the sewage explosion tank and communicates with the heat pump arranged on the bottom surface, the deodorization cover is arranged on the sewage explosion tank, and a deodorization filter screen is arranged in the middle region of the deodorization cover. According to the invention, the heat pump is used for absorbing heat, the sewage treatment energy is large, the odor evaporation and heat energy are large, a heat pump technology is adopted, so that the odor evaporation is reduced, the environmental influence is reduced, the heat energy and heating are provided for a sewage plant in autumn and winter, the natural energy is fully applied, and a sustainable economic technology is developed.

Owner:SHAANXI SIJICHUN CLEANING HEAT

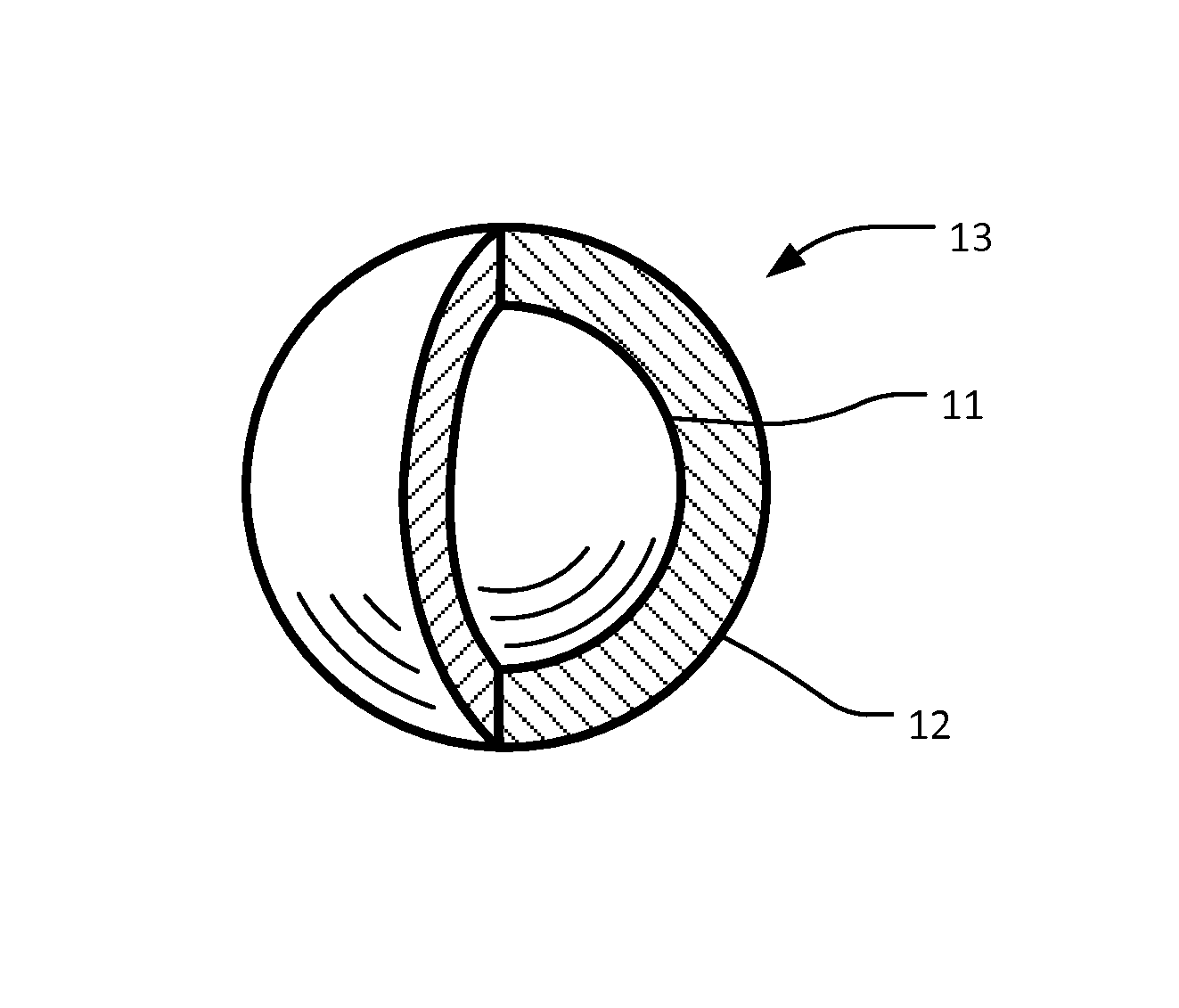

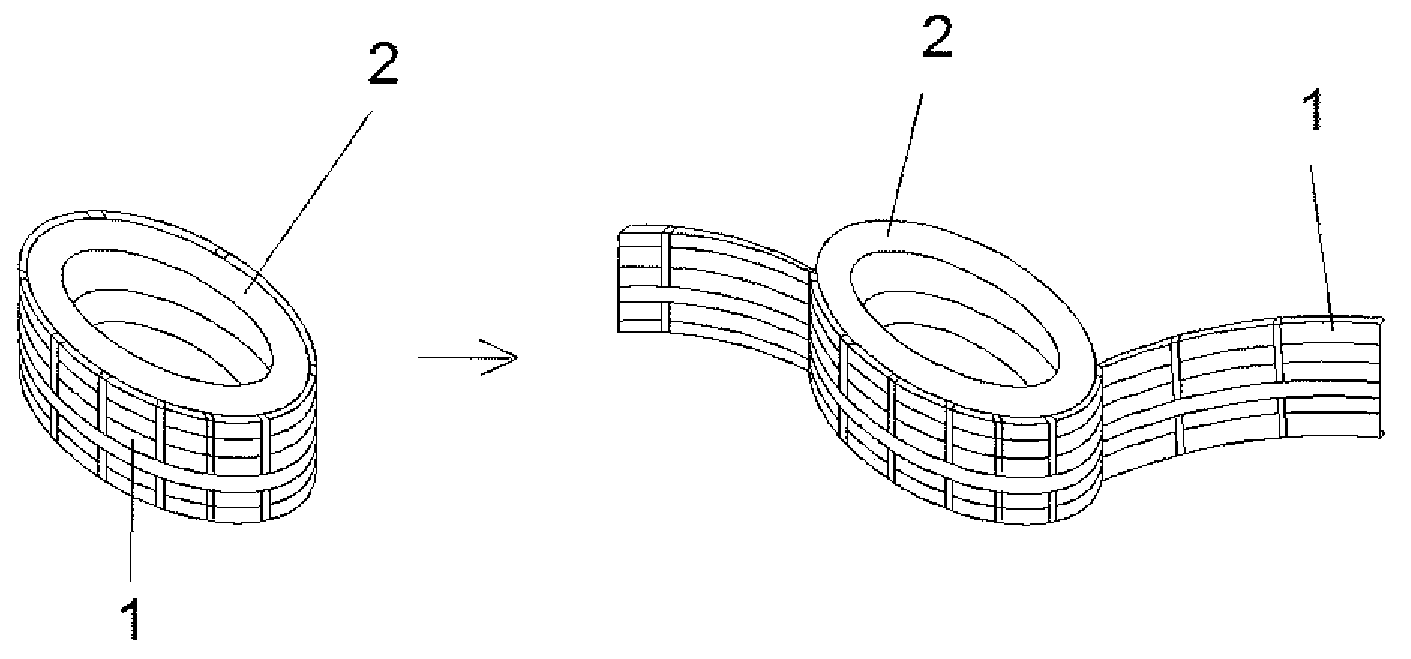

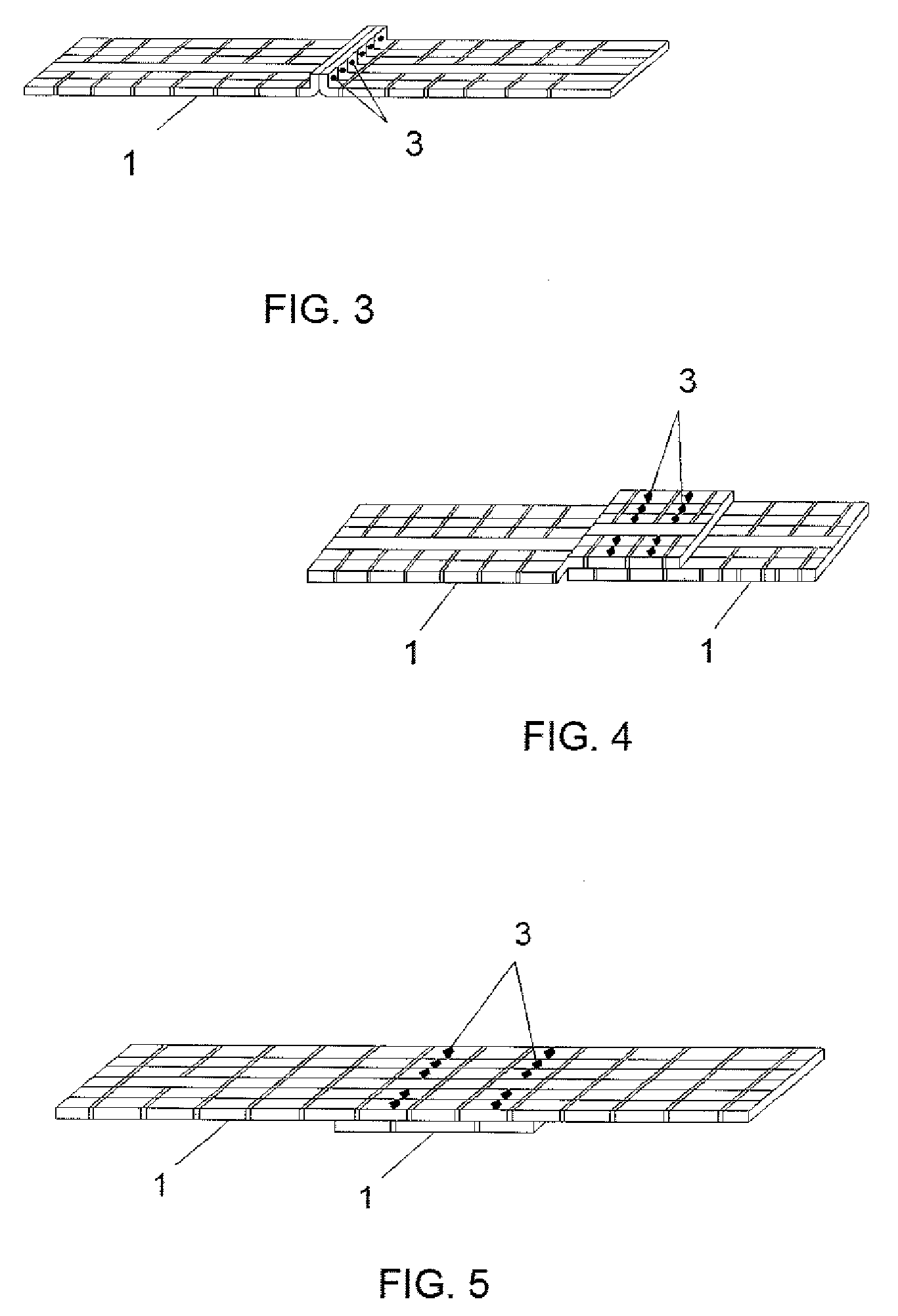

Process for closing orifices and/or protecting structures by reusing end-of-life tyres

InactiveUS20090266472A1Reduce environmental impactEfficient and cheap and simple processLayered productsPlastic recyclingEngineeringTread

Process for closing orifices and / or protecting structures by reusing end-of-life tyres, which reduces environmental impact by not recycling through crushing, but rather through direct reuse. The tyre treads (1) are cut, separated from the flanks (2) and flatly disposed, for the ultimate purpose of disposing these on the orifice or surface to be protected The treads (1) are mechanically joined by means of mechanical elements (3) and the structure created may be linear, two-dimensional or three-dimensional.

Owner:TOOL ULEE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com