Patents

Literature

310 results about "Skeletal structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

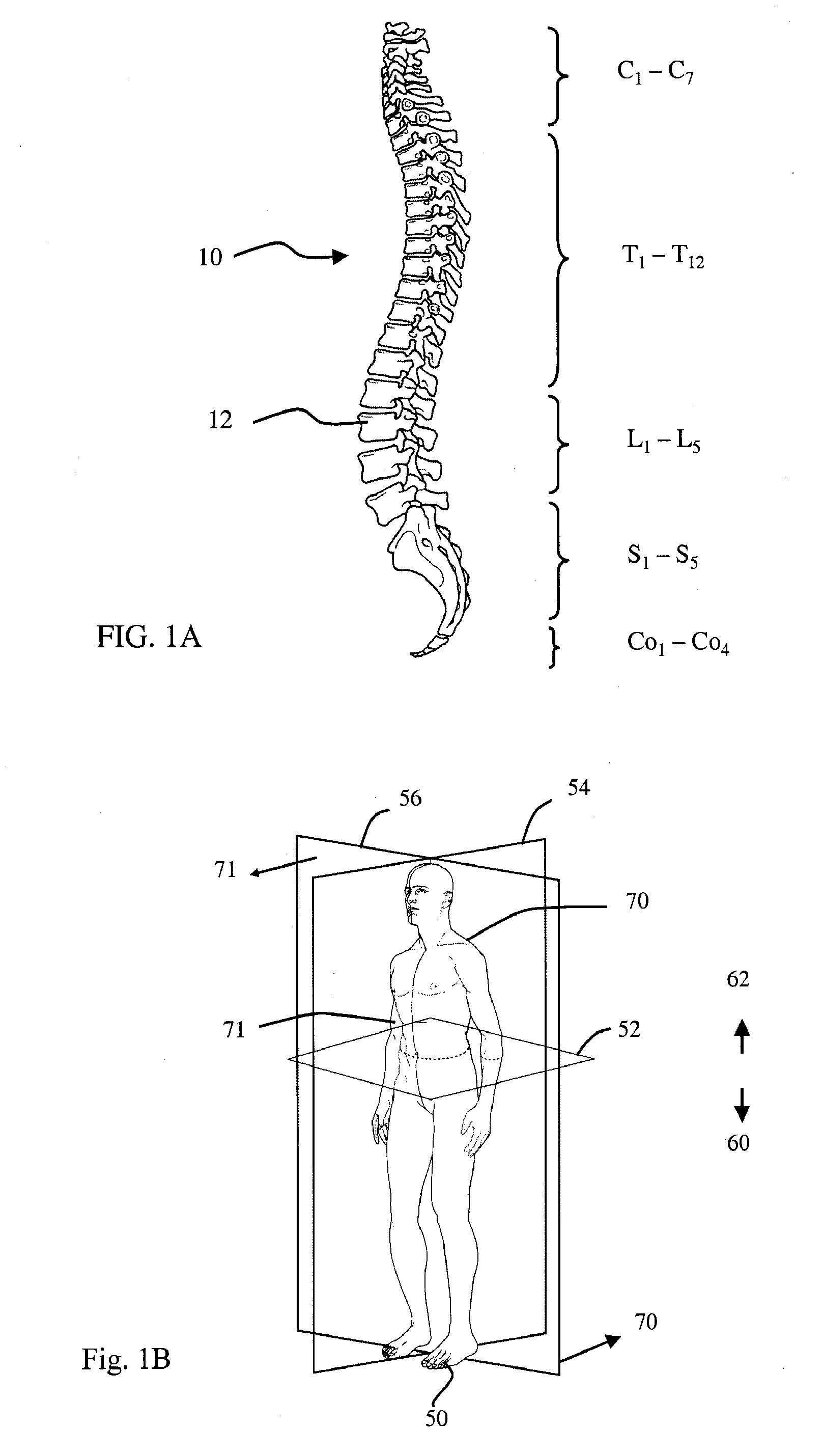

Skeletal Structure. The skeletal structure is divided into two groups named the axial skeleton and the appendicular skeleton. The axial skeleton consists of 80 bones which include the head and trunk of the human body. The appendicular skeleton is composed of over 126 bones in the lower region of the body.

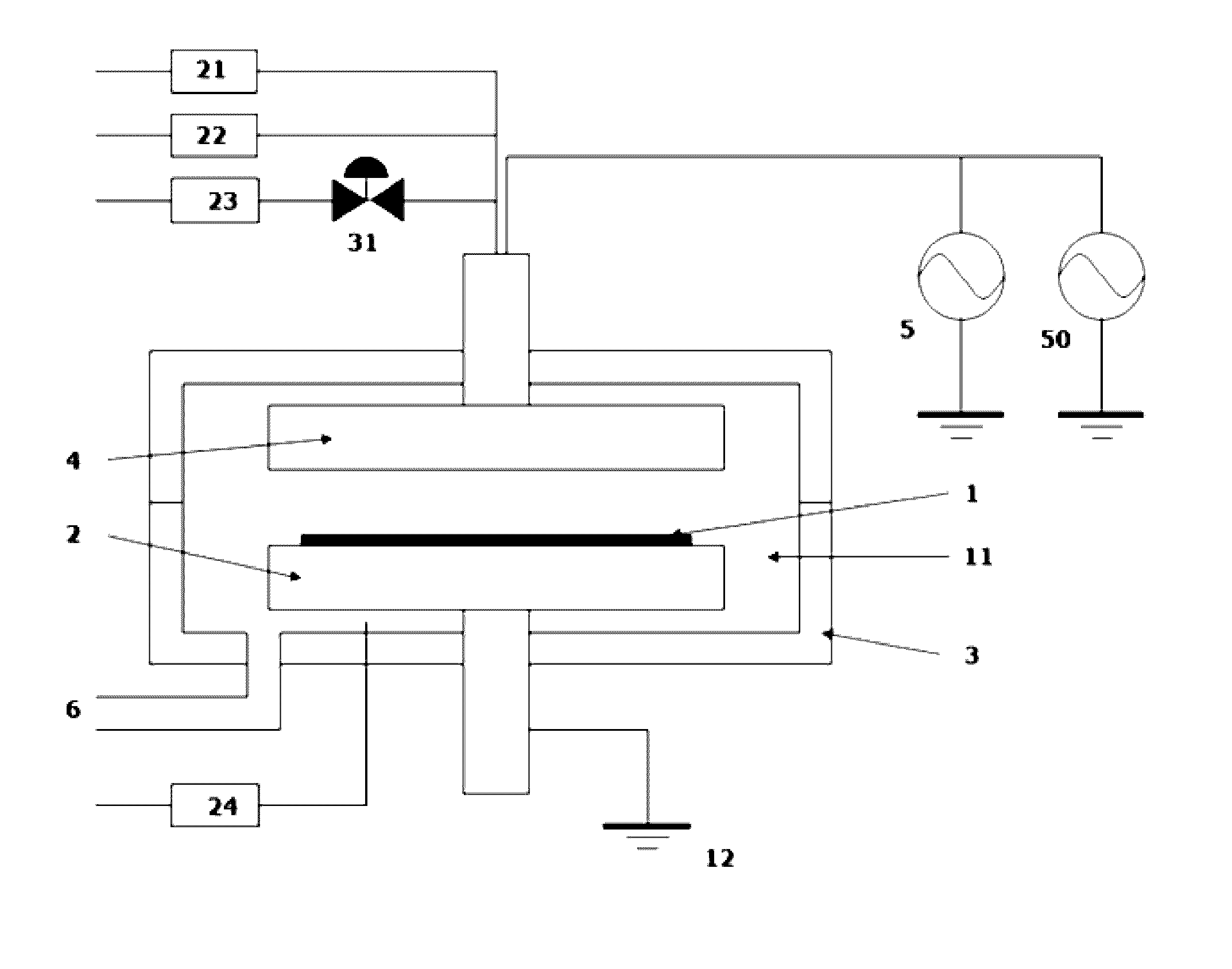

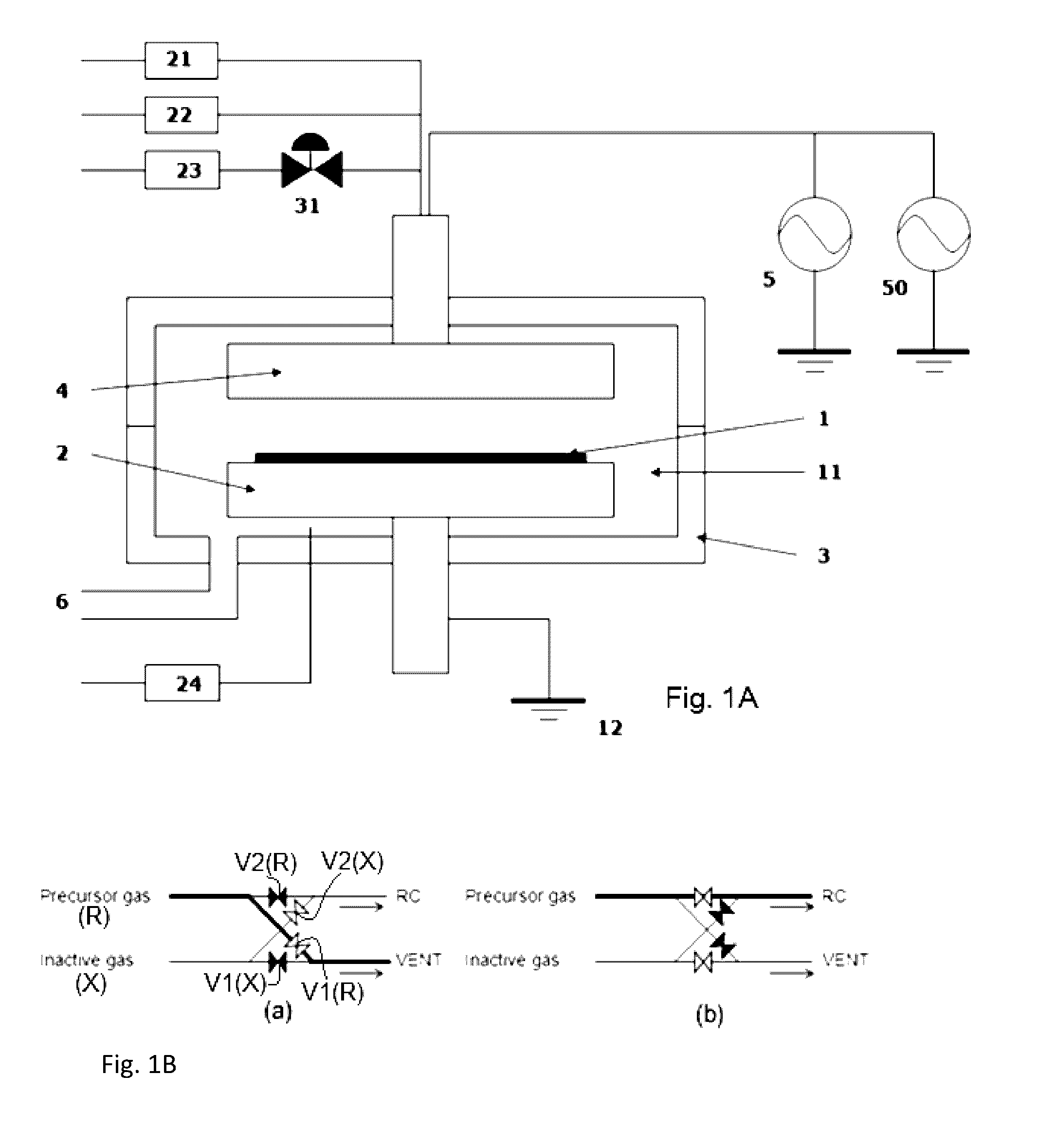

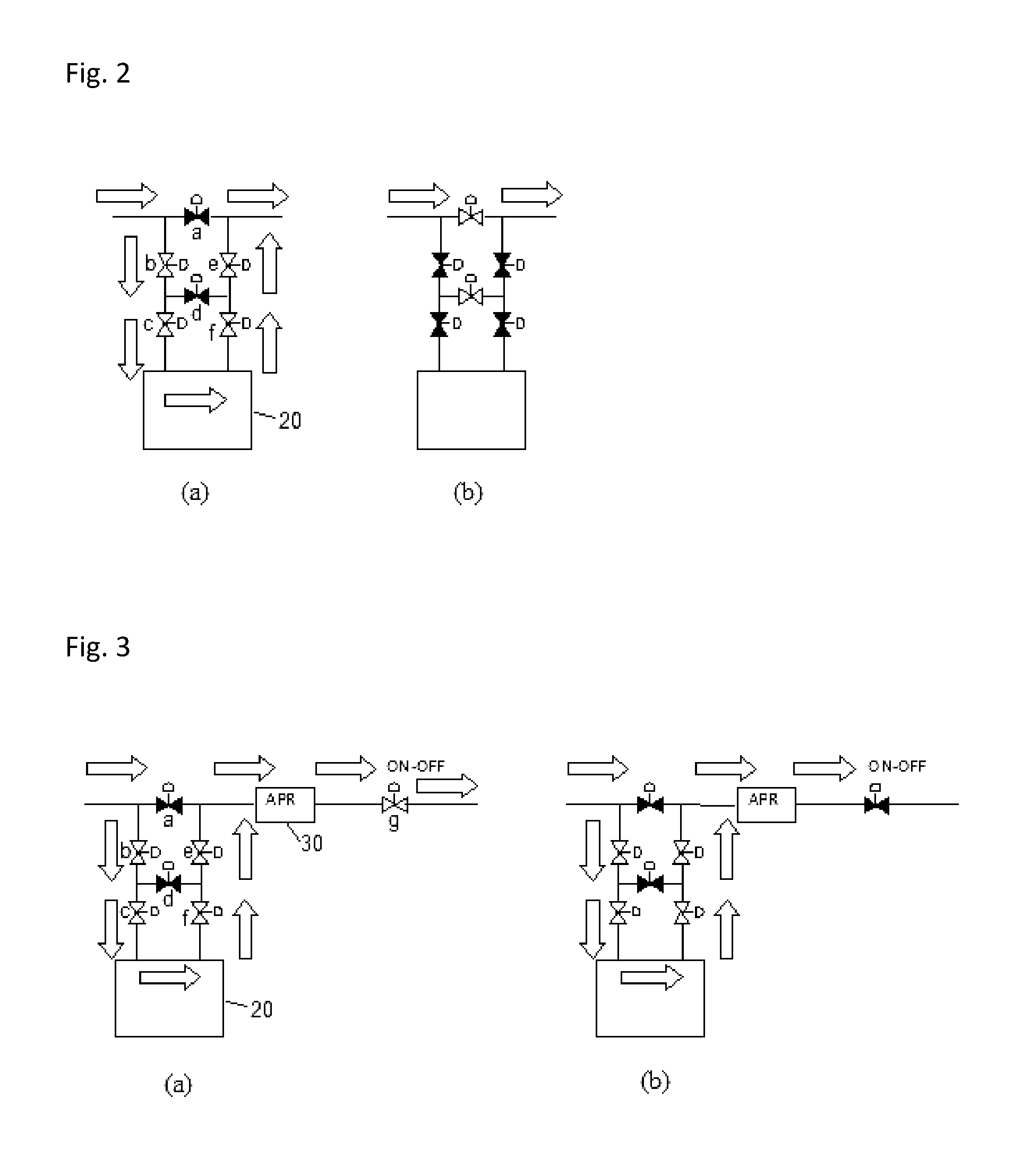

Method for forming sin or sicn film in trenches by peald

InactiveUS20170051405A1Step-coverage is poorImprove responseChemical vapor deposition coatingHalogenAtomic layer deposition

A method for forming a SiN or SiCN film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) conducts one or more process cycles, each process cycle including: (i) feeding a precursor in a pulse to a reaction space where the substrate is place, said precursor having a Si—N—Si bond in its skeletal structure to which at least one halogen group is attached; and (ii) applying RF power to the reaction space in the presence of a reactant gas and in the absence of any precursor to form a monolayer constituting a SiN or SiCN film.

Owner:ASM IP HLDG BV

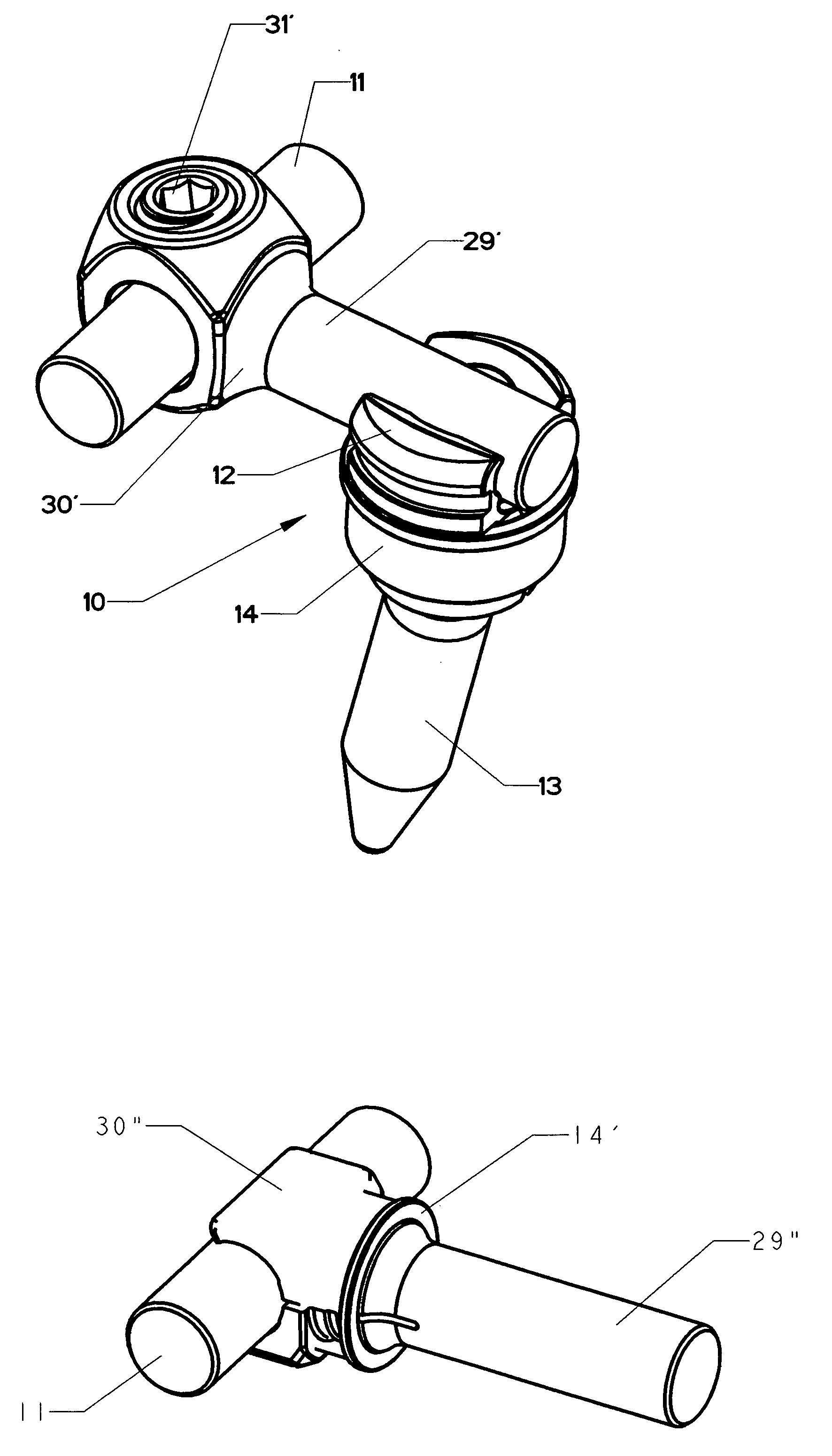

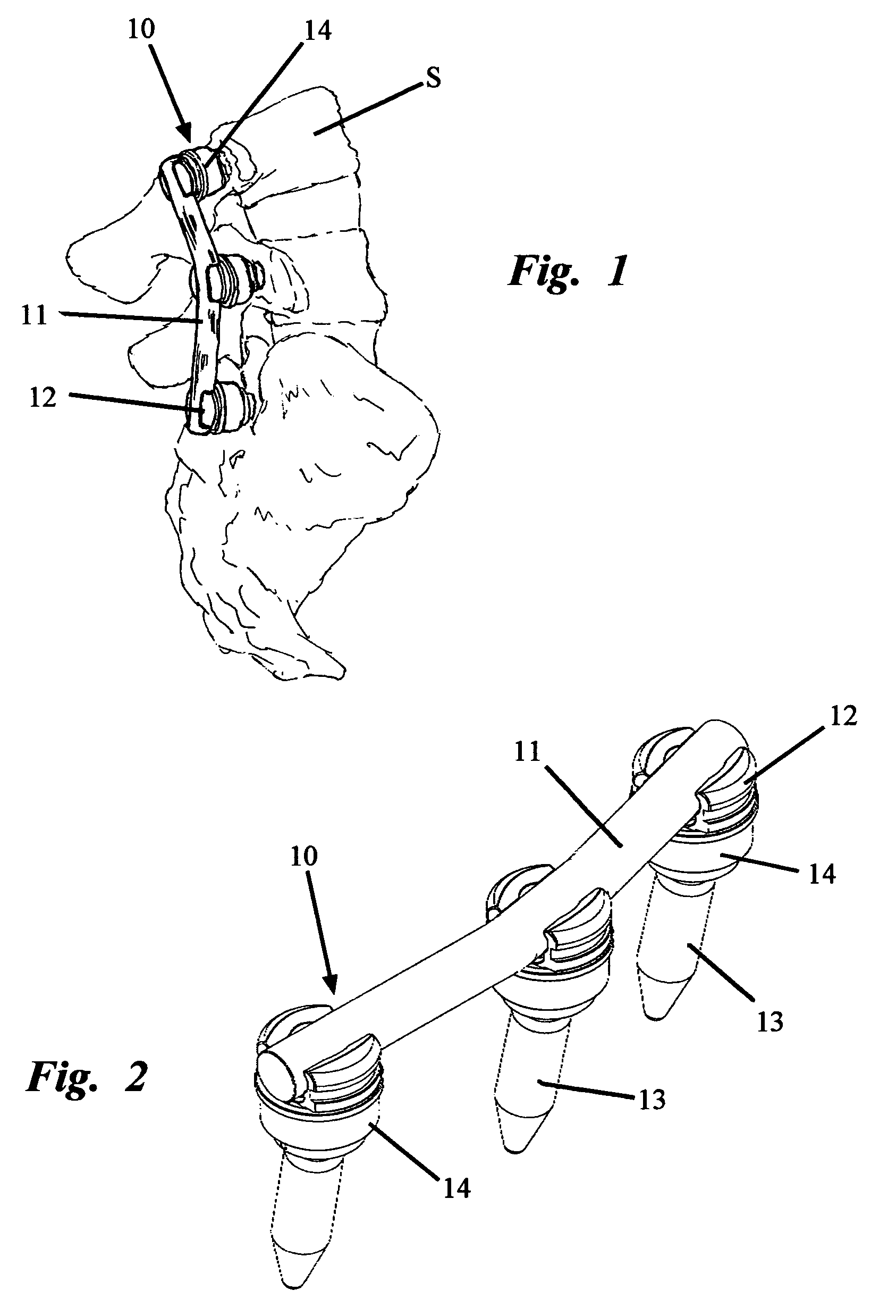

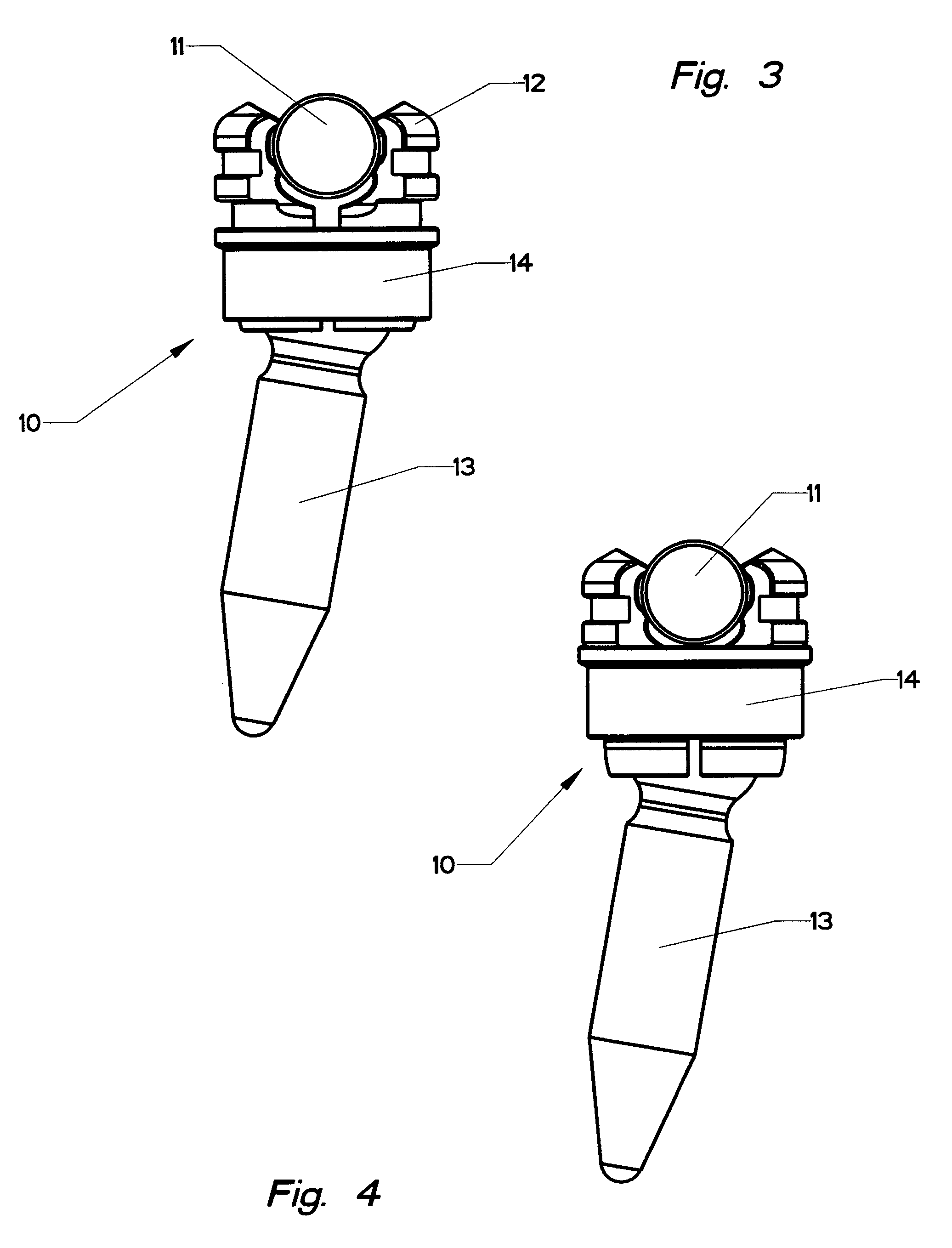

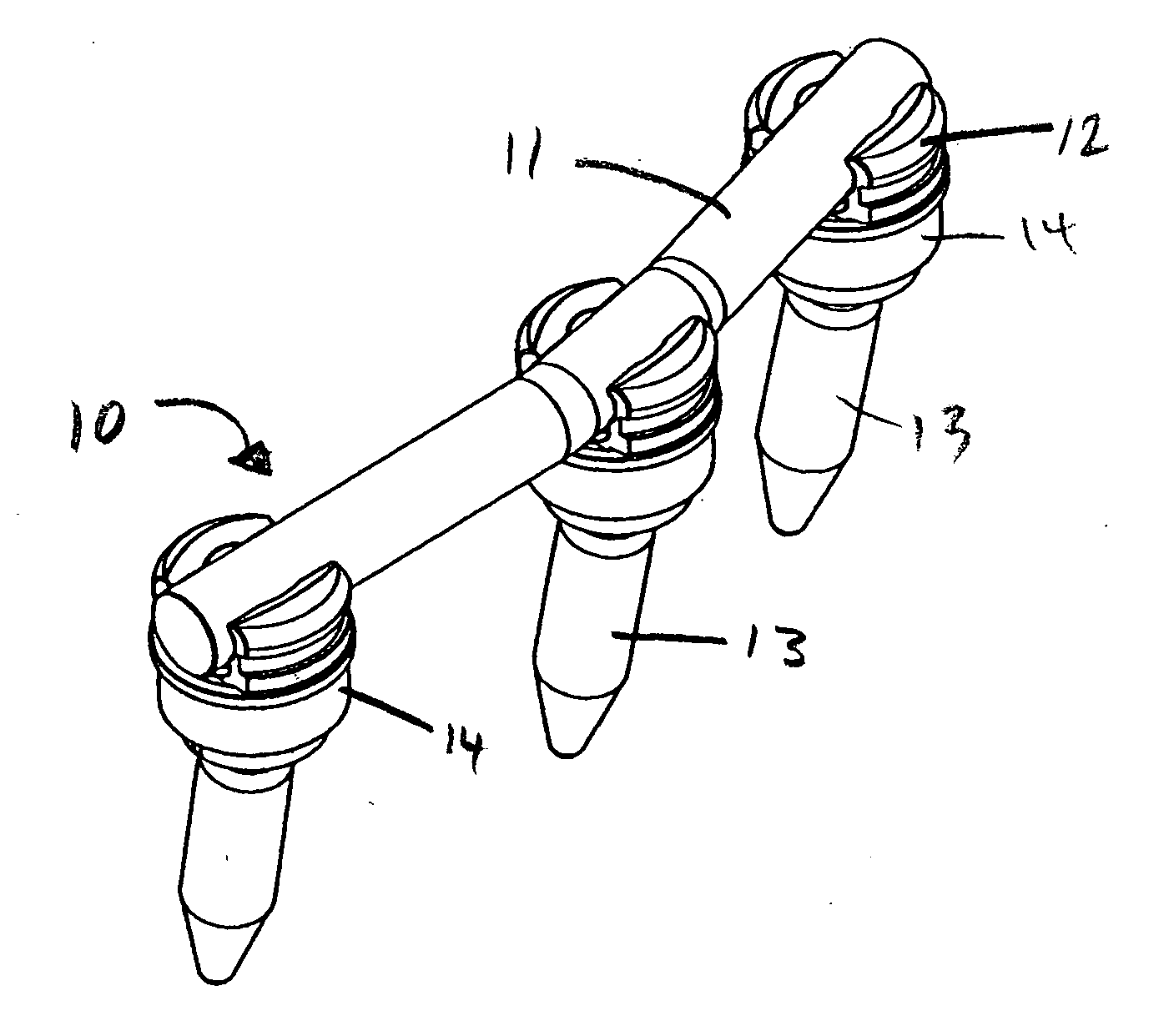

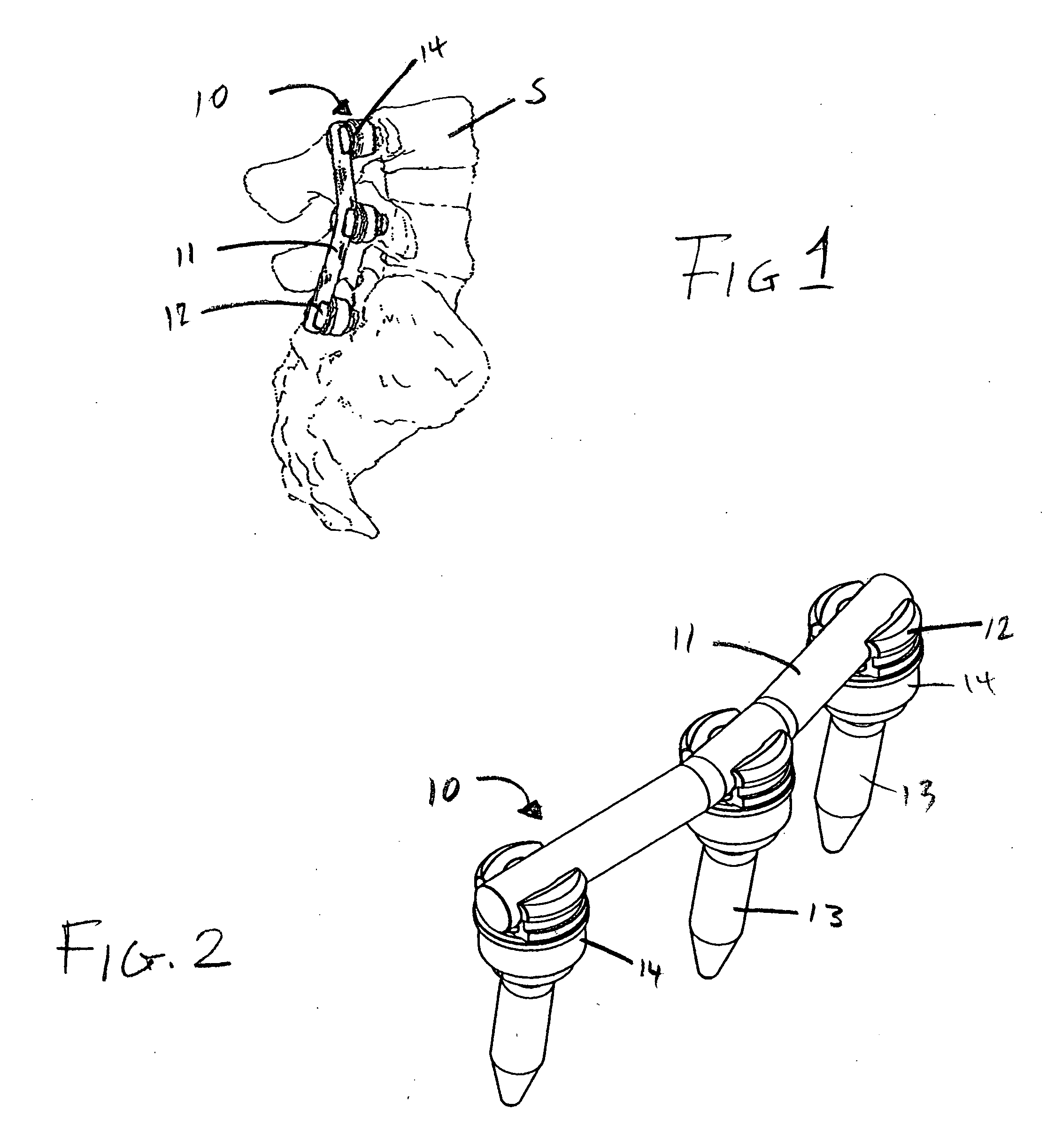

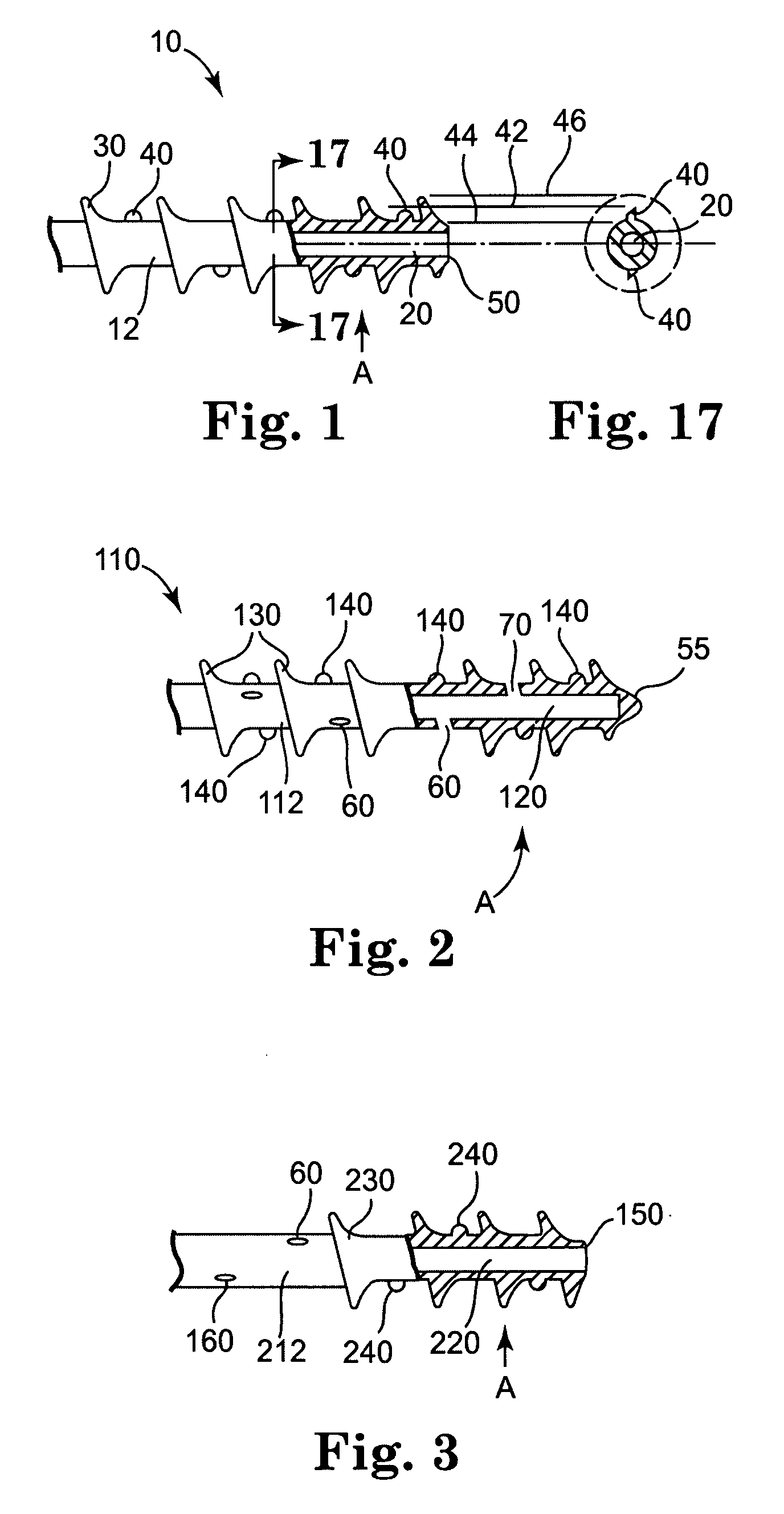

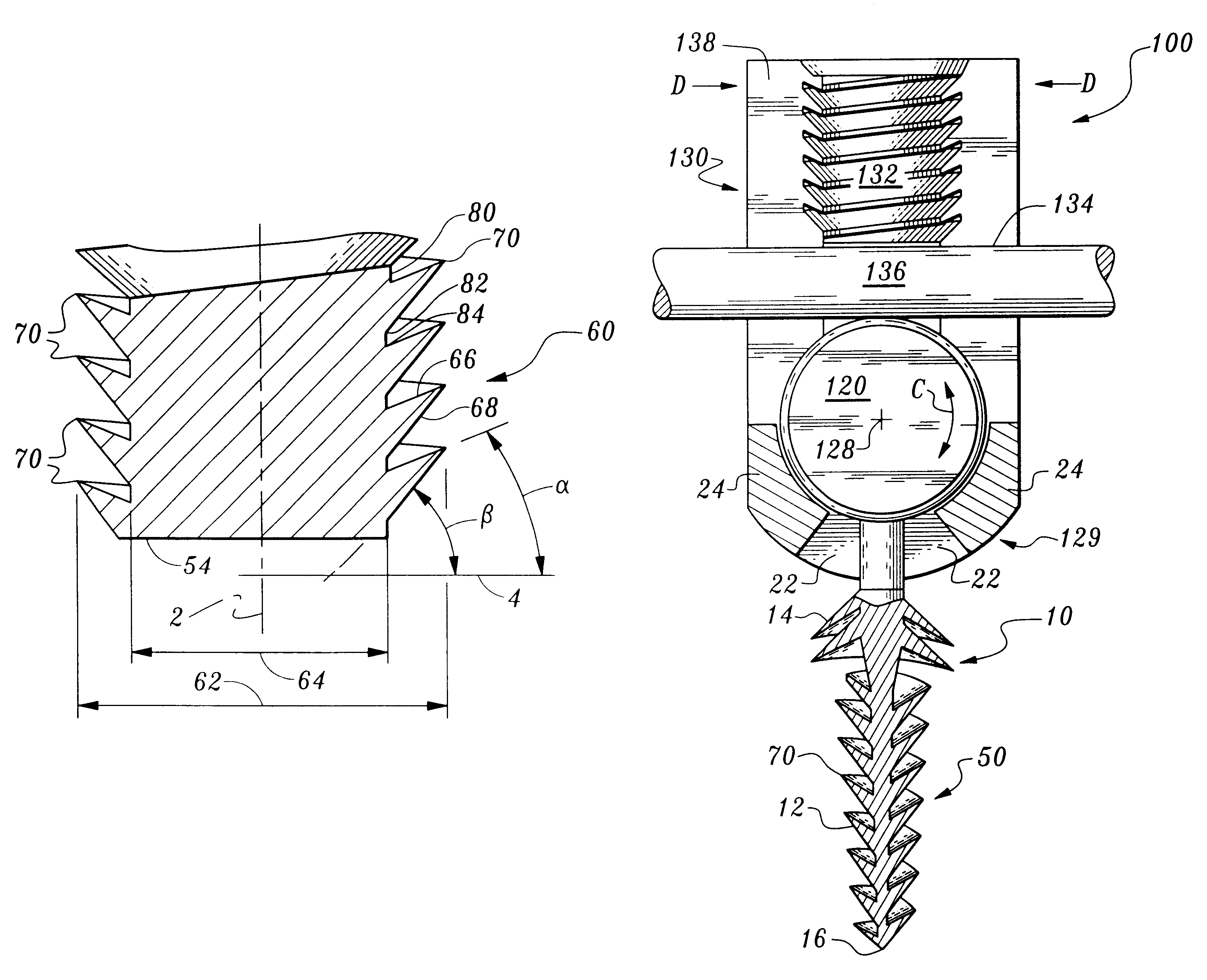

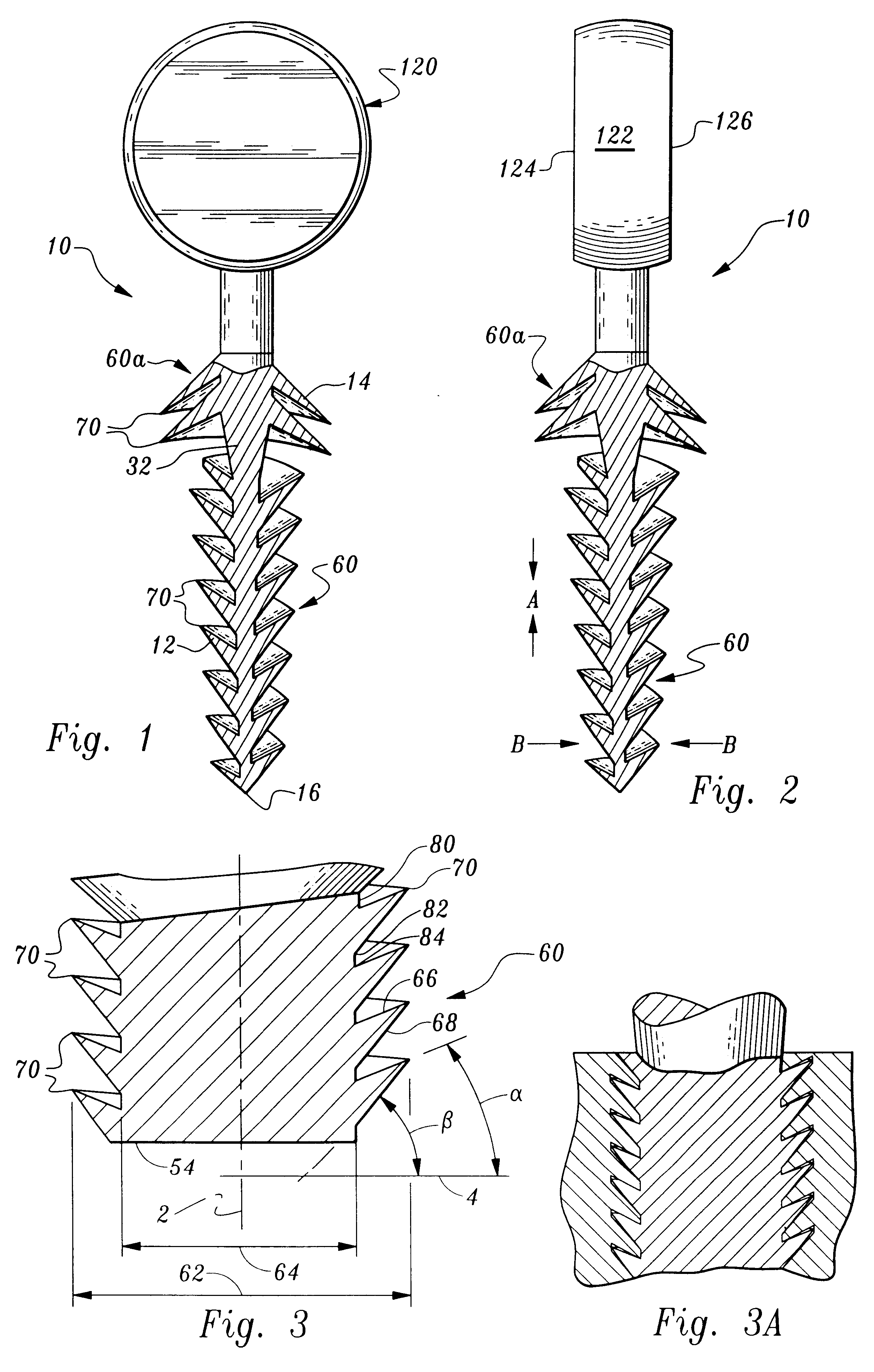

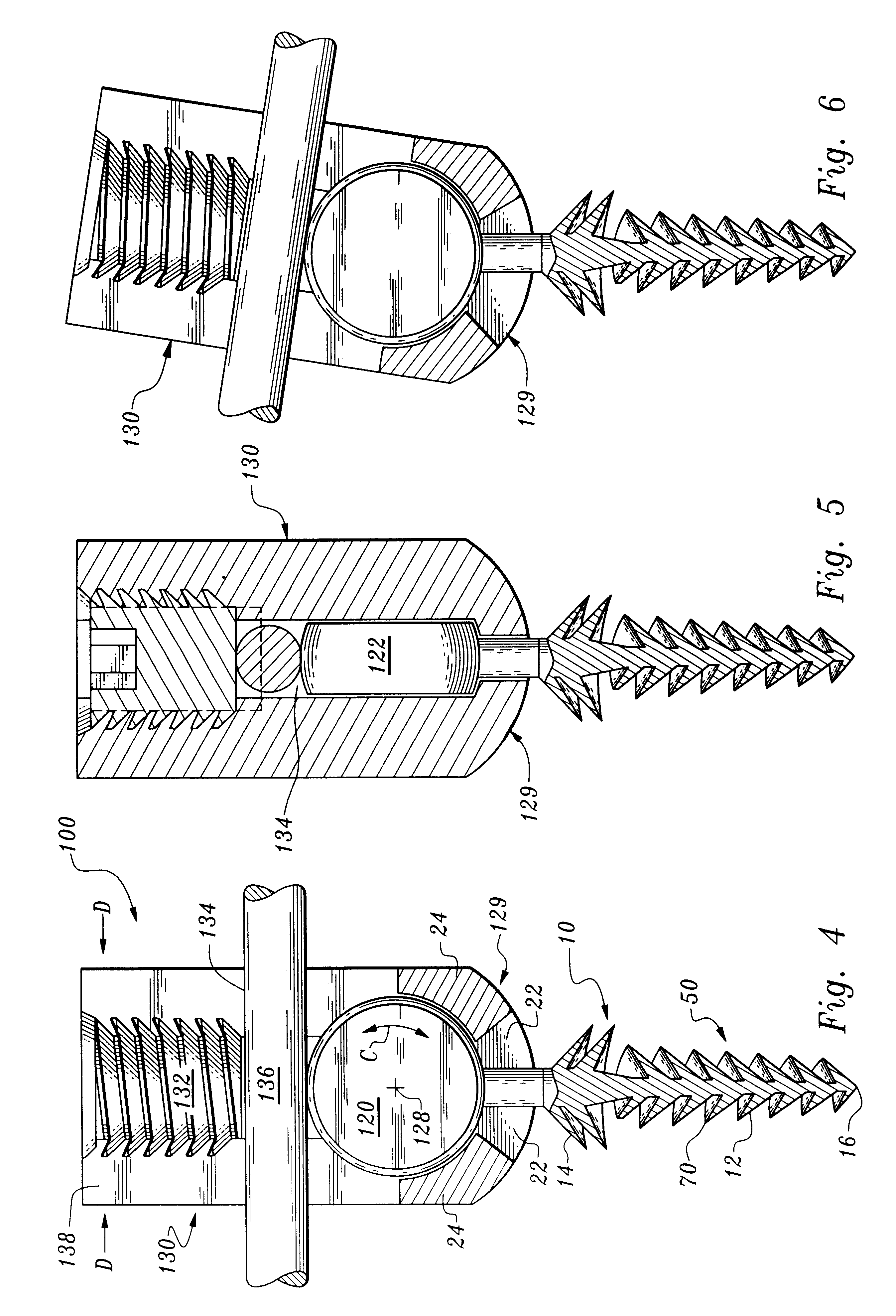

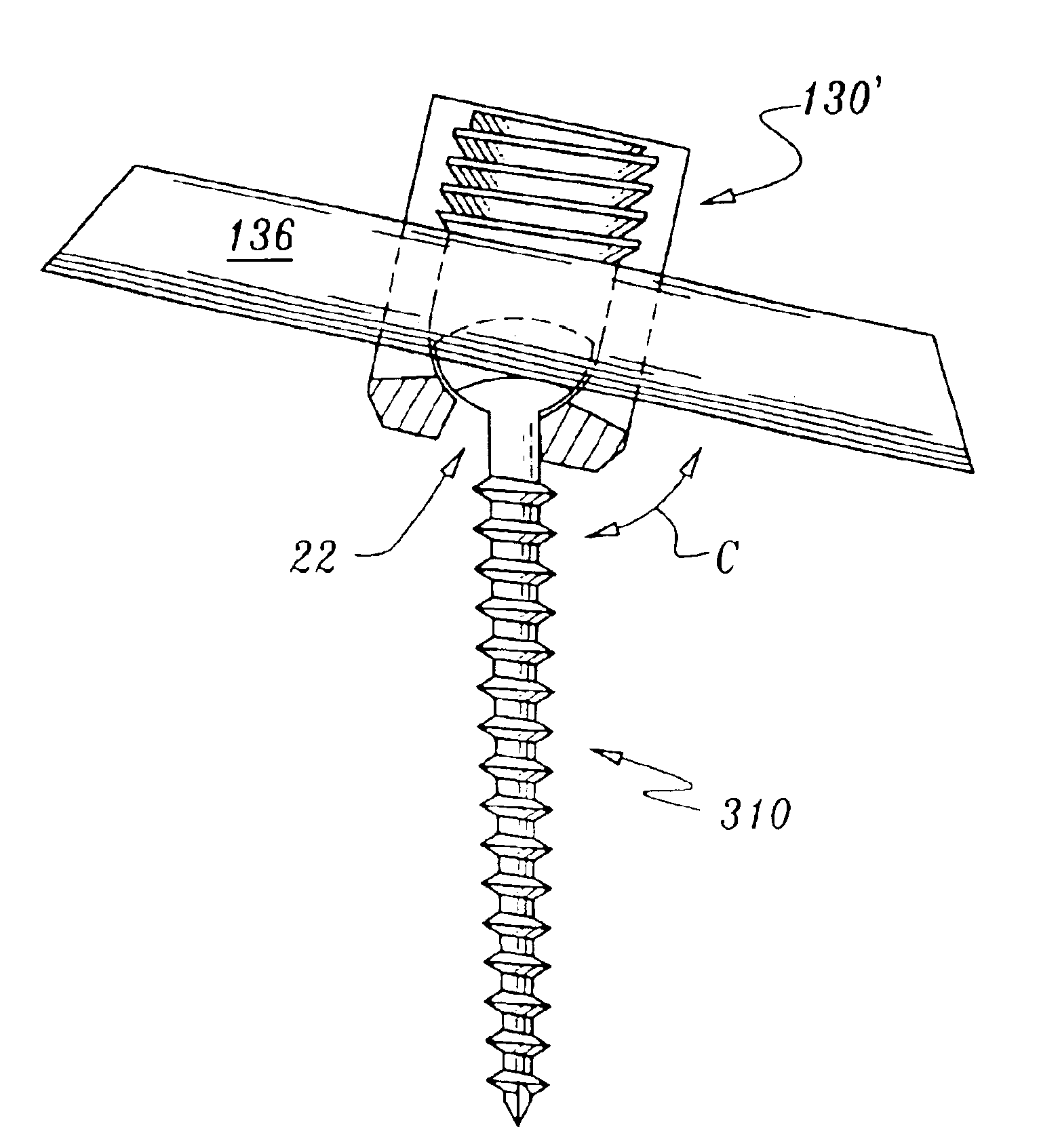

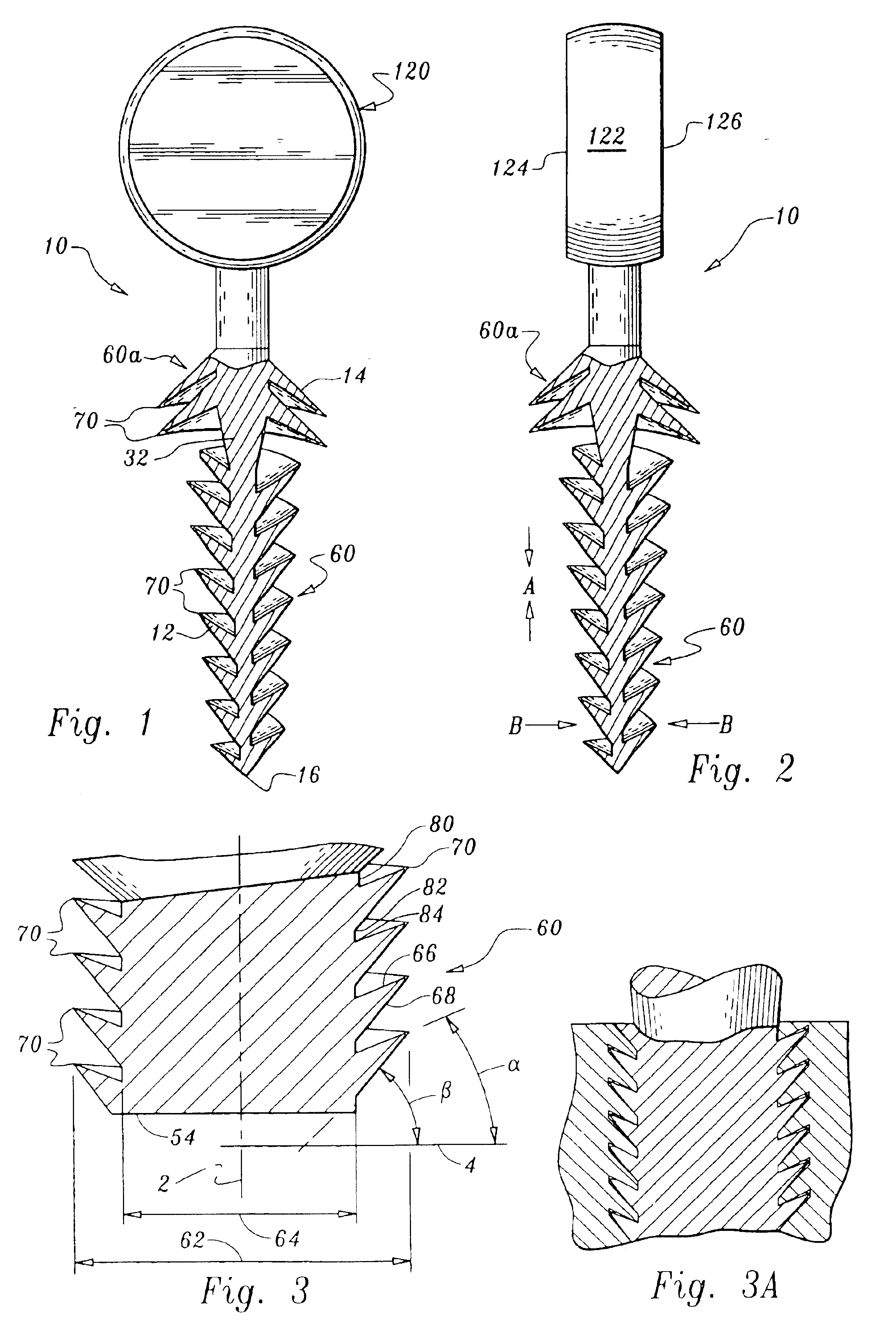

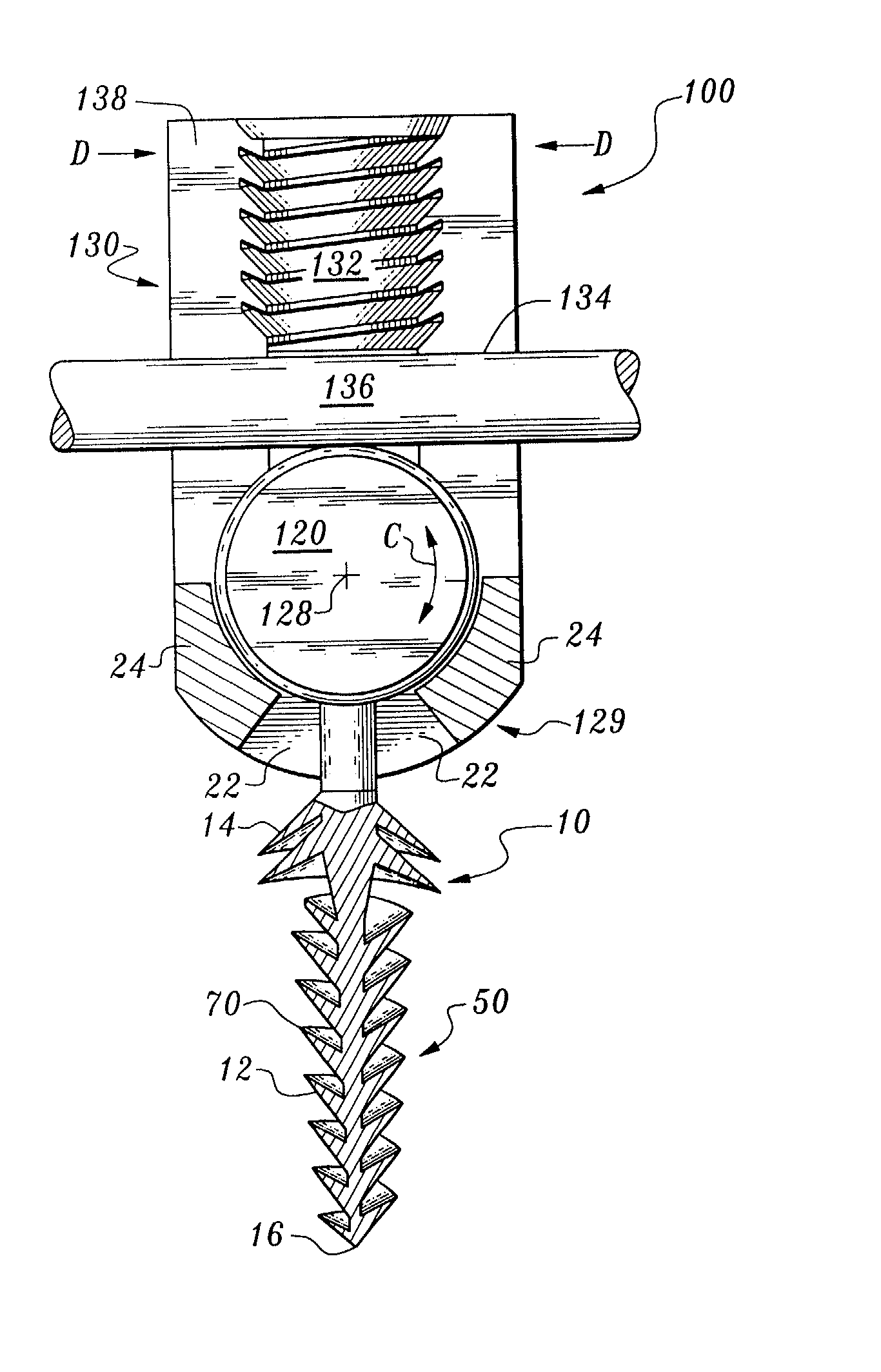

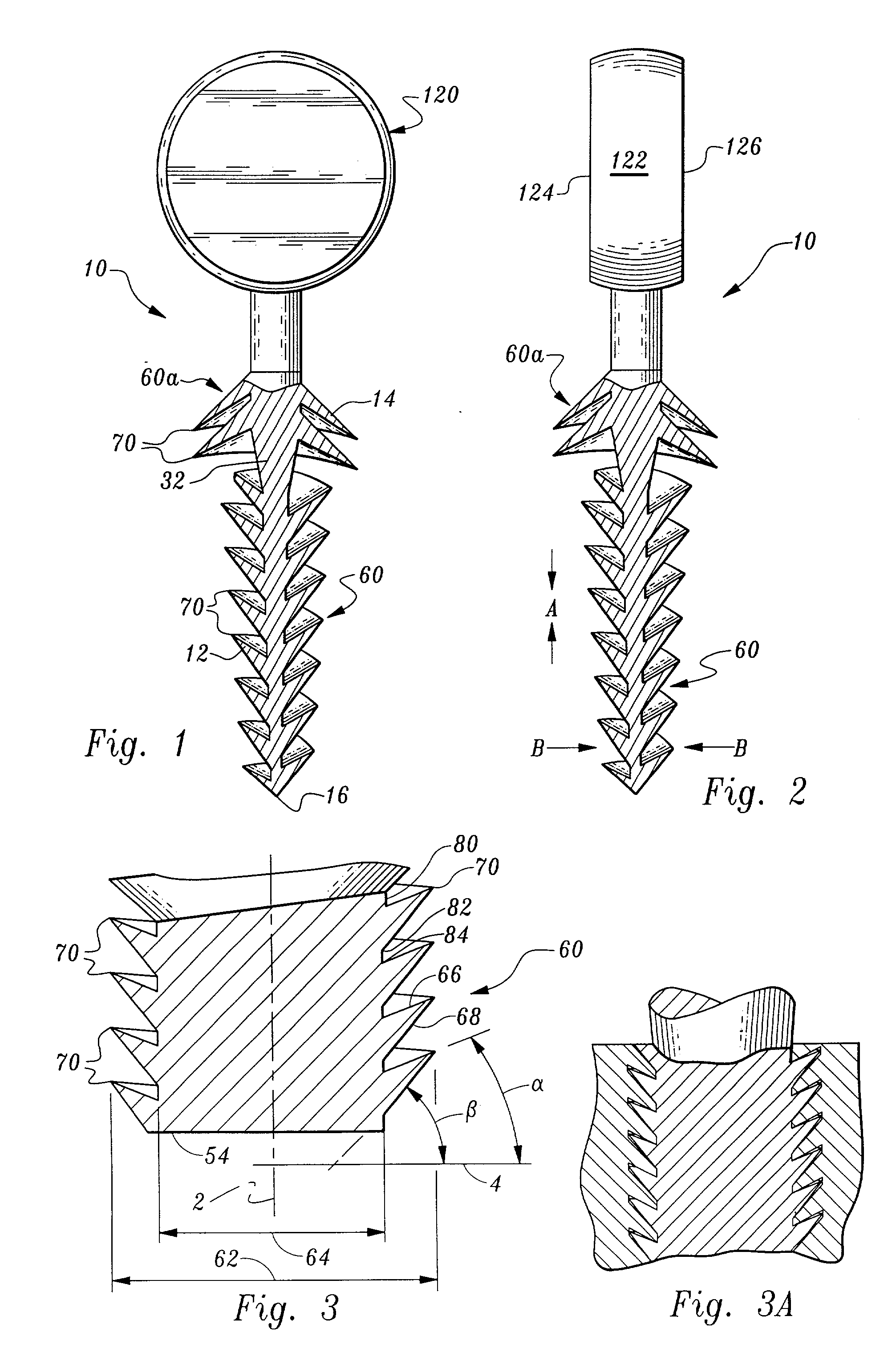

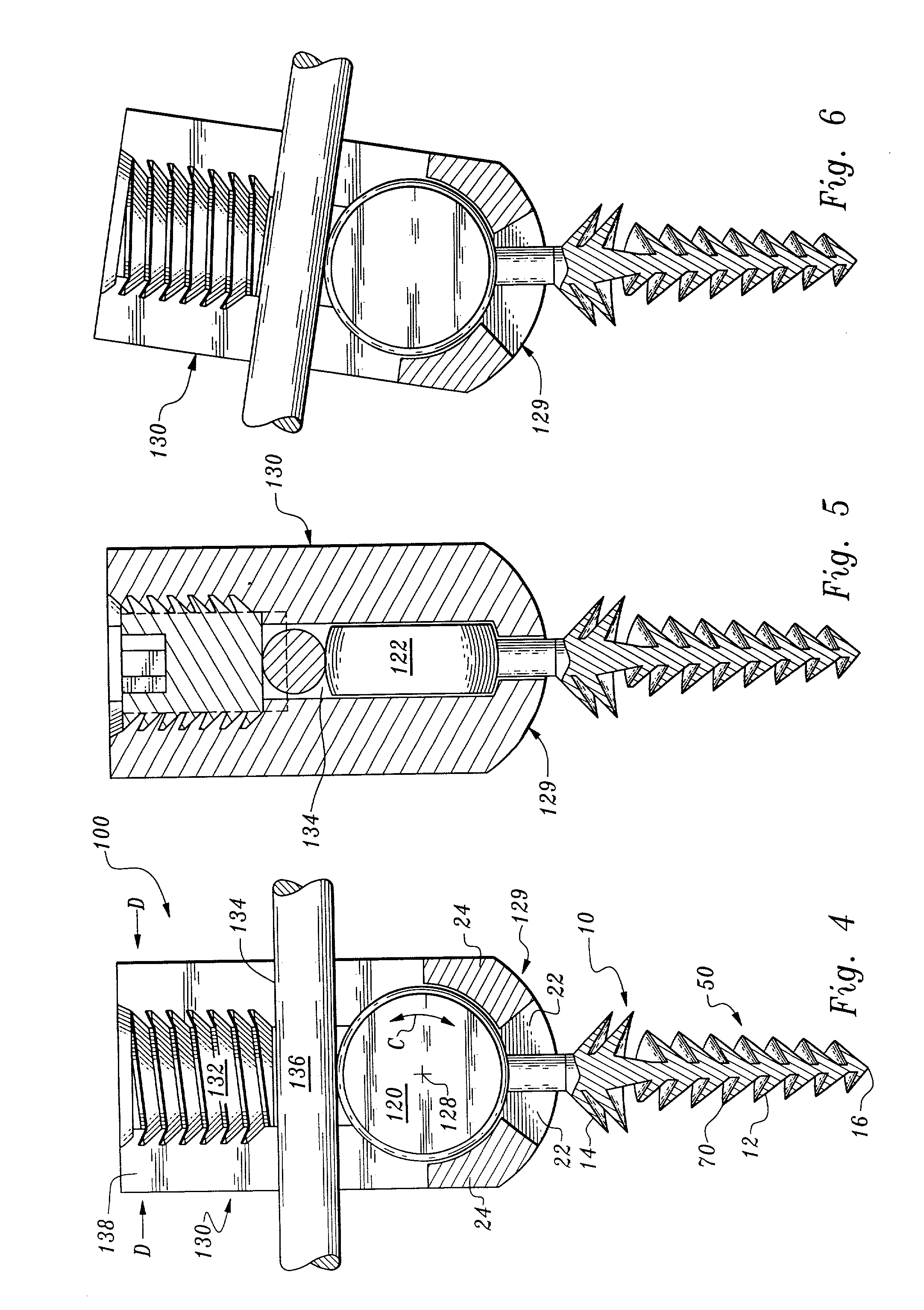

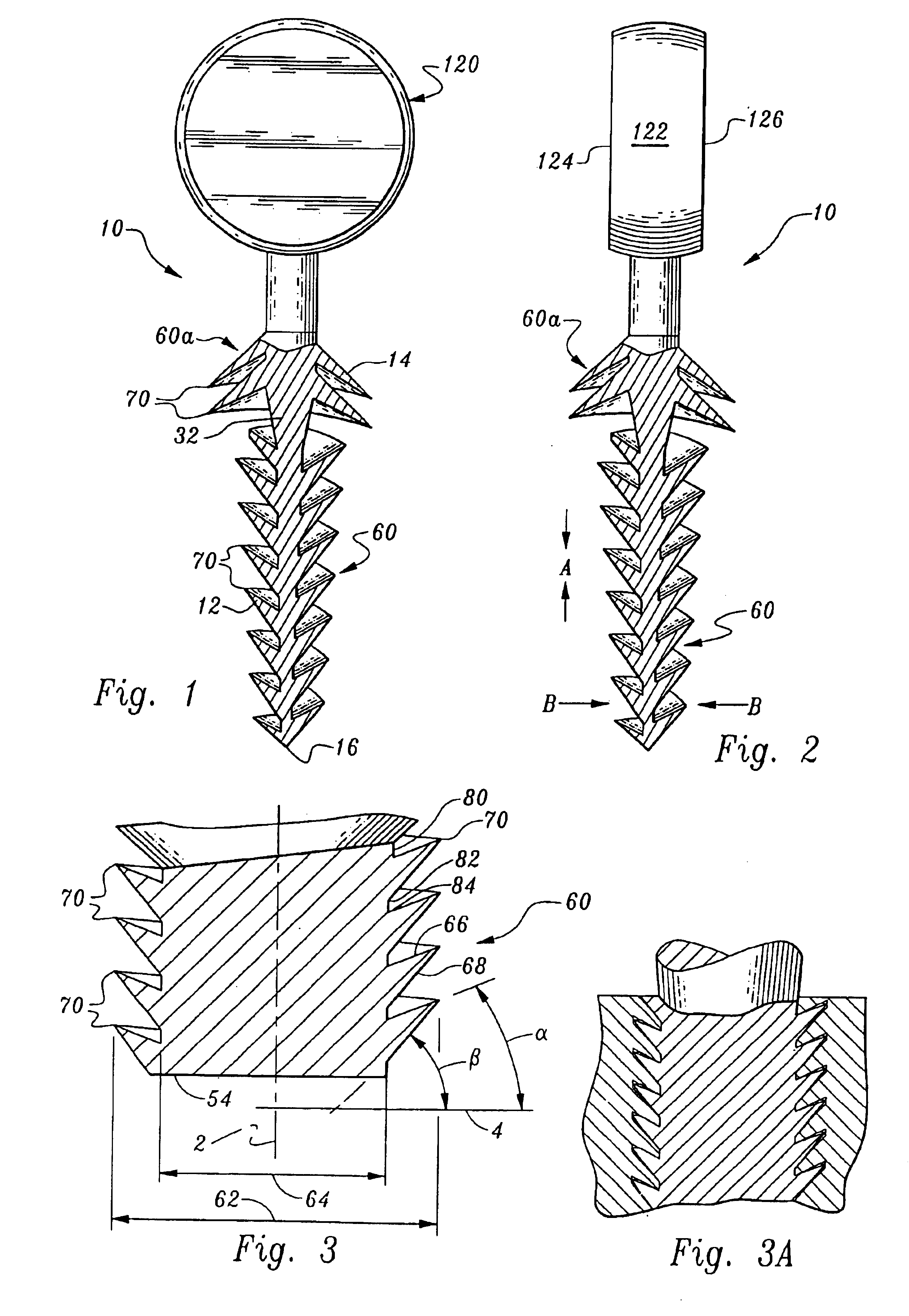

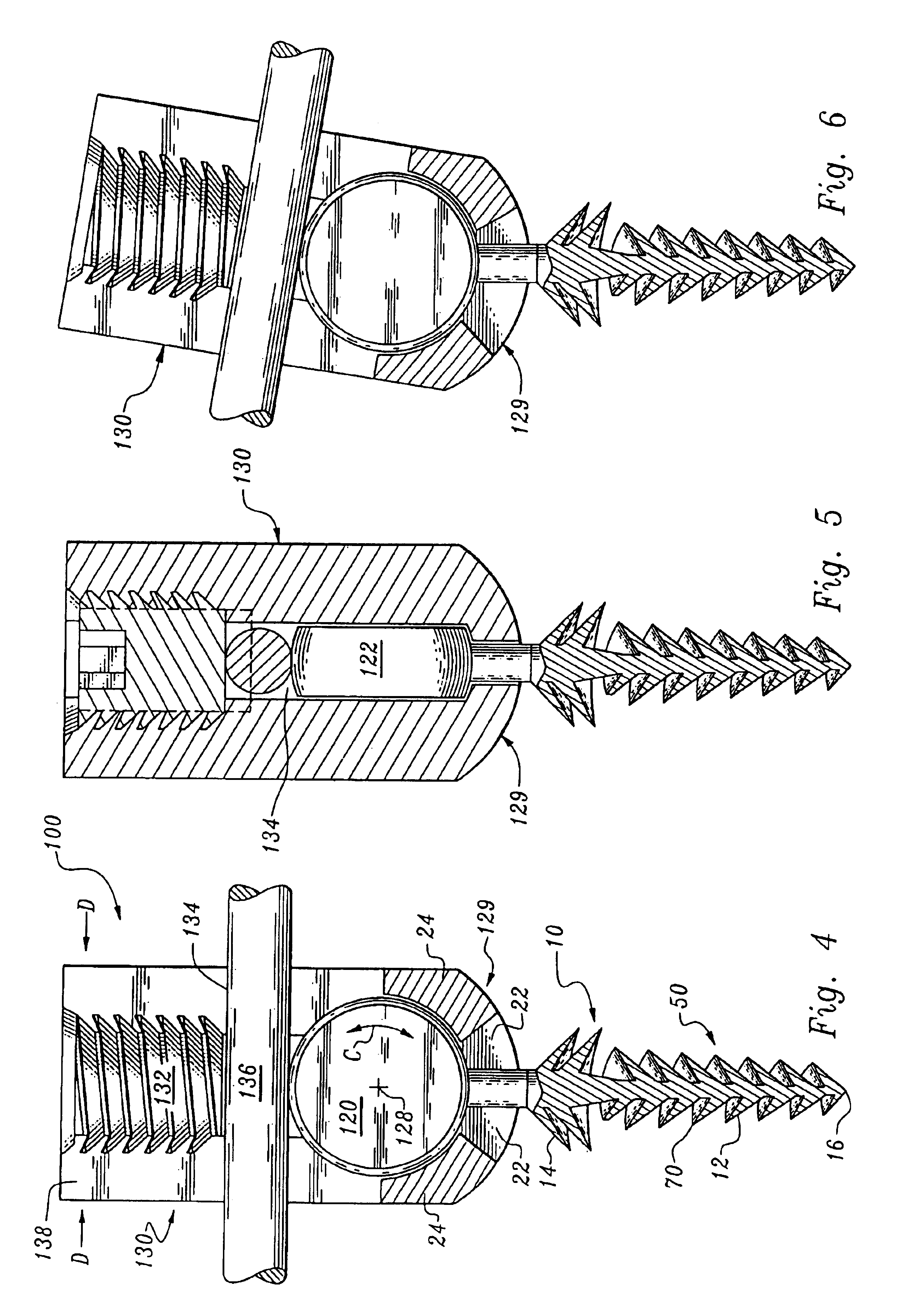

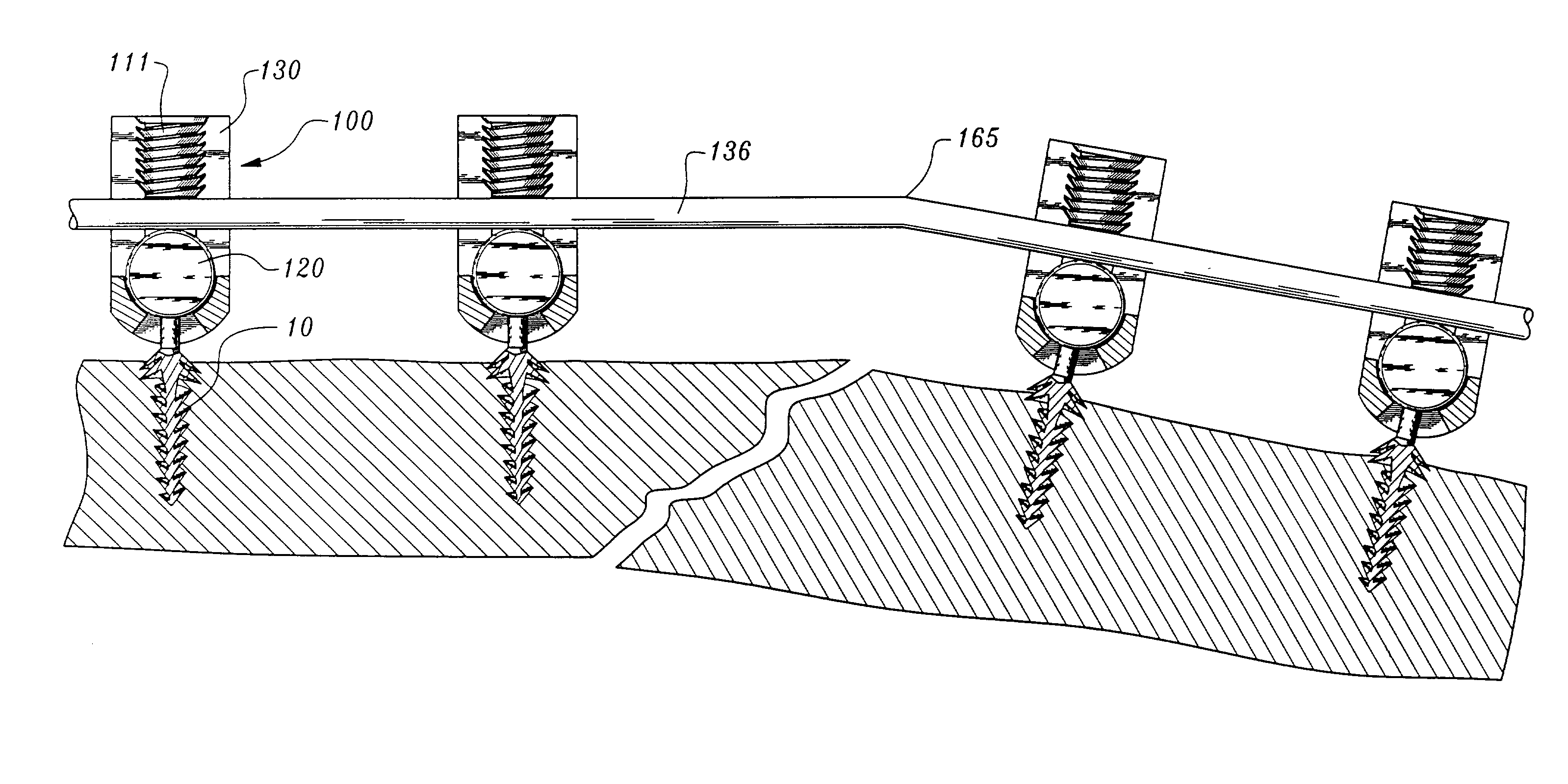

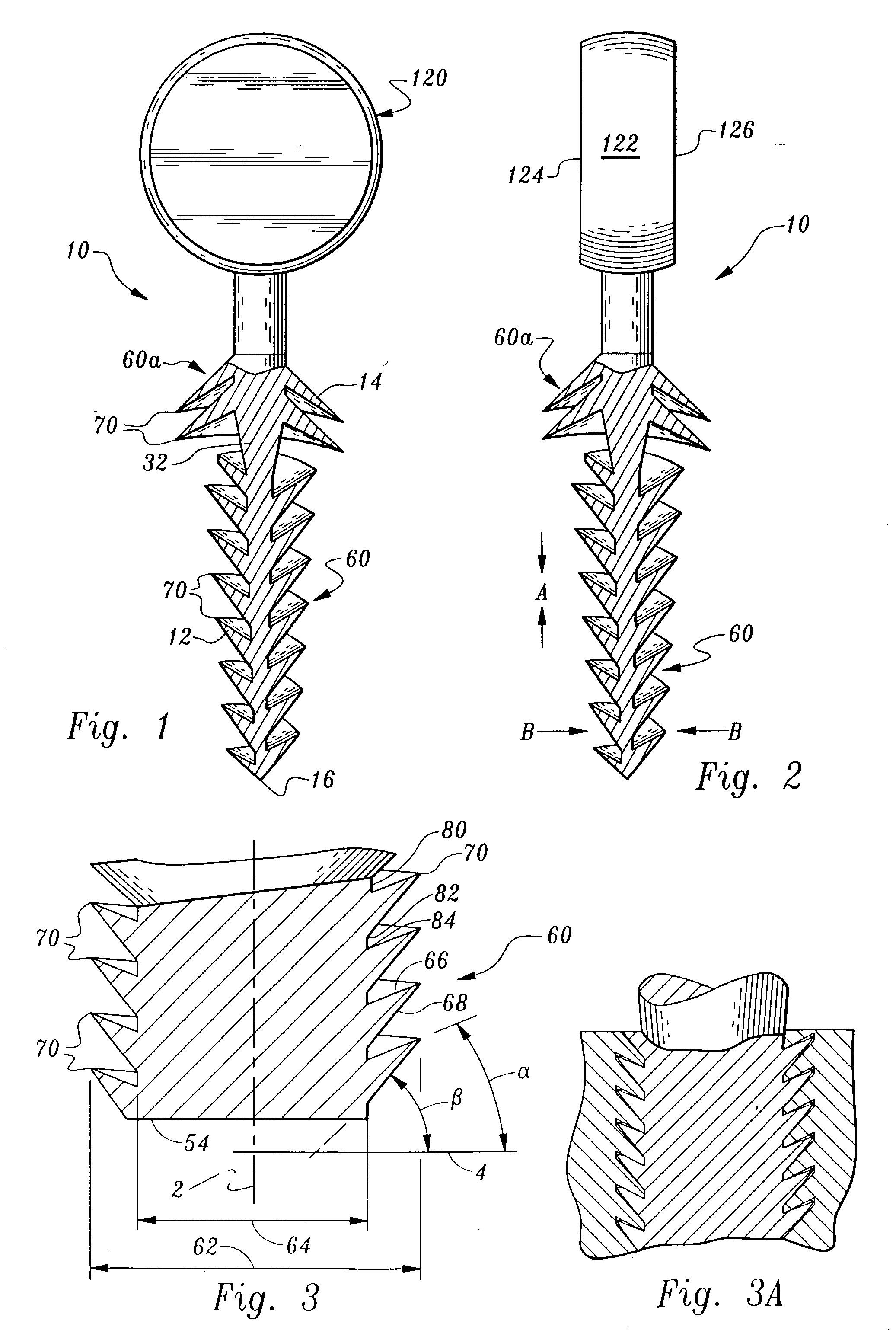

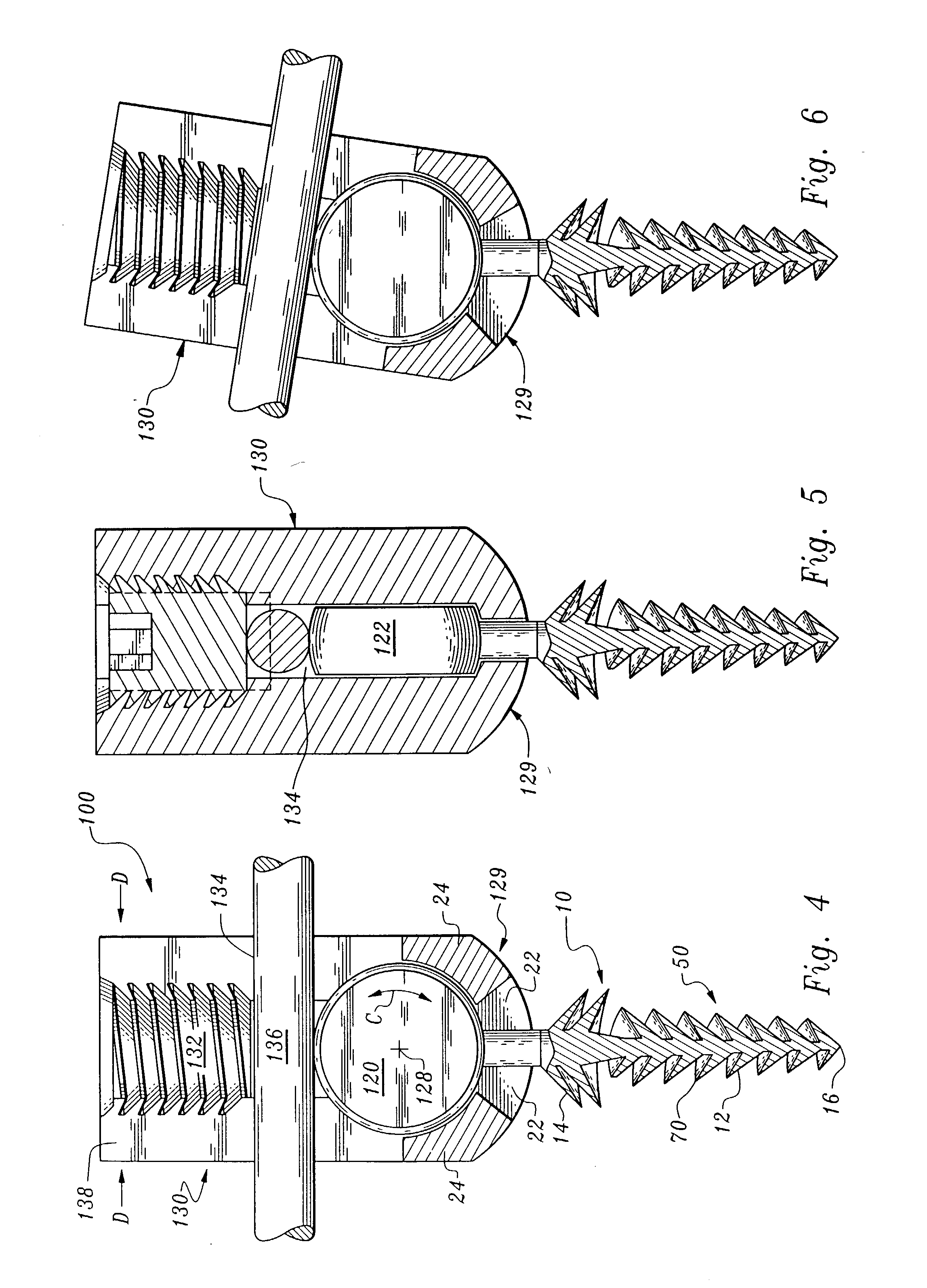

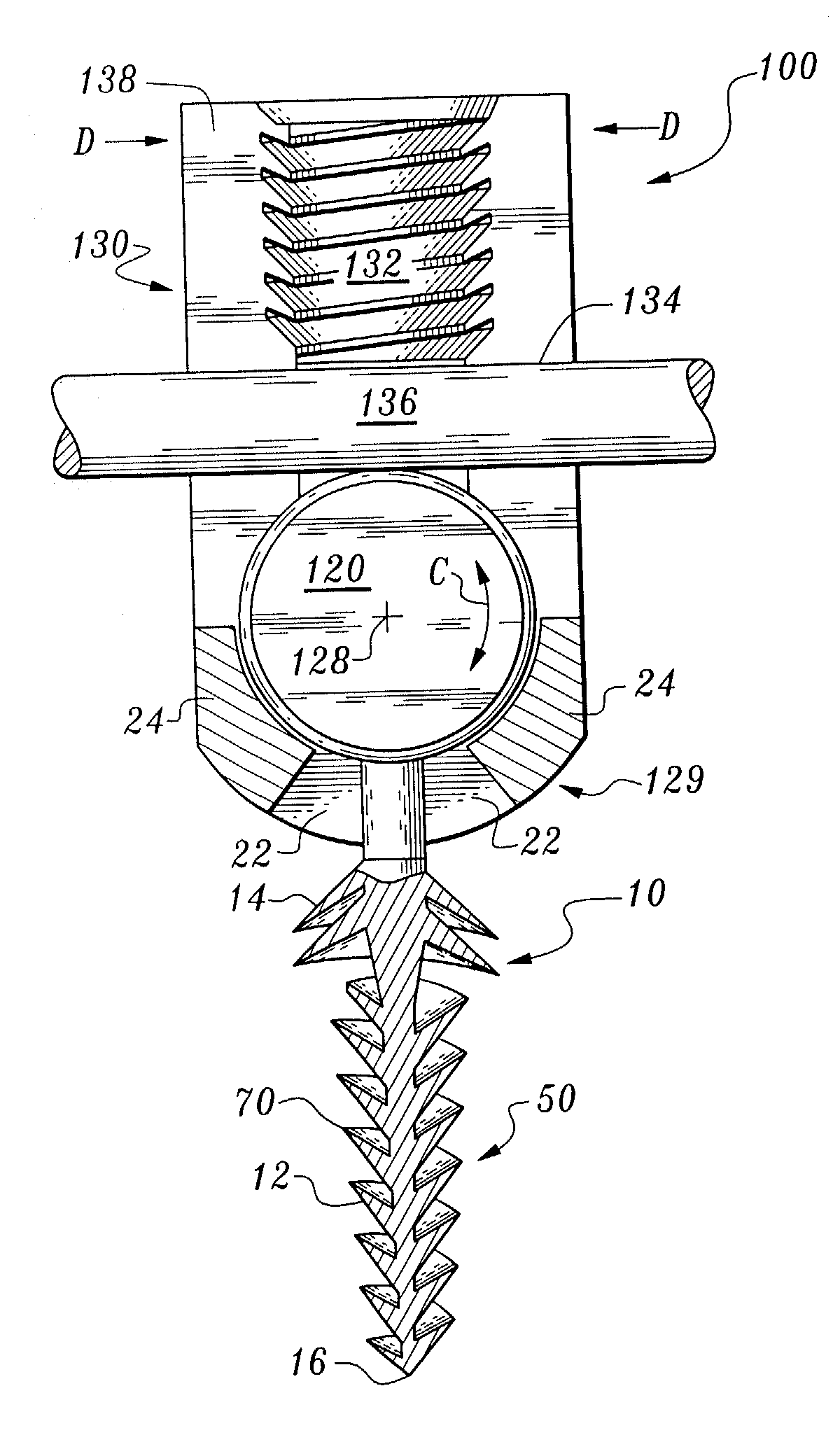

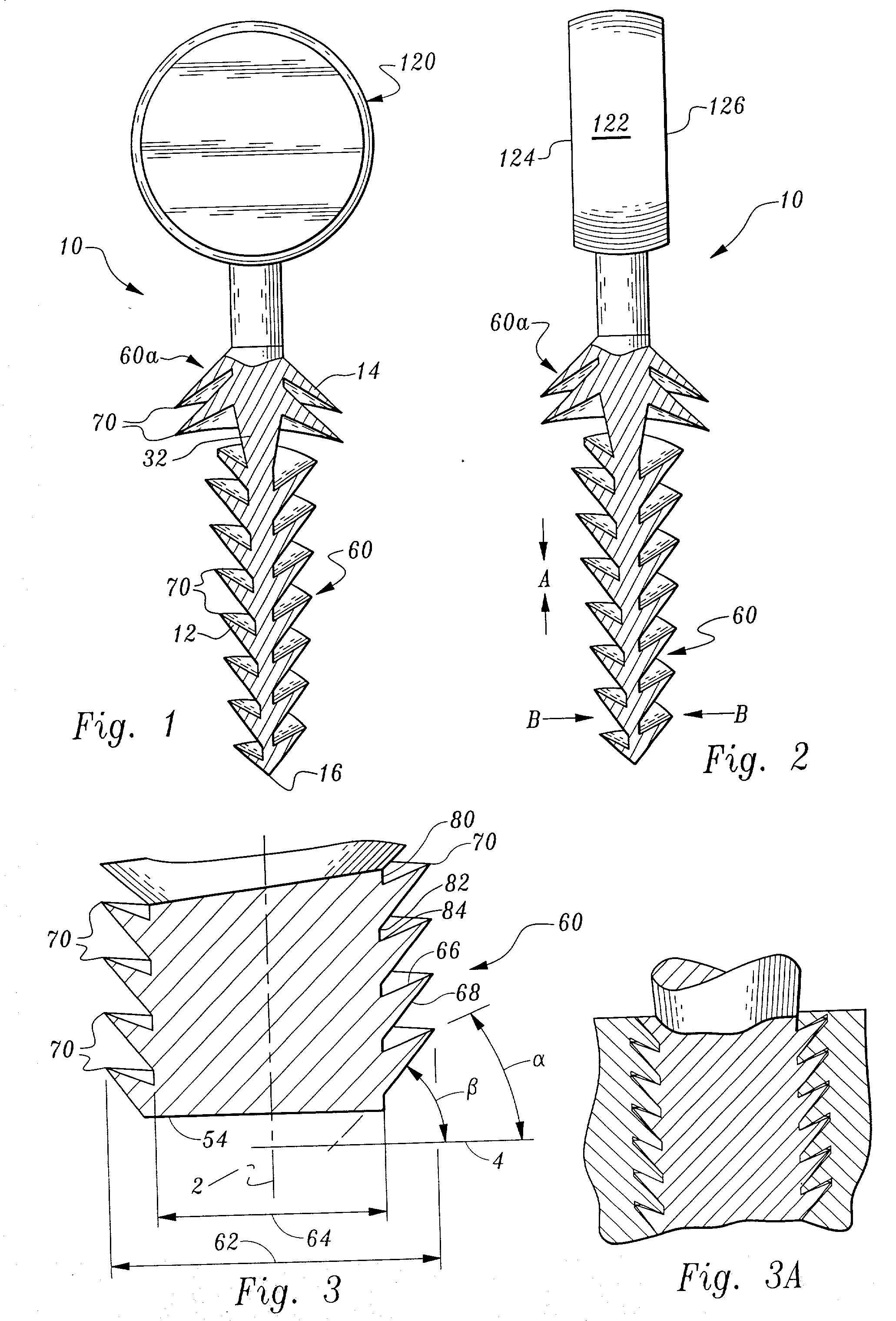

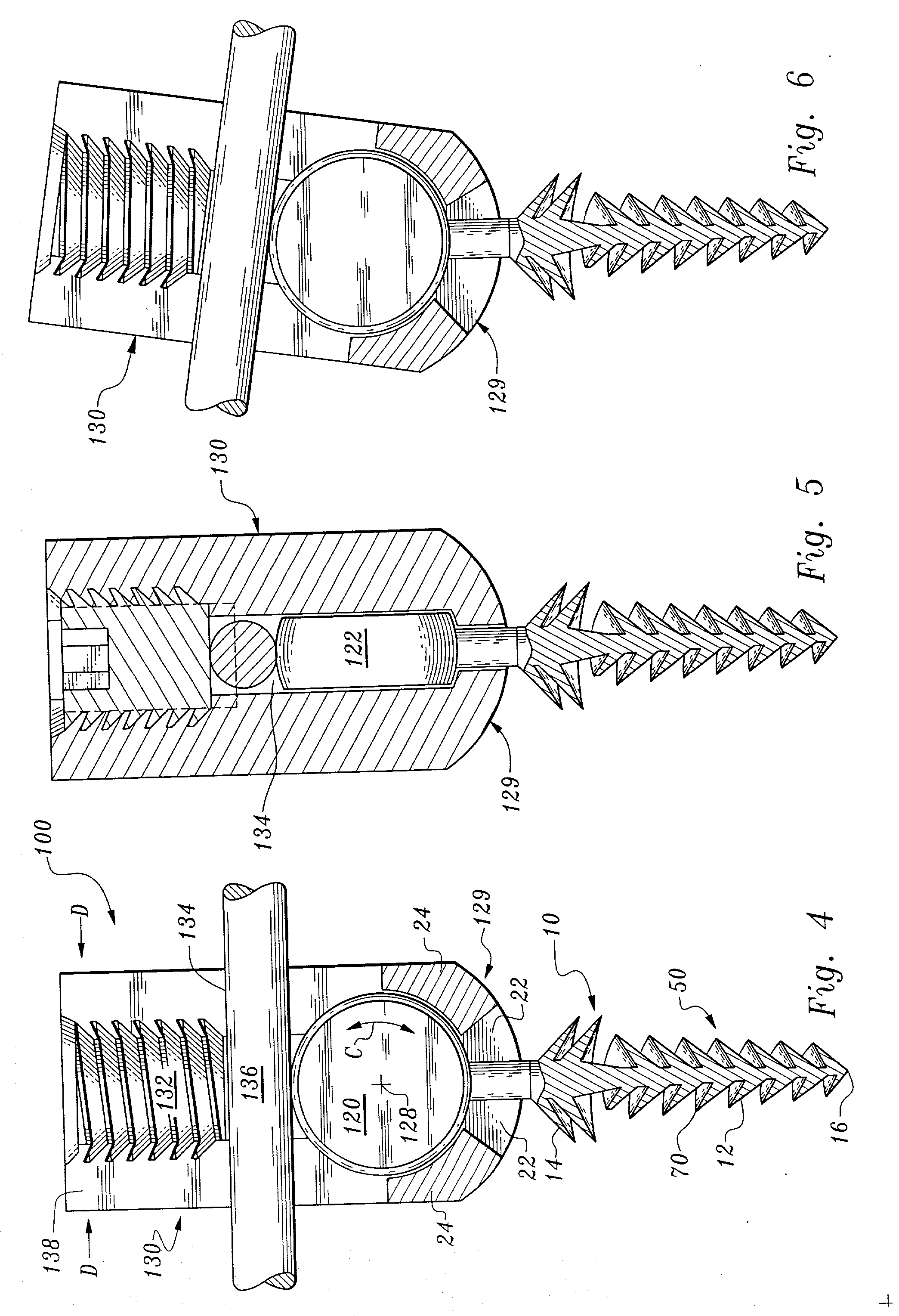

Bone fixation system with low profile fastener

A low profile orthopedic device is used to fix and stabilize bones to correct anomalies in skeletal structure occurring naturally or by trauma. Bone screws are screwed into bones by application of torque. Clamps are movably attached to the screws. Each clamp includes a compression ring. A connecting rod connects several screws through slots in the clamps. The clamps are tightened to hold the rod and the heads in a pre-selected position by linear movement of the compression rings.

Owner:SPINAL

Bone fixation system with low profile fastener

A low profile orthopedic device is used to fix and stabilize bones to correct anomalies in skeletal structure occurring naturally or by trauma. Bone screws are screwed into bones by application of torque. Clamps are movably attached to the screws. Each clamp includes a compression ring. A connecting rod connects several screws through slots in the clamps. The clamps are tightened to hold the rod and the heads in a pre-selected position by linear movement of the compression rings.

Owner:SPINAL

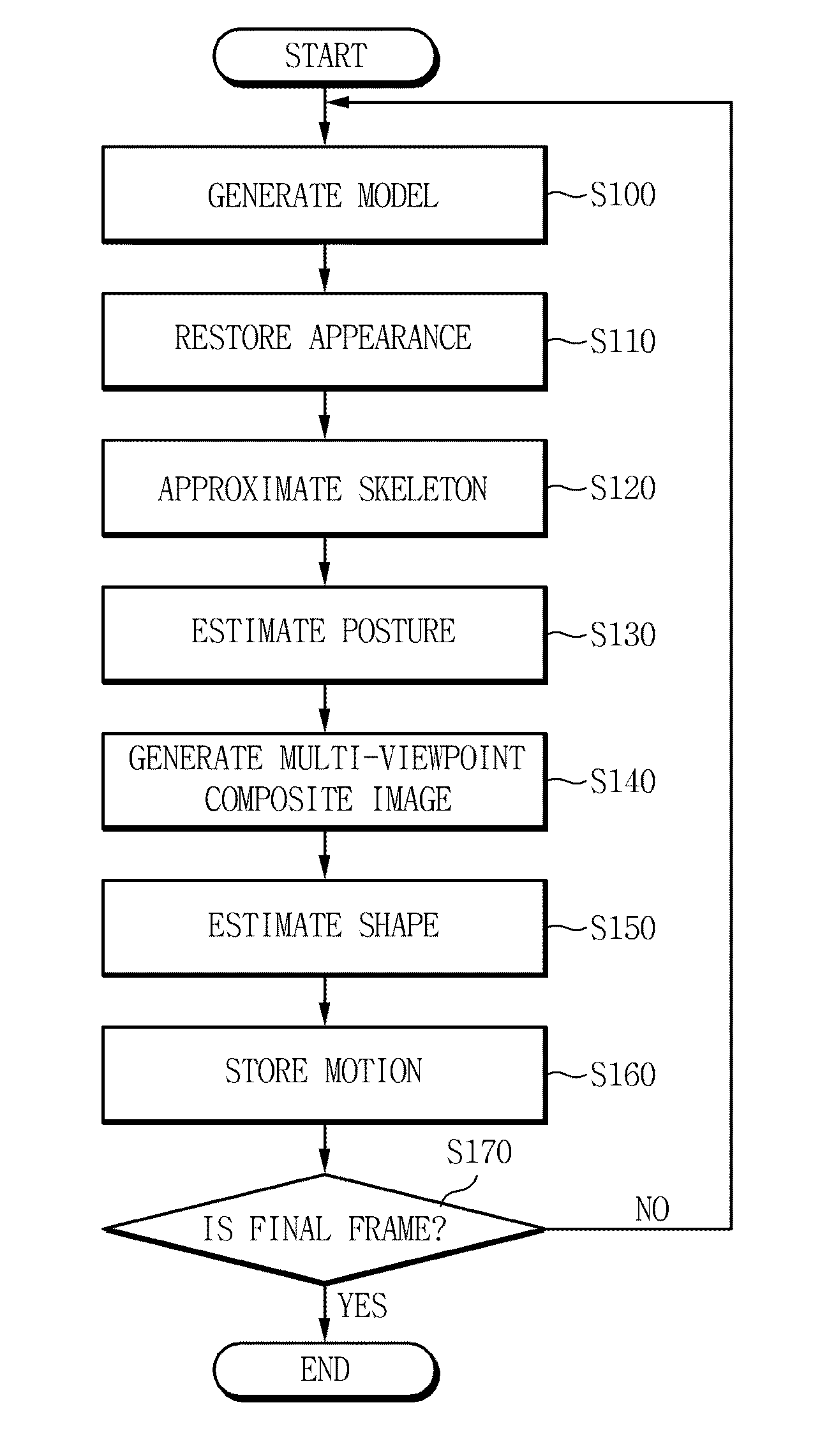

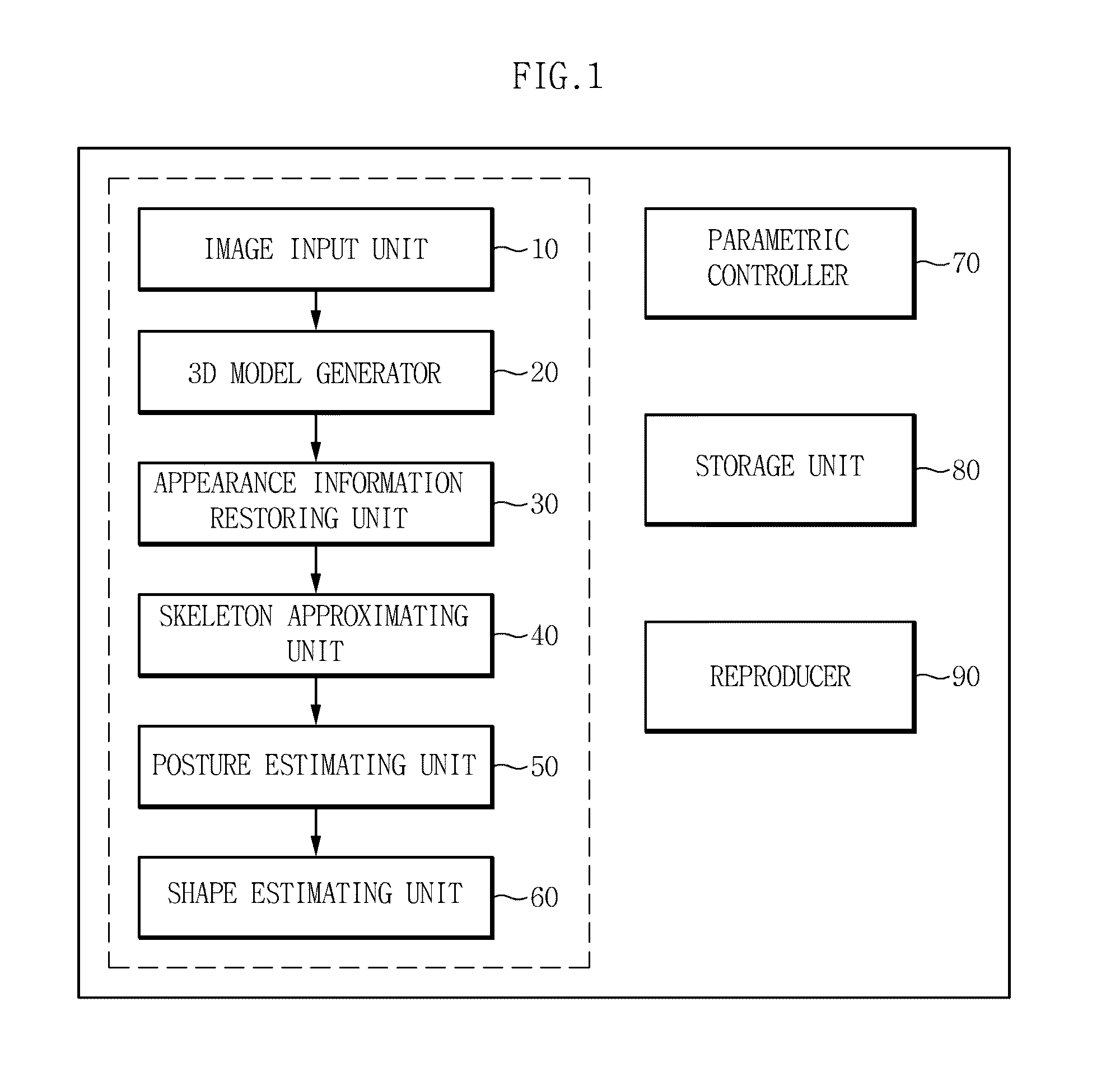

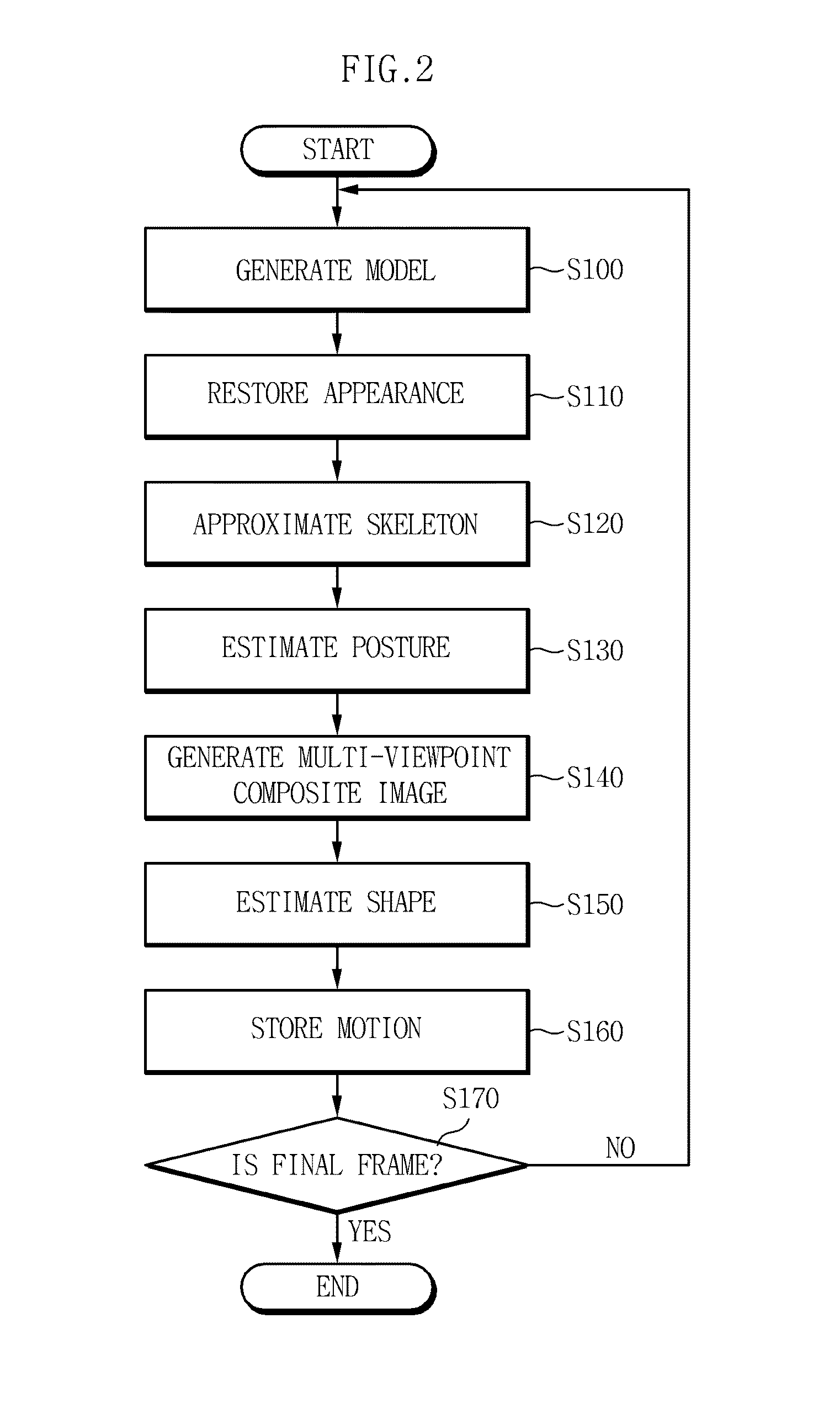

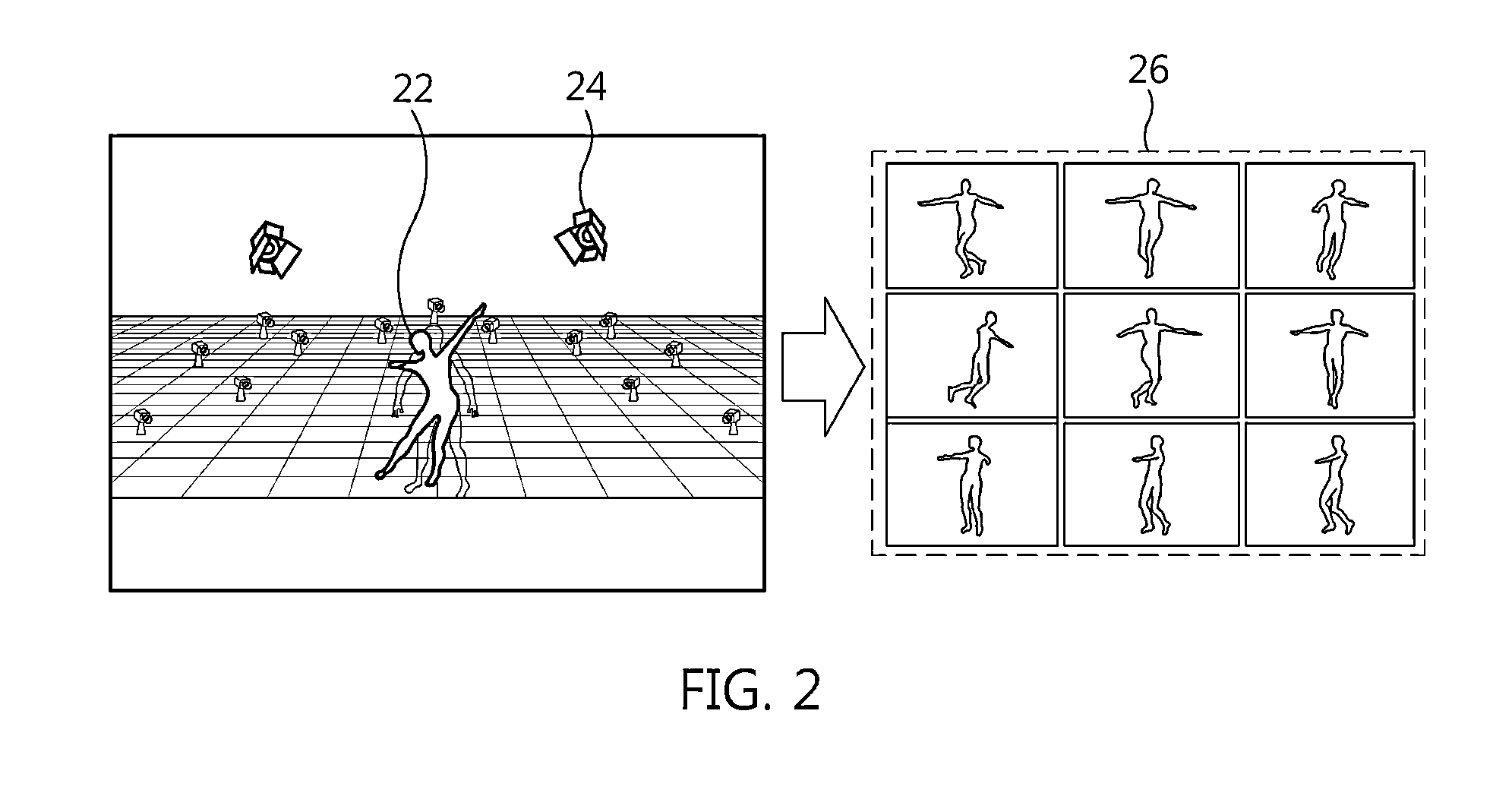

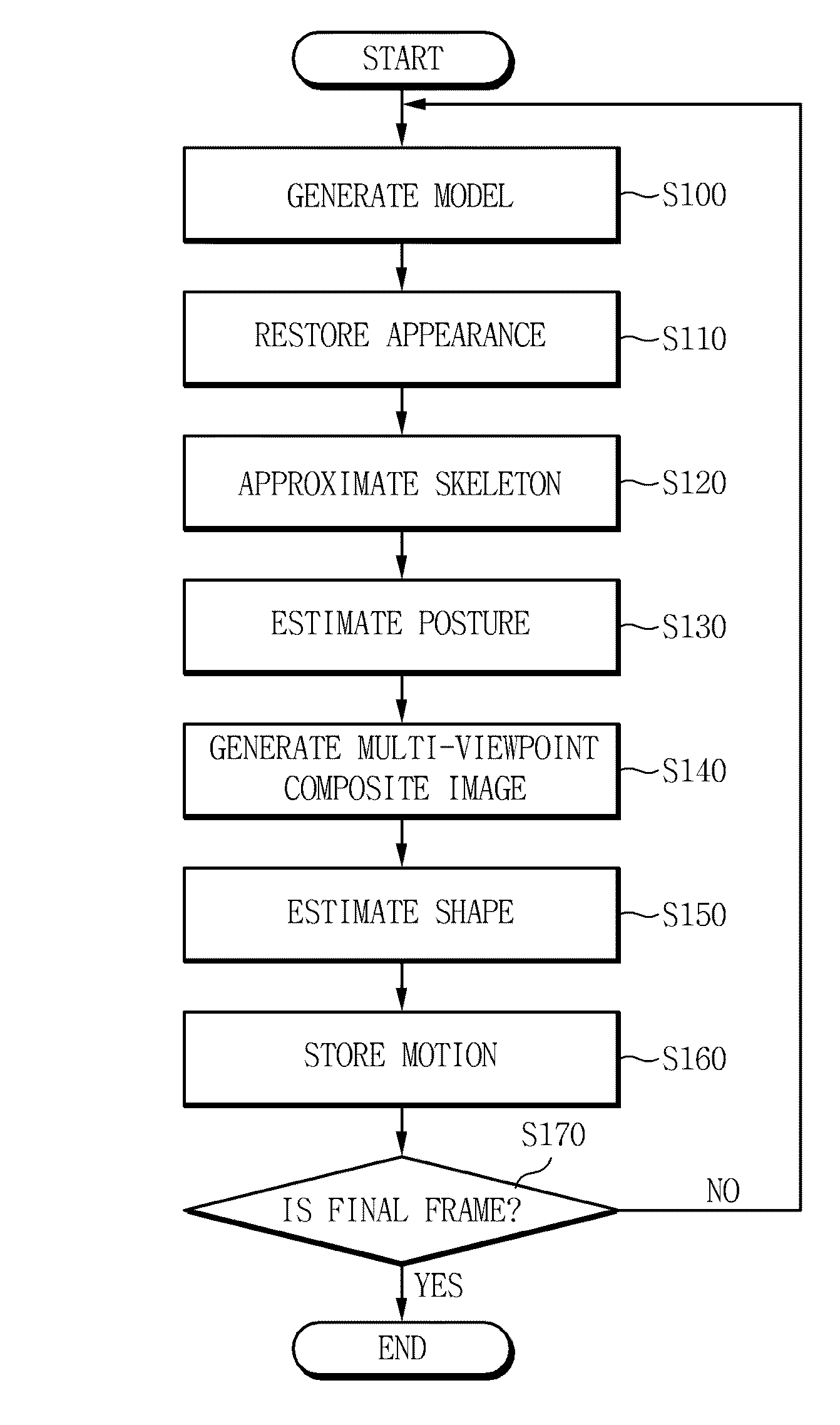

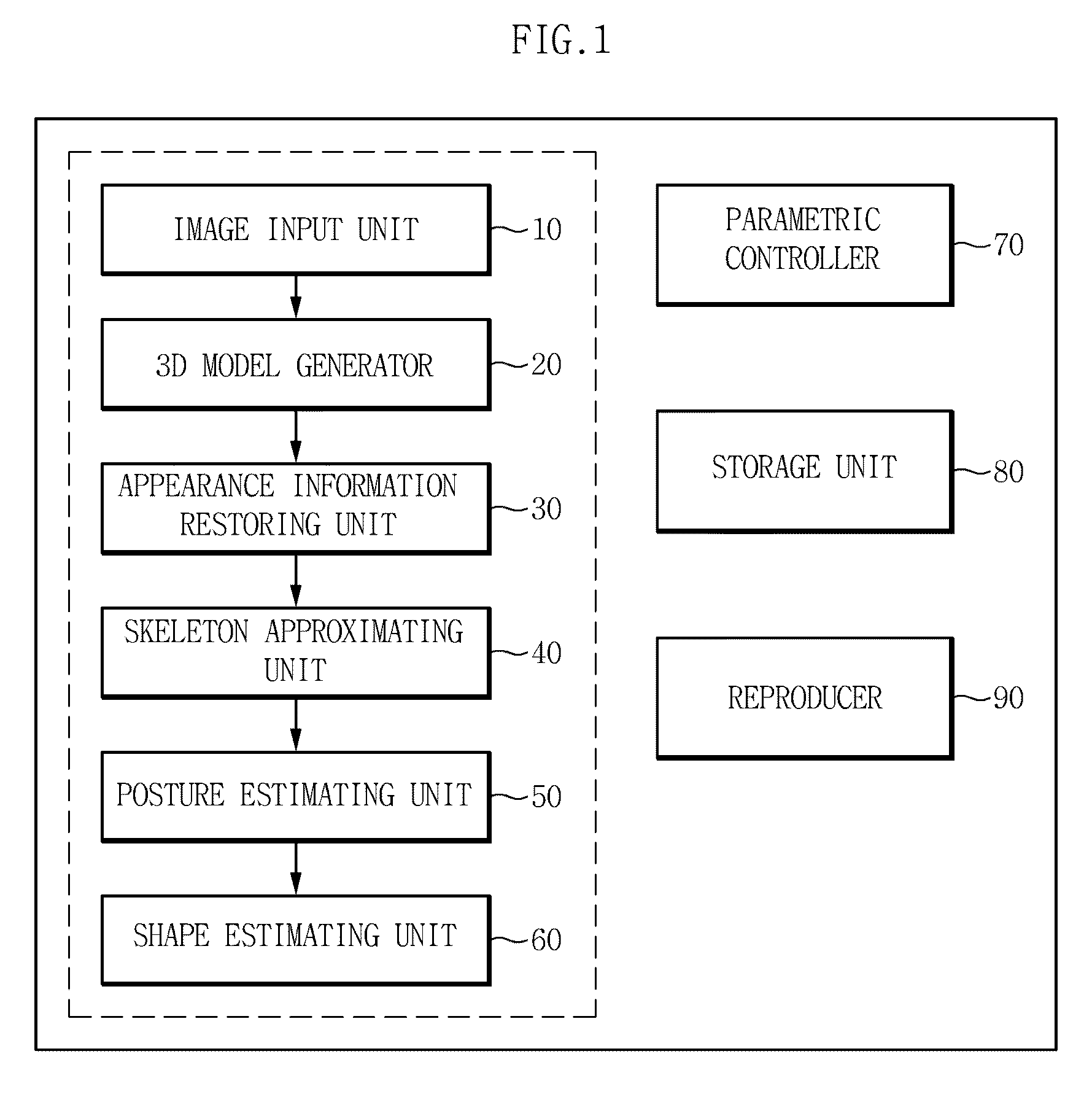

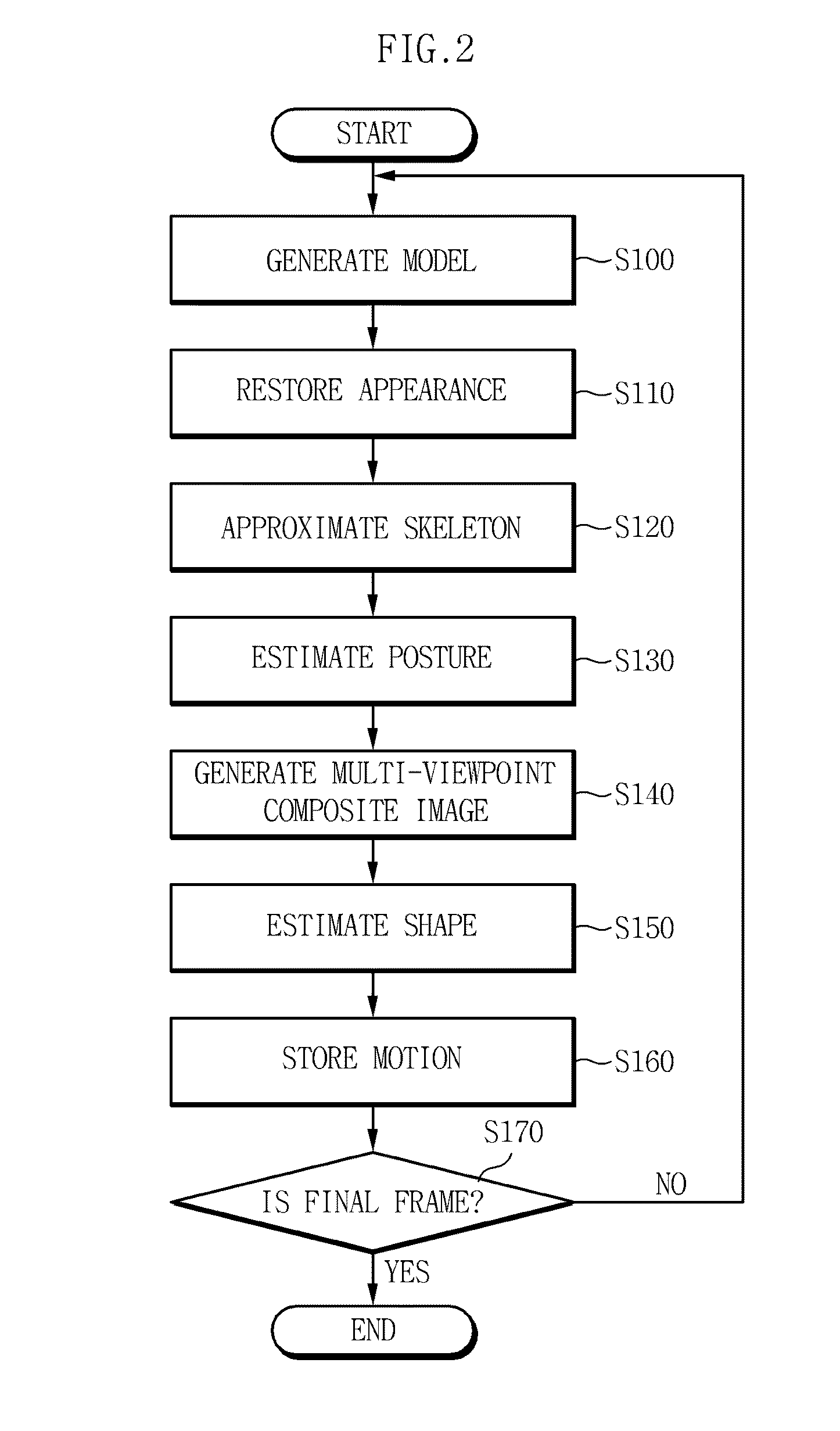

Method and apparatus for capturing motion of dynamic object

The present invention relates to a method and apparatus for capturing a motion of a dynamic object, and restore appearance information of an object making a dynamic motion and motion information of main joints from multi-viewpoint video images of motion information of a dynamic object such as a human body, making a motion through a motion of a skeletal structure on the basis of the skeletal structure, acquired by using multiple cameras. According to the exemplary embodiments of the present invention, it is possible to restore motion information of the object making a dynamic motion by using only an image sensor for a visible light range and to reproduce a multi-viewpoint image by effectively storing the restored information. Further, it is possible to restore motion information of the dynamic object without attaching a specific marker.

Owner:ELECTRONICS & TELECOMM RES INST

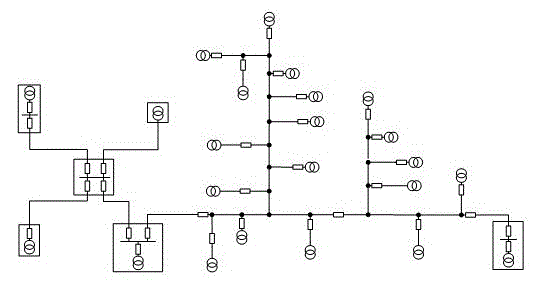

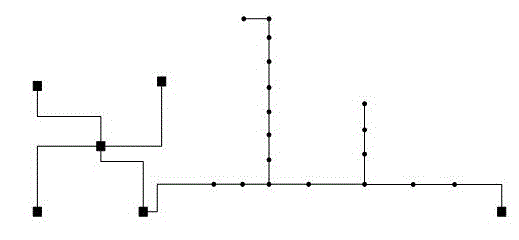

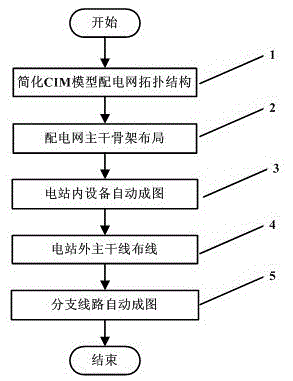

Automatic generation method used for single line diagram of distribution network and based on topological hierarchy

ActiveCN103150425ARealize automatic generationRealize a reasonable layoutSpecial data processing applicationsMassive gravityPower station

The invention discloses an automatic generation method used for a single line diagram of a distribution network and based on topological hierarchy. The method comprises the following steps: deleting related equipment in a topological structure of the distribution network, and simplifying the topological structure of the distribution network; acquiring key nodes of the topological structure of the distribution network, and generating a main framework of the topological structure of the distribution network; arranging the positions of the key nodes based on a gravitation-repulsion model, and obtaining a skeletal structure based on the gravitation-repulsion; describing the topological structure of the distribution network through an outgoing line-trunk line-T-shaped key node-branch line model of a power station; finishing the arrangement and the automatic mapping of the equipment in the power station on the basis of the topological structure of the equipment in the power station; and performing routing mapping without overlap or intersection on decibels of the trunk line and the branch line respectively. The automatic generation method achieves automatic generation of the single line diagram of the distribution network above a certain scale, and simultaneously, the generated single line diagram is clearer and more attractive through the routing algorithm without overlap or intersection.

Owner:SHANGHAI JIAO TONG UNIV

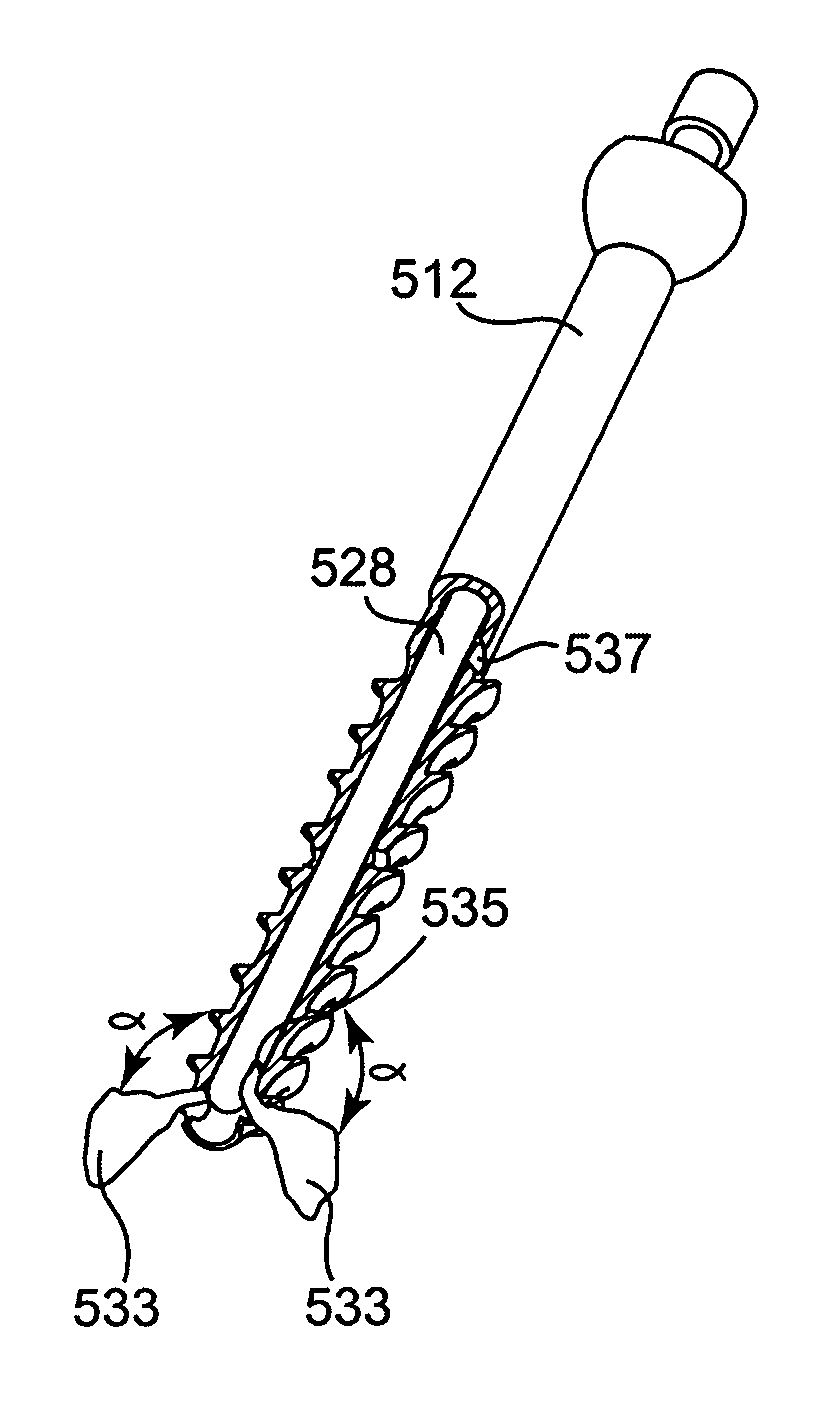

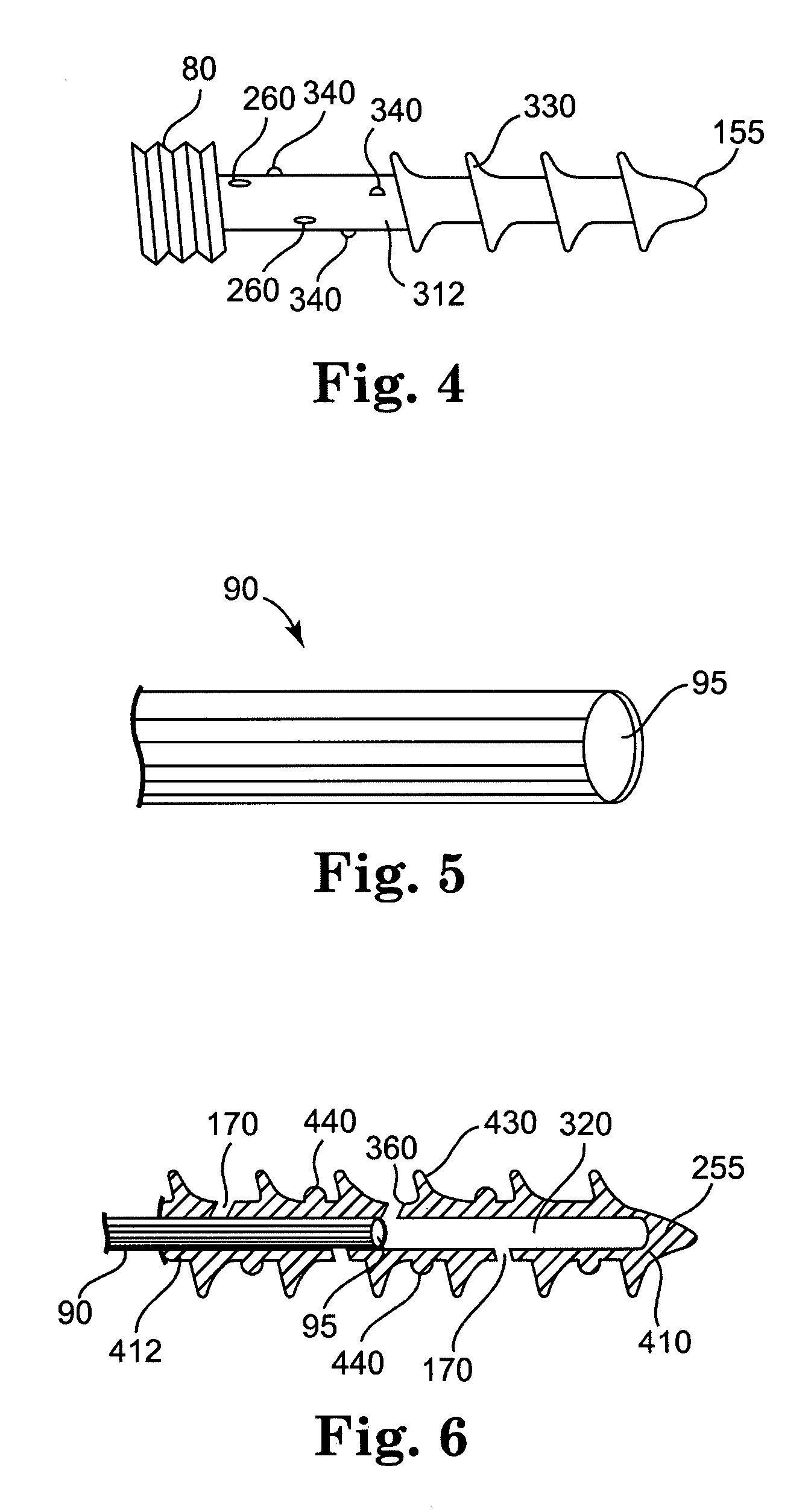

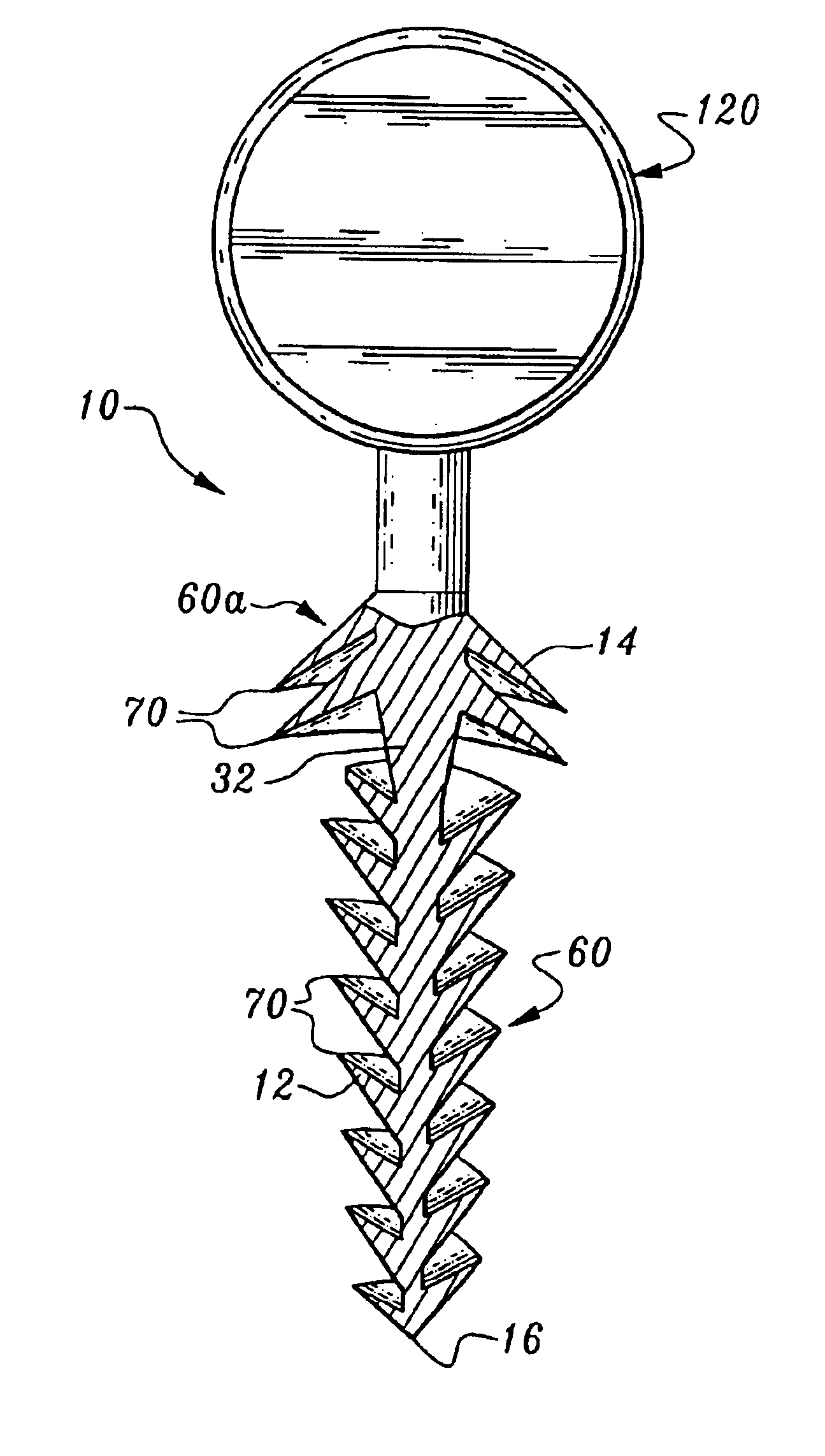

Bone screw with fluid delivery structure

A device and method to mechanically strengthen bone matrix and deliver tissue reinforcement material to weakened areas in skeletal structures. A preferred embodiment is an orthopedic screw configured to receive and directionally disperse a therapeutic fluid through the screw's channels and apertures.

Owner:MILLENNIUM MEDICAL TECH INC

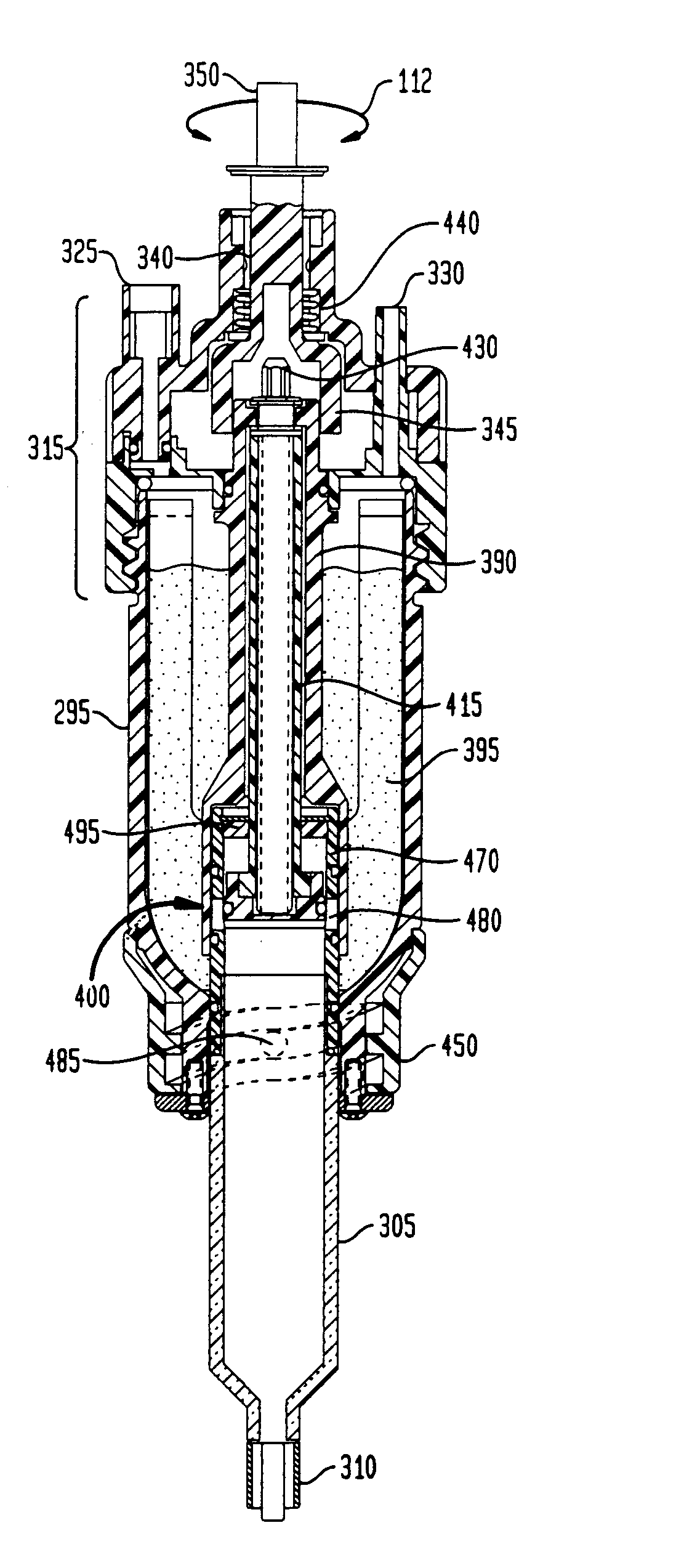

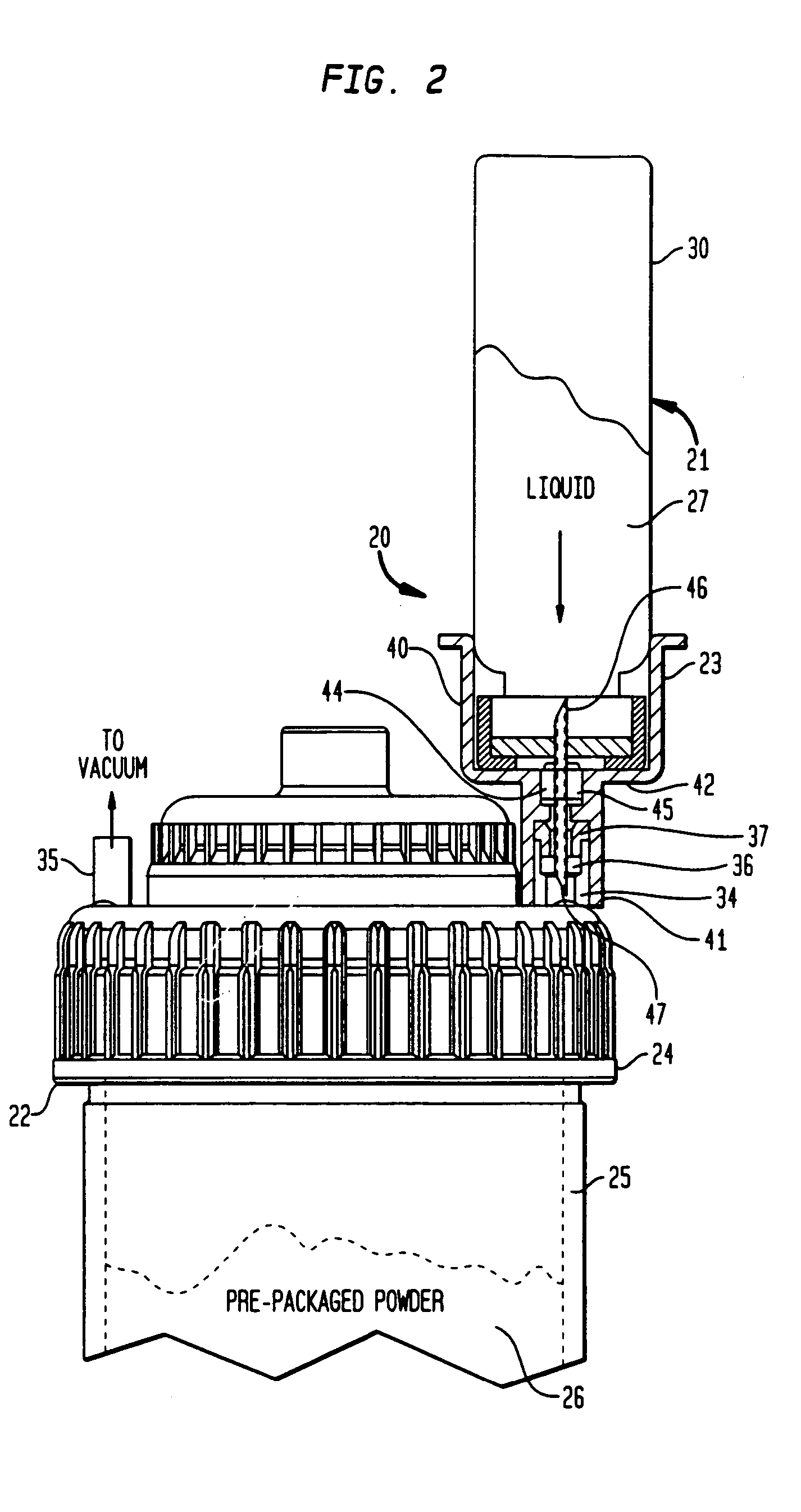

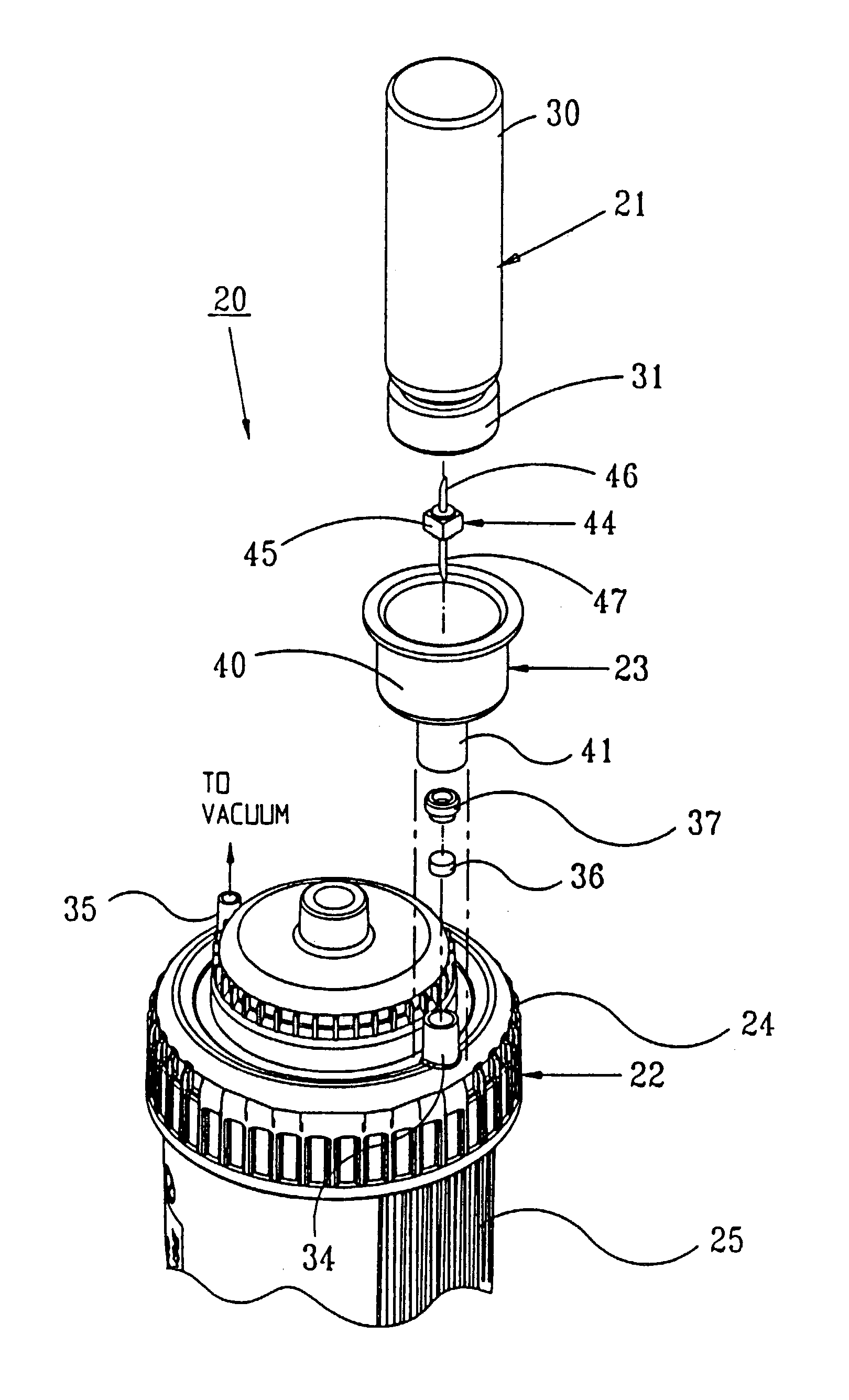

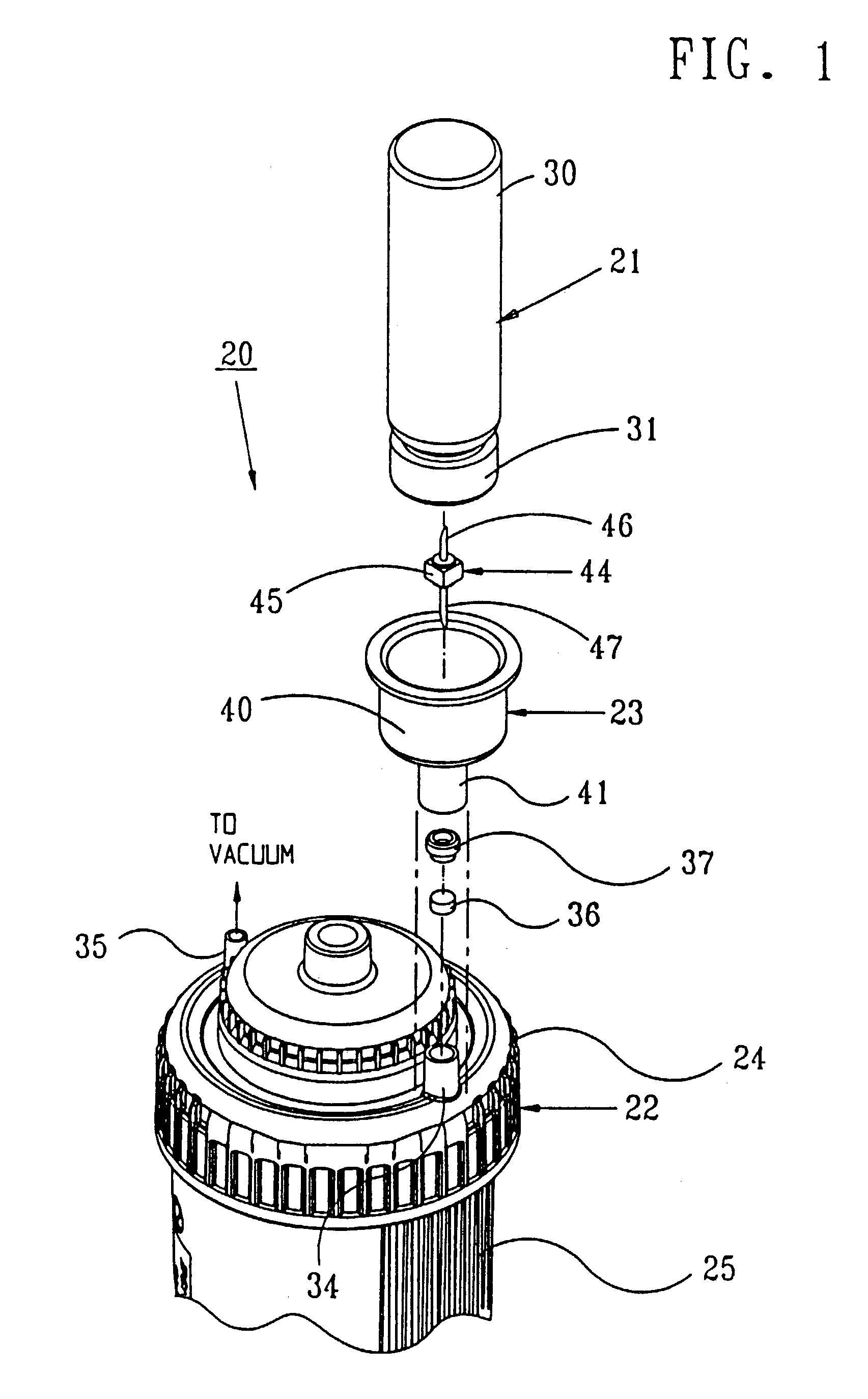

Apparatus for mixing and dispensing components

InactiveUS20040196735A1Exposure was also limitedReduce in quantitySurgical furnitureRotary stirring mixersEngineeringBone cement

Apparatus and methods for mixing and dispensing components. The methods and apparatus of the invention are particularly advantageous to manually mix the components of radiopaque bone cement and inject the resulting radiopaque bone cement into skeletal structures. The manually actuated apparatus of the invention comprises: (1) a sealed mixing chamber for mixing components; (2) a dispensing chamber isolated from the sealed mixing chamber; (3) a controllable portal to open a flow path between the sealed mixing chamber and the dispensing chamber so that the dispensing chamber can receive the mixed components after they are mixed; and (4) a drive mechanism associated with the dispensing chamber to force the mixed contents from the dispensing chamber.

Owner:GLOBUS MEDICAL INC

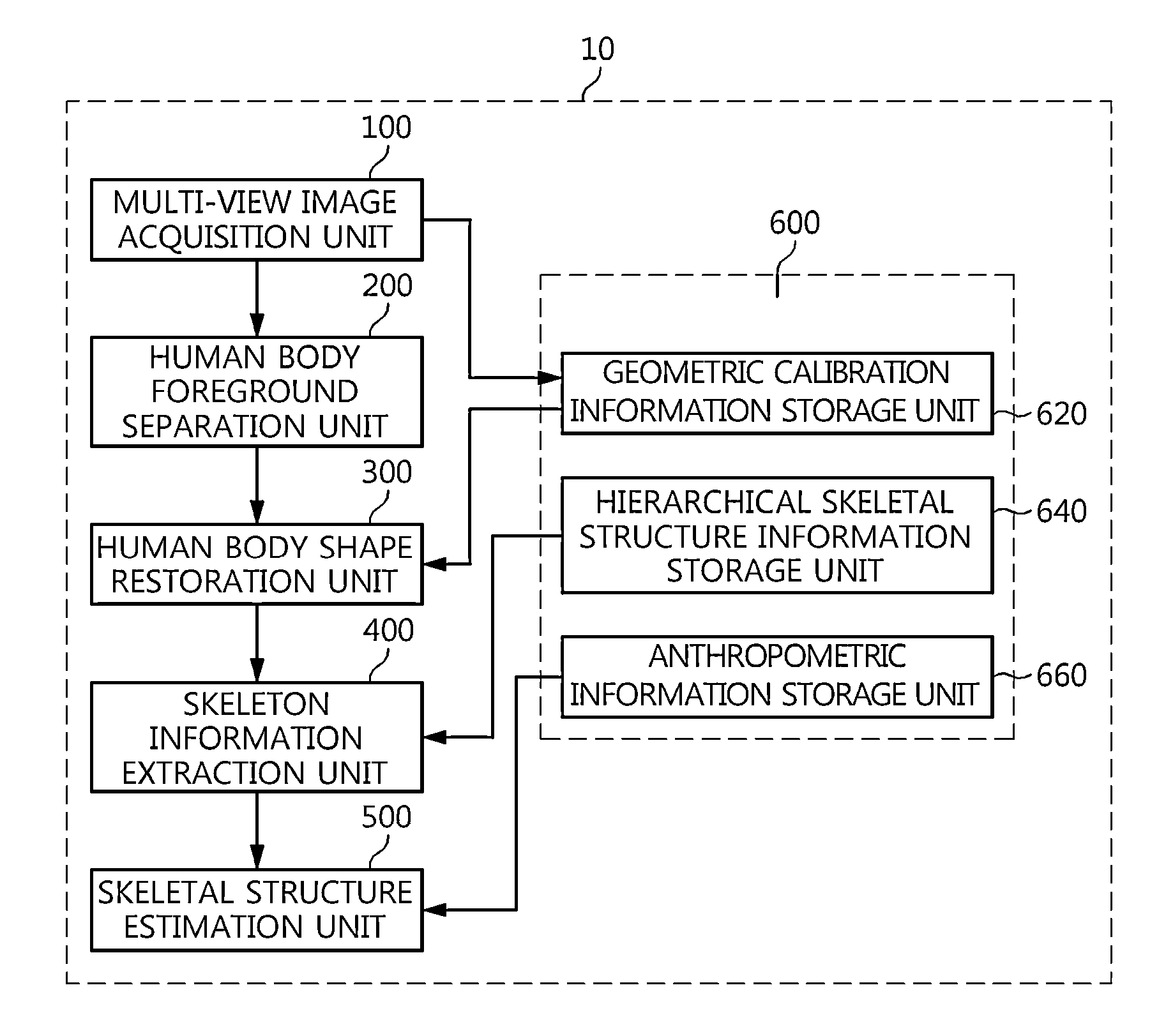

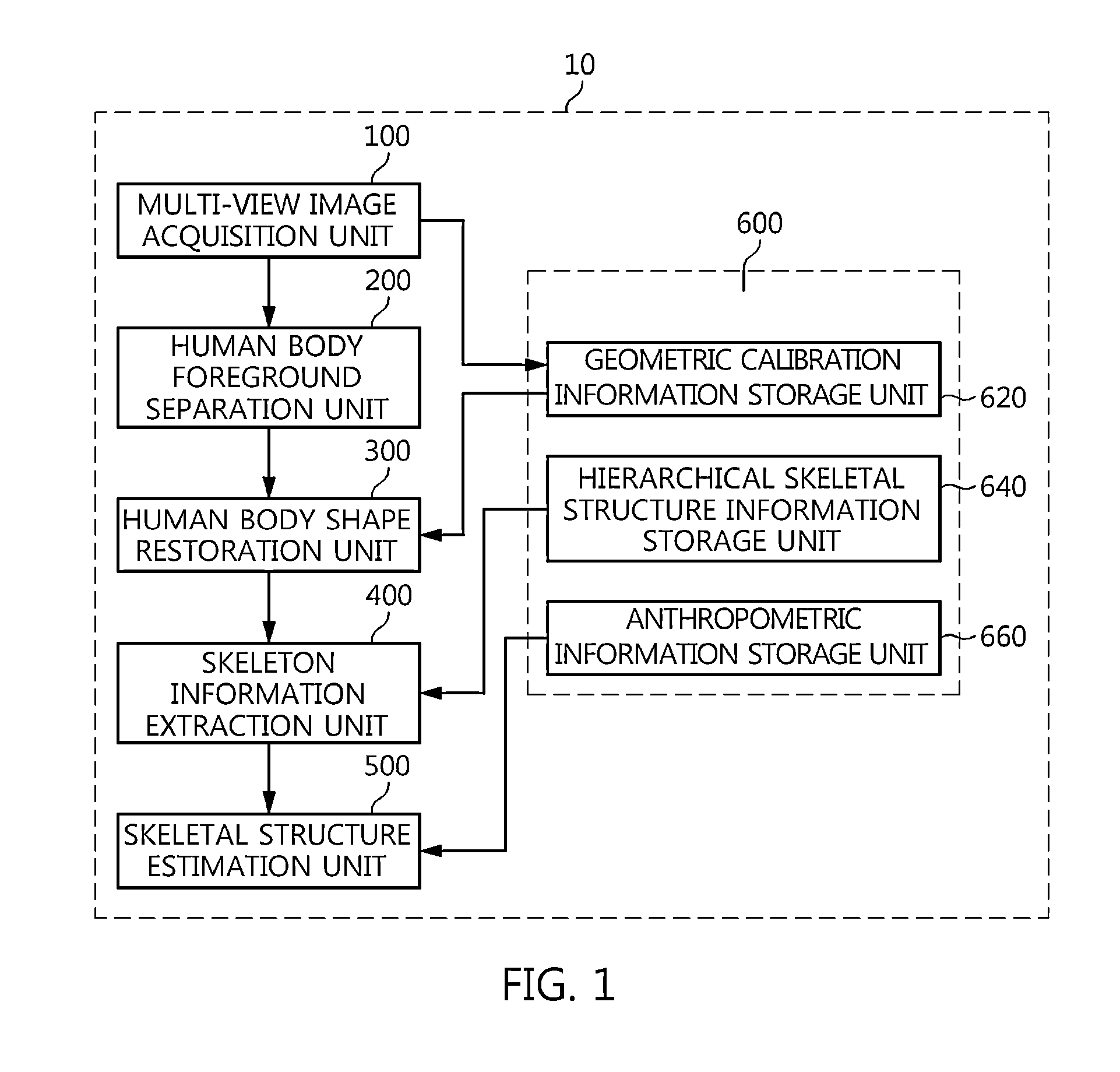

Apparatus and method for estimating joint structure of human body

Disclosed herein is an apparatus and method for estimating the joint structure of a human body. The apparatus includes a multi-view image acquisition unit for receiving multi-view images acquired by capturing a human body. A human body foreground separation unit extracts a foreground region corresponding to the human body from the acquired multi-view images. A human body shape restoration unit restores voxels indicating geometric space occupation information of the human body using the foreground region corresponding to the human body, thus generating voxel-based three-dimensional (3D) shape information of the human body. A skeleton information extraction unit generates 3D skeleton information from the generated voxel-based 3D shape information of the human body. A skeletal structure estimation unit estimates positions of respective joints from a skeletal structure of the human body using both the generated 3D skeleton information and anthropometric information.

Owner:ELECTRONICS & TELECOMM RES INST

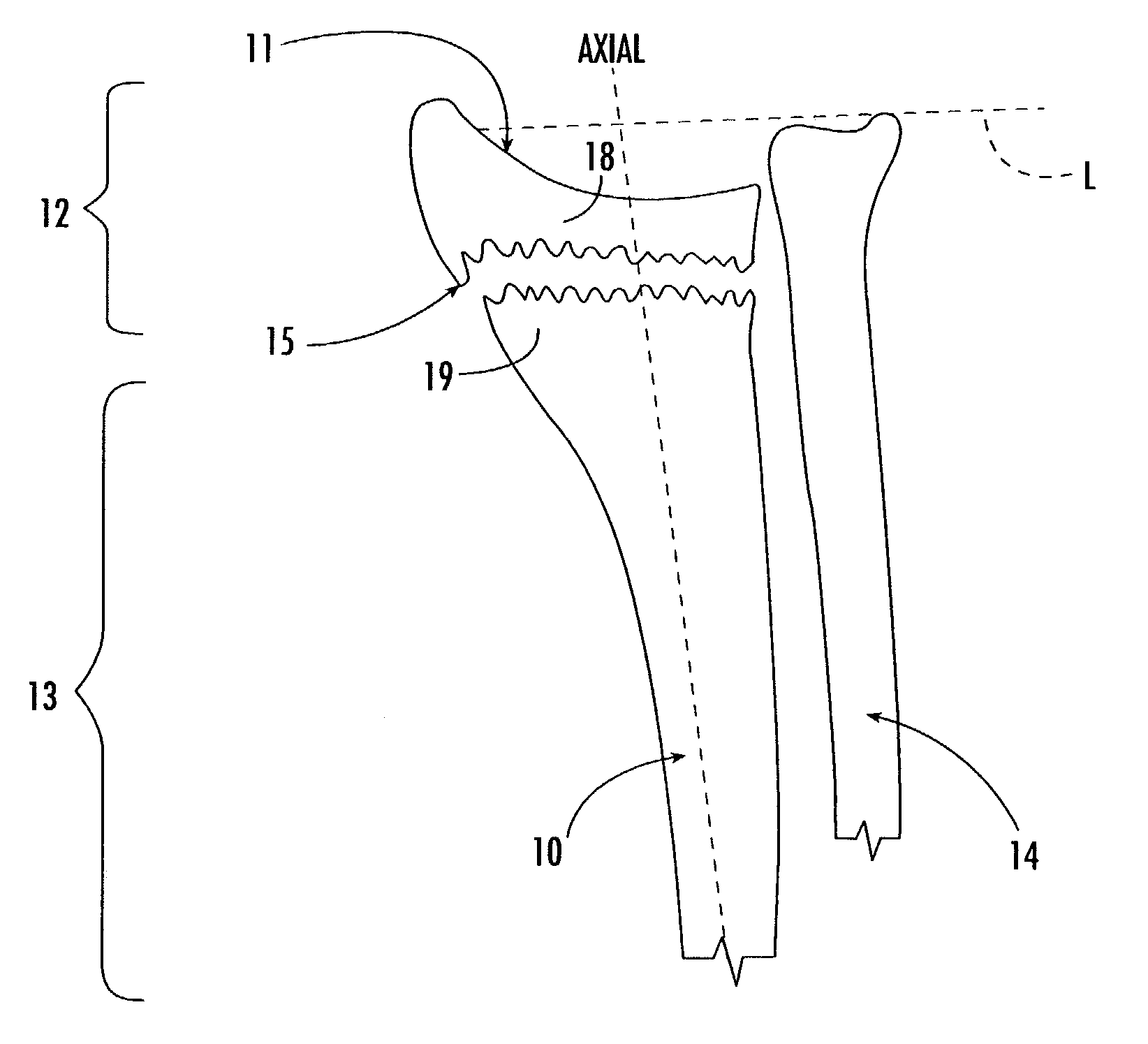

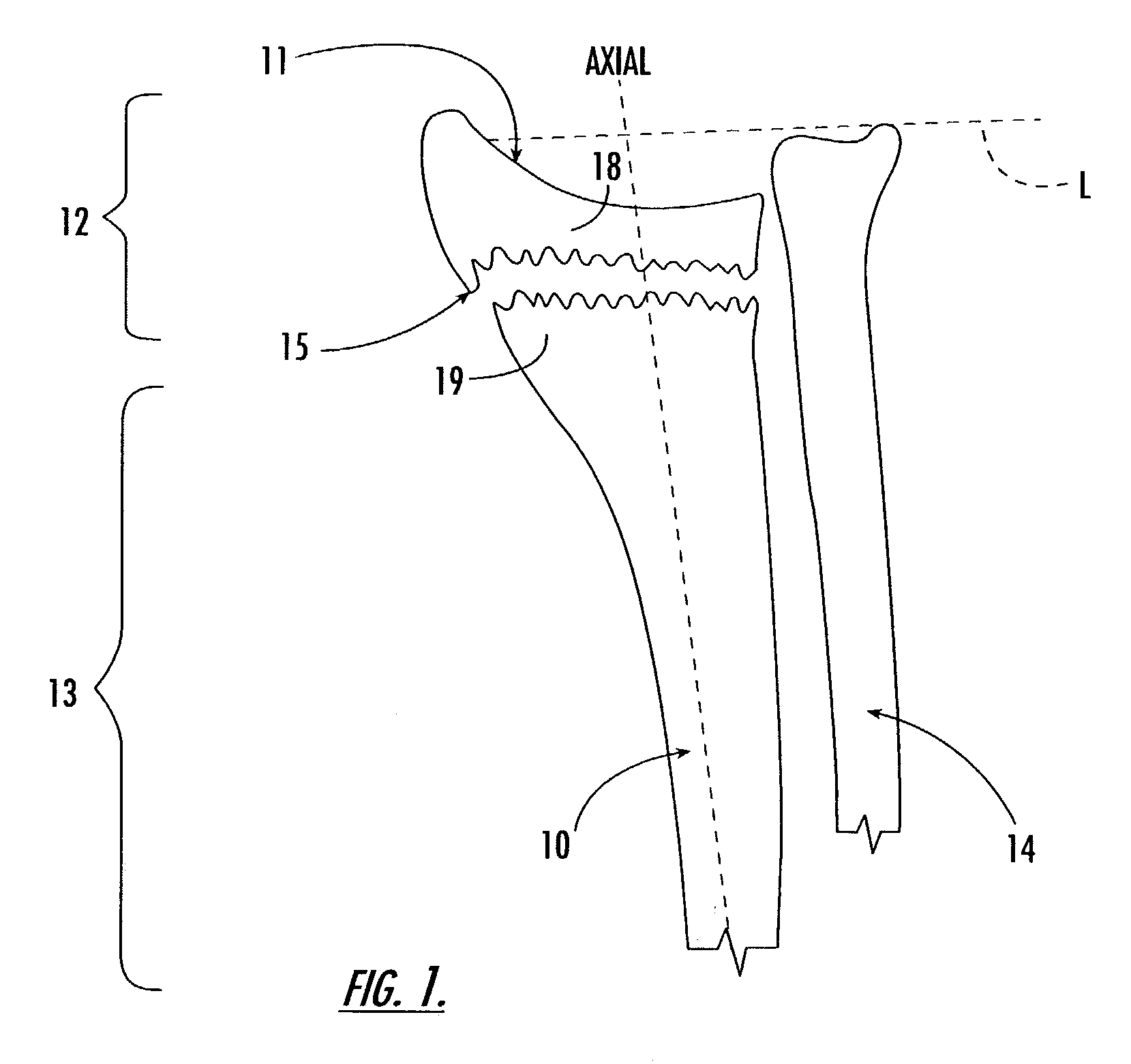

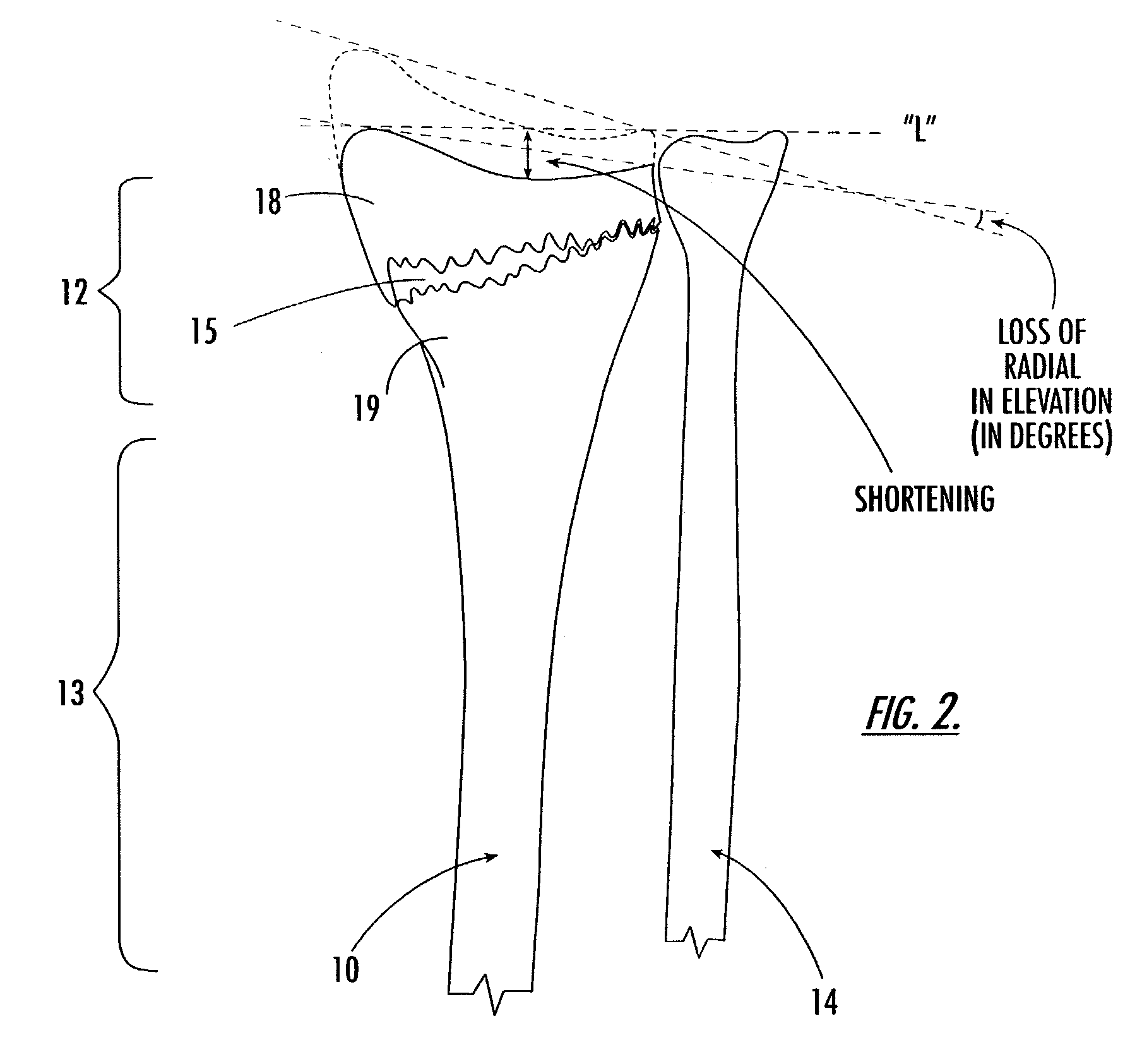

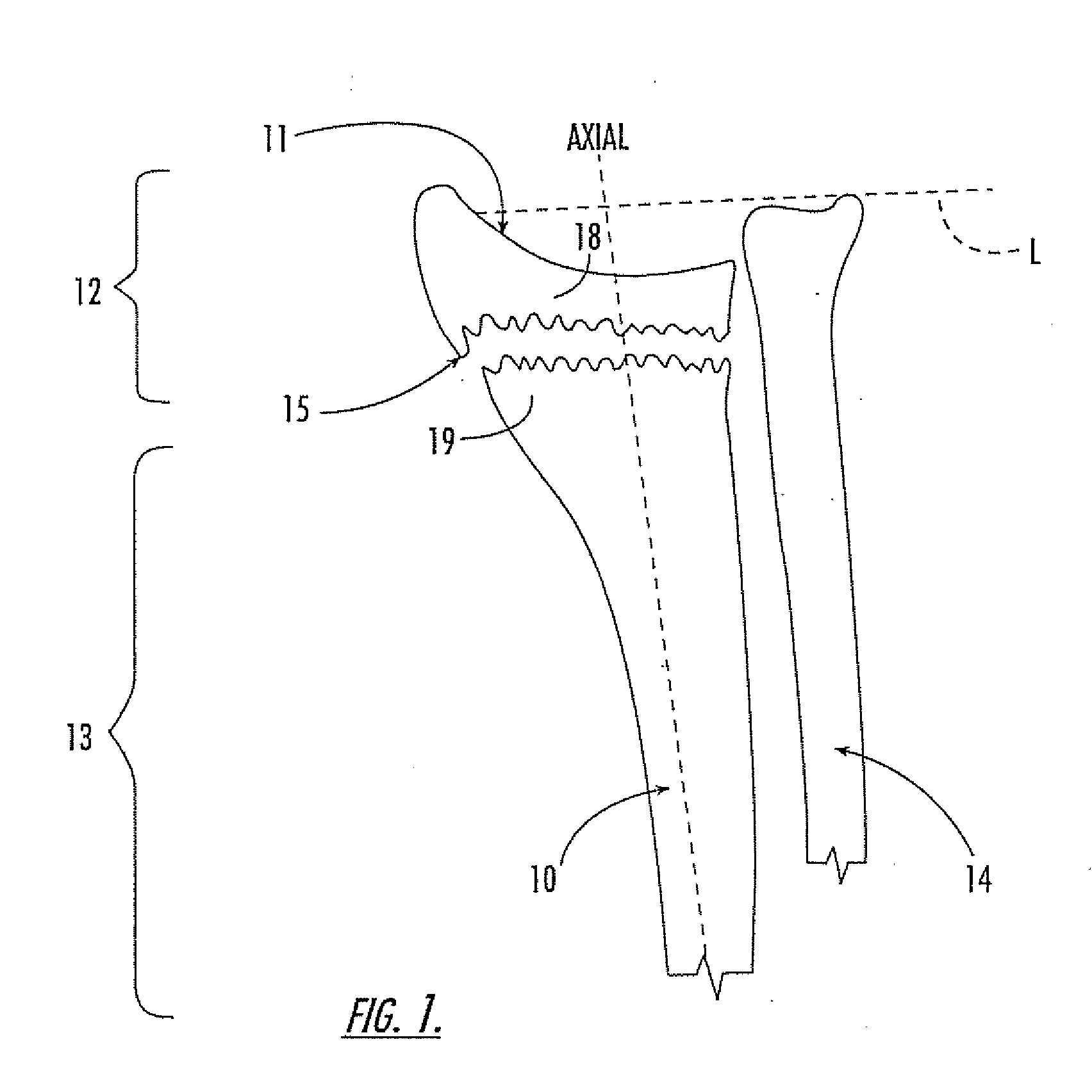

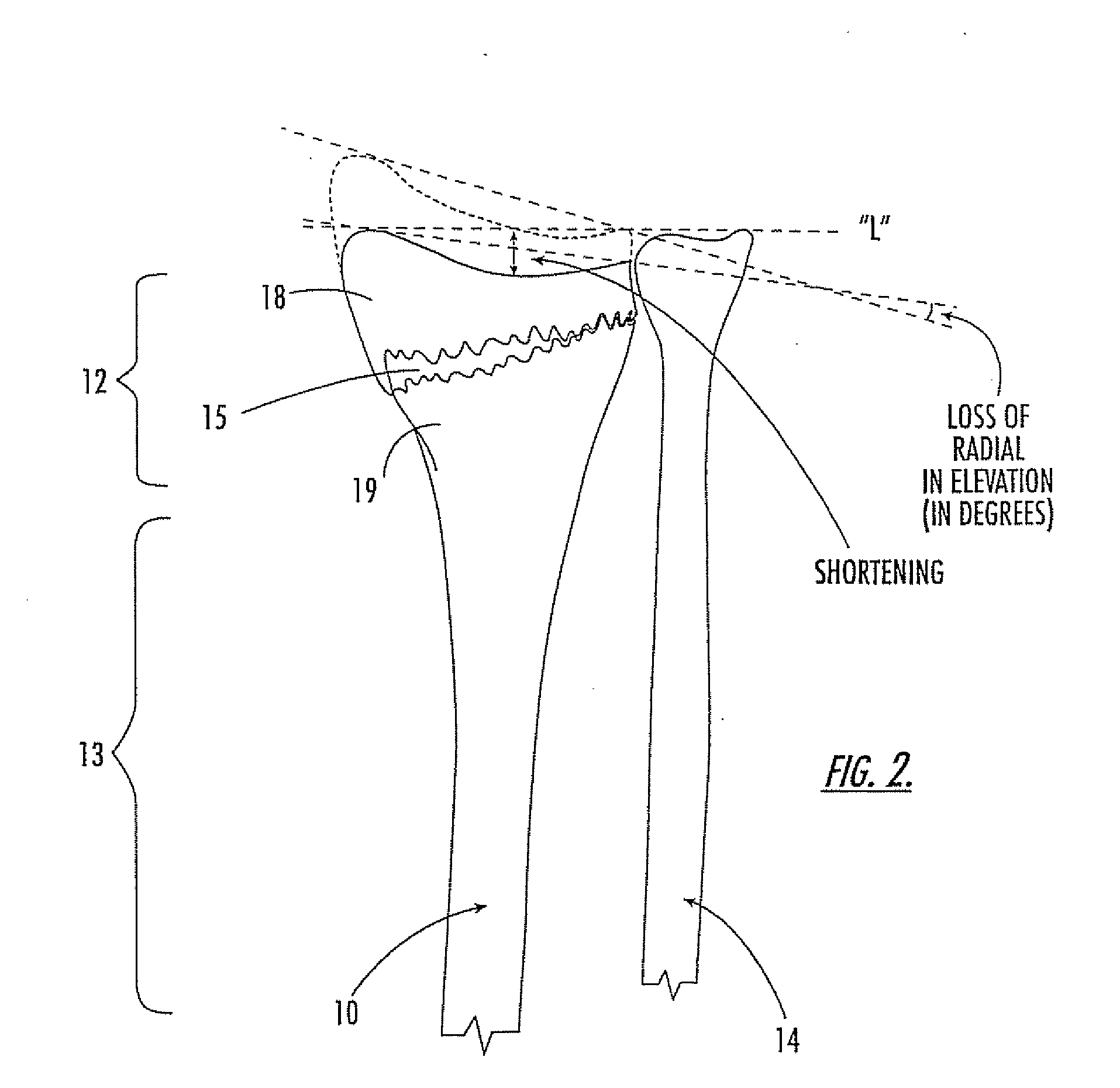

Intramedullary interlocking fixation device for the distal radius

InactiveUS7160302B2Inhibit amount of collapse and loss in skeletal lengthStabilizing and treating distal radius fractures of a patientInternal osteosythesisDiagnosticsSkeletal structuresDistal forearm

Methods and devices for treating fractures in or adjacent the wrist and distal forearm employ an intramedullary interlocking fixation rod (i.e, it interlocks the distal and proximal fracture fragments together) to stabilize the skeletal structure in a manner which can inhibit the amount of collapse or loss in skeletal length exhibited by a patient with a distal radius fracture.

Owner:WRIGHT MEDICAL TECH

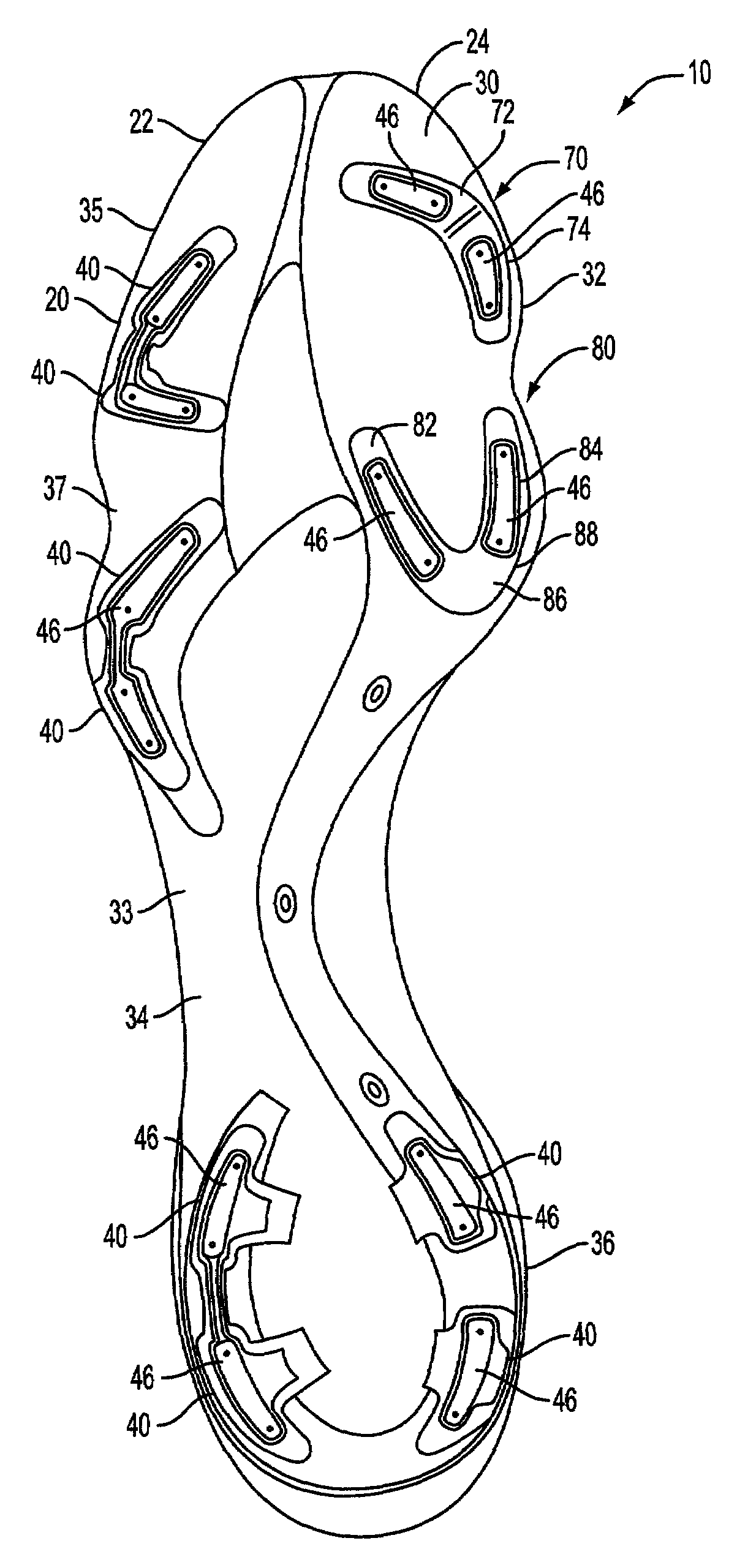

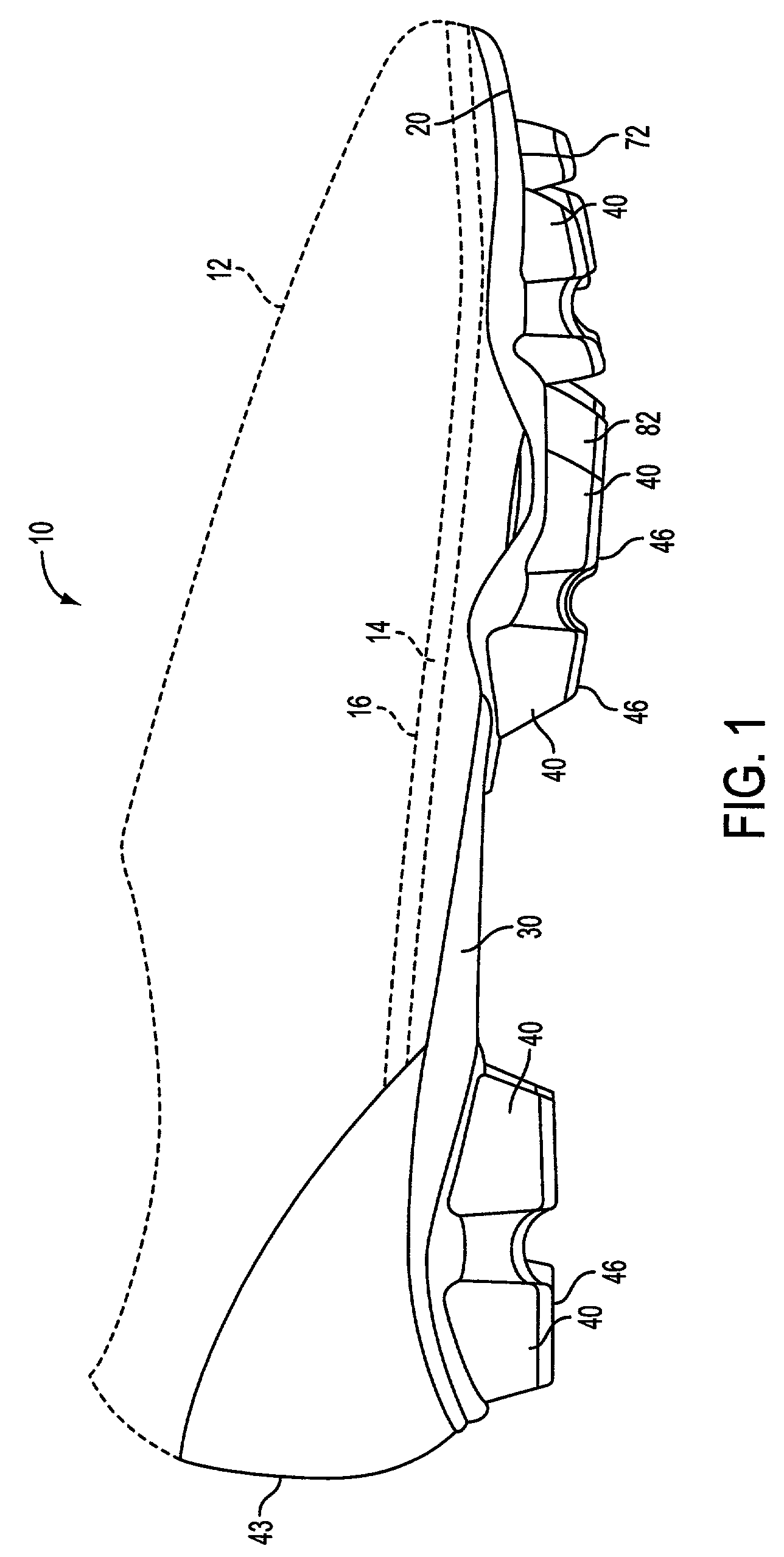

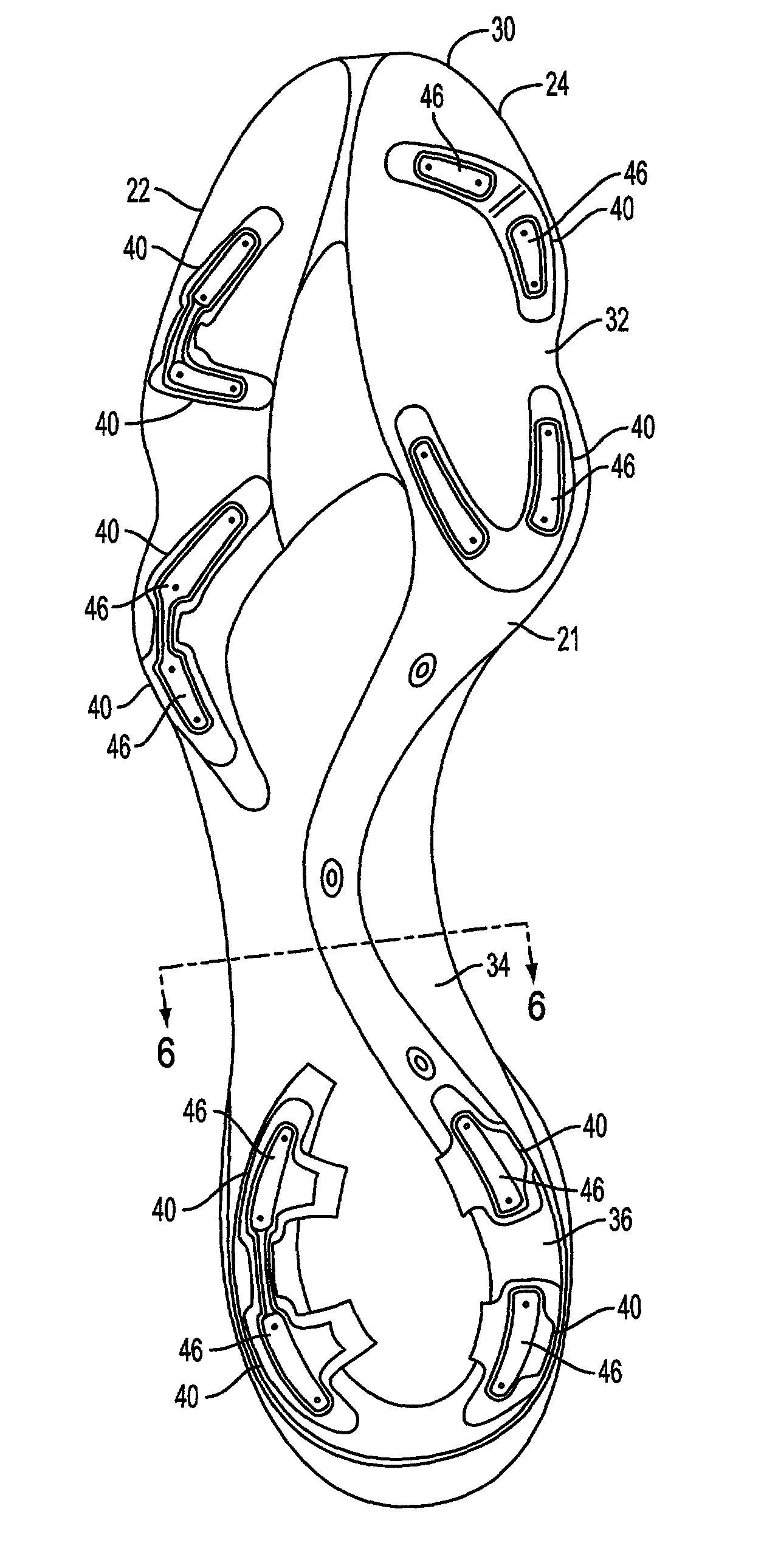

Article of footwear having a regional cleat configuration

InactiveUS7007410B2Reduce injuriesStud pressure reducedFasteningsUpperProximal phalanxFirst metatarsal

An article of cleated footwear comprises an upper for holding a foot of a wearer to a sole having an outsole plate. The outsole plate includes a predetermined first metatarsal region that generally overlies the respective skeletal structure of a human foot. Several ground engaging members extend downwardly from the outsole plate to provide traction on a ground surface. The outsole plate includes a downwardly extending metatarsal head cradle located on a lateral side and a medial side of the first metatarsal region to reduce stud pressure and provide traction control. The outsole plate may include a distal phalanx region and a predetermined proximal phalanx region. A first ground engaging member is located in the distal phalanx region and a second ground engaging member is located in the proximal phalanx region for toe off movements.

Owner:NIKE INC

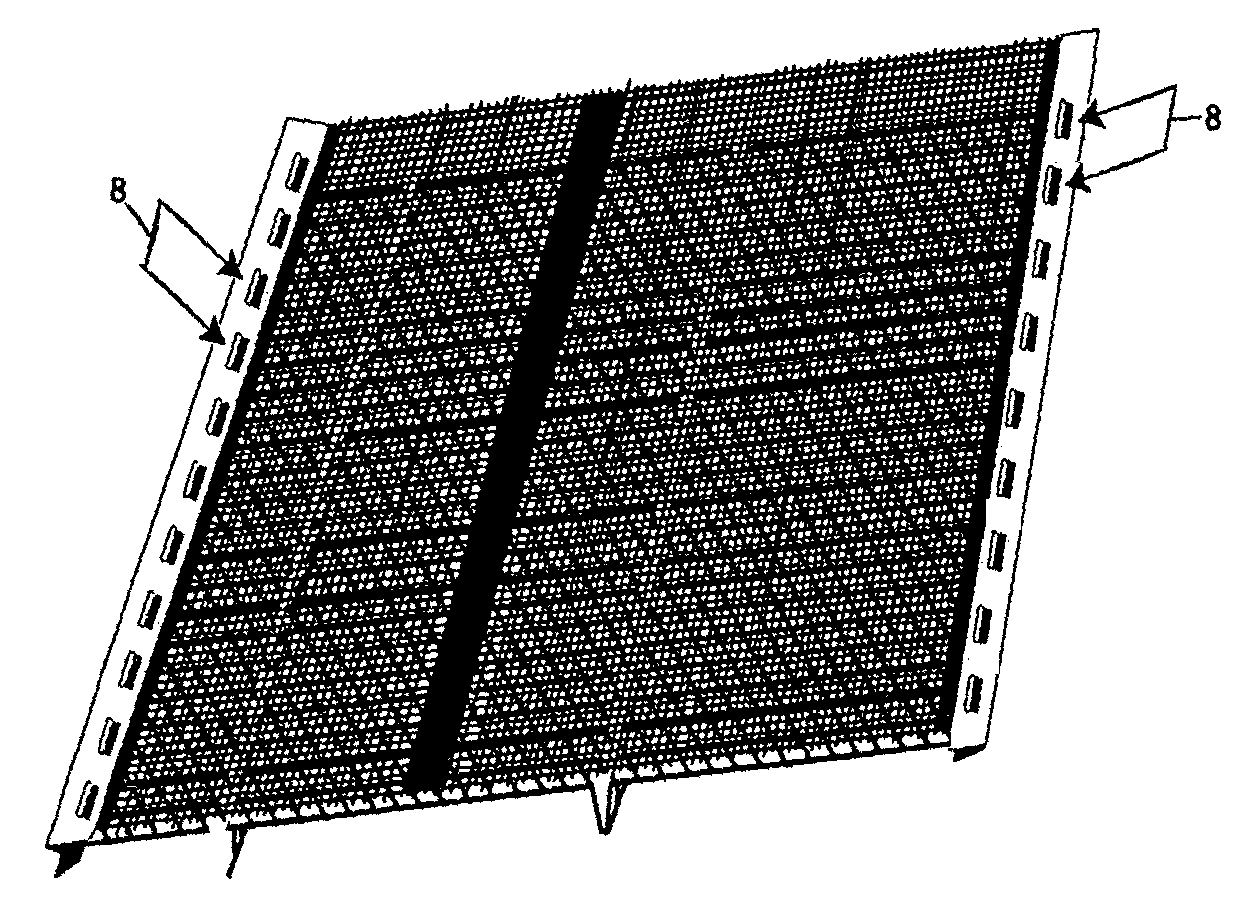

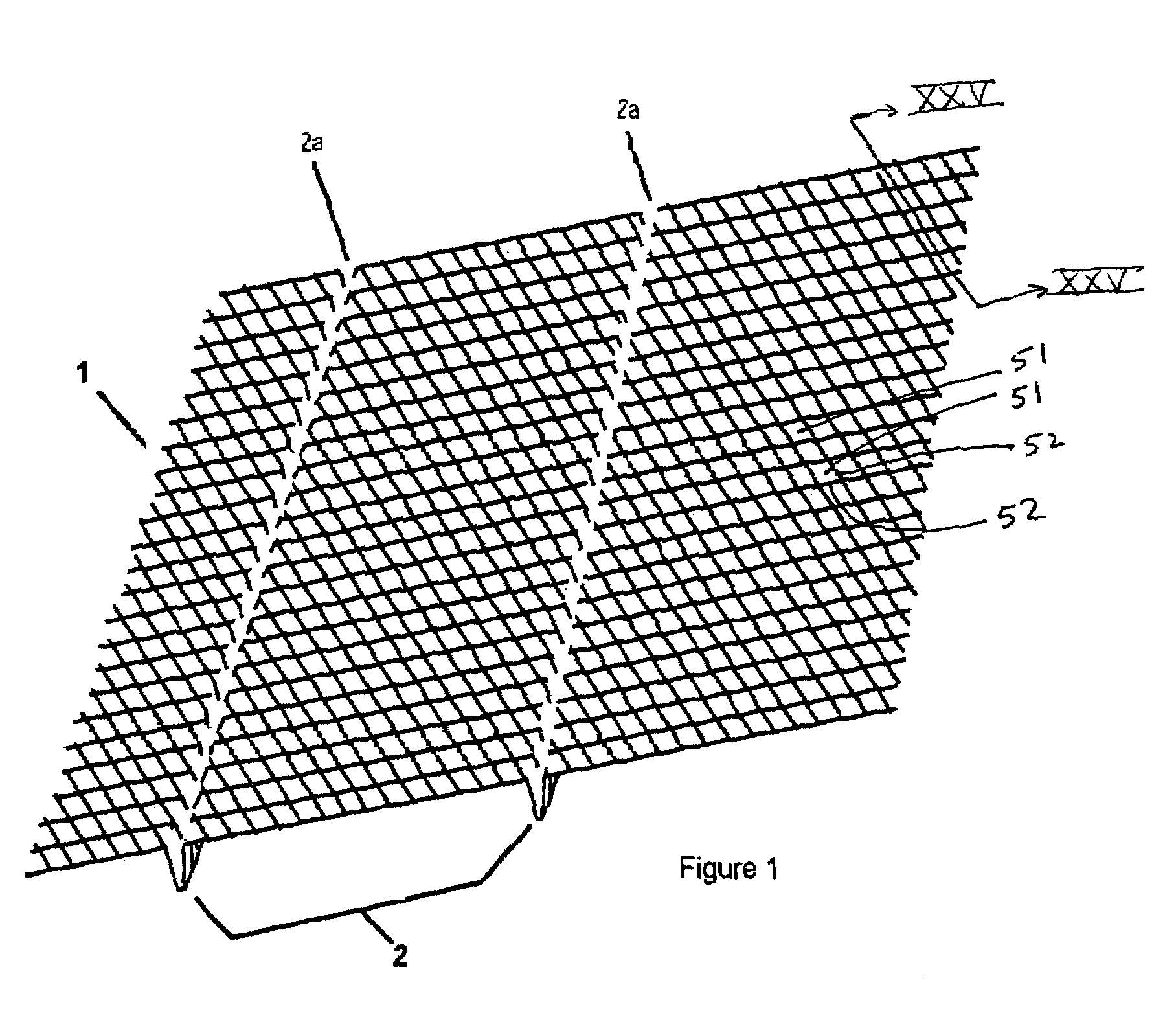

Non clogging screen

A filter assembly is provided that has a filtering screen and a skeletal structure, the skeletal structure being attached to the filtering screen. At least one of the filtering screen and the skeletal structure form a plurality of downward extending channels.

Owner:MGP MFG

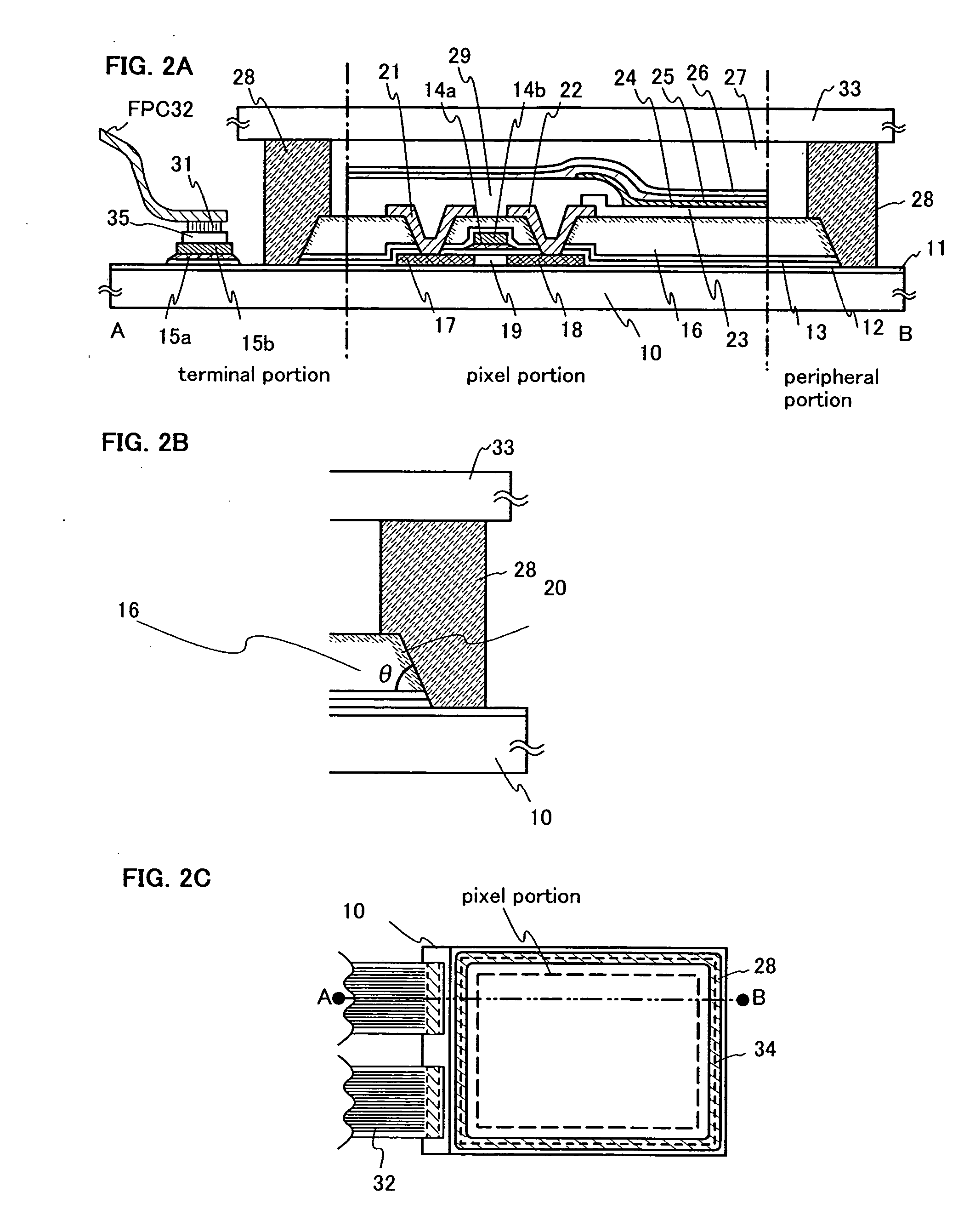

Electronics device, semiconductor deivce, and method for manufacturing the same

InactiveUS20050045891A1Show reliableDeterioration of propertyElectroluminescent light sourcesSolid-state devicesDisplay deviceAtomic radius

It is an object of the present invention to provide a high reliable EL display device and a manufacturing method thereof by shielding intruding moisture or oxygen which is a factor of deteriorating the property of an EL element without enlarging the EL display device. In the invention, application is used as a method for forming a high thermostability planarizing film 16, typically, an interlayer insulating film (a film which serves as a base film of a light emitting element later) of a TFT in which a skeletal structure is configured by the combination of silicon (Si) and oxygen (O). After the formation, an edge portion or an opening portion is formed to have a tapered shape. Afterwards, distortion is given by adding an inert element with a comparatively large atomic radius to modify or highly densify a surface (including a side surface) for preventing the intrusion of moisture or oxygen.

Owner:SEMICON ENERGY LAB CO LTD

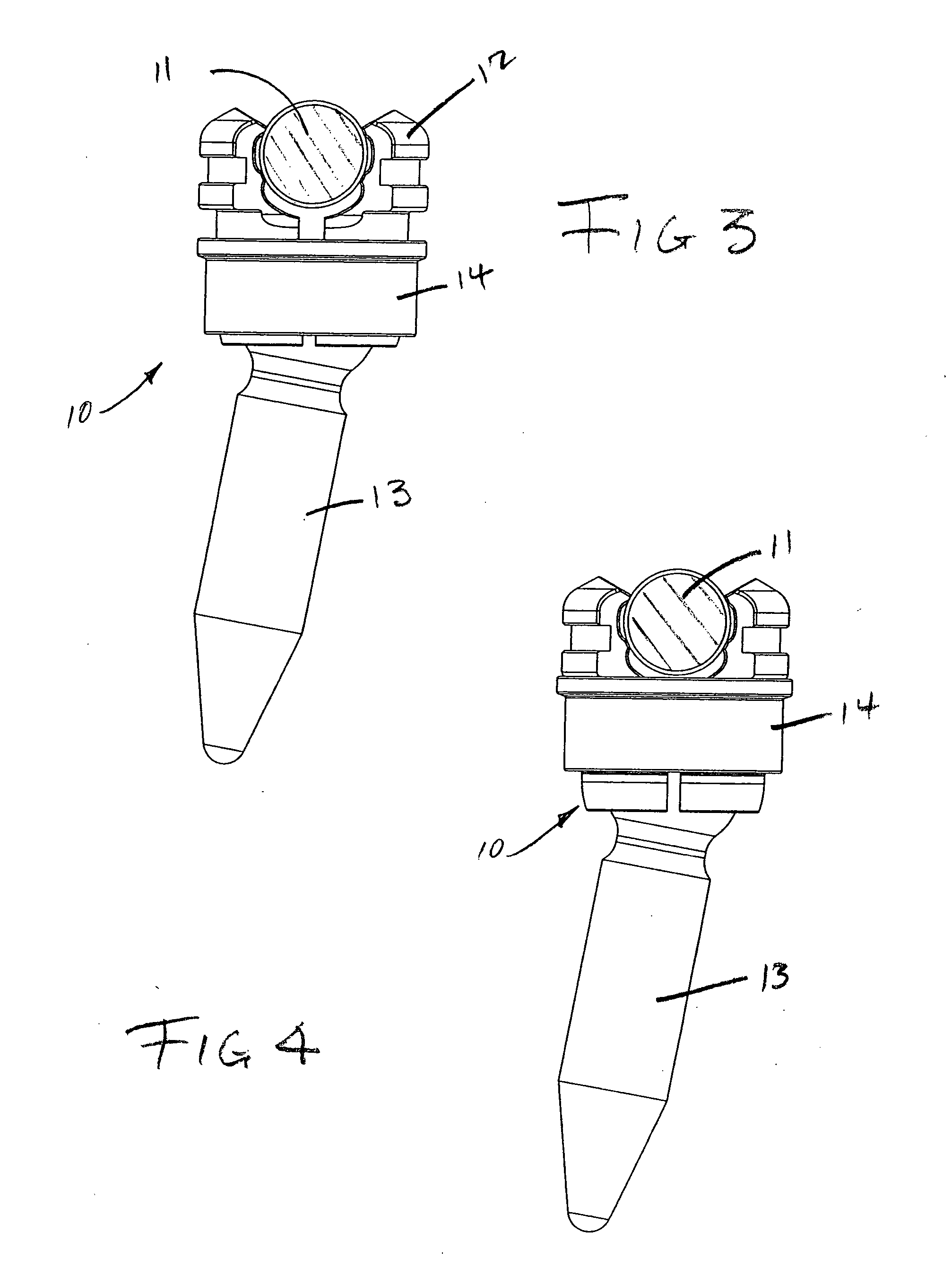

Orthopedic stabilization device and method

An orthopedic stabilization structure including a threaded fastener capable of articulation to accommodate various skeletal geometries, a rod, and a cup supporting the threaded fastener and the rod to be subsequently helps in fixed position with respect to the skeletal structure.

Owner:REED MEDICAL DEVICES

Orthopedic stabilization device and method

An orthopedic stabilization structure including a threaded fastener capable of articulation to accommodate various skeletal geometries, a rod, and a cup supporting the threaded fastener and the rod to be subsequently held in fixed position with respect to the skeletal structure.

Owner:REED MEDICAL DEVICES

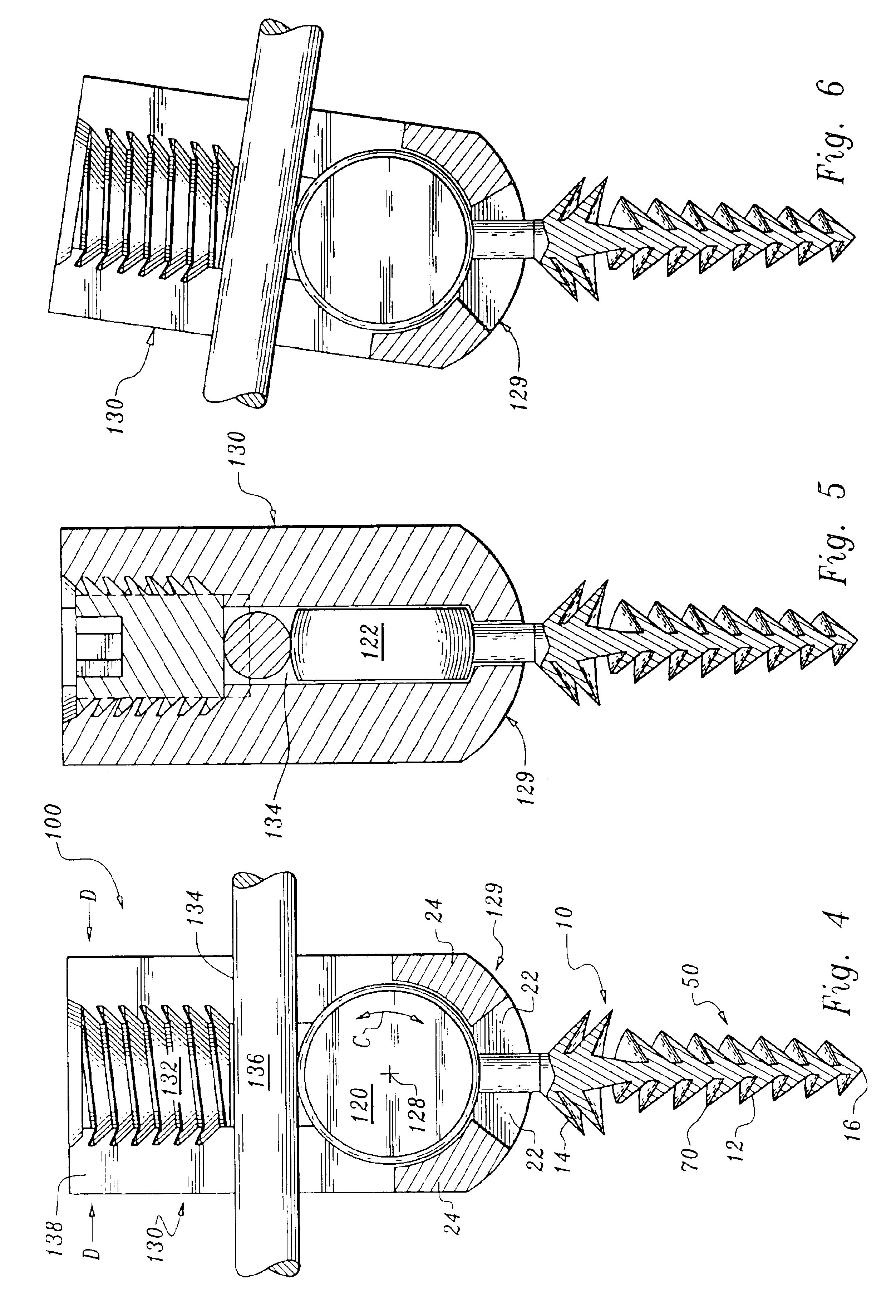

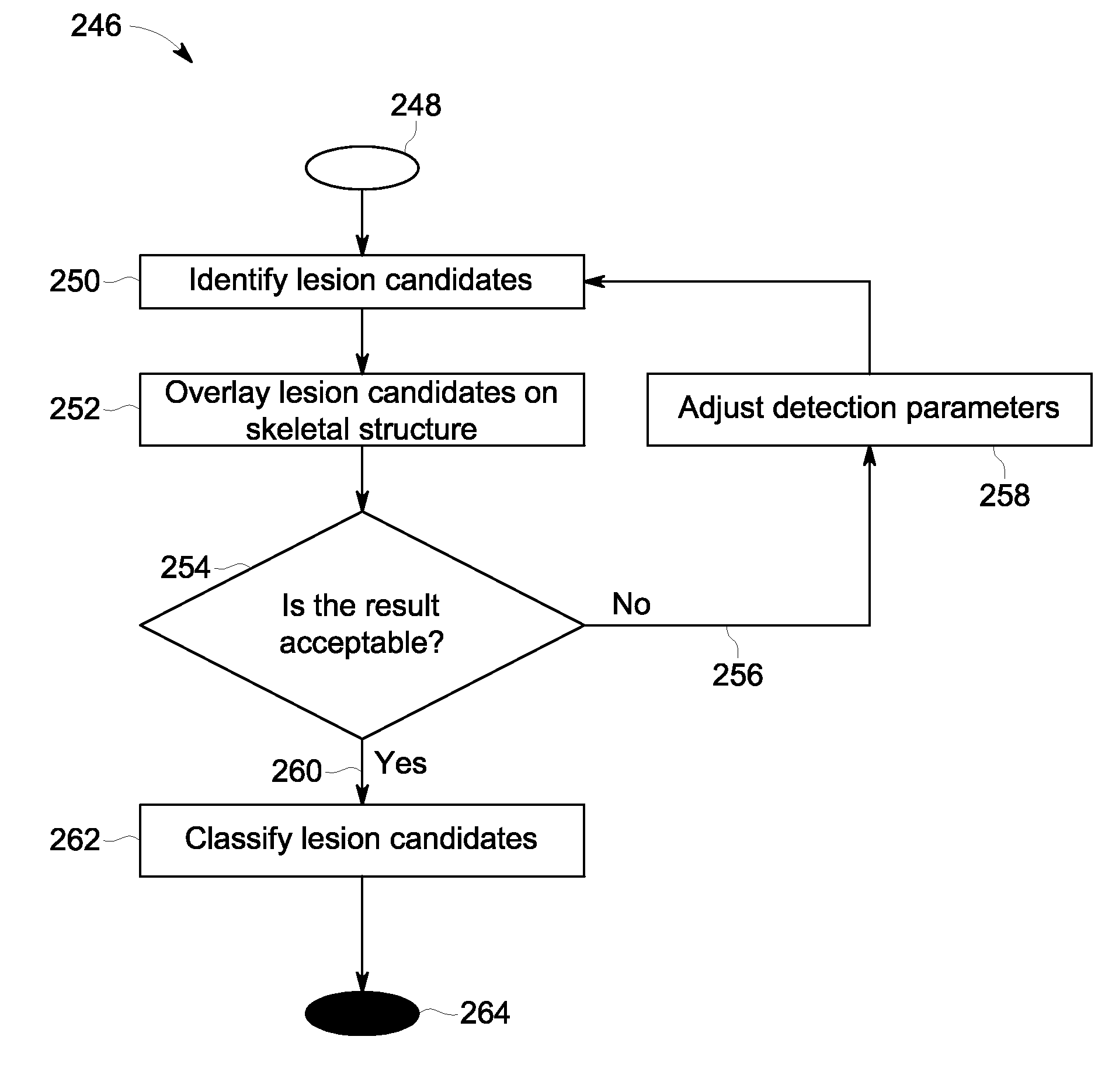

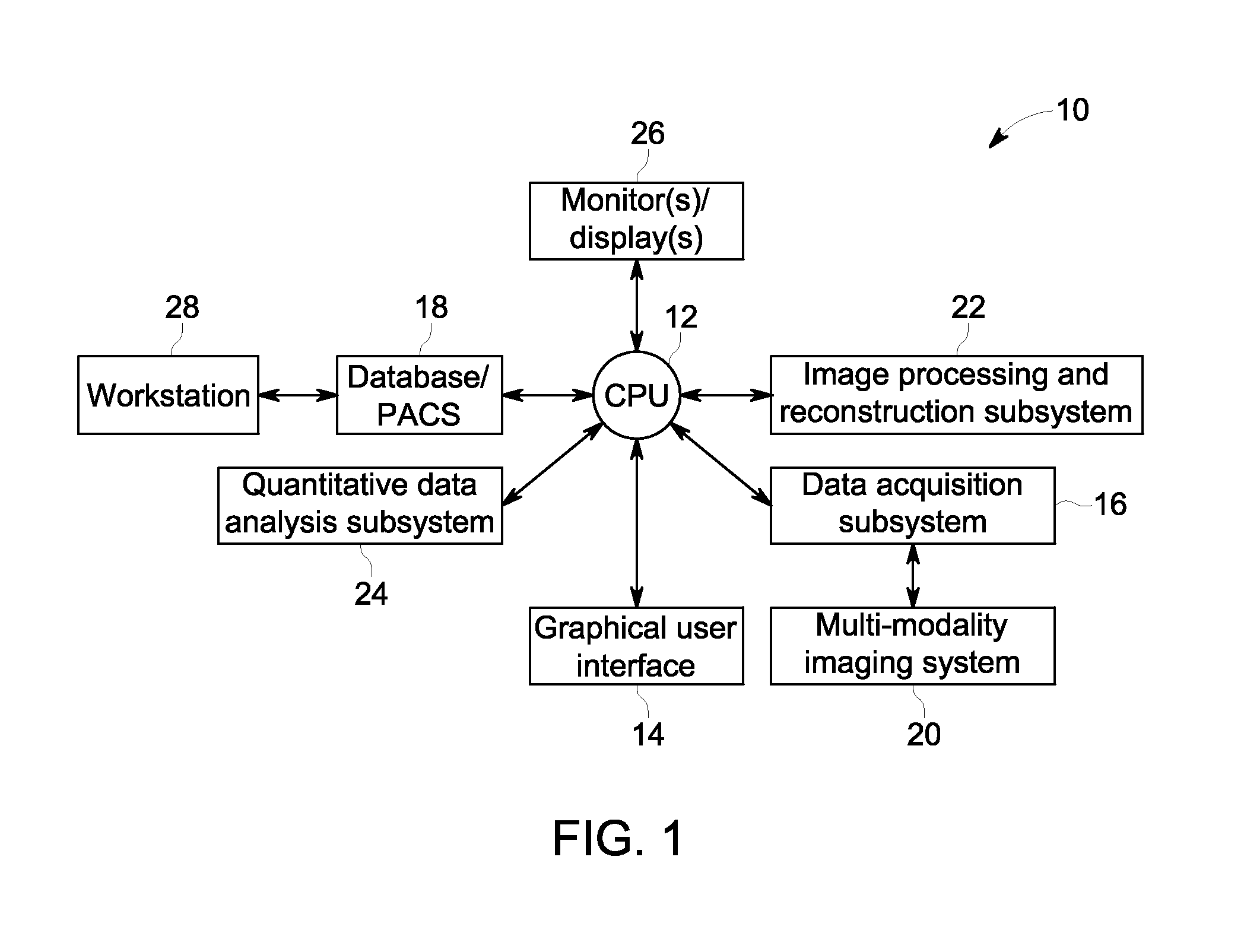

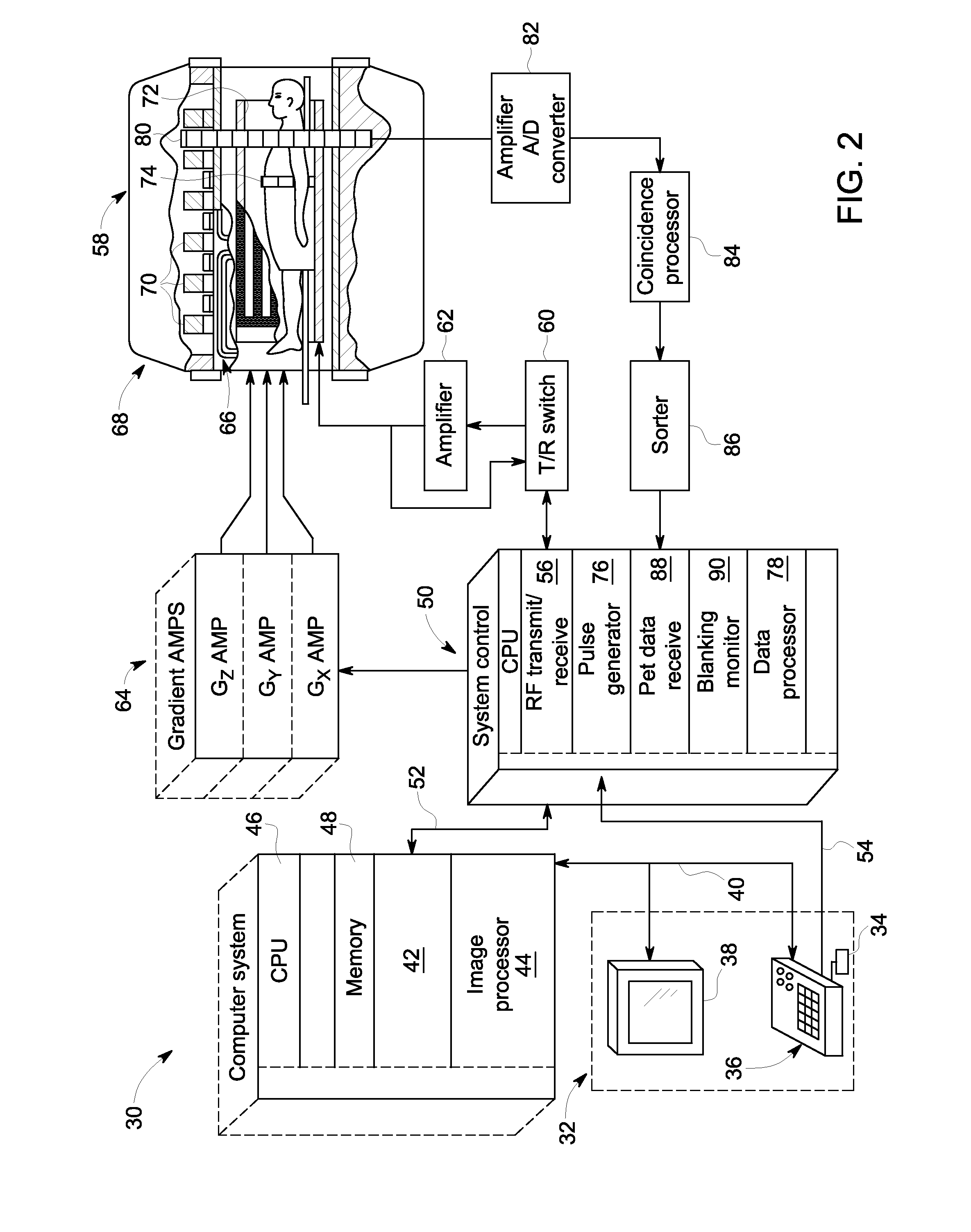

Methods and systems for evaluating bone lesions

Methods and systems for evaluating bone lesions include accessing a first dataset acquired from a patient with a first imaging modality and a second dataset acquired from the patient with a second imaging modality. A segmentation is performed on the first dataset to identify a subset of the first dataset corresponding to a skeletal structure of the patient and a patient skeletal metric representing a total bone volume of the patient is automatically calculated from the subset of the first dataset. The methods and systems further include detection of at least one lesion in the second dataset, classification of the at least one lesion as a bone or non-bone lesion, automatic calculation of a bone lesion metric based on the classification, and calculation of a lesion burden as a ratio of the bone lesion metric and the patient skeletal metric.

Owner:GENERAL ELECTRIC CO

Orthopedic stabilization device and method

An orthopedic stabilization structure including a threaded fastener capable of articulation to accommodate various skeletal geometries, a rod, and a cup supporting said threaded fastener and said rod to be subsequently held in fixed position with respect to the skeletal structure.

Owner:REED MEDICAL DEVICES

Apparatus for mixing and dispensing components

InactiveUS20040066706A1Exposure was also limitedReduce in quantitySurgical furnitureDiagnosticsBone cementBiomedical engineering

Apparatus and methods for mixing and dispensing components. The methods and apparatus of the invention are particularly advantageous to mix the components of radiopaque bone cement and inject the resulting radiopaque bone cement into skeletal structures. The apparatus of the invention comprises: (1) a sealed mixing chamber for mixing components; (2) a dispensing chamber isolated from the sealed mixing chamber; (3) a controllable portal to open a flow path between the sealed mixing chamber and the dispensing chamber so that the dispensing chamber can receive the mixed components after they are mixed; and (4) a drive mechanism associated with the dispensing chamber to force the mixed contents from the dispensing chamber.

Owner:GLOBUS MEDICAL INC

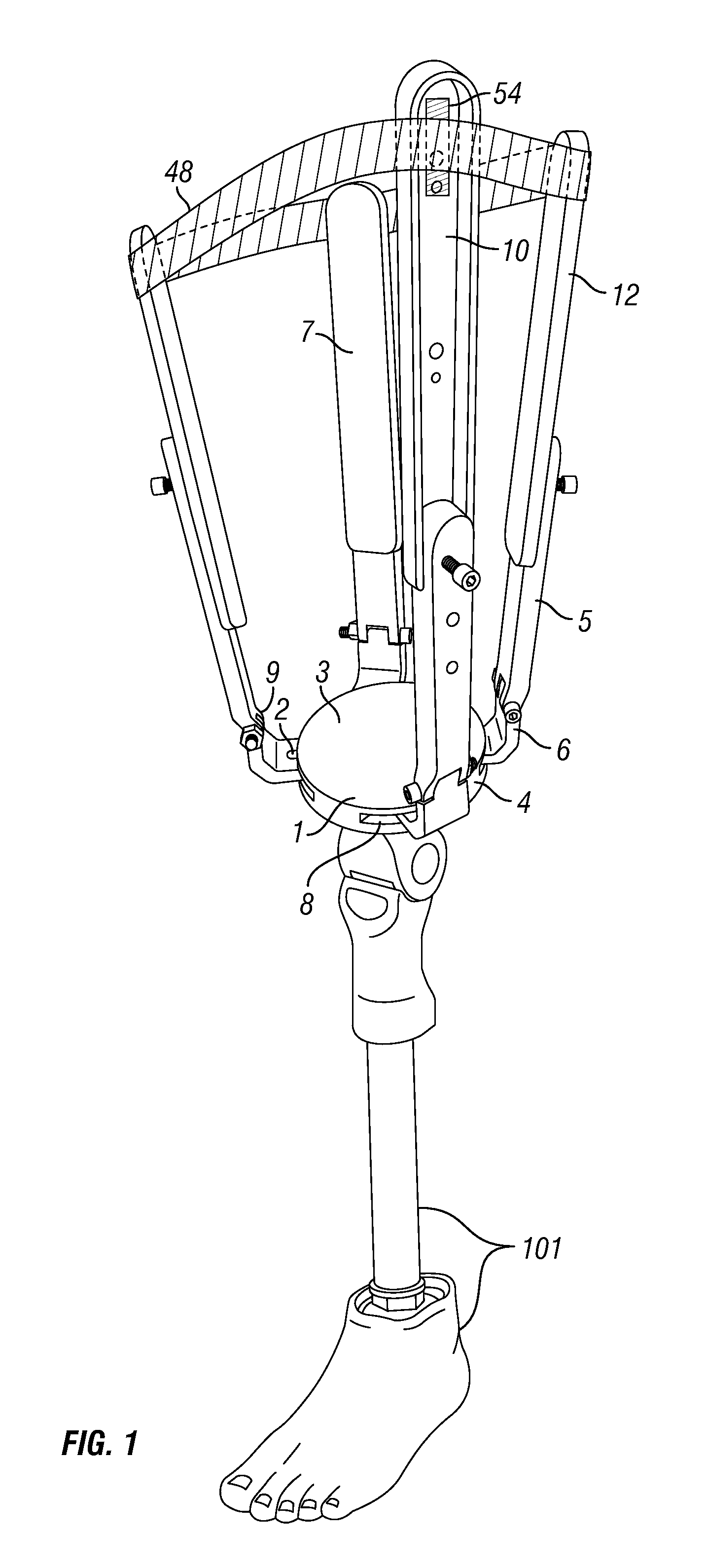

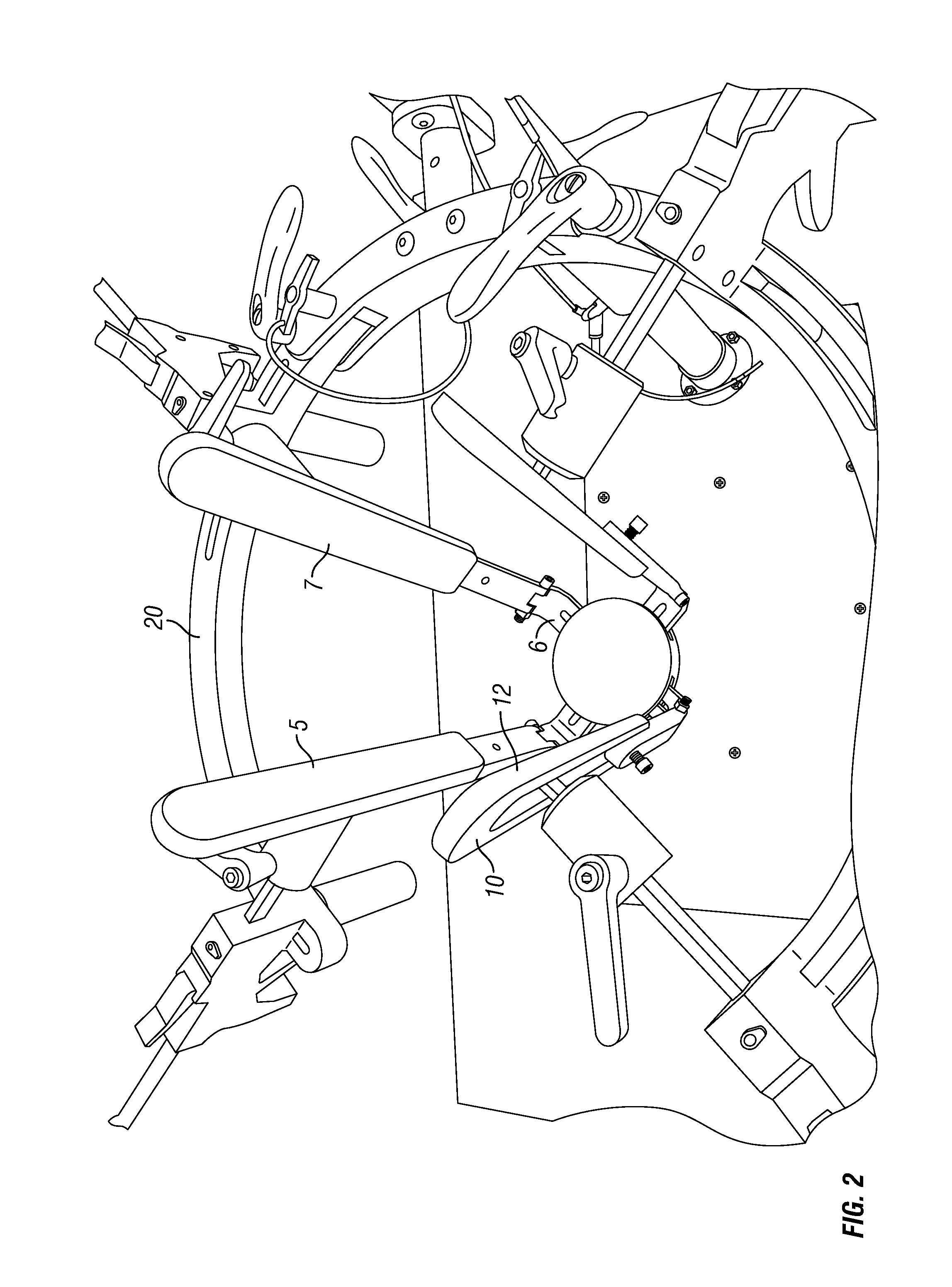

Adaptable Socket System, Method, and Kit

ActiveUS20140121783A1Improve load-bearing strengthStrengthen associationArtificial legsArtificial handsProsthesisOrthotic device

An adjustable socket system, method, and kit for use with prosthetic devices or orthotic, orthopedic, or exoskeletal support devices that includes a paddle and a compressing device coupled to the paddle. The paddle is chosen from a plurality of paddles of different shapes in such a way that the paddle inner surface is substantially coextensive with a soft tissue area overlying skeletal structures. The compressing device presses the paddle against the soft tissue area in order to minimize the motion of the paddle relative to the underlying skeletal structures without causing discomfort to the user or compressing areas not in contact with the paddle, allowing compressed tissue to flow into uncompressed areas. The system, method, and kit can include an external tool, sensors, actuators, and controllers, to assist fitting and for adjustment after fitting. A stabilizer can be added to resist the bending force on the paddle.

Owner:ALLEY RANDALL D

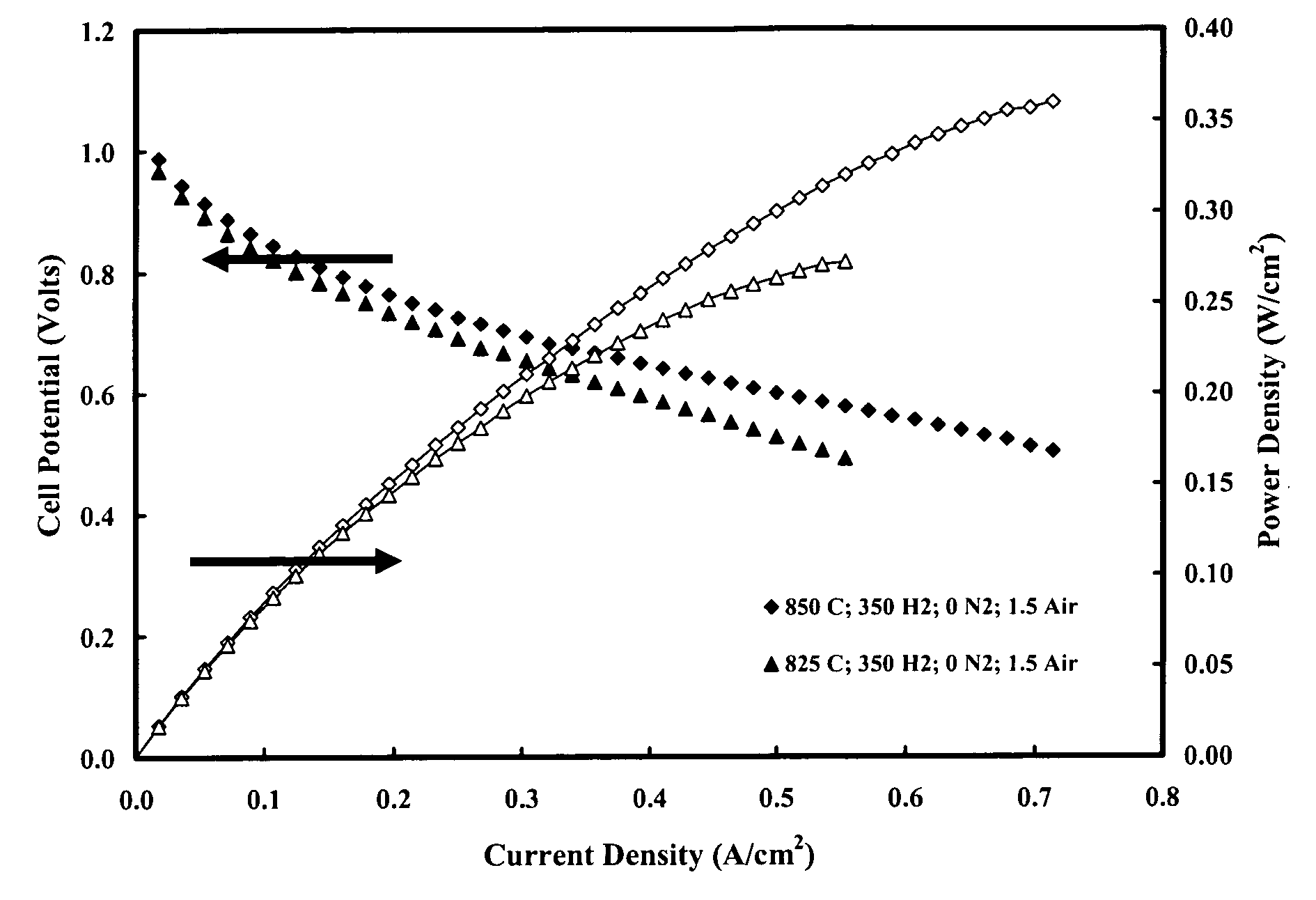

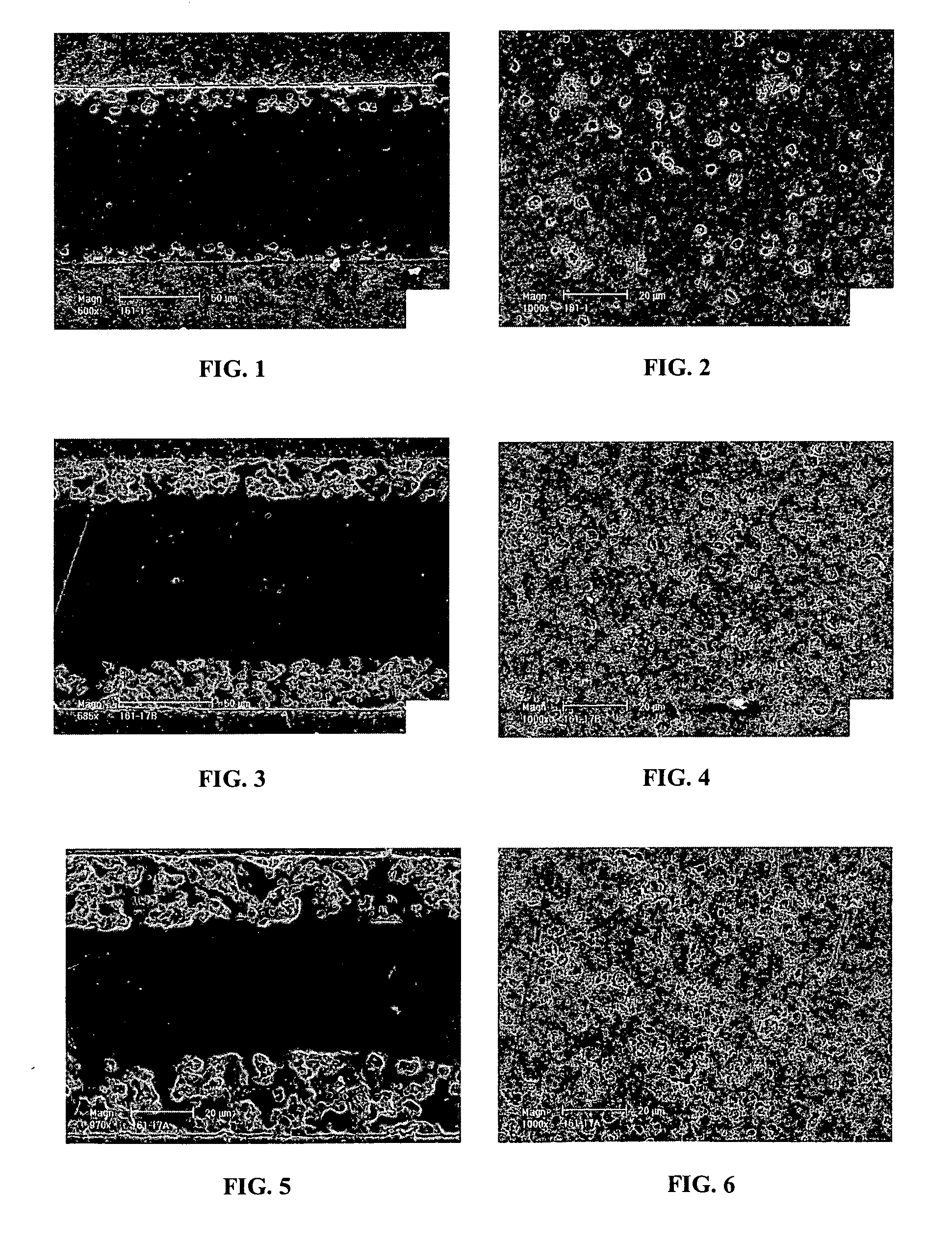

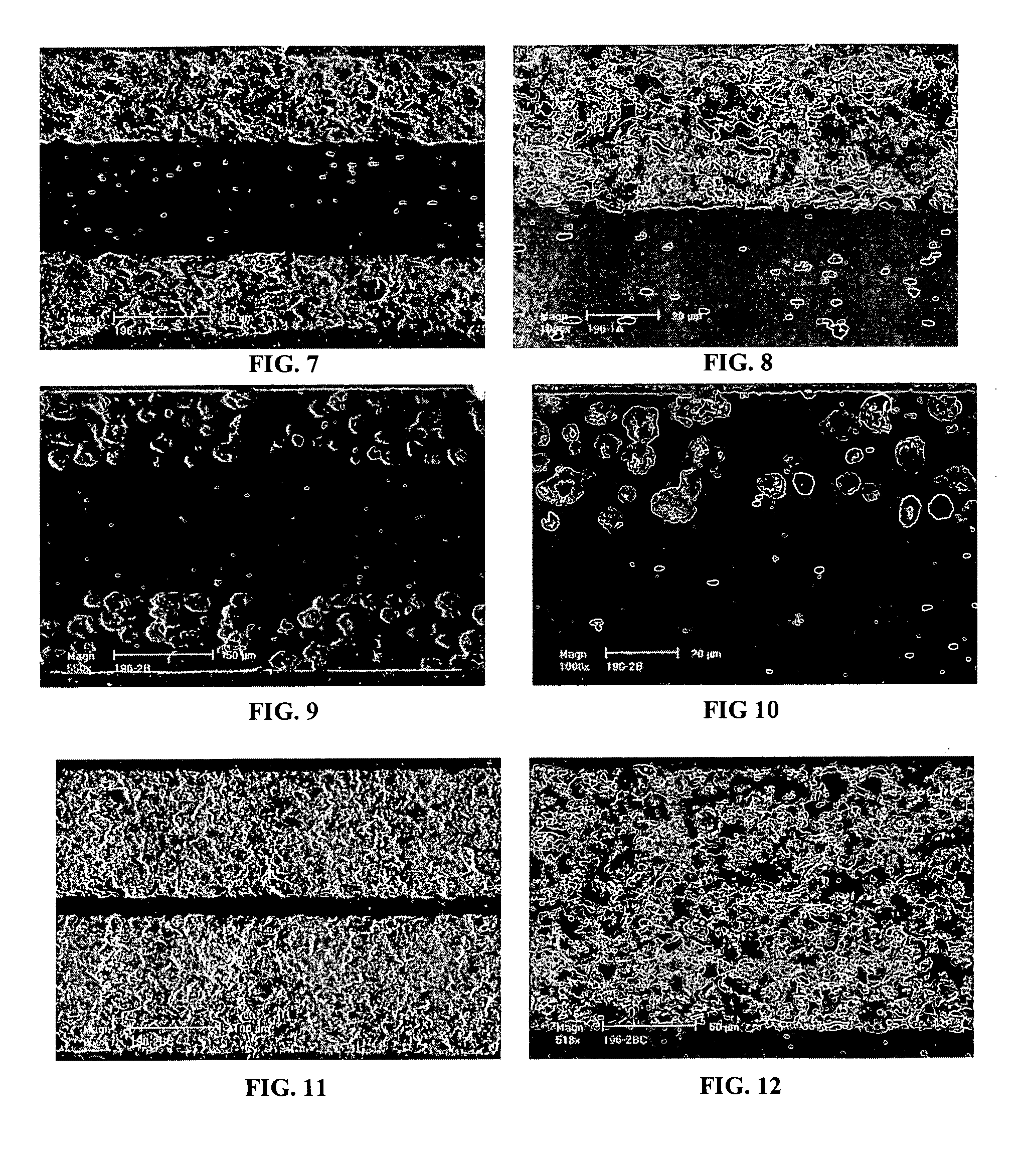

Supported ceramic membranes and electrochemical cells and cell stacks including the same

InactiveUS20060269813A1Advantage in processingAdvantage in mechanical integrityFuel cells groupingFinal product manufacturePorous ceramicsMaterials science

A dense ceramic electrolyte membrane supported by symmetrical porous ceramic electrolyte layers. The thin (t<100 microns) electrolyte layer is sandwiched between two fugitive-containing electrolyte support layers that become highly porous after firing. The heat treated fugitive-containing support layers form a skeletal structure of strongly adhered electrolyte with an interpenetrating network of pores that extends well always from the electrolyte surface. The porous layers can be infiltrated with a range of electrode materials or precursors to form a solid oxide fuel cell or other electrochemical cell as well as electrochemical cell stacks. The supported ceramic membrane provides electrochemical performance advantages and reduces warpage during sintering compared to conventional structures.

Owner:NEXTECH MATERIALS

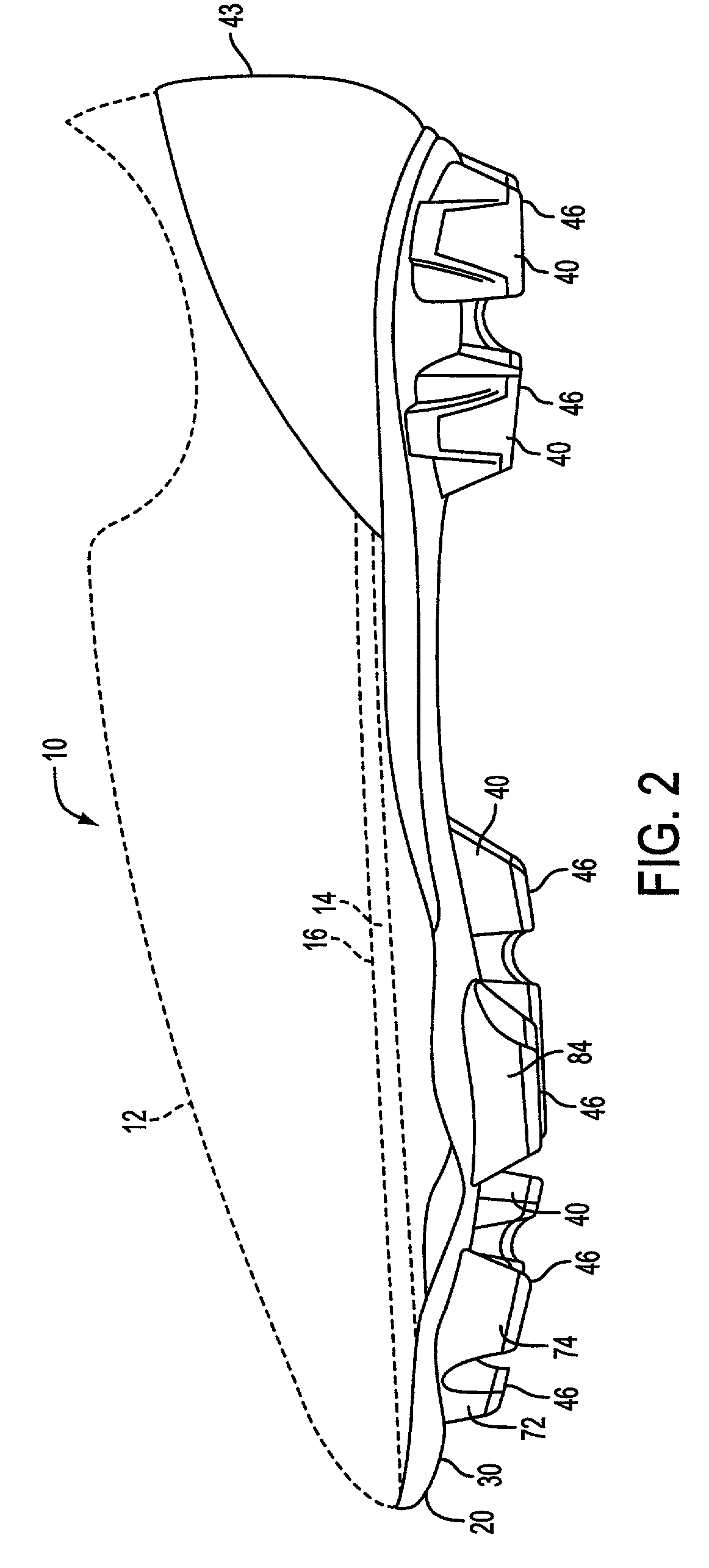

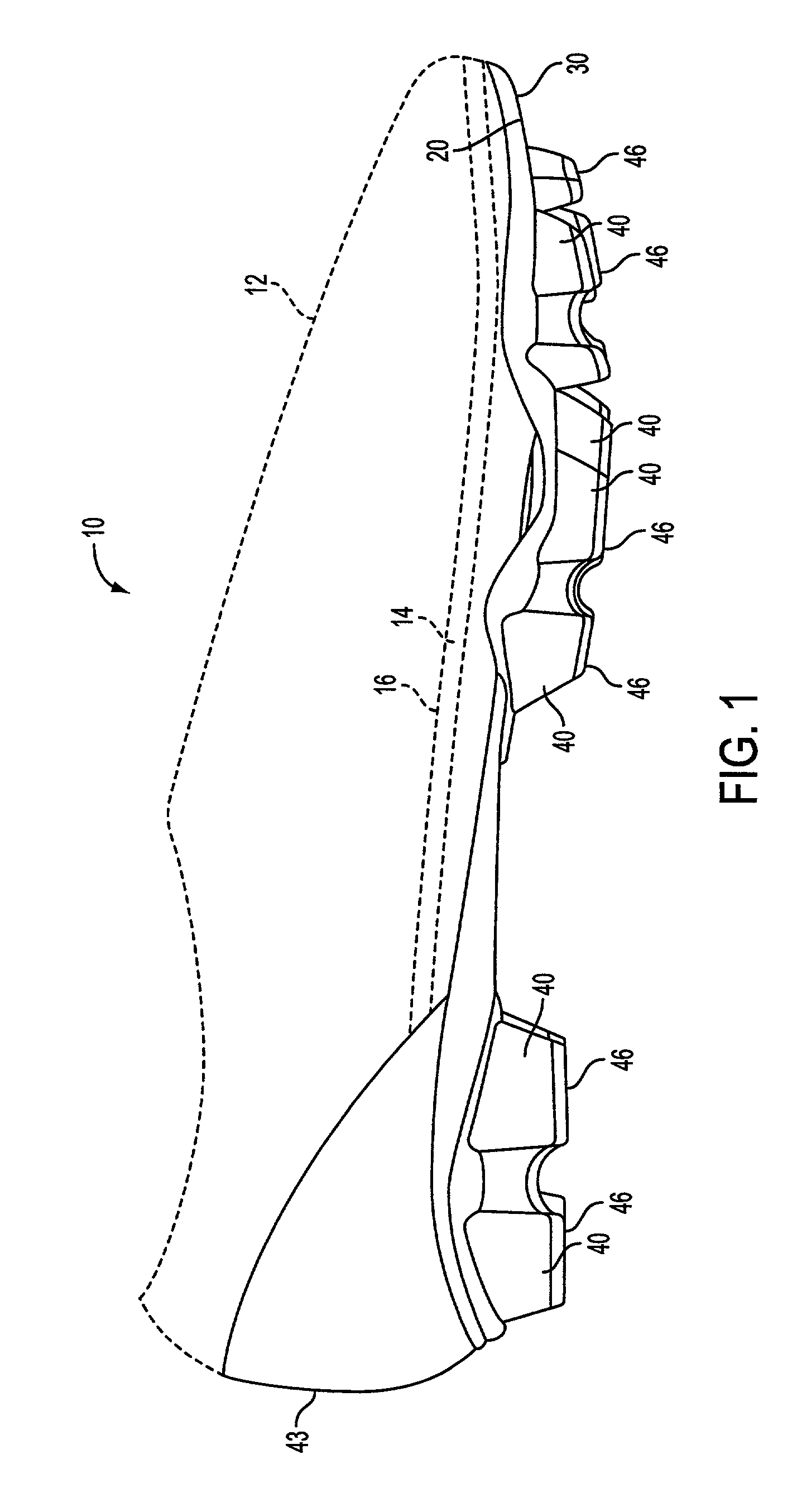

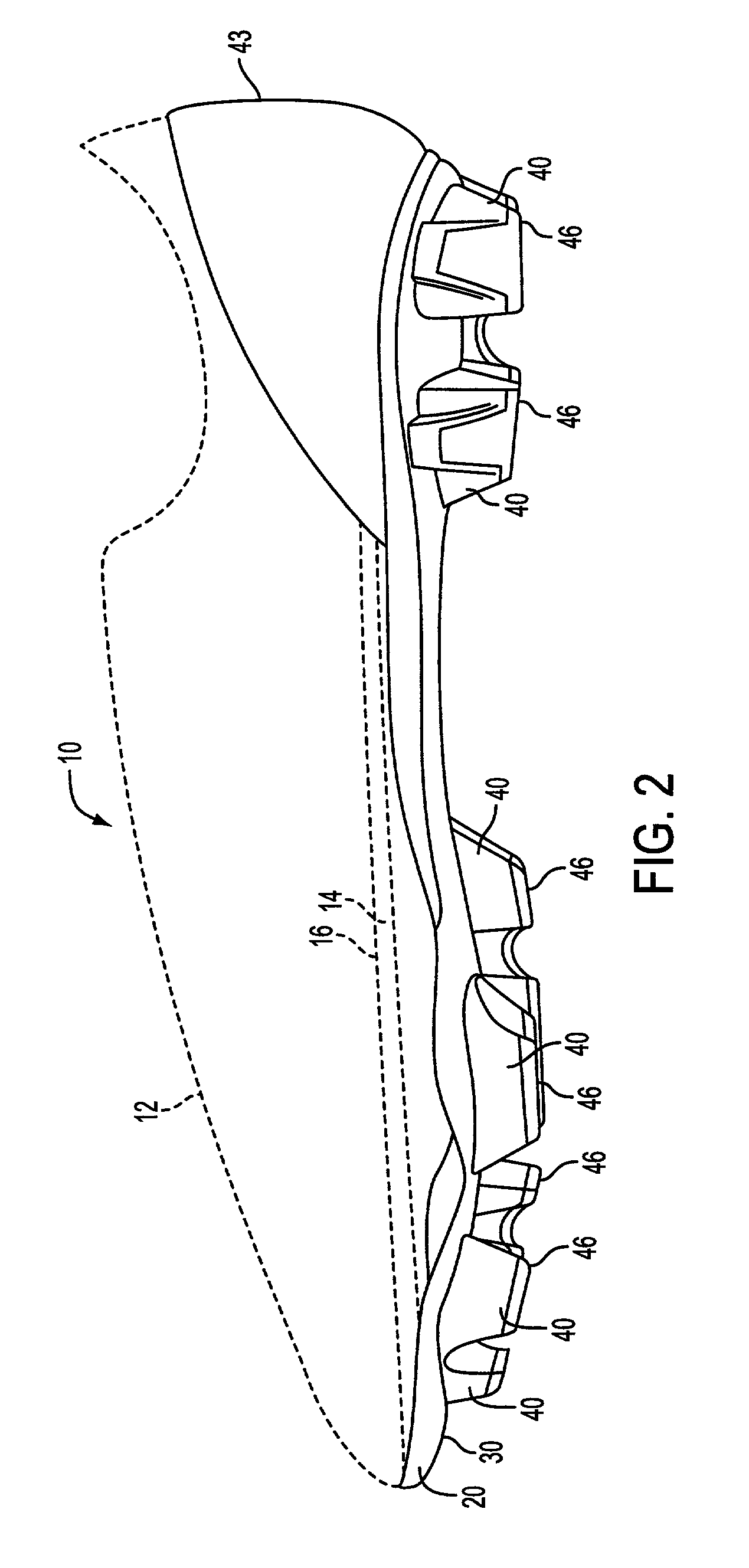

Article of footwear having a sole with a flex control member

InactiveUS7181868B2Increased spring-like energy returnFaster and stable acceleration movementSolesFasteningsFirst metatarsalEngineering

An article of footwear includes an upper for holding a foot of a wearer and a sole having an outsole plate. Several ground engaging members extends downwardly from the outsole plate to provide traction. The outsole plate includes a flex control member composed of a superelastic shape memory material or a nickel-titanium alloy. The flex control member can be coupled to an inside surface, or bottom surface of the outsole plate. The outsole plate may include a rearfoot region, a midfoot region, and a first metatarsal head region, in which the regions generally correspond to the skeletal structure of a human foot. The flex control member extends from a medial side of the rearfoot region through the midfoot region and into the first metatarsal head region of the outsole plate. The ground engaging members may be positioned to extend from the location of the flex control member.

Owner:NIKE INC

Method and apparatus for capturing motion of dynamic object

InactiveUS8659594B2Error minimizationMinimizing colorAnimation3D-image renderingViewpointsDynamic motion

Owner:ELECTRONICS & TELECOMM RES INST

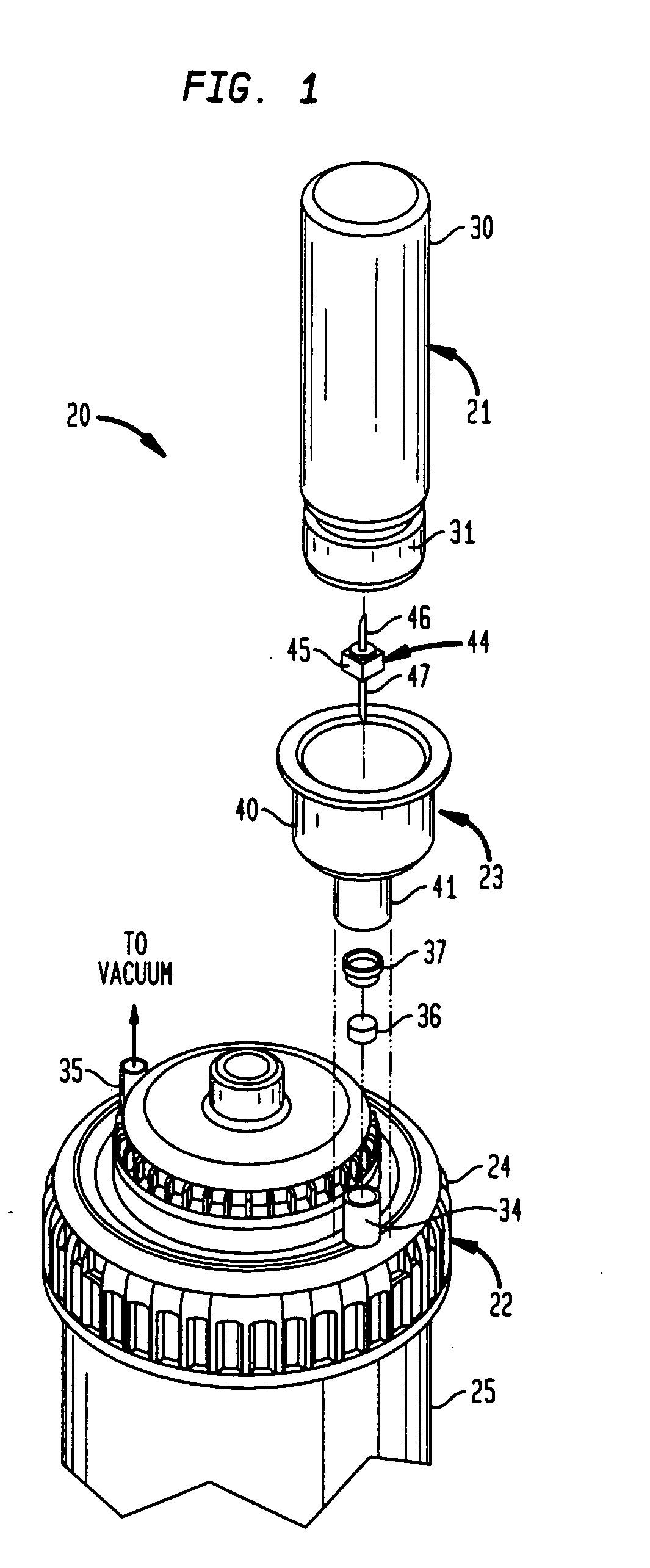

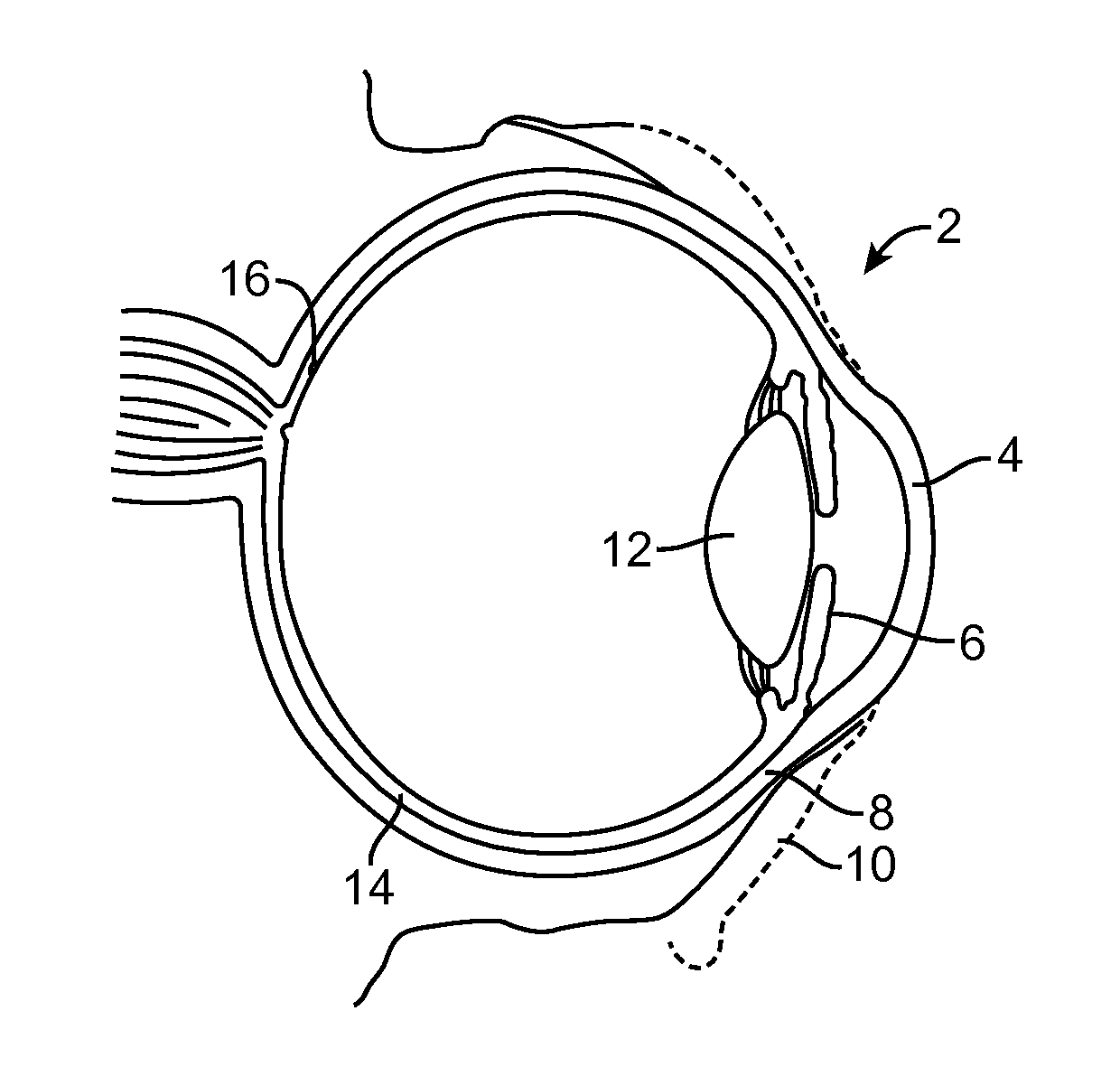

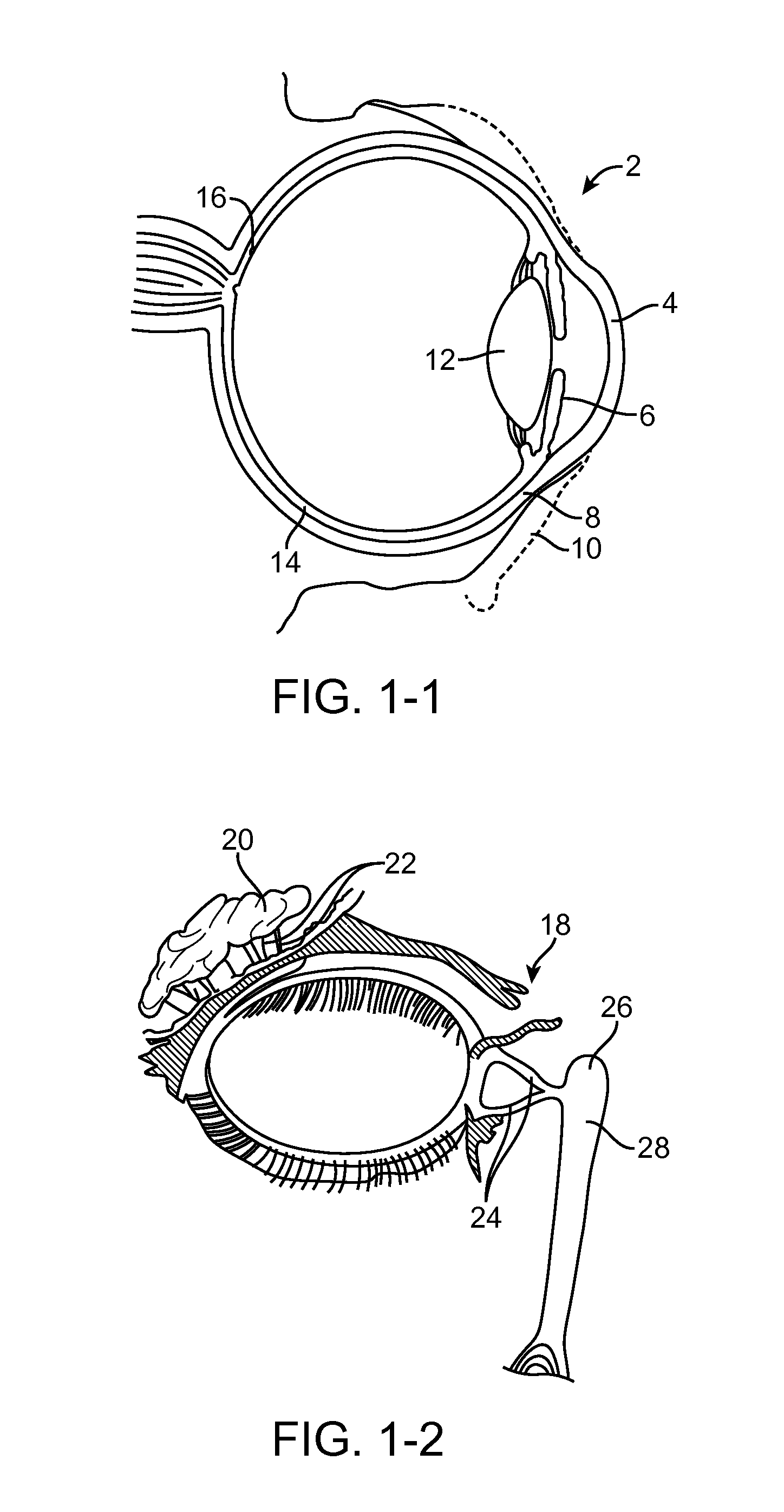

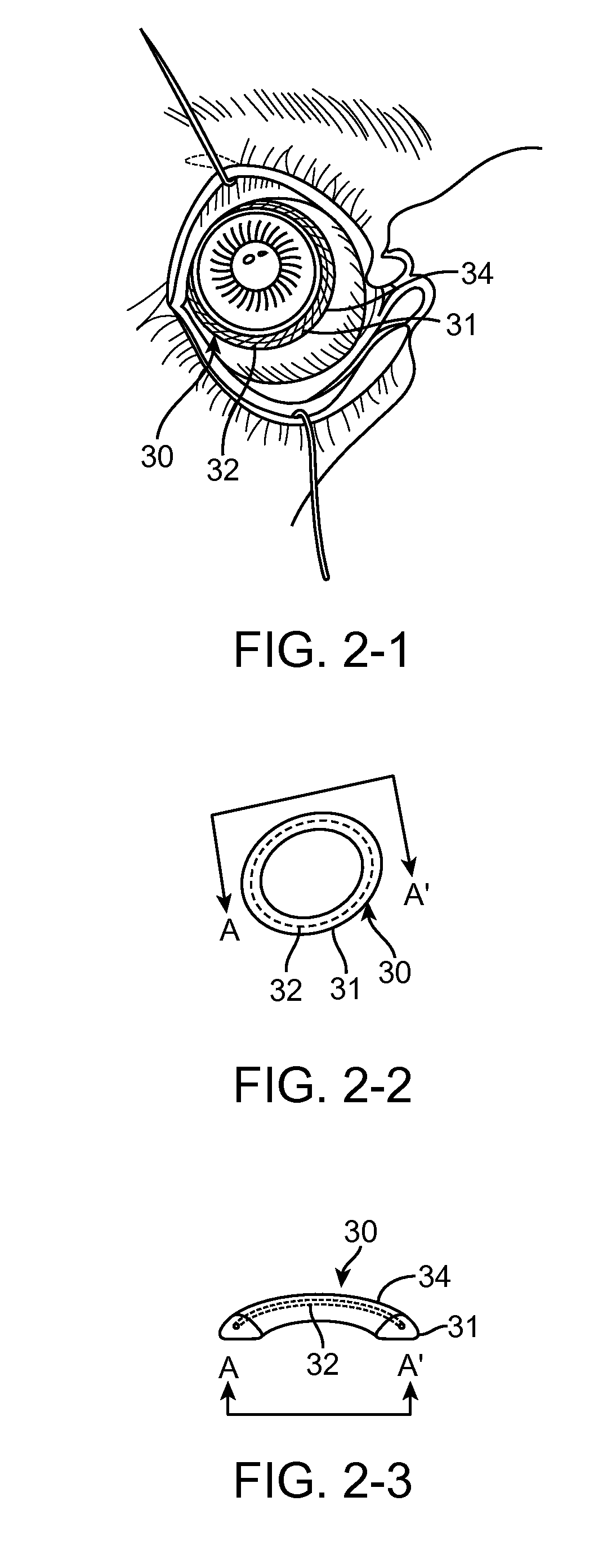

Anterior Segment Drug Delivery

ActiveUS20120136322A1Maintain positionProvide supportSenses disorderElcosanoid active ingredientsCushioningConjunctiva

A therapeutic system comprises an ocular insert placed on a region outside an optical zone of an eye. The ocular insert comprises two structures: a first skeletal structure and a second cushioning structure. The first structure functions as a skeletal frame which maintains positioning of the implant along the anterior portion of the eye and provides support to the second, cushioning structure. This first structure maintains the attachment of the therapeutic system to the anterior portion of the eye for at least thirty days. In some embodiments the first structure remains a constant size and shape, e.g. a ring shape, a ring with haptics, or a curvilinear ring that is confined to and restrainingly engages the inferior and superior conjunctival fornices so as to retain the implant within the tear fluid and / or against the tissues of the eye.

Owner:FORSIGHT VISION5 INC

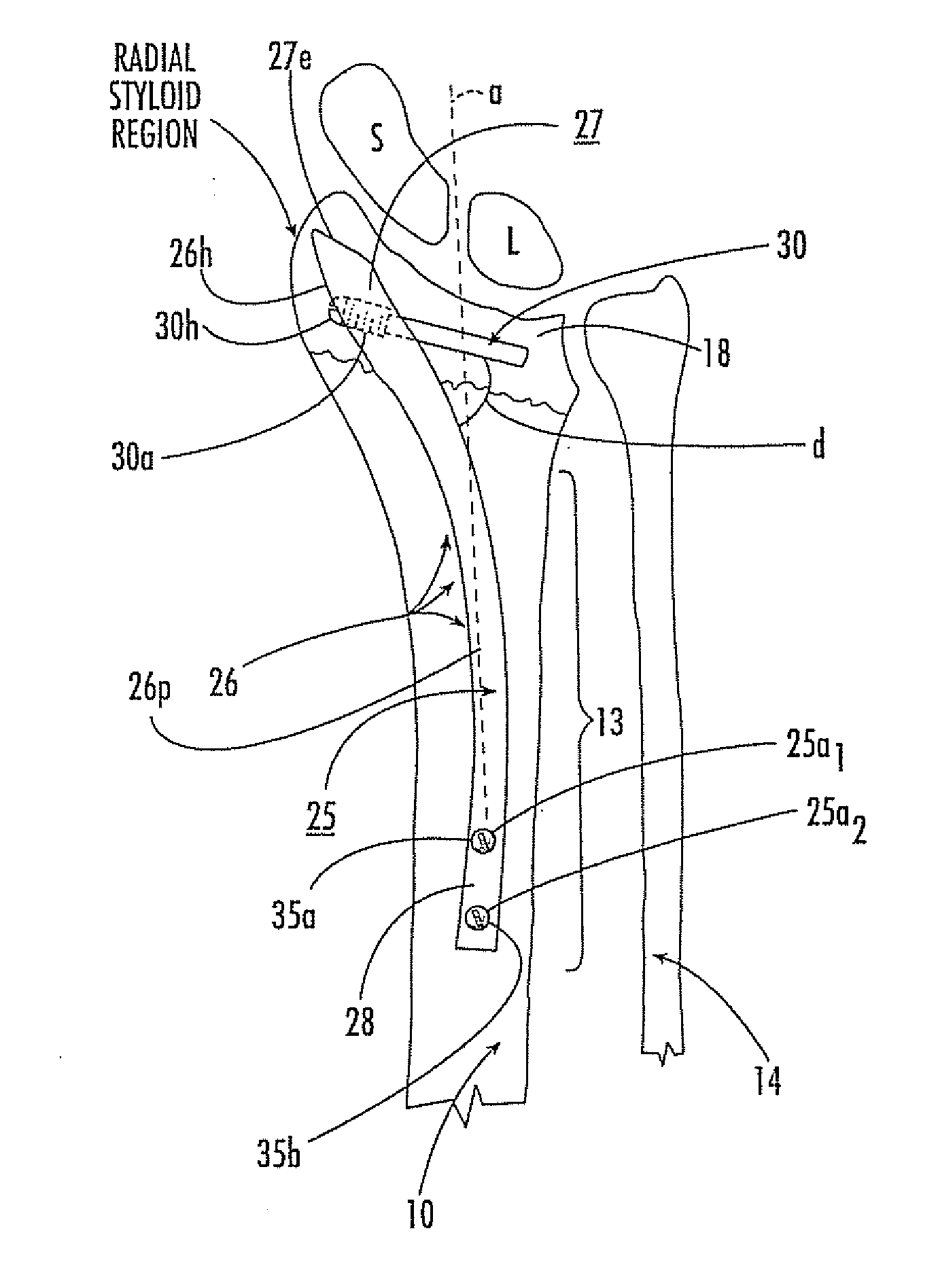

Kits with intramedullary interlocking fixation devices for the distal radius

InactiveUS20060200143A1Inhibit of loss in skeletal lengthInhibit amount of collapse and loss in skeletal lengthInternal osteosythesisDiagnosticsMedical treatmentSkeletal structures

Medical kits for treating fractures in or adjacent the wrist and distal forearm employ an intramedullary interlocking fixation rod (i.e, it interlocks the distal and proximal fracture fragments together) to stabilize the skeletal structure in a manner which can inhibit the amount of collapse or loss in skeletal length exhibited by a patient with a distal radius fracture.

Owner:WRIGHT MEDICAL TECH

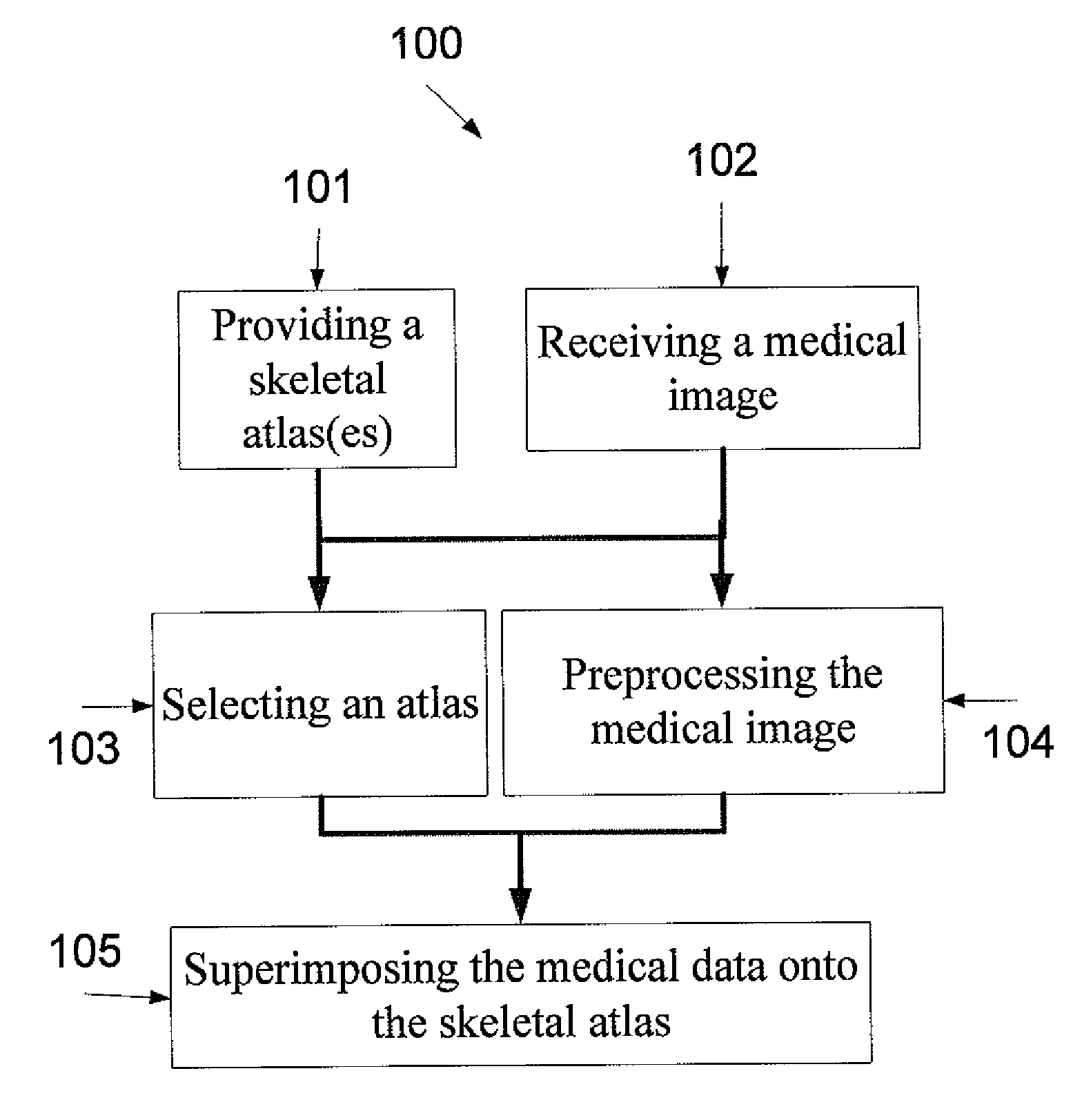

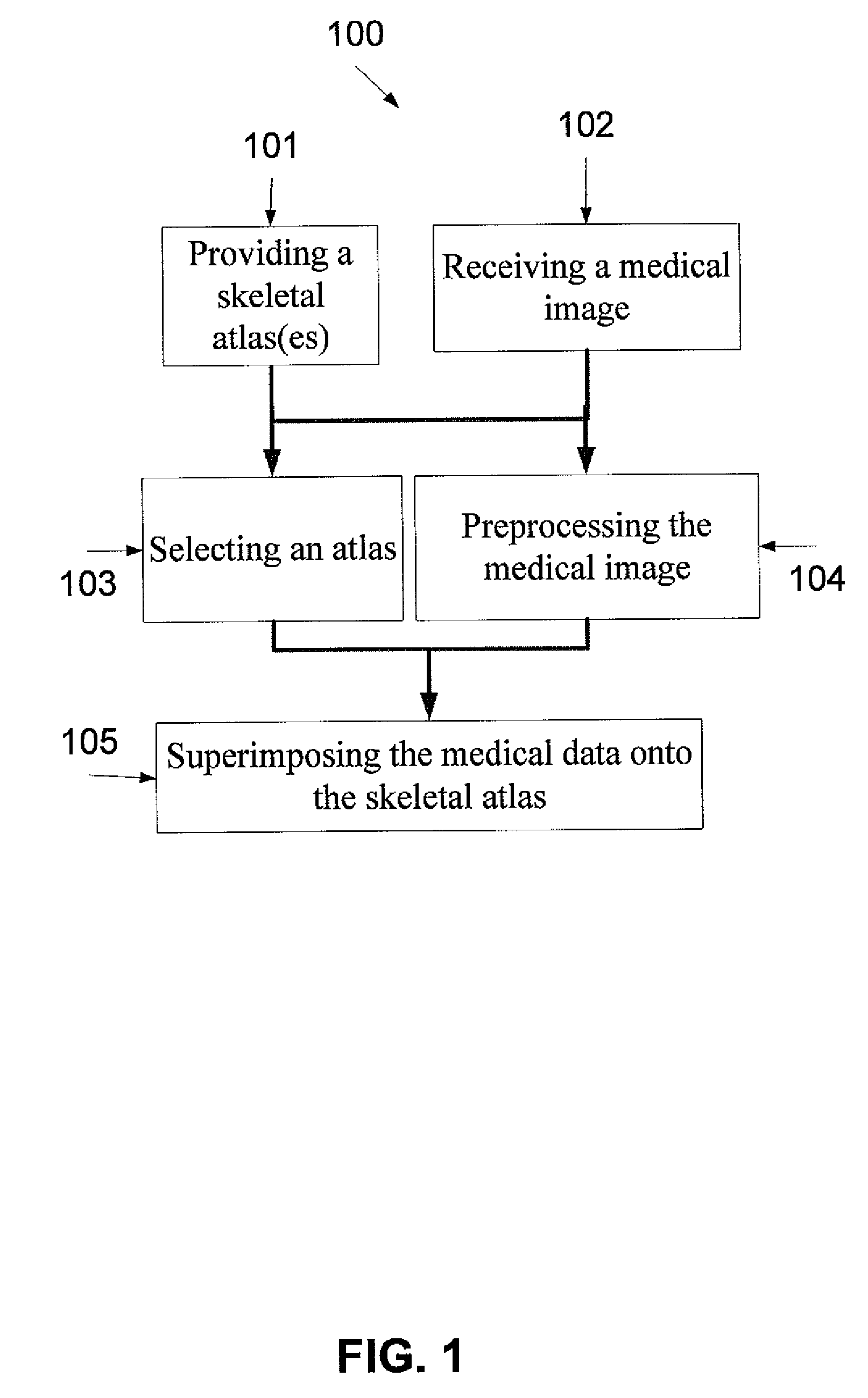

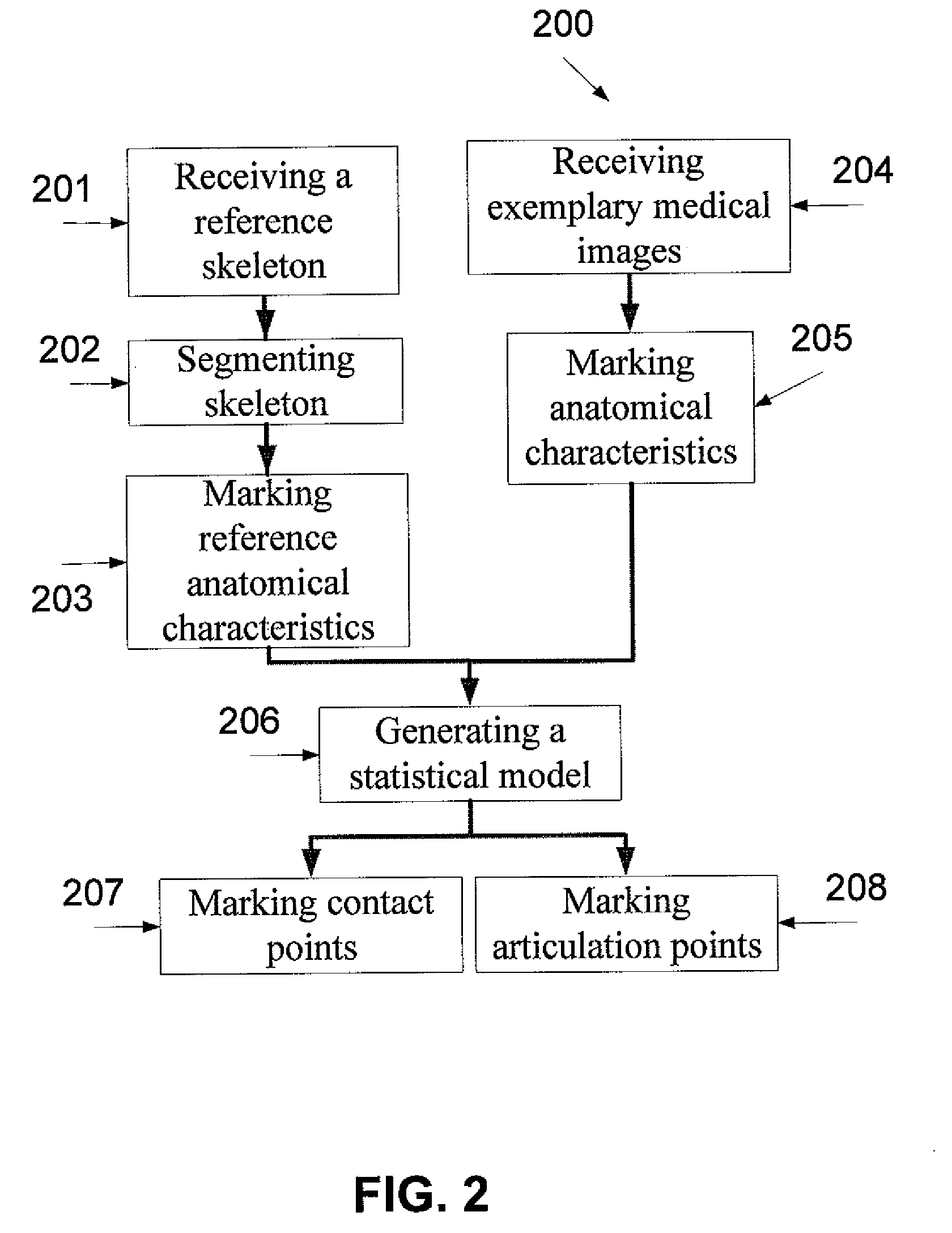

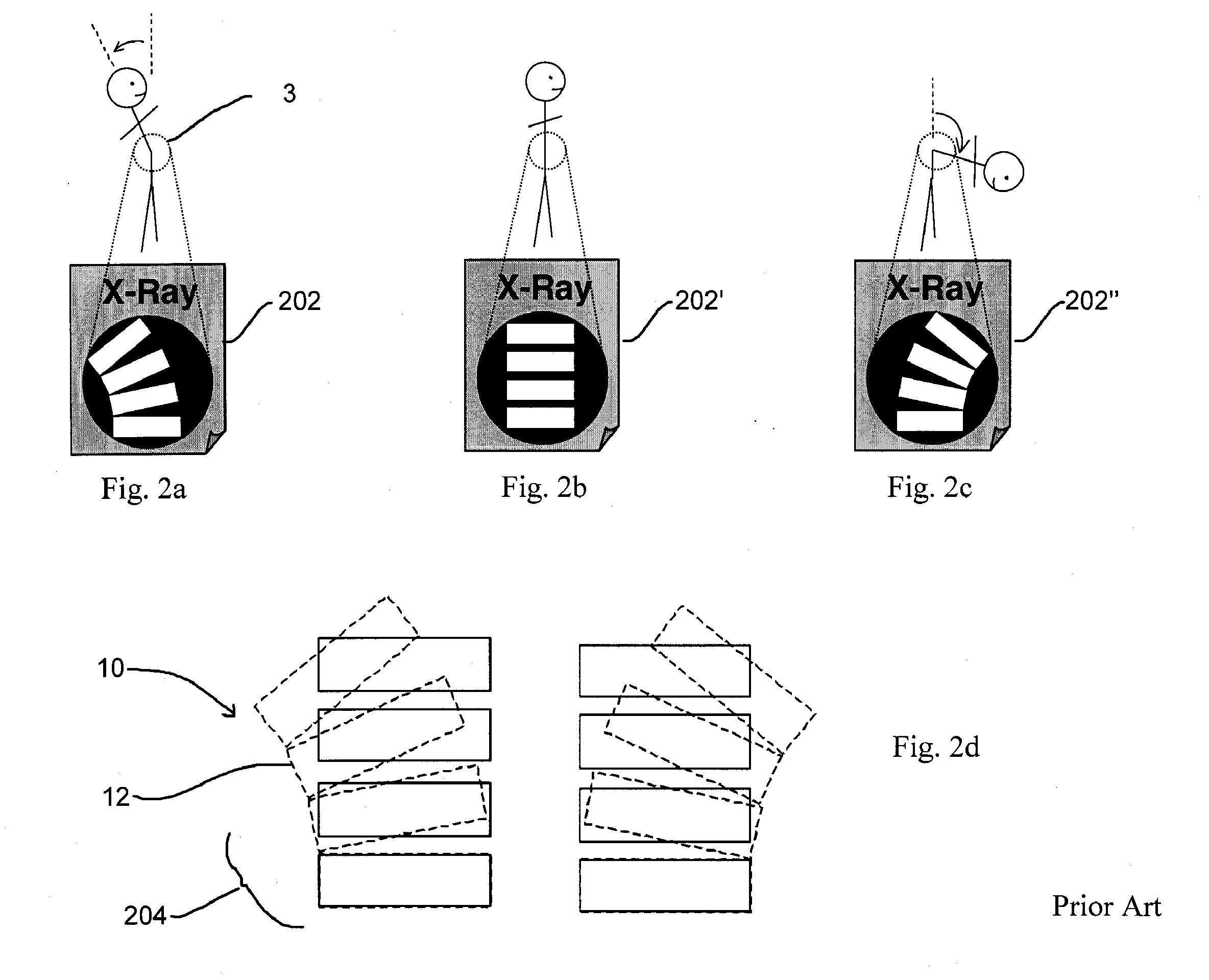

Method and system for registering a medical image

A method for registering a medical image with a model mapping a skeletal structure. The method comprises receiving a medical image depicting a plurality of bones, providing a statistical model mapping a reference skeletal structure having a plurality of reference anatomical elements, and registering medical image with the statistical model according to at least one constraint defined by the plurality of reference anatomical elements.

Owner:PHILIPS MEDICAL SYST TECH

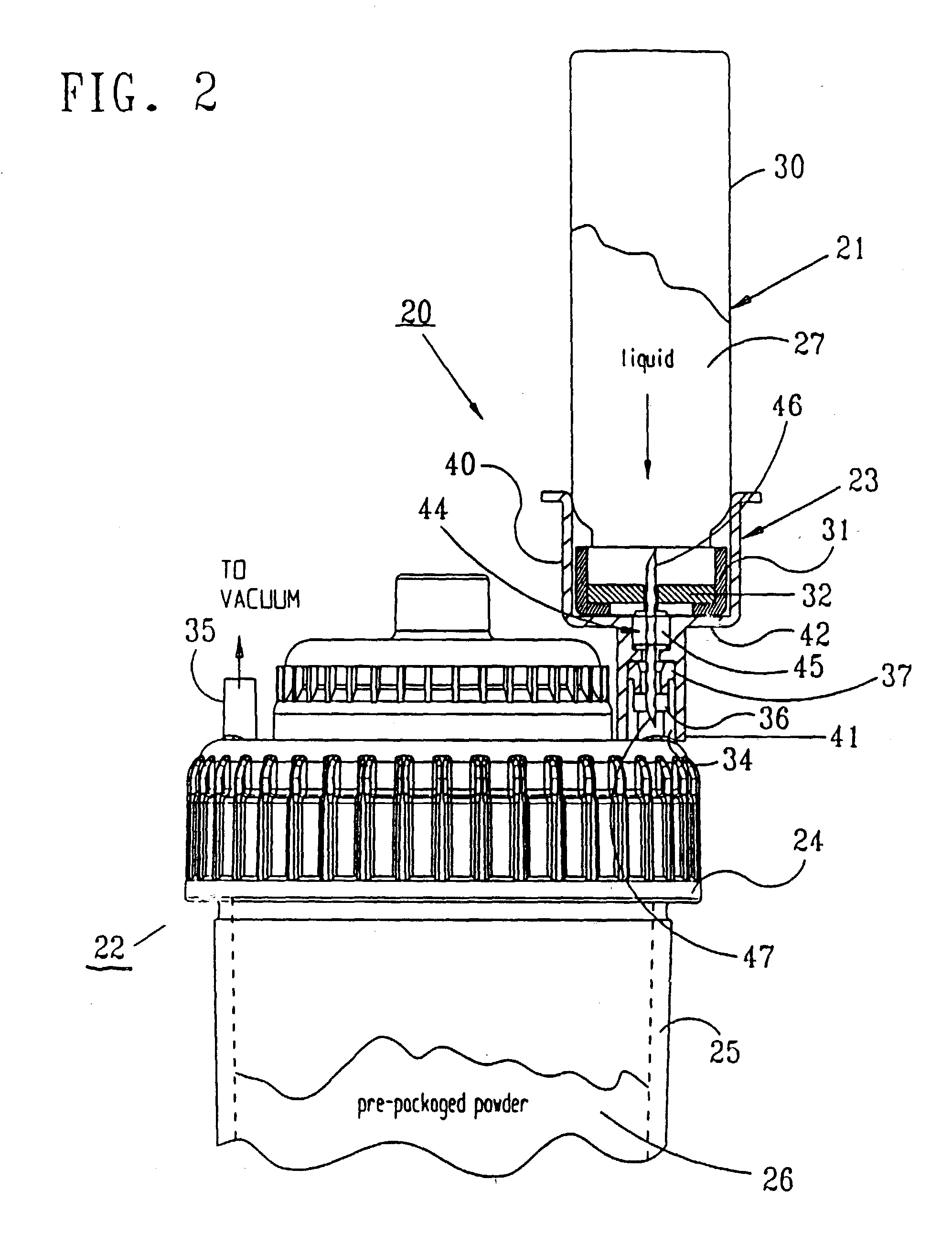

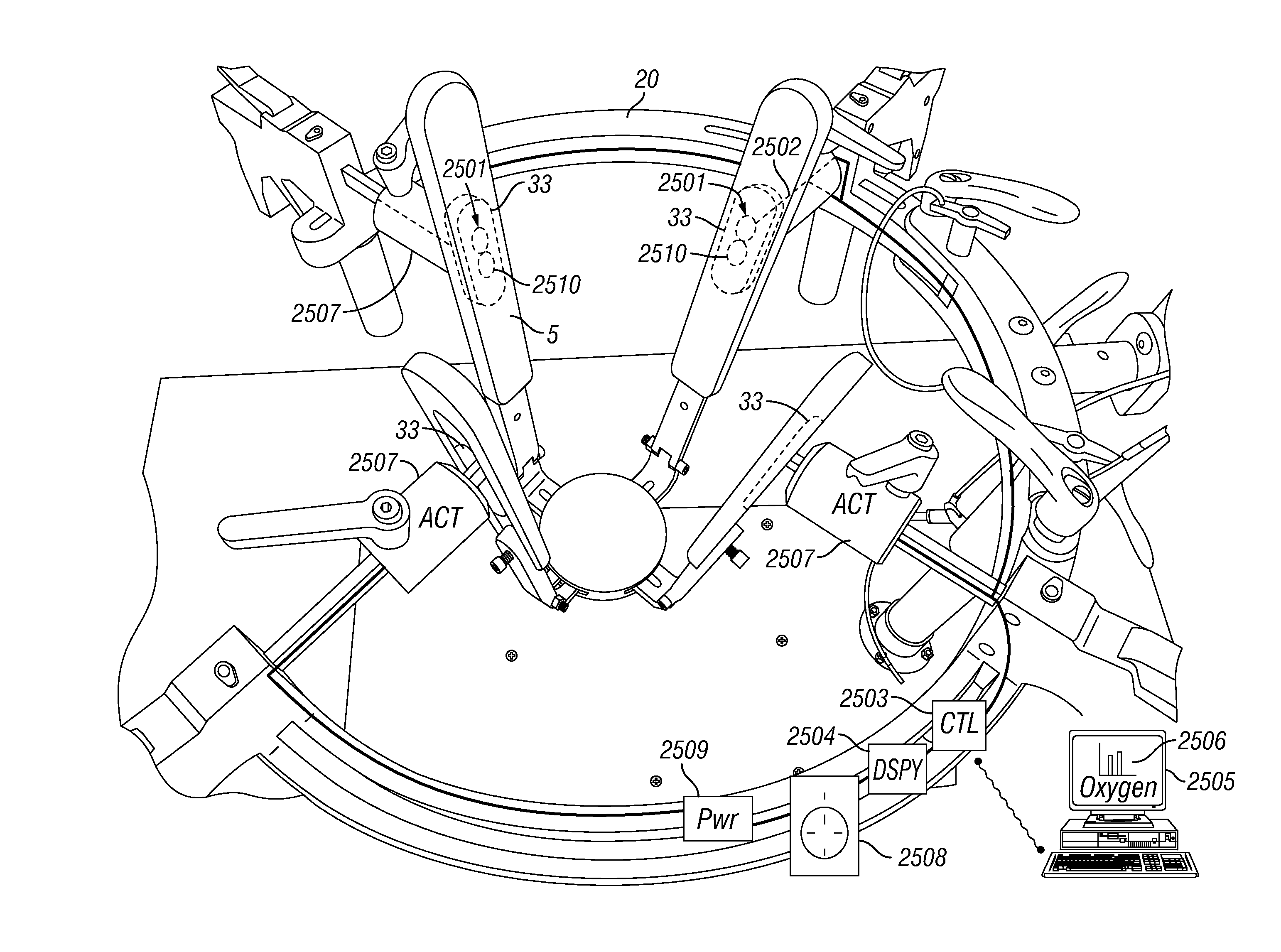

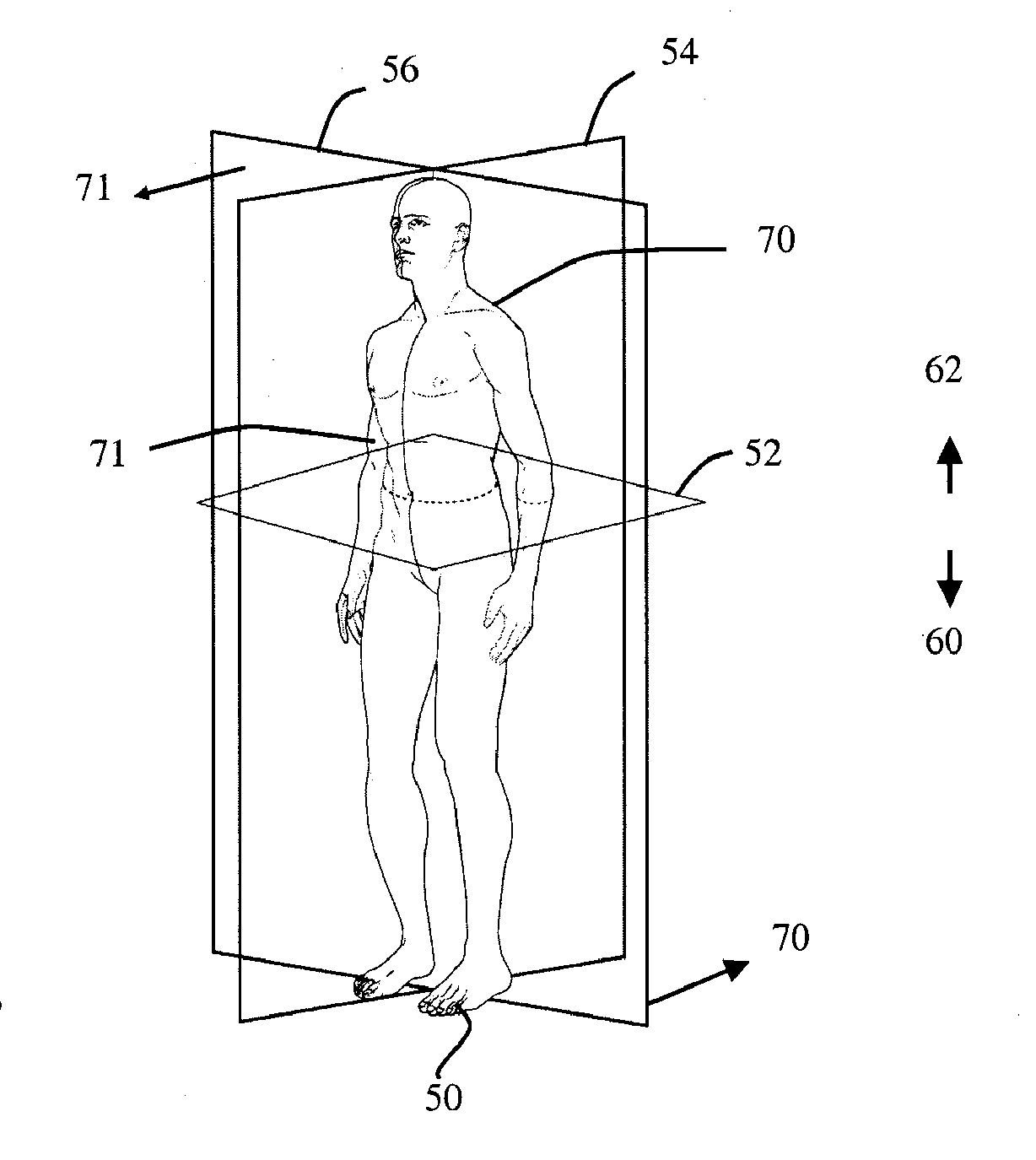

Devices, Systems and Methods for Measuring and Evaluating the Motion and Function of Joint Structures and Associated Muscles, Determining Suitability for Orthopedic Intervention, and Evaluating Efficacy of Orthopedic Intervention

An apparatus and process for measuring the motion of internal joint structures during and for measuring the function of muscles involved with the motion of a joint of a subject are disclosed. The apparatus can be configured in three forms: a horizontal, vertical, or butterfly motion control device. Each configuration comprises a static member and a moving member, in which the moving member operates to move or be moved by the subject being studied. Also disclosed are processes for using each apparatus to measure of the relative motion of a skeletal structures in a subject, in which the subject is positioned in the apparatus and commanded to move while diagnostic medical images are taken or captured. Additionally, processes for using each apparatus to specifically measure and collect data on the function of the subject's muscles are disclosed.

Owner:AECC ENTERPRISES

Orthopedic stabilization device and method

Owner:REED MEDICAL DEVICES

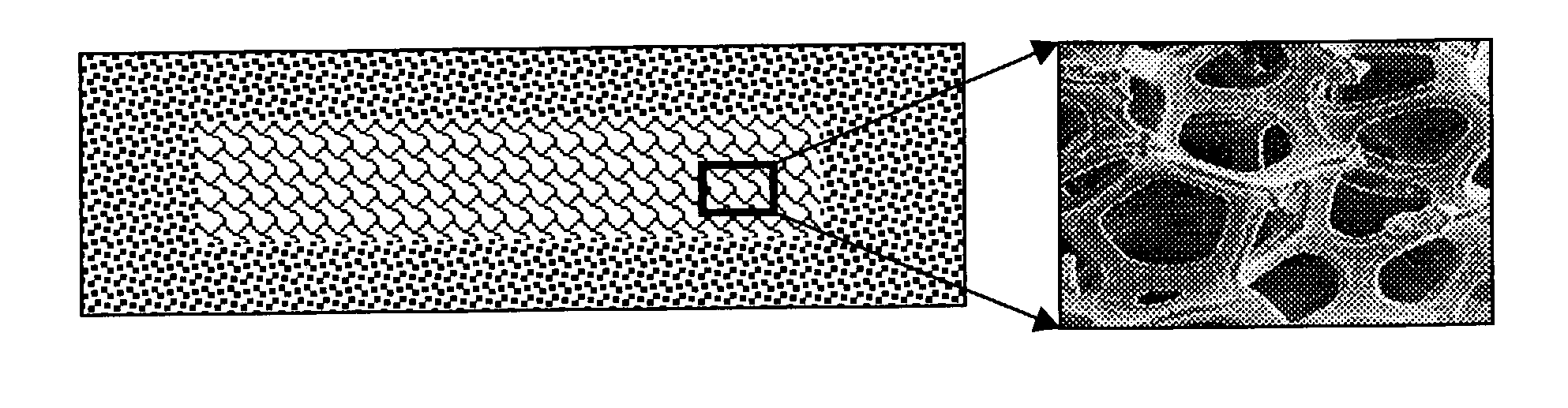

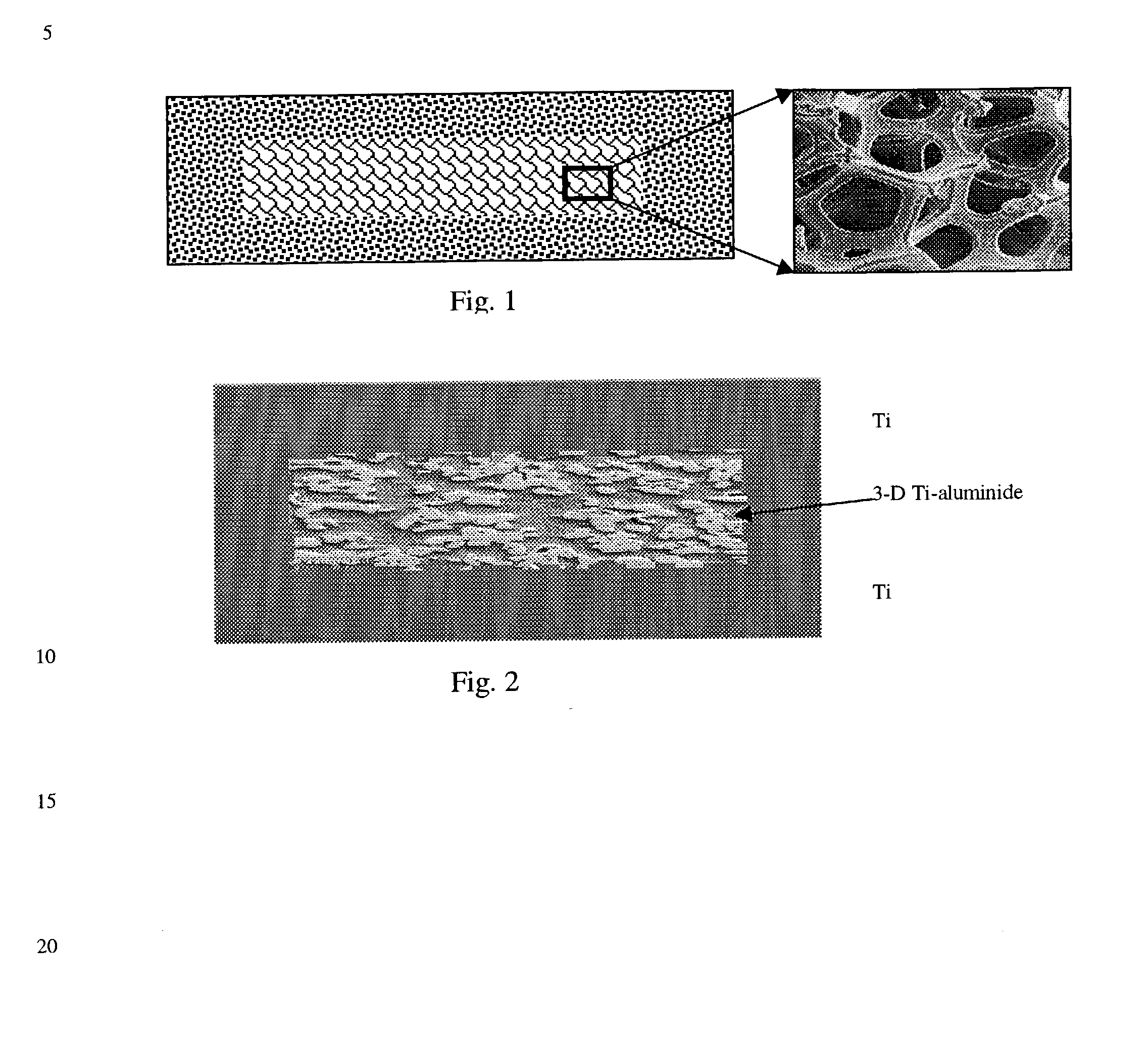

High-strength metal aluminide-containing matrix composites and methods of manufacture the same

(a) The metal matrix composite is suitable for the manufacture of flat or shaped titanium aluminide, zirconium aluminide, or niobium aluminide articles and layered metal composites having improved mechanical properties such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and airfoils, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The composite material consists of a metal (e.g., Ti, Zr, or Nb-based alloy) matrix at least partially intercalated with a three-dimensional skeletal metal aluminide structure, whereby ductility of the matrix metal is higher than that of the metal aluminide skeleton. The method for manufacturing includes the following steps: (a) providing an aluminum skeleton structure having open porosity of 50-95 vol. %, (b) filling said skeleton structure with the powder of a reactive matrix metal, (c) compacting the aluminum skeleton / matrix powder composite preform by cold rolling, cold die pressing, cold isostatic pressing, and / or hot rolling, (d) consolidating the initial or compacted composite preform by sintering, hot pressing, hot rolling, hot isostatic pressing, and / or hot extrusion to provide, at least partially, a reaction between aluminum skeleton and matrix metal powder, and (e) diffusion annealing followed by any type of heat treatment needed to provide predetermined mechanical and surface properties of the resulting metal matrix composite. The combination of ductile matrix and metal aluminide skeletal structure results in significant improvement of mechanical properties of the composite material, especially hot strength. This high-strength aluminide-based material can also be used as a core component in multilayer metal matrix composites.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

Orthopedic stabilization device and method

An orthopedic stabilization structure including a threaded fastener capable of articulation to accommodate various skeletal geometries, a rod, and a cup supporting said threaded fastener and said rod to be subsequently held in fixed position with respect to the skeletal structure.

Owner:REED MEDICAL DEVICES

Orthopedic stabilization device and method

An orthopedic stabilization structure including a threaded fastener capable of articulation to accommodate various skeletal geometries, a rod, and a cup supporting said threaded fastener and said rod to be subsequently held in fixed position with respect to the skeletal structure.

Owner:REED MEDICAL DEVICES

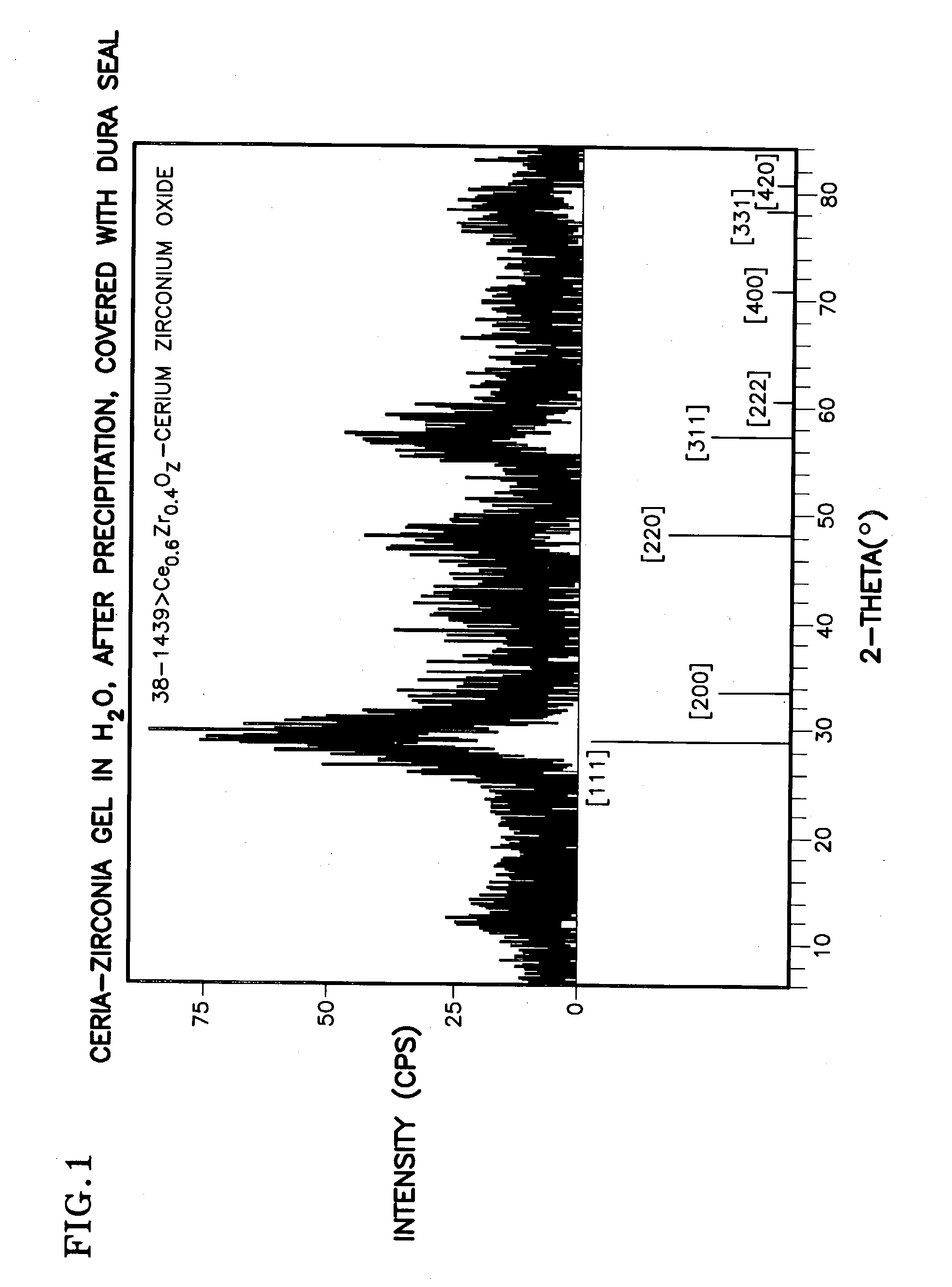

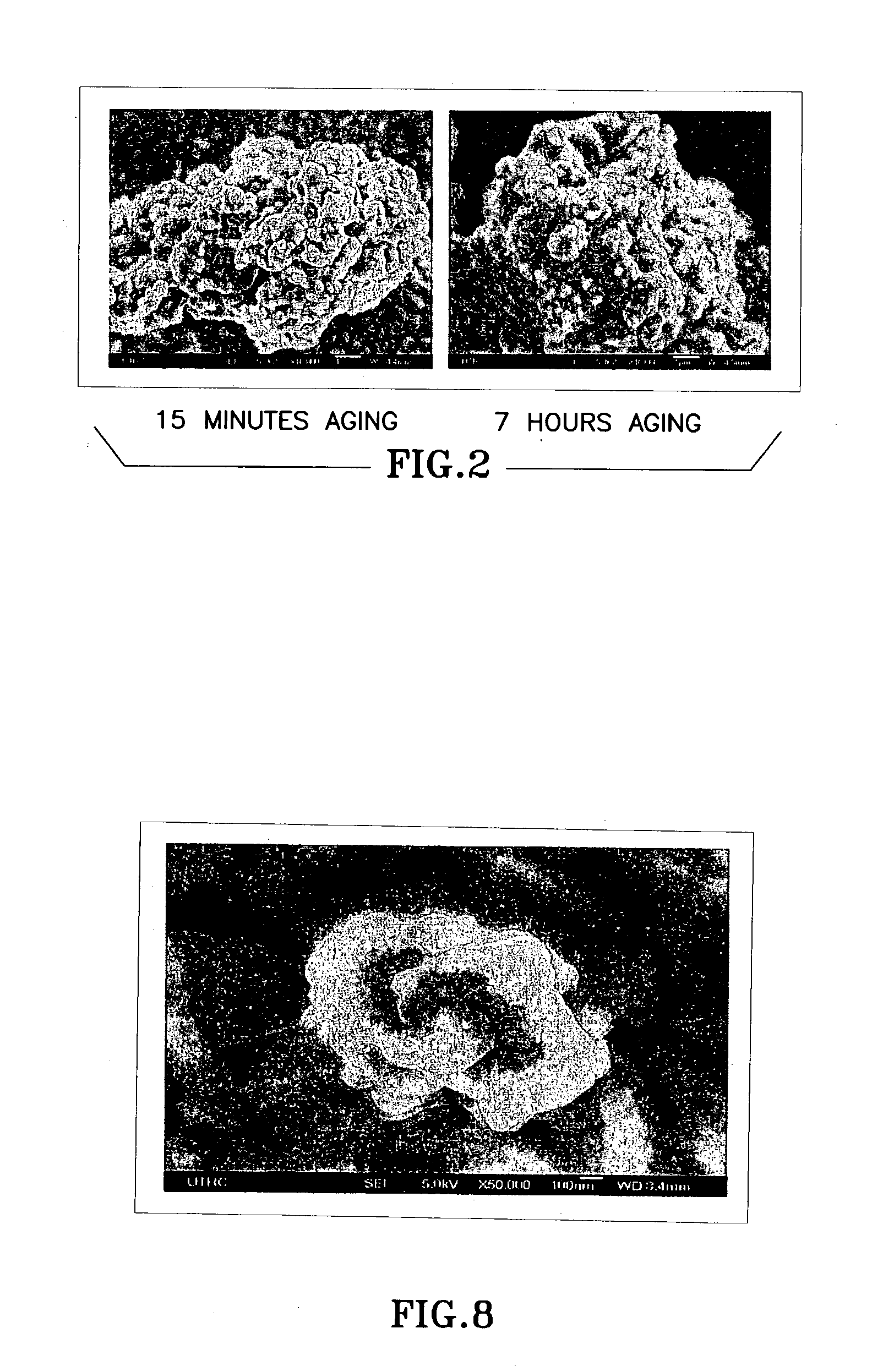

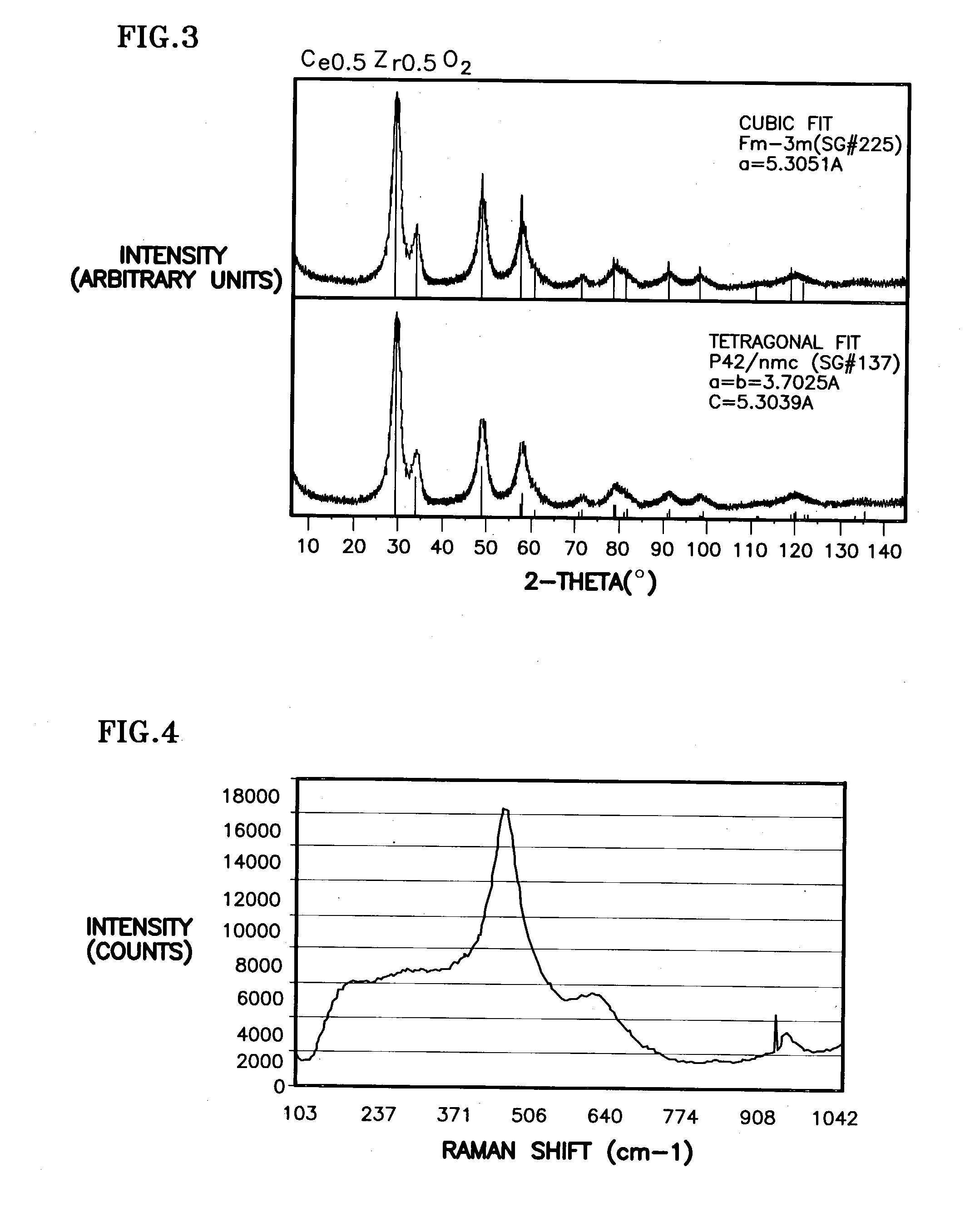

Ceria-based mixed-metal oxide structure, including method of making and use

InactiveUS20030235526A1Increased internal surface areaHigh catalytic activityRare earth metal oxides/hydroxidesMaterial nanotechnologyRheniumFuel cells

A homogeneous ceria-based mixed-metal oxide, useful as a catalyst support, a co-catalyst and / or a getter has a relatively large surface area per weight, typically exceeding 150 m<2> / g, a structure of nanocrystallites having diameters of less than 4 nm, and including pores larger than the nanocrystallites and having diameters in the range of 4 to about 9 nm. The ratio of pore volumes, VP, to skeletal structure volumes, VS, is typically less than about 2.5, and the surface area per unit volume of the oxide material is greater than 320 m<2> / cm<3>, for low internal mass transfer resistance and large effective surface area for reaction activity. The mixed metal oxide is ceria-based, includes Zr and or Hf, and is made by a novel co-precipitation process. A highly dispersed catalyst metal, typically a noble metal such as Pt, may be loaded on to the mixed metal oxide support from a catalyst metal-containing solution following a selected acid surface treatment of the oxide support. Appropriate ratioing of the Ce and other metal constituents of the oxide support contribute to it retaining in a cubic phase and enhancing catalytic performance. Rhenium is preferably further loaded on to the mixed-metal oxide support and passivated, to increase the activity of the catalyst. The metal-loaded mixed-metal oxide catalyst is applied particularly in water gas shift reactions as associated with fuel processing systems, as for fuel cells.

Owner:AUDI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com